Page 1

HEATER PROOFERS

MODEL

(E)9451-12CDCP, (E)9451-12SDCP,

(E)9451-34CDCP, (E) 9451-34CDCP

Installation, Operation & Parts Manual

2M-Z18494 Rev. - May 12, 2014

Page 2

SAFETY SYMBOL

CAUTION WARNING

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

Authorized Service Agent Listing

Model No.

Serial No.

Voltage

Purchase Date

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

2M-Z18494, Heater Proofer 9451- Series

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

2

Page 3

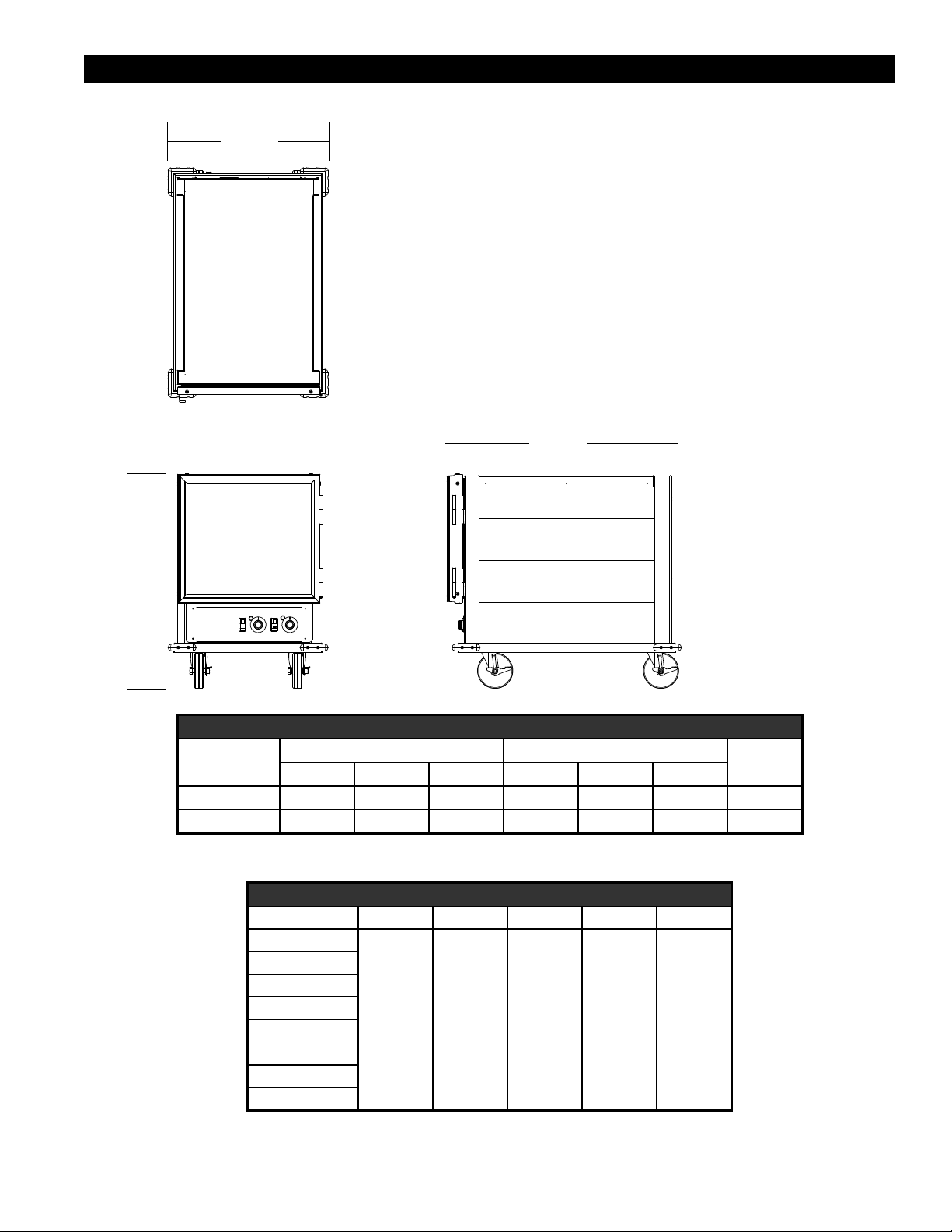

Front

Side

IL2431

Width

Top

9451 HP SERIES SERVICE SPECIFICATIONS

The Heater Proofer is an aluminum transport cabinet with heaters to function

as a hot food holding cabinet, and/or as a proong cabinet.

