Page 1

FW0393

Notice to Installer: Instructions must remain with installation.

Quality Products Since 1866

Product information presented

here reflects conditions at time

of publication. Consult factory

regarding discrepancies or

inconsistencies.

MAIL TO: 95 North Oak Street • Kendallville, IN 46755

(260) 347-1600 • 1 (800) 345-9422 • FAX (260) 347-0909

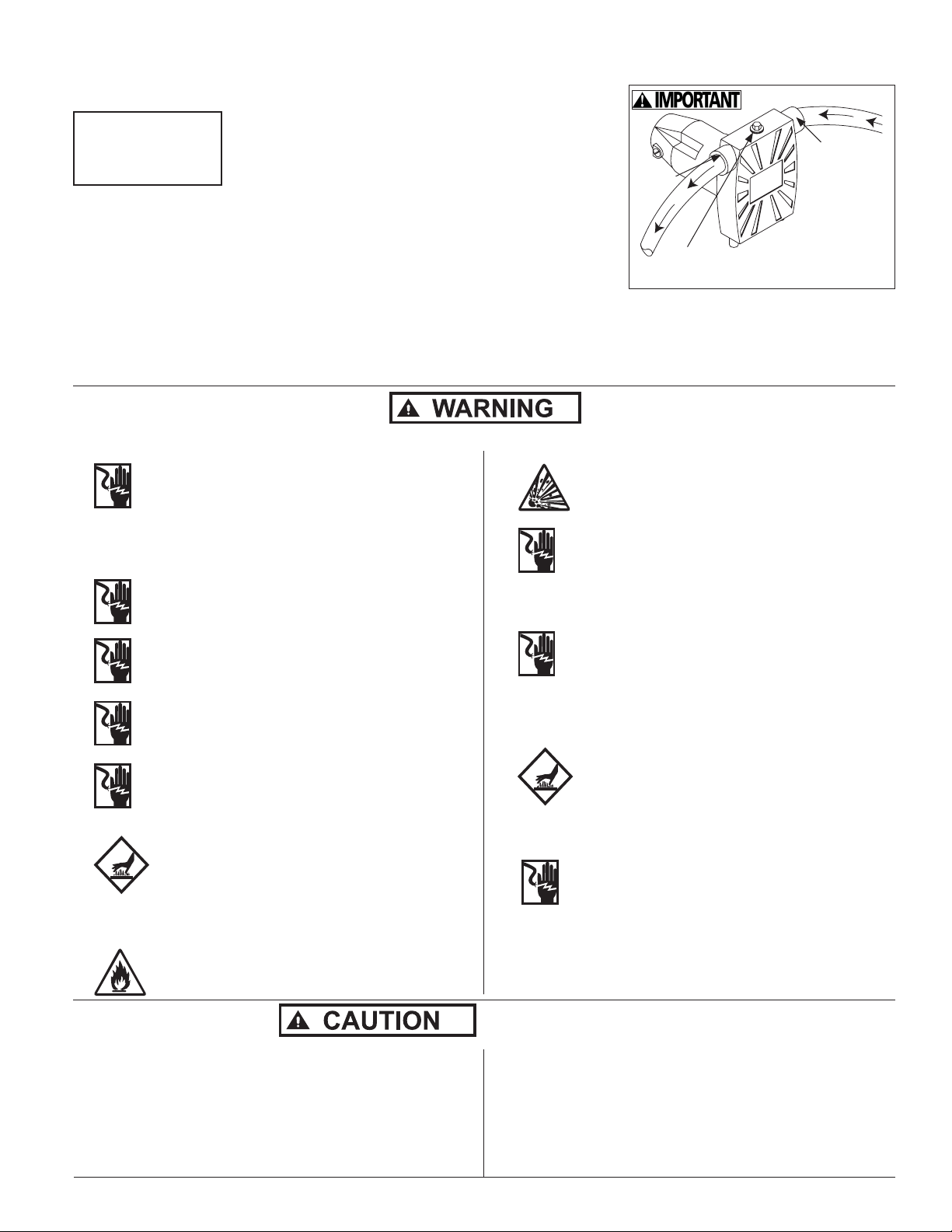

PumpMate®

OUT

Supersedes

IN

Portable Utility Pump

INSTALLATION INSTRUCTIONS

These installation instructions are applicable for Models CS511,

CF511 and C511 Portable Utility Pumps

PREINSTALLATION CHECKLIST - ALL INSTALLATIONS

ATTENTION: READ CAREFULLY BEFORE ATTEMPTING TO INSTALL OR OPERATE YOUR PUMP. PROTECT YOURSELF AND OTHERS BY

OBSERVING ALL SAFETY INFORMATION AND ADDITIONAL INSTRUCTIONS INCLUDED WITH EQUIPMENT. FAILURE TO COMPLY WITH

INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE! RETAIN FOR FUTURE REFERENCE.

SEE BELOW FOR LIST OF WARNINGS

Pump must be lled with water

before running.

IL0387

0611

0909

1.

2.

3.

4.

5.

6.

7. This pump is designed for water only. It has not been evaluated for pump-

8.

Make sure that the pump is plugged into a properly

grounded electrical receptacle. Use an Underwriters Labo-

ratory listed circuit analyzer to test for proper installation of

the circuit and ground. Any service to circuits or receptacles

should be conducted by a qualified licensed

electrician.

Do not remove the ground pin from the plug under any

circumstances. If the ground pin is damaged, replace the

power cord or plug before use.

All electrical installations must conform to the requirements of

the National Electric Code and all local codes.

It is strongly recommended that the unit (Model CS511, CF511

or C511) be plugged into a GFI protected circuit.

Disconnect power before servicing the pump or motor by

unplugging the unit from the outlet.

Do not touch the motor when operating and allow the motor

to cool before touching it afterwards.

ing of chemicals.

Do not use this product to pump flammable or explosive

liquids.

9.

10.

11. Models CS511, CF511 and C511 are supplied with an automatically

resetting thermal overload device and can restart without warning.

12.

13. Secure the discharge line before starting the pump. An unsecured

hose can whip, possibly causing personal injury or property damage.

14.

15. Do not operate this product while unattended.

16.

17. According to the state of California (Prop 65), this product contains

chemicals known to the state of California to cause cancer and birth

defects or other reproductive harm.

Do not use this product in hazardous environments or any-

where a spark could potentially ignite explosive gases.

Do not handle this product with wet hands or while standing in

water or on a wet or damp surface.

Do not submerge the pump or motor in water.

Provide a means of pressure relief if the pump dis-

charge can be shut off or obstructed. Pumps operating against a closed discharge can create very hot

pumped liquid, which can cause burns.

Product is portable, and not intended to be permanently

installed outdoors. If installed outdoors, care should be

taken to protect the unit from rain and other elements of the

weather.

1. Make certain that the power source conforms to the requirements of

the equipment as stated on the product nameplates.

2. Check hoses for weak or worn conditions before use and make certain

that all connections are secure.

3. Periodically inspect the pump for damage and perform routine

maintenance as required.

© 2011. All rights reserved.

SEE BELOW FOR LIST OF CAUTIONS

4. The maximum temperature of the pumped liquid must not exceed

120° F. The minimum allowable temperature is 40° F.

5. Use a screen or strainer on the inlet to prevent solids from entering

the pump.

6. To avoid internal pump damage, pump should not be run for more than

five minutes while attempting to prime.

1

Page 2

DESCRIPTION

This portable utility pump is designed to be used as a transfer pump for

such applications as emptying water heaters, swimming pools, livestock

tanks, boats, etc. Pump can also be used for an intermittent pressure

booster for applications such as washing cars, cleaning driveways, etc.

The motor is air cooled. It is NOT designed to operate under water.

5. Use a strainer when pumping from a creek, pond, or source where

foreign objects may be sucked into the pump. The strainer should

prevent solids from entering the inlet line.

