Star MCP300 SERIES, MCM300 SERIES Manual Manual

VISUAL CARD READER/WRITER

MCP300 SERIES

MCM300 SERIES

PROGRAMMER'S MANUAL

Federal Communications Commission

Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own

expense.

For compliance with the Federal Noise Interference Standard, this equipment requires a shielded

cable.

This statement will be applied only for the printers marketed in U.S.A.

Statement of

The Canadian Department of Communications

Radio Interference Regulations

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

The above statement applies only to printers marketed in Canada.

CE

Manufacturer’s Declaration of Conformity

EC Council Directive 89/336/EEC of 3 May 1989

This product, has been designed and manufactured in accordance with the International

Standards EN 50081-1/01.92 and EN 50082-1/01.92, following the provisions of the Electro

Magnetic Compatibility Directive of the European Communities as of May 1989.

EC Council Directive 73/23/EEC and 93/68/EEC of 22 July 1993

This product, has been designed and manufactured in accordance with the International

Standards EN 60950, following the provisions of the Low Voltage Directive of the European

Communities as of July 1993.

The above statement applies only to printers marketed in EU.

Trademark acknowledgments

MCP300,MCM300: Star Micronics Co. Ltd.

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever,

without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time

of going to press. However, should any errors be detected, STAR would greatly appreciate

being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this

manual.

©

Copyright 1998 Star Micronics Co., LTD.

Please read this manual carefully and follow the instructions to fully understand

the contents, before using this product. Misuse can cause an accident, or damage the

product and/or the peripherals.

● At the Installation:

1) This system is a precision type. Install this system at a solid and horizontal

plane. Do not apply shock or vibration to the system.

2) Do not install this system at a place where the system may be exposed to direct

sunlight, heavy dust, heat and humidity.

3) Do not install this system at a place where the system inside may be exposed to

water, oil and metal powder or where the system may be exposed to corrosive

gas and chemical steam.

4) This system prints to a human readable area by using magnetic field. Do not

install this system at a place where the system is exposed to magnetic field.

5) Be sure to apply the specified power supply of AC120, 230, 240V, 50/60Hz.

6) Do not share the power outlet with a noise causing electric instrument.

7) Prepare the earth ground at the power supply connector.

8) Keep an ample amount of space to operate the system and which allows for

radiation.

● During the operation:

1) Do not use any other card than our specified card.

2) Do not use the card if wet, stained with oil, etc. After using the dirty/wet card

accidentally, clean up both the card and the system (reader/writer).

3) Do not touch the card with a hand stained with oil, etc.

4) Keep the card away from magnetized or electric devices that cause magnetic

fields, such as speakers, TV set etc.

5) Do not use a bent card, otherwise the card may be caught inside the system.

6) Insert the card in the specified direction only.

Precautions

<Specified Direction>

7) Do not insert any other material in the card slot other than the card.

8) Do not turn off the power switch during card processing.

9) When any of the anomalous (noise, off-flavor, smoke, firing, etc.) is found,

turn off the power switch and disconnect the power cable immediately.

10) Do not start the system after changing the environmental condition (temperature, humidity etc.), even if under the specified condition. Leave the

system about one hour in the new conditions before you start. Do not use

the system under condensation.

11) It is recommended to clean the system at regular intervals, in order to keep

the reliability of the system.

12) MCP300/MCM300 has no method to detect insertion of invalid card. If

printing on the human readable area is executed when an invalid card is

inserted, damage can occur to the mechanism and/or card. Care should be

taken not to print visual data to an incorrectly inserted card.

