Page 1

CONVERTIBLE JET PUMP

QUICK REFERENCE

GUIDE

SEE INSTRUCTION

MANUAL FOR

COMPLETE DETAILS

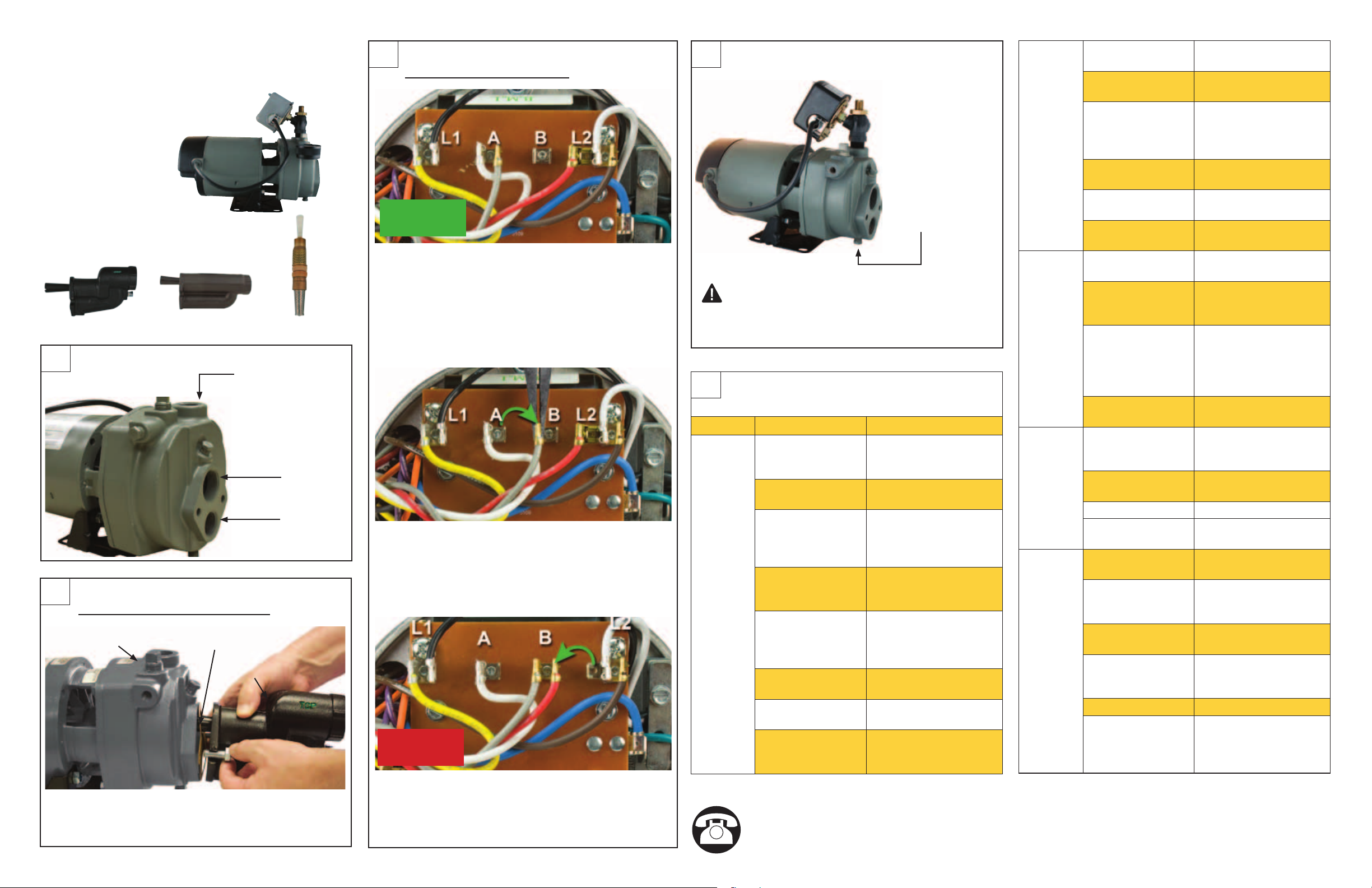

EJECTORS

(Purchase separately)

Shallow Well Convertible Single Pipe

PIPE SIZES

1

3/4 in. Discharge

(1/2 & 3/4 HP)

1 in. Discharge

(1 & 1-1/2 HP)

1-1/4 in.

Suction

1 in.

Pressure

INSTALLATION

2

Shallow Well Application Only

Priming Port

Attach ejector to face of pump with two (2) bolts

and gasket provided. Venturi tube on the ejector

inserts into the top tapping of the face of the pump.

