Page 1

DOT MATRIX PRINTER

NX-1001

LC-20

TECHNICAL MANUAL

[ SIXTH EDITION ]

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any

form whatsoever, without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents

of this manual at the time of going to press. However, should any

errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility

for any errors in this manual.

© Copyright 1990-1997 Star Micronics Co.,Ltd.

Page 3

INTRODUCTION

This manual is an introduction to dot matrix printers as shown below.

It is intended for use as a reference for periodic inspections and maintenance procedures.

This manual is prepared for use at a technical level and not for the general user.

1

Model Destination

NX1001 MULTI-FONT For American, Asian, and Russian market

LC-20 For European and Pacific market

This manual is divided into the following sections:

•

Chapter 1 General Specifications

Chapter 2 Theory of Operation

Chapter 3 Adjustments

Chapter 4 Parts Replacement

Chapter 5 Maintenance and Lubrication

Chapter 6 Troubleshooting

Chapter 7 Parts List

First edition : Jul. 1990

•

Second edition : Feb. 1991

Third edition : Mar.1993

Fourth edition : Aug.1994

Fifth edition : Aug.1996

Sixth edition : Aug.1997

2

3

4

5

6

7

Page 4

(Blank Page)

Page 5

C 1

Se

Si

G S

1.

GeneralSpecifications

2. ExternaiAppearanceandComposition

2 N o P

2

2 CoP Co. . . . . . . . . . . . . . . . . . . . . . . . . ...

3.

3 GeSpe. . . . . . . . m..m..

3 Con. . . . . . . . . . u-.-..

4 Ser(o

4

4 Co

D S

Paraiieiinterface

GeSpe

DiSe

4

....................................................................................................

.........................................................................................

..............................................................

........................................................................................................

. - . ----

........................................................................................

............................................................................................

a FuDe...

...............................................................................................

3

5

5

8

9

9

10

Page 6

I

Page 7

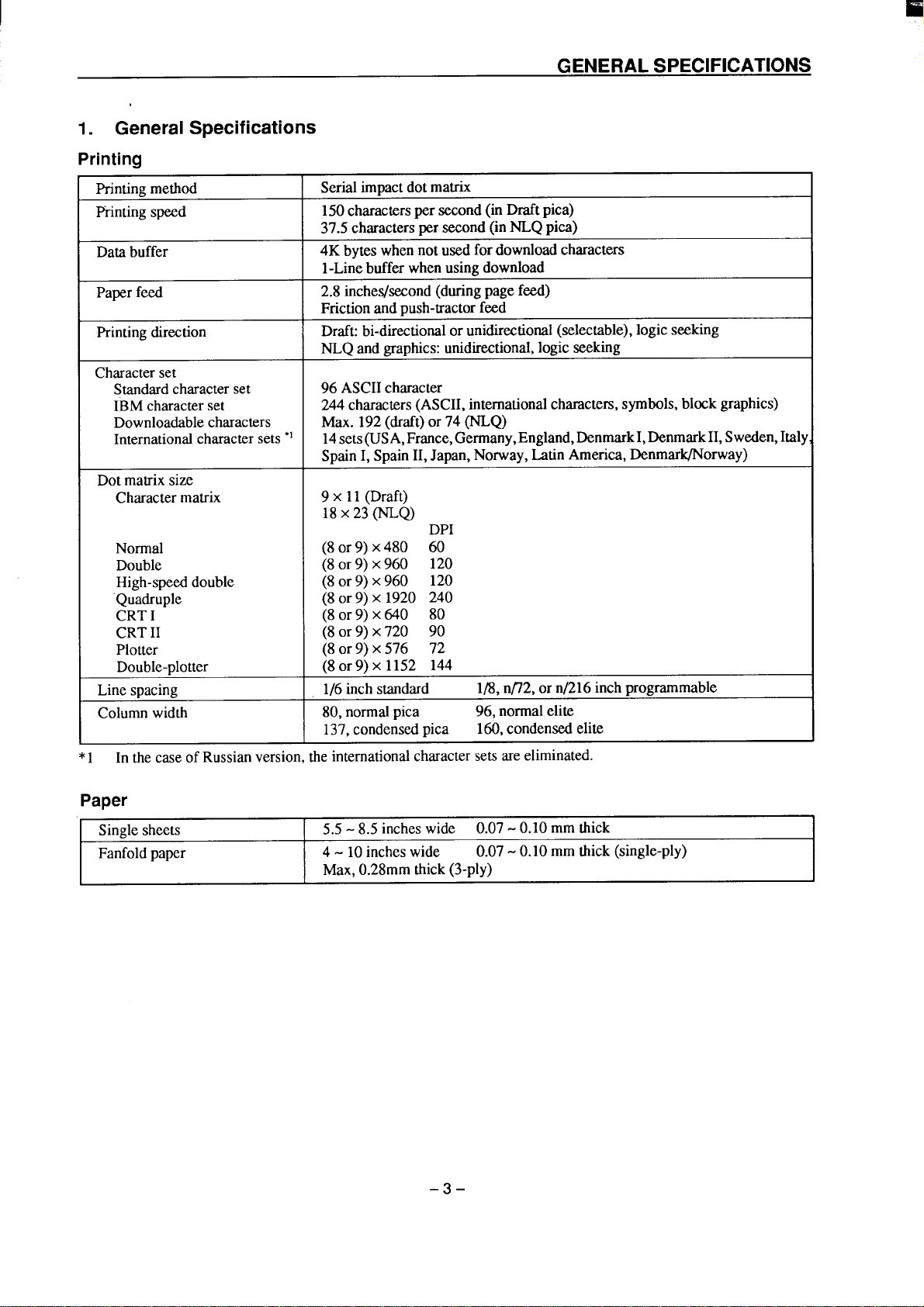

GENERAL SPECIFICATIONS

1. General Specifications

Pr

Printingmethod

Piintingspeed

Databuffer

Paperfeed

Printingdirection

Characterset

Standardcharacterset

IBMcharacterset

Downloadablecharacters

Internationalcharactersets”’

Dotmatrixsize

Charactermatrix

Normal

Double

High-speeddouble

Quadruple

CRTI

CRTII

Plotter

Double-plotter

Linespacing

Columnwidth

InthecaseofRussianversion,theinternationalcharactersetsareehmmated.

*1

Serialimpactdotmatrix

150characterspersecond(in Draft pica)

37.5charactersper second(inNLQpica)

4Kbyteswhennotusedfordownloadcharacters

l-Linebufferwhenusingdownload

2.8inches/second(duringpagefeed)

Frictionandpush-tractorfeed

Draft:bi-directionalor unidirrxxional(selectable),logicseeking

NLQandgraphics:unidirectional,logicseeking

96ASCIIcharacter

244characters(ASCII,internationalcharacters,symbols,blockgraphics)

Max.192(draft)or74(NLQ)

14sets(USA,France,Germany,England,DcnmarkI,DenmarkII,Sweden,Italy

SpainI, SpainII,Japan,Norway,LatinAmerica,Denmark/Norway)

9 x 11(Draft)

18X23(NLQ)

DPI

(8or9) x480 60

(8or9) x960 120

(8or9) x960 120

(8or9) x 1920 240

(8or9) x640 80

(8or9)x 720 90

(80r9) x576 7

(8or9) x 1152 144

1/6inchstandard

80,normalpica

137,condensedpica

1/8,nf72,orn/216inchprogrammable

96,normalelite

160,condensedelite

.. . .

P

Singlesheets

Fanfoldpaper

5.5- 8.5incheswide 0.07-0.10 mmthick

4-10 incheswide 0.07-0.10 mmthick(single-ply)

Max,0.28mmthick(3-ply)

-3-

Page 8

GENERAL SPECIFICATIONS

Pr

Dimensions

Weight

Power

Powerconsumption

Environment

Print head

Ribbon

Option

Pain

Interface

Synchronization

Handshaking

Logiclevel

Connector I 57-30360Am~henol

Height120mm(4.7inches)

Depth301mm(11.8inches)

5.1kg (11.2pounds)

120VAC*1O%,60 Hz.

240VAC+1O’%,50/60Hz.

Typ.36W.Max.80W

Operatingtemperature:5 to 40”C(41to I04”F)

Operatinghumidity:10to 80%,noncondensation

Storagetemperature:–30to 65°C(-22 to 149°F)

Storagehumidity:10%to 95%(at40°C)(nocondensation)

9 pins

Life:100milliondots

Fabricribboncartridge

Life:1milliondraftcharacters

Automaticsheetfeeder

Serial-Parallelconverter(SPC-8K)

Centronics-compatible

Byexternalsuppliedstrobepulses

ByACKor BUSYsignals

Width396mm(15.6inches)

220VAC+1O%,50/60Hz.

%

I

I

Fig. 1-1ExternalDimensions

–4-

Page 9

I

“a’enK

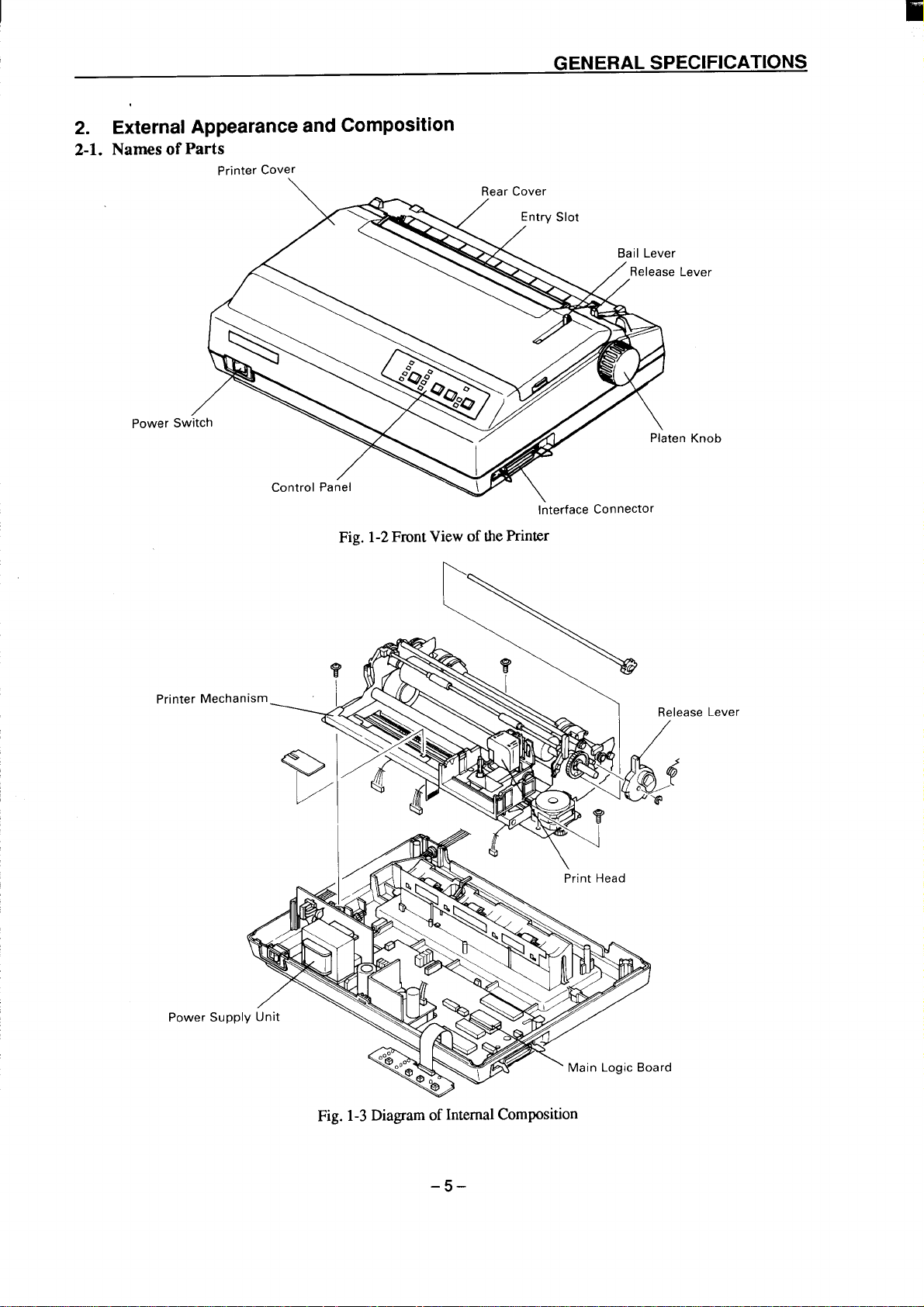

GENERAL SPECIFICATIONS

External Appearance and Composition

2.

N P

2

P C

R C

B L

/ L

‘ C

Fig. 1-2FrontViewofthePrinter

P M

-

I C

a L

Fig.1-3DiagramofInternalComposition

-5-

Page 10

GENERAL SPECIFICATIONS

2 S S

\

/

I

1

Fig. 1-4TheDIPSwitchesarelocatedunderthePrinterCover

1) ExceptforRussianversion

Switch

1-1

Function

Printermode

ON OFF

Standard IBM

I 1-2 I Usageof RAM I Buffer

1-3

1-4

1-5

\ 1-6 I Oratorlowercase

1-7

1-8

k

1

AutoLF

No Yes

Autosheetfeeder Inactive

Pawr-outdetector

Enabled Disabled

I Smallcam I Lowercase

Pagelength

1

(See right)

Characterset

2-1

Characterset

(Standardmode) ‘raphics ‘wlics

(IBMmode) ‘et#2

2-2

2-3

Internationalcharacterset(Seeright)

2-4

D S 1

I Download

Active

Set#1

/

D S 2

O

P l

Inc s

Country

U.S.A.

France

Germany

England

DenmarkI*

Sweden

Italy

SpainI

Denmark/Norwaywhenswitc2-1is ON.

*

2 2

ON ON ON

OFF ON ON

ON OFF ON

OFF OFF ON

ON ON

OFF

ON

OFF OFF

ON

OFF OFF

2

OFF

OFF

OFF

2) ForRussianversion

I Switch \

Function

I 1-1 I Printermode

1-2

1-3

I-4

UsageofRAM Buffer Download

AutoLF No Yes

Autosheetfeeder Inactive Active

I 1-5 I Parer-outdetector

14

Character/Command

1-7

PageLength 11inches 12inches

Characterset Set#1 Set#2

Codepage

t---i

1-8

2-1

2-2

2-3

I 2-4 I Notused

ON

I

\ OFF

I Standard I IBM I

I Enabled I Disabled \

(Seeright)

(See right)

I I

-

Ch

I

( s 1 i o

Character/Command

Italiccancel

Italicselect

MSBnotcontrol

MSB=l

1-6

ON

OFF

ON

OFF

1-7

ON

ON

OFF

OFF

C p

Codepage

‘ R 1%---wl

#3840IBM-Russian

Gost

2-2

1

OFF

I OFF / OFF

2-3

I

ON

I

Page 11

2

1)

2)

Atoffline

H

tl

Hold

Push

S p f

S p p

Agingmode

R m

Forwardm

F

w

*1 In thecaseof Russianversion,“ORATOR”fontis eliminated.

–7–

Page 12

G SPECIFICATIONS

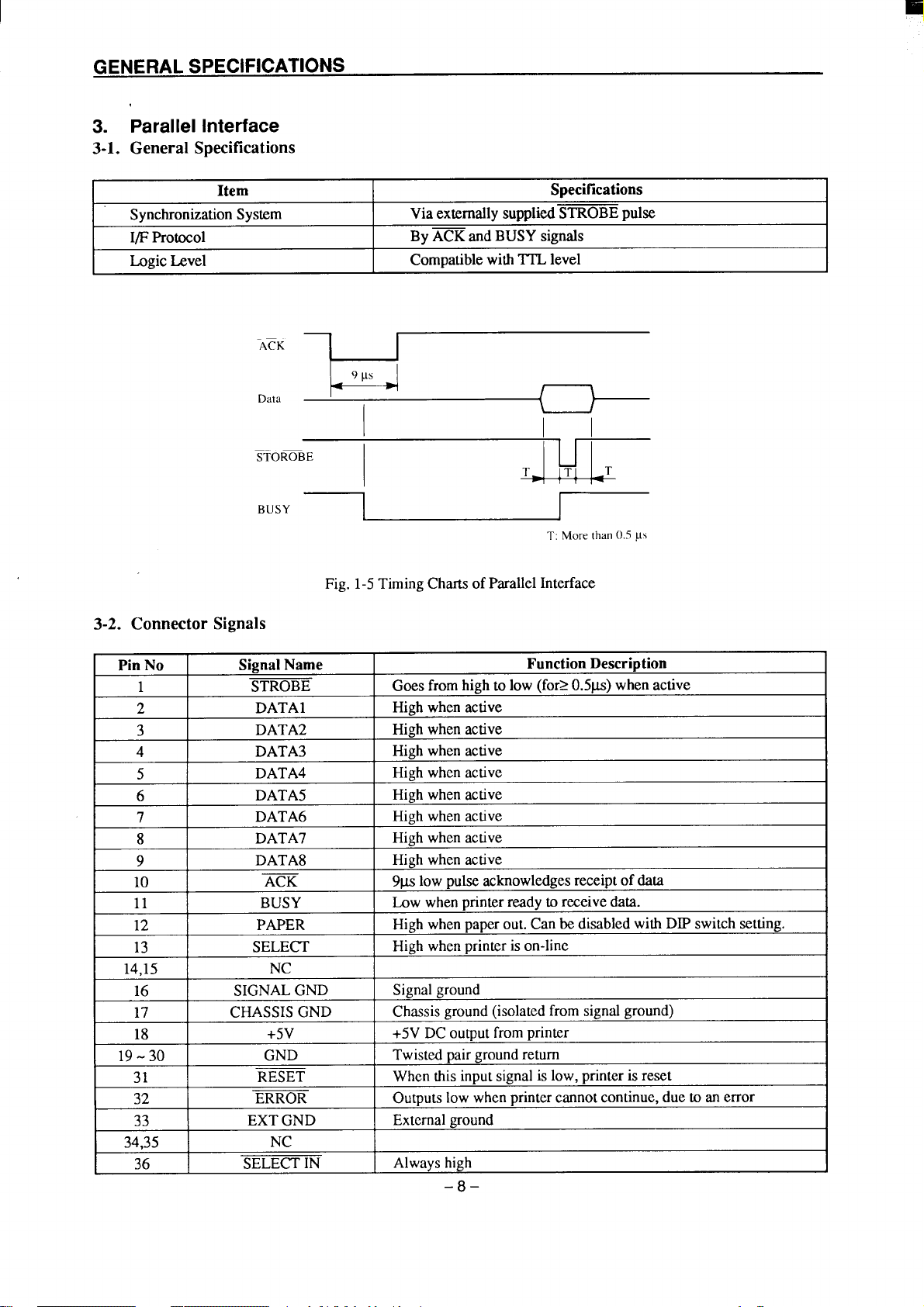

3. Parallel interface

3-1.GeneralSpecifications

Item

SynchronizationSystem

I/FProtocol

I LogicLevel

‘“d ~

STOROBE

Busy

3-2. ConnectorSignals

ACK

ViaexternallysuppliedSTROBEpulse

ByACKandBUSYsignals

I CompatiblewithTTLlevel

9 ~s

h

1

Fig. 1-5TimingChartsofParallelInterface

Specifications

I

T

+

T: More than().5 ILS

PinNo SignalName

1

STROBE

2 DATA1

3

DATA2

4 DATA3

5

6

7

8

9

10

11

DATA4

DATA5

DATA6

DATA7

DATA8

ACK

BUSY Lowwhenprinterreadytoreceivedata.

