Page 1

Star

Manufacturing

International Inc.

10 Sunnen Drive

St. Louis, MO 63143

Phone: (314) 678-6303

Fax: (314) 781-2714

2M-Z7906 Rev. B 8/25/11

Installation

and

Operating

Instructions

ULTRA-MAX GAS RADIANT CHARBROILER

MODELS

8124RCB, 8136RCB,

8148RCB, 8160RCB, and 8172RCB

ULTRA-MAX GAS LAVA ROCK CHARBROILER

MODELS

8024CB, 8036CB,

8048CB, 8060CB, and 8072CB

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read

the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

FOR YOUR SAFETY: Do not store or use

gasoline or other ammable vapors or liquids

in the vicinity of this or any other appliance.

WARNING: This appliance shall be installed

in accordance with current regulations and

used only in well-ventilated space. Refer to

instructions before installing and using this

appliance.

In addition, there should be posted, in a

prominent location, detailed instructions to

be followed in the event the operator smells

gas. Obtain the instructions from the local

gas supplier.

1

Page 2

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

Page 3

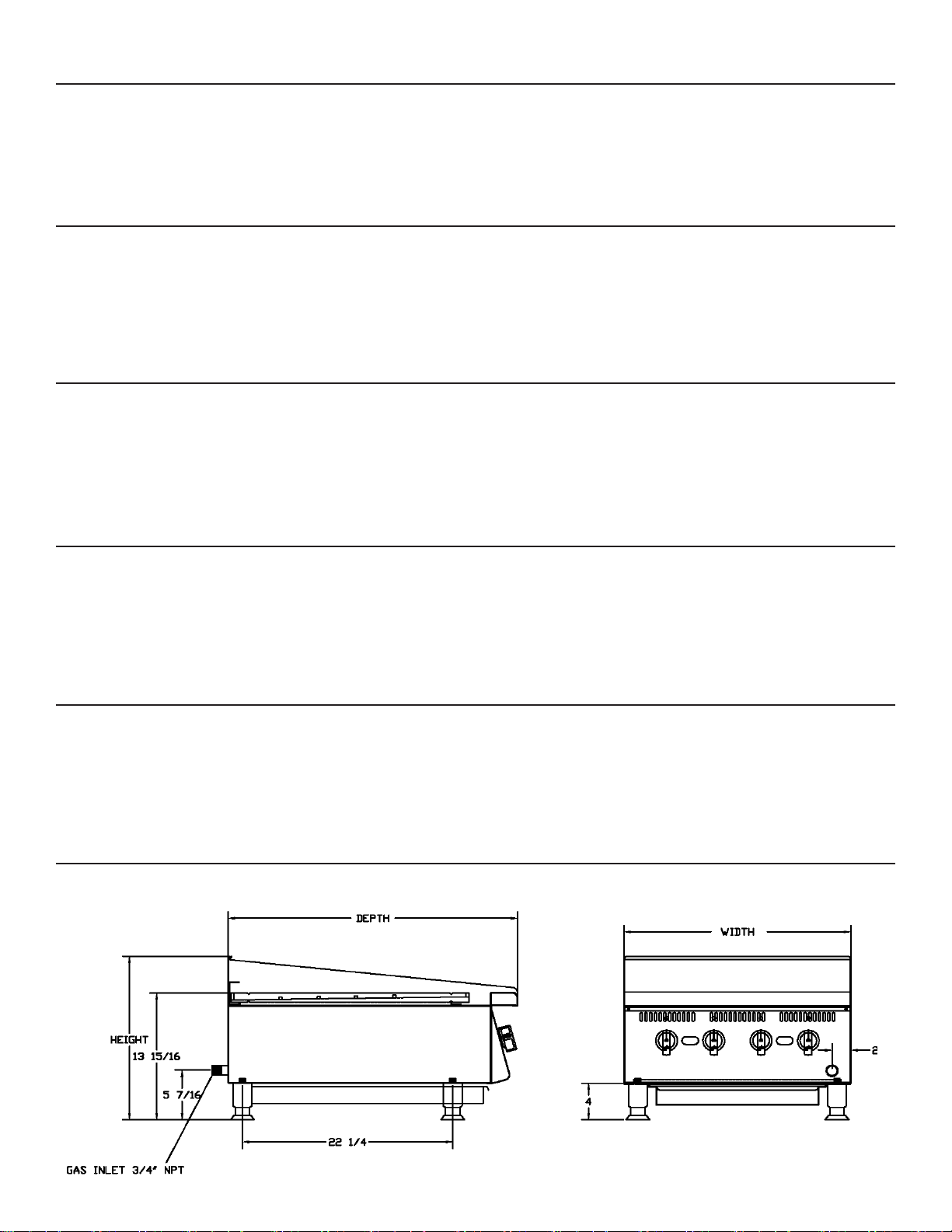

SPECIFICATIONS

8124RCB - Radiant, 8024CB - Lava Rock

Type: Manual Control

4 Controls, 80,000 BTUH (20,000 BTUH Nat/LP per burner)

603 sq. in. (3,890 sq. cm) Grid Area

Approximate Weight: Installed - 174 Lb s (78.9 kg), shipping - 240 Lbs (108.9 kg)

Dimensions: 24" - Width, 30 5/8" - Depth, 18" - Height

(61 cm - Width, 77.8 cm - Depth, 45.7 cm - Height)

8136RCB - Radiant, 8036CB - Lava Rock

Type: Manual Control

6 Controls, 120,000 BTUH Total (20,000 BTUH Nat/LP per burner)

906 sq. in. (5,845 sq. cm) Grid Area

Approximate Weight: Installed - 240 Lbs (108.9 kg), shipping - 316 Lbs, (143.3 kg)

Dimensions: 36" - Width, 30 5/8" - Depth, 18" - Height

(91.4 cm - Width, 77.8 cm - Depth, 45.7 cm - Height)

8148RCB - Radiant, 8048CB - Lava Rock

Type: Manual Control

8 Controls, 160,000 BTUH Total (20,000 BTUH Nat/LP per burner)

1,209 sq. in. (7,800 sq. cm) Grid Area