6. A regular 3/4” garden hose may be used as a discharge line. Keep the

total length as short as possible to prevent excessive friction loss.

OPERATION

INSTALLATION

attempting to install, service or maintain the pump. Never handle a pump

with wet hands or when standing on wet or damp surface or in water.

Fatal electrical shock could occur.

1. A ground fault circuit interrupter (GFCI) is recommended.

with a grounding conductor and grounding type attachment plug. A grounded

receptacle in conformance with current NEC and local codes must be used

(See Figure 1).

2. This pump operates on 115V, 60Hz AC, single phase.

off the round grounding prong. Cutting the cord or plug will void the

warranty and make the pump inoperable.

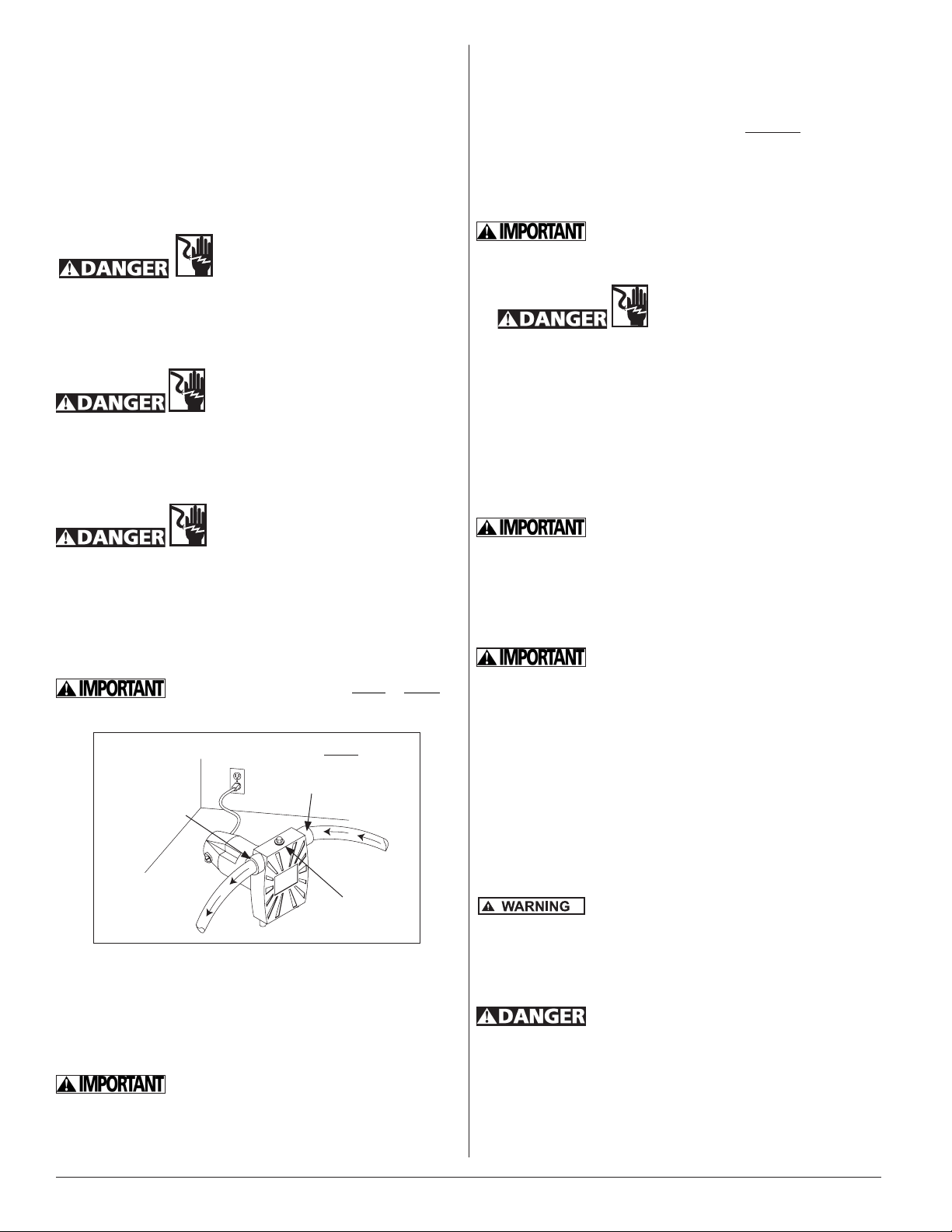

3. Figure 2 shows a typical installation. Threaded adapters are furnished

for attaching garden hose where conditions permit its use. In no case

should the pump be more than 15 feet above or away from inlet source.

Use of foot valve on inlet line is recommended.

Make sure the inlet hose is NOT coiled or kinked

above or below water level.

Always disconnect power source before

Risk of electrical shock. This pump is supplied

Risk of fatal electrical shock. Never cut

Pump must be filled with water before operation.

Running the pump dry or pumping any sand or other abrasives will cause

damage to the shaft seal or impeller and void the warranty.

1.

permanently installed outdoors. If installed outdoors, care should be

taken to protect the unit from rain and other elements of the weather.

Product is portable, and not intended to be

This unit is not waterproof or weatherproof and is not intended to

be used in showers, saunas, or other potentially wet locations. The

motor is designed to be used in a clean, dry location with access to

adequate cooling air. Ambient temperature around the motor should

not exceed 104°F (40°C).

2. Remove priming plug and fill with water. Reinstall plug.

To help with the priming of the pump, a foot valve

can be installed on the inlet line. The use of a foot valve is strongly

recommended to be installed on inlet lines lifting over five feet.

3. Plug power cord into GFCI protected electrical outlet. The pump will

prime in a few minutes, depending on inlet line length.

To avoid internal pump damage, if after five minutes

the pump has not begun pumping water, turn off the pump, remove

priming plug, re-fill pump with water, reinstall priming plug and plug

pump back in.

15 Ft. Inlet Line Length Max.

IN

OUT

Fill with

water

IL0123

Figure 2

4. The inlet line may be galvanized pipe, plastic pipe, or non-collapsible

hose. Small leaks in inlet line greatly reduce efficiency of pump and

may prevent priming.

Regular garden hose will collapse under suction

conditions and should not be used in the inlet, except for pressure

boosting situations.

© 2011. All rights reserved.

4. In the case of pressure boosting, turn water on before starting pump.

This force primes the pump. Then, plug power cord into GFCI protected

electrical outlet.

5. Unplug cord to turn unit off.

MAINTENANCE

Let pump cool for at least 20 minutes before

attempting to service. Motor may be extremely hot. Personal injury may

result.

1. Pump should be checked periodically for proper operation.

Always disconnect the electrical supply before

attempting to install, service, or perform any maintenance. If the power

source is out of sight, lock and tag in the open (off) position to prevent

unexpected power applications. Disconnect electrical cord from power

supply. Failure to do so could result in fatal electrical shock. Only

qualified electricians should repair this unit. Improper repair could result

in fatal electrical shock.

2

Page 3

Brush Replacement

T

l

D

i

H

d

F

Brushes for this pump should be inspected after

every 100 hours of operation.

2. Remove brush caps with screwdriver.

3. Remove old brush assembly.

Pumps with excess of 100 hours of operation may stop operating or

fail to start. This could be due to worn brushes or carbon build-up. The

brushes should be removed and carbon removed. Worn brushes are not

covered under warranty.