Goesfromhighto low(for>0.5ps)whenactive

Highwhenactive

Highwhenactive

Highwhenactive

Highwhenactive

Highwhenactive

Highwhenactive

Highwhenactive

Highwhenactive

9VSlowpulseacknowledgesreceiptof data

FunctionDescription

12 PAPER Highwhenpaperout.Canbe disabledwithDIPswitchsetting.

13

SELECT

Highwhenprinterison-line

14,15 NC

16

17

18

SIGNALGND

CHASSISGND

+5V +5VDCoutputfromprinter

19-30 GND

31

32

33

34,35

RESET Whenthisinput signalis low,printerisreset

ERROR

EXTGND Externalground

NC

36 SELECTIN

Signalground

Chassisground(isolatedfromsignalground)

Twistedpairgroundreturn

Outputs lowwhenprintercannotcontinue,duetoan error

Alwayshigh

-8–

Page 13

GENERAL SPECIFICATIONS

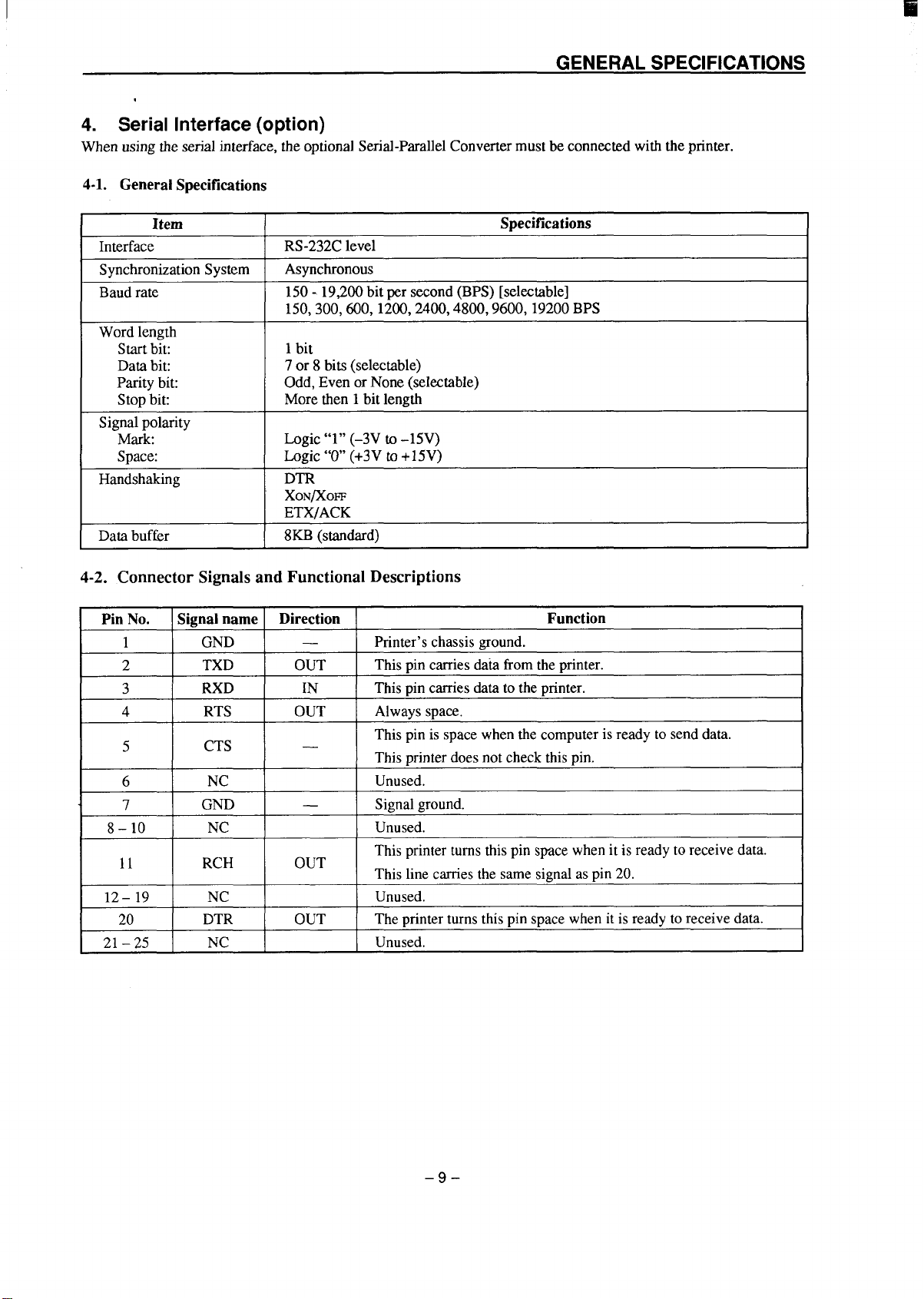

Serial Interface (option)

Whenusing theserialinterface,theoptionalSerial-PmallelConvertermustbeconnectedwiththeprinter.

4-1. GeSpe

Item

Interface

SynchronizationSystem

Baudrate

Wordlength

Startbit:

Databit: 7or8 bits(selectable)

Paritybit: Odd,EvenorNone(selectable)

Stopbit:

Signalpolarity

Mark:

Space:

Handshaking

Databuffer 8KB(standard)

4-2. Connector Signals and Functional Descriptions

Pin No. \Signal name I Direction

I

1 GND

2

3

4

5

6

7

8-10

11

12– 19

20

21–25 NC

TXD OUT

RXD IN

RTS OUT Alwaysspace.

CTS

NC

GND

NC

RCH OUT

NC

DTR OUT

RS-232Clevel

Asynchronous

150-19,200 bitpersecond(BPS)[selectable]

150,300,600>1200,2400,4800,9600, 19200BPS

1bit

Morethen1bit length

Logic“l” (-3V to-15V)

Logic“O”(+3Vto+15V)

DTR

XON/xOFF

ETX/ACK

—

.

—

Printer’schassisground.

Thispincarriesdaiafromtheprinter.

Thispincarriesdatato theprinter.

Thispinis spacewhenthecomputerisreadyto senddata.

Thisprinterdoesnotcheckthispin.

Unused.

Signalground.

Unused.

Thisprinterturnsthis pin spacewhenit is readymreceivedata.

Thislinecarriesthesamesignalaspin20.

Unused.

Theprinterturnsthispinspacewhenitisreadyto receivedata.

Unused.

Specifications

Function

–9–

Page 14

GENERAL SPECIFICATIONS

4-3. DIP Switch Settings

Switch

I

1 8data bits

2

3

4

5

6

7

8

AllswitchedaresetON whentheprinterleavesthe factory.

I

I

Baud rate Switch 6

150

Noparity

Handshakingprotocols- seetablebelow

Oddparity

Datatransferrate– seetablebelow

Protocol

DTRmode

XON/XOFFmode

ETX/ACKmode

300

600

I

I

1200

2400

4800

9600

19200

ON

7 databits

Paritychecked

Evenparity

Switch

I

I

Switch 7

OFF

OFF

OFF

OFF

\

ON

ON

ON

ON

I

I

I

3

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

I

I

I

I

Switch 4

ON

OFF

ON

Switch 8

OFF

ON

OFF

ON

OFF

ON

OFF

ON

I

I

I

I

I

1

I

–10 –

Page 15

C 2

T O

1. B Di

M L B

2

2 GeF C

D I Op

2 PaIn

2 S In

2 Ed........................................................................................9

2 P H D C

2 P H TeDeC

2 CaM D C

2-2-5. CaM S C

2-2-6.P F M D C

.....................................................................................................

................................................................................................

.............................................................................................

................................................................................................

...................................................................................................

...............................................................................................

.................................................................................

......................................................

.........................................................................

.........................................................................

....................................................................

1

1

1

1

1

1

1

1

20

2

2

l

2

2

2

P S U

3

4 Me

4-1.

4

4

4

4

R Ci

R b + L V De

PrCi

P H Me

P H CaMe

I R F Me

P F Me

De

..........................................................................................................

..................................................................

..................................................................................................

..............................................................................................

.........................................................................................................

..........................................................................................

..........................................................................

................................................................................

........................................................................................

................................................................................................................

2

2

2

2

2

2

2

2

2

30

Page 16

I

Page 17

I

THEORY OF OPERATION

Block Diagram

1.

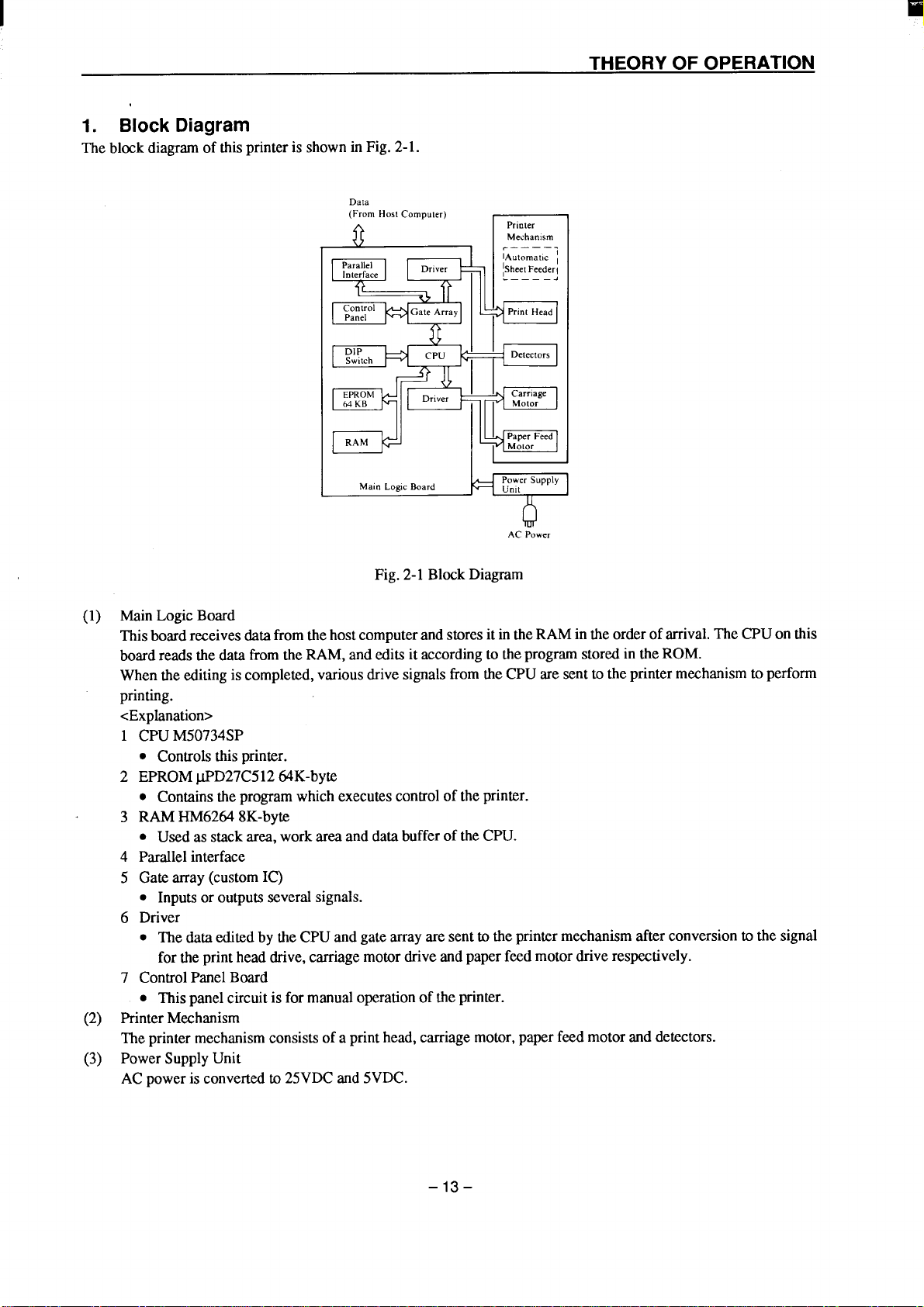

Theblockdiagramofthisprinteris shown in Fig.2-1.

DaLa

(From Host Comp.tcr)

8

Parallel

Interface

Driver

Printer

Mechamsm

~-———.

IAutomat,c ~

~SheetFeederl

.——— —.

Control

[

EPROM

64 KB

I

+};

Panel

~ju~

DIP

Switch

RAM

Main Logic Board

Gate Array

Driver

7 .~

Print Head

Detectors

!’

Carriage

4

Paper Feed

Motor

Power

Unit

AC Power

Motor

1

s

(

Fig.2-1BlockDiagram

(1) MainLogicBoard

Thisboardreceivesdatafromthehostcomputerandstoresit intheRAMinthe orderofarrival.TheCPUon this

boardreadsthedatafromtheRAM,andeditsitaccordingto theprogramstoredin theROM.

Whentheeditingiscompleted,variousdrivesignalsfromtheCPUare sent to theprintermechanismto perform

printing.

<Explanation>

1

CPUM50734SP

● Controlsthis printer.

2

EPROMP.PD27C51264K-byte

. Containstheprogramwhichexecutescontroloftheprinter.

RAMHM62648K-byte

3

● Usedasstackarea,workareaand databufferof theCPU.

4

Parallelinterface

5

Gatearray(customIC)

. Inputsoroutputsseveralsignals.

Driver

6

● ThedataeditedbytheCPUandgatearrayare sent to theprintermechanismafterconversionto the signal

fortheprintheaddrive,carriagemotordriveandpaperfeedmotordriverespectively.

7

ControlPanelBoard

. Thispanelcircuitis formanualoperationoftheprinter.

(2) PrinterMechanism

Theprintermechanismconsistsofa printhead,carriagemotor,paperfeedmotoranddetectors.

(3) PowerSupplyUnit

ACpowerisconvertedto25VDCand 5VDC.

