Page 1

®

®

®

®

CONTACT

TOASTER

MODEL

HCT13M, HCT13S

HCTE13M, HCTE13S

Installation and

Operation

Instructions

2M-Z19028 Rev. F 11/2018

IL2845b

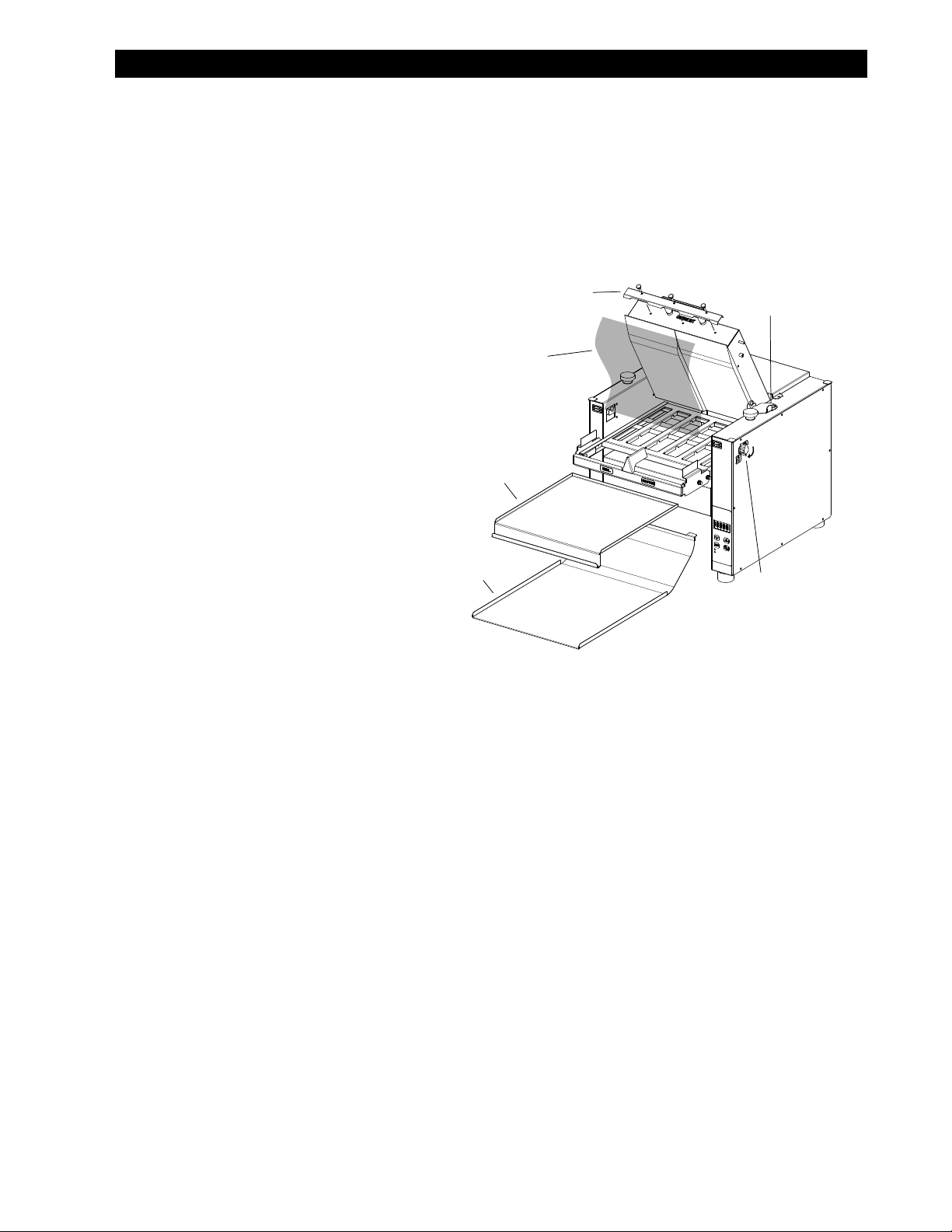

HCT13 & HCTE13

(Shown with optional butter wheel)

Page 2

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it

ready when you call to ensure a faster service.

Authorized Service Agent Listing

Model No.

Serial No.

Voltage

Purchase Date

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail customerservice@star-mfg.com

Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone:

Fax:

E-mail

Website:

Mailing Address: Star Manufacturing International Inc.,Company

(800)-264-7827

(314)-781-2714

customerservice@star-mfg.com

www.star-mfg.com

265 Hobson St.

Smithville, Tennessee 37166,

U.S.A

2M-Z19028; Holman Contact Toaster

2

Page 3

TABLE OF CONTENTS

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features & Benets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Uncrating & Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly & Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Toaster Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Daily Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 & 6