Approximate Weight: Installed - 314 Lbs (142.4 kg), shipping - 398 Lbs, (180.5 kg)

Dimensions: 48" - Width, 30 5/8" - Depth, 18" - Height

(122 cm - Width, 77.8 cm - Depth, 45.7 cm - Height)

8160RCB - Radiant, 8060CB - Lava Rock

Type: Manual Control

10 Controls, 200,000 BTUH Total (20,000 BTUH Nat/LP per burner)

1,512 sq. in. (9,754 sq. cm) Grid Area

Approximate Weight: Installed - 386 Lbs (175.1 kg), shipping - 486 Lbs, (220.4 kg)

Dimensions: 60" - Width, 30 5/8" - Depth, 18" - Height

(152.4 cm - Width, 77.8 cm - Depth, 45.7 cm - Height)

8172RCB - Radiant, 8072CB - Lava Rock

Type: Manual Control

12 Controls, 240,000 BTUH Total (20,000 BTUH Nat/LP per burner)

1,815 sq. in. (11,710 sq. cm) Grid Area

Approximate Weight: Installed - 530 Lbs (240 kg), shipping - 665 Lbs, (301 kg)

Dimensions: 72" - Width, 30 5/8" - Depth, 18" - Height

(182.9 cm - Width, 77.8 cm - Depth, 45.7 cm - Height)

3

Page 4

CAUTION

GENERAL INSTALLATION DATA

CAUTION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home

nor for use directly by the general public in food service locations.

The Ultra-Max™ series gas charbroiler is equipped for the type of gas indicated on the

nameplate mounted on the front panel. All units are shipped from the factory for use with

natural gas. The unit can easily be converted for use with propane gas: see propane

gas.

-IMPORTANTBe sure to remove all paper protection and packing material from unit prior to

lighting.

INSTALL IN NON-COMBUSTIBLE LOCATIONS ONLY! Clearance from noncombustible construction must be 3" minimum from back and sides. For servicing,

6" is recommended from back of unit.

The installation of the Appliance must conform to the NATIONAL FUEL GAS

CODE "ANSI Z223.1 - LATEST EDITION" AND ALL LOCAL GAS COMPANY

RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE

CURRENT CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE OR CAN/

CGA-B149.2 PROPANE INSTALLATION CODE AND LOCAL CODES WHERE

APPLICABLE.