– 13–

Page 18

THEORY OF OPERATION

2. Main Logic Board

I O

2-1-1. PaIn

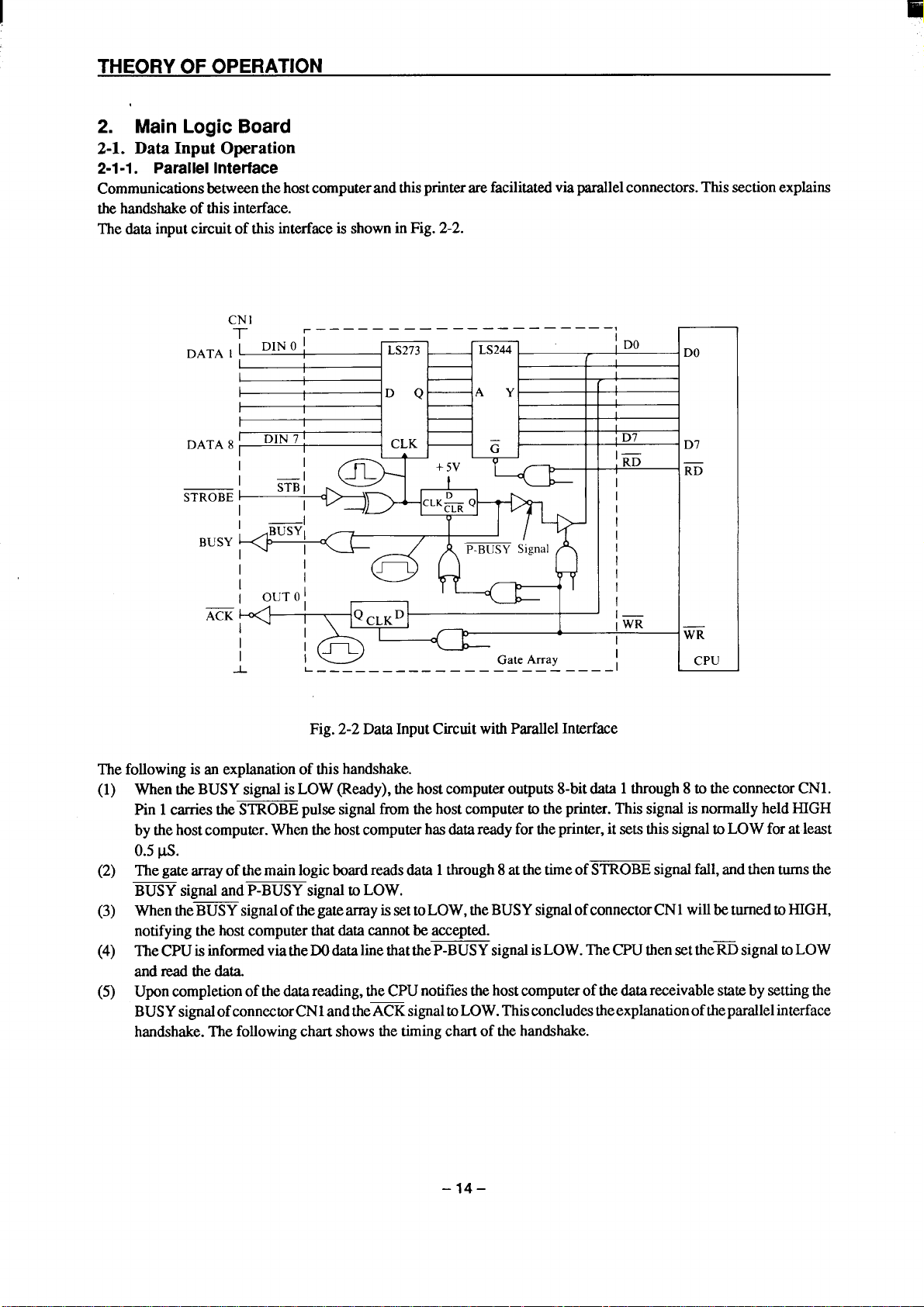

Communicationsbetweenthehostcomputerandthisprinterarefacilitatedviaparallelconnectors.Thissectionexplains

thehandshakeof thisinterface.

Thedatainputcircuit of thisinterfaceisshowninFig.

2-2.

CNI

1-

DATA1I

I

I

DATA8

STROBE

BUSY

I

I

ACK

~ ————————————————————,

DIN O]

DIN 7 \

—1

STBI

(

1

I

I

I

I

@

LS273

DQ

CLK

A

I

I

I

L ————————— — — — — —— ———

Q

LS244

AY

ii

5V

+

GateArray

————

; DO

r

1

I

r

I

1

I

[

i D7

!= ~

I

I

I

I

I

I

I

l—

IWR

I

I

I L

DO

- D7

Iii

CPU

Fig.2-2DataInputCircuitwithParallelInterface

Thefollowingisan explanationofthis handshake.

(1)

WhentheBUSYsignalis LOW(Ready),thehost

computer outputs 8-bitdata 1through8 totheconnectorCN1.

Pin 1carriestheS&OBE pulsesignd-hm thehost~mputer &theprinter.ThissignalisnormalIyheld HIGH

bythe hostcomputer.Whenthehostcomputerhasdatareadyfortheprinter,itsetsthissignaltoLOWforatleast

0.5p.s.

(2)

gatearrayofthemainlogicboardreadsdata1through8atthetimeofSTROBEsignalfall,andthenturnsthe

The

BUSYsignalandP-BUSYsignaltoLOW.

Whenthe BUSYsignalofthegatearrayissettoLOW,theBUSYsignalofconnectorCNlwillbeturnedtoHIGH,

(3)

notifyingthehost computerthatdatacannotbe accepted.

(4)

TheCPUisinformedviatheDOdatalinethattheP-BUSYsignalisLOW.TheCPUthensettheRDsignaltoLOW

andread thedata.

(5)

Uponcompletionofthedatareading,theCPUnotifiesthehostcomputerofthedatareceivablestatebysettingthe

BUSYsignalofconrtectorCNIandtheACKsignaltoLOW.Thisconcludestheexpkmationoftheparallelinterface

handshake.Thefollowingchartshowsthetimingchartof thehandshake.

–14 –

Page 19

““K u

D

w

THEORY OF OPERATION

9

)

I

STOROBE

- i

BUSY

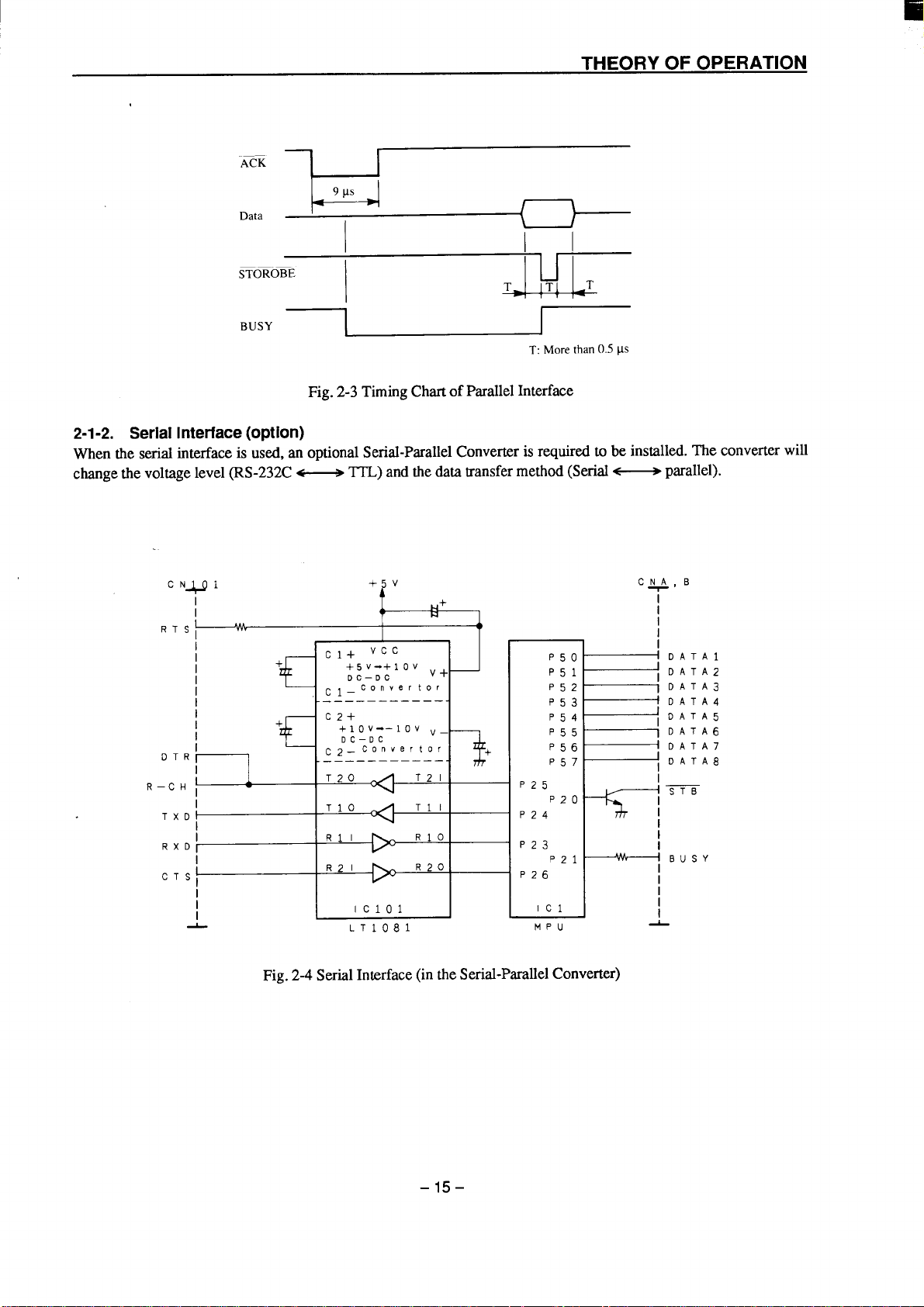

2-Ser(o

Whentheserialinterfaceis used,an optionalSerial-ParallelConverterisrequired to be installed.The converterwill

changethevoltagelevel(RS-232C

C 1

I

R

T

,

1

~ TTL)andthedatatransfermethod(Serial

I

Fig.2-3TimingChartof ParallelInterface

R

I 4

T

I

T

TT

J-Ill

I

M t (

~ parallel).

C B

P50

P

P

P

P

P

P

P

T=

P

P

P

P

P

P

, D

,

, D

1

I

I

I

D

D

D

D

D

S

B

I

$-

1

Fig.2-4SerialInterface(intheSeriai-ParaiielConverter)

– 15-

M

I

Page 20

THEORY OF OPERATION

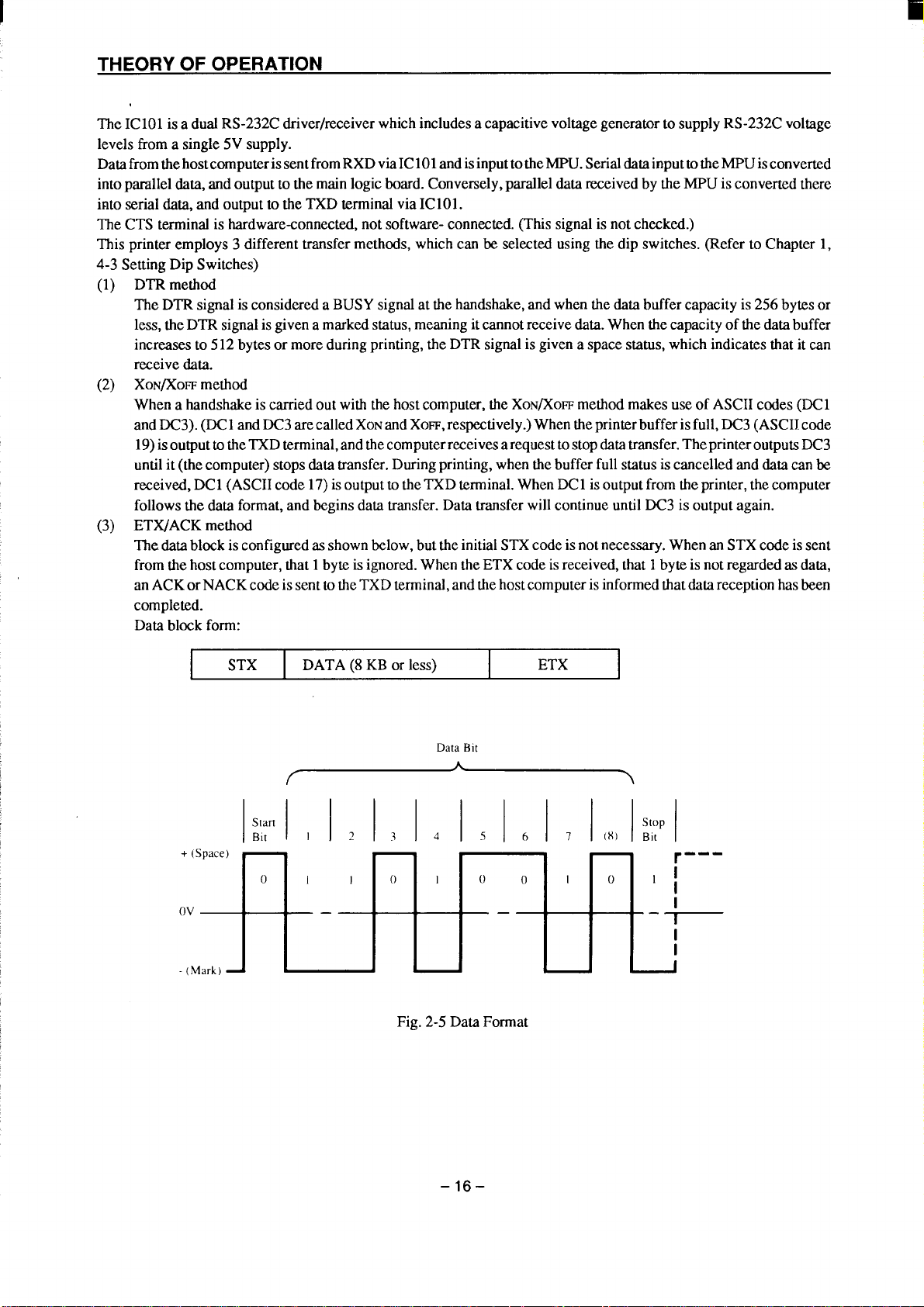

TheIC101isadualRS-232Cdriver/receiverwhichincludesa capacitivevoltagegeneratorto supplyRS-232Cvoltage

levelsfroma single5Vsupply.

DatafromthehostcomputerissentfromRXDviaICIOlandisinputtotheMPU.SerialdatainputtotheMPUisconverted

intoparalleldata,andoutputtothemainlogicboard.Conversely,paralleldatareceivedbytheMPUisconvertedthere

intoserialdata,andoutputtothe TXDterminalviaIC101.

TheCTSterminalishardware-connected,notsoftware-connected.(Thissignalisnotchecked.)

Thisprinter employs 3 differenttransfermethods,whichcanbe selectedusingthedip switches.(Referto Chapter1,

4-3

SettingDipSwitches)

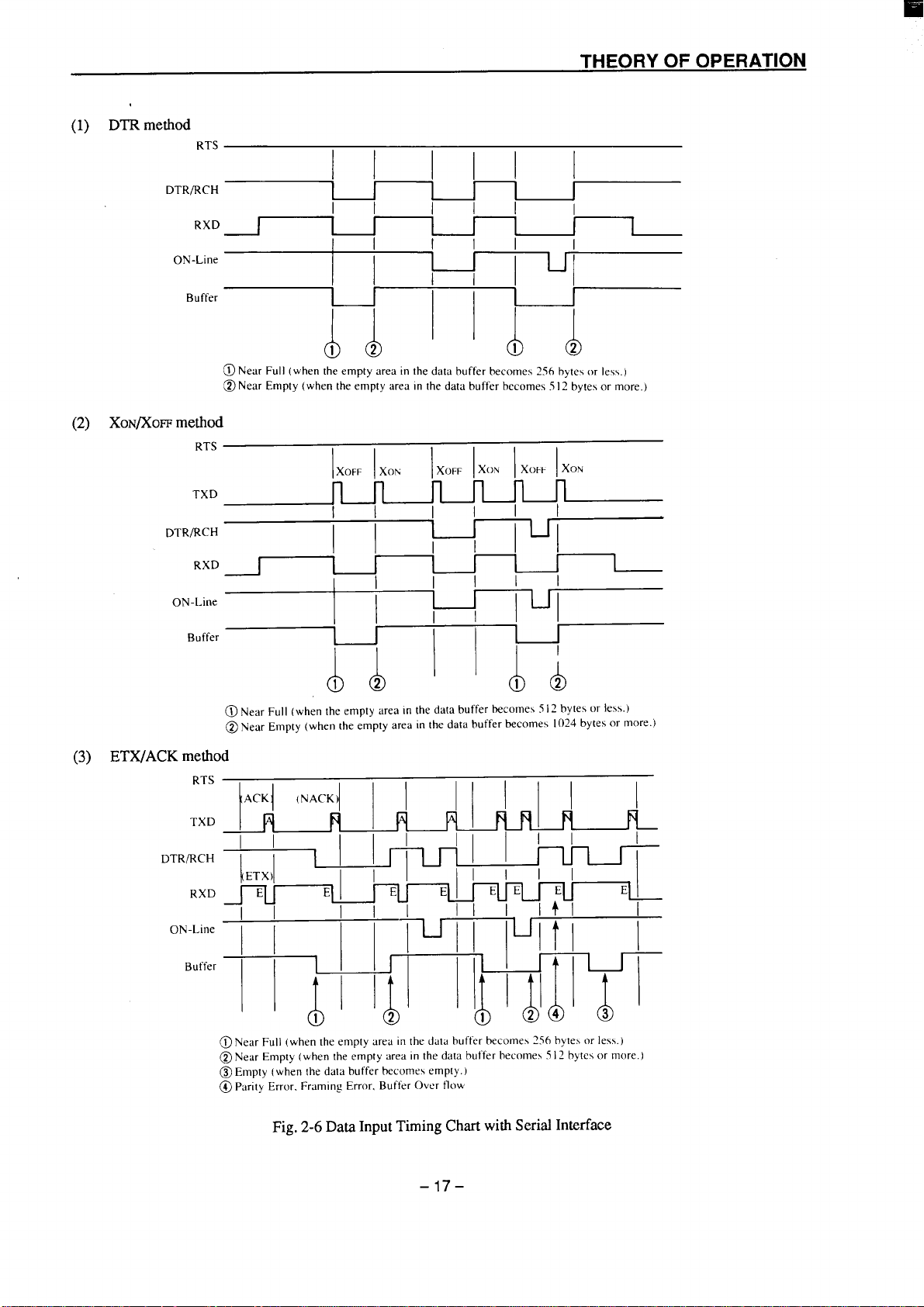

(1)

DTRmethod

TheDTRsignalisconsideredaBUSYsignalatthehandshake,andwhenthedata buffercapacityis256bytesor

less,theDTRsignalis givena markedstatus,meaningitcannotreceivedata.Whenthecapacityofthedatabuffer

increasesto512bytes or moreduringprinting,theDTRsignalis givena spacestatus,whichindicatesthatit can

receivedata.