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-17

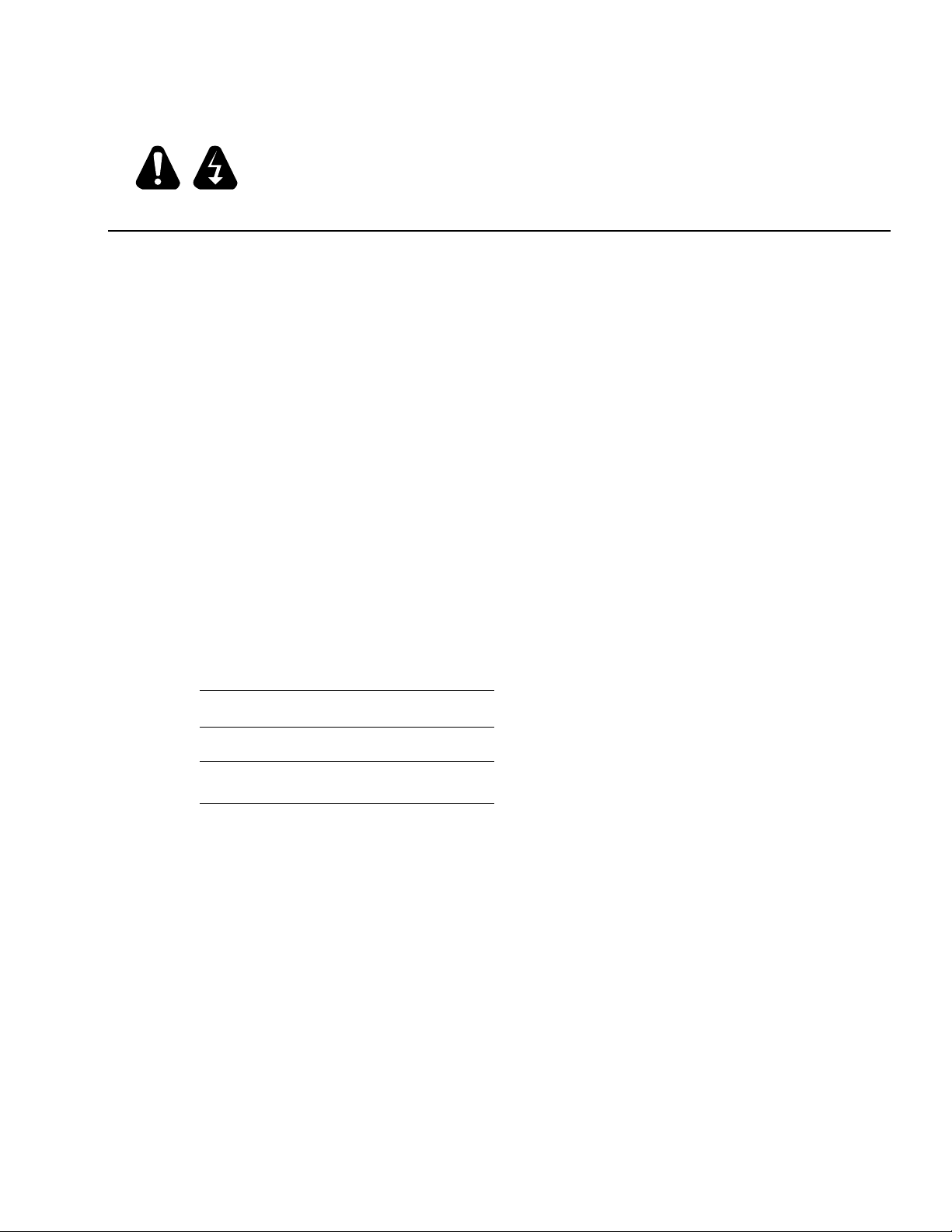

SPECIFICATIONS

19.25”

24.662”

20”