1. OUTLINE.....................................................................................1

2. UNPACKING ...............................................................................2

3. APPEARANCE AND NOMENCLA TURE.................................3

4. CONNECTION TO EXTERNAL UNITS AND SETTING ........5

5. DIP SWITCH SETTING..............................................................8

6. PROTOCOL ................................................................................11

7. HOW TO USE CLEANING CARD ...........................................25

8. TROUBLESHOOTING ..............................................................26

9. GENERAL SPECIFICATIONS ..................................................27

10. EXTERNAL VIEW AND DIMENSIONS..................................28

CONTENTS

-1-

The MCP300 series is a reading/writing device for specified IC card or reading

device for ISO magnetic stripe type plastic card.

It also has print/erase capability to a re-writable human readable area on the surface of the card. This series is compatible with most host computers and various

P.O.S. systems.

The main features of the MCP300 series are as follows:

1. Reads data from a specified IC chip on the card.

2. Writes data to a specified IC chip on the card.

3. Reads data from a magnetic stripe on the card.

4. Prints characters to a human readable area and erases them.

4. Serial interface of RS-232C(MCP300 housed unit), or CMOS(MCM300 mechanism unit).

5. The human readable area of the card may be re-used up to 10,000 times under

the proper condition.

6. Number of printing characters:

3 lines of 29 characters by 12 X12 dot font

3 lines of 22 characters by 16 X 16 dot font

2 lines of 14 characters by 24 X 24 dot font

Model Name

<Housed unit (with IC controller PCB and power supply)>

MCP310TD Specified IC card read/write, Magnetic stripe read

MCP310RD Magnetic stripe read

MCP390TD Specified IC card read/write

<Mechanism unit>

MCM310X IC card contact, Magnetic stripe read

MCM310R Magnetic stripe read

MCM390X IC card contact

OUTLINE1

-2-

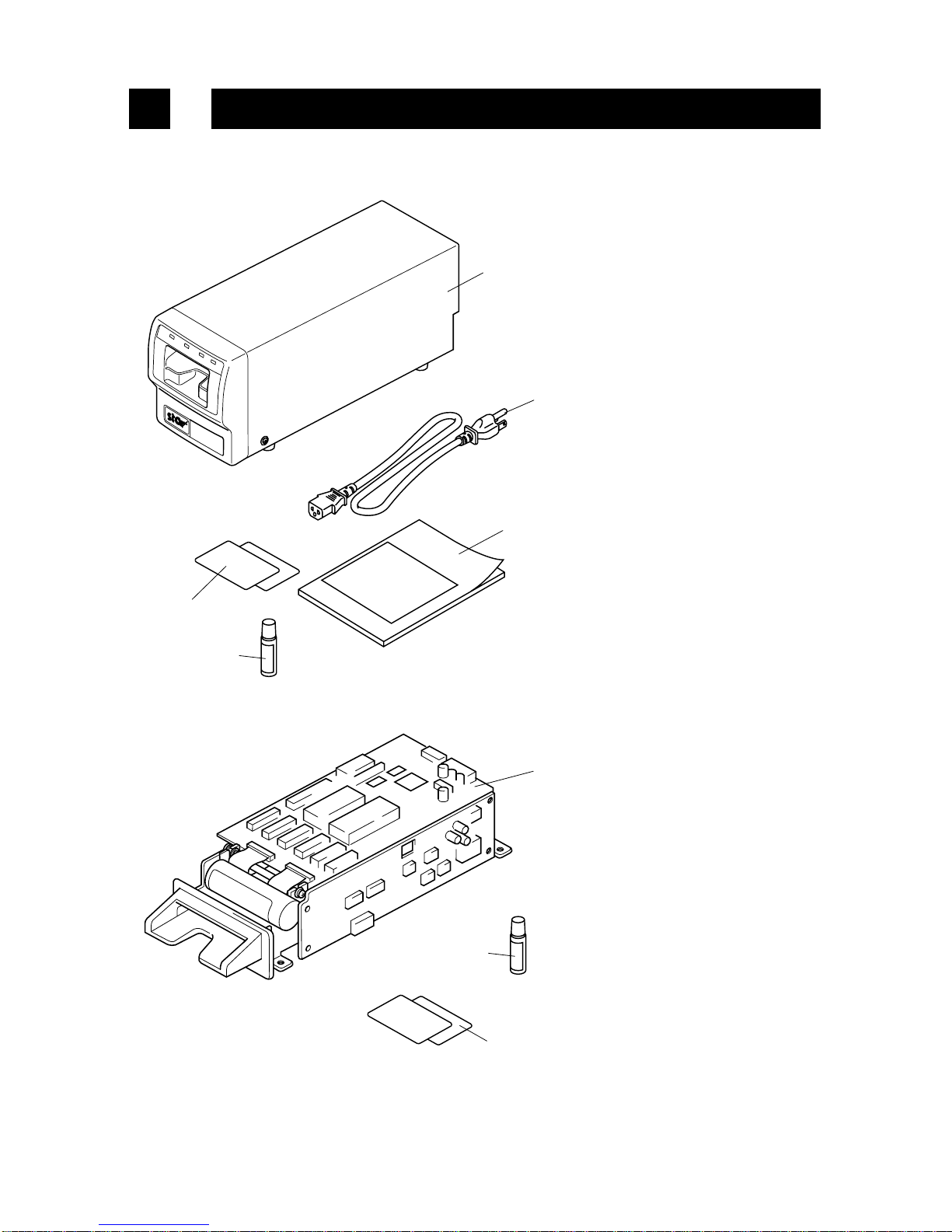

MCM300 mechanism unit

1 MCM300

2 Cleaning card (2 pcs)

3 Cleaning liquid

UNPACKING2

MCP300 housed unit

1 MCP300

2 Power cable

3 Cleaning card (2 pcs)

4 Cleaning liquid

5 Installation manual

After unpacking the unit, check that all the accessories are included in the indi-

vidual box.