(2)

XoN/Xommethod

Whena handshakeiscarriedoutwiththehost computer,theXoN/Xommethodmakesuseof ASCIIcodes(DCl

andDC3).(DClandDC3arecalledXONandXom,respectively.)Whentheprinterbufferisfull,DC3(ASCIIcode

19)is outputtotheTXDterminal,andthecomputerreceivesarequesttostopdatatransfer.ThepnnteroutputsDC3

untilit(thecomputer)stopsdatatransfer.Duringprinting,whenthebufferfullstatusiscancelledanddatacanbe

received,DC1(ASCIIcode17)isoutputtotheTXDterminal.WhenDC1isoutputfromtheprinter,thecomputer

followsthedataformat,andbeginsdatatransfer.DatatransferwillcontinueuntilDC3 isoutputagain.

(3)

ETX/ACKmethod

Thedatablockisconfiguredasshownbelow,buttheinitialSTXcodeisnotnecessary.WhenanSTXcodeissent

fromthehostcomputer,that1byteisignored.Whenthe ETXcodeisreceived,that1byteisnotregardedasdata,

anACKorNACKcodeis senttotheTXDterminal,andthehostcomputerisinformedthatdatareceptionhasbeen

completed.

Datablockform:

+(

—

ETX

6 7

0

(

1

0

1

stop

B

---

,;

–-+

I

I

STX

S

B

—

(

DATA(8KBorless)

I ? 3 4

—

Fig. 2-5DataFormat

D B

5

1

–16 –

Page 21

(1) DTRmethod

THEORY OF OPERATION

R

‘T~

“

O

(2) XoN/xoFFmethod

R

T

D

R

O

I I

I

I

I I

Ill

I

,

1

I 2

All

X();t ‘

1

1

12

u

@

N F (w t e a t d b b 2 h l )

@ N E ( t e a t d b b b m

X

X

1

1

II

X x

1

1111

II

1

I

B

(3) ETX/ACKmethod

R

T

D

R

O

B

@ N F (w t e a t d b b 2 h l )

@ N E ( [ e a t d b b b m

@ E ( t d b b e )

@ P E F E B O f

@ N F ( t e f t d b b b l

@ N E ( [ e a t d b b 1 b m

A (

I

II

v

II

E

E

1

F

F

II

E

E E

I I I II I

1111

F N

F

II

‘1tI

I

I I 11 I

F–

E

Fig. 2-6DataInputTimingChartwithSerial Interface

– 17–

Page 22

THEORY OF OPERATION

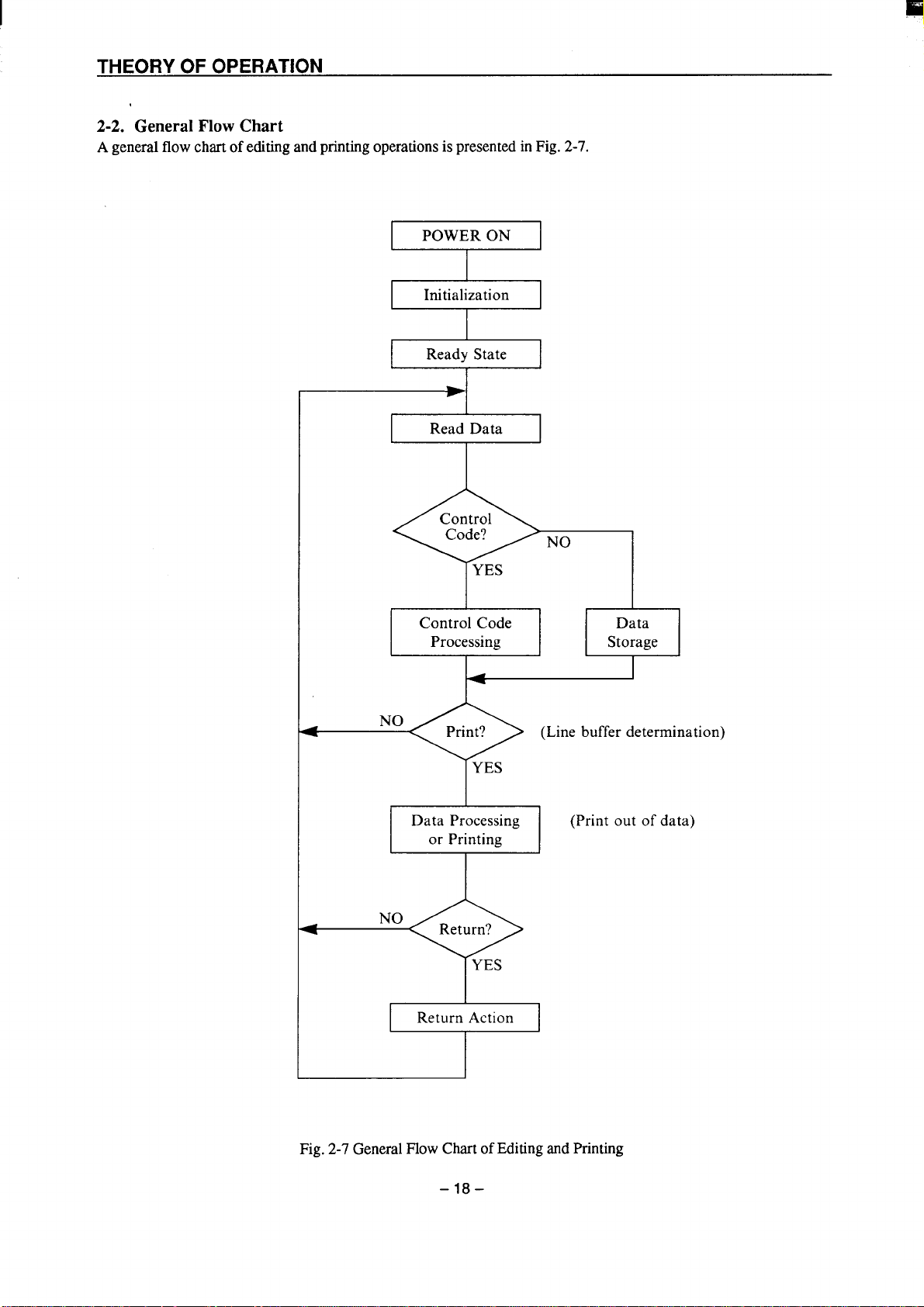

2 General Flow C

Ageneralflowchartofeditingand printingoperationsispresentedinFig.2-7.

POWER ON

I

1

&

Read Data

T

NO

YES

Control Code

Processing Storage

4

Data

t (L

Data Processing

or Printing

(Print out of data)

Q

4

Fig.2-7GeneralFlow ChartofEditingandPrinting

NO

Return Action

–18 –

Page 23

THEORY OF OPERATION

2-2-1. Editing

Datastoredin theRAMisreadoutsequentiallyby theCPUandtheneditedaccordingtoa functioncodethathasbeen

specifiedinadvance.

ThiseditingtakesplacesuntiltheCRorCR+ LF codeappearsorthe linebufferbecomesfull.

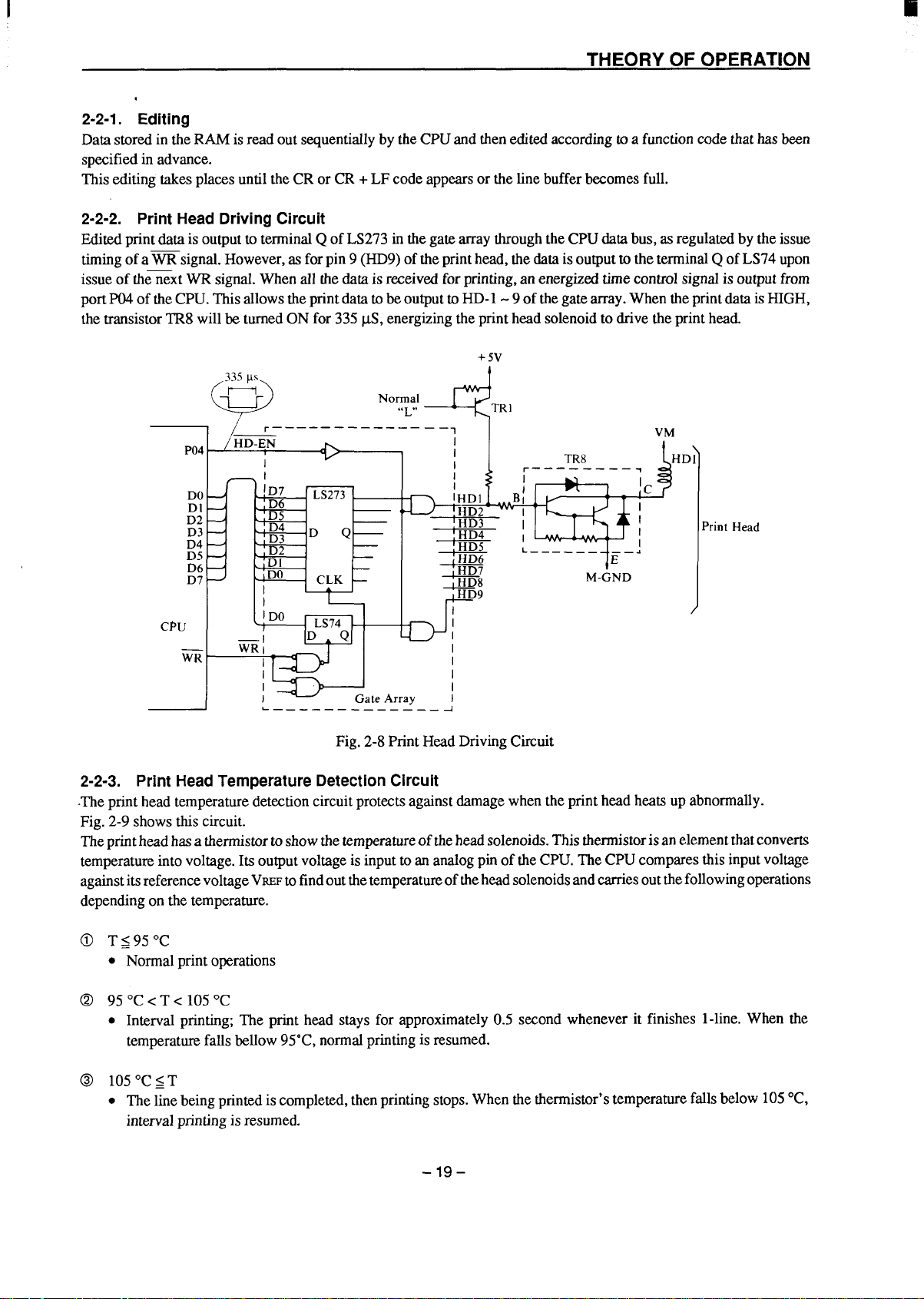

2-2-2. P H DrCi

EditedprintdataisoutputtoterminalQof LS273inthegatearraythroughtheCPUdatabus,asregulatedbytheissue

timingofa WRsignal.However,as forpin9 (HD9)oftheprinthead,thedataisoutputtotheterminalQofLS74upon

issue of thenextWRsignaI.Whenallthe datais receivedforprinting,anenergizedtimecontrolsignalis outputfrom

portP04oftheCPU.ThisallowstheprintdatatobeoutputtoHD-1-9 ofthegatearray.WhentheprintdataisHIGH,

thetransistorTR8willbe turnedONfor 335pS, energizingtheprintheadsolenoidto drivetheprint head.

+ 5V

\

D1

p H

/

Fig.2-8Print HeadDrivingCircuit

2-2-3. P H TeDeC

.Theprintheadtemperaturedetectioncircuitprotectsagainstdamagewhentheprint headheatsup abnormally.

Fig.2-9 shows thiscircuit.

Theprintheadhasa thermistortoshowthetemperatureoftheheadsolenoids.Thisthermistors anelementthatconverts

temperatureintovoltage.Itsoutputvoltageisinputto an analogpinof theCPU.TheCPUcomparesthisinputvoltage

againstitsreferencevoltageVwFtofindoutthetemperatureoftheheadsolenoidsandcarriesoutthefollowingoperations

dependingonthetemperature.

0 Ts95“C

● Normalprint operations

@ 95“C c T < 105‘C

. Intervalprinting;The print head stays for approximately0.5 secondwheneverit finishesl-line. When the

temperaturefallsbellow95”C,normalprintingisresumed.

@ 105‘C ST

. Thelinebeingprintediscompleted,thenprintingstops.Whenthethermistor’stemperaturefallsbelow105“C,

intervalprintingisresumed.

- 19–

Page 24

+5V

T

Y $

F ( ~

I

Fig.2-9Print HeadTemperatureDetectionCircuit

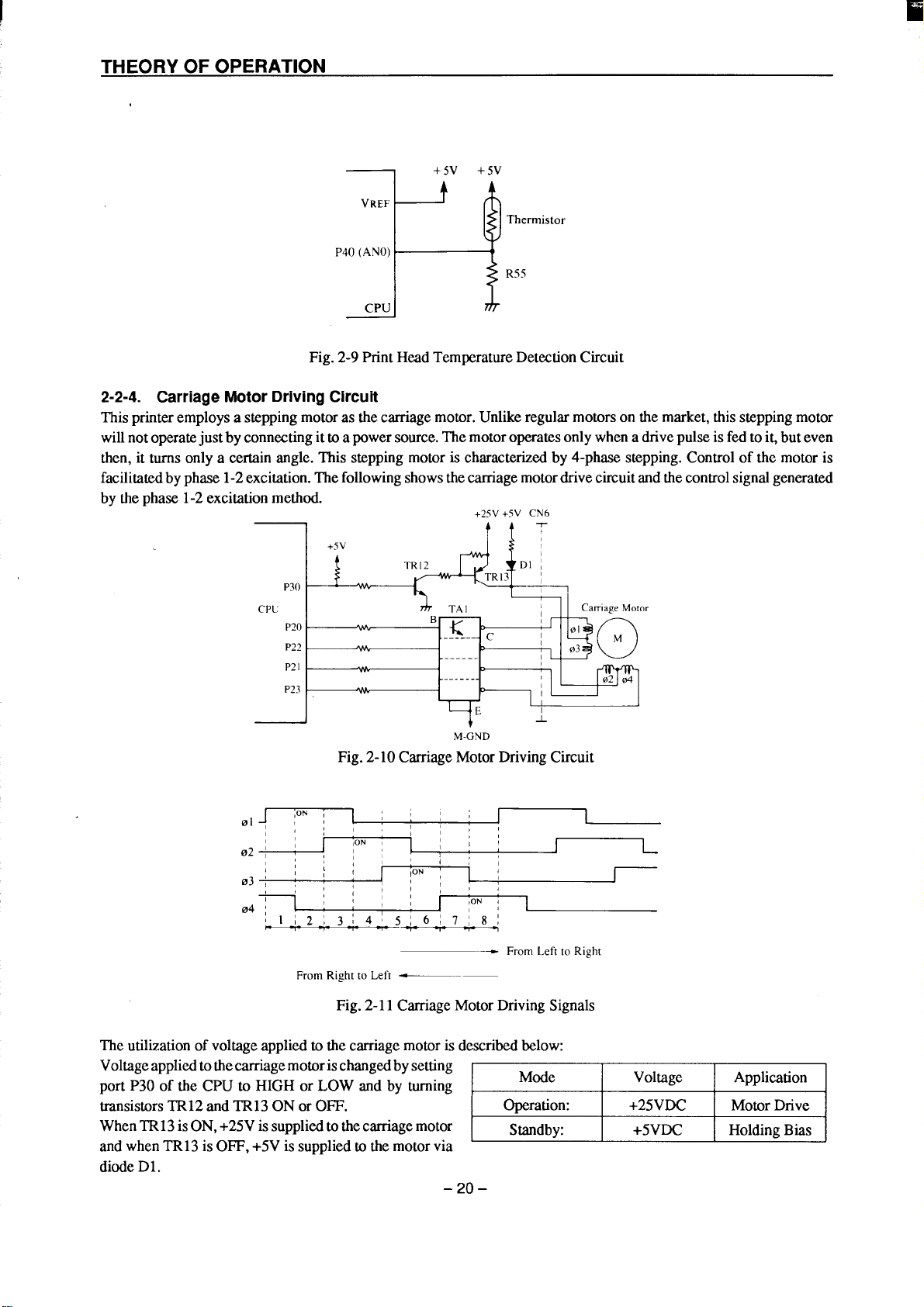

2-2-4. CaM DrC

This printeremploysasteppingmotorasthecarriagemotor.Unlikeregularmotorsonthemarket,this steppingmotor

willnotoperatejustby connectingittoa powersource.Themotoroperatesonlywhena drivepulseisfedtoit,buteven

then,it turnsonlya certainangle.This steppingmotoris characterizedby 4-phasestepping.Controlof the motoris

facilitatedbyphase1-2excitation.Thefollowingshowsthecarriagemotordrivecircuitandthecontrolsignalgenerated

bythephase

1-2

excitationmethod.