Electrical Specicaons

Model Voltage Hz Ph Amps Watts Powercord

HCTE13M

HCTE13S

208V 60

230V 50 12 2750 CEE7/VII

240V

208V 12.25 2550 6-20P

230V 50 10.5 2450 CEE7/VII

240V 60 11 2650 6-20P

60

1

13.5 2800 6-20P

12.5 3000 6-20P

IL2844

HCT13M

HCT13S

208V 60

230V 50 12 2750 CEE7/VII

240V

208V 12.25 2550 6-20P

230V 50 10.5 2450 CEE7/VII

240V 60 11 2650 6-20P

60

1

13.5 2800 6-20P

12.5 3000 6-20P

1

Page 4

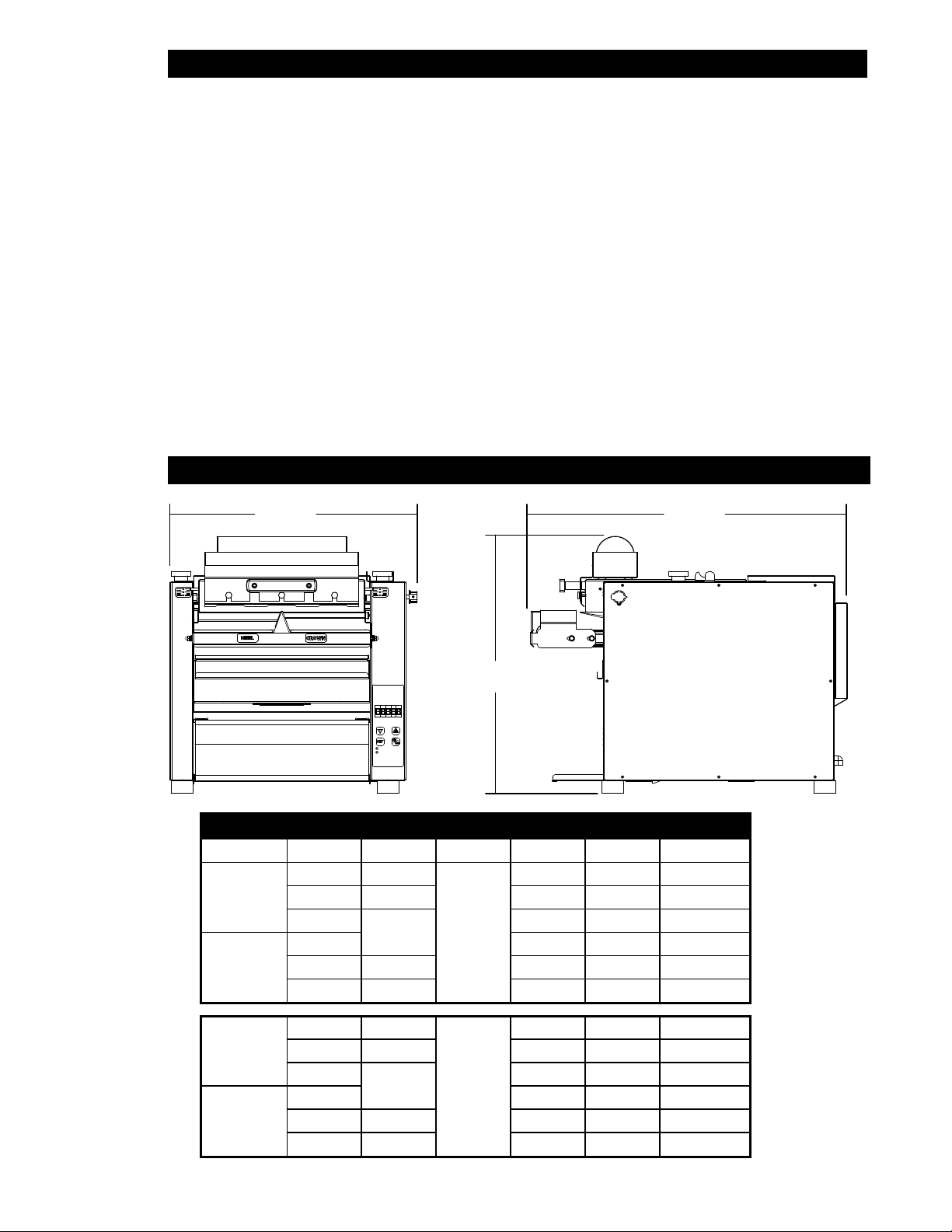

FEATURES & BENEFITS

N

M

L

K

J

Namplate

A

B C

D

E

IL2846a

F

G

HI

A Platen Height Indicator Indicates the height of the upper platen

B Platen Support Bracket Keeps the upper platen in the up position, useful while cleaning

Interrupts the heater tube connections if the air temperature in the control box

C High Limit

D Platen Height Knob Controls the height of the upper platen

E Locking Platen Latch Keeps the upper platen in the down position.

F Control Board Controls the conveyor speeds, turns unit on & off, & temperature settings.

G Foot Silicone foot keeps unit rmly in place.

H Crumb Tray Slide out crumb tray used to catch particles from falling

I Toaster Chute Removable Chute returns product for easy access.

J Conveyor Takes the heel and crown separately through their toasting process

K Burn Guard Protects users from touching the conveyor belt

Durable Non-Stick Coated

L

Sheet

M Upper Platen Assy Heating surface designed to toast the product as it slides across the surface

exceeds 190°F (88°C). This limit switch can be reset manually by pushing the

button in the center of the switch.

Non-Stick surface between the upper platen and the product, allowing the product

to slide easily through the toasting process.

N Optional Butter Wheel Saves time for preparing buns for toasting

2

2M-Z19028; Holman Contact Toaster

Page 5

CAUTION

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor

for use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels

associated with the unit prior to putting it into operation. Make sure all people associated

with its use understand the units operation & safety before they use the unit.

INSPECTION

UN-CRATING AND INSPECTING

Unpack the unit and components from the shipping container. Remove all visible packing

material and those from inside the cooking chamber. If damage is discovered, le a claim

immediately with the carrier that handled the shipment. Do not operate the unit if it was

damaged during shipping. All shipping containers should be checked for freight damage

both visible and concealed. This unit has been tested and carefully packaged to insure

delivery of your unit in perfect condition. If equipment is received in damaged condition,

either apparent or concealed, a claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is

unpacked, a request for inspection of concealed damage must be made with carrier within

15 days. Be certain to retain all contents plus external and internal packaging materials for

inspection. The carrier will make an inspection and will supply necessary claim forms.

ELECTRICAL CONNECTION

Disconnect the unit from the power source before installing or removing any parts.

Be absolutely sure that the ground connection for the receptacle is properly wired.

Do not connect equipment to power without proper ground connections. Improper

grounding may result in personal injury or death.

CAUTION

Allow enough space around the toaster for adequate ventilation. Do not operate the unit

without the crumb tray properly positioned. Overheating and poor toasting may occur.

Read all labels on the unit and follow their instructions.

WARNING

Before making any electrical connection to this unit, check that the power

supply is adequate for the voltage, amperage and requirements stated on the

rating plate. A wiring diagram is included.

WARNING

DO NOT CUT OR REMOVE THIS PLUG OR THE GROUNDING PRONG FROM

THE PLUG. FAILURE TO COMPLY MAY RESULT IN DEATH OR SERIOUS

INJURY.

WARNING

CONNECT/PLUG UNIT INTO DEDICATED A. C. LINE ONLY SPECIFIED ON THE

DATA PLATE OF THE UNIT.

CAUTION

SOME SURFACES ARE EXTREMELY HOT DURING OPERATION AND CARE SHOULD

BE TAKEN WHILE USING THIS UNIT.

3

Page 6

ASSEMBLY AND INSTALLATION

The unit was shipped fully assembled and ready to plug into a standard outlet specied for its

voltage and amp draw. If improper electrical supply is determined, contact a qualied electrician

prior to using the unit. Removal and replacement of the power cord and plug voids the warranty.

For assistance, contact your local authorized service agent for service or required maintenance.

