Star HSCO14 Operators Manual

ELECTRIC SPEED

®

IL1493

CONVEYOR OVEN

MODEL

HSCO14 & HSCO16

Installation and

Operation

Instructions

2M-Z11612 Rev. B 4/9/2012

HSCO14

1

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

FOR SERVICE IN EUROPE CONTACT:

Middleby Worldwide, Europe

Telephone: +34-94-454-2815

E-mail: mwweurope@middleby.com

2

PROBLEMS, QUESTIONS or CONCERNS

Before you proceed consult you authorized service agent directory

or

Call the Technical Service & Parts Department at 314-678-6303.

TABLE OF CONTENTS

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Oven Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Purchaser's Responsibility

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Uncrating & Assembly Instructions

Ventilation & Clearance . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . 10

Operating & Programming

Manager Lock Modes . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Menu Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Menu Programming . . . . . . . . . . . . . . . . . . . . . . . . 13

Energy Saving Programming . . . . . . . . . . . . . . . . . . . 13

Bake Time Versus Temperature .

Conveyor Speed. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Time of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning Instructions

Daily .

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Annually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Nozzle Plate Assemblies . . . . . . . . . . . . . . . . . . . . . 15

Conveyor Belt Tension . . . . . . . . . . . . . . . . . . . . . . 16

Conveyor Belt Link Removal . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . 8 - 9

. . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . 13

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring Diagram

Exploded View & Parts List

Main Body Assembly

Details A, B & C . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 23

Details D & DA. . . . . . . . . . . . . . . . . . . . . . . . . .24 - 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . 20 - 21

NOTICE Service on this or any other Holman appliance must be performed by

qualied personnel only. Consult your Authorized Service Agent Directory.

You can call our tech service line at 314-678-6303 or visit our website

www.star-mfg.com for the service agent nearest you.