+ + C

1 *

C

p

P

P

P

Fig.2-10CarriageMotorDrivingCircuit

1

;

(

–20

I

;

F L R

Mode

Operation: +25VDC

Standby:

–

01 :

03 ; :

Theutilizationof voltageappliedtothecarriagemotorisdescribedbelow:

Voltageappliedtothecarriagemotorischangedbysetting

portP30 of the CPU to HIGH or LOW and by turning

transistorsTR12andTR13ONorOFF.

WhenTR13isON,+25Vissuppliedtothecarriagemotor

andwhenTR13isOFF,+5Vis suppliedtothemotorvia

diodeD1.

;ON :

; , I : I

,,; ,

F R L ~

L

Fig.2-11CarriageMotorDrivingSignals

Carriage MOICN

Voltage Application

MotorDrive

+5VDC HoldingBias

Page 25

I

THEORY OF OPERATION

2-2-5. Carriage M S C

Sincethecarriagemotoris a steppingmotor,tie carriagecanbestoppedatadesiredpositionbycontrollingacceleration

anddeceleration.Thecarriagecanalsomovebackward.

Therotationalspeedof thecarriagemotoris setby thenumberof pulsespertimeunit.Thecharacterpitch(horizontal

chamctersize)in eachprintmodeisdeterminedby changingthisrotationalspeed(orcarriagetransferspeed).

(1) Atstart-upof themotor:

Thenumberofpulsesinput to themotorincreasein steps,reachinga certainfrequency.

(2) Tostop themotoc

Thenumberof pulsesinputtothemotordecreasesinsteps,in orderto graduallybringthemotortoa halt.

(3) Whenprintingiscarriedout:

Pulsesof a uniformpulsewidthare suppliedforprinting.

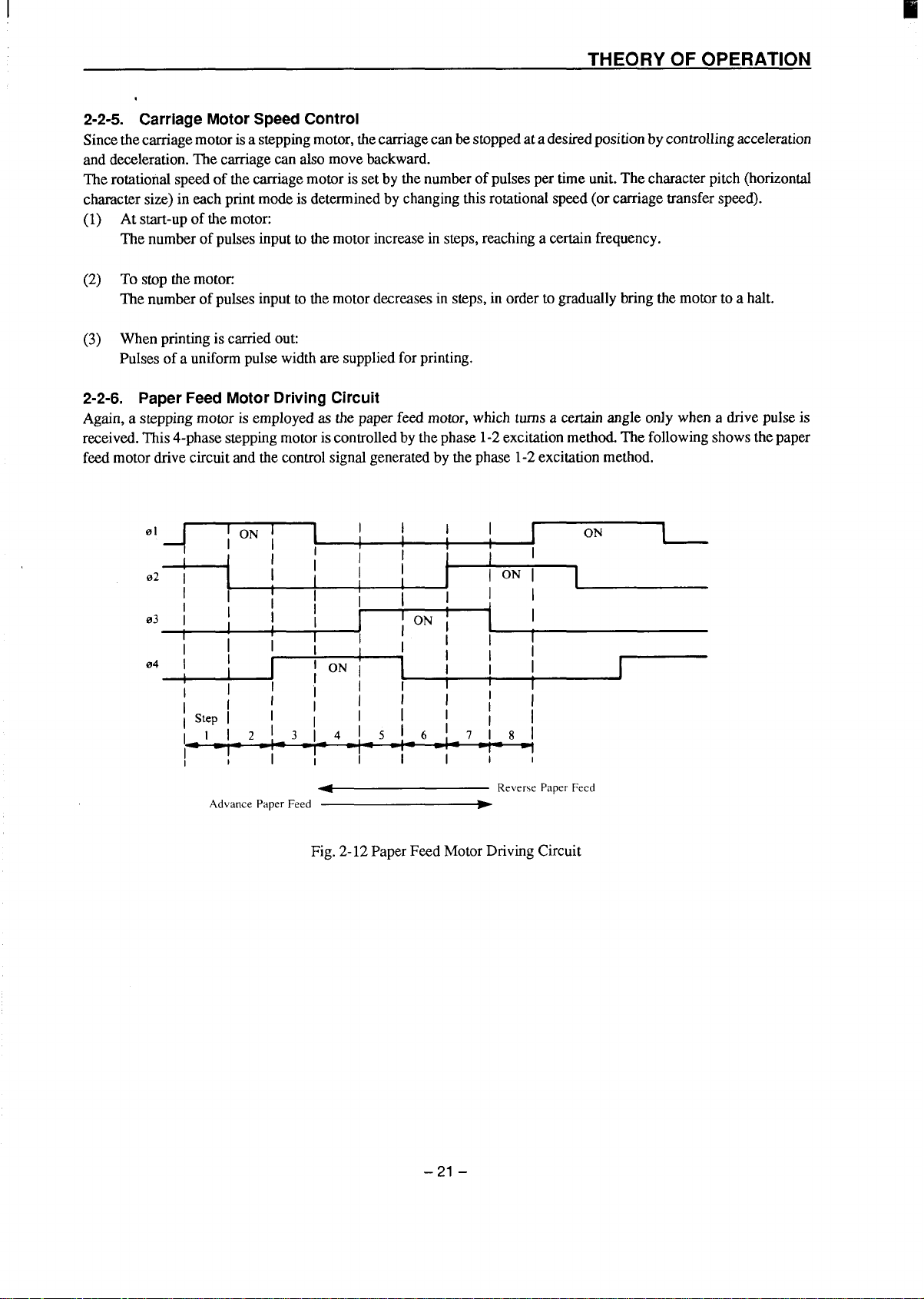

2-2-6. P F M DrC

Again,a steppingmotoris employedasthepaperfeed motor,whichturnsa certainangleonlywhena drivepulseis

received.This4-phasesteppingmotoriscontrolledby the phase1-2excitationmethod.Thefollowingshowsthepaper

feedmotor drivecircuitand thecontrolsignalgeneratedbythephase1-2excitationmethod.

Fig.2-12PaperFeedMotorDrivingCircuit

-21 –

Page 26

6

+

T

P

T

P

P

T

P

T

P

)

)

t

C

I

I

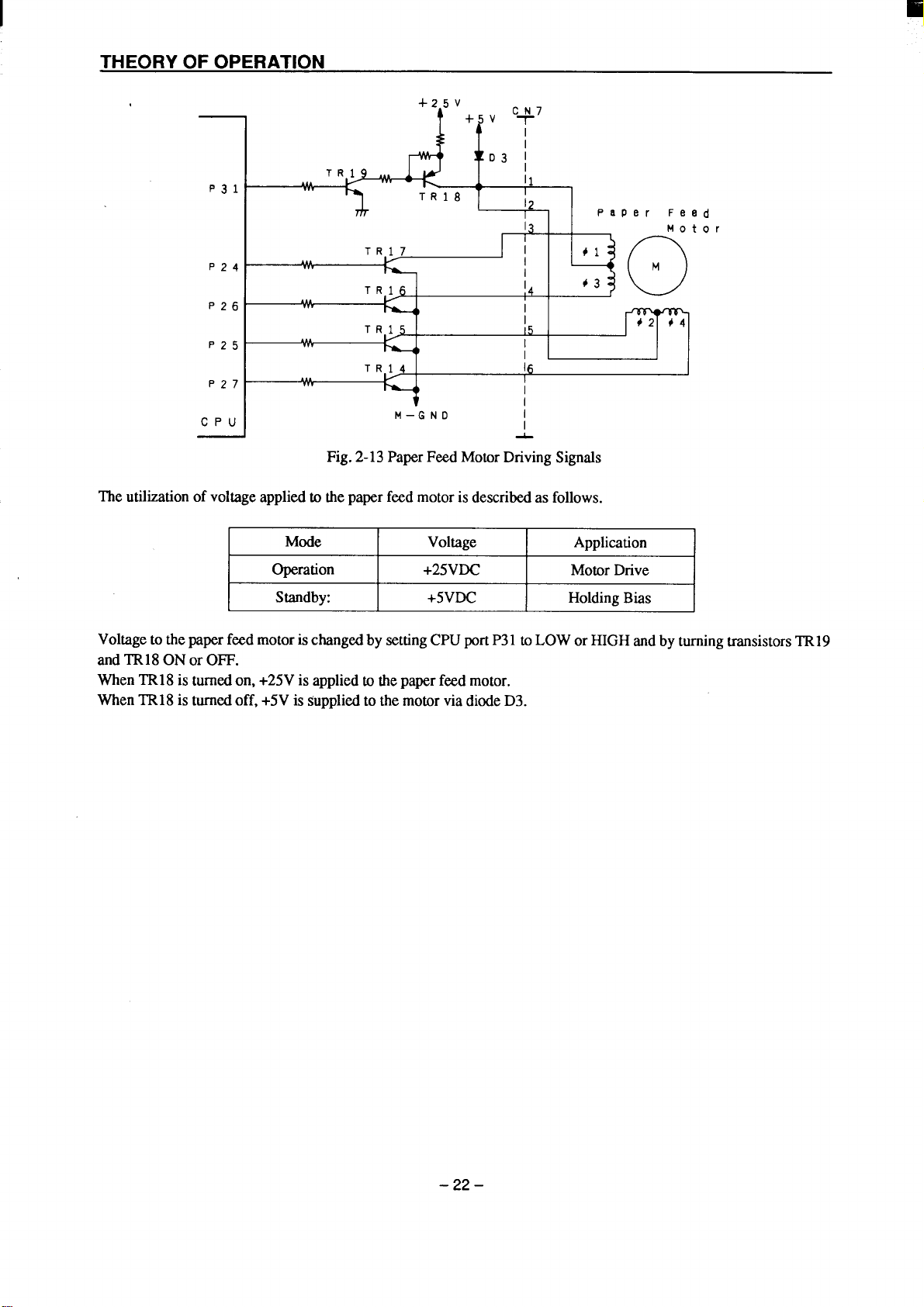

Fig.2-13PaperFeedMotorDrivingSignals

Theutilizationof voltageappliedto thepaper feedmotorisdescribedasfollows.

Mode Voltage Application

1

LD3 I

C

I

I I

13

+3

-+0

4

I

I

I

I

&

P F

M

d

Mot

Operation

Standby:

VoltagetothepaperfeedmotorischangedbysettingCPUportP31toLOWor HIGHandbyturningtransistorsTR19

andTR18ONorOFF.

WhenTR18isturnedon,+25Visappliedtothepaperfeedmotor.

WhenTR18isturnedoff,+5Vis suppliedtothemotorviadiodeD3.

+25VDC

+5VDC HoldingBias

MotorDrive

- 22–

Page 27

1

THEORY OF OPERATION

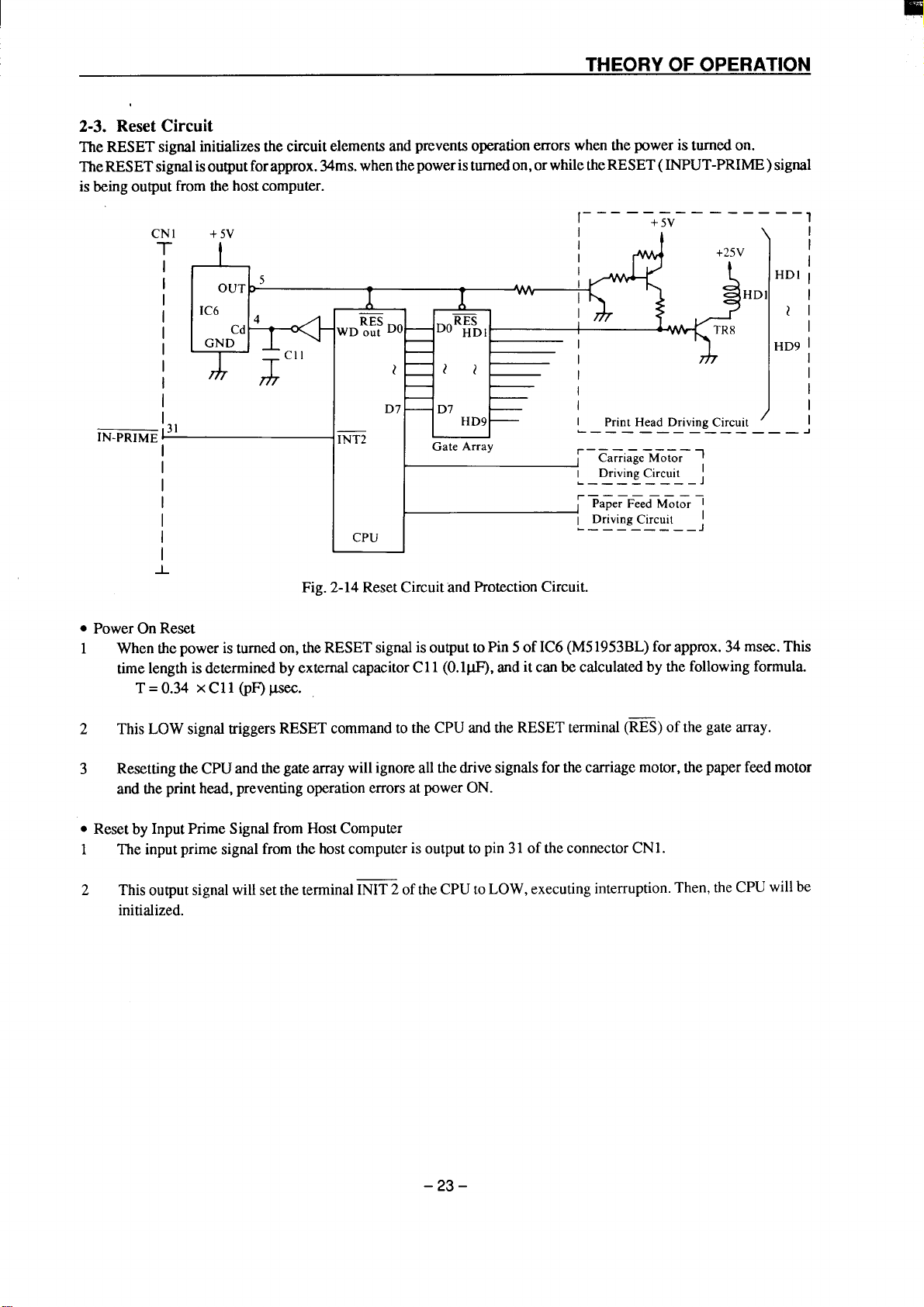

2 R Ci

T RESETsignalinitializesthecircuitelementsandpreventsoperationerrorswhenthepoweristurned on.

TheRESETsignalisoutputforapprox.34ms.whenthepoweristumedon,orwhiletheRESET(INPUT-PRIME)signal

is beingoutputfromthehostcomputer.

——

\

HDI

HD

(

HD9

IN-PRIME

CN1

T

I

I

/

I

+ .5V

t

OUT D

IC6 ~

GND

.———————— — ———

I

I

I

5

1

,

c1 1

J=

WD%? Do —

)

r I

1

DOR&

))

I

I

I

d

+ 5V

A

+25V

I

Fig.2-14ResetCircuitandProtectionCircuit.

● PowerOnReset

1 Whenthepoweristurnedon,theRESETsignalisoutputtoPin5 ofIC6(M51953BL)forapprox.34msec.This

timelengthisdeterminedbyexternalcapacitorCl 1(0.lP.F),anditcanbe calculatedbythe followingformula.

T = 0.34

2 ThisLOWsignaltriggersRESETcommandto theCPUandtheRESETterminal(RES)of thegatearray.

Resettingthe CPUandthegatearraywillignoreallthedrivesignalsforthe carriagemotor,thepaper feedmotor

3

andthe printhead,preventingoperationerrorsatpowerON.

. Resetby InputPrimeSignalfromHostComputer

1 Theinputprimesignalfromthehostcomputerisoutputtopin 31of theconnectorCN1.

2 ThisoutputsignalwillsettheterminalINIT2 oftheCPUtoLOW,executinginterruption.Then,theCPUwillbe

initialized.

X Cll (PF)WK.