1. Place the unit in its operating location.

2. Wipe down the exterior with a damp cloth.

3. Place the Toaster Chute & Crumb Tray into position.

4. Unlock the Platen Latch and raise the platen, move the Platen Support Bracket to hold the

platen in the up position.

Sheet Retainer

5. Loosen the Sheet Retainer and

install the non-stick sheet into

position, and secure.

Non-Stick Sheet

6. Lower the Platen and latch in

place.

CAUTION

Failure to use non-stick sheets can

lead to damaging the unit and a loss

of warranty. The durable non-stick

coated sheets are not a warranty

item.

TOASTER SETTINGS

Before using the unit for the rst time,

test the pass time of the conveyor

belt.

The pass time through the toaster

should be between 16 to 20 seconds for standard setting.

Crumb Tray

Toaster Chute

Platen Support

Bracket

IL2848a

Platen Latch

1. Turn unit ON and wait for it to complete the PRE-HEAT process.

2. Set the Platen height by adjusting the two (2) Platen Height Knobs on top of the unit.

3. Make sure the platen lock is on.

4. Place a bun on the conveyor belt, cut side up, “HEEL” on one side and

“CROWN” on the other.

IF TO DARK: Decrease TEMP.

IF TO LIGHT: Increase TEMP. or lower platen

2M-Z19028; Holman Contact Toaster

4

Page 7

DAILY OPERATION ELECTONIC CONTROL

IL2856

RUN

CLEAN

SET

TEMP

ON

OFF

CHANGING TEMPERATURE

1. Push and hold the "SET TEMP" button for three seconds.

2. The display will ash the current top temperature setting.

3. Using the ↑ and ↓ adjust the top heat to desired temperature (increments

of 10°)

4. Press the "SET TEMP" button again to change the bottom heat setting.

5. Using the ↑ and ↓ adjust the bottom heating setting (0 – 10).

6. Press the "SET TEMP" button again to save the settings and exit

program mode.

CHANGING CONVEYOR SPEED

1. Push and hold the ↑ and ↓ for three seconds

2. Using the ↑ and ↓ adjust the motor speed to the desired

setting (1 through 99)

3. Press the "SET TEMP" button to exit the program

CHECK TEMPERATURE SETTING

1. Press the "SET TEMP" button to check the platen temperature.

CLEAN MODE

1. Press the "CLEAN" button to enter the clean mode

a. Elements will be turned OFF and the belt will continue to run

b. The screen will ash CLEAN and WAIT.

c. When the platen has lowered to a safe temperature the screen will ash CLEAN and

READY.

2. Press the "ON/OFF" button to exit the clean mode.

CHANGING BUN THICKNESS SETTING

1. Set the "Height Adjustment Knobs" to their desired settings.

2. Turn unit ON, allow to warm-up before proceeding.

3. Place buns on the conveyor, cut side up.

4. Toasted buns will drop down the toaster chute.

5. Turn the "Height Adjustment Knobs" to lower the platen for darker buns, raise for lighter buns.

CERTAIN SURFACES ARE EXTREMELY HOT DURING OPERATION AND

CARE SHOULD BE TAKEN WHILE USING THIS UNIT.

CAUTION

5

Page 8

DAILY OPERATION MANUAL CONTROL

OPERATING

1. Turn the Power Switch to the "ON" position

2. The conveyor belt will begin to move.

3. Using Temperature Knob, move it from the "OFF" position to your desired

temperature.

4. The Element Power Light will turn "ON" when the unit is calling for heat.

When your desired temperature is reached, the light will turn "OFF". Wait

for the Element Power Light to cycle twice before using.

5. When nished using, turn the Temperature Knob to the "OFF" position, but

leavet the Power Switch in the "ON" position to allow the cooling fan to run.

6. Once cooled, move the switch to the "OFF" position.

HCT

HORIZONTAL CONTACT

TOASTER

ELEMENT

POWER

CHANGING CONVEYOR SPEED

Changing conveyor speed is only capable on the electronically controlled units.

CERTAIN SURFACES ARE EXTREMELY HOT DURING

OPERATION AND CARE SHOULD BE TAKEN WHILE USING

CAUTION

THIS UNIT.

CHANGING BUN THICKNESS SETTING

1. Set the "Height Adjustment Knobs" to their desired settings.

2. Turn unit ON, allow to warm-up before proceeding.

3. Place buns on the conveyor, cut side up.

4. Toasted buns will drop down the toaster chute.

5. Turn the "Height Adjustment Knobs" to lower the platen for darker

buns, raise for lighter buns.

POWER

ON (I)

OFF (O)

Height Adjusting Knob

Height Indicator

MAIN

POWER

IL2912

IL2849

2M-Z19028; Holman Contact Toaster

6

Page 9

CLEANING

Preventive maintenance for your Ultra-Max Contact Toaster consists of the following recommended

cleaning procedures. To keep your toaster in top operating condition, these steps should be performed

daily or weekly as indicated.

Daily Cleaning

1. MANUAL: Turn the temp knob to the "OFF" position, and the power switch in the "ON" position.

ELECTRONIC: Press and hold the CLEAN button to enter cleaning mode.

a. The screen will ash “CLEAN” “WAIT” while the unit cools down to a safe temperature.

b. Unlock platen using knob on side, raise the platen and prop open to speed up cool down.

Always remove Butter before raising platen if used.

c. The screen will ash “CLEAN” “READY” when the unit has cooled to a safe temperature.

IMPORTANT: Allow the unit to cool before attempting to clean it.

2. Wipe down moving belt with mild detergent and damp cloth.

(an abrasive pad can be used on metal belt).

