Page 1

IL0458

FW0667

0611

Supersedes

0707

PORTABLE LAWN

SPRINKLER AND UTILITY

PUMP

Description

This pump is designed to sprinkle lawns and small

gardens from lakes, ponds, or rivers, empty or fill

stock tanks, remove standing water from flooded

areas, transfer water or boost water pressure.

Flammable liquids such as gasoline, chemicals or

corrosive liquids should never be used with this pump.

Safety Guidelines

This manual contains information that is very

important to know and understand. This information

is provided for SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this information,

observe the following symbols.

Danger indicates an imminently

hazardous situation which, if not avoided, will result

in death or serious injury.

Warning indicates a potentially

hazardous situation which, if not avoided, could result

in death or serious injury.

Caution indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury.

NOTE: Indicates important information, that if not

followed, may cause damage to equipment.

General Safety Information

1. Read these rules and instructions carefully. Failure

to follow these instructions could cause serious

bodily injury and/or property damage.

This pump is non-submersible.

This product contains chemicals

known to the State of California to cause cancer and

birth defects or other reproductive harm.

Pump only clear water.

Do not pump flammable or explosive fluids

such as gasoline, fuel oil, kerosene, etc. Do

not use in a flammable and/or explosive

atmosphere. Personal injury and/or property damage

could result.

NOTE: This pump is not designed to handle salt water,

brine, laundry discharge or any other application

which may contain caustic chemicals and/or foreign

materials. Pump damage could occur if used in these

applications and will void warranty.

All wiring must be

performed by a qualified electrician. The

pump must be installed in compliance with

all local and national codes.

2. Connect this product to a grounded circuit

equipped with a ground fault circuit interruptor

(GFCI) device.

3. Before installing this product, have the electrical

circuit checked by an electrician to ensure proper

grounding.

4.

5. Be sure the water source and piping are clear of

sand, dirt and scale. Debris will clog pump and

void warranty.

6. Failure to protect pump and piping from freezing

could cause severe damage and will void the

warranty.

7. Do not run pump dry.

BE CERTAIN the pump power source

is disconnected before installing or

servicing pump.

Installation

PUMPING FROM LAKES, PONDS OR SMALL STREAMS

1. Locate pump as close as possible to the water

source, keeping the vertical distance from the

water to pump as small as possible. Place pump

on level support. Protect against flooding and

excessive moisture.

2. Long lengths of pipe or hose and use of many

fittings will reduce pump flow. Use the smallest

number of fittings and shortest possible length of

pipe or hose.

