Page 1

OWNERS GUIDE TO INSTALLATION

AND OPERATION

FW0078

0813

Supersedes

0112

READ THESE INSTRUCTIONS CAREFULLY

Read these installation instructions in detail before installing your pump. Be sure to check the

following:

1. Be certain the motor is connected for the correct line voltage being used (check motor

nameplate).

2. Be certain the pump is completely primed before starting. Otherwise damage may occur to the

seal.

Every pump is tested before leaving the factory, and its performance depends largely on the

installation.

END SUCTION CENTRIFUGAL PUMPS

IL0412

GENERAL SAFETY INFORMATION

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and

the Occupational Safety and Health Act (OSHA).

2. Replace damaged or worn wiring cord

immediately.

3. Do not kink power cable and never allow the

cable to come in contact with oil, grease, hot

surfaces or chemicals.

4. Protect the power cable from coming in contact

with sharp objects.

5. Be careful when touching the exterior of an

operating motor - it may be hot enough to be

painful or cause injury.

6. Make certain that the power source conforms

to the requirements of your equipment.

7. Always disconnect power source before

performing any work on or near the motor or

its connected load. If the power disconnect

point is out-of-sight, lock it in the open position

and tag it to prevent unexpected application

of power. Failure to do so could result in fatal

electrical shock.

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

Drain Plug

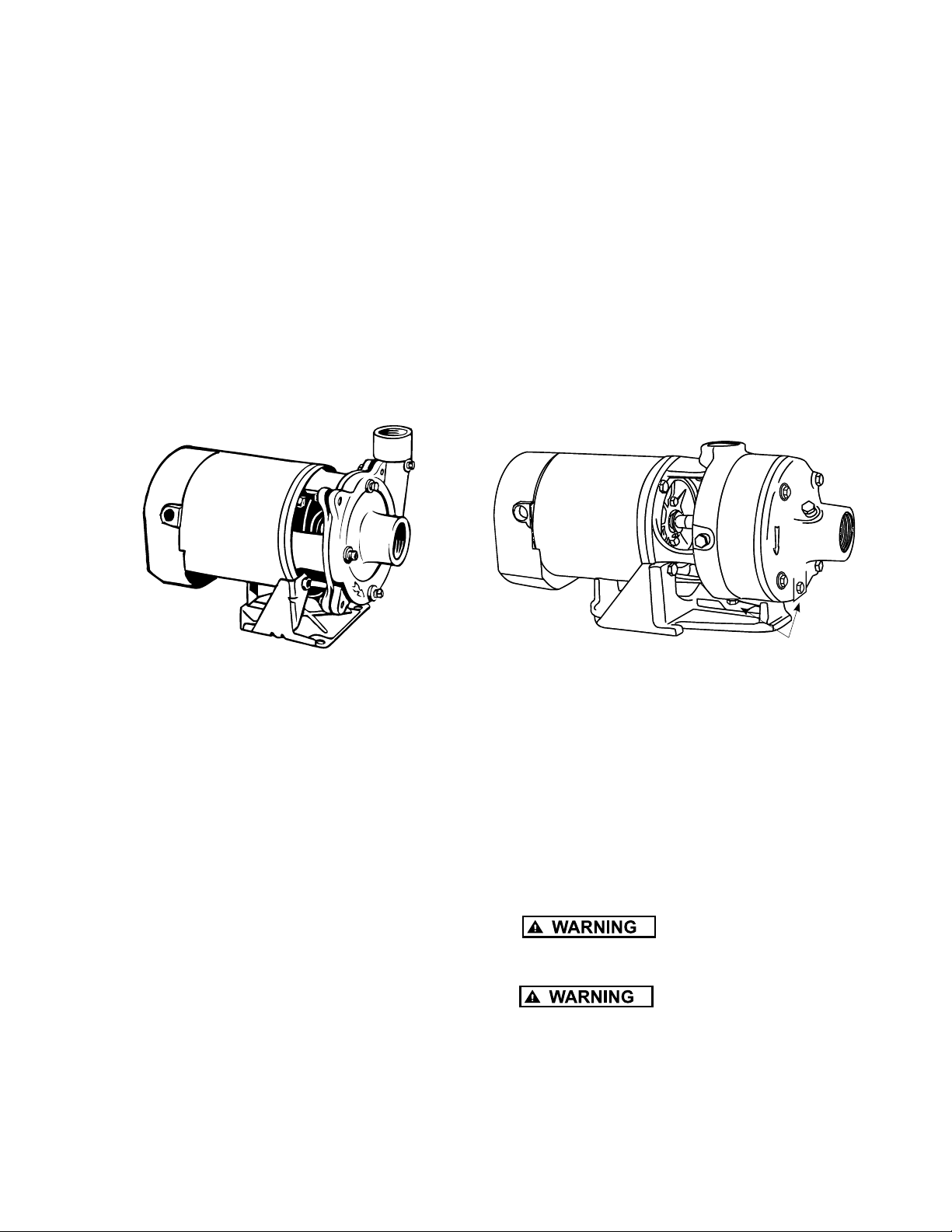

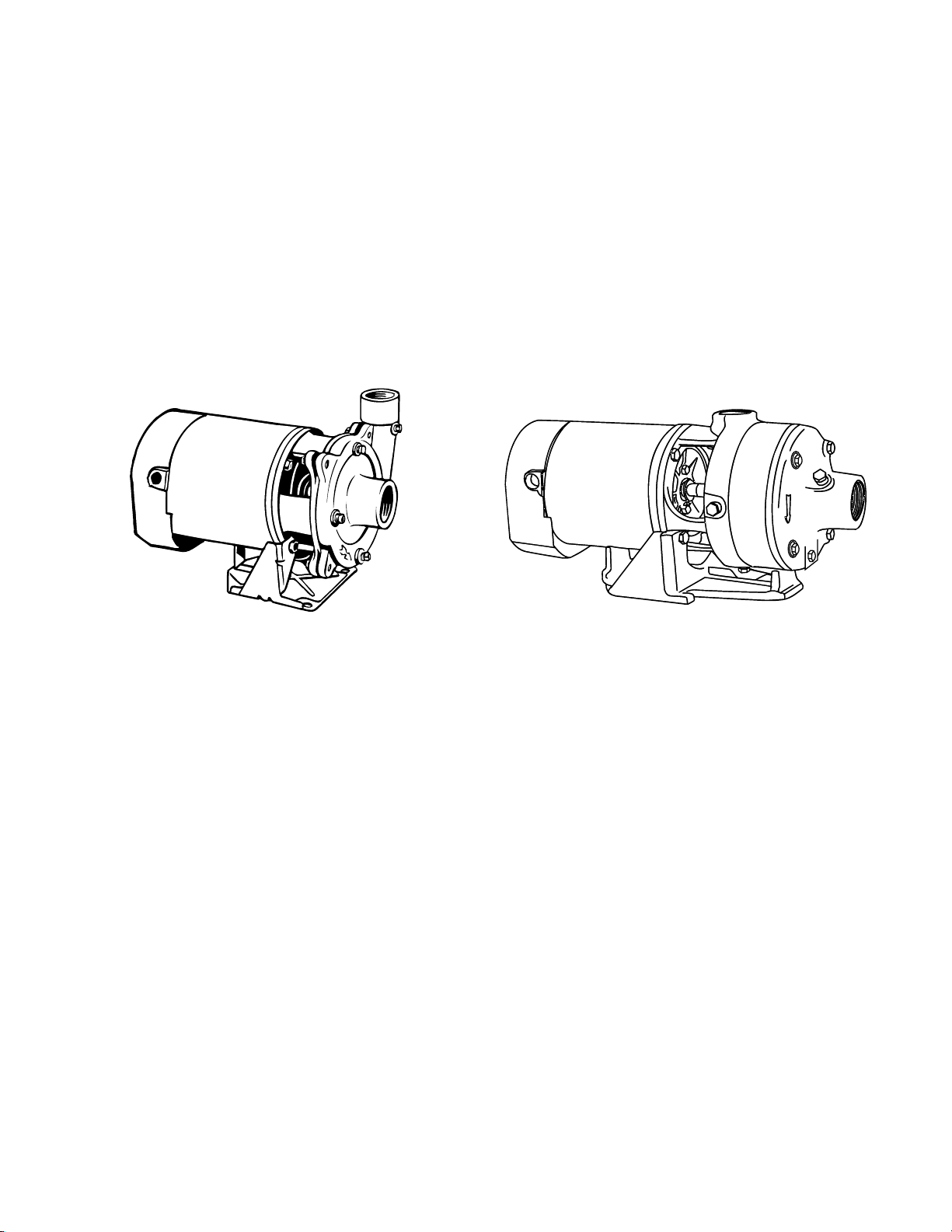

Figure 2 - CJ101 SeriesFigure 1 - CJ103 Series

8. Do not handle the pump with wet hands or

when standing in water as fatal electrical shock

could occur. Disconnect main power before

handling unit for ANY REASON!

9. Unit must be securely and adequately

electrically grounded. This can be

accomplished by wiring the unit to a ground

metal-clad raceway system or by using a

separate ground wire connected to the bare

metal of the motor frame or other suitable

means.

10.

pump has not been investigated for use in

swimming pool areas.

11.

chemicals known to the State of California

to cause cancer and birth defects or other

reproductive harm.

NOTE: Pumps with the “CSA” mark are tested to

UL standard UL778 and certified to CSA standard

C22.2 No. 108.