NOTICE

When this appliance is installed with casters, it must be installed with the casters supplied, a

connector complying with either ANSI Z21.69 or CAN/CGA-6.16 and a quick-disconnect device

complying with either ANSI Z21.41 or CAN1-6.9. It must also be installed with restraining means to

guard against transmission of strain to the connector, as specied in the appliance manufacturer's

instructions.

For your protection, we recommend a qualied installing agency install this appliance.

They should be familiar with gas installations and your local gas requirements. In any

case, your gas company should be called to approve the nal installation.

This appliance, its pressure regulator and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of that system at test pressures

in excess of 1/2 PSIG. This appliance and its pressure regulator must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than 1/2 PSIG.

EXHAUST CANOPY

Open hearth broilers inherently create a good deal of heat and smoke and should be installed

under an efcient exhaust hood with ame proof lters. A vertical distance of not less than 48"

shall be provided between the top of the appliance and lters or any other combustible material.

Exhaust installation must conform to local codes.

CAUTION

AIR SUPPLY

Provisions for adequate air supply must be provided.

CAUTION

Air for combustion enters from the bottom of the unit. Do not obstruct this area.

4

Page 5

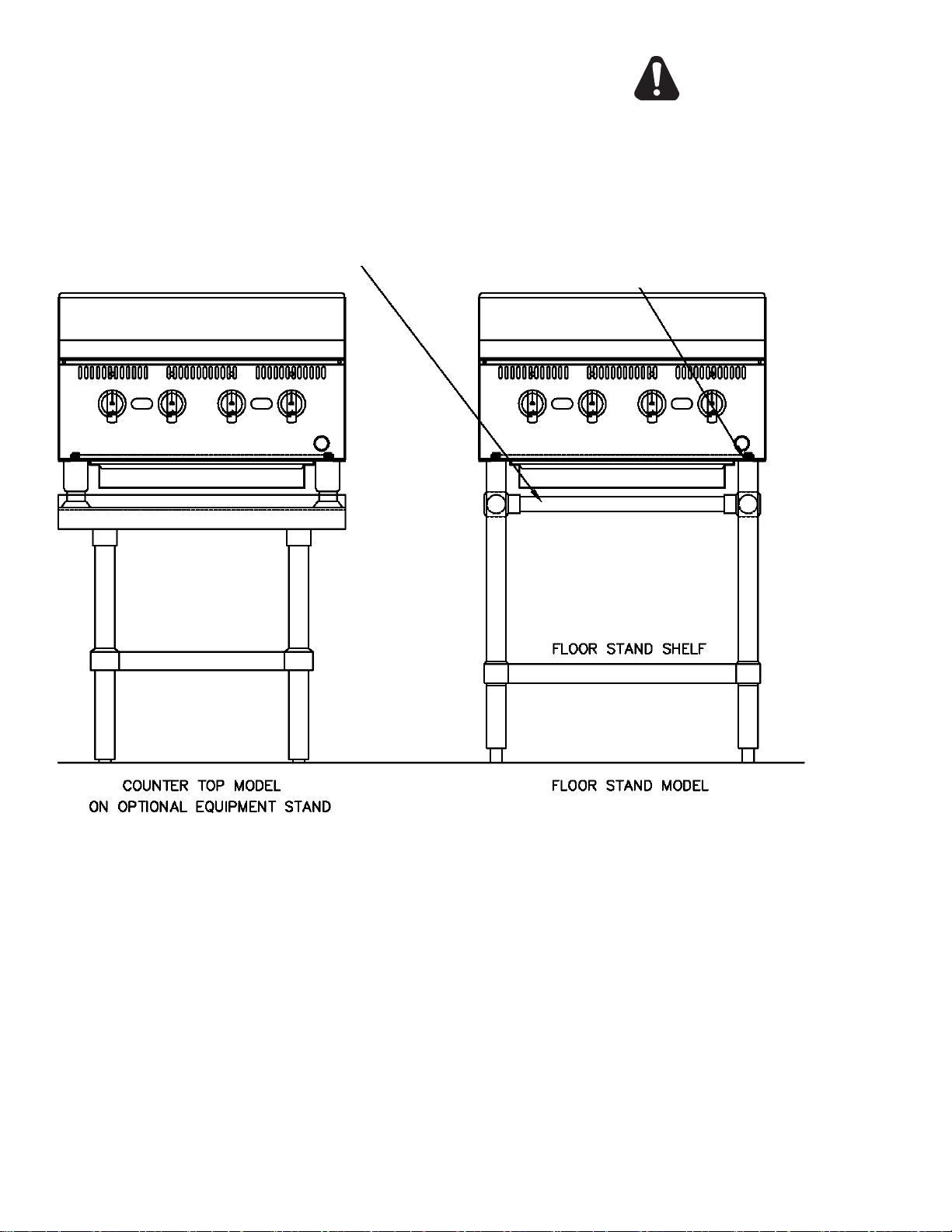

LEVELING UNIT

This charbroiler is supplied with 4 feet or oor stand

legs which must be screwed into the body. Unit must

be level. Level unit by adjusting the (4) feet which

have an adjustment of 1-3/4" for accurate and perfect

line-up with other units.

STIFFENING SUPPORTS ON 8148, 8160,

AND 8172 MODELS ONLY

CAUTION

DO NOT INSTALL WITHOUT ATTACHING FEET

OR SUPPLIED STAND LEGS AND SHELF - DO

NOT REMOVE FEET.

SCREW LEGS INTO MOUNTING NUTS ON BOTTOM

Caster Kits: Casters can be used with oor stand models or optional equipment stand. For installation, carefully

mark and cut off from the bottom of each leg using a straight cutting saw and de-burr the inside tube wall prior

to installing the caster. Cut leg should measure 19" tube length, not overall length. Casters add about 6-1/4" of

height to the unit. Be sure to use approved strain relief means for protecting gas line connection. If an appliance

is equipped with casters and is gas connected with a quick connect coupling, all personnel must be aware that

there is a restraint on the appliance and if disconnected for service or cleaning it must be reconnected as originally

installed prior to use.

5

Page 6

GENERAL INSTALLATION DATA (continued)

PLACING RADIANTS - RCB SERIES