1. Disconnect electrical cord from power supply.

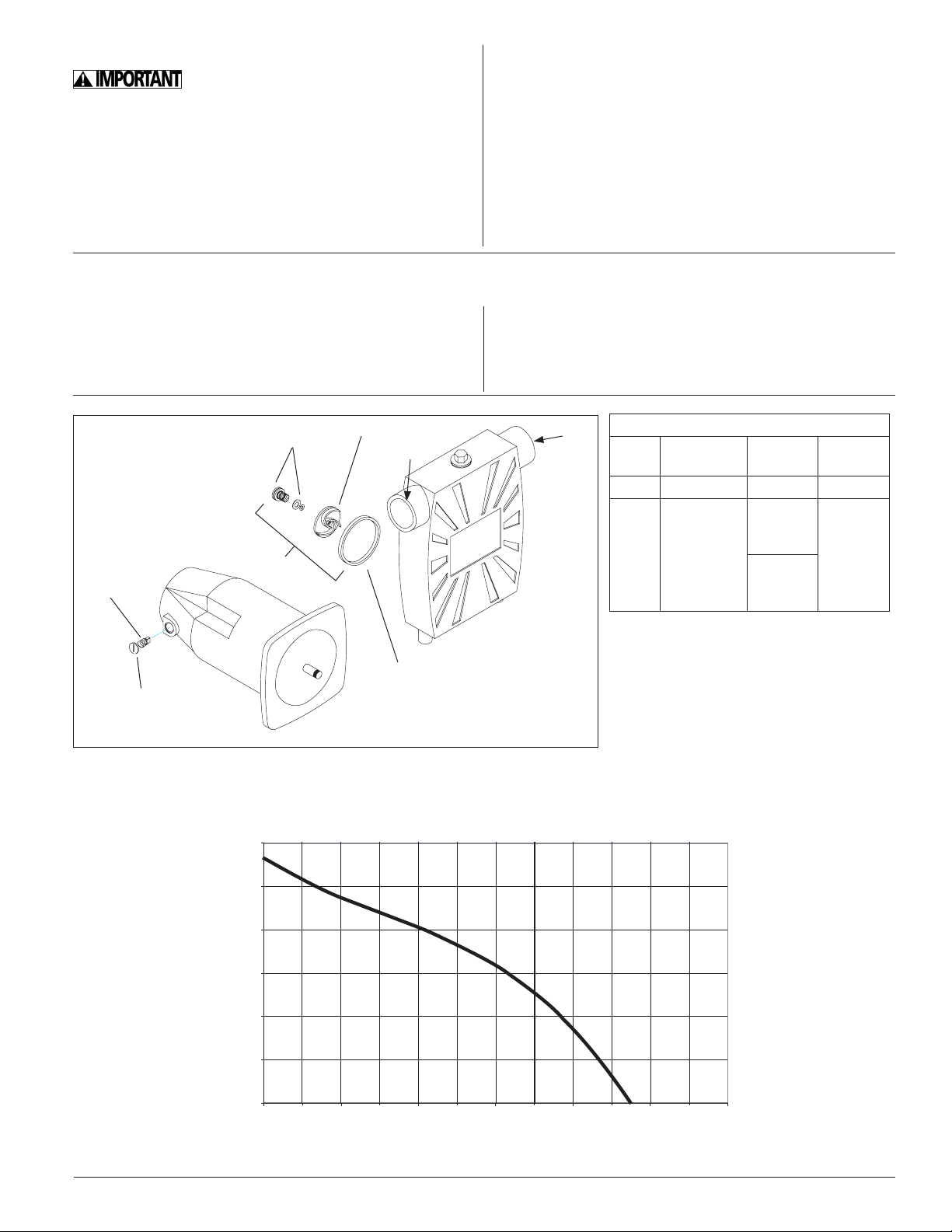

SPECIFICATIONS

Motor .............1/2 HP Single Phase, 115V, 60Hz, 8,000 RPM

..................Series Wound (brush type) AC operation

Maximum Fluid Temperature ..........................120° F

Shaft Seal

2

Brush/Spring

Impeller

OUT

4. Insert new brush assembly.

5. Replace brush caps.

For other problems, consult troubleshooting chart.

Inlet/Outlet Openings ..............................3/4” NPT

Maximum Case Pressure ...........................100 PSI

IN

REPLACEMENT PARTS LIST

Ref.

No. Description

1 Brush Kit* 015846 1

2 Impeller

and Seal

Kit

Part

Number

020387

Pump

Rev A

150380

Pump

Rev B

Req’d

Quantity

1

*Kit includes one pair of brushes.

1

Brush Cap

Volute Seal

IL0142

PERFORMANCE

Model CF511

120

t.

100

-

ea

80

c

60

ynam

40

ota

20

0

0 5 10 15 20 25 30

Flow - GPM

© 2011. All rights reserved.

3

IL0153

Page 4

TROUBLE SHOOTING GUIDE

ELECTRICAL PRECAUTIONS- Before servicing a pump, always shut off the main power breaker and then unplug the

pump. Make sure you are not standing in water and are wearing insulated protective sole shoes. Under flooded conditions, contact your local

electric company or a qualified licensed electrician for disconnecting electrical service prior to pump removal.

TROUBLESHOOTING

A. Pump will not begin pumping

or retain prime after operating, or stops pumping water

1. Air leak in inlet line

2. Fittings not tight

3. Hose kinked or looped

4. Inlet hose out of water

5. Clogged inlet

6. Inlet lift too high

7. Impeller blocked

8. Worn seal

1. Repair or replace inlet line, make

sure ttings are air tight, use Teon

tape if necessary

2. Tighten ttings air tight, use Teon

tape if necessary

3. Straighten hose

4. Submerge inlet hose end

5. Clean inlet

6. Lower pump

7. Remove blockage

8. Replace seal

B. Pump will not start or run 1. Blown fuse

2. Low line voltage

3. Worn brushes

4. Impeller blocked

5. Defective motor

C. Flow rate is too low 1. Piping or hose is kinked or damaged

2. Low line voltage

3. Too much discharge hose friction

D. Seal leaks 1. Worn seal

2. Pump head loose on motor

LIMITED WARRANTY

This product is warranted for one year from the date of purchase or two years

from the date of manufacture, whichever occurs first. Subject to the conditions

hereinafter set forth, the manufacturer will repair or replace to the original

consumer, any portion of the product which proves defective due to defective

materials or workmanship. To obtain warranty service, contact the dealer from

whom the product was purchased. The manufacturer retains the sole right and

option to determine whether to repair or replace defective equipment, parts or

components. Damage due to conditions beyond the control of the manufacturer is

not covered by this warranty.

THIS WARRANTY WILL NOT APPLY: (a) To defects or malfunctions resulting from

failure to properly install, operate or maintain the unit in accordance with printed

instructions provided; (b) to failures resulting from abuse, accident or negligence or

use of inappropriate chemicals or additives in the water; (c) to normal maintenance

services and the parts used in connection with such service; (d) to units which are

not installed in accordance with normal applicable local codes, ordinances and

good trade practices; and (e) the unit is used for purposes other than for what it

was designed and manufactured.

RETURN OF WARRANTED COMPONENTS: Any item to be repaired or replaced

under this warranty must be returned to the manufacturer at Kendallville, Indiana or

such other place as the manufacturer may designate, freight prepaid.

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL OTHER EXPRESS

WARRANTIES, AND MAY NOT BE EXTENDED OR MODIFIED BY ANYONE.

ANY IMPLIED WARRANTIES SHALL BE LIMITED TO THE PERIOD OF

THE LIMITED WARRANTY AND THEREAFTER ALL SUCH IMPLIED

WARRANTIES ARE DISCLAIMED AND EXCLUDED. THE MANUFACTURER

SHALL NOT, UNDER ANY CIRCUMSTANCES, BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES, SUCH AS, BUT NOT LIMITED

TO DAMAGE TO, OR LOSS OF, OTHER PROPERTY OR EQUIPMENT,

LOSS OF PROFITS, INCONVENIENCE , OR OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY TYPE OR NATURE. THE LIABILITY OF

THE MANUFACTURER SHALL NOT EXCEED THE PRICE OF THE PRODUCT

UPON WHICH SUCH LIABILITY IS BASED.

This warranty gives you specific legal rights, and you may have other rights which

vary from state to state. Some states do not allow limitations on duration of implied

warranties or exclusion of incidental or consequential damages, so the above

limitations may not apply to you.

