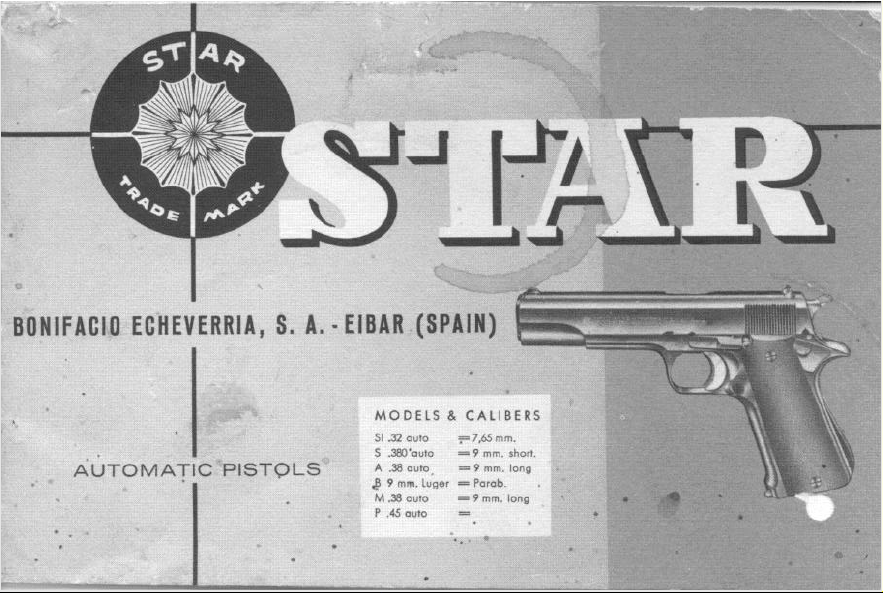

Page 1

Page 2

AUTOMATIC PISTOL

"STAR"

STAR, BONIFACIO ECHEVERRIA, S. A.

EIBAR (SPAIN)

MODELS

SI .32 auto = 7,65 mm.

S. 380 auto = 9 mm. short.

A .38 auto = 9 mm. long

B 9mm. Luger = Parab.

M .38 Auto = 9 mm. long

P .45 auto =

CALIBERS

Page 3

LOADING AND FIRING OPERATION OF STAR PISTOLS

MODELS SI - S - A - B - M & P

TO LOAD THE MAGAZINE

Hold the magazine (53) in the left hand and place a cartridge on the front end

magazine follower (54) until it can be slid in under the lips of the magazine well. Place

another cartridge on top of the first one and force down and slide in. Follow this procedure

until the magazine contains whatever cartridges are to

Insert the magazine in the grip and push in until the magazine catch (28) engages

in its slot in the magazine well.

TO LOAD THE PISTOL

Hold the pistol firmly

guard and grasp the slide (65) firmly at its serrated section with the left hand and draw to

the rear as far as it will go. (If the hammer (06) is cocked before the slide is withdrawn.

the slide will come back much easier because it has less spring tension to overcome.)

Release the slide. The recoil spring (83) pulls it forward. The front breechblock face

of the slide strips the cartridge from

extractor (66) set in the face of the breechblock, snaps into the extracting groove of the

cartridge case.

FIRING OPERATION

Hold the weapon firmly. Pressure on the trigger (19) will free the hammer (06) from

the sear (14) to permit the hammer spring (09) pushing upward on the strut (which is

2

in the right hand with the trigger finger outside the trigger

between the magazine lips and chambers it. The

be used.

of

the

Page 4

attached to the hammer) to rock the hammer forward on its axis (11) to strike the firing

pin (70) mounted in its slot in the slide. The firing pin will fly forward to strike and fire the

cartridge in the chamber.

When the powder in the cartridge case is ignited by the primer it generates a huge

volume of gas. This gas expands in all directions, but as the least resistance is offered

by the bullet directly ahead of it, it starts the bullet down the barrel

following along after it during its travel. Meanwhile, the outward thrust of the gases press

the brass cartridge case firmly against the walls of the firing chamber, preventing gas

from leaking back past the cartridge case.

The backward thrust of the gases inside the cartridge case press the case back

against the breechblock which, in these pistols, is part of the slide.

The barrel and slide are locked together

which engage slots in the underside of the slide. They remain securely locked together

during the moment of high breech pressure. They go back for a short distance firmly

locked together.

As the bullet leaves the barrel and the chamber pressure falls to safe limits, the

resilient brass case contracts to its normal size, moving

chamber. The barrel, swinging backwards on its link, which is firmly attached to the frame

by the slide stop pin passing through it, is forced downward by the continuing rearward

motion. The rear of the barrel strikes against its stop in the frame and its reaward action

is halted: while the slide continues on backwards in a straight line in its grooves in the

frame. The extractor, mounted in the breechblock face, carries the empty cartridge case

out of the firing chamber with it.