After the unit is unpacked and installed, place 1 radiant above each burner. Install each radiant

on 2 slots of the rear wall and on 1 pin of the front wall of the liner weld assembly. Refer to the

exploded view in this manual for orientation of the radiants.

PLACING LAVA ROCKS- CB SERIES

Open the lava rock bags and place rock evenly on the lower internal grates - not the top cooking

grates. Spread the lava rock evenly on the grates approximately 1 layer thick. Do not cover

the grates with more than two layers of lava rock. Do not put more than 5 pounds of rock per

burner section.

GAS PIPING

Gas piping shall be of such size and so installed as to provide a supply of gas sufcient to meet

the full gas input of the appliance. If the appliance is to be connected to existing piping, it shall

be checked to determine if it has adequate capacity. Joint compound shall be used sparingly and

only on the male threads of the pipe joints. Such compounds shall be resistant to the action of

L.P. gases. WARNING: Any loose dirt or metal particles which are allowed to enter the gas lines

on this appliance will damage the valve and affect its operation. When installing this appliance,

all pipe and ttings must be free from all internal loose dirt.

GAS PRESSURE REGULATOR

A convertible pressure regulator is provided with each charbroiler. It should be connected to the

inlet pipe at the rear of the unit. The gas supply is then connected to it. The supply pressure to

the regulator is not to exceed 1/2 PSIG. It is shipped set for 5" water column manifold pressure

for use with natural gas.

MANUAL SHUT OFF VALVE

A manual shut off valve should be installed upstream from the manifold and within six feet of

the charbroiler.

CONNECTING GAS SUPPLY LINE

The gas inlet of the charbroiler is sealed at the factory to prevent entry of dirt. Do not remove

this seal until the actual connection is made to the gas supply line.

PROPANE GAS - CONVERSION

This charbroiler is equipped with xed orice hoods and is shipped from the factory for use with

natural gas. To convert to propane gas, install the burner orice hoods, located in the water

pan, as follows:

1. Remove grates, radiants and burners.

2. Remove the burner orice hoods and install the orice hoods supplied.

3. Replace the burners, radiants, and grates.

4. Set manifold pressure to (10) inch water column. A 1/8" pipe plug on the burner manifold

can be removed for attaching a pressure gauge. Remove the slotted, or hex-threaded plug

from the pressure regulator. Invert the plug and re-install. The letters "LP" should now be

visible on the plug. The regulator is now set for 10" (25.4 cm) water column. Attach the

conversion label, supplied with the unit, close to the nameplate.