3. Wipe down exterior of toaster with mild detergent and damp cloth.

4. Remove non-stick sheet and clean with mild detergent and damp cloth. (If excess buildup is unable

to be removed and causing buns to stick to the sheet, a new sheet may need to be installed.)

5. Remove crumb tray and toast slide and wash in a sink with mild detergent.

6. Dry and return crumb tray, toast slide, and non-stick sheet back into position.

7. Turn the power switch to the "OFF" position, until you need

DO NOT IMMERSE OR LET THE UNIT STAND IN WATER.

DO NOT HOSE DOWN THE UNIT OR THE TABLE/COUNTER IF THE

UNIT IS ON THE TABLE/COUNTER.

WARNING

KEEP AWAY FROM RUNNING WATER.

Sheet Retainer

DO NOT use caustic

cleaners on any surface

CAUTION

of the unit, conveyor belt

or Durable Non-Stick

Coated Sheets

Platen Suppot Bracket

IL2859b

Locking Platen Latch

Crumb Tray

Toaster Chute

7

Page 10

TROUBLESHOOTING GUIDE

A. Unit Will Not Heat, Conveyor Belt Will Not Move.

1) Be sure the main circuit breaker is switched to the ON

2) Check to see if the toaster is plugged in and all controls are turned to the ON position.

B. Unit Has Heat Only On One Side, Conveyor Belt Turns Freely.

1) Contact your local service agent,, as heating element may need replacing.

C. Conveyor Will Not Turn, Unit Heats Properly.

To check for mechanical binding:

1) DISCONNECT UNIT FROM POWER SOURCE.

3) Remove 4 screws on the back of the toaster and remove back panel.

4) Remove the right side panel.

5) Loosen the four screws that hold the drive motor in place.

6) Slide the motor up allowing the drive chain to be removed from the sprockets.

7) Move the conveyor belt by hand to check for mechanical binding. If conveyor moves freely,

contact your local service agent,, as the drive motor and/or speed control

may need replacing.

8) Re-install the rear and side panels.

D. Heat Limit Switch (Reset)

Your Ultra-Max contact toaster is equipped with an automatically activated heat limit switch

that interrupts the heater tube connections if the ambient temperature in the control box

exceeds 190°F (88°C). This switch can be reset manually by pushing the red button located

behind the right side panel as shown in the Components Illustration on Page 2.

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Check to see if air intake area in the bottom center of the control box cover is free of dust,

grease or other obstructions.

3) Check if crumb tray is in place. .

4) If no obstructions to the airow can be found

contact your local service agent, for assistance.

E. Conveyor Turns At One Speed Regardless Of Speed Control Setting

(HCTE models only).

1) Contact your local service agent,, as speed control should be replaced.

F. Product Sticking To Conveyor Or Slide

Your Ultra-Max Contact Toaster is designed to toast product that is current room temperature.

DO NOT attempt to put frozen, refrigerated material in the toaster.

Doing so may cause it to come out doughy or very moist, as well as possibly sticking to parts of the

unit. Follow the cleaning procedures.

2M-Z19028; Holman Contact Toaster

8

Page 11

MAINTENANCE PROCEDURES

A. Replacing the Bottom Element

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove the side panels and bottom panel.

3) Remove element wire from terminal block connection, keeping top and

bottom wires separate.

4) Lift element retainers by loosening retaining screws and removing the retainer plate up.

5) Gently, pull defective element out of unit.

6) Gently, put new element into unit.

7) Slide the retainer back into place. Tighten the screw to secure the retainer in place

over the ends of the elements.

B. Replacing the Fan Motor

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove the toaster slide.

3) Remove screws from the bottom panel.

4) Unplug power supply cord from fan motor.

5) Remove (4) screws, which hold fan motor and grill to bottom of unit and remove fan.

6) Put replacement motor and grill in place and secure to the bottom of unit with screws.

7) Reconnect power supply cord to fan motor.

8) Replace bottom panel. Fasten with screws removed in step 2.

C. Replacing the Belt Drive Motor

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove the right side and bottom panels.

3) Remove sprocket from motor shaft, using an Allen wrench and loosening the set-screw.

4) Remove the wire from terminal block connecting the drive motor to internal wiring.

On units rated 208 or 240 volts, note which color leads are being used for these connections

and which lead is capped with white tape. The new motor should use the same arrangement.

5) Remove screws holding motor in place and remove motor from unit.

6) Put new motor in place and attach loosely with mounting screws.

7) Replace sprocket on motor shaft.

NOTE The two sprockets should line up parallel with each other, so the chain does not twist

any during operation. Also the hub gets installed closets to the motor.

8) Slide motor until the drive chain has about 1/4” slack when lightly pushed at the center of its top

open run. See chain tensioning illustration.

9) Tighten screws to secure motor.

10) Rewire leads same as removed in step 4.

11) Replace previously removed panels.

D. Clean the Air Intake (Once A Week)

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Place unit on its backside.

3) Use a vacuum cleaner and or a damp cloth to clean

the air intake.

E. Lubricate the Chain & Sprockets (Every 6 Months)

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove enclosure exposing chain drive.

3) While wearing rubber gloves and using an extreme pressure,

synthetic chain lubricant with a temperature range up to

400°F (204°C) lubricate chain and sprockets. Apply liberally.

This grease is available as part no. 1L-Z12397.

4) Replace enclosure, Reconnect power source and test unit.