When the breechblock end of the slide passes completely over the mouth of the

magazine below, the ejection port in the right-hand side of the slide is fully exposed.

by

the locking ribs on the top of the barrel

away

(61),

the gas pressure

from the walls of the firing

Page 5

At thispoint the cartridge case strikes against the ejector in the frame which frees it from

the extractor and hurls it out the right-top-side of the pistol.

The barrel bushing (78) around the muzzle of the barrel, which also locks and

supports the recoil spring plug (84), presses back against the plug to compress the recoil

spring (83) below the barrel over the recoil spring guide (80). This stores up energy for

return movement of the slide.

The momentum of the slide strikes the hammer a sharp blow, driving it back to the

full-cock position where the sear spring (16) forces the point of the sear (14) into the

notch on the hammer to hold it at full-cock.

As the hammer (06) rocks back on its axis (11), it forces down the strut which is

attached to it and the bottom of the strut, being mounted in the hammer spring plunger

(10) above the hammer spring (09) in the grip, thrust downward to compress the hammer

spring to provide energy for the next forward motion of the hammer.

At the first rearward motion of the slide, the beveled niche in the underside of

the slide exerts pressure on the rounded head of the interrupter (25), forcing it down

against the sear bar (23) to diesengage it from the tail of the sear (14) while finger

pressure on the trigger is maintained.

The fore-end of the sear bar (23) presses against the trigger plunger (22) which

returns the trigger to firin position, under the pressure of its spring (21) to permit

engagement of the sear (14) when the slide next goes forward to the fully closed position

and finger pressure on the trigger is momentarily released.

The magazine spring (56) forces the follower (54) up, pressing the cartridges inside

the magazine well against the magazine retaining lips so that the head of the top cartridge

is in direct line with the breechblock which will strip it forward into the firing chamber

when the slide again goes forward.

4

Page 6

When the magazine has been emptied, the slide stop (41) engages the slide and

holds it open, thus serving as an indicator to remind the shooter that the empty magazine

must be replaced by a loaded one.

Pressing down the slide stop will depress the magazine follower and permit the

slide to go forward. If a loaded magazine is inserted before the slide stop is depressed,

this forward motion of the slide will load the firing chamber, leaving the pistol ready for

inmediate action.

SAFETIES

A thumb safety (36) is provided, which when at its topmost position, positively locks

the hammer and slide.

TO DISASSEMBLE THE PISTOL FOR CLEANING PURPOSES

First, check to be sure that there is no cartridge left in the firing chamber. Depress

1.

the magazine catch button (29) on the left side of the pistol back of the trigger, and

withdraw magazine.

2.

Push the recoil spring plug (84) below the barrel muzzle inward with the index finger

of the right hand (or butt of magazine) far enough to permit the barrel bushing (78)

which locks the barrel to be turned to the right until the plug goes forward under

the tension of the recoil spring. (Care should be taken not to let the plug to jump

away). (See fig. 3 and 4).

Page 7

3.

Cock the hammer. Pull the slide back until the rear edge of the smaller recess in the

lower edge of the slide is even with the rear end of the slide stop. Press the index

finger of the right hand against the end of the slide stop which protudes from the

opposite side of the frame obove the trigger guard and pull out the slide stop

(See fig. 5).

4.

As this slide stop is the medium by which the barrel link and slide are locked to the

frame, withdrawing it releases the barrel and slide assembly, which may then together

be drawn from the frame, carrying also the recoil spring, recoil spring guide and

barrel bushing. (See fig. 6).

5.

The barrel bushing, recoil spring and its guide may now be pulled out of the slide.

(See fig. 7).

6.

The barrel

This is all the disassembling necessary to properly clean the pistol.

may

then be drawn out if the link is tilted forward (See fig. 8).

TO REASSEMBLE THE PISTOL AFTER CLEANING

Reverse this procedure. When replacing slide on frame, pull slide back so that the

barrel link lines up with the hole from which the slide stop was removed.

6

Page 8

Fig, 1

Fig.

2

7

Page 9

Page 10

Page 11

i’

RECESS

SLIDE

SLIDE

STOP

REAR END OF SLIDE STOP

Fig. 5

10

Page 12

BARREL LINK

Page 13

8

Fig, 7

12

Page 14

Fig. 8

13

Page 15

IMPORTANT INSTRUCTIONS FOR BEST PERFORMANCE OF THE PISTOLS

1.

All moving parts should be lightly oiled.

Clean the barrel and chamber after firing. The barrel and chamber should be cleaned

2.

from the breech avoid cleaning from the muzzle. Always wipe off the exterior of the

pistol after use with a slightly oily cloth to protect the finish.

3.

Use only standard loads for which the pistol is designed and make sure that the bore

is free from obstructions before loading and shooting.

4.