CHECKING FOR GAS LEAKS

Check entire piping system for leaks. Soap and water solution or other material acceptable for

the purpose, shall be used in locating gas leakage.

CAUTION

CAUTION

Matches, candle ame or other sources of ignition shall not be used for locating

gas leaks.

6

Page 7

PILOT LIGHTING INSTRUCTIONS

The charbroiler is equipped with standing pilots, and should be lit immediately after the gas is

turned on.

1. Turn off main valve to unit.

2. Turn off all knobs and pilot valves and wait 5 minutes to clear gas.

3. The pilot lights on this broiler have been pre-set at the factory. Turn the adjustable screw

counterclockwise to open and clockwise to close.

4. Turn on main valve and light all pilots.

5. Adjust pilot light ames as small as possible, usually about 1/2" high, but high enough to

light burner immediately when burner valve is turned on high.

6. Turn burner knobs to desired setting.

7. To turn burners off, turn knobs off.

BURNER IGNITION AND ADJUSTMENT

1. To ignite burners turn burner valve knob counter clockwise to "ON"position.

2. Slowly decrease openings of air shutters to give a soft blue ame having luminous tips,

then slowly increase openings to a point where the yellow tips disappear and a hard blue

ame is obtained.

GENERAL OPERATING INSTRUCTIONS

WATER PAN

The water pan is located at the bottom of the unit, and is easily removed from the front of the

unit. Water should be added to the water pan to just cover bottom and replaced as necessary.

The water pan helps prevent are ups and catches grease.

BURNER OPERATION

Each burner is controlled by an individual high-low, on-off valve. A variety of broiling temperatures

may be obtained by turning the burner valve knob to any position between on and off. It is

possible through this arrangement to have a high heat or searing section, while having a low heat

nishing or holding section. For the searing operation, turn the valve counter clockwise for the

section to a position of "ON" or close to it. For holding or nishing, turn the valves closer to the

"OFF" position on the dial. You select the heat pattern you like, and set the valves accordingly.

Be sure burners are staying fully lit when set in low positions.

LIGHTING

When broiler is rst lit, it will smoke for approximately 20-30 minutes until the preservation

oils and impurities are burned off.

BROILING

Turn valves on and pre-heat unit on "ON" before attempting to broil. You will have to

experiment with the grate settings and the valve settings for your particular food products.

Check water pans frequently and add a sufcient amount of water when necessary. Hot

water vapors rising from the water pans and through the combustion chamber helps

reduce are ups. Exercise care when using your broiler.

TILTING THE GRATE

Raise or lower the grate to the next step by lifting the grate at the back of the charbroiler

where the grate rests. Use potholders or gloves to reposition.

7

Page 8

CAUTION

CAUTION

CHARBROILERS ARE HOT! NEVER ATTEMPT TO CHANGE THE GRATE

POSITION WHILE FOOD PRODUCTS ARE COOKING. FLARE UPS CAN OCCUR

UNEXPECTEDLY. TURN OFF CHARBROILER, AND ALLOW THE CHARBROILER

TO COOL.

SHUTTING DOWN INSTRUCTIONS

Turn the burner valve knobs to the off position to turn burners off and close manual valve gas

shutoff.

CLEANING

Clean regularly. Remove grate section to sink for washing. Brush out carboned particles.

Remove and wash water pan. Wipe exterior surfaces with detergent and a cloth. A nonabrasive cleaner can be used on caked areas.

8

Page 9

2M-4497-2 6/1312

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

Visit our Website at: www.star-mfg.com Email: service@star-mfg.com

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in which

the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the transportation

company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of the unit.

LIMITED EQUIPMENT WARRANTY

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the Ultra-Max, Hot Plates, Griddles, Charbroilers is (3) years parts & labor.

* The warranty period for the Star-Max, Charbroilers, Griddles, Hot Plates, Fryers & Finishing Oven is (2) years parts & labor.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is ve (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners, abrasive pads, product identiers and

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted, the labor to replace the part is NOT warranted.

SERVICES NOT COVERED BY WARRANTY

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16. Replacement of bulbs

17. Replacement of fuses

18. Repair of damage created during transit, delivery, &

installation OR created by acts of God

* The Model 510FD, 510FF Fryer.