9

1/4”

Chain Tension

Page 12

MAINTENANCE continued

REMOVING & REPLACING SILICONE BELT

1. Disconnect unit from power allow to cool before beginning process.

2. Remove guard from in front of the belt.

3. Rotate belt by hand until belt seam is visible.

4. The Idler Shaft is spring loaded. Press on the front idler shaft to remove tension from the

belt. (Continuous pressure is required).

5. Pull splicing rod from belt.

6. Carefully release pressure from idler shaft so the roller is not propelled from the unit by the

springs.

7. Installation is similar to removal. Feed the belt around the drive shaft and idler shaft rollers

making sure the tracking guide on the backside of the belt is seated in the roller grooves.

8. Press the front roller to create slack in the belt.

9. Feed the splicing rod through the two ends of the belt.

10. Remove pressure from roller and install belt guard.

11. Plug unit back into outlet and test for proper operation.

Top Panel

Burn Guard

CAUTION

Groove

Idler Shaft

Locking Platen Latch

Platen Support Bracket

Above: Removing and Installing Silicone Belt

Drive Shaft

Groove

IL2857

DISCONNECT THE POWER SUPPLY BEFORE SERVICING OR

CLEANING THIS OVEN. SAFEGUARD THE POWER SO IT CANNOT BE

ACCIDENTALLY RESTORED. FAILURE TO DO SO COULD RESULT IN

DISMEMBERMENT, ELECTROCUTION, OR FATAL INJURY.

10

2M-Z19028; Holman Contact Toaster

Page 13

Visit our Website at: www.star-mfg.com Email: customerservice@star-mfg.com

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in which

the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the transportation

company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of the unit.

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

LIMITED EQUIPMENT WARRANTY

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the Ultra-Max, Hot Plates, Griddles, Charbroilers is (3) years parts & labor.

* The warranty period for the Star-Max, Charbroilers, Griddles, Hot Plates, Fryers & Finishing Oven is (2) years parts & labor.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* ThewarrantyperiodfortheChrome-MaxGriddlesisve(5)yearsonthegriddlesurface.Seedetailedwarrantyprovidedwithunit.

* The warranty period for Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Dura-Teccoatingsfromimpropercleaning,maintenance,useofmetallicutensils,orabrasivecleaners,abrasivepads,productidentiersand

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted, the labor to replace the part is NOT warranted.

SERVICES NOT COVERED BY WARRANTY

1. Traveltimeandmileagerenderedbeyondthe50mileradiuslimit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damagesduetoimproperinstallation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

* TheModel510FD,510FFFryer.

* TheModel526TOAToasterOven.

* TheModelJ4R,4oz.PopcornMachine.

*TheModel518CMA&526CMACheeseMelter.

* TheModel12MC&15MC&18MCPHotFoodMerchandisers.

* TheModel12NCPW&15NCPWNachoChip/PopcornWarmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* AllQCS/RCSSeriesToastersexcept Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

PARTS WARRANTY

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resettingofcircuitbreakersorsafetycontrolsorresetbuttons

16. Replacementofbulbs

17. Replacementoffuses

18. Repairofdamagecreatedduringtransit,delivery,&

PORTABLE EQUIPMENT

FOR ASSISTANCE

installationORcreatedbyactsofGod

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

11

2M-4497-2 11/21/14

Page 14

STAR MANUFACTURING INTERNATIONAL INC.

FAN

CONVEYOR

MOTOR

TOP ELEMENT

BOTTOM ELEMENT

HI-TEMP

SWITCH

HB1

HT1

L1

F1

M1

L2

OT2

M2

F2

OT1

HB2 HT2

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

DATE

TOLERANCES UNLESS OTHERWISE NOTED

FRACTIONS ±1/64 DECIMALS ±.015 ANGLES ±1°

STAR MANUFACTURING INTERNATIONAL INC.

#10 SUNNEN DRIVE, ST. LOUIS, MO. 63143, USA

CK.

MATERIAL

FINISH

PART NO.

DESCRIPTION OF CHANGE

REVISIONS

MODEL NO.

TITLE

DATE

LTR

DR

DR.

-

-

-

-

-

MH

SK-2799

WIRING DIAGRAM, SINGLE BOTTOM

-

-

MRC

7/11/14

120V

240V

240V

120V

120V

#10 SUNNEN DRIVE, ST. LOUIS, MO. 63143, USA

DR.

MRC

CK.

MH

DATE

7/11/14

TOLERANCES UNLESS OTHERWISE NOTED

FRACTIONS ±1/64 DECIMALS ±.015 ANGLES ±1°

MATERIAL

-

FINISH

-

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

TOP ELEMENT

BOTTOM ELEMENTS

120V

120V

240V

HT2

240V

HB2

HI-TEMP

SWITCH

HB1

HT1

120V

OT1

F2

M2

L2

L1

F1

M1

OT2

MODEL NO.

HCTE

TITLE

REVISIONS

13M

WIRING DIAGRAM, PARALLEL BOTTOM

LTR

-

CONVEYOR

MOTOR

PART NO.