WARRANTY VALID IN CANADA AND MEXICO.

1. If blown, replace with proper sized

fuse or reset breaker

2. If voltage is under 108 volts, check

wiring size

3. Replace brushes

4. Remove blockage

5. Replace pump

1. Clean or replace

2. If voltage is under 108 volts, check

wiring size

3. Shorten and/or increase diameter

of hose

1. Replace seal

2. Insure proper assembly and no

obstructions, tighten bolts

© 2011. All rights reserved.

4

Page 5

Aviso para el instalador: Las instrucciones deben permanecer con la instalación.

Productos de alta calidad desde 1866

La información de producto que

se presenta en este documento

refleja las condiciones existentes

en el momento de publicación.

Consulte con la fábrica en caso de

discrepancias o inconsistencias.

MAIL TO: 95 North Oak Street • Kendallville, IN 46755

(260) 347-1600 • 1 (800) 345-9422 • FAX (260) 347-0909

PumpMate® Bomba

portátil

IMPORTANTE

Salida

FW0393

0611

Supersedes

0909

Entrada

INSTRUCCIONES DE INSTALACIÓN

IL0387

Estas instrucciones de instalación corresponden a las bombas portátiles

de uso general modelo CS511, CF511 y C511.

LISTA DE COMPROBACIÓN PREVIA A LA INSTALACIÓN: PARA TODAS LAS INSTALACIONES

ATENCIÓN: LEA DETENIDAMENTE ESTAS INSTRUCCIONES ANTES DE INSTALAR O UTILIZAR LA BOMBA. PROTÉJASE Y PROTEJA A LOS

DEMÁS OBSERVANDO TODA LA INFORMACIÓN DE SEGURIDAD Y LAS INSTRUCCIONES ADICIONALES PROVISTAS CON EL EQUIPO. EL

INCUMPLIMIENTO DE LAS INSTRUCCIONES PUEDE PROVOCAR LESIONES O DAÑOS MATERIALES. CONSERVE ESTAS INSTRUCCIONES

COMO REFERENCIA.

VEA LA LISTA DE ADVERTENCIAS QUE SE PRESENTA A CONTINUACIÓN

1.

2.

3.

4.

5.

6.

7. Esta bomba ha sido diseñada para usarse únicamente con agua, aunque

8.

Compruebe que la bomba esté conectada a una toma eléctrica

debidamente puesta a tierra. Use un analizador de circuitos

homologado por Underwriters Laboratory para revisar la instalación

correcta del circuito y la puesta a tierra. Todo servicio a los circuitos

o las tomas deberá ser realizado por un electricista certificado y

calificado.

En ningún caso quite la pata de puesta a tierra de la clavija. Si

la pata de puesta a tierra está dañada, reemplace el cordón eléctrico o la clavija antes de usar la bomba.

Todas las instalaciones eléctricas deben cumplir los requisitos del

Código Eléctrico Nacional de EEUU. y de todos los códigos locales.

Recomendamos enfáticamente que la unidad (modelo CS511,

CF511 o C511) sea conectada a un circuito protegido por un interruptor accionado por pérdida de corriente a tierra (GFI).

Desconecte el suministro eléctrico antes de dar servicio a la

bomba o el motor, desconectando la unidad de la toma eléctrica.

No toque el motor mientras está funcionando y permita que el

motor se enfríe antes de tocarlo.

puede utilizarse para añadir anticongelante de glicol de polipropileno a líneas

de calefacción por radiación. No ha sido evaluada para bombear sustancias

químicas.

No use este producto para bombear líquidos inflamables o explo-

sivos.

9.

10.

11. Los modelos CS511, CF511 y C511 tienen un dispositivo de protección contra

sobrecargas térmicas. Este dispositivo se restablece en forma automática y

por lo tanto la bomba puede reencenderse sin advertencia.

12.

13. Asegure la línea de descarga antes de encender la bomba. Una manguera no

asegurada puede latiguear y causar lesiones o daños materiales.

14.

15. No deje funcionando este producto sin supervisión.

16.

17. Este producto contiene sustancias químicas que de acuerdo al estado de

California pueden causar cancer y defectos de nacimiento u otros daños en

la reproducción.

No use este producto en entornos peligrosos ni en lugares donde

una chispa podría encender gases explosivos.

No manipule este producto con las manos mojadas o al estar de pie

en agua o en una superficie mojada o húmeda.

No sumerja la bomba o el motor en agua.

Proporcione un mecanismo de liberación de presión si la línea

de descarga de la bomba puede cerrarse u obstruirse. Las

bombas que funcionan con una línea de descarga cerrada

pueden generar líquido bombeado muy caliente, que puede

provocar quemaduras.

El producto es portátil; no ha sido diseñado para instalarse de

manera permanente al aire libre. Si se instala al aire libre, deberán

tomarse medidas para proteger la unidad de la lluvia y del clima.

La bomba se debe llenar con agua

antes de cebarla.

1. Compruebe que el suministro eléctrico corresponda a los requisitos del equipo,

tal como se especifica en las placas de datos del producto.

2. Revise las mangueras en busca de puntos débiles o desgastados antes de usarlas,

y compruebe que todas las conexiones sean firmes.

3. Inspeccione periódicamente la bomba en busca de daños y lleve a cabo el man-

tenimiento rutinario que se requiera.

© 2011. Reservados todos los derechos.

VEA LA LISTA DE PRECAUCIONES QUE SE PRESENTA A CONTINUACIÓN

4. La temperatura máxima del líquido bombeado no debe exceder 49° C (120° F).

La temperatura mínima permitida es de 4,5° C (40° F).

5. Utilice una malla o un cernidor en la entrada para evitar que entre materia sólida

en la bomba.

6. Para evitar que el interior de la bomba se dañe, se recomienda que la bomba no

funcione durante más de cinco minutos mientras que se intenta cebar la bomba.

1

Page 6

DESCRIPCIÓN

La bomba portátil de uso general ha sido diseñada para usarse como

bomba de transferencia en aplicaciones tales como el vaciado de

calentadores de agua, piscinas, bebederos para ganado, barcos,

etc. La bomba también puede utilizarse como reforzador intermitente

de presión en aplicaciones como lavado de automóviles, limpieza

de entradas, etc. El motor es enfriado por aire. La bomba NO está

diseñada para funcionar debajo del agua.

INSTALACIÓN

IMPORTANTE

condiciones de succión y por lo tanto no pueden emplearse como línea

de entrada, excepto en situaciones de refuerzo de presión.

Las mangueras de jardín típicas se colapsan en

5. Utilice un cernidor al bombear de un arroyo, lago o cualquier fuente

de donde la bomba pueda succionar objetos extraños.

6. Puede utilizar una manguera de jardín normal de 1,9 cm (3/4 de

pulgada) como línea de descarga. Mantenga la longitud total lo más

corta posible para evitar pérdidas excesivas por fricción.

eléctrica antes de instalar la bomba o realizar actividades de servicio

o mantenimiento. Nunca manipule la bomba con las manos mojadas o

si está de pie en agua o sobre una superficie húmeda o mojada, ya que

podría ocurrir una electrocución fatal.

Siempre desconecte la alimentación

1. Se recomienda el uso de un interruptor de circuito accionado por

pérdida de corriente a tierra (GFCI).

Riesgo de electrocución. Esta bomba se

entrega con un conector de puesta a tierra y una clavija de tipo puesta

a tierra. Debe emplearse una toma puesta tierra de conformidad con el

Código Eléctrico Nacional de EE.UU. y los códigos locales (vea la figura

1).

2. Esta bomba funciona con un suministro eléctrico de 115 V, 60 Hz,

CA, una fase.

Riesgo de electrocución fatal. Nunca corte la

pata redonda de puesta a tierra. Si corta el cordón o la clavija, se anulará

la garantía y la bomba no funcionará.