3

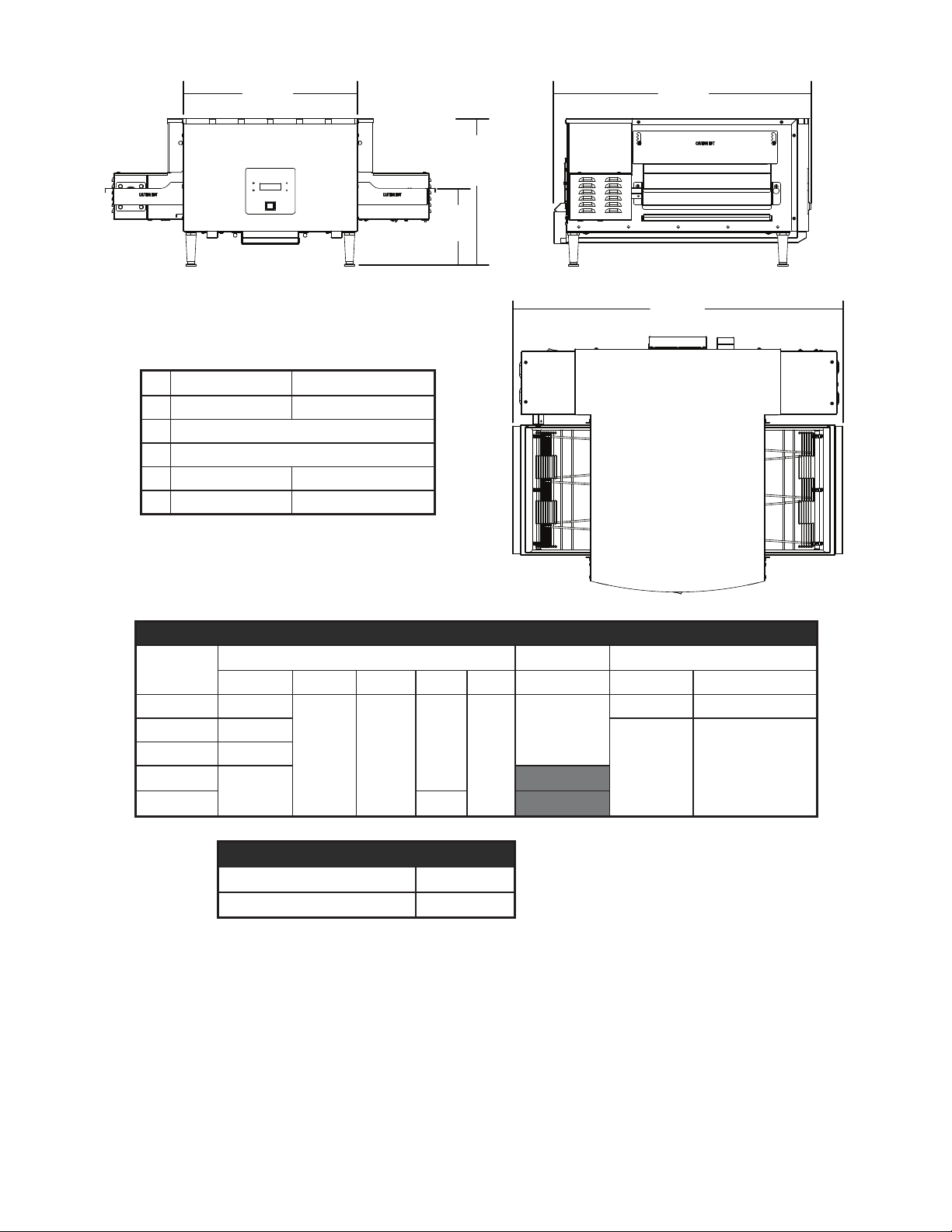

E

D

A

C

B

IL1492

HSCO14 HSCO16

A 20.8” (52.8 cm) 22.8” (57.9 cm)

B 9.4” (23.9 cm)

C 17.8” (45.2 cm)

D 30.7” (78 cm) 32.7” (83.1 cm)

E 39.8” (101.1 cm) 41.8” (106.2 cm)

SPECIFICATIONS

Model

HSCO14 208/240V

HSCO16 208/240V

HSCO16P 208/240V

HSCO16P

HSCO16Q 20/22

Voltage Hz Watts Amp Phase Cord Installed Shipping

230V

Electrical Weight

34/38

50/60Hz 15,900

3Ph

NEMA 15-50

154lbs / 70kg 259lbs / 117.7kg

188lbs /

85.5kg

293lbs / 133.2 kg

Recommended Minimum Clearances

Rear of Oven to Wall 0” (0 cm)

Conveyor Extensions to Wall 6” (15.2 cm)