DESCRIPTION OF CHANGE

DATE

-

-

-

SK-2798

DR

-

FAN

HCTE

13S

2M-Z19028; Holman Contact Toaster

12

Page 15

2M-Z19028; Holman Contact Toaster

13

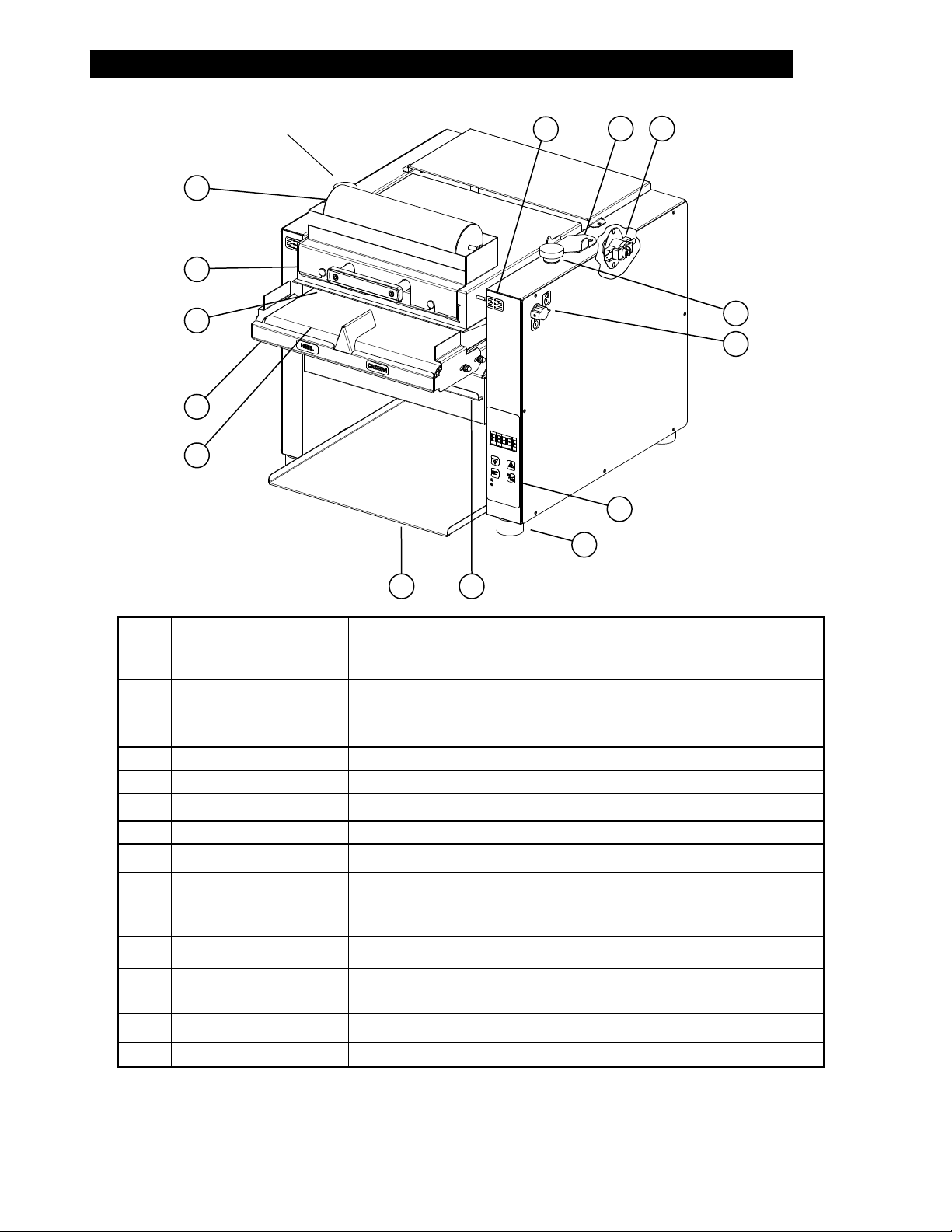

Page 16

Optional Accessory

1

2

HCT13 Manual Control

52 73

37

74

21

22

23

75

20

19

76

37

36

77 78

24

32

33

15

27

25

26

28

17

30

29

18

31

16

9

8

5

4

3

6

10

11

7

HCTE13 Electonic Control

14

1312

68

67

69707172

66

65

64

58

57

63

62

59

60

6137

Model: HCTE & HCT Contact Toasters

w/electronic & manual controls

56

55

53

54

45

34

46

35

44

37

43

42

47

SK2797 Rev. A 10/28/14

41

36

40

49

48

52

37

50

38

39

51

2M-Z19028; Holman Contact Toaster

®

14

Page 17

PARTS LIST October 13, 2015, Rev. E

Model: HCTE13 & HCT13 Contact Toaster

Fig No Part No Quantity Description Application

1 HC-CT0018 Optional Butter Wheel Weldment

2 HC-CT0017 Optional Butter Wheel Base Weldment

3 2I-05-07-0013 1 BOOT SWITCH HCT13

4 2M-Z18461 1 LABEL, POWER, ON & OFF HCT13

5 Z1-70-07-0343 1 SWITCH GUARD HCT13

6 2J-31157 1 LIGHT SIGNAL RED, MAIN POWER HCT13

7 2J-31157 1 LIGHT SIGNAL RED, ELEMENT PWR HCT13

8 2R-Z18145 1 KNOB, SG 1.75 X .25 SHAFT HCT13

9 2M-Z19266 1 LABEL, HCT HCT13

10 2T-Z18396 1 THERMOSTAT, 150-550°F HCT13

11 2E-30330 1 SWITCH ON OFF TOGGLE 20A HCT13

12 2M-Z18207 1 LABEL, HCTE HCTE13

13 2J-Z17717 1 ELECTRONIC CONTROL SPEC HCTE13

14 2U-200592 1 QCSE PWRBRD,W/RIBBONCABLE HCTE13

15 HC-CT0005 1 PLATEN COVER ASY

16 2K-Z17714 2 BUSHING, OUTER

17 2C-6517 6 NUT 1/4-20 HEX STL NP

18 2A-Z17716 2 SUPPORT, 1/4-20 X 11/32

19 2A-Z17727 2 SPACER, 5/8”OD X 0.266”ID

20 2R-Y2830 1 HANDLE HARRY DAVIES 4560

21 2C-Z18503 2 SCREW, SOCKET CAP 1/4-2O

22 HC-Z17713 1 RETAINER, PTFE SHEET

23 2A-Z17712 3 THUMBSCREW 8-32 X .375

24 HC-Z17724 1 THERMOPROBE BRKT HCTE13

25 HC-Z17711 1 ELEMENT COVER

26

27 2F-Z17708 1 13” TOP CASTING

28 2A-Z18504 1 SPACER, 3/8IN X 1/4IN

29 2C-Y7595 1 BOLT 1/4-20X1/2 THS STL

30 2H-Z18588 1 PTFE SHEET, 0.003 TK

31 HC-CT0006 1 BACK PANEL ASY

32 2C-Z10075 1 SCREW-1/4-20X3/8 SS THS

33 HC-Z17737 1 PLATEN SUPPORT BRKT

34 2E-200566 1 SWTCH,RSET,0796-190F TRPS

35

36 HA-112261 2 BEARING ASSY PTFE/BRONZE

37 2C-Z6929 34 NUT, 10-24 KEPS SS

38 2P-200646 1 SPROCKET, 25B20 X 5/16

2N-Z17710

1

2N-Z17749 ELEMENT, METAL 2300W 208V 208V

2A-CT0015

1 BELT DRIVE SHAFT ASSEMBLY