–23 –

Page 28

THEORY OF OPERATION

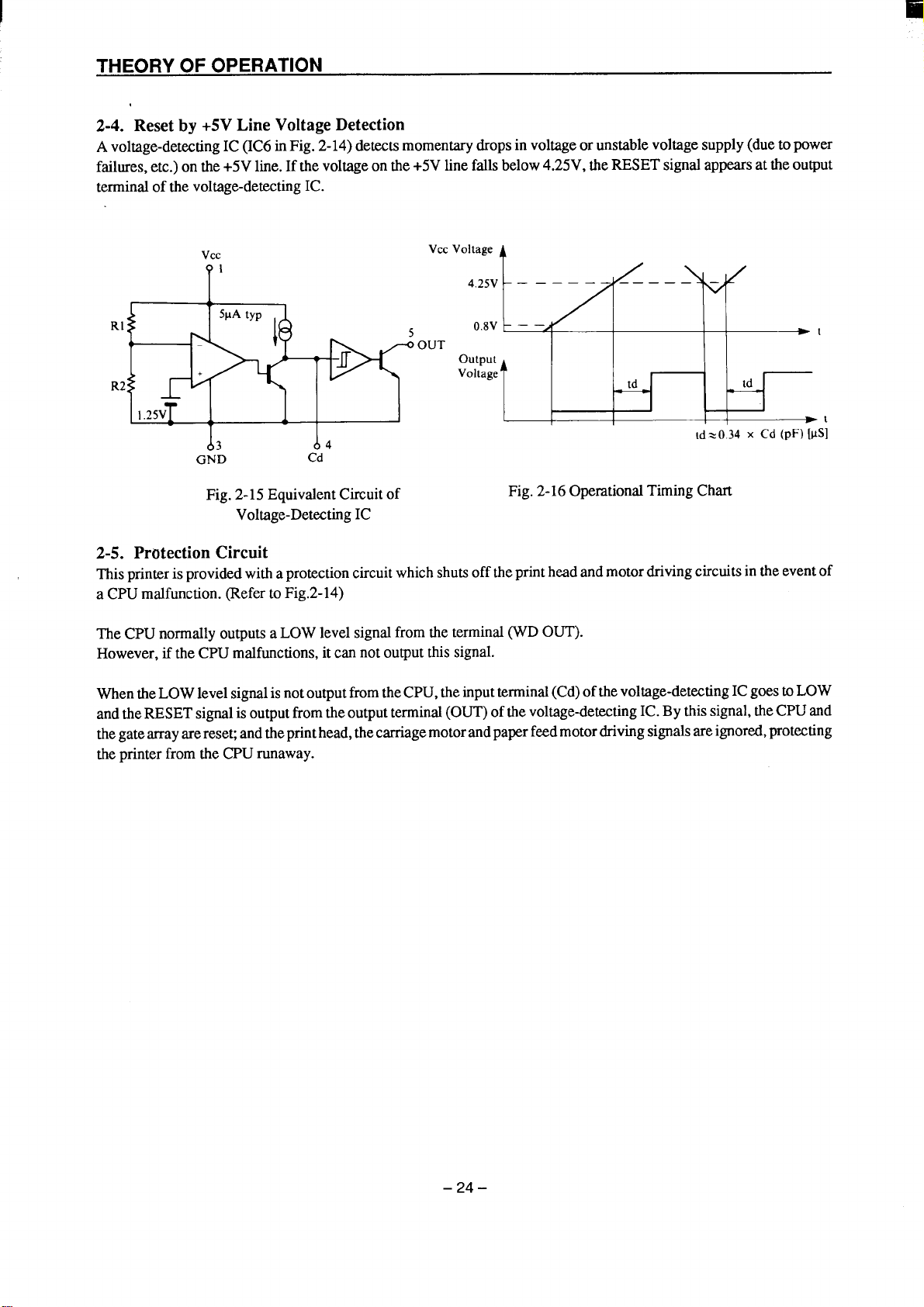

2 R b + V D

Avoltage-detectingIC(IC6inFig.2-14)detectsmomentarydropsin voltageorunstablevoltagesupply(duetopower

failures,etc.)on the+5Vline.Ifthevoltageonthe+5Vlinefallsbelow4.25V,theRESETsignalappearsattheoutput

terminalofthe voltage-detectingIC.

V

5

OUT

VoltageA

o

V A

–— – ——

~

=

*

X ( [

t

w

R2::

()

1,~sv

V

91

t

5pA

+

1

. .

A4

GND

Cd

Fig.2-15EquivalentCircuitof

Fig.2-16OperationalTimingChart

Voltage-DetectingIC

2

PrWection Circuit

Thisprinterisprovidedwitha protectioncircuitwhichshutsofftheprintheadandmotordrivingcircuitsin theeventof

a CPUmalfunction.(RefertoFig.2-14)

TheCPUnormallyoutputsaLOWlevelsignalfromtheterminal(JVDOUT).

However,iftheCPUmalfunctions,itcan notoutputthissignal.

Whenthe LOWlevelsigmlisnotoutputfromtheCPU,theinputterminal(Cd)ofthevoltage-detectingICgoestoLOW

andtheRESETsigmlisoutputfromtheoutputterminal(OUT)of the voltage-detectingIC.Bythissignal,theCPUand

thegatemay arereset;andtheprirtthead,thecarriagemotorandpaperfeedmotordrivingsignalsareignored,protecting

theprinter fromthe CPUrunaway.

–24 -

Page 29

THEORY OF OPERATION

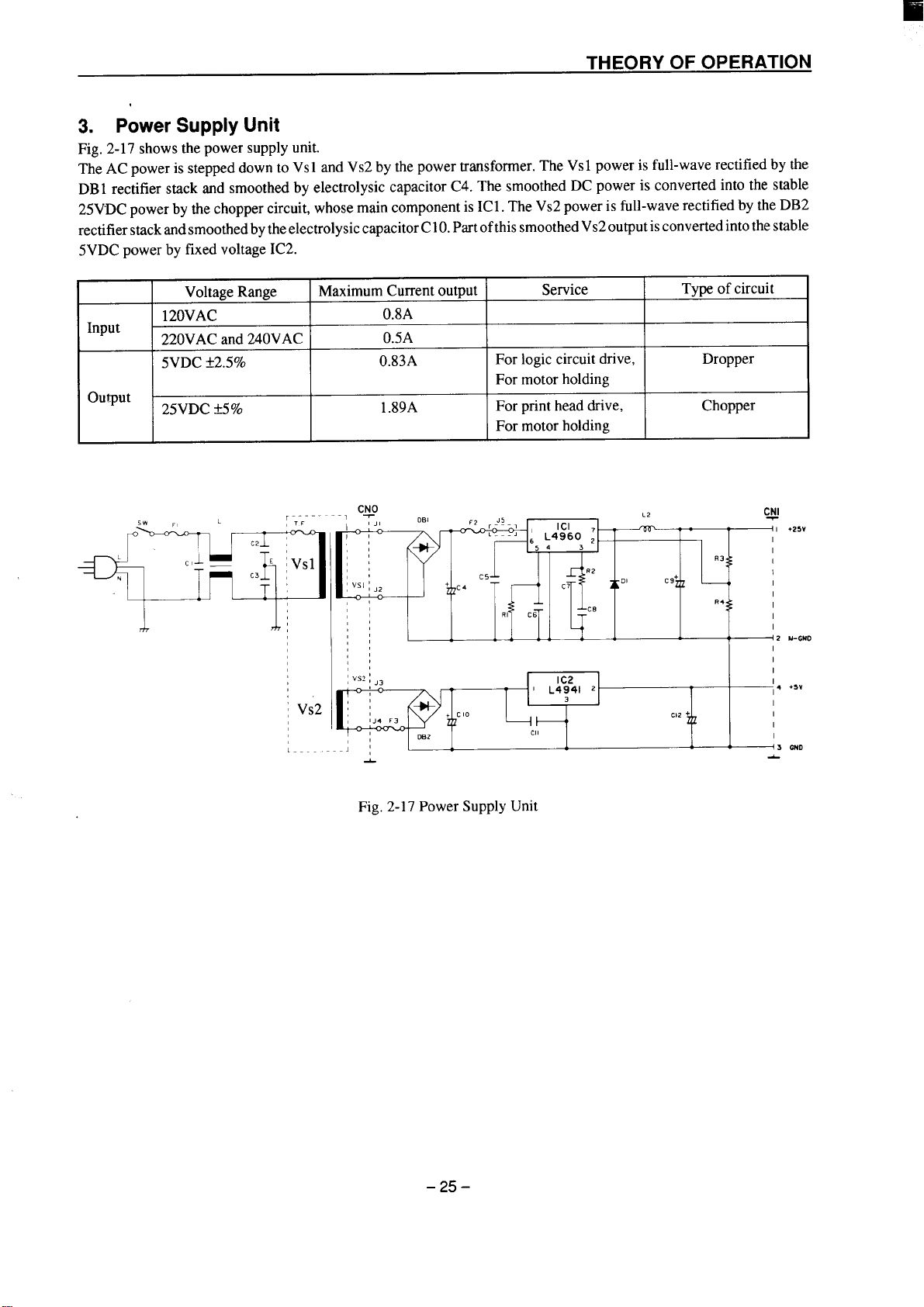

3. Power Supply Unit

Fig.2-17showsthepowersupplyunit.

TheACpowerissteppeddownto Vsl andVS2bythepowertransformer.TheVsl powerisfull-waverectifiedbythe

DB1rectifierstackandsmoothedby electrolysiscapacitorC4. The smoothedDCpoweris convertedintothe stable

25V’DCpowerbythechoppercircuit,whosemaincomponentisIC1.TheVS2 powerisfull-waverectifiedbytheDB2

rectifierstackandsmoothedbytheelectrolysiscapacitorClO.PartofthissmoothedVs20utputisconvertedintothestable

5VDCpowerbyfixedvoltageIC2.

Input

output

VoltageRange

120VAC

220VACand240VAC

MaximumCurrentoutput

0.8A

0.5A

5VDC?2.5% 0.83A

25VDCti%

1.89A

Service

Forlogic circuitdrive,

Formotor holding

Forprintheaddrive,

Formotor holding

Typeofcircuit

Dropper

Chopper

+25V

t

+5V

Fig.2-17PowerSupplyUnit

–25 –

Page 30

THEORY OF OPERATION

WewillexplainthechoppercircuitintermsofFig.2-18,a simplifiedversionofFig.2-17.IC1isa pulse-widthcontrol

switchingregulator.It hasa referencevoltagesection,oscillationsection,pulse-widthcontrol section,and power

transistors.Fig.2-19showsanequivalentcircuitforIC1.

ThechoppercircuitswitchesthepowertransistorsinIC1onandofftodivideinputvoltage

thosepulseswithchokecoilL2andcapacitorC9toobtainthedesiredoutputvoltage

Since thepulse width control sectiondetermines theratio of thetimethatthepower transistorsareonandoff bycomp~ing

the output voltage with the reference voltage, the output

voltagecanbeheldsteady.

Inorderwords,iftheoutputvoltagefallsbelowthereferencevoltage,thepulsewidthcontrollerextendsthetimethatthe

powertransistorsare on,thusraisingtheoutputvoltage.TheoutputvoltageVOUTcanbeexpressedwiththefollowing

equation.

VINintopulsesandsmoothes

VOUT.

Vour = VIN.

TON :

TOFF :

T:

Durationthepowertransistorsareon

Durationthepowertransistorsareoff

TON+ TOFF(constant)

TON

TON+ TOFF

= VIN. +

DiodeD1formsa pathwaythroughwhichtheenergyaccumulatedonchokecoilL2whilethepowertransistor

dischargedwhilethepowertransistorsareoff.

—————————._——————

I

PowerTransistor

o

V

o

I

I

I

I

I

I

I

i

i

I

I

Ic 1

PulseGenerator

Block

I

————

I

1

1—

I

I

I

1 L

LZ

Y

D1

R3

+

4)

z C9

o

o

L _ –

Fig. 2-18ChopperCircuit

a on

is

r-=w-

Os

F C

1

3

(

Inh

\

;w’M

s

‘

I

F

F

R Q--

Q-

1 r

Iv

D

G

i

4

1

Fig. 2-19 Equivalent Circuit for Voltage Regulator IC1

–

–26

Page 31

I

THEORY OF OPERATION

4. Mechanism

P M

Theprintheadconsistsof9 needlewiresand9 printsolenoids.Thefollowingexplainshoweachneedlewireoperates

duringprinting.

(1) Whentheprintsolenoidisenergized,theclapperisattractedbytheironcoreand theneedlewireisdriventoward

theplaten.

(2) Thisneedlewirehitstheplatenviatheinkribbonandpaper.Asingledotisprintedon thepaper.

(3) Whentheprintsdenoidisale-energized,theneedlewireisreturnedtoitsoriginalpositionbyreboundenergyand

springandclapperholder(leafspring)force.

P G

P

I I

S S

N W

I I

.

C H

C

1

4-2.

P C M

print headcarryingmechanismconsistsmainlyofa carriage,timingbelt,carriagemotor,andhomepositiondetec-

tor.

(1)

Carriage

Thecarriageissupportedhorizontallyby meansofthecarriagestayandrearangle,anditmovesfromsidetoside

withtheprintheadmountedaboveit.Atimingbeltis clampedtothebaseof thecarriageanda plateis mounted

atthebaseforhomepositiondetection.

(2)

TimingBelt

Thetimingbeltissuspendedbetweenthetimingpulleyofthecarriagemotorandthetimingpulleyofthetension

lever,and it maintainsaconstanttension.

Thetimingbelt is alsoclampedtothebaseofthecarriagesothatitcanmovethecarriageaccuratelywithdriving

forcefromthecarriagemotor.

(3)

CarriageMotor

Thecarriagemotorisa HB (Hybrid)type,four-phaseand192-polepulsemotor,whichisdrivenbypulsesignals

fromthecontrolcircuit.Therotationalratedependsonthenumberofpulsesperunittime.Byvaryingthisrotational

rate(thatis,thecarriagecarryingrate),the sizeof the horizontalletterscanbe changedineachprint mode.

D

1

o

P I

Fig,2-20OutlineofPrintHeadMechanism

I R

G

I C

B

–27 –

Page 32

I

THEORY OF OPERATION

T B

C M

Fig.2-21PrintHeadCarryingMechanism

4

iswoundupautomaticallywhilethecarriagemovesleftorright.

Theribkm feedmechanismisdrivenbytorquefromthecarriagemotor,andcarriagemovementallowstheidlergearto

rotate.

Thisrotationisconveyedsequentiallytothegearsthatworktowindtheribbon.Thecarriageisequippedwitha clutch

leversothat thedirectionofcassettegearrotationremainsconstantregardlessofthedirectionoftheidlergearrotation.

R M

inkribbonfeedmechanismislinkedtotheprintheadcarryingmeehanismdeseribedpreviouslysothattheinkribbon

C G

T P

f?”

\

I G

G t C L

Fig. 2-22RibbonFeedMechanism

- 28–

Page 33

THEORY OF OPERATION

4-4. Paper Feed Mechanism

paperfeedmotoris aPM type,four-phaseand48-polepulsemotor.

The

Minimumpaperfeedis setat 1/216inch.

Therearetwowaysoffeedingpaperavailablewiththisprinter:FrictionmethodandTractormethod.Youcanselectone

ofthetwomethods,usingtherelease lever.

I Positionofreleaselever

Linkagebetweentractor

gearandtractorclutch

Platenrollerandholderroller

Releaseleverpositiondetector

I Paperfeedingmehd

(1)

Friction Method

Frictionmethodisselectedwhenthereleaseleveris position@.

Withthismethod,paperispressedbetweentheplatenrollerandtheholderroller;therefore,paperisfedastherollers

turn.

Asthe paperfeedmotorisdriven,themotorgear, throughtheidler gear,turnstheplatengearin thepaperfeeding

direction.However,sincethetractorgearandthetractorclutcharenotlinkedat thistime,thetractorunitwillnot

bedriven.

(2) TractorMethod

Tractormethodisselectedwhenthereleaselever is position@.

Paperfeedingisfacilitatedbyrotationofthesprocketpinofthetractorunit.Whenthetractormethodisselected,

thetractorgearis linked to thetractorclutch,enablingthedriveforcegeneratedbythepaperfeed motor to be

transferredtothetractorunitviatheidIergearandtheplatengear.

l

Not

I

Pressed

Closed

I Friction I Tractor I

I

Linked

Not

Open

I

P G T G

L

o

Fig.2-23PaperFeedMechanism

–29 –

Page 34

I

THEORY OF OPERATION

D

HomePositionDetector

(1)

Aleafswitchisusedinthe homepositiondetector,whichis setat theleftsideof theframeunit.

Open/CIOsesignalsaregeneratedaccordingtothepositionoftheshieldplatemountedatthebaseofthecarriage,

andthe printingpositionisdeterminedby thesesignals.

(2)

PaperOutDetector

Apaperoutdetectorislocatedatthepaperinsertionslit.Whenpaperispresent,theprecisionsnap-actingswitch

ofthedetectorisCLOSE.Assoonaspaperrunsout,theswitchissettoOPEN,outputtingapaperemptysignal.

Fig.2-24HomePositionDetector

BailLeverPositionDetector

(3)

Upondetectingthe positionofthebaillever,theautoloadingoperationwillbeactivated.Theleafswitchis open

whenthebailrollersisin contactwiththeplatenroller,andit is closedwhenthebailrolleris sepmatedformthe

platenroller.

(4)

ReleaseLeverPositionDetector

Theleafswitchisclosedwhenthereleaseleveris in thefrictionposition,andis openin thetractorposition.

+5V

R

De

S

L

L

Fig.2-26BailLeverPositionDetector

Fig.2-25PaperOutDetector

+5V

R

D

S

Fig.2-27ReleaseLeverPositionDetector

L

L S

7

–30-

Page 35

C 3

A

Thisprinterhasundergonevariousadjustmentsso thatit will achievestandardperformance.

Inthischapter,abriefexplanationisgivenof themethodsof adjustments.

Followtheinstructionwhenmakingmaintenanceinspectionsorwhenreplacingpartstocorrectmalfunctions.

1.

GapAdjustmentBetweenPrintHeadand Platen

MeG B P H a P

1-1.

Ad

1

Adjustmentof TimingBeitTension

GapBetweenPrintHeadandPlaten

..................................................................

............................................33

................................................

3

..................................................33

34

Page 36

I

Page 37

I

ADJUSTMENTS

1.

Gap Adjustment Between Print Head and Platen

M B P P -

Removetheuppercaseunitaccordingtoprcxxdures

(1)

describedinChapter4.

(2)

Settheindexlever 0 at steptwo.

Removetheribbonguide @ .

(3)

Inserta thicknessgauge @)betweentheprinthead

(4)

(@ rmdtheplaten @ ,andmeasure thegap.

Thismeasurementmustbe carriedoutat thecenter

(5)

0.

Thestandardgapvalueis0.30to0.40 mm.

(6)

Ifthegapdoesnotliewithinthisrange,adjustitby

(7)

followingtheprocedureinitem1-2.

Fig.3-1Gap Adjustment

Step2

Fig.3-2Positionof AdjustmentLever

1-2.