The heater, or heat drawer, is slid into place on the oor of the cabinet. An

electrical socket on the back of the drawer is provided to accept the supplied

power cord, which is plugged into the drawer through an access hole in the

back of the cabinet.

The main power switch on the front of the drawer, when switched “ON”, will

turn on the light in the switch and turn on the air circulating fan in the drawer.

The circulating fan will operate continuously while the unit is “ON”.

The thermostat control knobs are mounted to the left and right of the heat/proof

switch. The left thermostat knob controls the heat in the cabinet from 1 (low

heat: approximately 80°F) to 9 (high heat: approximately 185°F). The right

thermostat knob controls the humidity from 1 (approximately 20% relative

humidity) to 9 (in excess of 100% relative humidity). Average setting will be

approx. 6 (approximately 85% relative humidity).

Depth

Height

9451-12 30.3125” 22.8125” 33.3125” 15.625” 18.125” 27.5” 100lbs

9451-34 67.5625” 23.3125” 33.875” 51.75” 18.125” 27.5” 140lbs

Model Volts Watts Phase Hz NEMA

9451-12CDCP

2M-Z18494, Heater Proofer 9451- Series

9451-12SDCP

9451-34CDCP

9451-34SDCP

E9451-12CDCP

E9451-12SDCP

E9451-34CDCP

E9451-34SDCP

SIZE SPECIFICATIONS

Exterior Interior

Height Width Depth Height Width Depth

ELECTRICAL SPECIFICATIONS

120V 1.5 kW 1 50/60 Hz 5-20P

Weight

Shipping

3

Page 4

CAUTION

This equipment is designed to hold food at a constant temperature, and supply humidity for proong

when the application applies, this is NOT a cooking appliance. This unit is sold for commercial use only

by personnel trained and experienced in its operation and is not sold for consumer use in and around the

home nor for use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated with the

unit prior to putting it into operation. Make sure all people associated with its use understand the units

operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed. This unit has

been tested and carefully packaged to insure delivery of your unit in perfect condition. If equipment is

received in damaged condition, either apparent or concealed, a claim must be made with the delivering

carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a

request for inspection of concealed damage must be made with carrier within 15 days. Be certain to

retain all contents plus external and internal packaging materials for inspection. The carrier will make an

inspection and will supply necessary claim forms.

INSTALLATION

This unit is equipped for the voltage indicated on the nameplate mounted the side of the unit. They will

operate on alternating current (AC) only.

The electrical connection must be made in accordance with local codes or in the absence of local codes

with NFPA No.70 latest edition (in Canada use: CAS STD. C22.1). The electrical service is provided by a

cord and plug. Each appliance requires a 120 volt grounded supply. Supply wires must be 14 gauge or

larger to carry the load for one proofer.

WARNING

DO NOT CONNECT TO DIRECT CURRENT (DC).

THIS APPLIANCE IS EQUIPPED WITH A 3-PRONG (GROUNDED) PLUG FOR YOUR

PROTECTION AGAINST SHOCK HAZARD AND MUST BE PLUGGED DIRECTLY INTO A

PROPERLY GROUNDED 3-PRONG RECEPTACLE.

GENERAL OPERATING PROCEDURES

Proong

Proong is one of the most important and delicate stages in baking. About 50% of the product volume

is created in the proofer. Proong accelerates the fermentation of yeast in a warm moist environment

causing the dough to rise. The proofer humidity should be between medium high and high. For optimum

results, rolls should be removed from the hot proofer and transferred to the cold proofer at minimum

proof. This will ensure that they can be held for 40 minutes without becoming over-proofed.

2M-Z18494, Heater Proofer 9451- Series

4

Page 5

OPERATING INSTRUCTIONS

Startup

1. Push ON/OFF rocker switch to “ON” position

2. Push HEAT/PROOF switch to HEAT for heating.

3. Turn HEAT thermostat knob fully clockwise for pre-heat.

4. Allow 45 minutes for pre-heating, then turn thermostat to desired setting.

5. For proong, push HEAT/PROOF switch to PROOF. DO NOT RUN WATER PAN EMPTY.

Note: While in proof mode only the element around the water pan is on.