1

Risk of electric shock. This

This product contains

130441

IL0201

Page 2

IL0413

IL0414

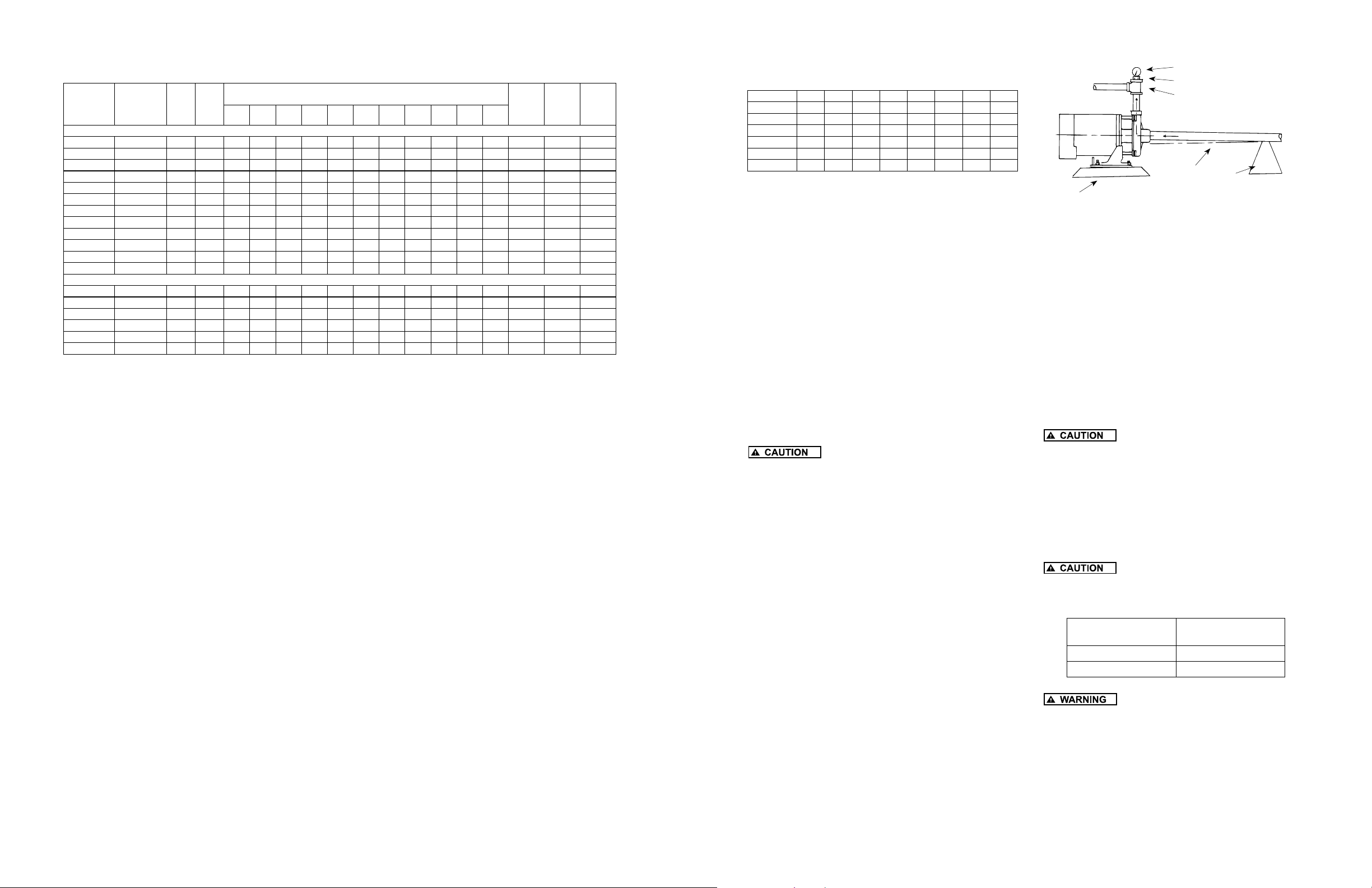

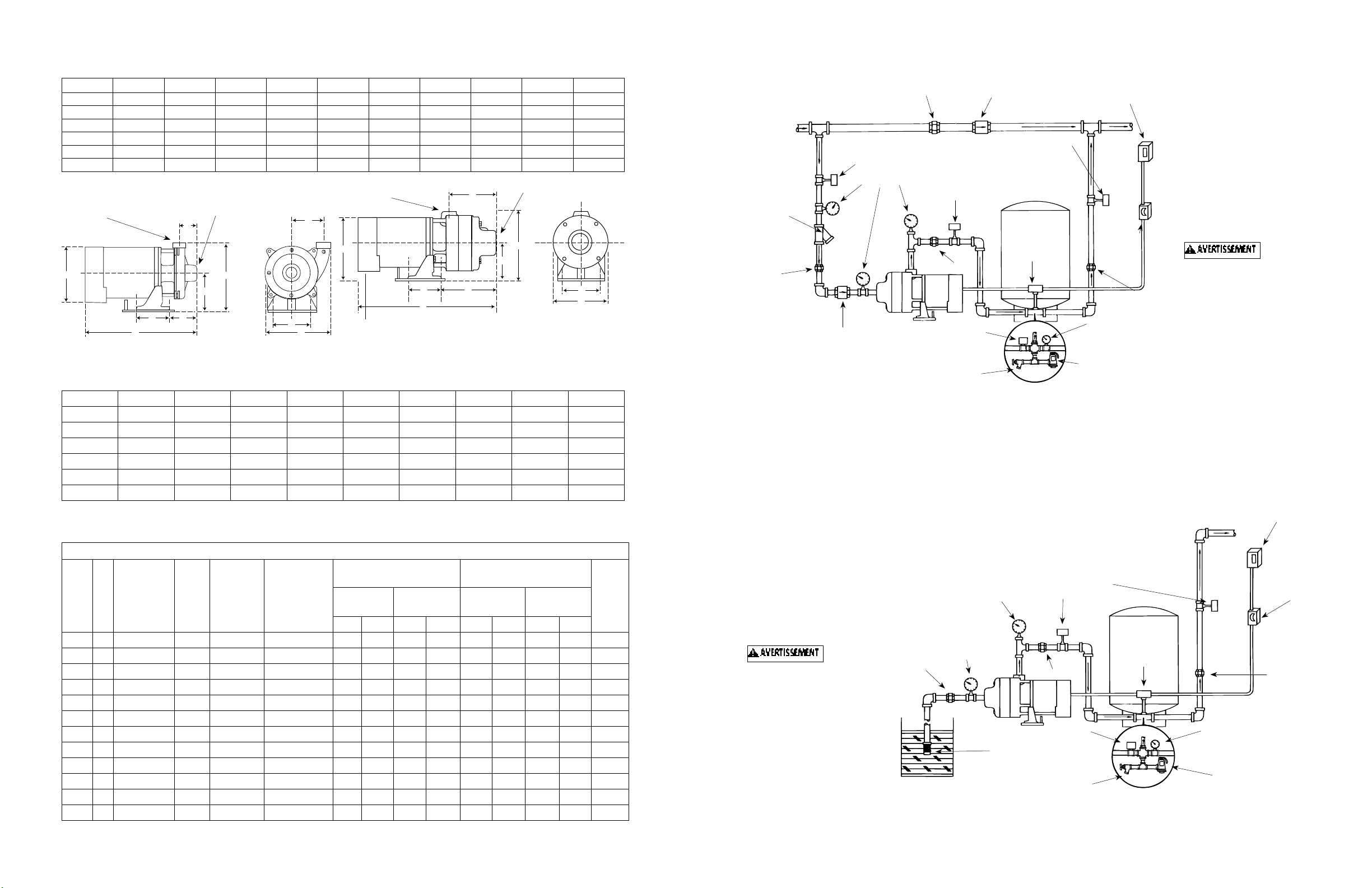

Dimensions (In Inches) CJ103 Series Chart A

HP A B C D E F G H J K

1/3 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/2 8-1/4 8-1/8 13-1/4 3-7/8

1/2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 13-1/2 3-7/8

3/4 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 14 3-7/8

1 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 14-1/2 3-7/8

1-1/2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 15-1/8 3-7/8

2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 15-5/8 3-7/8

1-1/4” Discharge

H

A

J

Figure 3 - CJ103 Single Stage Booster Pump

1-1/2” Suction

F

E

D

C

IL0396

1-1/4” Discharge

K

H

A C

B

G

Figure 4 - CJ101B Two and Three Stage Booster Pump

J

F

1-1/2” Suction

E

D

B

G

IL0395

CJ101 Series Chart B

HP A B C D E F G H J

3/4 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 17-7/8

1 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 18-3/8

1-1/2 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 19

2 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 19-1/2

2 * 4 4-5/8 9-7/16 4-13/16 8-3/4 8-1/8 7 8-1/8 21-3/8

3 * 4 4-5/8 9-7/16 4-13/16 8-3/4 8-1/8 7 8-1/8 21-3/8

(*) Three Stage

Motor Data Chart C

MOTOR

HP PH VOLTS HZ RPM

1/3 1 115/230 60 3450 115 V 8.6 4.3 — — 26.0 13.0 — — K

1/2 1 115/230 60 3450 115 V 13.0 6.5 — — 36.0 18.0 — — K

3/4 1 115/230 60 3450 230V 14.0 7. 0 — — 52.0 26.0 — — K

1 1 115/230 60 3450 230V 18.0 9.0 — — 70.0 39.0 — — L

1-1/2 1 115/230 60 3450 230V 21.0 10.5 — — 98.0 49.0 — — J

2 1 115/230 60 3450 230V 25.0 12.5 — — 116.0 58.0 — — H

3 1 230 60 3450 230V — 13.5 — — — 53.0 — — D

3/4 3 208-230/460 60/50 3450/2850 230V — — 3.5 1.75 — — 19.0 9.5 K

1 3 208-230/460 60/50 3450/2850 230V — — 4.5 2.25 — — 26.9 13.5 K

1-1/2 3 208-230/460 60/50 3450/2850 230V — — 5.7 2.85 — — 33.5 16.8 K

2 3 208-230/460 60/50 3450/2850 230V — — 7. 4 3.0 — — 44.0 22.0 K

3 3 208-230/460 60 3450 230V — — 9.8 4.9 — — 48.0 24.0 D

VOLTAGE

(FACTORY)

CONNECT.

SERVICE FACTOR MOTOR

AMPS

THREE

PHASE

115 V 230V 230V 460V 115 V 230V 230V 460V

PHASE

LOCKED ROTOR AMPS

SINGLE

PHASE

THREE

PHASE

KVASINGLE

Street Supply

Gate/Ball Valve

(Normally Open)

Line Strainer

or Filter

(Optional)

Union

Check Valve

Figure 5

To size pressure tank

properly, match the

drawdown of the tank

to the capacity of the

pump.

(*) For manual

operation, omit the

pressure tank and

pressure switch. Wire

motor direct to fuse

box.

Install

a pressure relief valve

on any installation

where pump pressure

can exceed the pressure

tank’s maximum working

pressure or on systems

where the discharge

line can be shut off or

obstructed. Extreme

over pressure can result

in personal injury or

property damage.

Typical Installations

Union

Pressure

Gauge

Figure 6

Gate/Ball Valve

(Normally Open)

Union

Pressure Switch

Drain

Vacuum

Gauge

Union

Check Valve

Gate/Ball Valve

(Normally Open)

Pressure Tank

Pressure

Switch

Pressure

Gauge

Pressure Switch

Foot Valve

with Strainer

Fuse Box

or Switch

Pressure Gauge

Pressure Relief Valve

Gate/Ball Valve

(Normally Open)

Union

Drain

Main Power Box

Union

Pressure Tank

Pressure

Switch

To size pressure tank

properly, match the

drawdown of the tank

to the capacity of the

pump.

(*) For manual

operation, omit the

pressure tank and

pressure switch. Wire

motor direct to fuse

box.

Install

a pressure relief valve

on any installation

where pump pressure

can exceed the pressure

tank’s maximum working

pressure or on systems

where the discharge

line can be shut off or

obstructed. Extreme

over pressure can result

in personal injury or

property damage.

Main Power Box

Fuse Box

or Switch

Union

Pressure Gauge

Pressure Relief Valve

2

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

3

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

Page 3

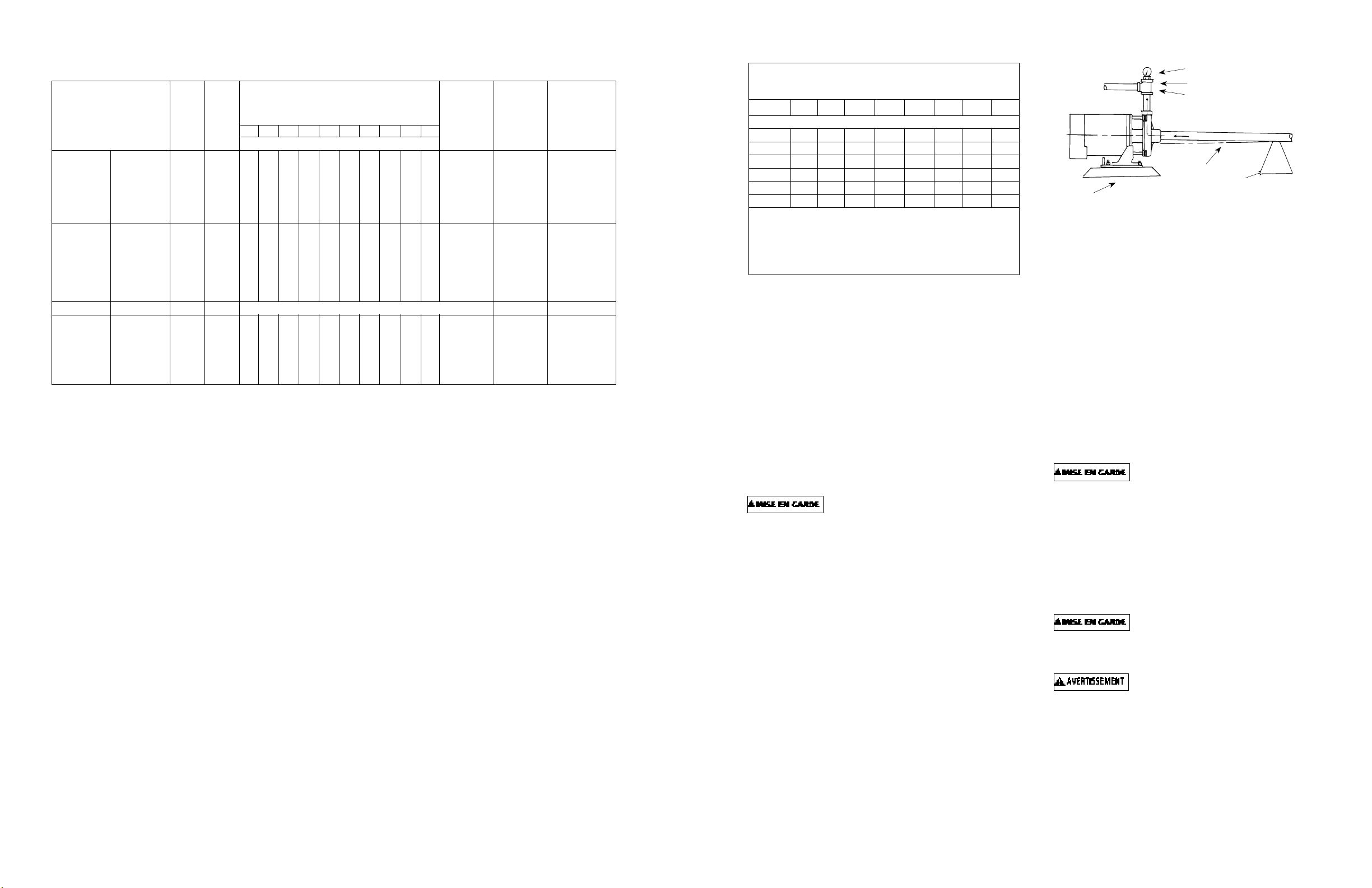

Pump Performance Chart D

Single

Phase

Model No.