Venturi Tube

Ejector

ELECTRICAL CONNECTIONS

3

To change from 115V to 230V

115V

1. The motor of this pump is dual voltage and can

run on either 115V or 230V. In general, 230V is

more economical to run, and requires a smaller

wire size. 1/2 and 3/4 HP pumps are pre-set in

the factory to run at 115V. (Fig. 1)

2. For 230V service, change the following wires

on the terminal board:

a. Using a pair of needle nose pliers, pull the

gray wire with the female ag connector

from the “A” terminal spade post. Place it

to the right on the “B” terminal space post.

(Fig. 2a)

230V

b. Pull the red wire with the female ag

connector from the “L2” terminal. Place it to

the left on the “B” terminal space post.

(Fig. 2b)

WINTERIZING

4

PREVENT

PUMP

DAMAGE!

Remove plug

in freezing

weather

CAUTION: Drain the entire system if there

is danger of freezing. A drain plug is provided at

the bottom of the pump case for this purpose.

TROUBLESHOOTING

5

Problem Possible Cause Corrective Action

Little or no

discharge

1. Casing not

initially lled with

water

2. Suction lift too

high, or too long

3. Hole or air leak in

suction line

4. Foot valve too

small

5. Foot valve or

suction line not

submerged deep

enough in water

6. Motor wired

incorrectly

7. Casing gasket

leaking

8. Suction or

discharge line

valves closed

1. Fill pump casing

2. Move pump closer to

water source

3. Repair or replace.

Use pipe tape

and pipe sealing

compound

4. Match foot valve to

piping or install one

size larger foot valve.

5. Submerge lower in

water

6. Check wiring diagram

7. Replace

8. Open

SEE REVERSE FOR PRIMING INSTRUCTIONS

Questions? Call 1-800-742-5044

Copyright © 2011 Star Water Systems. All rights reserved.