* The Model 526TOA Toaster Oven.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model 518CMA & 526CMA Cheese Melter.

* The Model 12MC & 15MC & 18MCP Hot Food Merchandisers.

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* All QCS/RCS Series Toasters except Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

9

Page 10

1

2

6

5

USED ONLY ON 48",

60" & 72" MODELS

4

12

15

13

10

11

9

3

7

16

14

17

18

8B

8A

STAR MANUFACTURING INTERNATIONAL, INC.

CERTAIN INSTANCES MAY NOT BE AVAILABLE

ILLUSTRATIVE PURPOSES ONLY AND IN

SOME ITEMS ARE INCLUDED FOR

MODEL:

SK1865 REV. C 5/9/06

8124RCB, 8024CB

8136RCB 8148RCB

8160RCB 8172RCB

8036CB 8048CB

8060CB 8072CB

10

Page 11

PARTS LIST August 25, 2011, Rev B

8124/8136/8148/8160/8172 Ultra-Max Radiant Gas Charbroiler

8024/8036/8048/8060/8072 Ultra-Max Lava Rock Gas Charbroiler

MODEL

Number

Key

Number

1 2R-Z4997 4/6/8/10/12 KNOB ALL

2 H5-CB0012 1 FRONT PANEL ASSEMBLY 8124, 8024

H5-CB0013 1 FRONT PANEL ASSEMBLY 8136, 8036

H5-CB0014 1 FRONT PANEL ASSEMBLY 8148, 8048

H5-CB0015 1 FRONT PANEL ASSEMBLY 8160, 8060

H5-CB0063 1 FRONT PANEL ASSEMBLY 8172, 8072

3 H5-Z4743 1/2 PAN, WATER 8124, 8024 / 8148, 8048

H5-Z4744 1 PAN, WATER 8136, 8036

H5-Z4746 2 PAN, WATER 8160, 8060

H5-Z4744 2 PAN, WATER 8172, 8072

4 H5-Z4856 1 PAN SUPPORT BRACKET 8148, 8048, 8160, 8060, 8172, 8072

5 2A-Z4614 4 FOOT (5/8-11 STUD) ALL

6 2K-Z4755 1 MANIFOLD PIPE 8124, 8024

2K-Z4756 1 MANIFOLD PIPE 8136, 8036

2K-Z4757 1 MANIFOLD PIPE 8148, 8048

2K-Z4758 1 MANIFOLD PIPE 8160, 8060

2K-Z7798 1 MANIFOLD PIPE 8172, 8072

7 2J-Z4686 1 REGULATOR ALL

8A 2F-Z4685 4/6/8/10/12 BURNER 8124 / 8136 / 8148 / 8160 / 8172

8B H5-CB0064 4/6/8/10/12 BURNER ASSEMBLY 8024 / 8036 / 8048 / 8060 / 8072

9 2F-Z4693 4/6/8/10/12 RADIANT 8124 / 8136 / 8148 / 8160 / 8172

10 2V-Y8832 4/6/8/10/12 GAS VALVE ALL

11 2J-Y7216 4/6/8/10/12 HOOD BURNER ORIFICE #47 NAT. ALL

2J-Y7250 4/6/8/10/12 HOOD BURNER ORIFICE #55 LP ALL

12 2V-Z4736 4/6/8/10/12 PILOT TUBE ALL

13 2V-6671 4/6/8/10/12 PILOT VALVE ALL

14 2F-Z4692 4/6/8/10/12 TOP GRATE (5-7/8 W x 25-1/4 L) ALL

15 2M-Z4751 1 CONTROL LABEL 8124, 8024

2M-Z4752 1 CONTROL LABEL 8136, 8036

2M-Z4753 1 CONTROL LABEL 8148, 8048

2M-Z4754 1 CONTROL LABEL 8160, 8060

2M-Z7799 1 CONTROL LABEL 8172, 8072

16 H5-Z4726 1 BURNER SUPPORT BRACKET 8124, 8024

H5-Z4727 1 BURNER SUPPORT BRACKET 8136, 8036

H5-Z4728 1 BURNER SUPPORT BRACKET 8148, 8048

H5-Z4729 1 BURNER SUPPORT BRACKET 8160, 8060

H5-Z7790 1 BURNER SUPPORT BRACKET 8172, 8072

17 2F-Z7802 2/1/1 LAVA ROCK GRATE 10-1/2" 8024 / 8036 / 8048

2F-Z7803 2/3/5/6 LAVA ROCK GRATE 11-3/8" 8036 / 8048 / 8060 / 8072

18 H5-Z7826 1 FRONT SUPPORT BRACKET 8024

H5-Z7827 1 FRONT SUPPORT BRACKET 8036

H5-Z7828 1 FRONT SUPPORT BRACKET 8048

H5-Z7829 1 FRONT SUPPORT BRACKET 8060

H5-Z7830 1 FRONT SUPPORT BRACKET 8072

-- E5-UM24SF 1 FLOOR STAND 24" (optional, not shown) 8124, 8024

-- E5-UM36SF 1 FLOOR STAND 36" (optional, not shown) 8136, 8036