3. En la figura 2 se ilustra una instalación típica. Se proveen

adaptadores roscados para conectar una manguera de jardín si las

condiciones lo permiten. La bomba no debe estar en ningún caso a

más de 4,5 m (15 pies) de altura o distancia de la fuente de entrada.

Se recomienda el uso de una válvula de pie en la línea de admisión.

OPERACIÓN

IMPORTANTE

utilizarse. La operación de la bomba en seco o el bombeo de arena

u otros materiales abrasivos dañarán el sello del eje o el impulsor y

anularán la garantía.

1.

diseñado para instalarse de manera permanente al aire libre. Si

se instala al aire libre, deberán tomarse medidas para proteger la

unidad de la lluvia y del clima.Esta unidad no es a prueba de agua

ni a prueba de la intemperie, y no ha sido diseñada para utilizarse

en duchas, saunas y otros lugares mojados. El motor ha sido

diseñado para utilizarse en un lugar limpio y seco, con acceso a aire

refrigerante suficiente. La temperatura ambiental alrededor del motor

no debe exceder 40° C (104° F).

2. Quite el tapón de cebado y llene la bomba con agua. Vuelva a

colocar el tapón.

IMPORTANTE

instalar una válvula de pie en la línea de admisión. Se recomienda muy

enfáticamente instalar una válvula de pie en las líneas de aspiración que

levantan el agua más de 1,52 metros (5 pies).

3. Conecte el cordón eléctrico a una toma protegida por un interruptor

de circuito accionado por pérdida de corriente a tierra (GFCI). La

bomba se cebará en pocos minutos, dependiendo de la longitud de

la línea de admisión.

La bomba debe llenarse con agua antes de

Para ayudar al cebado de la bomba, puede

El producto es portátil; no ha sido

IMPORTANTE

enrollada o plegada por debajo del nivel del agua.

Longitud máxima de línea de

admisión: 4,57

metros (15 pies)

Asegúrese de que la manguera de admisión NO esté

Llenar con

agua

Entrada

Salida

IL0123

Figura 2

4. La línea de entrada puede ser una tubería galvanizada, una tubería

de plástico o una manguera a prueba de colapso. Las fugas

pequeñas en la línea de admisión reducen considerablemente la

eficiencia de la bomba y pueden impedir el cebado.

© 2011. Reservados todos los derechos.

IMPORTANTE

si después de cinco minutos la bomba no ha comenzado a bombear

el agua, apague la bomba, quite el tapón de cebado, vuelva a llenar la

bomba con agua, reinstale el tapón de cebado y reconecte la bomba.

Para evitar que el interior de la bomba se dañe,

4. Si está reforzando la presión, abra el suministro de agua antes de

encender la bomba. Esta fuerza cebará la bomba. Después conecte

el cordón eléctrico a una toma protegida por un interruptor de

circuito accionado por pérdida de corriente a tierra (GFCI).

5. Desconecte el cordón para apagar la unidad.

MANTENIMIENTO

Deje que la bomba se enfríe al menos 20 minutos

antes de realizar actividades de servicio. El motor puede estar muy

caliente y puede ocasionar lesiones.

1. Periódicamente debe revisarse el funcionamiento correcto de la

bomba.

2

Page 7

Model CF511

T

ota

l

D

ynam

i

c

H

ea

d

-

F

t.

Siempre desconecte el suministro eléctrico antes de

instalar la bomba o de realizar actividades de servicio o mantenimiento.

Si el suministro eléctrico no está a la vista, bloquee y rotule el suministro

en la posición abierta (apagado) para evitar la aplicación inesperada

de la energía eléctrica. El incumplimiento de esta precaución puede

provocar electrocuciones fatales. Esta unidad sólo debe ser reparada por

electricistas calificados. Desconecte el cordón eléctrico de la toma. Una

reparación incorrecta puede causar electrocuciones fatales.

Reemplazo de las escobillas

IMPORTANTE

después de cada 100 horas de uso.

Las bombas con más de 100 horas de uso pueden dejar de funcionar

o no arrancar. Esto puede deberse al desgaste de las escobillas o a la

acumulación de carbón. Quite las escobillas y elimine los residuos de

Las escobillas de la bomba deben inspeccionarse

ESPECIFICACIONES

Motor ................1/2 HP, una fase, 115 V, 60 Hz, 8.000 RPM

Devanado en serie (tipo escobilla), funcionamiento con CA

Temperatura máxima del líquido..................49° C (120° F)

carbón. Las escobillas desgastadas no están cubiertas por la garantía.

1. Desconecte el cordón eléctrico de la toma.

2. Quite los tapones de las escobillas utilizando un destornillador.

3. Quite el conjunto de las escobillas.

4. Coloque un nuevo conjunto de escobillas.

5. Vuelva a colocar los tapones de las escobillas.

Si se presentan otros problemas, consulte la tabla de identificación y

resolución de problemas.

Orificios de entrada y salida .......NPT de 1,9 cm (3/4 de pulgada)

Presión máxima de la caja ...........................100 PSI

Escobilla y

resorte

Tapón de

escobillas

Sello de eje

2

1

Impulsor

Sello en

espiral

Salida

Núm.

Ref. Descripción

Entrada

*El juego contiene un par de escobillas.

IL0142

REPLACEMENT PARTS LIST

Número de

1 Juego de

escobillas*

2 Juego de

impulsor y

sellos

Bomba de

revisión A

Bomba de

revisión B

Cantidad

catálogo

015846 1

020387

150380

requerida

1

Rendimiento

Presión de elevación dinámica

®

120

100

total de la bomba PumpMate

80

60

40

20

Presión de elevación total (pies)

0

0 5 10 15 20 25 30

Caudal (GPH)

Flow - GPM

© 2011. Reservados todos los derechos.

3

IL0153

Page 8

GUÍA DE IDENTIFICACIÓN Y RESOLUCIÓN DE PROBLEMAS

PRECAUCIONES ELÉCTRICAS Antes de dar servicio a la bomba, siempre apague el interruptor eléctrico principal

y desconecte la bomba. Compruebe que no esté de pie en agua y que esté usando calzado con suela protectora. En caso de inundación,

comuníquese con la compañía eléctrica de su localidad o con un electricista certificado para conocer la forma de desconectar el servicio eléctrico

antes de extraer la bomba.

A. La bomba no comienza

a bombear ni permanece

cebada después de que ha

estado

B. La bomba no arranca o no

funciona.

C. El caudal es demasiado

bajo.

D. Fugas en los sellos. 1. Sello desgastado

1. Fuga de aire en la línea de admisión

2. Conectores no apretados

3. Manguera doblada o en bucle

4. Manguera de admisión fuera del agua

5. Entrada obstruida

6. Demasiada elevación de admisión

7. Impulsor bloqueado

8. Sello desgastado

1. Fusible fundido

2. Bajo voltaje de línea

3. Escobillas desgastadas

4. Impulsor bloqueado

5. Motor defectuoso

1. La tubería o manguera está plegada o

dañada

2. Bajo voltaje de línea

3. Demasiada fricción en la manguera de

descarga.

2. El cabezal de bombeo del motor está

suelto

1. Repare o reemplace la línea de admisión. Asegúrese de

que las conexiones sean herméticas; utilice cinta Teflón si

es necesario.

2. Apriete las conexiones hasta que éstas estén herméticas;

utilice cinta Teflón si es necesario.

3. Enderece la manguera.

4. Sumerja el extremo de la manguera de admisión.

5. Limpie la entrada.

6. Baje la bomba.

7. Elimine el bloqueo.

8. Reemplace el sello.

1. Si el fusible está fundido, reemplácelo por otro de tamaño

apropiado o restablezca el cortacircuitos.

2. Si el voltaje es menor que 108 V, revise el calibre del cable.

3. Reemplace las escobillas.

4. Elimine el bloqueo.

5. Reemplace la bomba.

1. Limpie o reemplace.

2. Si el voltaje es menor que 108 V, revise el calibre del cable.

3. Acorte la manguera o aumente el diámetro de ésta.

1. Reemplace el sello.

2. Compruebe que la bomba esté bien armada y sin

obstrucciones; apriete los pernos.