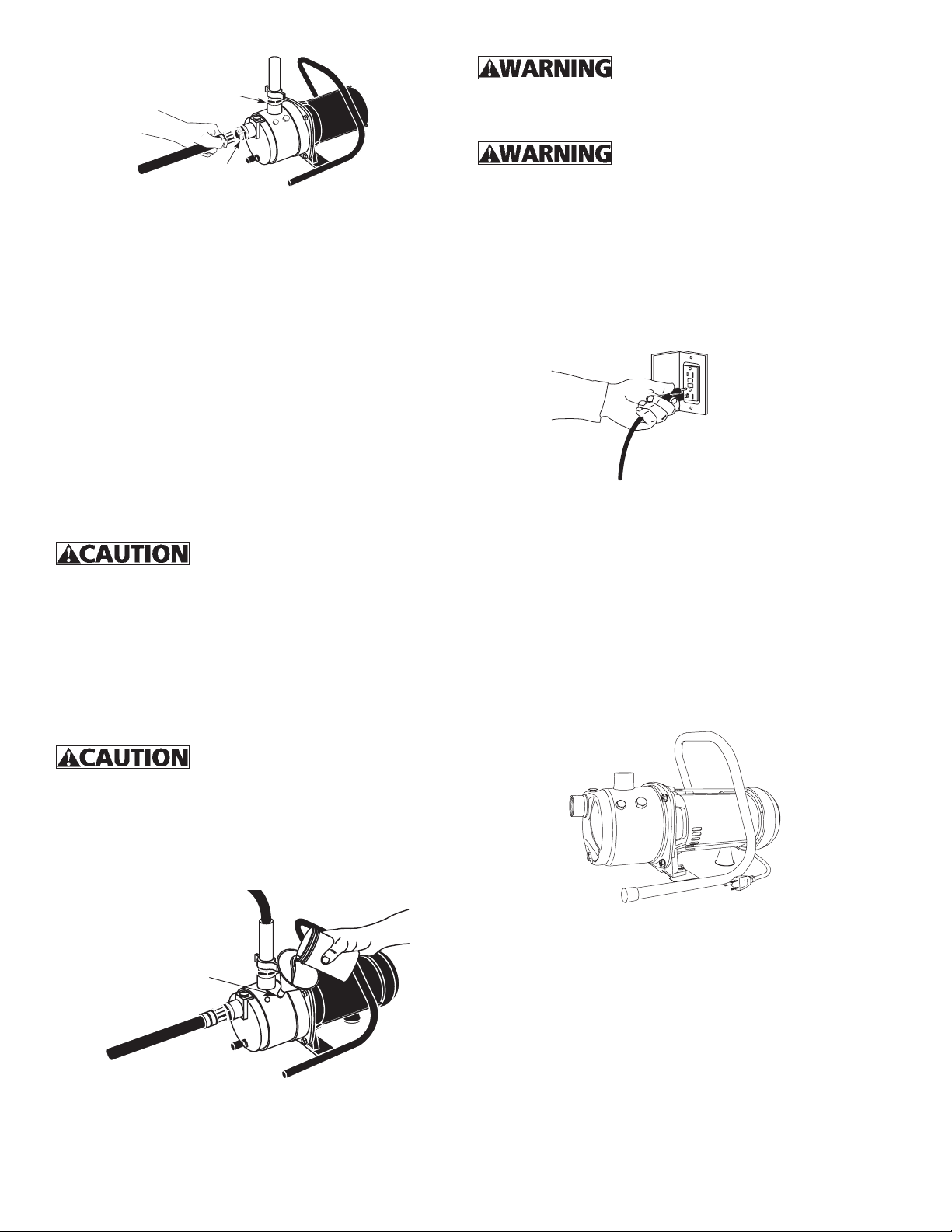

4. Connect inlet pipe or hose to pump. The inlet

connection is designed for 1” NPT thread. Rigid

pipe such as PVC will work fine for inlet and outlet

pipe. (Reminder: Minimize length of pipe and

number of fittings.) An adapter for garden hose is

included (see Figure 1).

1

© 2011. All rights reserved.

Page 2

Risk of electrical shock! This pump

O pmuP

teltu

is supplied with a grounding conductor and grounding

type attachment plug. Use a grounded receptacle to

reduce the risk of fatal electric shock.

telnI pmuP

Figure 1

IL0455

NOTE: The inlet hose must be a reinforced type when

pumping from lakes, ponds, or small streams. Regular

garden hose will collapse and lead to pump failure.

5. A foot valve with strainer should be used to

maintain prime during operation.

6. Seal all connections in the inlet hose. An air leak in

the fittings, hose, pipe or connections will draw air

even though no water leaks out. These inlet leaks

will reduce pump performance and lead to pump

failure.

7. Connect outlet pipe or hose to pump. The outlet

connection is designed for 1” NPT thread. Rigid

pipe such as PVC or garden hose may be used. An

adapter to garden hose thread is included (Figure

1).

BOOSTING WATER PRESSURE

Do not run pump with outlet pipe

or nozzle closed. The hose may burst from excessive

pressure. Use only reinforced high-pressure hose or

pipe for outlet pipe.

1. Connect inlet pipe or hose to pump. An adapter to

garden hose thread is included (Figure 1).

2. Connect the other end of inlet line to water supply.

3. Connect outlet pipe, or hose to pump.

Operation

Never cut off the round grounding

prong on the power cord. Cutting the cord or plug

will make the pump unsafe to operate and void the

warranty.

2. Turn the pump switch to the “off” position.

3. This pump is only for use on 120 volt (single

phase), 60 Hz, 15 amp service and is equipped with

a 3-conductor cord and e-prong, grounding type

plug. Insert power cord directly into GFCI outlet

(see Figure 3).

IL0459

Figure 3

4. Turn pump switch to the “on” position (see Figure

4). If the pump does not pump water within 5

minutes, turn off pump and refill with clean water.

If the pump does not operate after repeated

attempts, check the following:

- Vertical distance of pump to water level must not

be over 20 feet.

- Suction line must be airtight.

- All valves in suction and discharge line must be

open.

Never run the pump dry. Running

pump without water will cause seal failure. Fill pump

with water before starting.

1. Remove priming port on pump and fill with water.

Reinstall priming port on pump (see Figure 2). For

boosting water pressure: Do not remove priming

port. Turn on water supply.

Priming

troP

s

Figure 2

© 2011. All rights reserved.

IL0458

Maintenance

Maintain adequate ventilation for the pump motor.

The motor bearings are permanently lubricated at the

factory. Additional lubrication is not required.

DRAINING FOR WINTER

Always protect pump and piping against freezing

temperatures. If there is any danger of freezing, drain

the system.

1. Disconnect suction and discharge lines from

pump.

2

Page 3

2. Remove plug from lower front face of pump.

3. Drain all piping below the frost line, or store piping

indoors.

4. Store pump indoors.

See Figure 5 for replacement parts.

Troubleshooting Chart

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not run 1. Disconnect switch is off

2. Fuse is blown

3. Starting switch is defective

4. Wires at motor are loose, disconnected

or wired incorrectly.

Motor runs hot and overload kicks

off

Motor runs but no water is

delivered. NOTE: Check prime

before looking for other causes.