Pump will

not deliver

water or

develop

pressure

Loss of

suction

Pump

vibrates

and/or

makes

excessive

noise

Pump will

not start or

run

BEFORE Returning Product

1. No priming water

in casing

2. Leak in suction

line

3. Discharge line

is closed and

priming air has

nowhere to go

4. Suction line (or

valve) is closed

5. Foot valve is

leaking

6. Suction screen

clogged

1. Air leak in suction

line

2. Suction lift too

high

3. Insufcient inlet

pressure or

suction head

4. Clogged foot

valve or strainer

1. Mounting plate

or foundation not

rigid enough

2. Foreign material

in pump

3. Impeller damaged 3. Replace

4. Worn motor

bearings

1. Improperly wired 1. Check wiring diagram

2. Blown fuse or

open circuit

breaker

3. Loose or broken

wiring

4. Stone or foreign

object lodged in

impeller

5. Motor shorted out 5. Replace

6. Thermal overload

has opened

circuit

1. Fill pump casing

2. Repair or replace

3. Open ball valve

4. Open

5. Replace foot valve

6. Clean or replace

1. Repair or replace

2. Lower suction lift,

install foot valve and

prime

3. Increase inlet

pressure by adding

more water to tank

or increasing back

pressure

4. Unclog

1. Reinforce

2. Disassemble pump

and clean

4. Replace

on motor

2. Replace fuse or close

circuit breaker

3. Tighten connections,

replace broken wiring

4. Disassemble pump

and remove foreign

object

6. Allow unit to cool,

restart after reason

for overload has been

determined

023539 A

Page 2

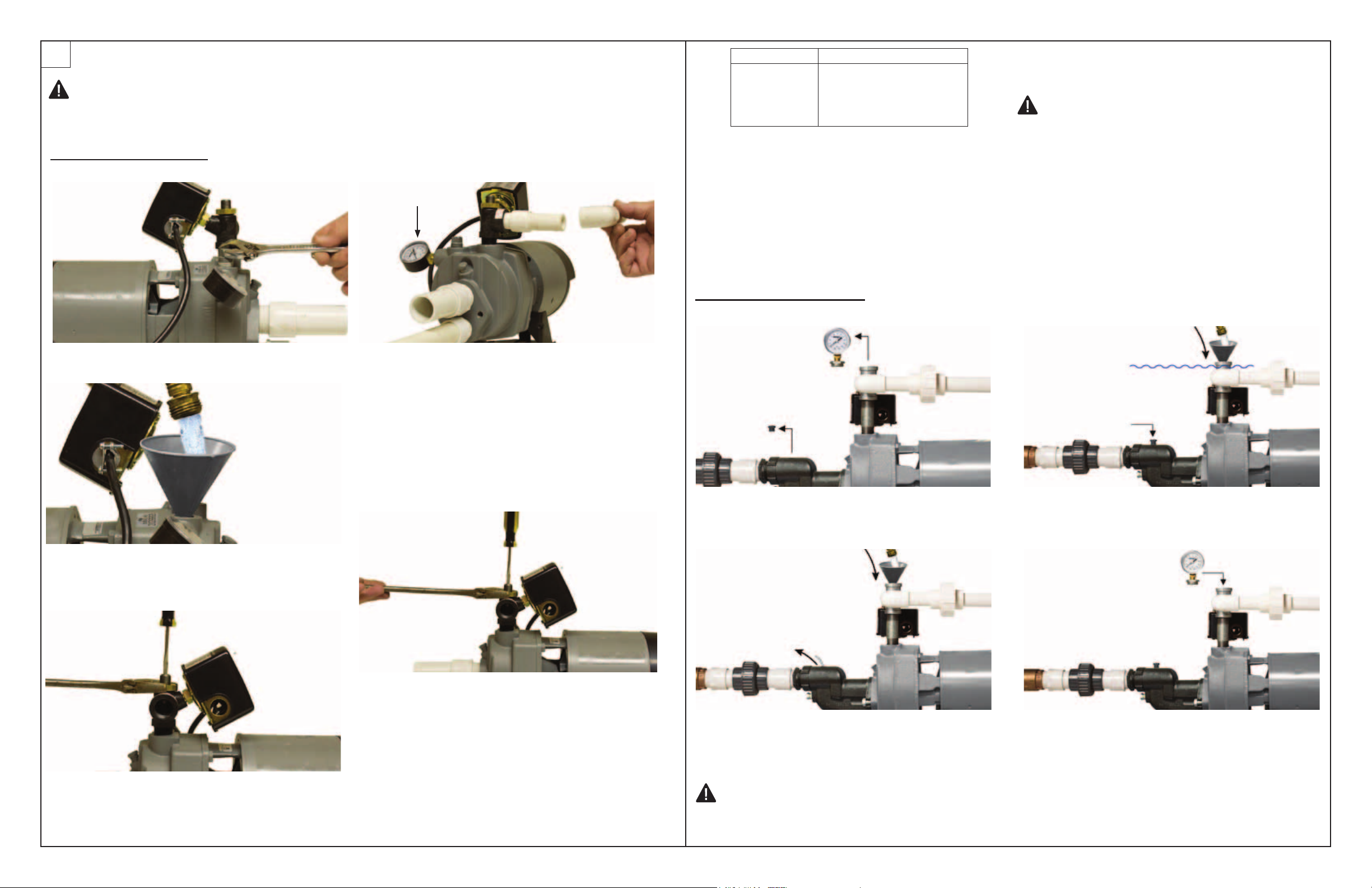

PRIMING

6

CAUTION: All pumps must be primed (lling the cavity with water) before they are rst

operated. This may take several gallons of water, as the suction line will be lled in addition to

the pump cavity.

Deep Well Application Only:

Pressure gauge

HP Pressure Setting

1/3

1/2

3/4

1

The correct control valve setting will depend on the

type of well installation and pressure switch setting

for the particular pump.

Shallow Well Application Only

24 PSI

27 PSI

38 PSI

46 PSI

NOTE: If the pump is being used for shallow well

applications, the ow control screw should be set in

the full open position.

IMPORTANT: If the pump fails to prime within

ve minutes:

Turn power off at the breaker box. Look for leaks

or a milky color in the discharged water, which

indicates an air leak. Re-prime if necessary,

following steps 1 through 5 above. Reset breaker at

the breaker box. All connections must be water and

air tight in order for pump to operate.

1. Remove the 1/2 in.priming plug. (Fig. 1)

2. Fill pump cavity with water until full and replace

priming plug. (Fig. 2)

4. If pump is properly primed, pressure will

quickly build and register on the gauge

mounted directly on the pump body. If

pressure does not build repeat priming

operation. All air must be vented from the

drive and suction pipes as well as the body

before the pump will prime. The pump body

may need to be lled several times in order to

achieve the prime. (Fig. 4)

Priming plug

with pressure

gauge

Air relief plug

1. Remove the 1/2 in. priming plug with pressure

gauge and air relief plug. (Fig. 1)

Water

level in

pump

cavity

3. Replace air relief plug and continue adding

water to pump cavity until water reaches the

top of the priming plug. (Fig. 3)

3. Tighten ow control screw completely by turning

clockwise, then loosen two turns. Now start the

pump. (Fig. 3)

5. With pump operating at high pressure, open

two or more faucets and slowly unscrew

the ow control screw until maximum ow

is obtained. This steady pressure will be

minimum operating pressure and should agree

with the pressure shown below. The ow

control screw diverts the proper amount of

water to operate the ejector. (Fig. 5)

2. Slowly ll pump cavity until water comes out of

air relief hole on top of the pump. (Fig. 2)

IMPORTANT: If the pump hums instead of pumping or turns off repeatedly, shut pump off immediately.

Check voltage. Make sure your incoming voltage matches the pump wiring voltage. See wiring guide in the

instructions.

4. Thread in priming plug and then open optional

ball valve if installed (see page 5) by turning

handle to line up with the pipe. (Fig. 4)

5. Turn on breaker to start pump

Copyright © 2011 Star Water Systems. All rights reserved.

Loading...

Loading...