2A-CT0015SB HCTE13S

ELEMENT, METAL 2300W 240V 240V, 230V

HCTE13M

15

Page 18

PARTS LIST October 13, 2015, Rev. E

Model: HCTE13 & HCT13 Contact Toaster

Fig No Part No Quantity Description Application

39 2P-150013 1 DRIVE CHAIN #25 ROLLER

40 2P-200648 1 SPROCKET, 25B32 X 5/16

41 2E-Z17514 1 SENSOR, SPEED HCTE13

42 HC-CT0008 1 SPEED CONTROL BRKT ASY HCTE13

43 2U-Z9657 1 MOTOR,11RPM-CW,NEW STYLE

44 2K-Y3240 1 BUSHING HEYCO SR 17-2

45

46 HC-CT0013 1 RIGHT ADJUSTMENT BRKT ASY

47 HC-CT0014 1 PLATEN LATCH ASY

48 2M-Z18513 1 LABEL, UNLOCK SYMBOL

49 2M-Z18512 1 LABEL, LOCK SYMBOL

50 2R-Z17729 1 KNOB, 1-1/4 X 5/8 X 1/2

51 HC-Z17742 1 PANEL, RIGHT COVER

52 2C-6349 24 SCREW #8X3/8 B THP STL NP

53 2R-200562 1 FAN GUARD

54 HC-Z17740 1 MOTOR HOUSING COVER

55 2U-200561 1 MOTOR, FAN 240V 23BTM

56 2R-Z18201 4 FOOT 1.69X1 SIL 1/4 20

57 HC-Z17723 1 TOAST SLIDE

58 HC-Z17736 1 CRUMB TRAY

59 2P-Z18587 2 BEARING SPRING 2IN

60 2P-200700 2 BRG SPRING LOADED

61 2C-2559 4 NUT 10-24 ACHD BR NP

62 2M-Z17750 1 LABEL, CROWN

63 2M-Z17735 1 LABEL, HEEL

64 HC-CT0009 1 BELT GUARD ASM

65

66 2K-200464 2 BUSHING, WIRE RING 7/8”

67 2M-Z18258 2 LABEL, SCALE

68 2A-Z17720 8 SPACER-.375”OD X .192”ID

69 2V-Z17744 1 PLATEN SUPPORT

70 HC-CT0012 1 LEFT ADJUSTMENT BRKT ASY

71 HC-CT0007 2 ELEMENT SUPPORT ASY

72 HC-Z17731 1 ELEMENT RETAINER

73 HC-Z17741 1 PANEL, LEFT COVER

2E-Z10406

1

2E-Z14254 TERMINAL BLOCK 6-POLE HCT13

2A-CT0016

1 BELT IDLER SHAFT ASSEMBLY

2A-CT0016SB HCTE13S

TERMINAL BLOCK 4 POS HCTE13M

HCTE13M

2M-Z19028; Holman Contact Toaster

16

Page 19

PARTS LIST October 13, 2015, Rev. E

Model: HCTE13 & HCT13 Contact Toaster

Fig No Part No Quantity Description Application

74

75 2C-1810 16 WASHER 3/16 BURR STL NP

76 2K-Z17715 2 BUSHING, INNER

77 HC-Z16924 1 SHAFT ACCESS COVER PLATE

78 2A-CT0011 2 ADJUSTMENT KNOB ASY

NI 2E-Z17719 1 TYPE K PROBE HCTE13

NI 2B-Z17743 1 CONVEYOR BELT CG10 X.062

NI PS-CT0034 1 SILICONE BELT, 13” X 41.04

NI HA-120244 1 CORDSET ASSY QCS1-230C 230V

NI HA-120245 1 CORDSET ASSY NEMA 6-20P 208,240V

2N-Z17718 1 ELEMENT, METAL 350W 240V HCTE13S

2N-Z17718 2 ELEMENT, METAL 350W 240V HCTE13M

17

Page 20

STAR MANUFACTURING INTERNATIONAL INC.

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

265 Hobson St.,

Smithville, Tennessee 37166 U.S.A.

(800) 264-7827

www.star-mfg.com

Loading...

Loading...