Unscrew priming plug and see if

water is in priming hole.

Pump does not deliver water to full

capacity

1. Motor is wired incorrectly

2. Voltage is too low

3. Pump house not properly vented

1. Pump in new installation did not pick

up prime through:

a. Improper priming

b. Air leaks

c. Leaking foot valve

2. Pump has lost prime through:

a. Air leaks

b. Water level below suction of pump

3. Impeller is plugged

4. Check valve or foot valve is stuck in

closed position

5. Pipes are frozen

6. Foot valve and/or strainer are buried in

sand or mud

1. Water level in well is lower than

estimated

2. Steel piping (if used) is corroded or

limed, causing excess friction

3. Piping is too small in size 3. Use larger piping

1. Be sure switch is on

2. Replace fuse

3. Replace starting switch

4. Refer to wiring instructions. Check and

tighten all wiring.

be hazardous. To discharge capacitor, touch

short capacitor terminals with an insulated

screwdriver. BE SURE to hold handle of

screwdriver while making contact with

capacitor terminals.

1. Refer to wiring instructions

2. Check with power company. Install heavier

wiring if wire size is too small (See Wiring

Chart).

3. Be sure pump has sufficient ventilation to

cool the motor

New Installation:

a. Re-prime according to instructions

b. Check all connections on suction line

c. Replace foot valve

2. Existing Installations:

a. Check all connections on suction line and

shaft seal

b. Lower suction line into water and re-prime.

If receding water level in well exceeds

suction lift, a deep well pump is needed

3. Clean impeller

4. Replace check valve or foot valve

5. Thaw pipes. Bury pipe below frost line. Heat

pit or pump house

6. Raise foot valve and/or strainer above well

bottom

1. A deep well jet pump may be needed (over

25 ft. (7.6M) to water)

2. Replace with plastic pipe where possible,

otherwise with new steel pipe

Capacitor voltage may

3

© 2011. All rights reserved.

Page 4

REPLACEMENT PARTS LIST

MODEL HSPJ100, SPJ100

1

2

3

4

6

7

5

IL0456

Ref. No. Description Part Number Qty.

*1 Shaft seal and gasket

*2 Impeller 1

*3 Diffuser 1

Kit #021337

*4 Nozzle assembly 1

5 Pump housing 021334 1

6 Large plug & O-Ring 021335 1

7 Small Plug & O-Ring 021336 3

*Purchase as a kit. Order #021337.

1

ONE YEAR LIMITED WARRANTY

This product is warranted for one year from the date of purchase or two

years from the date of manufacture, whichever occurs first. Subject to the

conditions hereinafter set forth, the manufacturer will repair or replace to the

original consumer, any portion of the product which proves defective due to

defective materials or workmanship. To obtain warranty service, contact the

dealer from whom the product was purchased. The manufacturer retains

the sole right and option to determine whether to repair or replace defective

equipment, parts or components. Damage due to conditions beyond the

control of the manufacturer is not covered by this warranty.

THIS WARRANTY WILL NOT APPLY: (a) To defects or malfunctions

resulting from failure to properly install, operate or maintain the unit in

accordance with printed instructions provided; (b) to failures resulting

from abuse, accident or negligence or use of inappropriate chemicals or

additives in the water; (c) to normal maintenance services and the parts

used in connection with such service; (d) to units which are not installed in

accordance with normal applicable local codes, ordinances and good trade

practices; and (e) the unit is used for purposes other than for what it was

designed and manufactured.

RETURN OF WARRANTED COMPONENTS: Any item to be repaired

or replaced under this warranty must be returned to the manufacturer at

Kendallville, Indiana or such other place as the manufacturer may designate,

freight prepaid.

© 2011. All rights reserved.

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL OTHER

EXPRESS WARRANTIES, AND MAY NOT BE EXTENDED OR MODIFIED

BY ANYONE. ANY IMPLIED WARRANTIES SHALL BE LIMITED TO THE

PERIOD OF THE LIMITED WARRANTY AND THEREAFTER ALL SUCH

IMPLIED WARRANTIES ARE DISCLAIMED AND EXCLUDED. THE

MANUFACTURER SHALL NOT, UNDER ANY CIRCUMSTANCES, BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES,

SUCH AS, BUT NOT LIMITED TO DAMAGE TO, OR LOSS OF, OTHER

PROPERTY OR EQUIPMENT, LOSS OF PROFITS, INCONVENIENCE

, OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

TYPE OR NATURE. THE LIABILITY OF THE MANUFACTURER SHALL

NOT EXCEED THE PRICE OF THE PRODUCT UPON WHICH SUCH

LIABILITY IS BASED.

This warranty gives you specific legal rights, and you may have other rights

which vary from state to state. Some states do not allow limitations on

duration of implied warranties or exclusion of incidental or consequential

damages, so the above limitations may not apply to you.

WARRANTY VALID IN CANADA AND MEXICO.

4

Loading...

Loading...