CJ103031 - 1/3 1 41 30 10 27 100 200°F

CJ103051 CJ103053 1/2 1 48 40 27 30 10 0 200°F

CJ103071 CJ103073 3/4 1 62 58 46 31 33 100 200°F

CJ103101 CJ103103 1 1 70 66 58 48 34 40 100 200°F

CJ103151 CJ103153 1-1/2 1 * 75 70 61 51 36 44 100 200°F

CJ103201 CJ103203 2 1 * * 79 77 68 57 45 100 200°F

CJ101B071 CJ101B073 3/4 2 * * 32 29 25 22 5 53 160 200°F

CJ101B101 CJ101B103 1 2 * * 35 32 29 27 23 3 62 160 200°F

CJ101B151 CJ101B153 1-1/2 2 * * 42 39 37 34 28 19 68 160 200°F

CJ101B201 CJ101B203 2 2 * * 45 44 43 40 34 26 70 160 200°F

CJ101C201 CJ101C203 2 3 * * 42 41 40 38 35 31 27 20 7 93 160 200°F

CJ101C301 CJ101C303 3 3 * * 51 50 49 43 41 40 35 29 21 95 160 200°F

CJ101P071 CJ101P073 3/4 2 * * 31 28 23 20 48 160 160°F

CJ101P101 CJ101P103 1 2 * * 34 31 30 29 19 60 160 160°F

CJ101P151 CJ101P153 1-1/2 2 * * 46 44 41 37 31 14 61 160 160°F

CJ101P201 CJ101P203 2 2 * * 45 44 42 39 31 21 65 160 160°F

CJ101D201 CJ101D153 2 3 * * 41 40 38 37 33 29 24 17 89 160 160°F

CJ101D301 CJ101D303 3 3 * * * 46 45 45 42 38 33 27 18 93 160 160°F

To convert to feet of head, multiply by 2.31.

* Operation of pump in this range may result in m

Do not exceed the maximum case pressure and maximum liquid temperature rating of the pump.

Suction & Discharge Tapping: 1-1/2” X 1-1/4”

Motor Voltage:

Three

Phase

Model No.

Single

Three

HP Stage

phase:

phase:

15 20 25 30 35 40 50 60 70 80 90

THERMOPLASTIC IMPELLER MODELS

1/3

1/2

- 115V; 1/2 thru 2 HP - 115/230V; 3 HP - 230V, 60HZ

thru 2 HP - 208-230/460V - 50/60HZ

HP - 208-230/460V - 60HZ

3

INSPECTION AND STORAGE

When unpacking the unit, inspect carefully for any

damage that may have occurred during shipment.

If the unit is received sometime before it can be

used, it should be inspected, recrated and stored

in a dry location.

LOCATION

IMPORTANT: In installations where property

damage might result from an inoperative or

leaking pump due to power outages, discharge

line blockage or any other reason, a back-up

system (s) and/or warning system (s) should be

used.Install a gate valve and union in the suction

and discharge lines. For removal of the pump for

service, close the gate valve and disconnect the

union.

1. Locate pump as close to the fluid source as

possible.

GPM at Total Pressure in PSI

BRASS IMPELLER MODELS

otor

damage.

4. Allow ample clearance around unit for free air

circulation.

5. CJ103 Series pumps incorporate a discharge

port on the pump casing that can be adjusted

in 90 increments. If necessary, adjust the

discharge port to accommodate the specific

application. Pump performance will not be

affected by the position of the discharge port.

SUCTION LIMITATIONS

1. Units are non self-priming. Normally after

being primed the total suction lift of the pump

is 25 feet. Suction lift varies depending upon

elevation (altitude) and water temperature. See

Practical Suction Lift chart.

2. Where liquids at or near their boiling points

are being handled, the supply must be located

above the suction, so that the available NPSH

will be greater than that required by the unit.

Press.

2. Place unit where the motor electrical

components and piping are protected from the

weather and extremes of heat, humidity and

below freezing temperatures.

3. Mount unit in a dry location that is easily

accessible for inspection and maintenance. If

a dry location is not available, mount it on a

foundation well above the wet floor.

Max.

PSI

Max.

Case

Press.

PSI

Max.

Liquid

Temp.

Practical Suction Lifts at Various Elevations and

Water Temperatures in Degrees Fahrenheit

Altitude 60º 80º 100º 120º 140º 160º 180º 200º

Sea Level -22 -21 -20 -18 -15 -10 -4 +5

2000 -20 -19 -18 -16 -12 -7 -1 +8

4000 -17 -16 -15 -13 -10 -4 +2 +12

6000 -15 -14 -13 - 11 -7 -2 +6 +16

8000 -13 -12 -10 -8 -4 +2 +9 —

10000 -10 -9 -8 -6 -2 +4 +13 —

This table gives the maximum permissible suction lift or

the minimum head permitted on the suction side of a pump

at various altitudes and liquid temperatures. A minus sign

before a number indicates suction lift. A plus sign before a

number indicates minimum head. These figures are to be

used as a guide.

PIPING

1. Use galvanized piping, rigid plastic or other

suitable pipe that will not collapse under

suction or rupture due to pressure.

2. The diameter of the suction and discharge pipe

should be no smaller than the corresponding

tappings of the pump (see Figure 3 & 4). If long

runs are encountered larger pipe should be

used. Smaller pipe will reduce the capacity of

the pump.

3. All joints and connections should have Teflon

tape or pipe sealing compound (male threads

only) applied and drawn up tightly.

The entire system must be air and

water tight for efficient operation.

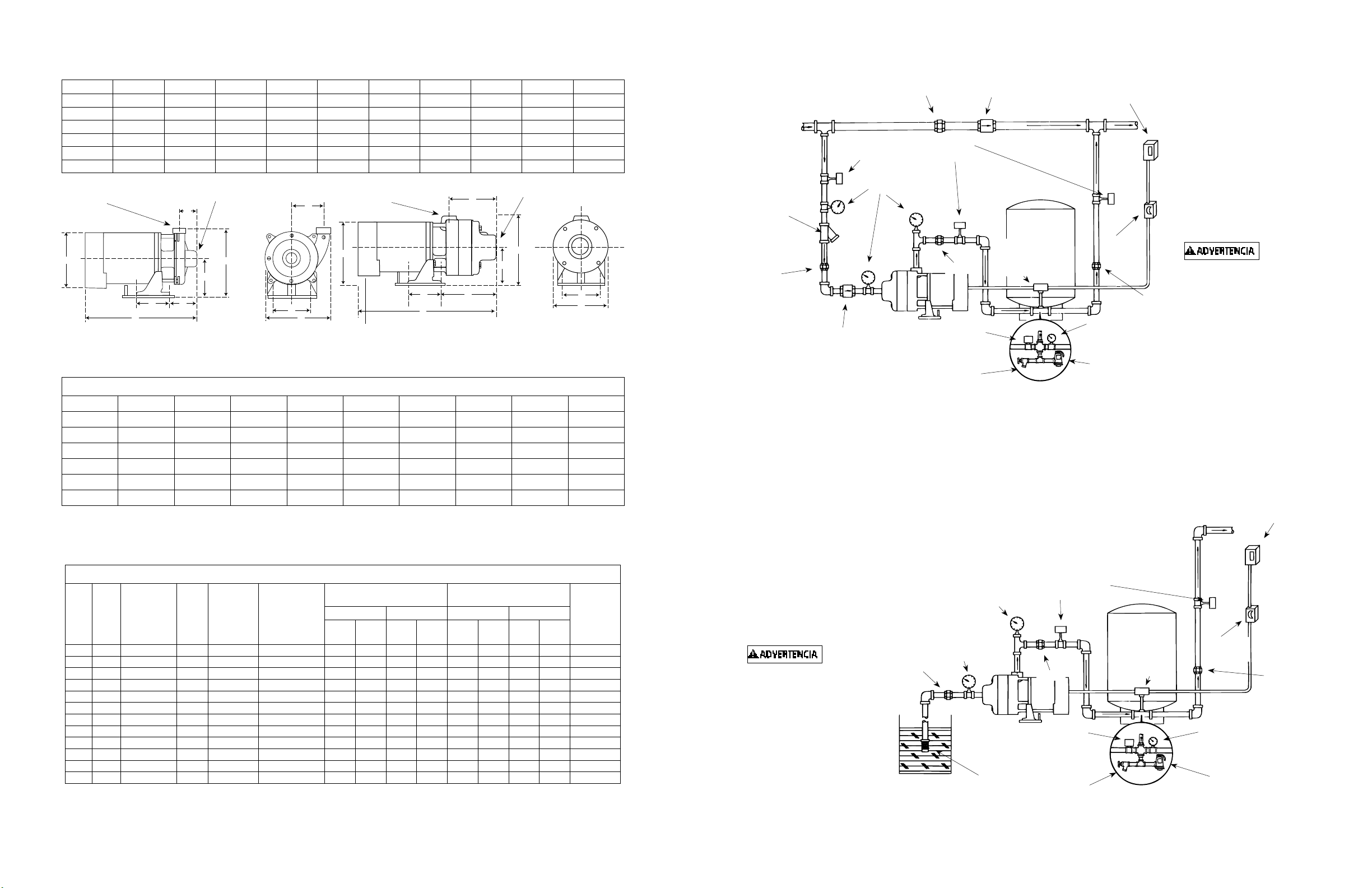

PUMP INSTALLATION

Refer to Figures 5, 6, and 7 for typical installations.

Both the suction and discharge pipe should be

supported at a point near the pump to avoid

strains being placed on the pump.

1. If the pump is used as part of a permanent

installation, secure to a rigid foundation with

appropriate fasteners.

2. Locate the pump as close to the water as

possible, keeping the suction pipe as short as

conditions permit.

3. Avoid dips or pockets in offset piping or air

will accumulate at high points which will make

priming difficult.

4. The suction pipe should slope upward to the

pump inlet. A horizontal suction line must have

a gradual rise to the pump.

Pressure Gauge

Priming Plug

Discharge Tee

Suction Pipe Installed with

Gradual Rise to Pump Inlet

Level

Rigid

Foundation

Figure 7

Pipe

Support

5. On suction lift installations, a foot valve located

in the water or a check valve located as close

to the water as possible will reduce priming

time of the pump and help maintain prime. A

strainer must be used on the suction line to

filter out dirt and debris.

6. A priming tee installed in the pump discharge

port allows water to be poured into the pump

case and suction piping, which is required for

priming on suction lift installations.

7. Install a gate valve and union in the suction and

discharge lines. For removal of the pump for

service, close the gate valve and disconnect the

union.

Do not use a globe valve or other

restricting type of valve at the discharge. This will

seriously restrict the capacity of the pump.

8. Pressure Gauges - Properly sized vacuum or

pressure gauges can be installed in both the

suction and discharge pipe. The gauges will

enable observation of the pump’s performance

as well as detecting cavitation, vapor binding or

other unstable operation.

Use only components that are rated

higher than shut-off pressure of the system. Do not

exceed the pump’s maximum case pressure as listed in

the following table.

capacity must be installed on any installation where

the pump pressure can exceed the pressure tank’s

maximum working pressure or on systems where

the discharge line can be shut-off or obstructed.

Not providing a relief valve can cause extreme over

pressure which could result in personal injury and/or

property damage.

Models

CJ103 100 PSI

CJ101 160 PSI

Maximum Case

Pressure

A pressure relief valve of adequate

4

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

5

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

Page 4

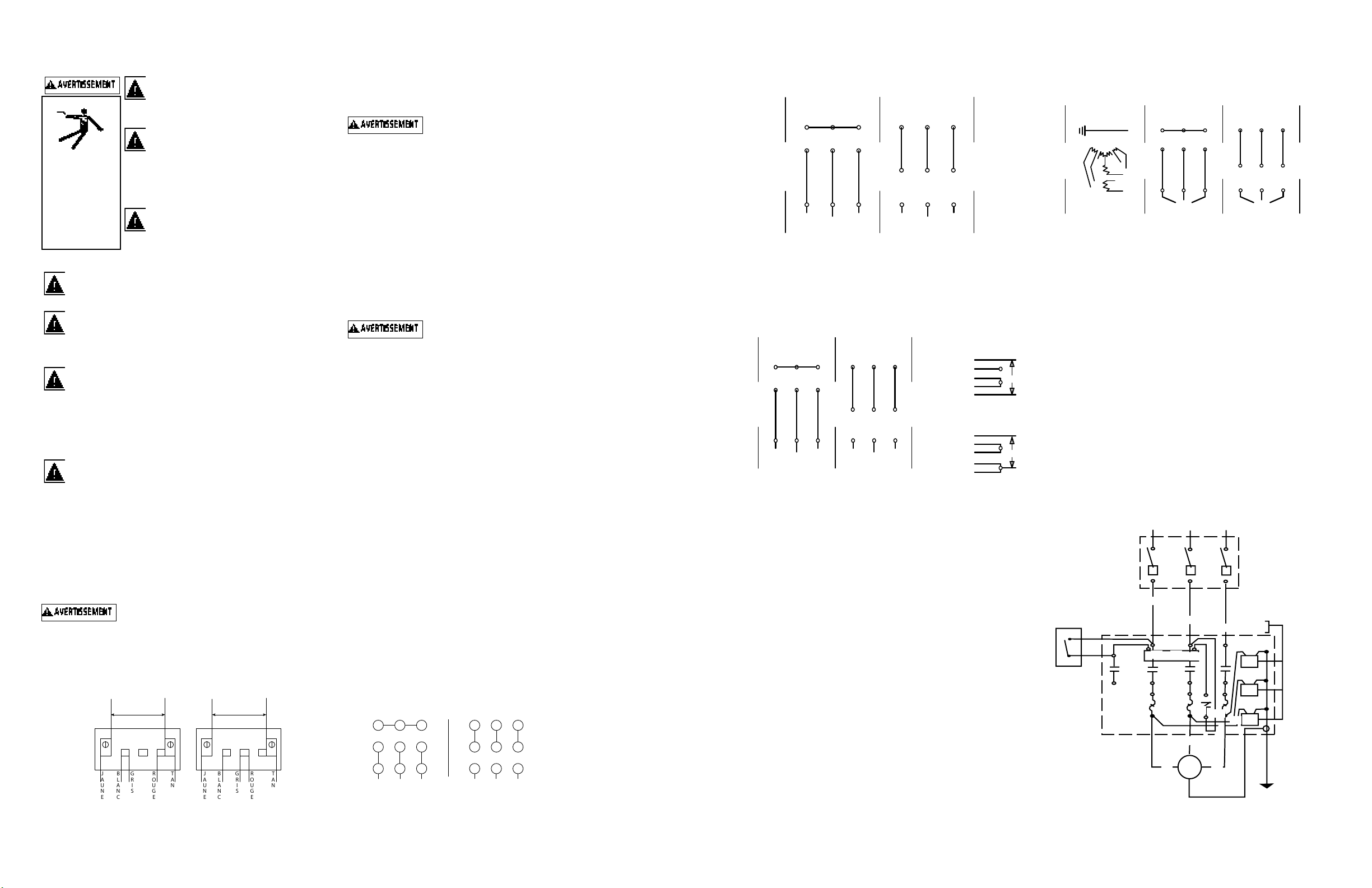

ELECTRICAL

Ground motor before connecting

to electrical power supply.