1

2

3

4

5

1

2

3

-3-

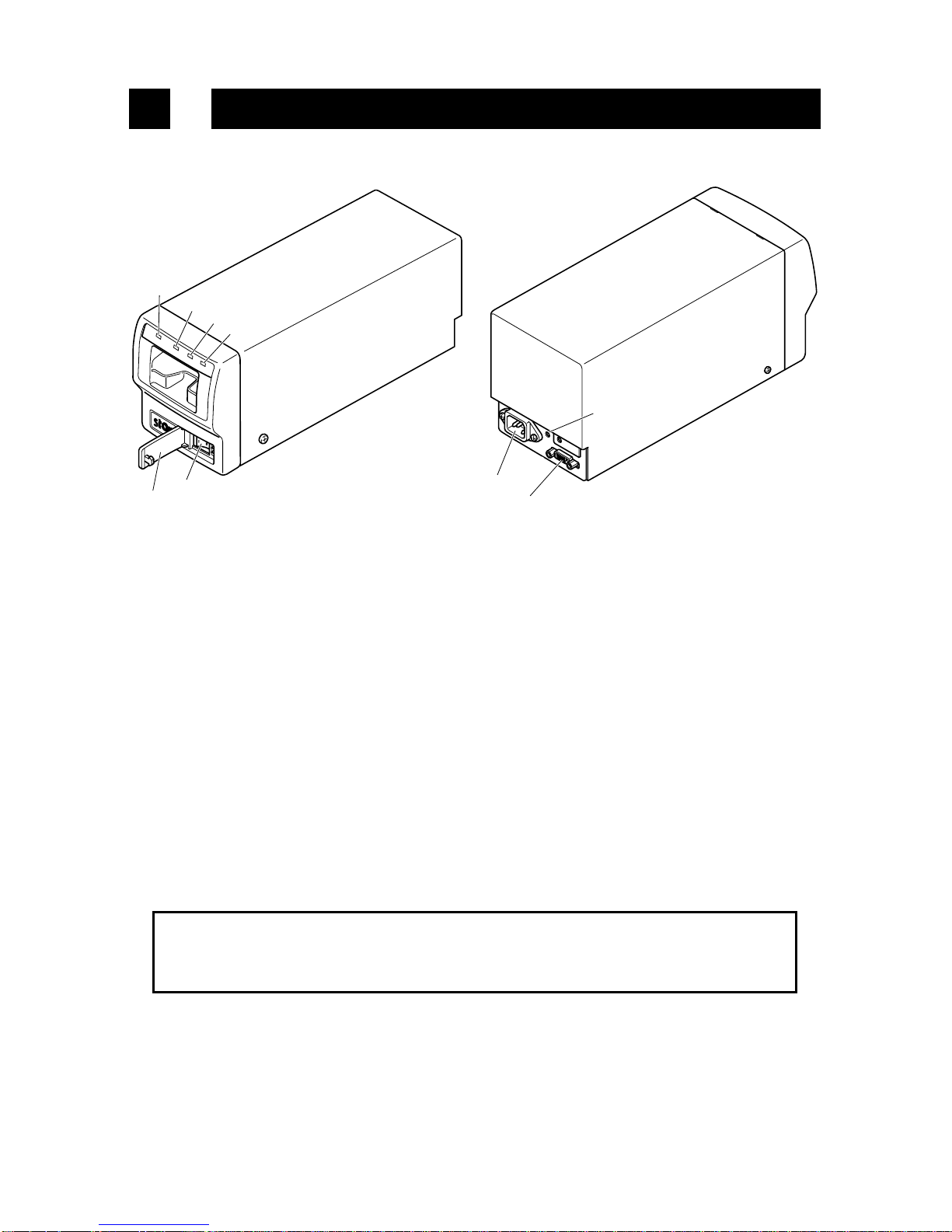

APPEARANCE AND NOMENCLA TURE3

3-1. MCP300 Housed Unit (with IC controller and power supply)

1 Switch Cover This cover protects the power switch of the system.

Push to open and close.

2 Power Switch This switch turns the power of the system on/off.

3 POWER LED This LED indicates that the power of the system is on.

4 READY LED This LED mainly indicates that the card processing is ready.

5 OK LED This LED mainly indicates that the card has been processed

without error.

6 ERROR LED This LED mainly indicates that the card has not been read

due to an error e.g. jamming of the card in the Reader/Writer.

*The function of 4 to 6 LED is defined by the software of host computer.

7 RS-232C serial connector

This connector interfaces the connection between host computers and the Reader/Writer.

8 AC Power Inlet Connect this inlet to the power source with the attached AC

power cable.

9 Reset Switch In order to reset MCP300 reader/writer, please insert a pin

and push the internal reset switch.

IMPORTANT!

A three terminal earth grounded power supply cable is attached with MCP300

housed unit. For safety, do not remove the ground pin.