GARANTÍA LIMITADA

La garantía de este producto expirará después de transcurrido el más corto de

los siguientes lapsos: un año contado a partir de la fecha de compra o dos años

contados a partir de la fecha de fabricación. Sujeto a las condiciones establecidas a

continuación, el fabricante reparará o reemplazará al consumidor original cualquier

porción del producto identificada como defectuosa debido a materiales o mano de

obra defectuosos. Para obtener servicio en garantía, acuda al establecimiento donde

fue comprado el producto. El fabricante retiene el derecho y discreción exclusivos

para determinar si se debe reparar o reemplazar un equipo, parte o componente

defectuoso. Daños debidos a condiciones que estén fuera del control del fabricante no

están cubiertos por esta garantía.

ESTA GARANTÍA NO CUBRE: (a) defectos o disfunciones resultantes de una

instalación, operación o mantenimiento de la unidad de una forma diferente a la

establecida en las instrucciones impresas proporcionaadas; (b) fallas producidas

por abuso, accidente o negligencia, o por el uso de productos químicos o aditivos

inapropiados en el agua; (c) servicios de mantenimiento normales así como las partes

usadas en conexión con tales servicios; (d) aquellas unidades que no hayan sido

instaladas de conformidad con los códigos, ordenanzas y buenas prácticas locales

aplicados normalmente en esta industria; y (e) unidades usadas para fines diferentes

a aquéllos para los que fueron diseñadas y fabricadas.

DEVOLUCIÓN DE COMPONENTES GARANTIZADOS: Todo ítem que deba ser

reparado o reemplazado de conformidad con esta garantía deberá ser devuelto, porte

pagado, a la dirección del fabricante en Kendallville, Indiana, EE. UU. o al lugar que

indique el fabricante.

LA GARANTÍA AQUÍ ESPECIFICADA REEMPLAZA TODAS LAS DEMÁS

GARANTÍAS EXPRESAS, Y NO PODRÁ SER EXTENDIDA NI MODIFICADA

POR NADIE. TODA GARANTÍA IMPLÍCITA ESTARÁ LIMITADA AL PERÍODO

DE LA GARANTÍA LIMITADA, MÁS ALLÁ DEL CUAL DICHAS GARANTÍAS

IMPLÍCITAS QUEDARÁN ANULADAS Y EXCLUIDAS. BAJO NINGUNA

CIRCUNSTANCIA EL FABRICANTE PODRÁ SER RESPONSABILIZADO DE

DAÑOS INCIDENTALES, INDIRECTOS O ESPECIALES TALES COMO,

AUNQUE NO TAXATIVAMENTE, PÉRDIDA DE OTRA PROPIEDAD O EQUIPO,

LUCRO CESANTE, INCOMODIDADES U OTROS DAÑOS INCIDENTALES O

INDIRECTOS DE CUALQUIER TIPO O NATURALEZA. LA RESPONSABILIDAD

DEL FABRICANTE NO PODRÁ EXCEDER EL PRECIO DEL PRODUCTO SOBRE

EL CUAL ESTÁ BASADA DICHA RESPONSABILIDAD.

Esta garantía le otorga derechos legales específicos, y usted podría tener también

otros derechos que varían de un estado a otro. Algunos estados no permiten

limitaciones en la duración de las garantías implícitas o la exclusión de daños

incidentales o indirectos, en cuyo caso las limitaciones antes mencionadas podrían no

ser aplicables a su caso.

GARANTÍA VÁLIDA EN CANADÁ Y MÉXICO.

© 2011. Reservados todos los derechos.

4

Page 9

Note aux installateurs : Laissez les instructions sur le lieu de l’installation.

Des produits de qualité depuis 1866 !

Les informations présentées ici

concernant le produit reètent

les dispositions applicables au

moment de la publication. Prière

de consulter l’usine pour toute

incohérence ou contradiction.

PumpMate® Pompe

utilitaire portable

MAIL TO: 95 North Oak Street • Kendallville, IN 46755

(260) 347-1600 • 1 (800) 345-9422 • FAX (260) 347-0909

Sortie

FW0393

0611

Supersedes

0909

Entrée

INSTRUCTIONS D’INSTALLATION

IL0387

Ces instructions d’installation s’appliquent aux pompes utilitaires

portables modèles CS511, CF511 et C511

Il faut remplir la pompe d’eau avant de

l’amorcer.

LISTE DE VÉRIFICATION AVANT INSTALLATION DE TOUTES INSTALLATIONS

ATTENTION : LIRE ATTENTIVEMENT LA NOTICE AVANT D’INSTALLER OU DE FAIRE FONCTIONNER LA POMPE. SE PROTÉGER, AINSI QU’AUTRUI, EN

RESPECTANT TOUTES LES CONSIGNES DE SÉCURITÉ ET INSTRUCTIONS SUPPLÉMENTAIRES COMPRISES AVEC L’ÉQUIPEMENT. LE NON-RESPECT DE

CES INSTRUCTIONS POURRAIT ENTRAÎNER DES BLESSURES CORPORELLES ET/OU ENDOMMAGER LA PROPRIÉTÉ ! CONSERVER CES INSTRUCTIONS

POUR RÉFÉRENCE ULTÉRIEURE.

VOIR LA LISTE DES CONSIGNES DE PRUDENCE CI-DESSOUS

1.

2.

3.

4.

5.

6.

7. Cette pompe a été conçue pour être utilisée uniquement avec de l’eau. Toutefois,

Assurez-vous que la pompe est branchée dans une prise électri-

que correctement mise à la terre. Utilisez un multimètre classé UL

(Underwriters Laboratory) pour vous assurer de la bonne installation

du circuit et de la mise à la terre. Tous les travaux à apporter aux circuits ou aux prises devraient être effectués par un électricien qualifié

agréé.

Ne retirez jamais la broche de mise à la terre de la prise, quelles

que soient les circonstances. Si la broche de mise à la terre est

endommagée, remplacez le cordon d’alimentation ou la prise avant

utilisation.

Toutes les installations électriques doivent être conformes aux exigen-

ces du National Electric Code ainsi que de tous les codes locaux.

Il est fortement recommandé de brancher l’unité (Modèle CS511,

CF511 ou C511) dans un circuit protégé par un interrupteur de défaut

à la terre.

Coupez l’alimentation électrique avant d’effectuer des travaux

sur la pompe ou sur le moteur. Pour cela, débranchez l’unité de la

prise d’alimentation.

Ne touchez pas le moteur lorsqu’il est en marche et laissez le

moteur refroidir avant de la toucher.

on peut l’utiliser pour ajouter de l’antigel au propylèneglycol dans les conduites de

chauffage par rayonnement. Cette pompe n’a pas été évaluée pour le pompage

de produits chimiques.

8.

9.

10.

11. Les modèles CS511, CF511 et C511 sont fournis avec un dispositif de sur-Les modèles CS511, CF511 et C511 sont fournis avec un dispositif de surcharge thermique se remettant automatiquement à zéro. Ils peuvent donc

redémarrer sans prévenir.

12.

13. Attachez le tuyau de refoulement avant de démarrer la pompe. Si le tuyau n’est

pas attaché, il risque de se déplacer et de fouetter, ce qui pourrait provoquer

des blessures corporelles ou endommager la propriété.

14.

15. Ne laissez pas cet équipement fonctionner sans surveillance.

16.

17. Ce produit contient des produits chimiques dont l’état de la Californie a déter-

miner comme étant la cause de cancer et de déficiences à la naissance ou

autres dommages reproductifs.

N’utilisez pas cet appareil pour pomper des liquides inflammables

ou explosifs.