-- E5-UM48SF 1 FLOOR STAND 48" (optional, not shown) 8148, 8048

-- E5-UM60SF 1 FLOOR STAND 60" (optional, not shown) 8160, 8060

-- E5-UM72SF 1 FLOOR STAND 72" (optional, not shown) 8172, 8072

-- 2F-Y7193 5lbs per 12" LAVA ROCK 2", 8LBS BAG 8024 / 8036 / 8048 / 8060 / 8072

Part

Number

Per

Unit

Description and Model Designation

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

11

Page 12

Page 13

Page 14

6

12

un produit nettoyant non abrasif.

extérieures à l’aide d’un chiffon et d’un détergent. Sur les surfaces encroûtées, on peut utiliser

à la brosse les particules carbonisées. Enlever et laver le bac à eau. Nettoyer les surfaces

Nettoyer le barbecue régulièrement. Enlever la section du grille et la laver dans l’évier. Enlever

NETTOYAGE

Pour éteindre les brûleurs, tourner les boutons des brûleurs sur la position de fermeture.

INSTRUCTIONS POUR ÉTEINDRE LE BARBECUE

ET LE LAISSER SE REFROIDIR.

FLAMBÉES PEUVENT SE PRODUIRE À L’IMPROVISTE. ÉTEIGNER LE BARBECUE

POSITION DU GRIL PENDANT LA CUISSON DES PRODUITS DE VIANDE. DES

LES BARBECUES SONT BRÛLANTS! NE JAMAIS ESSAYER DE CHANGER LA

MISE EN GARDE

Page 15

13

6

où repose le grille. Utiliser des maniques ou des gants pour le repositionner.

Élever ou abaisser le grille à la position suivante en soulevant le grille à l’arrière du barbecue

INCLINAISON DU GRILLE

l’utilisation du barbecue.

à travers la chambre de combustion aident à réduire les ambées. Faire attention lors de

lorsque nécessaire. Les vapeurs d’eau chaude qui s’évaporent des bacs à eau et qui passent

vos spécialités de viande. Vérier souvent les bacs à eau et ajouter sufsamment d’eau

gril. Vous devriez expérimenter avec les réglages du gril et les réglages des boutons selon

Ouvrir les vannes et préchauffer l’appareil sur «HI» avant de commencer la cuisson sur le

CUISSON SUR LE GRIL

huiles de protection et les impuretés brûlent.

Lors du premier allumage du barbecue, il se formera un nuage de fumée jusqu’à ce que les

ALLUMAGE

entièrement allumé quand positionnement en basses positions.

vous aimez, et a mis les valves en conséquence. Soyez sûr que les brûleurs restent ont

plus près de la position de “OFF” sur le cadran. Vous sélectionnez le modèle de la chaleur que

la section à une position de “ON” ou près d’elle. Pour se tenir ou terminer, tournez les valves

l’exécution desséchante, tournez la valve dans le sens contraire des aiguilles d’une montre pour

haute chaleur ou brûlant section, en ayant une basse chaleur nir ou tenir la section. Pour

quelle position entre "ON" et "OFF." C'est possible à travers cet arrangement pour avoir une

de cuisson sur le gril peut être obtenue en tournant la molette de valve de brûleur à n’importe

Chaque brûleur est contrôlé par un individu haut bas, sur fermé valve. La variété des températures

L'OPÉRATION DU BRÛLEUR

selon les besoins. Le bac à eau aide à prévenir les ambées et attrape la graisse.