Connect the motor frame to

Hazardous voltage.

Can shock, burn

or cause death.

Failure to follow

warnings can

cause fatal or

severe shock

hazard or

equipment failure.

equipment grounding conductor by

using green screw. Do not connect

green ground wire to any of the motor

leads.

Do not ground to a gas supply

line.

Turn off power to motor before working on electrical

connections.

Supply voltage must be within ±10% of nameplate

voltage. If in doubt consult a licensed electrician.

Use wire size specified in wiring Chart E. If possible,

connect pump to a separate branch circuit with no other

appliances on it. If wiring diagram on motor model plate

differs from diagram shown in figures 8, 9 & 10, follow

diagram on motor.

All wiring should be performed by a qualified electrician

and in accordance with the national and local electric

codes.

WIRING

1. Motor voltages will vary depending upon the

motor horsepower and phase. Refer to the

motor nameplate and the Motor Data Chart

(Chart C) for voltage and electrical data.

Make certain that the power supply

conforms to the electrical specifications of the motor

supplied. Failure to do so may cause premature motor

failure and will void the warranty.

2. To change voltage, remove the rear access

cover, which is held in place with two (2)

screws. For proper electrical connection, refer

to the connection diagram located on the motor

nameplate or figures 8, 9, 10, 11 & 12.

indicates trouble in the motor or power lines

and immediate attention is needed.

Never examine, make wiring changes

or touch the motor before disconnecting the main

electrical supply switch. The thermal device may have

opened the electrical circuit.

2. Three phase motors do not have a built in

thermal protection. It is recommended that a

properly sized magnetic or manual starter (both

with properly sized heaters) be used with all

three phase motors. Install starters following

instructions of the starter manufacturer. See

Figure 13 for magnetic starter wiring diagram.

3. All motors (single and three phase) should be

equipped with a correctly fused disconnect

switch to provide protection. consult local

or national electric codes for proper fuse

protection based on motor data chart (see

Charts C & E).

115 VOLT

SINGLE PHASE

LINE

L1

L2A B

YELLOW

WHITE

GRAY

RED

TAN

Figure 8 - Wiring Diagram for Single Phase

1/3-2 HP

LOW VOLTAGE 230V HIGH VOLTAGE 460 V

4 5 6

7 8 9

1 2 3

L1 L3L2 L1 L3L2

IL0770

Figure 9 - Wiring Diagram for Three Phase

3-ø

230 VOLT

SINGLE PHASE

LINE

L1

YELLOW

WHITE

4 5 6

7 8 9

1 2 3

L2A B

GRAY

RED

TAN

IL0180

3 Phase

HIGH VOLTAGELOW VOLTAGE

5

5

6

9

3

IL1229

Figure 10 - Wiring Diagram for Baldor TEFC 3 Phase

motors

4

8

7

2

1

LINE LINE

6

9

3

3 Phase

HIGH VOLTAGELOW VOLTAGE

5

5

6

9

4

8

7

6

9

2

3

3

1

LINE

IL1230

Figure 11 - Wiring Diagram for Franklin Electric TEFC 1

Phase and 3 Phase motors

8

2

LINE

4

7

1

8

2

BROWN

VIOLET

BLACK

YELLOW

BLUE

BROWN

VIOLET

YELLOW

BLACK

BLUE

4

7

1

1 Phase

HIGH VOLTAGE

(10)

(9)

(2)

(3)

(4)

LOW VOLTAGE

(10)

(9)

(3)

(2)

(4)

LINE

LINE

3 Phase

HIGH VOLTAGELOW VOLTAGEGROUND

T5

T1

X2

T6

T9

T3

Lightning

Arrestor

L3

T3

T5

T6

(WHEN REQ)

T7

T8

T5

T6

T3

IL1231

Figure 12 - Wiring Diagram for Marathon TEFC 3 Phase

motors

Pressure

Switch

T2

03

02

T9

T1

T3

L1

MV W

T1

T8

LINE

T2

T4

T7

T2

L2

T2

T4

T8

T7

T2

T1

LINE

Fused

Disconnect

Switch

Replace rear access cover before

starting or operating pump. Failure to do so can result

in personal injury.

MOTOR PROTECTION

1. All single phase motors have built in thermal

protection for all voltages. The overload

protects the motor against burnout from

overload of low voltage, high voltage and other

causes. The device is automatic and resets

itself once the temperature has dropped to

a safe point. Frequent tripping of the device

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

T3

Motor

T1

IL0102

#10 or Heavier Copper Ground Wire, Connect

to 10 Ft. Ground Rod or Well Casing

Figure 13 - Magnetic Starter Wiring Diagram Three Phase

6

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

7

Page 5

PRIMING

1. Before starting any centrifugal pump, it is

absolutely necessary that both the casing and

suction pipe be completely filled with liquid.

This priming can be accomplished by any of

the following methods:

2. When the liquid supply level is above the center

line of the pump, it is primed by opening the

2. Proper rotation of pump impeller is critical for

three phase pumps. Pump motor should turn

counterclockwise (CCW) when facing pump

suction tapping. Momentarily “bump” (apply

power for less than a second) the motor to check

for proper rotation. To change rotation on three

phase units, interchange any two (2) incoming

line (power) leads.

suction and discharge valves. The inflowing

liquid will displace the air and fill the suction

line, pump casing, and discharge line up to the

level of supply.

3. Where the pump is operating with suction

lift and the suction line is equipped with a

foot valve, remove the priming plug from the

discharge tee (see Figures 5-8) and fill the

pump body and suction pipe completely with

water. No additional water will be needed for

Figure 14 - Correct Motor Rotation

IL0416

subsequent start-ups unless the pump body is

drained.

4. After the pump is turned on it will require 2-5

minutes before all air is evacuated from the

suction line and water begins to flow. If there

is no water after 5 minutes, turn the pump off

and check the following:

5. Any air leaks on the suction line must be

eliminated.

6. Suction pipe inlet should be a minimum of 5

feet below the water level.

7. Total suction lift cannot be greater than 25 feet.

8. Any restrictions in the discharge pipe, such as a

closed valve must be eliminated.

NOTE: Unit must be full of liquid before operating.

Never run dry, or against a closed discharge. Dry

running or running unit against a closed discharge

will cause damage to the shaft seal. Do not pump

dirty water or abrasive liquids, otherwise the same

may occur as if running dry.

MOTOR ROTATION

1. Single phase models are one (1) rotation only

(counterclockwise when facing the pump

suction tapping) and cannot be reversed.

MAINTENANCE

Lubrication

The pumps and motors require no lubrication.

The ball bearings of the motor have been greased

at the factory. Under normal operating conditions

they should require no further greasing.

Winterizing your Pump

Cracked pump housings caused by freezing are

not covered by warranty. To protect your pump

from freezing, for best results remove the pump

and store in a warm environment. If pump cannot

be removed from your system, remove both

drain plugs, one on the suction flange and one

at the bottom rear of the pump (see fig 2 in the

instructions.) Allow the water to completely drain

from the pump. Re-install both drain plugs and fill

pump with RV type antifreeze. Antifreeze also acts

as a rust inhibitor. It will help keep rust build up to

a minimum and seals lubricated inside the pump

while it is not in use.

ROTARY SEAL ASSEMBLY REPLACEMENT

Disassembly

When disassembling the pump, care

should be taken not to damage the gaskets. If torn or

Chart E

DISTANCE FROM

MOTOR TO FUSE

BOX METER,

OR ELECTRICAL

OUTLET

0-50’ 14 14 12 14 12 14 10 14 10 12 10 12 10 14 14 14 14 14 14 14 14 14 14

50-100’ 14 14 12 14 12 14 10 14 8 12 8 12 10 14 14 14 14 14 14 14 14 14 14

100-150’ 14 14 12 14 10 14 10 12 6 12 6 12 10 14 14 14 14 14 14 14 14 14 14

150-200’ 12 14 12 14 10 12 8 12 * 10 * 10 10 14 14 14 14 12 14 12 14 12 14

200-300’ 12 14 10 14 8 12 6 10 * 10 * 10 8 14 14 12 14 12 14 10 12 10 12

Breaker Size

(Amps)

(*) Not economical to run in 115 volt, use 230 volts

1/3 HP 1/2 HP 3/4 HP 1 HP 1-1/2 HP 2 HP 3 HP 3/4 HP 1 HP 1-1/2 HP 2 HP 3 HP

115V 230V 115V 230V 115V 230V 115V 230V 115V 230V 115V 230V 230V 230V 460V 230V 460V 230V 460V 230V 460V 230V 460V

15 15 20 15 20 15 30 15 30 20 30 20 30 15 15 15 15 15 15 15 15 15 15

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

MINIMUM COPPER WIRE SIZE CHART (GAUGE)

SINGLE PHASE MOTORS THREE PHASE MOTORS

8

damaged, replace with new gasket (see parts list).

1. Remove the four (4) pump through bolts that

connect the mounting ring to the pump body.

Remove the pump body, taking care not to

damage the gasket or o-ring.

2. Remove the impellers. CJ103 Models are

single stage units, having one impeller. Using

a 9/16” open end wrench, hold the motor shaft

flat and unthread the impeller by turning it

counterclockwise. The motor shaft flat area is

located in the middle of the mounting ring.

3. CJ101 models are multi stage units, having

two or more impellers and one or more

intermediate stages. Using an 11/16” open

end wrench on the motor shaft extension

flat, remove the first impeller by turning or

counterclockwise. Remove the intermediate

stage (stages) taking care not to damage the

gasket (gaskets) and unthread the remaining

impellers.

4. Remove the mechanical seal assembly. The

rotary portion of the seal assembly (carbon

ring, Buna-N gasket and spring) will easily slide

off the end of the shaft. The ceramic portion

can be pried out of the rubber seating using

two (2) screwdrivers (see Figure 15).

Reassembly

The precision lapped faces of the

mechanical seal are easily damaged. Handle the

replacement seal carefully. Short seal life will result if

seal faces (ceramic & carbon) are nicked, scratched or

dirty.

1. Clean the seal cavity of the mounting ring and

the motor shaft thoroughly.

2. Apply liquid soap (one drop only) to the outside

of the Buna-N gasket that houses the ceramic

seal seat. With thumb pressure, press the

ceramic seat, polished face up, squarely into

the seal cavity (see Figure 16).

3. If seal does not seat squarely, remove and

Figure 15 - Remove Mechanical Seal

IL0173

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

IL0168

Figure 16 - Press in Seal

reclean the seal cavity. Place a cardboard

washer over the polished seal face and carefully

press into place using a piece of pipe or tubing

(see Figure 17). Discard cardboard washer.

4. Apply liquid soap (one drop only) to the inside

diameter of the rubber drive ring. Slip rubber

drive ring (carbon face down) and the spring

over the shaft.

5. Reassemble the pump by following the reverse

order of the disassembly instructions.

MOTOR REPLACEMENT

1. Nema J motors can be replaced in the field

with any standard Nema J jet pump motor by

referring to the following instructions and the

attached parts list.

2. Follow steps as outlined under Rotary Seal

Replacement to remove the pump body,

diffuser, impeller and rotary seal.

3. Remove bolts that connect the motor to the

mounting ring and pull motor away.

4. Replace motor with standard Nema J jet

pump motor by positioning motor against the

mounting frame and assembling with four (4)

3/8” x 3/4” cap screws. The mounting base is

connected at the bottom of the mounting frame

with two (2) 3/8” x 1/2” cap screws.

5. Follow steps of Rotary Seal Assembly to

reassemble the remainder of the pump.

BECAUSE DAMAGE TO THE SHAFT SEAL IS

MOST LIKELY TO OCCUR IN DISASSEMBLY, A

NEW SEAL WILL BE NECESSARY.