4

2M-Z11612 HSCO TURBO-MAX ELECTRIC SPEED CONV OVEN

B

A

C

D

E

F

G I

J

Front

Rear

K

L

H

E

O

M

N

H

IL1508

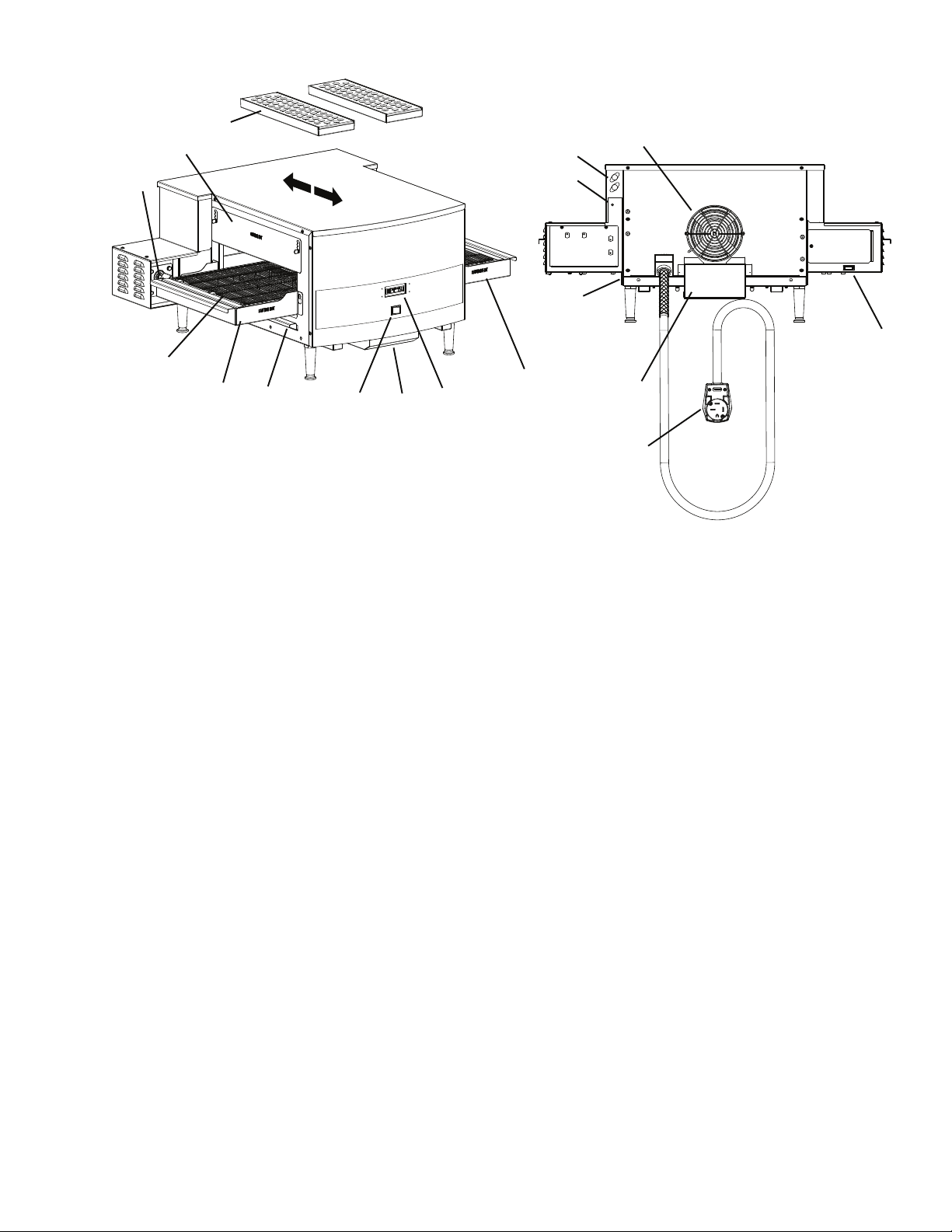

OVEN COMPONENTS

2M-Z11612 HSCO TURBO-MAX ELECTRIC SPEED CONV OVEN

OVEN COMPONENTS DESCRIPTION

A: Fingers: Projects streams of hot air onto the product.

B: Heat Shutter: Can be adjusted to various settings, depending on product being placed in the

oven, to prevent heat loss.

C: Drive Cog / Drive Collar: This connects the drive motor to the conveyor assembly.

You can disengage the conveyor by simply by pulling back on the drive collar.

This makes for easy removal of the conveyor assembly.

D: Conveyor Assembly: Moves the product through the oven, & is easily removed for cleaning

E: Crumb Tray: Catches crumbs and other material that drops through the conveyor belt.

Located at each end of the conveyor assembly.

F: Cooking Chamber Crumb T

conveyor belt. Located at inside the cooking chamber, under the lower heating elements.

G: Power Switch:

H: Cooling Air Duckwork: Keeps the front control panel from overheating, the lower duct is

held in by thumb screws, DO NOT operate without ductwork in place.

I: Control Panel: Easy to read Display for easy notication of ovens current operation, and

buttons for making quick modications. Located in front of the oven away from the areas

which may cause burns.

J: Hi-Limit Reset:

reaches above 690°F.

K: Air Intake: Located in the back of the oven. DO NOT BLOCK this area, and wipe it clean on

a regular basis.

L: Conveyor Direction:

M: Nameplate:

well as the units serial number which is needed for any service that will be required.

This number should be written in the inside cover of this manual and kept for future needs

N: Electrical Input: Electrical Supply connection must meet all national and local electrical

code requirements.

O: Fuse: Easily replaceable fuses, can be serviced easily without tools.

Turns the unit on & off.

Monitors inside cooking temperature and will only trip when temperature

This switch changes the direction of the conveyor belt.

Has specic information regarding this units electrical & gas requirements as

ray: Catches crumbs and other material that drops through the

5

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor for

use directly by the general public in food service locations.

First and foremost, each crate should be examined before signing the Bill of Lading to report

any visible damage by the trucker in transit and to account for the proper number of crates.

If there is apparent damage, arrangements should be made to le a claim against the carrier.

Interstate Commerce Regulations require that the claim must be initiated by the consignee.

Proper and secure storage facilities should be arranged for the oven(s) if necessary to protect

it from outdoor or damp conditions at all times before installation.

CAUTION

WARNING

When you have all the crates unloaded, open the crates and remove all plastic covers. Inspect

at once for concealed damage. If anything appears to be damaged, contact the appropriate

persons immediately to le a damage claim. After completing this inspection, nish unpacking

the oven. Be sure to remove all paper protection and packing material from the unit

prior to heating.