1

2

3

4

5

6

7

8

9

-4-

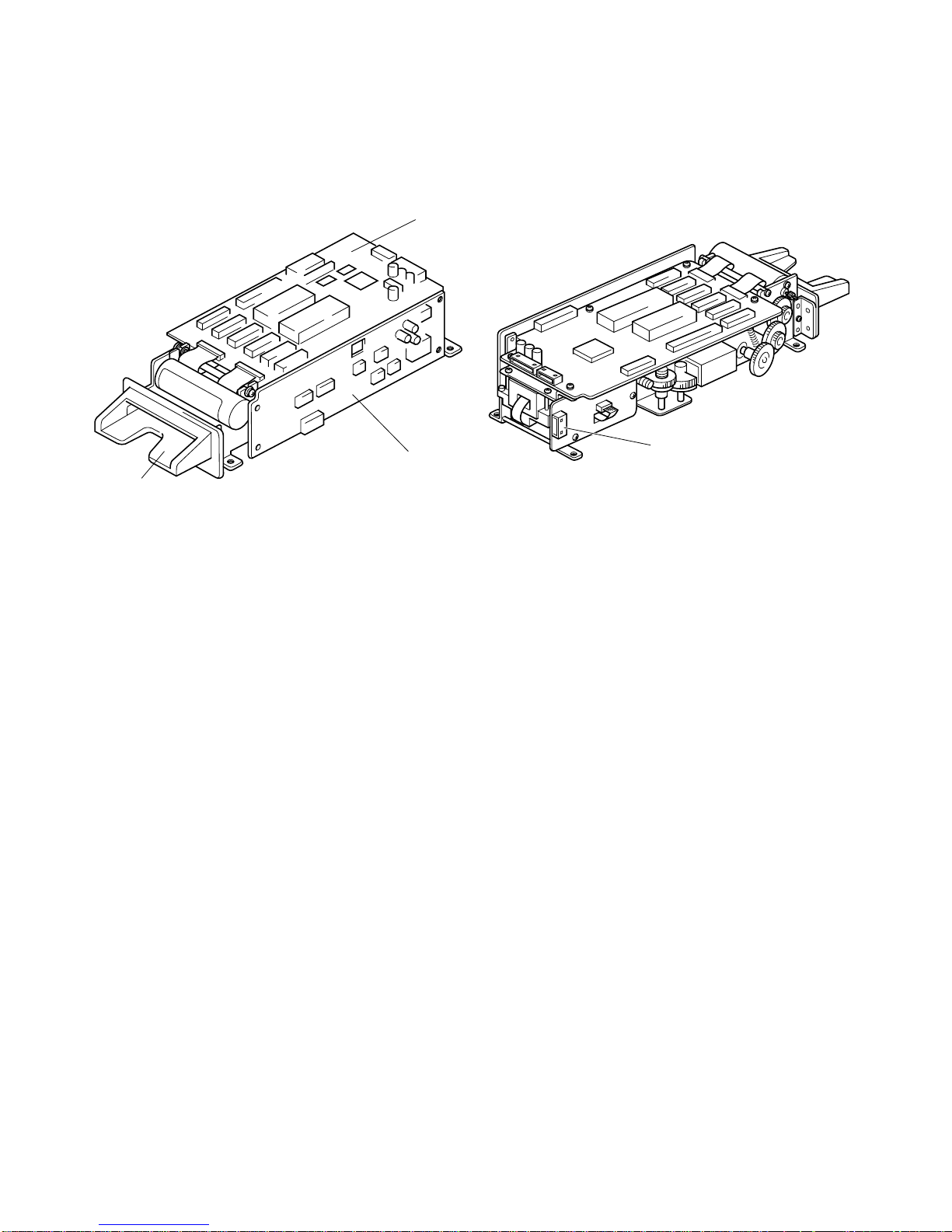

1 Card Slot

2 Control Board (serial interface connector, power supply connector)

3 Driver Board

4 IC connector (usable with MCM310X, MCM390X)

3-2. MCM300 Mechanism unit (without IC controller PCB)