A B P P

Ifthegapdoesn~tliewithinthestandardrange,adjustitby

carryingoutthefollowingprocedures.

(1) RemovetheprintermechanismacccxdingtotheprO-

ceduresdescribedinChapter4.

(2) Loosenthescrew@)securingtheadjustmentlever

@ andtheindexlever~.

(3) Holdingtheindexlever @ atthepositionshownin

Fig. 3-2, shift the adjustmentlever @ for gap

adjustment.

Whentheshaft isloweredtotheplatenside,thegap

isreduced,andwhenloweredto the oppositeside,

thegapisexpanded.

(4)

Afteradjusting,tightenthescrew @ .

[0

Fig.3-3GapMeasurement

A

\-

\

Fig.3-4Gap Adjustment

–33 -

Page 38

ADJUSTMENTS

2. Adjustment of Timing Belt Tension

Thetimingbelt tension shouldbe set atfrom14gto 18g.

(Thebelt tensionmustremeasured with thedesignatedtensiongauge @) .)

Afterthebelthasbeenusedforalong time,

deteriorationor wear.In thesecases,make

(1)

Removetheuppercaseunit accordingtotheproceduresdescribedin Chapter4.

(2)

MovetheCarriageunit@ rightandlefttwoorthreetimesinordertofamiliarizeyourselfwiththetimingbelt @ .

(3)

Settheindexlever @ atstep2asshowninFig. 3-2.

(4)

Movethecarriageunit @ to therightend.

(5)

Setthearm @ ofthetensiongauge @ 152mmaparthorn theframeL.

(6)

Movethetensiongauge@) in thedirectionoftheplaten (@untilitstops.Thenplacethearm @ ofthetension

gaugeon thetimingbelt O .

(7)

Loosenthescrew @ .

Insertaflat-bladescrewdriverintothesquareholeofthetensionarm @)andadjustthebelttensionbymovingthe

(8)

tensionarm @)leftorrigh~

(9)

Whenthebelthasbeenadjustedtotheprescribedtension,tightenthesettingscrew @ .

(lo)

Ifthebeltcannotbe adjustedtotheprescribedtension,replaceit withanew timingbelt @ .

however,itmaybedifficulttomaintainprescribedtensionbecauseofbelt

adjustmentsby followingthe procedureslistedbelow.

Fig.

3-5AdjustmentofTimingBelt- ‘

II

A

@

Fig.3 TensionMeasurement

-34-

Page 39

C 4

P R

This chapterexplains disassemblyand reassemblyof the printer.Note the followingprecautionsduring

disassemblyandreassembly.

1.

Disconnecttheprinterfmm thewalloutletbeforeservicingit.

2.

Assemblyis thereverseofdisassemblyunlessotherwisespecified.

Afterreassembly,coat the screwheadswithlockingsealant.

3.

4.

Lubricationinformationisnotprovidedinthischapter.Referto item2 in chapter5.

1.

UpperCase Unit

2.

PrinterMechanism

PowerSupplyUnit

3.

4.

MainLogicBoard

Fuses

5.

PrintHead

6.

7.

CarriageMotorUnit

8.

PlatenUnit

TractorUnit

9.

....................................................................................................................

..................................................................................................

..............................................................................................

..............................................................................................

................................................................................................

............................................................................................................

............................................................................................

...........................................................................................................

..........................................................................................................

37

37

38

38

39

39

40

40

41

A

E,

10.

DetectorUnit

.......................................................................................................

41

Page 40

Page 41

1. Upper Case Unit

(1) Turnoff thepowerswitch @ .

(2) Remove

● Printercover

. Rearcover

. Platenknob @

● Fourscrews@

(3) Movethecarriageunit @ overtothenghtsothatit

alignswiththecut-outoftheuppercaseunit @ .

(4) Remove

● Uppercaseunit @

. Controlpanelboard (@

2. Printer Mechanism

(1) Remove

●

Uppercaseunitaccordingto the proceduredescribedinitem1.

●

Releaseleverspring @

●

Stopring @

●

Releaselever @

●

Releaseshaftunit @)

●

Threetappingscrews@

●

Connectorcover @

Liftupthetaboftheconnectorcover,andslideit

tothe rightforremoval.

●

Printerheadcable@

●

Threeconnectors@

●

Printermechanism@

Caution in assembly:

Align the

A markon the releaseshaftunit @ to install the

releaselever @ .

A markonthereleaselever @ withthe

–37 -

Page 42

PARTS REPLACEMENT

3. Power Supply Unit

(1) Remove

Uppercaseunitaccording to the proceduredescribedinitem1.

Connector@

Twotappingscrews @

Twotappingscrews @

Twoscrewso

Powerswitch @

Powersupplyunit@

4. Main Logic Board

(1) Remove

●

Printermechanismaccordingto the procedure

describedinitem2.

●

Power supplyunit accordingto the procedure

describedinitem3.

●

Comector @

●

Threetappingscrews@

●

Mainlogicboard @

–38 -

Page 43

PARTS REPLACEMENT

5. Fuses

(1) Remove

● Power supplyunit accordingto the procedure

describedinitem3.

(2) Inspeet

● Fuse F1 @

c FuseF2 @

● Fuse F3 @

Defective~ Replacefuseas follows:

ACVoltage

120V

220V1240V

Destination F2,F3

US,UK,AS

EC,HK,WG,LA,SU EAK3.15A

Newfuseblown+ Inspectcircuit

6. Printer Head

(1) Remove

●

Printercover

●

Inkribboncartridge

●

Conneetorcover@

●

Twotappingscrews@

●

Headcable@

●

Print head@)

WARNING:

Theprint

forit tocoolbeforeremovingit.

(2) Adjust

. Gapbetweenprintheadand platen

Refertoitem1ofChapter3.

headbecomeshotafterprintingsowait

F1

5’ITIA

630mA

1

5TT3A

–39 –

Page 44

I

PARTS REPLACEMENT

7. Carriage Motor Unit

(1) Remove

1

●

Printermechanismaccordingto the procedure

describedinitem2.

●

Cordfastenerbindingtheleadwires

●

Connector@

●

Twoscrews @

●

Carriagemotorunit @)

8. Platen Unit

(1) Remove

●

Printermechanismaccordingto the procedure

describedinitem2

●

Twonuts @

●

Tractorstay @

●

Stopring @

●

Groundcontactspring @

●

PlatenholderR @

●

PlatenholderL (@

Lift the tabs @ of platen holdersR and L to

allowremovalofplatenholdersRandL fromthe

frame.

●

Platenunit @

Cautioninassembly:

Whenassemblingtheplatengearassembly@onthe

idlergear@,aligntheteethofgearAandgemB(be

suretoaligntheholes~ in the twogears).

(2) Adjust

● Gapbetweenprint headandplaten.

Referto item 1of chapter3.

–40 –

Page 45

I

PARTS REPLACEMENT

9. Tractor Unit

(1) Remove

1

●

Uppercaseunitaccordingto the proceduredescribedinitem1.

●

Stopring @

●

Releaselever@

●

Twonuts @)

●

Twotractorbushings@)

Liftthetab@of thetractorbushtoallowremowd

ofthetractorbush fromtheframe.

●

Tractorunit @

Caution in assembly:

Forreassembly,holdthe sheetguide @ at the

.

centerofthetractorshaftandpushtheguideinto

the printer.

. Alignthemark(A or1)on thereleaselever@

withthemark

(Aor 1)onthereleasegear@ to

installthe releaselever@.

O p

N p

10. Detector Unit

(1) Remove

●

Printermechanismaccordingto the procedure

describedin item2.

●

Cordfastenerbindingtheleadwires

●

Sub-guide@

Liftthesub-guidetoremovethecut-out @ from

theprojectionand slideit totheleftto remove.

●

PEdetectoro

●

Screw@

●

Homepositiondetector@

●

Connector@

–41 –

Page 46

Page 47

CHAPTER 5

Em

MAINTENANCE AND LUBRICATION

1. Maintenance

1-1.

Cleaning

1-2. Checks

2. Lubrication

2-1. Lubricant

2-2.

2-3 LubricatedAreas...................................................................................................

LubricatingMethod...............................................................................................

........................................................................................................

.................................................................................................................

....................................................................................................................

...........................................................................................................

................................................................................................................

45

45

45

46

46

46

46

Page 48

Page 49

I

MAINTENANCE AND LUBRICATION

1. Maintenance

Inorderto maintaintheoptimumperformanceof thisprinterandtopreventtrouble,maintenancemustbe carriedout

accordingtothefollowingitems.

1-1.

Cleaning

(1)

Removalofdirt

Wipeoffdirtwitha softclothsoakedin alcoholorbenzine.

*Note: Donotuse thinner,trichleneorketonesolventsbecausetheymaydamageplasticparts.Alsoduring

cleaning,becarefulnottomoistenordamageelectronicparts,wiring,ormechanicalparts.

Removalofdus~pile,etc.

(2)

Vacuumcleaning(withan electriccleaner)isprefen’ed.Removealldus~etc.,inside theprinter.

*Note: Aftercleaning,checktheoil level.If it is notadequatedueto cleaning,replenishit.

1-2.

Checks

Checksmustbecarriedout at twolevels:a“dailycheck”whichtheoperatorcaneasilycarryoutduringoperation,and

a “periodiccheck”whichanexpertshouldcan-yout.

(1) Dailycheck

Whenthe printeris usedon a dailybasis,checkthattheprinteris usedproperly.Makesurethattheprinteris

operatingunderthebestconditions.

● Is anypaperstuckinthepaperboxorprintercase?

● Is thecartridgeribbonsetat therightposition?

. Isthereanyforeignmatterinsidetheprinter?(Removeifany.)

. Istheprintheadgettingexcessivelydirty?

(2) Periodiccheck

After6 monthsorprinting1millionlines, theperiodiccheckand lubricationmustbe carriedout.

. Checkfordeformationofsprings.

● Checkthegapbetweentheplatenandtheprinthead.

● Removedust, m etc.,aroundthedetectors.

–45 -

Page 50

MAINTENANCE AND LUBRICATION

2. Lubrication

Lubricationis veryimportanttomaintainoptimumperformanceandtopreventtrouble.

2-1. Lubricant

The type of lubricant greatly affects the performance and durability of the printer, especially in a low temperature

environment. We recommend use of the grease and lubrication oils listed below for this printer.

I

I FLOILGB-TS-OandGB-1OO

2-2. Lubricating

Whenlubricationiscarriedoutinassemblyanddisassembly,washpartswelltoremovedustanddirtbeforelubrication.

Lubricationmustbecarriedoutregularlyonceevery6 monthsorafter1millionlineshavebeenprinted.Lubricationis

necessaryirrespectiveoftheregularlubricationwheneverlubricantbecomesdeficientaftercleaningorwheneverparts

havebeendisassembledorreplaced.

2.1.

- -. ---- ------ ------

Productname

I

I KantoChemicalsCo.,Ltd.

KF96-1OOOCSandKF96-SP ShinetsuChemicalIndustry

Mobil1

Method

1.llhriontdAreas

NO.

1

2

3

4

5

6

7

8

9

10 Rubbingsurfacesofrearangleandcarriage

11

12 Rubbingsurfacesofbushingandcarriagestay

13

14

15

16

17

18 Rubbingsurfacesofidlerassy711andgearcover

19

20

21

Rubbingsurfacesof idlergear16x72x 0.5andidlergearshaft

Rubbingsurfacesof gear40x 0.5 andgearshaft

Rubbingsurfacesof timingpulleyandpulleybushing

Rubbingsurfacesoftimingpulleyandpulleyshaft

Rubbingsurfacesof twotractorbushingsandtractorshaft

Rubbingsurfacesof idlergear17x 41 x 0.3 andclutchlever

Rubbingsurfacesof idlergear16x 1-40x 0.3andcarriage

Rubbingsurfacesofribboncassettegearandcarriage

Rubbingsurfacesof idlergear43x 63 x 0.3andcarriage

Rubbingsurfacesof Adjustingleverandframe

Rubbingsurfacesof bailrollerand shaft

Rubbingsurfacesoftimingpulleyandstopring

Rubbingsurfacesoftractorholderandtractorcover

Rubbingsurfacesofreleaseshaftandframe

Rubbingsurfacesof releaseleverandtractorshaft

Rubbingsurfacesof wavewasherandpoly-slider

RubbingsurfacesofidlerassyTRXandgearcover

RubbingsurfacesofrearangleandidlerassyTRX

Mobiloil

Maker

LubricatingPoint Grease/Oil

GB-TS-O

GB-TS-O

GB-1OO

GB-TS-O

GB-TS-O

GB-TS-O

GB-TS-O

GB-TS-O

GB-TS-O

GB-TS-O

GB-TS-O

Mobil1

KF96-SP

GB-TS-O

KF96-1OOOCS

GB-TS-O

GB-TS-O

GB-TS-O

GB-TS-O

GB-TS-O

GB-TS-O

–46 –

Page 51

MAINTENANCE AND LUBRICATION

Detail- B

Fig.5-1LubricatedAreas

-47-

%

Page 52

Page 53

CHAPTER 6

TROUBLESHOOTING

TroubleshootingProcedures

1.

Unit ReplacementPriorityChart

2.

Repalrby Unit Replacement

3.

Repalrby PartsReplacement

4.

4-1. DoesnotOperateatAll

4-2.

PowerSupplyCircuitAbnormal

4-3. DefectiveMotorOperation

4-4. DefectivePrintHeadOperation

4-5. DefectiveInterfaceOperation

.............................................................................

........................................................................

..............................................................................

.............................................................. ..............

withPoweron

..........................................................................

...................................................................................

...........................................................................

..............................................................................

...............................................................

51

52

53

59

59

60

61

62

63

Page 54

Page 55

TROUBLESHOOTING

1. Troubleshooting Procedures

Troubleshootingisnevereasybecausevariousproblemsarisedependingupontheparticularlocationofthebreakdown.

Thefollowingproceduresshouldbetakenin makingrepairs.

(1) Thefirstmethodistomakerepairsthroughunitreplacements.Thetwodisplaycodesappearingintheflowchat

aredefinedasfollows:@indicatesmainlogicboardreplacement;and@indicatesprintermechanismreplacement,

tobecarriedoutif problemhasnotbeencorrected.

0

@

Checkagainatthistimewhetherthereplacedunitismalfunctioning,(Thisis donetoruleouttroublecausedbyimproper

contactofconnector.)

Replacxxbleunitsincludethefollowing:

● Powersupplyunit

. Mainlogic board

. Printermechanism

Inreplacingtheseunits,alwaysreferto theunitreplacementchart.

(2) Thesecondmethodistomakerepairsby partsreplacementtoreplacedefectiveelementsinsideaparticularunit.

(Note1) Beforestartingtorepair, be suretocheckvisuallythecontactofthe connectorandthemountingoftheIC

intheIC socket.

(Note,2)

(Note3)

(Note4)

(Note5) BeCarefultoavoidinjuryhorn staticelectricitywhenhandlingICSandmainlogicboard.

Alwaystumoffpowersourceandremovepowerplugbeforereplacingany unitsor parts.

Allchak itemsshownin the flowchartmustbe checked.Otherwise,newlymountedpartsorunits may

becomedarnaged.

If,intheprocessofmakingrepairs,thereisanyconfusionaboutproperprocedures,restartthejob fromthe

beginning.

MainLogicBoardReplacement

PrinterMechanismReplacement

-51-

Page 56

TROUBLESHOOTING

2. Unit Replacement Priority Chart

Category

3

3

g

c onlycannotk 1

“:

j

%

~

?.?

B

s

~~

.2 +’

E’

~e

~j

h

g

~

g DIPswitch

:

3

g

a

a

%

~

u

Problem

Details

Specificdisplay

lamponlywill

notglow

Specificswitch

input

Buzzerdoesnot

sound(sound

volume

inadequate)

Srrangesounds

duringoperation

No motor

holdingpower

(powervery

weak)

;;;;~!ght

Inkribbon

snagged

(wiresticksout)

Absenceofpaper

notdettxted

Leverposition

notdetected

Incorrectprinting

Inkribbonnot

forwarded

Nooperationat

setting

Faultyoperation

whenpoweris

turnedon/off

Abnormalmotor

operatingspeed

(slow)

Fuseblown

duringoperation

Power

supplyunit

UnitExchangeSequence

2

3

Main

logicboard

1

1

1

1

2

2

2

2

1

1

1

1

1

1

Printer

mechanism

2

2

1

1 Replaceinkribbon

1

1

2

1

2

2

Remarks

CheckI/Fcable

Note:Thefigures1,2 and3 meanthepriorityof replacement.

-52-

Page 57

3. Repair by Unit Replacement

* Turn power off.

* Remove l/F cable.

* Mount ink ribbon.

* Set paper.

* Move carriage to center. ]

Turn power on.

I

TROUBLESHOOTING

@

YES

NO

Replace printer

mechanism.

@

*I See (6) and (7) waveform

in item 8 of chapter 7.

NO

@ Replace main logic

board.

@ Replace printer

mechanism.

I

NO

I

@ Replace main logic

board.

@ Replace printer

mechanism.

,

I

-53-

(9

Page 58

TROUBLESHOOTING

YES

NO

Press paper feed switch.

operation is normal?

YES

Turn power off.

I

Holding paper feed switch,

turn power on.

NO

Replace main logic

board

NO

Self

printing:

4

Q

motor drive waveform

Replace printer

mechanism.

@

*2 See (8) and (9) waveform

in item 8 of chapter 7.

NO

@ Replace main logic

board.