-IMPORTANT-

CAUTION

FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

INSTALLATION

The ovens are equipped for the voltage indicated on the nameplate mounted on the right side

of the body under the control box. They will operate on alternating current (AC) only. A cord is

provided with a NEMA 6-50 plug. A matching receptacle with 50A supply must be provided.

WARNING

DO NOT CONNECT TO DIRECT CURRENT (DC).

The installation of the electric oven should conform to the:

NATIONAL ELECTRIC CODE AND ALL LOCAL ELECTRIC CODES AND

ORDINANCES AND THE LOCAL ELECTRIC COMPANY RULES AND

REGULATIONS.

PURCHASER'S RESPONSIBILITY

It is the responsibility of the purchaser:

1. To see that the electric services for the oven are installed on site in accordance with the

manufacturer's specications.

2.

To unload, uncrate, and install the oven in its proper location and in accordance with this

installation operation manual.

3.

To see that electric services are connected properly by a qualied installer of your choice.

All such connections must be in accordance with applicable code requirements.

4.

To arrange for inspection and operation check-out by an authorized service technician.

6

2M-Z11612 HSCO TURBO-MAX ELECTRIC SPEED CONV OVEN

CAUTION

IMPORTANT SAFETY INFORMATION

Do not attempt to operate the oven until connection of utility service has been fully inspected

by an authorized service technician or a Star Service Representative. This service is required

by Star in order to assist the purchaser in proper start-up of the oven on site. Please note the

specic details on the Warranty and make certain that service connections are made to proper

utility services.

The warranty shall not apply if the oven is started up and operated prior to the utilities and oven

being inspected and check-out made by an authorized service technician or a Star Service

Representative.

CAUTION

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ

ALL INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

CAUTION

CAUTION

WARNING

Minimum clearances must be maintained from all walls and combustible materials. Minimum

clearances for this unit should be 0 inches from the rear (rear bumpers provided must be in place)

and 6 inches from both sides. Keep the oven free and clear of all combustible material.

CAUTION

CAUTION

Do not obstruct the ventilation holes in the control panels as these provide cooling air for the

controls.

WARNING

The oven is to be operated only on the type of electricity shown on the specication plate.

INSTALLATION INFORMATION

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF

QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR

SERVICE BY OTHER THAN QUALIFIED PERSONNEL MAY RESULT IN DAMAGE

TO THE OVEN AND/OR INJURY TO THE OPERATOR.

Qualied installation personnel are individuals, a rm, a corporation, or a company which either

in person or through a representative are engaged in and responsible for:

1. The installation of electrical wiring from the electric meter, main control box, or service outlet

to the electric appliance.

Qualied installation personnel must be experienced in such work, familiar with all precautions

required, and have complied with all requirements of state or local authorities having

jurisdiction.

2M-Z11612 HSCO TURBO-MAX ELECTRIC SPEED CONV OVEN

7

LOCATION

IL1500

Drive

Collar

Drive

Cog

IL1500

IL1501

CONVEYOR

The well-planned and proper placement of your oven will result in long-term operator conve-

nience and satisfactory performance.

It is essential that an adequate air supply to the oven be maintained to provide a sufcient

ow of ventilation air. Follow these guidelines:

1. Place the oven in an area that is free of drafts.

2. Keep the oven area free and clear of all combustibles such as paper, cardboard, ammable

liquids, and solvents.

3. Do

not place the oven on a curb base or seal to a wall. This will restrict the ow of air

and prevent proper ventilation to the blower motors. This condition must be corrected to

prevent permanent damage to the oven.

4. On

all models, tripping of the blower motor's thermal overload device indicates an excessive

ambient temperature at the back of the oven. This condition must be corrected to avoid

permanent damage to the oven.