N’utilisez pas cet appareil dans des environnements dangereux

ou dans les endroits où des étincelles pourraient éventuellement

enflammer des gaz explosifs.

Ne touchez pas cet appareil si vous avez les mains mouillées ou

humides, si vous avez les pieds dans l’eau ou si vous vous tenez sur

une surface mouillée ou humide.

Ne submergez ni la pompe ni le moteur.

Prévoyez un moyen de détente de pression si le refoulement de la

pompe peut être coupé ou obstrué. Les pompes dont le refoulement est coupé peuvent chauffer le liquide pompé à des températures très élevées, ce qui peut provoquer des brûlures.

Ce produit est portable. Il n’a pas été conçu pour l’installation per-

manente à l’extérieur. S’il est installé à l’extérieur, le produit doit être

protégé de la pluie et des éléments.

1. Assurez-vous que la source d’alimentation est conforme aux exigences de l’équipement,

tel qu’indiqué sur les plaques signalétiques de l’appareil.

2. Vérifiez les tuyaux pour vous assurer qu’ils ne sont pas usés ou abîmés et vérifiez

que tous les raccordements sont bien connectés.

3. Inspectez régulièrement la pompe pour vous assurer qu’elle n’est pas endommagée

et effectuez l’entretien régulier exigé.

© 2011. Tous droits réservés.

VOIR LA LISTE D’AVERTISSEMENTS CI-DESSOUS

4. La température maximale du liquide pompé ne doit pas être supérieure à 49º C (120°

F). La température minimale admissible est de 4,5º C (40° F).

5. Utiliser un filtre ou une crépine sur l’admission pour éviter que des solides ne pénètrent

dans la pompe.

6. Pour éviter tout dommage interne à la pompe, ne la faites pas tourner plus de cinq

minutes si elle n’a pas été amorcée.

1

Page 10

DESCRIPTION

Cette pompe utilitaire portable est conçue pour être utilisée comme

pompe de transfert dans des applications telles que vider les chauffeeau, les piscines, les bacs pour bétail, les bateaux, etc. La pompe peut

également être utilisée comme appoint intermittent d’accroissement

de pression pour des applications telles que laver les voitures, nettoyer

les allées, etc. Le moteur est refroidi à l’air. Il N’EST PAS conçu pour

fonctionner dans l’eau.

INSTALLATION

Un tuyau d’arrosage normal s’affaissera lors de

l’aspiration et ne devrait par conséquent pas être utilisé sur l’admission,

sauf comme moyen d’accroissement de la pression.

5. Utilisez un filtre lorsque vous pomper l’eau dans un ruisseau, un étang

ou dans une source où des corps étrangers pourraient être aspirés

dans la pompe.

6. Un simple tuyau d’arrosage de 1,9 cm (3/4 po.) peut être utilisé comme

ligne de refoulement. Faites en sorte qu’il soit aussi court que possible

pour éviter des pertes de charge excessives.

d’alimentation avant d’installer, d’effectuer des travaux ou d’entretenir

la pompe. Ne manipulez jamais la pompe avec les mains mouillées ou

si vous vous tenez sur une surface mouillée ou humide. Il existe des

risques mortels d’électrocution.

Débranchez toujours la source

1. Il est recommandé d’avoir un disjoncteur différentiel (GFCI).

pompe est fournie avec un conducteur de mise à la terre et une fiche de

raccordement de type mise à la terre. Il est exigé d’utiliser une fiche mise

à la terre en conformité avec les codes NEC et locaux actuels (voir le

schéma 1).

Il existe des risques d’électrocution. Cette

2. Cette pompe fonctionne sur un courant alternatif de 115 V, 60 Hz,

monophasé.

Il existe des risques mortels d’électrocution.

Ne coupez jamais la broche ronde de mise à la terre. Couper le cordon ou

la prise annulera la garantie et rendra la pompe inutilisable.

3. Le schéma 2 présente une installation type. Des adaptateurs filetés

sont fournis pour attacher un tuyau d’arrosage lorsque les conditions

permettent une telle utilisation. La pompe ne devrait en aucun cas se

situer à plus de 4,50 m (15 pieds) au-dessus ou éloignée de la source

d’alimentation. Il est recommandé d’installer un clapet anti-retour à

pédale sur la ligne d’admission.

Assurez-vous que le tuyau d’aspiration N’EST NI

enroulé ni plié au-dessus ou au-dessous de la surface de l’eau.

Sortie

Remplissez d’eau

FONCTIONNEMENT

Remplir la pompe d’eau avant de l’utiliser. Le

fonctionnement à sec de la pompe ou le pompage de sable ou autres

matières abrasives endommagera le rotor ou le joint d’étanchéité de

l’arbre et annulera la garantie.

1.

conçu pour l’installation permanente à l’extérieur. S’il est installé à

l’extérieur, le produit doit être protégé de la pluie et des éléments.

Cette unité n’est pas étanche et ne peut pas être mise à l’épreuve

des intempéries. Elle n’est donc pas conçue pour être utilisé dans des

douches, saunas ou autres lieux potentiellement mouillés. Le moteur

est conçu pour être utilisé dans des lieux propres et secs offrant

suffisamment d’air de refroidissement. La température ambiante autour

du moteur ne devrait pas dépasser 40°C (104°F).

2. Retirez le bouchon d’amorçage et remplissez la pompe d’eau. Remettez

le bouchon en place.

Pour faciliter l’amorçage de la pompe, un clapet

de pied peut être installé sur la conduite d’aspiration. Il est fortement

conseillé d’utiliser un clapet de pied dans les conduites

d’aspiration d’une hauteur de plus de 1,5 mètre d’eau.

3. Branchez le cordon d’alimentation dans la prise électrique protégé par

le disjoncteur différentiel. La pompe s’amorcera en quelques minutes,

en fonction de la longueur de la ligne d’admission.

Pour éviter tout dommage interne à la pompe

lorsque le pompage de l’eau n’a toujours pas commencé au bout de cinq

minutes, arrêtez la pompe, retirez le bouchon d’amorçage, remplissez de

nouveau la pompe d’eau, remettez le bouchon d’amorçage en place et

redémarrez la pompe.

Ce produit est portable. Il n’a pas été

Longueur

maximale

de conduite

d’aspiration :

4,5 m

IL0123

Entrée

Schéma 2

4. La ligne d’admission peut être une tuyauterie galvanisée, une tuyauterie

en plastique ou un tuyau semi-rigide. De petites fuites sur la ligne

d’admission réduisent considérablement l’efficacité de la pompe et

peuvent empêcher l’amorçage.

© 2011. Tous droits réservés.

4. En cas d’utilisation d’un dispositif d’accroissement de pression, faites

venir l’eau avant de démarrer la pompe. Cette force amorcera la pompe.

Branchez ensuite le cordon d’alimentation dans une prise électrique

protégée par un disjoncteur différentiel.

5. Débranchez le cordon d’alimentation pour éteindre l’unité.

ENTRETIEN

Laissez la pompe refroidir pendant au moins 20

minutes avant d’effectuer des travaux d’entretien. Le moteur pourrait

être extrêmement chaud. Des blessures corporelles pourraient par

conséquent avoir lieu.

2

Page 11

1. La pompe devrait être vérifiée régulièrement pour assurer un bon

Model CF511

T

ota

l

D

ynam

i

c

H

ea

d

-

F

t.

fonctionnement.

Débranchez toujours l’alimentation électrique avant

d’installer ou d’effectuer des travaux d’entretien ou de maintenance sur la

pompe. Si la source d’alimentation électrique n’est pas visible, verrouillez

et étiquetez l’appareil en position ouverte (arrêt) pour empêcher toute

application d’électricité accidentelle. Le non-respect de cette consigne

pourrait entraîner une électrocution. Seuls des électriciens qualifiés

devraient réparer cette unité. Débrancher le cordon électrique de la

source d’alimentation. De mauvaises réparations pourraient entraîner des

électrocutions mortelles.