@ Replace printer

mechanism.

I

YES

NO

Replace printer

mechanism.

(9

-54-

*I See (6) and (7) waveform

in item 8 of chapter 7.

NO

@

Replacemainlogic

board.

@ Replaceprinter

mechanism.

Page 59

2

Q

YES

NO

NO

Replace printer

mechanism.

@

TROUBLESHOOTING

*3 See(4) and(5) wavef’orm

in item 8 of chapter 7.

NO

@ Replace main logic

I board.

@ Replace printer

mechanism.

1

I

*2 See (8) and (9) waveform

in item 8 of chapter 7.

YES

Terminates self printing.

Check host computer

connection.

I

Turn power off and

check I/F cable.

Turn power on.

NO

O Replace ink ribbon.

@ Replaceprinter mechanism.

@

I

I

Replace printer mechanism.

I

o

YES

I

@)Replace main logic board.

@ Replace printer mechanism. I

I

I

Send print program

from host computer.

-55-

Page 60

TROUBLESHOOTING

Stop print

program.

I

END

-(D

(IJ Replace I/F cable.

@ Replace main logic

board.

@ Check host computer,

o

NO

Turn power off.

I

Replace fuse.

Remove cormqctor

CN5

from

main logic board.

1

Turn power on.

[

4

0

I

I

YES

I

@ Replace main logic

board.

@ Replace printer

mechanism

I

I

I

Replace power supply

unit.

*4

+25V Line

+5V Line

+2SV*5%

+5V*2.5YC

●

●

Pin I of CN I

Pin 4 of CN I

-56-

Page 61

TROUBLESHOOTING

NO

Replace power supply

I

Turn power off.

I

I

#

unit.

Connect connector

CN5 from

I

Turn power on.

Replace fuse.

@ Replace main logic

board.

@ Replace printer

mechanism

F

@

I

I

NO

●

*4

+25V

+5V Line

Line

+25V*5%

+5V~2.5T0

Pin I of CN1

Pin 4 of CN 1

–57 -

Page 62

TROUBLESHOOTING

cl

Check hardware or host

computer print program.

*5 See(l O)waveforrnin

item 8 of chapter 7.

YES

No

YES

*

m

Change I/F mode.

Replace I/F cable.

@

@ Replace main logic

board.

4

Y

o

@

-58-

Page 63

4. Repair by Parts Replacement

4-1.Doesnot Operateat AllwithPoweron

TROUBLESHOOTING

w

I

YES

YES

NO

NO

NO

DC Power abnormal.

I

Check RESET circuit;

replace parts.

Check crystal circuit;

replace parts.

See 4-2. Power Supply

I

Circuit Abnormal.

*

YES

Carriage motor abnormal.

4

I

Check operation.

I

END

NO

@ Replace CPU or ROM,

@ Check ~elevant circuit.

1

See (2) waveform in item 8 of chapter 7.

*2

See (1) waveform in item 8 of cbapter 7.

*3

*1

+25V Line

+5V Line

+25vf570

+5V*2.570

Pin I of CN1

Pin 4 of CN1

b

*

Page 64

TROUBLESHOOTING

4-2. Power Supply Circuit Abnormal

(1) RemoveconnectorCN5fromthemainlogicboard.

START

YES

Replace

Fuse F1

I

YES

Replace

Transformer

I

I

1

No

Replace

Tritnsformer

4

YES

Connect the

Connector CN5

I

The no load voltages are below:

-

+

NO

A

YES

YES

1

Check and replace

(D ICI

@Dl

~ DB 1

I

I

Check and replace

c IC2

@ DB2

I

I

-60–

Page 65

4-3. DefectiveMotor Operation

TROUBLESHOOTING

START

7

YES

NO

Check and replace

c’ TR201

a’ TR19

@

NO

Check and replace

o TR14-17

@ CPU

CPU

1

1

I

NO

Check and replace

YES

-1

YES

4

●

1

Replace

CR-motor

@ TR201

@ TR 12

@

NO

Check and replace

@ TAI

a’CPU

I

I

CPU

1

1

I

w

Check operation.

*4 See (8) waveform in item 8 of chapter 7.

*5 See (9) waveform in item 8 of chapter 7.

* 6 See (6) waveform in item 8 of chapter 7.

*7 See (7) wavefo~ in item 8 of chapter 7.

1

Check operation

-61 –

Page 66

TROUBLESHOOTING

4-4. DefectivePrintHeadOperation

NO

*

Check and replace

@ TR1

@ TR2

o Gate array

YES

●

YES

NO

I

Power supply

unit abnormal.

(Refer to item 4-2.)

1

I

Check and replace

@ Gate array

@)

CPU

NO

4

NO

1

Check and replace

@ TR3-1 I

YES

I

Adjust gap

(Refer to chapter 3.)

I

Check and replace

~ Print head

I

L

*8 See (4) waveform in item 8 of chapter 7.

-62-

Page 67

4-5. DefectiveInterfaceOperation

START

T

TROUBLESHOOTING

I

YES

CheckI/Fcable.

[

Checkandreplace

@IC5

@Gatearray

@CPU

4

Check operation

-63–

Page 68

I

Page 69

CHAPTER 7 PARTS LIST

HOW TO USE PARTS LIST

(1) DRWG. NO.

This column shows the drawing number of the illustration.

(2) REVISED EDITION MARK

This column shows a revision number.

Parts that have been added in the revised edition are indicated with “#”.

Parts that have been abolished in the revised edition are indicated with “*”. For example,

#1 : First edition → Second edition #2 : Second edition → Third edition

*1 : First edition → Second edition *2 : Second edition → Third edition

(3) PARTS NO.

Parts numbers must be notified when ordering replacement parts.

(4) PARTS NAME

Parts names must be notified when ordering replacement parts.

(5) Q’TY

This column shows the number of the part used as indicated in the figure.

(6) REMARKS

When there are differences in the specifications of the fuse, destinations, etc., the differences are described in

words or indicated by two letters.

US ..... U.S.A. EC .... EC UK ... United Kingdom HK .......Hong Kong

AS ..... Austraia WG ... Germany LA ... Latin America SU........ Russia

The seal number of ROM is described in this column. The “**” mark of seal number is a variable representing

on the software version.

(7) RANK

Parts marked “S” are service parts. Service parts are recommended to be in stock for maintenance.

1.Printer Assembly .................................. 66

1-1. Disassembly Drawing....................... 66

1-2. Parts List............................................ 67

2.Printer Mechanism ............................... 69

2-1. Disassembly Drawing....................... 69

2-2. Parts List............................................ 70

3.Sub-assembly ....................................... 71

3-1. Lower Case Unit................................ 71

3-2.

Serial-Parallel Converter

(Option).....................................................

3-3. Frame Unit ......................................... 73

3-4 Platen Unit ......................................... 74

3-5. Tractor................................................ 75

72

4.Wiring Scheme of Printer .................... 76

5.Main Logic Board .................................. 78

5-1. Circuit Diagram ................................. 78

5-2. Component Layout ........................... 82

5-3. Parts List............................................ 84

6.Power Supply Unit ................................ 87

6-1. Circuit Diagram ................................. 87

6-2. Component Layout ........................... 88

6-3. Parts List............................................ 89

7.Serial-Parallel Converter Board

(Option)

7-1. Wiring Scheme .................................. 91

7-2. I/F Board ............................................ 92

7-2-1. Circuit Diagram ........................ 92

7-2-2. Component Layout .................. 92

7-3-3. Parts List .................................. 92

7-3. CPU Board ......................................... 93

7-3-1. Circuit Diagram ........................ 93

7-3-2. Component Layout .................. 94

7-3-3. Parts List .................................. 94

................................................... 91

7

– 65 –

Page 70

1. Printer Assembly

1-1. Disassembly Drawing

– 66 –

Page 71

1-2. Parts List

Printer Assembly

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

1 89060790 MECHANISM WITH HEAD DP891F 1 S

2 87801010 LOWER CASE UNIT ZL-10 1 S

3 87802010 MAIN LOGIC BOARD UNIT ZL-10 1 EXCEPT FOR HK,SU S

87802080 MAIN LOGIC BOARD UNIT ZL-10 HK 1 FOR HK S

#2 87805250 MAIN LOGIC BD UNIT ZL-10 SU 1 FOR SU S

4 87803010 POWER SUPPLY UNIT ZL-10 US 1 FOR US S

87803030 POWER SUPPLY UNIT ZL-10 EC 1 FOR EC,WG,LA S

87803040 POWER SUPPLY UNIT ZL-10 UK 1 FOR UK S

87803200 POWER SUPPLY UNIT ZL-10 HK 1 FOR HK S

#1 87803270 POWER SUPPLY UNIT ZL-10 AS 1 FOR AS S

#2 87803620 POWER SUPPLY UNIT ZL-10 SU 1 FOR SU S

5 82040070 SUB-GUIDE 891 1 S

6 *3 83023900 UPPER CASE ZL-10 1 S

#3 83023901 UPPER CASE ZL-10 1 S

7 80086660 OPERATION SHEET ZL-10 1 EXCEPT FOR SU S

#2 80087070 OPERATION SHEET SPECIAL ZL-10 1 FOR SU S

8 80083060 BRAND SEAL NX-1001 1 FOR US,HK,LA,SU S

80083160 BRAND SEAL LC-20 1 FOR EC,UK,AS,WG S

9 83023920 PRINTER COVER ZL-10 1 S

10 87806010 PAPER GUIDE UNIT ZL-10 1 S

11 *2 83023930 REAR COVER ZL-10 1 S

*3 83023931 REAR COVER ZL-10 1 S

#3 83023933 REAR COVER ZL-10 1 S

12 83902760 PLATEN KNOB ZL-10 1 S

13 *4 80981560 INK RIBBON CARTRIDGE UP NX1000 1 FOR US,LA S

#4 80980850 INK RIBBON CARTRIDGE UPC LC9 1 FOR US,LA S

*4 80981160 INK RIBBON CARTRIDGE JA NX1000 1 EXCEPT FOR US,LA S

#4 80982290 INK RIBBON CARTRIDGE JAN LC9 1 EXCEPT FOR US,LA S

14 87805010 RELEASE SHAFT UNIT ZL-10 1 S

15 *2 83400800 RELEASE LEVER 891F 1 S

#2 83400801 RELEASE LEVER 891F 1 S

16 *3 80530840 RELEASE LEVER SPRING 891F 1 S

17 *1 83910840 CABLE HOLDER 891 1 S

#1 83910841 CABLE HOLDER 941 1 S

18 *1 82900772 RIBBON HOLDER 891 1 S

#1 82900773 RIBBON HOLDER 891 1 S

19 01903060 SCREW TAT 3-8 PT-FL 2 S

20 *3 01914036 SCREW TR 4-5 WS 2 EXCEPT FOR HK,SU S

#3 01914036 SCREW TR 4-5 WS 2 EXCEPT FOR HK S

*3 01914036 SCREW TR 4-5 WS 1 FOR HK,SU S

#3 01914036 SCREW TR 4-5 WS 1 FOR HK S

21 01914034 SCREW TAT 4-8 CT-WF 3 S

22 *3 01914040 SCREW TAS 4-10C1P 2 FOR US S

#3 01914031 SCREW TAT 4-12 PT-FL 2 FOR US S

*2 01914031 SCREW TAT 4-12 PT-FL 2 EXCEPT FOR US S

*3 01914043 SCREW TAT 4-12 PT WB 2 EXCEPT FOR US S

#3 01914031 SCREW TAT 4-12 PT-FL 2 EXCEPT FOR US S

23 01914031 SCREW TAT 4-12 PT-FL 3 S

24 01914030 SCREW TAT 4-15 PT 4 S

25 04020016 STOP RING SE4.0 1 S

26 89595010 S-P CONVERTER SPC-8K UPC 1 OPTION: FOR US,LA

89595020 S-P CONVERTER SPC-8K JAN 1 OPTION: EXCEPT US,LA

27 *3 80994450 RUBBER SHEET ZL-10 1

28 #2 80087630 SILENT SALESMAN ZL-10 US 1 FOR US

- 89590203 ASF SF-10DR US 1 OPTION: FOR US,LA

89590201 ASF SF-10DR WG 1 OPTION: FOR EC,WG

– 67 –

Page 72

Printer Assembly

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

- 89590200 ASF SF-10DR UK 1 OPTION: FOR UK

#1 89590205 ASF SF-10DR AS 1 OPTION: FOR AS

89590206 ASF SF-10DR HK 1 OPTION: FOR HK,SU

– 68 –

Page 73

2. Printer Mechanism

2-1. Disassembly Drawing

– 69 –

Page 74

2-2. Parts List

Printer Mechanism

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

1 87060210 FRAME UNIT 891F 1 INC. NO.5,6,11,14,24

2 89130060 PRINT HEAD DP8901F 1 S

3 87061120 CARRIAGE MOTOR UNIT 891F 1 S

4 87067020 BAIL ROLLER SHAFT UNIT 891 1

5 83400440 BAIL LEVER R 891 1 S

6 83400460 BAIL LEVER L 891 1 S

7 87063050 PLATEN UNIT 891B 1 S

8 *2 81370521 TRACTOR STAY 891 1

#2 81370522 TRACTOR STAY 891 1

9 87066010 TRACTOR UNIT 891 1 S

10 87067010 TENSION LEVER UNIT 891 1

11 87065060 DETECTOR ASSY B 891F 1 S

12 83400790 ADJUSTING LEVER 891F 1

13 82401220 INDEX LEVER 891F 1

14 80530510 BAIL LEVER SPRING 891 2 S

15 80530571 GROUND CONTACT SPRING 921 1 S

16 01902612 SCREW TAT 2.6-16 PT 2 S

17 *1 00920503 SCREW TAT 2-5 CT 1 S

#1 00926603 SCREW TAT 2.6-6 CT 1 S

18 00926603 SCREW TAT 2.6-6 CT 1 S

19 00630504 SCREW TR 3-5 2 S

20 01903018 SCREW TR 3-6 WS/WF 1 S

21 01903075 SCREW TBT 3-6 PT 1 S

22 04020016 STOP RING SE4.0 1 S

23 *2 02040403 TOOTHED NUT NHK4 4 S

#2 02020401 HEXAGON NUT NH4-2 4 S

24 87060840 CARRIAGE UNIT 891F 1

- 04991204 FASTENER T18S 1 S

04991230 MINI CORD CLAMP UAMS-05-SN 4 S

– 70 –

Page 75

3. Sub-assembly

3-1. Lower Case Unit

Lower Case Unit

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

2-1 *1 83023910 LOWER CASE ZL-10 1

*3 83023911 LOWER CASE ZL-10 1

#3 83023912 LOWER CASE ZL-10 1

2-2 82011050 LOWER CASE CHASSIS ZL-10 1

2-3 83200890 HOLDER ROLLER 891F 3

2-4 81301320 ROLLER SHAFT 891 3

2-5 87801320 DETECTOR UNIT A ASSY ZL-10 1 S

2-6 82501150 RELEASE SPRING 891F 3

2-7 00926803 SCREW TAT 2.6-8 PT 1 S

2-8 00930803 SCREW TAT 3-8 PT 2 S

2-9 *2 01903064 SCREW TAT 3-5 CT 1 S

*2 01903094 SCREW TAT 3-5 DT 1 S

- #1 80991610 RUBBER FOOT NB24-10 2

– 71 –

Page 76

3-2.

Serial-Parallel Converter (Option)

Serial-Parallel Converter

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

26-1 83024060 UPPER CASE SPC-8K 1

26-2 87590010 CPU BOARD UNIT SPC-8K 1

26-3 87590020 IF BOARD UNIT SPC-8K 1

26-4 87591020 LOWER CASE UNIT SPC-8K 1

26-5 82901600 CORD HOLDER SPC-8K 1

26-6 01903047 SCREW TAT 3-12 PT-FL 3

26-7 01903060 SCREW TAT 3-8 PT-FL 1

26-8 #2 82902150 CORD HOLDER PLATE SPC-8K 1

- 09990716 FERRITE CORE HF70RU12X5 2

– 72 –

Page 77

3-3. Frame Unit

Frame Unit

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK

1-1 83910853 GEAR COVER 891 1 S

1-2 *1 83901613 CARD HOLDER 891 1 S

#1 83901614 CARD HOLDER 891 1 S

1-3 *1 83902740 CARRIAGE 891F 1

#1 87060590 CARRIAGE ASSY 891F 1 INCLUDE DRWG.NO.1-4

1-4 *1 80210480 BUSHING 12X14X10 891B 2

1-5 80902050 TIMING BELT HTD102 364X3.2 1

1-6 83100490 IDLER GEAR 43X63X0.3 1 S

1-7 83120450 RIBBON CASSETTE GEAR 891 1 S

1-8 *3 83100501 IDLER GEAR 16X1-40X0.3 1 S

#3 87312460 IDLER ASSY TRX 1 S

1-9 83100541 IDLER GEAR 17X41X0.3 1 S

1-10 82210031 WAVE WASHER 891 1 S

1-11 83400410 CLUTCH LEVER 891 1 S

1-12 87060610 PAPER FEED MOTOR ASSY 891 1 S

1-13 83100510 GEAR 40X0.5 1 S

1-14 83100520 IDLER GEAR 16X72X0.5 1 S

1-15 01903064 SCREW TAT 3-5 CT 2 S

1-16 02304025 POLY-SLIDER WP4X0.25 1 S

– 73 –

Page 78

3-4. Platen Unit

Platen Unit

DRWG.NO. REV. PARTS NO. PARTS NAME Q’TY REMARKS RANK