3/4” Pipe

- Press

Carefully

IL0169

Figure 17- If Necessary, Press with

Cardboard and Pipe

9

NOTE:

Cardboard Washer

Protects Seal Face

Seal

Seal

Cavity

Page 6

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Little or no

discharge

Loss of suction 1. Air leak in suction line 1. Repair

Pump vibrates

and/or makes

excessive noise

Pump will not start

or run

Pumps leaks at

shaft

1. Pump not primed 1. Prime unit

2. Total head too high 2. Shorten suction lift and/or discharge head

3. Suction head higher than pump

3. Lower pump inlet

designed for

4. Impeller clogged 4. Clean

5. Incorrect rotation 5. Refer to wiring information

6. Leak in suction line 6. Repair or replace

7. Inadequate foot valve 7. Make needed adjustments

8. Impeller damaged 8. Replace

9. Foot valve or suction line not

9. Submerge lower in water

submerged deep enough in

water

10. Insufficient inlet pressure or

suction head

10. Increase inlet pressure by adding more

fluid to fluid source

11. Wrong size piping 11. Make needed adjustments

12. Casing gasket leaking 12. Replace gasket

13. Suction or discharge line

13. Open

valves closed

2. Suction head too high 2. Lower pump inlet

3. Insufficient inlet pressure or

suction head

3. Increase inlet pressure by adding more

fluid to fluid source

4. Clogged foot valve or strainer 4. Clean or replace

1. Mounting plate or foundation

1. Reinforce

not rigid enough

2. Foreign material in pump 2. Clean

3. Damaged impeller 3. Replace

4. Cavitation present 4. Check suction line for proper size and be

certain valve is open. Remove excessive

loops in suction line

5. Worn motor bearings 5. Replace

6. Bent impeller shaft 6. Replace

1. Improperly wired 1. Refer to wiring diagram

2. Blown fuse or open circuit

2. Replace fuse or close circuit breaker

breaker

3. Loose or broken wiring 3. Tighten connections and replace broken

wiring

4. Impeller clogged 4. Clean

5. Motor shorted out 5. Replace

1. Worn mechanical seal 1. Replace

2. Bent impeller shaft 2. Replace

10

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

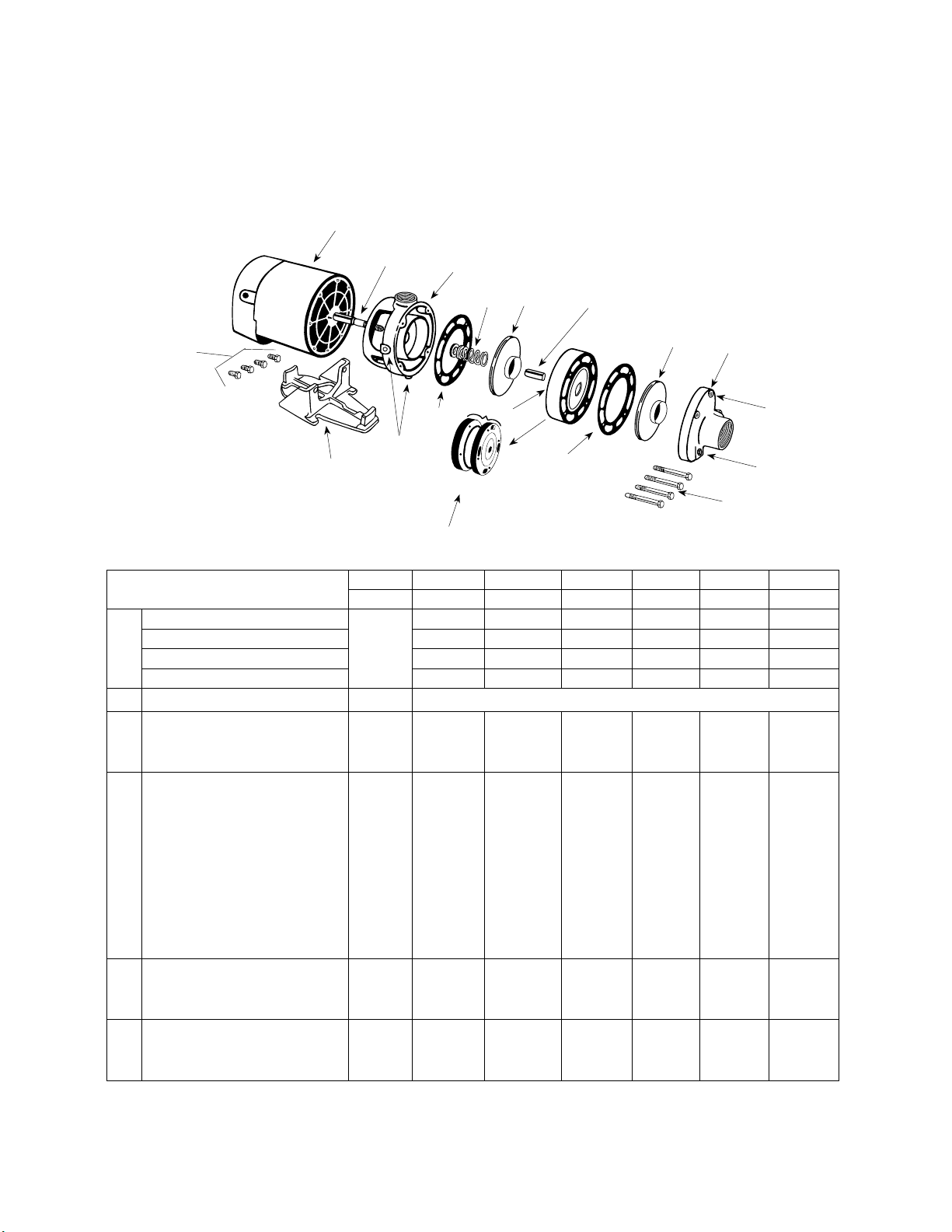

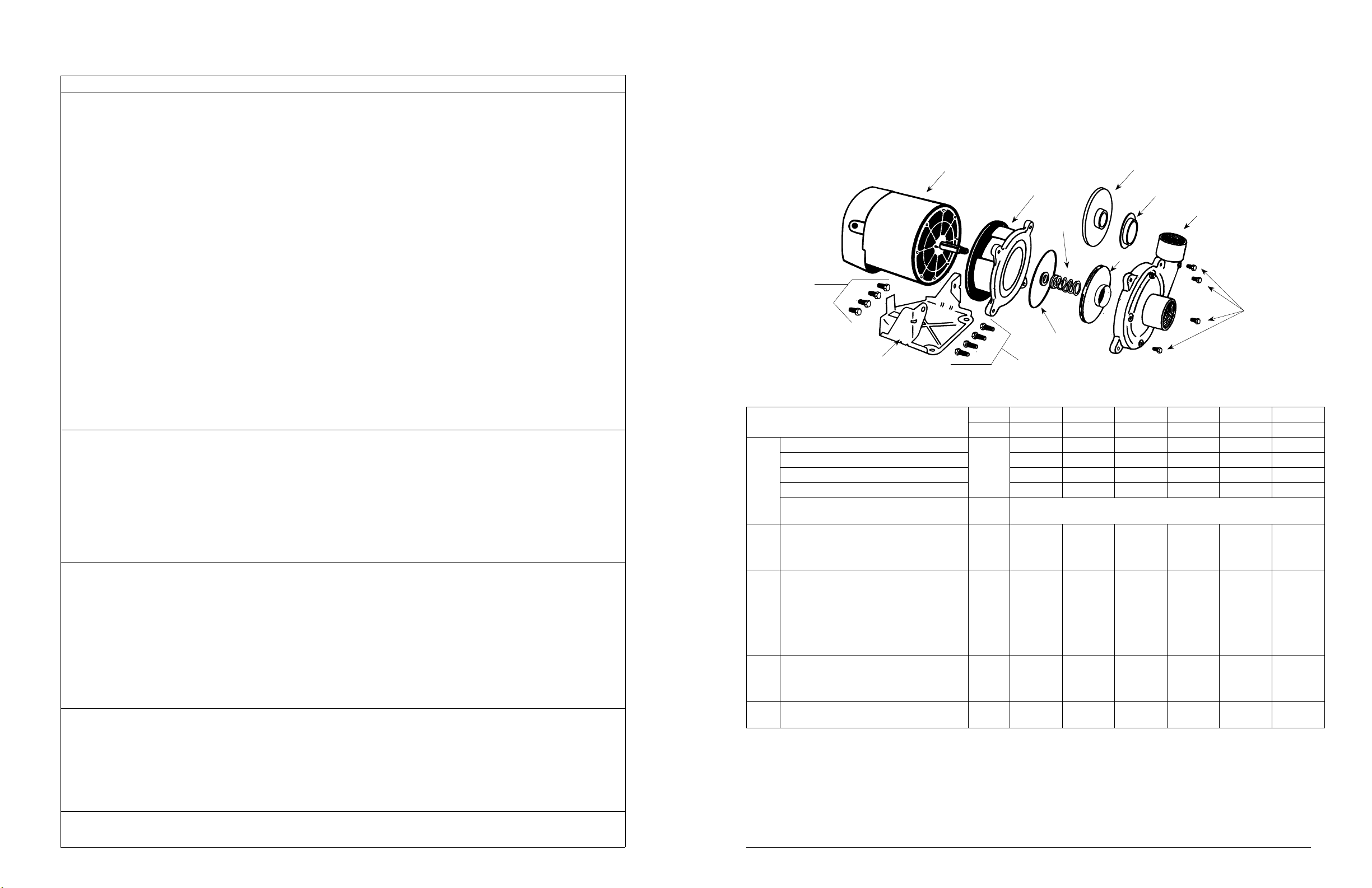

CENTRIFUGAL PUMP REPAIR PARTS

“CJ103” SERIES

(For Pricing Refer To Repair Parts Price List)

1

3

10

HP 1/3 1/2 3/4 1 1-1/2 2

STAGE 1 1 1 1 1 1

SINGLE PHASE

BRASS IMPELLER

THREE PHASE

BRASS IMPELLER

ITEM

11Motor, Nema J - 1PH

‡

2

3

4

5

5A

5B

6

7

‡

8

910Hex Hd. Cap Screws 3/8 x 1”

(*) Standard hardware item

(‡) Not shown

(†) For pumps wi h paper gasket, replace with part number 127782

(

∆) Kit Includes: Access Cover, Screws & Wiring Diagrams

SINGLE PHASE

PLASTIC IMPELLER

THREE PHASE

PLASTIC IMPELLER

DESCRIPTION

Motor, Nema J - 3 PH

Motor Access Cover

Screws, Access Cover

Slinger Washer

Mounting Ring

Hex Hd. Cap Screws 3/8 x 3/4”

Seal, Rotary w/Spring

Impeller - Brass

Impeller - Plastic

Clearance Ring

Ring, Square Cut †

Body Assembly - Brass Impeller

Body Assembly - Plastic Impeller

Suction Clearance Ring-Brass

Pipe Plugs, 1/8” NPT

Base

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

MODEL

NO.

PART

NO.

021301R

021302

126905

134107

131100

132583

021439

125855

CJ103031 CJ103051 CJ103071 CJ103101 CJ103151 CJ103201

CJ103P031 CJ103P051 CJ103P071 CJ103P101 CJ103P151 CJ103P201

*

*

*

98J103

—

1

2

1

1

4

1

130403A

133426

N/A

1

127870

1

127869A

4

4

1

FORM NO. FW0039

SUPERSEDES 1009

PAGE 4-1A REPAIR PARTS

5A

2

4

6

9

CJ103053 CJ103073 CJ103103 CJ103153 CJ103203

CJ103P053 CJ103P073 CJ103P103 CJ103P153 CJ103P203

98J105

98J305

1

2

1

1

4

1

126900A

139222

138138

1

127870

1

127869A

4

4

1

98J107

98J307

127805

021280

134240

127780

N/A

5B

7

5

8

IL0417

QTY.

98J110

1

2

1

1

4

1

1

1

4

4

1

98J310

1

2

1

1

4

1

127804

135248

134240

1

127780

1

N/A

4

4

1

98J115

98J315

1

2

1

1

4

1

127806

021279

134240

1

127780

1

N/A

4

4

1

98J120

98J320

127848

127780

11

0110

1

2

1

1

4

1

N/A

N/A

1

N/A

N/A

4

4

1

Page 7

FORM NO. FW0040

0813

SUPERSEDES 0811

CENTRIFUGAL PUMP REPAIR PARTS

“CJ101” SERIES

(For Pricing Refer To Repair Parts Price List)

1

2

4

13

12

3

6

5

8

9

Detail of

Intermediate Stage

Assembly

Square

Cut Ring

HP 3/4 1 1-1/2 2 2 3

STAGE 2 2 2 2 3 3

SINGLE PHASE - BRASS IMPELLER

ITEM

THREE PHASE - BRASS IMPELLER

SINGLE PHASE - PLASTIC IMPELLER

THREE PHASE - PLASTIC IMPELLER

MODEL

NO.

CJ101B071 CJ101B101 CJ101B151 CJ101B201 CJ101C201 CJ101C301

CJ101B073 CJ101B103 CJ101B153 CJ101B203 CJ101C203 CJ101C303

CJ101P071 CJ101P101 CJ101P151 CJ101P201 CJ101D201 CJ101D301

CJ101P073 CJ101P103 CJ101P153 CJ101P203 CJ101D203 CJ101D303

DESCRIPTION PART NO. QTY

11Motor, Nema J - 1 PH

Motor, Nema J - 3 PH

Motor Cover w/Screws

Screws, Cover

‡

Slinger Washer

2

Shaft

3

Mounting Ring

4

Hex Hd. Cap Screws 3/8 x 3/4”

5

Seal, Rotary w/Spring

6

Impeller, Brass

6

Impeller, Thermoplastic

7

Spacer, Shaft

8

Gasket

9

Intermediate Stage Assy-Brass**

9

Intermediate Stage Assy-Plastic**

‡

Suction Clearance Ring

‡

Hub Clearance Ring

‡

Square Cut Ring Interm. Stg.