6. Adjust the heat and humidity thermostat knobs to control desired temp and humidity. 45 min pre-heating.

Note: The internal air circulation blower will operate continuously when the power switch is turned “ON”.

ON

HEAT

HEATER/PROOFER

OFF

POWER HUMIDITY

HEAT

PROOF

IL2823

Heat Knob (Heat Mode)

The controlling range is 80° to 185°F ( 26° to 85°C) temperatures vary slightly between insulated and non-insulated

units. The dial has setting from 1 to 9 that do not relate to any specic calibrated temperatures. Temperature settings

must be obtained through familiarization with the unit. While in the heat mode this knob controls the two elements in

the air stream, in the “OFF” position the elements are turned off. During the “Proof” mode one of these elements is

not in use.

Humidity Knob (Proof Mode)

To control the humidity range from 30% to 100% humidity, settings must be obtained through familiarization with the

unit. The dial has a range of 1 - 9 which determins the temperature of the water in the pan, if you have the knob in the

“OFF” position it will turn the proong element off. While in proof mode the unit will operate at a lower termperature.

Allow 45 minutes to pre-heat in both heat & proof cycle.

TROUBLESHOOTING

CAUTION: Before disassembling unit, electrical power must be disconnected by unplugging the unit. Failure to

unplug the unit prior to servicing may result in electrical shock.

Each unit is shipped with an instruction manual to be used as a reference guide for all service areas. The manual

shows a picture of the drawer, showing the location of electrical components and a description of each. If the unit

does not operate correctly, or malfunctions for any reason, the following checklist should provide a solution.

1) Check to make sure cord set is rmly plugged into the power receptacle in the back of the cabinet and

into the wall outlet.

2) Check circuit breaker of wall outlet and reset if necessary.

3) Remove heat drawer from cabinet. Remove bottom cover of drawer. Visually inspect for:

a) Loose or disconnected wires

2M-Z18494, Heater Proofer 9451- Series

b) Black marks or burning on any components

c) Loose heating elements.

4) If any burn marks or discoloration of wires is note on any components along with all wires attached to

damaged components must be replaced.

5) If heater element is loose, or if it has broken loose from mounting tabs, the wires will short out on the

Metal, causing permanent damage. Both the element and main power switch (with wires on switch) must

be replaced.

6) If temperature on “L.E.D. Thermometer” is not reading a constant temperature, it must be replaced. If

temperature has exceeded 200°F (93°C) it must be lowered immediately to maximum temperature of

185°F (85°C).