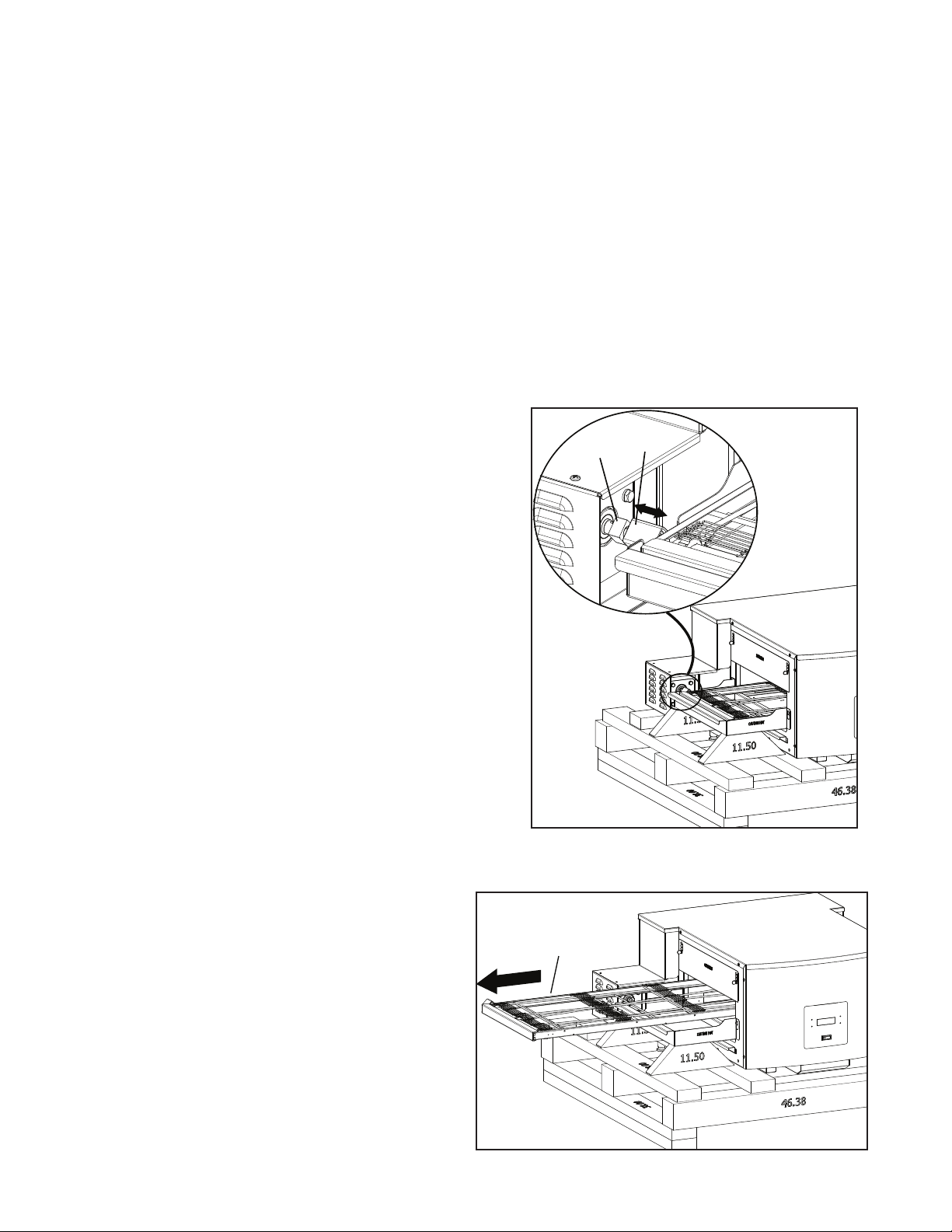

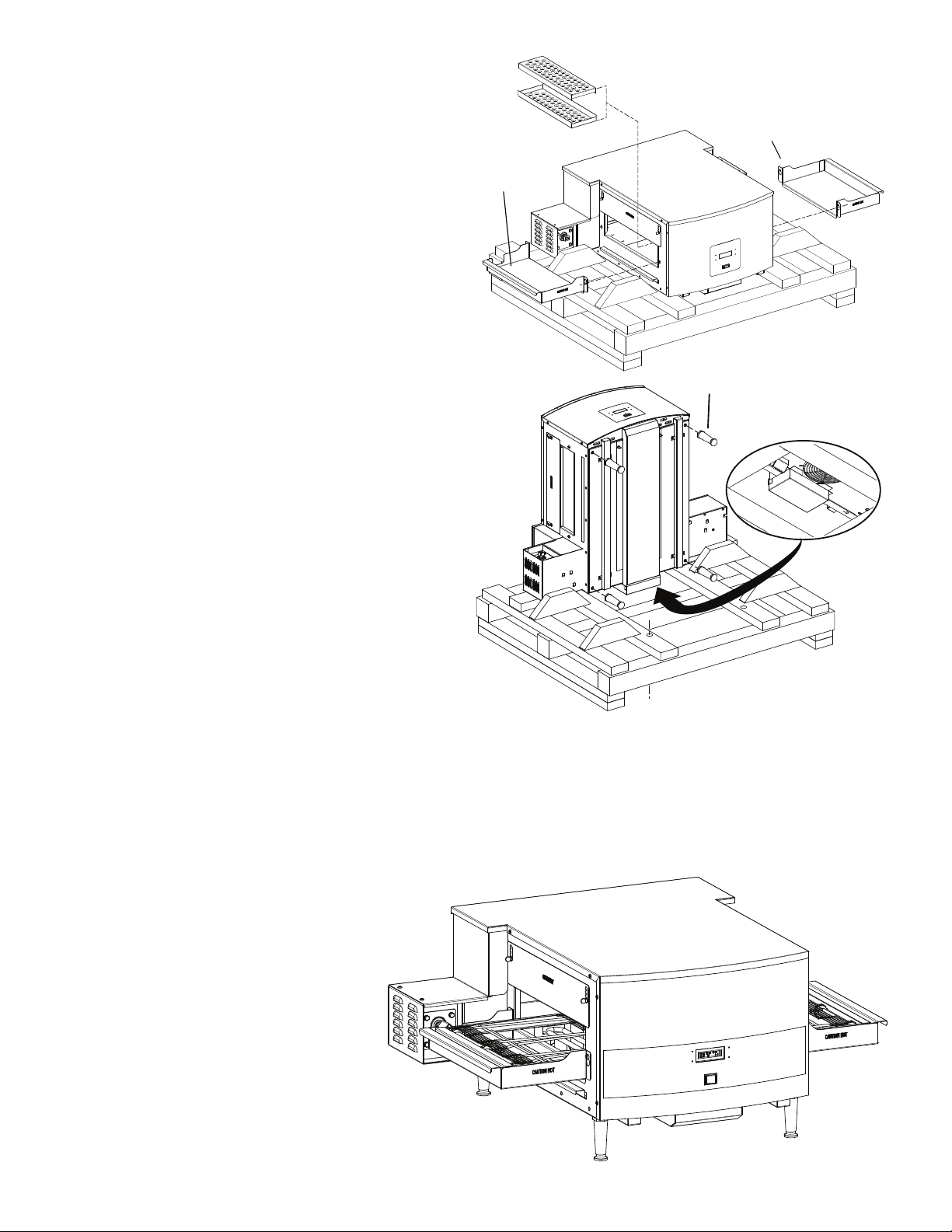

OVEN UNCRATING & ASSEMBLY INSTRUCTIONS

This Turbo-Max Oven comes completely

assembled and ready to use. These

instructions will step you through, removing the

unit from the skid and safely installing the legs,

so not to damage the unit or the installer.

1. Using lift equipment, move oven as close to

nal position as possible.

2. Inspect the oven for any damage which may

have been caused by freight transit or carrier.

If any, see general information section.

3. R

emove any packaging from around the unit

or inside the cooking chamber.

4. Disengage

the Drive Collar on the Conveyor

to the Drive Cog on the drive motor.

5. Lift and remove Conveyor from the

unit and set aside.

2M-Z11612 HSCO TURBO-MAX ELECTRIC SPEED CONV OVEN

8

6. Remove the Crumb Trays and set

Crumb Tray Left

Nozzle Plate Assy

Crumb Tray Right

IL1503

IL1502

CAUTION

DO NOT SET DIRECTLY ON

BACK WITHOUT SUPPORT

Legs

Shipping

Restraint

IL1493

aside.

7. Reach into the cooking area and

remove the two Nozzle Plate Assy.

Doing this will prevent them from

being damaged while completing

the unpacking.

8. Unbolt the unit from the skid by

removing the shipping restraints

shown here.

9. The unit weights 110lbs, so with

assistance, lift unit off the skid and

place it on its back using a couple

2 x 4’s.

NOTE: SETTING UNIT DIRECTLY

ON IT BACK, WITHOUT EXTRA

SUPPORT WILL DAMAGE THE

COOLING AIR INLET AND THIS

DAMAGE IS NOT COVERED BY

WARRANTY.

2M-Z11612 HSCO TURBO-MAX ELECTRIC SPEED CONV OVEN

10. Using the legs provided, screw

them into the holes shown here.

11. Set unit back on all four legs and place it into position.

12. Reinstall the nozzle and collumnating plates previously removed.

13. Re-install the crumb trays and conveyor belt assembly.

14. Engage the conveyor belts drive collar and the drive motors drive cog.

15. Assembly is complete.

9

Loading...

Loading...