10

Suction Flange Assembly-Brass

10

Suction Flange Assembly-Plastic

‡

Suction Clearance Ring

‡

Suction Bearing

11

Pump thru Bolts (Grade 5) 3/8” x 3-1/4”

11

Pump thru Bolts (Grade 5) 3/8” x 5”

12

Base w/ Bolts 3/8” x 1-1/4”

13

1/4" NPT Plug

(*) Standard hardware item

(†) For quantity required — See number of stages

(‡) Not shown

(**) Includes two castings, square cut ring, suction and hub clearance ring - See Detail Drawing

(∆) Kit Includes: Access Cover, Screws & Wiring Diagrams

021301R

021302

126905

125204

*

131100

133380

130968

131239B

023405

130957

131282

020240

125227A

023404

130957

020053

*

020054

*

98J107

98J307

1

2

1

135279A

1

2

1

†135280A

†133425

1

2

1

1

1

1

1

1

1

1

1

4

-1

4

98J110

98J310

1

2

1

135279A

1

2

1

†135281A

†133427

1

2

1

1

1

1

1

1

1

1

1

4

-1

4

8

†126900A

7

IL0159

98J115

98J315

1

2

1

135279A

1

2

1

†139180

1

2

1

1

1

1

1

1

1

1

1

4

-1

4

6

98J120

98J320

1

2

1

135279A

1

2

1

†126901A

†128472

1

2

1

1

1

1

1

1

1

1

1

4

-1

4

10

11

98J120

98J320

1

2

1

136612A

1

2

1

†139126A

†139221

2

3

2

2

2

2

2

1

1

1

1

-4

1

4

13

13

98J630

023251

1

2

1

136612A

1

2

1

†136951A

†139104

2

3

2

2

2

2

2

1

1

1

1

-4

1

4

12

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

Page 8

GUÍA DEL PROPIETARIO PARA

INSTALACIÓN Y OPERACIÓN

FW0078

0813

Supersedes

0112

LEA ESTAS INSTRUCCIONES CON CUIDADO

Lea estas instrucciones de instalación por extenso antes de instalar su bomba. Verifique lo seguiente:

1. Aseqúrese de que el motor esté conectado con el voltaje correcto siendo usado (vea la placa de

fabricante en el motor).

2. Asegúrese de que la bomba esté completamente cebada antes de arrancarla. De otra manera daños

pueden ocurrir al sello.

Se prueba cada bomba antes de salir de la fábrica, y su eficiencia depende mucho de la manera en que será

instalada.

BOMBAS CENTRÍFUGAS CON ASPIRACIÓN DEL TÉRMINO

IL0412

INFORMACIÓN GENERAL DE SEGURIDAD

1. Siga todos los reglamentos eléctricos y de

seguridad locales.

2. Substituya o repare el cordón eléctrico dañado

o gastado inmediatamente.

3. No enrede el cable de fuerza y nunca deje que

entre en contacto con aceite, grasa, superficies

calientes, ni químicos.

4. Proteja el cable de fuerza de contactarse con

objectos agudos.

5. Tome cuidado al tocar la parte exterior de un

motor en funcionamiento porque puede estar

suficientemente caliente para causar dolores

personales.

6. Asegúrese de que el servicio de fuerza

conforme con los requisitos de su equipo.

7. Siempre desconecte el servicio de fuerza antes

de hacer cualquier trabajo en o cerca del motor

o su carga conectada. Si el interruptor para

desconectar la fuerza está fuera de vista,

ciérrelo en la posición abierta y lo marque

para evitar una aplicación inesperada de la

fuerza. Falta de hacerlo podría resultar en un

choque eléctrico fatal.

IL0201

Figura 2 - Series CJ101Figura 1 - Series CJ103

8. No toque en la bomba con las manos mojadas

o al estar de pie en aqua como puede ocourrir

un choque eléctrico fatal. ¡Desconecte la

fuerza eléctrica antes de tocar en la bomba

por CUALQUIER MOTIVO!

9. Asegúrese de que la bomba esté seguramente

conectada a tierra. Esto se puede hacer al

atarle con alambres a un sistema de canal de

tierra eléctrica con recubrimiento metálico o al

utilizar una tierra eléctrica separada conectada

a la parte metálica a la armazón del motor o

de otra manera adecuada.

10. ADVERTENCIA: Risque de choc électrique.

Cette pompe n’a pas été testée pour être

utilisée près de piscines.

11. ADVERTENCIA: Este producto contiene

sustancias químicas que de acuerdo al

estado de California pueden causar cancer y

defectos de nacimiento u otros daños en la

reproducción.

Aviso: Las bombas con la marca CSA han side

probadas de acuerdo al estandard UL778. Las

bombas “Certificadas” estan certificad de acuerdo al estandard CSA C22.2 No. 108.

1

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

130441S

Page 9

IL0413

IL0414

Dimensiones (En Pulgadas) Serie CJ103 Tabla A

HP A B C D E F G H J K

1/3 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/2 8-1/4 8-1/8 13-1/4 3-7/8

1/2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 13-1/2 3-7/8

3/4 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 14 3-7/8

1 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 14-1/2 3-7/8

1-1/2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 15-1/8 3-7/8

2 4 4-5/8 3-11/16 4-13/16 9-3/16 2-1/8 8-1/4 8-1/8 15-5/8 3-7/8

1-1/4” Descarga

H

A

J

Figura 3 - CJ103 - Bomba Reforzadora de Etapa Única

1-1/2” Succión

F

E

D

C

IL0396

K

B

G

1-1/4” Descarga

H

A C

J

Figura 4 - CJ101B - Bomba Reforzadora de Dos y Tres Etapas

F

1-1/2” Succión

E

D

B

G

IL0395

Serie CJ101 Tabla B

HP A B C D E F G H J

3/4 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 17-7/8

1 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 18-3/8

1-1/2 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 19

2 4 4-5/8 7-9/16 4-13/16 8-3/4 6-1/4 7 8-1/8 19-1/2

2 * 4 4-5/8 9-7/16 4-13/16 8-3/4 8-1/8 7 8-1/8 21-3/8

3 * 4 4-5/8 9-7/16 4-13/16 8-3/4 8-1/8 7 8-1/8 21-3/8

(*) Tres Etapas

Datos De Motores Tabla C

VOLTIOS

DEL MOTOR

HP FASE VOLTIOS HZ RPM

1/3 1 115/230 60 3450 11 5V 8.6 4.3 — — 26.0 13.0 — — K

1/2 1 115/230 60 3450 11 5V 13.0 6.5 — — 36.0 18.0 — — K

3/4 1 115/230 60 3450 230V 14.0 7. 0 — — 52.0 26.0 — — K

1 1 115/230 60 3450 230V 18.0 9.0 — — 70.0 39.0 — — L

1-1/2 1 115/230 60 3450 230V 21.0 10.5 — — 98.0 49.0 — — J

2 1 115/230 60 3450 230V 25.0 12.5 — — 116.0 58.0 — — H

3 1 230 60 3450 230V — 13.5 — — — 53.0 — — D

3/4 3 208-230/460 60/50 3450/2850 230V — — 3.5 1.75 — — 19.0 9.5 K

1 3 208-230/460 60/50 3450/2850 230V — — 4.5 2.25 — — 26.9 13.5 K

1-1/2 3 208-230/460 60/50 3450/2850 230V — — 5.7 2.85 — — 33.5 16.8 K

2 3 208-230/460 60/50 3450/2850 230V — — 7. 4 3.0 — — 44.0 22.0 K

3 3 208-230/460 60 3450 230V — — 9.8 4.9 — — 48.0 24.0 D

(CONECTADO

EN LA

FÁBRICA)

AMPERIOS DEL MOTOR

FACTOR DE SERVICIO

FASE UNICA TRES FASES FASE UNICA TRES FASES

115 V 230V 230V 460V 115 V 230V 230V 460V

AMPERIOS DEL ROTOR

CERRADO

CÓDIGO

KVA

Suministró de Agua

Municipal

Válvula de Compuerta/Globo

(Normalmente Abierta)

Use Colador

o Filtro

(Opcional)

Unión

Válvula de

Retención

Figura 5

Para saber el tamaño

adecuado del tanque,

iguale la extracción

del tanque con la

capacidad de la bomba.

(*) Para una operación

manual, deje fuera el

tanque de presión y el

interruptor automático

por caída de presión.

Alambre el motor

directamente a la caja

de fusibles.

Instale

una válvula de alivio de

presión en cualquiera

instalación donde la

presión de la bomba

pueda exceder la presión

de trabajo máximo del

tanque de presión o en los

sistemas donde el tubo

de descarga puede estar

cerrado o obstruído. Una

sobrepresión extrema

puede resultar en daños

personales o danos a la

propiedad.

Instalaciones Típicas

Unión

Manómetro

Unión

Interruptor

Automático por

Caída de presión

Desagúe

Calibre

de Vacio

Unión

Figura 6

Válvula de

Retención

Tanque de

Presión

Interruptor

Automático

por Caída de

presión

Manómetro

Válvula

de Pie con

Colador

Válvula de

Compuerta/

Globo

(Normalmente

Abierta)

Unión

Interruptor

Automático por

Caída de presión

Desagúe

Caja de Fuerza

Principal

Caja de

Fusibles

Manómetro

Válvula de Alivio

de Presión

Tanque de

Presión

Interruptor

Automático

por Caída de

presión

Unión

Para saber el tamaño

adecuado del tanque,

iguale la extracción

del tanque con la

capacidad de la bomba.

(*) Para una operación

manual, deje fuera el

tanque de presión y el

interruptor automático

por caída de presión.

Alambre el motor

directamente a la caja

de fusibles.

Instale

una válvula de alivio de

presión en cualquiera

instalación donde la

presión de la bomba

pueda exceder la presión

de trabajo máximo del

tanque de presión o en los

sistemas donde el tubo

de descarga puede estar

cerrado o obstruído. Una

sobrepresión extrema

puede resultar en daños

personales o danos a la

propiedad.

Caja de Fuerza

Principal

Caja de

Fusibles

Unión

Manómetro

Válvula de Alivio

de Presión

2

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

3

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

Page 10

Rendimiento de la Bomba Tabla D

Modelo

Cu.m/hr en Pressión Total en Kg/sq cm.

HP Etapas

Presión

Máxima kg/

Sq Cm

Monofásico Trifásico

CJ103031

CJ103051

CJ103071

CJ103101

CJ103151

CJ103201

CJ101B071

CJ101B101

CJ101B151

CJ101B201

CJ101C201

CJ101C301

---

CJ103053

CJ103073

CJ103103

CJ103153

CJ103203

CJ101B073

CJ101B103

CJ101B153

CJ101B203

CJ101C203

CJ101C303

1/3

1/2

3/4

1

1-1/2

2

3/4

1

1-1/2

2

2

3

1,06 1,41 1,76 2,11 2,81 3,52 4,22 4,92 5,62 6,33

Modelos con impulsores de bronce

--

--

--

--

2,3

6,8

9,3

1

--

--

--

--

6,1

9,1

10,9

1

--

--

--

7, 0

10,5

13,2

14,1

1

--

--

--

10,9

13,2

15,0

15,9

1

--

--

8,2

13,9

15,9

1 7, 0

*

1

--

--

13,0

1 7, 5

1 7, 9

*

*

1

--

1,1

5,0

6,6

7, 3

*

*

2

0,7

5,2

6,1

7, 3

7, 9

*

*

2

4,5

6,6

8,0

9,1

9,5

*

*

2

6,1

7, 7

9,1

10,0

10,2

*

*

2

6,1

7, 0

8,0

8,6

9,3

9,5

*

*

3

8,0

9,1

9,5

9,8

11,4

11,6

*

*

3

1,90

--

--

--

2,11

--

--

--

2,32

--

--

--

2,81

--

--

--

3,09

--

--

--

3,16

--

--

--

3,73

--

--

--

4,36

--

--

--

4,78

--

--

--

4,92

--

--

--

6,54

1,6

4,5

6,68

5,0

6,6

Modelos con impulsores de termoplástico

CJ101P071

CJ101P101

CJ101P151

CJ101P201

CJ101D201

CJ101D301

CJ101P073

CJ101P103

CJ101P153

CJ101P203

CJ101D203

CJ101D303

3/4

1

1-1/2

2

2

3

2

4,22

--

--

--

00

4,3

6,6

7, 0

7, 7

*

*

2

4,29

--

--

--

3,2

7, 0

8,4

10,0

10,5

*

*

2

4,57

--

--

--

4,8

7, 5

8,9

10,0

10,5

*

*

2

6,26

--

3,9

5,5

6,4

7, 7

8,4

9,5

9,3

*

*

3

6,33

4,1

6,1

7, 5

8,6

9,5

10,2

10,5

10,5

*

*

3

3,38

--

--

--

--

--

4,5

6,7

7, 0

*

*

( ) No exceda la presión mEaxima de la caja y la temperatura máxima liquida de capacidad nominal de la bomba.