1

2

3

4

-5-

CONNECTION TO EXTERNAL UNITS AND SETTING

4

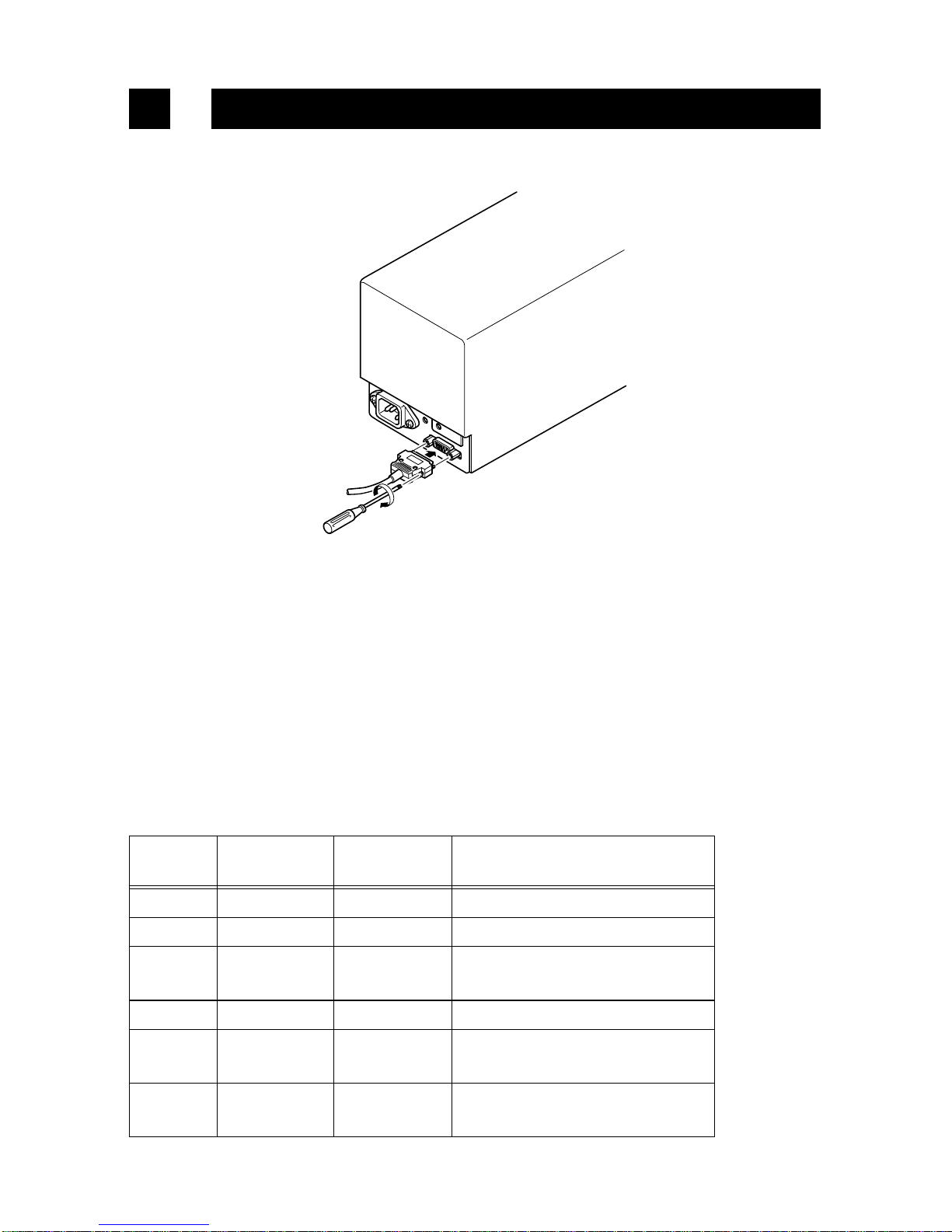

4-1. MCP300, housed unit (with IC controller PCB and power supply)

<Connecting the interface cable>

1 Turn off the power of the host computer and the Reader/Writer.

2 Plug in an end of the interface cable to the Reader/Writer connector and the

other end to the serial port of the host computer.

3 Fasten two screws located at both the shoulders of the interface cable connec-

tors.

<Serial Interface (RS-232C)>

1 Applicable connector: D-sub 9 pin(Male),

Socket DDK-17JE-13090-37(Female)

2 Connector terminals: See the table below

3 Level: RS-232C

Pin No.

Signal name Direction Function

No.

2 RXD IN Received data

3 TXD OUT Transmitted data

4 DTR OUT Data-terminal-ready

(always ON after reset)

5 S-GND - Signal ground

6 CTS/DSR IN Clear-to-send

Data-set-ready(no detection)

7 RTS OUT Request to send

(always ON after reset)

Loading...

Loading...