REMPLACEMENT DES BROSSES

Les brosses de cette pompe doivent être inspectées

après 100 heures de fonctionnement.

Les pompes ayant fonctionné pendant plus de 100 heures peuvent

arrêter de fonctionner ou ne pas démarrer. Cela peut être dû à

SPÉCIFICATIONS

Moteur ........................... 1/2HP, monophasé, 115 V,

60 Hz, 8.000 RPM Fonctionnement au courant alternatif, à enroulement

série (de type brosse)

Température maximale des fluides ................49º C (120° F)

l’usure des brosses ou à une accumulation de carbone. Les brosses

et le carbone devraient être retirés. Les brosses usées ne sont pas

couvertes par la garantie.

1. Débranchez le cordon d’alimentation électrique de la source

d’alimentation.

2. Retirez les capuchons des brosses à l’aide d’un tournevis.

3. Retirez les anciennes brosses.

4. Insérez les nouvelles brosses.

5. Remettez les capuchons en place.

Pour tout autre problème, consultez le tableau de recherche des

causes de pannes.

Ouvertures d’admission / refoulement .........¾ po. (1,9 cm) NPT

Pression de carter maximum .......................100 lb/po2

Brosse /

Ressort

1

Capuchon de

brosse

Joint d’arbre

120

100

80

60

40

Rotor

Sortie

2

Joint en volute

IL0142

Charge dynamique totale

Entrée

LISTE DES PIÈCES DE RECHANGE

Nº de

réf.

* Le kit comprend une paire de brosses.

Description

1 Kit de brosses 015846 1

2 Rotor et kit

d’étanchéité

Nº de

pièce

020387

pompe

révision A

150380

pompe

révision B

Quantité

exigée

1

20

Charge dynamique totale - pi

0

0 5 10 15 20 25 30

Débit – gal/h

Flow - GPM

© 2011. Tous droits réservés.

3

IL0153

Page 12

GUIDE DE RECHERCHE DES CAUSES DE PANNES

PRÉCAUTIONS À PRENDRE – Avant d’effectuer des travaux d’entretien sur une pompe, coupez toujours le disjonc-

teur principal et débranchez la pompe. Assurez-vous que vous ne vous tenez pas dans une flaque d’eau et que vous portez des chaussures à

semelles isolantes. En cas d’inondations, contactez votre compagnie d’électricité locale ou un électricien qualifié agréé pour couper le service

électrique avant de retirer la pompe.

A. Le pompage ne se fait pas ou la

pompe se désamorce après avoir

commencé à tourner.

B. La pompe ne démarre pas ou ne

tourne pas

C. Le débit est trop faible 1. Tuyauterie ou tuyau endommagé ou sale

D. Il existe une fuite au niveau du joint 1. Joint usé

1. Fuite d’air dans la ligne d’admission

2. Raccords desserrés

3. Tuyau plié ou entortillé

4. Tuyau d’admission hors de l’eau

5. Admission bouchée

6. Hauteur d’admission trop élevée

7. Rotor bloqué

8. Joint usé

1. Fusible grillé

2. Tension de ligne faible

3. Brosses usées

4. Rotor bloqué

5. Moteur défectueux

2. Tension de ligne faible

3. Friction trop élevée dans le tuyau de

refoulement.

2. Tête de pompe desserrée sur le moteur

1. Réparez ou remplacez la conduite

d’admission, vérifiez l’étanchéité des

raccords et utilisez du ruban de Téflon si

nécessaire.

2. Resserrez les raccords afin d’assurer une

bonne étanchéité et utilisez du ruban de

Téflon si nécessaire.

3. Déplier le tuyau

4. Mettre l’extrémité du tuyau dans l’eau

5. Nettoyer l’admission

6. Baisser la pompe

7. Retirer ce qui bloque le rotor

8. Remplacer le joint

1. Si le fusible est grillé, le remplacer par

un fusible adéquat ou réenclencher le

disjoncteur

2. Si la tension est inférieure à 108 volts,

vérifier la taille des fils

3. Remplacer les brosses

4. Retirer ce qui bloque le rotor

5. Remplacer la pompe

1. Nettoyer ou remplacer

2. Si la tension est inférieure à 108 volts,

vérifier la taille des fils

3. Réduire la longueur du tuyau et/ou en

augmenter le diamètre.

1. Remplacer le joint

2. S’assurer que le tout est correctement

monté et qu’il n’existe pas d’obstructions.

Serrer les boulons

GARANTIE LIMITÉE

Ce produit est garanti pendant la période expirant la première, un an après la date

d’achat ou deux ans après la date de fabrication. Selon les conditions établies ci-après,

le fabricant réparera ou remplacera pour le client d’origine, toute partie du produit qui

s’est avérée défectueuse à cause d’un défaut de matériau ou de main-d’œuvre. Pour

obtenir un service sous garantie, communiquer avec le détaillant qui a vendu le produit.

Le fabricant se réserve le droit et le choix de déterminer s’il remplacera ou réparera

l’équipement, les pièces ou les composants défectueux. Les dommages résultant de

conditions hors du contrôle du fabricant ne sont pas couverts par cette garantie.

CETTE GARANTIE NE S’APPLIQUE PAS : (a) Aux défauts ou mauvais

fonctionnements résultant d’une installation, d’une utilisation ou d’un entretien incorrects

de l’unité conformément aux instructions imprimées fournies; (b) Aux pannes résultant

d’un abus, d’un accident ou d’une négligence ou de l’utilisation d’additifs ou de produits

chimiques inappropriés dans l’eau; (c) Aux services d’entretien normaux et aux pièces

utilisées dans le cadre de cet entretien; (d) Aux unités qui n’ont pas été installées selon

la réglementation locale et les règles de l’art; et (e) L’unité est utilisée pour des fins autres

que celles pour lesquelles elle a été conçue et fabriquée.

RETOUR DES COMPOSANTS SOUS GARANTIE : Tout article à être réparé ou

remplacé selon les termes de la présente garantie doit être retourné au fabricant, à

Kendalville, Indiana, USA ou à tout autre endroit désigné par le fabricant, port payé.

© 2011. Tous droits réservés.

LA PRÉSENTE GARANTIE REMPLACE TOUTE AUTRE GARANTIE EXPRESSE

ET NE PEUT PAS ÊTRE PROLONGÉE OU MODIFIÉE PAR QUICONQUE. TOUTE

GARANTIE IMPLICITE DOIT ÊTRE LIMITÉE À LA PÉRIODE DE LA GARANTIE

LIMITÉE, ET PAR LA SUITE, TOUTE GARANTIE IMPLICITE SERA REFUSÉE

ET EXCLUE. LE FABRICANT NE DEVRA, EN AUCUNS CAS, ÊTRE TENU

RESPONSABLE DE TOUS DOMMAGES-INTÉRÊTS ACCESSOIRES, INDIRECTS

OU SPÉCIAUX, TELS QUE, MAIS SANS S’Y LIMITER, LES DOMMAGES

OU LA PERTE DE PROPRIÉTÉ OU ÉQUIPEMENT, PERTES DE REVENUS,

INCONVÉNIENTS, OU AUTRES DOMMAGES-INTÉRÊTS ACCESSOIRES OU

INDIRECTS DE QUELQUE NATURE. LA RESPONSABILITÉ DU FABRICANT

NE DOIT PAS DÉPASSER LE PRIX DU PRODUIT SUR LEQUEL UNE TELLE

RESPONSABILITÉ EST BASÉE.

Cette garantie confère à l’acheteur des droits précis et celui-ci peut en avoir d’autres

selon le lieu. Certains états ou provinces ne permettent pas de limiter la durée des

garanties implicites ou l’exclusion des dommages-intérêts accessoires ou indirects,

auquel cas les limitations ci-dessus ne s’appliquent pas.

GARANTIE VALIDE AU CANADA ET AU MEXIQUE.

4

Loading...

Loading...