(* ) La operación de la bomba en este rango puede disminuir la vida de la bomba y/o dañar el motor.

INSPECCIÓN Y ALMACENAJE

Al tirar la unidad de su embalaje, inspeccione

cuidadosamente por cualquier daño que pueda

haber ocurrido durante su transporte. Si Ud.

recibe la unidad un período de tiemp antes de que

vaya usarla, sería necesario inspeccionarla, volver

a encajarla y guardarla en un lugar seco.

LOCALIZACIÓN

IMPORTANTE: En las instalaciones en donde

daños a la propiedad pueden resultar de goteo

en la bomba o a una bomba inoperante debido a

paros eléctricos, atasco en el tubo de descarga, o

por cualquier otro motivo, es aconsejable tener un

otro sistema de reserva o sistema de aviso.

1. Es necesario localizar la bomba cerca de la

procedencia del flúido.

2. Se debe colocar la unidad donde el motor y

los componentes pueden estar protegidos del

tiempo y las extremas temperaturas de calor,

frío, y humedad.

3. Instale la unidad en un lugar seco que tiene fácil

4. Permita que haya bastante espacio alrededor de

la unidad para una mejor circulación de aire.

5. Las bombas de la Serie CJ103 tienen una

abertura para descarga en la caja de la bomba

que se puede ajustar en incrementos de 90

(grados). Cuando necesario, ajuste la abertura

de descarga para poder acomodar la aplicacón

específica. La posición de la abertura de

descarga no afectará el rendimiento de la

bomba.

LIMITACIONES DE SUCCIÓN

1. Las unidades no son de autocebado.

Normalmente, después de que la bomba está

cebada, el nivel total de succión es de 25 pies.

El nivel de succión varia dependiendo de la

altitud y la temperatura del agua. Refiérase a la

Tabla Práctica para Altura de Succión.

2. Cuando manosea líquidos cerca de o en sus

puntos de ebullición la procedencia del flúido

tiene que estar situada arriba de la succión para

que el NPSH disponsible será mayor que la

cantidad requerida por la unidad.

acceso para su mantenimiento e inspección. Si

un lugar seco no existe, móntela sobre una base

bastante arriba del suelo mojado.

4S

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

Presión

Máxima de

Caja Kg/Sq

Cm

7, 01

7, 01

7, 01

7, 01

7, 01

7, 01

11,3

11,3

11,3

11,3

11,3

11,3

11,3

11,3

11,3

11,3

11,3

11,3

Temperatura

Máxima

Liquida

93,3ºC

93,3

93,3

93,3

93,3

93,3

93,3

93,3

93,3

93,3

93,3

93,3

71,1ºC

71,1

71,1

71,1

71,1

71,1

Tabla Práctica De Niveles De Succión En Varias

Altitudes Y Con Varias Temperaturas De Agua

Mostrado En Grados Fahrenheit

Altitud 60º 80º 100º 120º 140º 160º 180º 200º

Nivel Del

-22 -21 -20 -18 -15 -10 -4 +5

Mar

2000 -20 - 19 -18 -16 -12 -7 -1 +8

4000 -17 -16 -15 -13 -10 -4 +2 +12

6000 -15 -14 -13 - 11 -7 -2 +6 +16

8000 -13 -12 -10 -8 -4 +2 +9 —

10000 -10 -9 -8 -6 -2 +4 +13 —

Esta tabla muestra el nivel máximo permitido de succión o la

carga de bombeo mínima en el lado de succión de la bomba en

las varias altitudes y temperaturas del líquido. Un signo menos

antes de un número indica nivel de succión. Un signo más indica

carga mínima. Use estas figuras solo como guía.

TUBERÍA

1. Use tubería galvanizada, de plástico rígido u otro

tipo de tubería adecuada que no se va a aplastar

o doblar o reventar bajo succión presión.

2. El diámetro de los tubos de succión o de

descarga no deben ser menores que los

aterrajados correspondientes de la bomba (vea

las Figuras 3 & 4). Si las distancias son grandes,

es aconsejable usar tubería de tamaño mayor.

Tubos menores irán a reducir la capacidad de la

bomba.

3. Todas las juntas y conexiones deben de tener

cinta Teflon o un compuesto sellador (rosca

macho únicamente) aplicados y las juntas

aprietadas.

El sistema entero debe estar estanque e

impermeable para una operación eficiente.

INSTALACIÓN DE LA BOMBA

Refiérase a las Figuras 5, 6 y 7 para las

instalaciones típicas. Es necesario soportar tanto el

tubo de succión como el de descarga en un punto

cerca de la bomba para evitar esfuerzo adicional en

la bomba.

1. Si está usando la bomba como parte de una

instalación permanente, segúrela en una base

rígida con sujetadores apropiados.

2. Situe la bomba lo más cerca posible al agua,

manteniendo el tubo de succión tan corto como

permitan las condiciones.

3. Evite ángulos o bolsillo en tubería desplazada o

el aire acumulará en los puntos altos resultando

en un cebado dificil.

4. El tubo de succión debería inclinar hacia

arriba hasta la entrada de la bomba. Un tubo

horizontal de succión tiene que tener una

inclinación gradual hasta la bomba.

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

Manómetro

Tapón de Cebado

Tubo “T” de Descarga

Tubo de Succión Instalada con

Una Inclinación Gradual Hacia la

Entrada de la Bomba

Nivel

Base

Soporte

del Tubo

Rígida

Figura 7

5. En las instalaciones para la carga de aspiración,

una válvula de pie o localizada en el agua o una

válvula de retención tan cerca al agua como

posible disminuirá el tiempo de cebado de

la bomba ayudando mantener el cebado. Es

necesario usar un colador en el tubo de succión

como filtro para suciedad.

6. Un tubo “T” para el cebado instalado en la

abertura de la descarga de la bomba permite

verter agua en la caja de la bomba y la tubería

de succión, lo cual es necesario para el cebado

en las instalaciones en la carga de succión.

7. Instale una válvula de compouerta y una unión

en el tubo de descarga. Para remoción de la

bomba para mantenimiento, cierre la válvula de

compuerta y desconecte la unión.

No use una válvula de globo u otro tipo

de válvula restrictora en la descarga. Esto restringirá

sériamente la capacidad de la bomba.

8. Manómetros — Los manómetros o

vacuómetros de tamaño adecuado pueden

estar instalados tanto en el tubo de succión

como en el de descarga. Los indicadores

permitirán la observación del rendimiento de la

bomba igual como la detección de cavitación

bloqueo de vapor u otra operación inestable.

Modelos

CJ103 100 PSI

CJ101 160 PSI

Utilice solamente componentes

asignados más altos que la presión de cierre del

sistema. Nunca exceda la presión máxima de la caja de

la bomba como alistada en la tabla abajo.

Es necesario instalar una válvula

reductora de tamaño adecuado en cualquier instalación

donde la presión de la bomba puede exceder la presión

máxima de trabajo del tanque o en sistemas donde se

puede cerrar la línea de descarga o puede estar obstruída.

El hecho de no usar una válvula reductora puede

resultar en una presión extrema que podría cuasar daños

personales o a la propiedad.

Presión Máxima De La

Caja

ELÉCTRICA

5

Page 11

IL0102

Haga una tierra eléctrica al motor

antes de conectarlo al sistema de

energía eléctrica.

Conecte la armazón del motor a

la tierra eléctrica del equipo usando el

Hazardous voltage.

Can shock, burn

or cause death.

Failure to follow

warnings can

cause fatal or

severe shock

hazard or

equipment failure.

tornillo verde. No conecte el alambre

verde de tierra eléctrica a los alambres

del motor.

No haga tierra eléctrica a un tubo

de suministro de gas.

Apague la corriente eléctrica al motor antes de

trabajar con las conexiones eléctricas.

El voltaje de suministro tiene que ser de 10% más o

menos del número de voltaje en la placa. Si existe duda,

consulte un electricista licensiado.

Use el tamaño de alambre especificado en la tabla

E de alambrado. Si posible, conecte la bomba a un

circuito lateral separado sin otros aparatos eléctricos. Si el

diagrama de instalación de la placa del motor es diferente

del diagrama mostrado en las figuras 9, 10, 11, 12 y 13,

entonces siga el diagrama del motor.

Todo el alambrado debe ser hecho por un electricista

calificado de acuerdo con los reglamentos locales.

ALAMBRADO

1. Los voltajes de los motores varian de acuerdo

al HP del motor y la fase. Refiérase a la placa

del motor y la Tabla de Datos del Motor (Tabla

C) para voltaje y datos eléctricos.

Asegúrese de que la fuerza eléctrica

esté conforme a las especificaciones eléctricas del

motor proporcionado. Falta de hacerlo puede resultar

en averías en el motor invalidando la garantía.

2. Para modificar el voltaje, remueva la cubierta

trasera que está fijada en su lugar con dos (2)

115 VOLTS

MONOFÁSICO

LÍNEA

L1

L2A B

AMARILLO

BLANCO

GRIS

ROJO

TOSTADO

NOTE: en el motor de voltaje dupla, cambie los

alambres de color rojo y gris al voltaje requerido

Figura 8 - Diagrama del Alambrado para

Monofásico de 1/3 - 2 HP

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

AMARILLO

230 VOLTS

MONOFÁSICO

L1

BLANCO

LÍNEA

GRIS

L2A B

ROJO

IL0180

tornillos. Para hacer una conexión eléctrica

correcta, vea el diagrama situado en la placa

del motor o en las figuras 9, 10, 11, 12 y 13.

Vuelva a poner la cubierta del aceso

trasero antes de encender u operar la bomba. Falta de

hacerlo podría resultar en daños personales.

PROTECCIÓN AL MOTOR

1. Todos los motores monofásicos tienen una

protección térmica integrada para todos los

voltajes. El sobrecarga protege el motor contra

quemado causado por sobrecarga de voltaje

bajo, alto, y por otras causas. El dispositivo es

automático y se restablece solo una vez que la

temperatura baje a un punto seguro. Disparos

frecuentes del dispositivo indican problemas

con el motor en las líneas de fuerza y requiere

atención inmediata.

Nunca examine, ni haga cambios al

alambrado, ni toque el motor antes de desconectar el

interruptor principal de la fuerza eléctrica. El dispositivo

térmico puede haber abierto el circuito eléctrico.

2. Los motores trifásicos no tienen una protección

térmica integrada. Se recomienda el uso

de un arrancador magnético o manual de

tamaño apropiado (ambos con calentadores

de tamaño correcto) con todos los motores

trifásicos. Instale los arrancadores siguiendo las

instrucciones del fabricante de los arrancadores.

Vea la figura 14 para el diagrama del alambrado

de arrancadores magnéticos.

3. Todos los motores (monofásicos y trifásicos)

deben ser equipados con un interruptor de

desconexión con fusibles correctos para

proporcionar protección. Consulte los

reglamentos locales para códigos eléctricos para

protección adecuada de los fusibles basada en las

tablas de datos de motores. (Vea las tablas C y E).

CEBANDO LA BOMBA

1. Antes de encender cualquier bomba centrífuga,

es absolutamente necesario que tanto la caja

como el tubo de succión estén completamente

llenos de líquido. Se puede llevar a cabo este

VOLTAJE BAJO VOLTAJE ALTO

4 5 6

7 8 9

1 2 3

TOSTADO

L1 L3L2 L1 L3L2

IL0770

CONEXIONES PARA TRIFÁSICO CON 9 ALAMBRES

NOTE: para invertir la rotación, intercambie

cualquier de dos alambres de la línea de fuerza

de entrada

Figura 9 - Diagrama de Alambrado para

Trifásico

6

3-ø

4 5 6

7 8 9

1 2 3

TRIFÁSICO

VOLTAJE BAJO VOLTAJE ALTO

5

5

6

9

3

LÍNEA

IL1229

Figura 10 - Diagrama del alambrado para motores trifásico

TEFC de Baldor

4

8

7

2

1

6

9

3

LÍNEA

TRIFÁSICO

VOLTAJE ALTOVOLTAJE BAJO

5

5

6

9

4

8

7

6

9

2

3

3

1

LÍNEA

IL1230

Figura 11 - Diagrama del alambrado para motores monofásicos y

trifásico TEFC de Franklin Electric

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

8

2

LÍNEA

4

7

1

8

2

Marrón

Violeta

Negro

Amarillo

Azul

Marrón

Violeta

Amarillo

Negro

Azul

4

7

1

MONOFÁSICO

VOLTAJE ALTO

(10)

(9)

(2)

(3)

(4)

(10)

(9)

(3)

(2)

(4)

LÍNEA

LÍNEA

TRIFÁSICO

LA TIERRA

ELÉCTRICA

(Cuando Requerido)

T7

T1

T8

T5

T6

T3

IL1231

Figura 12 - Diagrama del alambrado para motores trifásico

TEFC de Marathon

Interruptor

Automático

por Caída

de Presión

Figura 13 - Diagrama del Alambrado para Arrancador Magnético Trifásico

7

T2

L1

03

02

T1

T1

T5

T6

T9

T3

MV W

Motor

T4

T8

T7

T2

LÍNEA

L2

X2

T2

T2

T3

Alambre de Cobre Número 10

Para Tierra Eléctrica, Conecte a

una Varilla de Tierra o Tubo de

Revestimiento del Pozo.