Care should be taken to prevent the magazine from being dented or otherwise damaged.

NOTE: DO NOT POINT THE PISTOL, LOADED OR UNLOADED, AT ANYTHING YOU DO

NOT WANT TO SHOOT.

COMPLETE DISASSEMBLY OF THE PISTOL

Follow the same procedure as by disassembly for cleaning purposes.

Note: All the pins are removed from left to right, except the trigger pin which comes out

to the left.

Remove grips (95 & 96b) unscrewing the four screws (97).

Holding the pistol in the left hand, depress the magazine catch button (29) with the

index finger of the same hand far enough inwards to permit the catch lock (28) to be

turned to the left by means of the cleaning rod. The complete magazine catch assembly

may now be removed from the frame.

Page 16

Remove pin (20) from the trigger (19) and both pieces will come out without difficutly,

together with the sear bar (23) and interrupter (25), when pulling it downwards.

To remove the sear bar (23) from the trigger (19), push the sear bar pin out, thus

freeing it as well as the trigger plunger (22) and its spring (21).

Remove sear pin (15) and this will free the sear spring (16).

Using a copper or brass punch, drive out the hammer pin (11) from right to left from

the hammer (06). This releases both the spring (09) and plunger (10).

Withdraw the thumb safety (36), grasping the thumb piece and turning to the right,

lift it up. Care should be taken to let the plunger (38) and its spring (39) jump away when

released.

The slide stop (41) has a pin which when removed frees the retaining plunger and its

spring.

The extractor (66) may now be removed, pushing the pin (67) from below upwards.

This frees the spring (69).

Remove the rear sight (74) from right to left, drifting slightly with a copper punch.

Push the retaining pin (71) of the firing pin (70) upwards from the slide and tilting the

slide release this piece and its spring (72).

TO REASSEMBLE THE PISTOL

Reverse the beforementioned procedure.

Page 17

Page 18

CHART OF POSSIBLE FIRING INTERRUPTIONS

CAUSES

1. Failure of feeding:

May be due to magazine not fully inserted into the grip or to magazine

dents.

a Magazine blown. 2.

2. Failure to fire.

a Defective cartridge which prevent com-

plete locking of the pistol.

b Built-up residue in the firing chamber.

c Firing Pin broken.

d Defective cartridge primer.

3. Failure of extraction:

a Cartridge has insufficient gas pressure,

thus preventing complete backwards

stroke of the slide.

b Cartridge head (rim) broken.

c Defective extractor.

d Cartridge or case remains pressed

between breechblock and chamber.

1.

a Remove dent on magazine

a Replace the cartridge.

CORRECTIONS

Push the magazine completely into the

and

magazine is

b Disassemble the pistol and clean the

firing chamber thoroughly.

May be caused by excessive dry firing.

c

Replace firing pin.

d Remove defective cartridge.

3.

a Remove cartridge case.

b Remove cartridge case.

c Replace the extractor.

d

Draw the slide completely backwards

and while holding it back, push the

slide stop up to engage in the notch on

the slide. (Care should be taken to

prevent

with the gun). Remove magazine and

withdraw cartridge or case.

faulty,

any casualty

correct same.

while operating

if the

Page 19

“STAR“ PISTOL PARTS

Page 20

COMPONENT PARTS OF THE “STAR” PISTOL

Part N.º

01 Frame with Ejector,

06 Hammer with Strut and Pin.

09 Hammer Spring.

10 Hammer Spring Plunger.

11 Hammer Pin.

14 Sear.

15 Sear Pin.

16 Sear Spring.

19 Trigger.

20 Trigger Pin.

21 Trigger Plunger Spring,

22 Trigger Plunger.

23 Sear Bar.

25 Interrupter.

28 Magazine Catch Button.

29 Magazine Catch Lock.

30 Magazine Catch Lock Spring,

36 Safety thumb.

38 Safety Spring Plunger.

39 Safety Plunger Spring.

FOR REPLACEMENT PARTS SEE THE DEALER WHO SOLD YOU THIS GUN.

When ordering parts, please state model of pistol and its serial number.

Part N.º

41 Slide Stop.

53 Magazine Tube with Floor Plate.

54 Magazine Follower.

56 Magazine Spring.

61 Barrel with Link and Pin.

65 Slide with Front Sight.

66 Extractor.

67 Extractor Pin.

69 Extractor Spring.

70 Firing Pin.

71 Firing Pin Retainig Pin,

72 Firing Pin Spring.

74 Sight, rear.

78 Barrel Bushing.

80 Recoil Spring Guide.

83 Recoil Spring

84 Recoil Spring Plug.

92 Swivel.

95. Grip, right

96 Grip, left.

97 Grip Screw

Page 21

Page 22

BONIFACIO ECHEVERRIA, S. A.

EIBAR (SPAIN)

Loading...

Loading...