5

Page 6

SK2778 Rev. - 5/09/2012

3

2

1

11

10

7

9

4

See Detail A

Model: E9451 Heater / Proofer

6

8

5

2M-Z18494, Heater Proofer 9451- Series

6

Page 7

SK2779 Rev. - 5/09/2014

13

14

15

16

17

12

18

21

20

19

22

23

24

36

32

33

34

35

2M-Z18494, Heater Proofer 9451- Series

31

30

13

25

26

18

7

27

18

28

29

36

Detail A

Model: E9451 Heater / Proofer

7

Page 8

PARTS LIST March 12, 2014, Rev. -

Central Products: Heater / Proofer Model: E9451 & 9451

Fig No Part Number Qty Description Application

1 2R-4FM0705P 1 PULL,ALM DRWR,DIE CST,BUF

R2-AC1323

2

R2-WH2006 9451-34CDCP, 9451-34SDCP, E9451-34CDCP, E9451-35SDCP

3 2C-1525 2 SCREW 1/4-20X1-1/4 RH ST

R2-WASSY001

R2-WASSY003 ASSY,DOOR,SOLID,NHP-1836 9451-34SDCP, E9451-34SDCP

4

R2-WASSY022 ASSY,DOOR,RH,E9451-HP12CD 9451-12CDCP, E9451-12CDCP

R2-WASSY057 ASSY,DOOR,RH, SOLID DOOR 9451-12SDCP, E9451-12SDCP

2I-4FMD345P

5

2I-4FMD405P GASKET,BLK,MAG,18.63X16.5 E9451-12, 9451-12

6 2V-4FM0003P 2 HINGE,ASSY,2”,S/S

7 R2-TC0075 1 PAN ASSY.

8 2P-738ABK 4 CASTER,5x1.25,SWIVEL,POLY

9 2R-4FMBC01P 4 CORNER BUMPER J-J-B12 BLA

10 2C-Z15625 16 SCREW 10-32-1 FLT HD PHIL

11 R2-Z17184 1 CORD BRACKET

12 R2-WH2020 1 BOTTOM COVER

13 2I-6STRN05P 6 GROMMET,7/16X1/16X1/4X3/4

14 R2-WH2014 1 ELECT BULKHEAD

15 2U-WP-6FANS30P 1 6IN TRANSFLOW FAN 115V/60

16 2C-1493 7 SCREW 8-32X3/8 RHP STL NP

17 R2-WH2015 1 BULKHEAD, MOTOR

18 2C-8833 37 SCREW 8-18X1/2 HEX STL NP

19 2N-6FME755P 1 ELEMENT,120V,600W

20 2N-6WH0001P 1 ELEMENT,HTPRF 600W/120V

21 2N-6WH0002P 1 ELEMENT,HTPRF 900W

22 R2-WH2022 1 PROBE HOLDER TOP

23 R2-WH2023 1 PROBE HOLDER BOTTOM

24 2C-2582 7 NUT 1/4-20 HEX STL NP

25 2C-Z5557 7 WASHER 1/4 SPLIT SS

26 R2-AP2102 1 PROBE HOLDER

27 R2-WH2012 1 REAR COVER PLATE

28 2E-50-1382 1 OUTLET,NEMA 5-20R

29 2T-66-1150 1 DISC,SNAP,275*F

30 2T-66-1121 2 THERMOSTAT,85-180 DEG,MEC

31 R2-AC2337 1 FRONT CONTROL PNL

32 2M-Z18490 1 GRAPHIC, HEAT\PROOF

33 2J-50-0029 2 LIGHT,PILOT,RED NEON,125V

34 2E-50-1355 1 SWITCH,ROCKER,SPST,ON-OFF Main Power Switch

35 2R-50-0726 2 KNOB,TEMP.BOARD CONTROL

36 2E-50-1357 1 SWITCH,ROCKER,DPDT,ON-ON Heat / Proof Select Switch

37 R2-TC0092 1 HP MODULE

NI 2C-20304-02 1 NUT WING 1/4-20 STN STL

NI 2E-6WH0040P 1 CORD,POWER,6’FT LONG H-10

NI 2C-Z15532 1 CABLE CLAMP

NI R2-AC1330 1 SIDE, OUTER RIGHT 9451-12CDCP, 9451-12SDCP

NI R2-AC1331 1 SIDE, OUTER LEFT 9451-12CDCP, 9451-12SDCP

NI R2-AC2515 1 SIDE-O/D-LT 9451-34CDCP, 9451-35SDCP

NI R2-AC2516-C 1 SIDE-O/D-RT 9451-35CDCP, 9451-34SDCP

1 BAFFLE

ASSY,DOOR,CLEAR,NHPL-1836 9451-34CDCP, E9451-34CDCP

1

18.63X52.70 GSK, BLK, MAG E9451-34, 9451-34

1

9451-12CDCP, 9451-12SDCP, E9451-12CDCP, E9451-12SDCP

2M-Z18494, Heater Proofer 9451- Series

8

Page 9

WIRE GA COLOR

1 16 WHITE

1

1100W HEAT

7

2 16 WHITE

3 16 WHITE

4 16 WHITE

5 16 WHITE

6 16 WHITE

3

600W HEAT

8

7 16 BLACK

8 16 BLACK

9 16 BLACK

10 16 BLACK

11 16 BLACK

12 16 BLACK

14

600W PROOF

14

14 14 BLACK & WHITE

15 14 BLACK & WHITE

16 14 GREEN

4

9

BLOWER

41

6

2

5 5

12

3

2

10

7

POWER

2M-Z18494, Heater Proofer 9451- Series

HEATER PROOFER

WIRING DIAGRAM

2

IND

11 12

HEAT

T-STAT

IND

8

11

12

12

12

5

3

9

12 12

15

15

7

4

5

6

11

1

2

5

3

HEAT/PROOF

14 14

11

12

11

PROOF

T-STAT

11

1515

OVERLOAD

PROTECTION

10

2

16

SK2780 REV. - 5-09-14

9

Page 10

Page 11

Page 12

Loading...

Loading...