VOLTAJE ALTOVOLTAJE BAJO

T6

T9

T3

T1

Interruptor de

Desconexión

Fundido

L3

Apartarrayos

T3

T5

T8

T2

LÍNEA

T4

T7

T1

Page 12

cebado al sequir cualquier de los seguientes

IL0416

métodos:

2. Cuando el nivel de líquido está arriba de la

línea del medio de la bomba, el cebado de

la bomba se realiza al abrir las válvulas de

succión y de descarga. El líquido que viene

entrando desplazará el aire y llenará el tubo

de succión, la caja de la bomba, y el tubo de

descarga hasta el nivel de suministro.

3. Mientras que la bomba está operando con

carga de aspiración y el tubo de succión está

equipado con una válvula de pie, remueva el

tapón de cebado del “T” de descarga (vea las

figuras 3-6) y llene el cuerpo de la bomba y

el tubo de succión completamente con agua.

No es necesario poner agua adicional para

arranques posteriores a no ser que el cuerpo de

la bomba esté vacia.

4. Después de encender la bomba de 2 hasta 5

minutos serán necesarios antes de que todo el

aire esté vaciado del tubo de succión y que el

agua esté fluindo. Se el agua no sale después

de 5 minutos, apaque la bomba y verifique el

seguiente.

5. Es necesario eliminar cualquier fuga de aire en

el tubo de succión.

6. La admision del tubo de succión debe estar a

un mínimo de 5 pies abajo del nivel del agua.

7. La altura total de aspiración no puede estar a

más de 25 pies.

8. Cualquiera restricción en el tubo de descarga,

como una válvula cerrada tiene que ser

eliminada.

NOTE: La unidad tiene que estar llena de líquido

antes de empezar su operación. Nunca opere

la unidad en seco o con la descarga cerrada.

manecillas del reloj al estar de frente con el

roscado interno de succión) y no puede ser

invertido.

2. Rotación correcta del impulsor de la bomba es

esencial para bombas trifásicas. El motor de la

bomba debe girar en sentido contrario al de las

manecilas del reloj al estar de frente al roscado

interno del tubo de succión de la bomba. Toque

momentaneamente (arranque el motor por

menos de un segundo) la fuerza del motor para

verificar rotación correcta. Para cambiar la

rotación en las bombas trifásicas, intercambie

cualquiera de dos líneas de entrada de fuerza.

MANTENIMIENTO

Lubricación

Las bombas y los motores no requieren lubricación.

Los cojinetes de bolas del motor vienen con grasa

desde la fábrica. Bajo condiciones normales de

operación, no deberán requerer grasa adicional.

Congelación

Hay que purgar el sistema entera si existe el peligro

de congelación. Un tapón de desagüe se localiza al

fondo de la caja de la bomba para este motivo.

SUBSTITUCIÓN DEL ENSAMBLAJE DEL SELLO

ROTATORIO

Desmontaje

Al desmontar la bomba , tome cuidado

de no dañar los empaques. Si está rasgada o dañada,

substitúyalos por empaques nuevos (vea la lista de piezas).

1. Remueva los cuatro (4) pernos pasantes que

conectan el anillo de montaje al cuerpo de la

bomba. Quite el cuerpo de la bomba tomando

cuidado para no dañar el empaque ni el arosello.

2. Remueva los impulsores. Los Modelos CJ103 son

de una sola etapa, con un impulsor. Use una llave

Operación en seco o con la descarga cerrada

causará daños al sello del eje. No vaya a bombear

agua sucia ni líquidos abrasivos, otramente lo

mismo puede ocurrir como si estuviera operando en

seco.

ROTACIÓN DEL MOTOR

1. Modelos monofásicos son de rotación de una

dirección única (En sentido contrario al de las

Figura 14 - Rotación Correcta Del Motor

Tabla E

Distancia del

Motor al contador

de la caja de

fusibles, o el

tamaño de

corriente.

0-50’ 14 14 12 14 12 14 10 14 10 12 10 12 10 14 14 14 14 14 14 14 14 14 14

50-100’ 14 14 12 14 12 14 10 14 8 12 8 12 10 14 14 14 14 14 14 14 14 14 14

100-150’ 14 14 12 14 10 14 10 12 6 12 6 12 10 14 14 14 14 14 14 14 14 14 14

150-200’ 12 14 12 14 10 12 8 12 * 10 * 10 10 14 14 14 14 12 14 12 14 12 14

200-300’ 12 14 10 14 8 12 6 10 * 10 * 10 8 14 14 12 14 12 14 10 12 10 12

Tamaño del

Interruptor

(amperios)

(*) No es económico operar en 115 Voltios, use 230 Voltios

1/3 HP 1/2 HP 3/4 HP 1 HP 1-1/2 HP 2 HP 3 HP 3/4 HP 1 HP 1-1/2 HP 2 HP 3 HP

115V 230V 115V 230V 115V 230V 115V 230V 115V 230V 115V 230V 230V 230V 460V 230V 460V 230V 460V 230V 460V 230V 460V

15 15 20 15 20 15 30 15 30 20 30 20 30 15 15 15 15 15 15 15 15 15 15

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

TABLA DE MEDIDA MÍNIMA DE ALAMBRE (CALIBRE)

MOTORES MONOFÁSICOS MOTORES TRIFÁSICOS

8

de boca de 9/16” para segurar el eje al girarlo en

sentido contrario al de las manecillas del reloj. La

parte plana del eje del motor está en el medio del

anillo de montaje.

3. Los Modelos CJ101 son de varias etapas, con dos

o más impulsores y una o más etapas intermedias.

Usando una llave de boca de 11/16” en la parte

plana de la extensón del eje del motor, remueva

el primer impulsor al girarlo en sentido contrario

al de las manecillas del reloj. Remueva la etapa

intermedia tomando cuidado de no dañar el

empaque y desenrosque los otros impulsores.

4. Remueva el ensamblaje del sello mecánico. La

parte rotatoria del ensamblaje del sello (anillo de

carbono, el empaque Buna-N y resorte) facilmente

deslizarán del extremo del eje. La parte cerámica

separará del asiento de goma usando dos (2)

destornilladores (vea la figura 15).

REENSAMBLAJE

Es fácil dañar las superficies recubiertas con

presición de los sellos mecánicos. Manosee cuidadosamente

el sello de reemplazo. La vida útil del sello disminuirá si las

superficies del sello (carbono y níquel) si están melladas,

arañadas, o sucias.

1. Limpie la cavidad del sello del anillo de montaje y

el eje del motor por completo.

2. Aplique una gota de jabón en líquido al exterior

del empaque Buna-N que contiene el asiento del

sello de cerámica. Usando la presión del pulgar,

presione el asiento de cerámica, con la superficie

pulida hacia arriba, justamente dentro de la

cavidad del sello (vea la figura 16).

3. Si el sello no asienta correctamente, remueva y

vuelva a limpiar la cavidad del sello. Coloque

una arandela de cartón sobre la parte pulida de la

superficie del sello y con cuidado presione en su

lugar usando un pedazo de tubo o de tubería (vea

la Figura 17). Tire fuera la arandela de cartón.

4. Aplique jabón en líquido (solamente una gota) al

diámetro interior al anillo de goma de transmisión.

Deslice el anillo de goma de transmisión (con la

superficie de carbono hacia abajo) y el resorte

sobre el eje.

5. Vuelva a ensamblar la bomba al sequir las

instrucciones de desmontaje en orden invertida.

REEMPLAZO DEL MOTOR

1. Se puede reemplazar tanto los motores Nema

Figura 15 - Remueva el Sello Mecánico

IL0173

95 North Oak Street • Kendallville, IN 46755 • Copyright © 2012. All rights reserved.

IL0168

Figura 16 - Presione el Sello

J como los de armazón simples en el campo

de operaciones al referirse a las sequientes

instrucciones de la lista anexada de piezas.

2. Siga los pasos delineados bajo Reemplazo del

Sello Rotatorio para remover el cuerpo de la

bomba, difusor, impulsor, y sello rotatorio.

3. Remueva los pernos que conectan el motor al

anillo de montaje y separe el motor.

4. Substituya el motor con motor Nema J estándar

a chorro al posicionar el motor contra la armazón

de montadura y ensamblarlo con cuatro tornillos

de cabeza de 3/8” x 3/4”. La base de montadura es

concetada al fondo de la armazón de montadura

con dos de los cuatro tornillos de cabeza 3/8” x

3/4”.

5. Siga los pasos del Ensamblaje del Sello del Rotor

para ensamblar el resto de la bomba.

PORQUE ES PROBABLE CAUSARLE DAÑOS AL

SELLO DEL EJE EN EL DESMONTAJE, SERÁ

NECESARIO PONER UN SELLO NUEVO.

NOTA:

Arandela de

Tubo de 3/4”

Presione con

Cuidado

IL0169

Figura 17 - Si Necesario, Presione con

Cartón o el Tubo

9

Cartón Proteje

la Superficie del

Sello

Sello

Cavidad

del Sello

Page 13

Tabla De Detección De Fallas

Síntoma Causa De Los Defectos(s) Correción Del Defecto

Poca o Ninguna Descarga 1. Bomba sin cebado 1. Cébela

2. Carga de Succión demasiada Alta 2. Acorte la altura de

succión o cambie la carga

de succión

3. Capacidad o Altura de Succión 3. Abaje la altura de la

demasiada Altas entrada

4. Impulsor Obturado 4. Limpie

5. Rotación errada en la línea de 5. Refiérase a la información

succión

6. Goteo en el tubo de succión 6. Repare o hace

substitución

7. Válvula de pie demasiado pequeño 7. Ajuste de acuerdo

8. Impulsor dañado 8. Substituya

9. Válvula de pie o tubo de succión 9. Sumerja más en agua

no sumergidos suficientemente

en agua

10. Falta de presión de entrada o de 10. Aumente la presión de

carga de succión entrada adicionando más

agua al tanque o

aumentando la

contrapresión

11. Tubería de succión demasiado 11. Aumente al mismo

pequeña tamaño del tubo de

entrada o para uno mayor

12. Empaque de la caja está goteando 12. Substituya empaque

13. Válvulas de succión o de 13. Abra

descarga cerradas

Pérdida de Succión 1. Goteo de aire en el tubo de 1. Reparar

succión

2. Altura de succión demasiada alta 2. Baje la altura de la entrada

3. La presión de la entrada está 3. Aumente la presión de

insuficiente y la carga de succión entrada adicionando más

está insuficiente agua al tanque o

aumentando la

contrapresión

4. La válvula de pie o criba están 4. Limpie o reemplace

obstruídas

La Bomba Vibra y/o hace 1. El plato de montadura o el 1. Reforzar

demasiado ruído basamento no son bastante rígidos

2. Material ajena en la bomba 2. Desarme y limpie la

bomba

3. Impulsor dañado 3. Substituir

4. Cavitación presente 4. Verifique el tubo de

succión para el tamaño

correcto y aségurese de

que la válvula esté

abierta. Quite las vueltas

excesivas

5. Cojinetes del motor gastados 5. Substituya

6. Eje del impulsor doblado 6. Substituya

La bomba no arranca ni funciona 1. Alambrado errado 1. Verifique el diagrama del

alambrado en el motor

2. Fusible fundido o interruptor 2. Substituya fusible o cierra

automático abierto el interruptor automático

3. Alambrado suelto o quebrado 3. Apriete todas las

conexiones, substituya el

alambrado quebrado

4. Piedra a partícula ajena 4. Limpie

5. Motor puesto en corto circuito 5. Substituya

introducida en el impulsor

La bomba gotea en el eje 1. Sello mecánico gastado 1. Substituya

2. Eje del impulsor doblado 2. Substituya

PIEZAS DE REPUESTO DE LA BOMBA

CENTRÍFUGA SERIE CJ103

1

3

10

Hp

Etapas

Monofásico

Impulsor de latón

Trifásico

Impulsor de latón

ITEM

Monofásico

Impulsor de plástico

Trifásico

Impulsor de plástico

Descripción

1

Motor, Nema J - 1 PH

1

Motor, Nema J - 3 PH

Cubierta del Acceso al Motor

‡

Tornillos, Cubierta

‡

Arandela del Lanzador

2

Anillo de Montadura

3

Tornillos de Cabeza Hexagonales 3/8 x 3/4”

4

Sello, Rotatorio con Resorte

5

Impulsor - latón

5A

Impulsor - plástico

5B

Anillo separador

6

Anillo de corte cuadrado†

7

Cuerpo de la Bomba - Impulsor de latón

Cuerpo de la Bomba - Impulsor de plástico

‡

Anillo para espacio l ibre de succión

8

Tapones para tubos, 1/8” NPT

910Tornillos de Cabeza Hexagonales 3/8 x 1”

Base

(*) Item de Herraje Estandar

(‡) No mostrado

(†) For pumps with paper gasket, replace with part number 127782

(∆) Kit Includes: Access Cover, Screws & Wiring Diagrams

Número

Del

Modelo

Número

De Pieza

021301R

021302

126905

134107

*

131100

132583

021439

*

*

125855

2

4

6

9

5A

5B