L’eau devrait être ajoutée à la casserole de l’eau pour couvrir juste le bottam et être substituée

Le bac à eau est situé au bas de l’appareil et il est facile à enlever par la partie avant de l’appareil.

BAC À EAU

INSTRUCTIONS DE FONCTIONNEMENT

pointes jaunes disparaissent et une amme bleue dure est obtenu.

a des pointes lumineuses, alors lentement ouvertures de l'augmentation à un point où les

2. Lentement ouvertures de la baisse de volets de l'air à donnez une amme bleue douce qui

des aiguilles d’une montre à la position de “ON.”

1. Pour mettre à feu les brûleurs tournent la molette de valve de brûleur dans le sens contraire

IGNITION DU BRÛLEUR ET AJUSTEMENT

7. Pour éteindre les brûleurs, fermer les boutons.

6. Tourner les boutons des brûleurs sur le réglage désiré.

le brûleur immédiatement quand la valve du brûleur est allumée haut.

5. Ajustez des ammes de la lumière pilotes aussi petit que possible, mais haut assez allumer

4. Ouvrir le bouton principal et allumer les veilleuses.

montre à la n.

le sens contraire des aiguilles d’une montre pour s’ouvrir et dans le sens des aiguilles d’une

3. Les lampes témoin sur ce grilleur ont été pré-établies à l’usine. Tournez la vis réglable dans

2. Éteignez tous les boutons et valves du pilote et attendez 5 minutes éclaircir du gaz.

1. Éteignez la principale valve à unité.

est ouvert.

Le barbecue est équipé de veilleuses stationnaires et il faut l’allumer dès que le bouton de gaz

INSTRUCTIONS CONCERNANT LES VEILLEUSES D’ALLUMAGE

Page 16

14

5

d’allumage.

Ne pas utiliser d’allumettes, la amme d’une chandelle ou d’autres sources

MISE EN GARDE

de savon et d’eau ou une autre matière acceptable pour ce but.

Vérier l’étanchéité de toute la tuyauterie. Pour vérier l’étanchéité, il faut utiliser une solution

LA VÉRIFICATION LE GAZ FUIT

a coté de la plaque d'identication.

maintenant réglé pour 25,4 cm (10 po.) de colonne d’eau. Apposez l'étiquette de conversion

réinstaller. Les lettres "LP" doivent être maintenant visibles sur le bouchon. Le régulateur est

le bouchon entaillé ou leté hexagonal du régulateur de pression. Inverser le bouchon et le

bouchon de tuyau de 1/8 po. du collecteur du brûleur pour y attacher un manoMètre.Enlever

4. Régler la pression d’admission sur (10) pouces de colonne d’eau. On peut enlever un

3. Substituez les brûleurs, les éléments chauffants, et les grilles.

2. Enlever les orices de brûleurs et installer les orices fournis.

1. Retirez les grilles, les éléments chauffants et les brûleurs.

la casserole de l’eau, comme suit:

naturel. Pour convertir en gaz de propane, installez les capots d’orice de brûleur, situés dans

Ce barbecue est équipé d’orices xes et il est expédié de l’usine prêt pour l’utilisation au gaz

GAZ PROPANE - CONVERSION

N’enlever cette protection que juste avant d’effectuer le raccord à la canalisation de gaz.

L’admission de gaz du barbecue est scellée en usine an d’empêcher l’entrée des impuretés.

RACCORD DE LA CANALISATION DE GAZ

barbecue.

Il faut installer une vanne d’arrêt manuelle en amont du collecteur et à six pieds près du

VANNE D’ARRÊT MANUELLE

il est expédié réglé pour une pression d’admission de 5 po. de colonne d’eau.

d’approvisionnement au régulateur ne doit pas excéder 1/2 PSIG. Pour l’utilisation au gaz naturel,

tuyau d’admission à l’arrière de l’appareil. L’alimentation de gaz y est raccordée. La pression

Chaque barbecue est fourni avec un régulateur de pression convertible. Il doit être raccordé au

RÉGULATEUR DE PRESSION DU GAZ

et raccords doivent être exempts de toute impureté interne libre.

et en affectera le fonctionnement. Lors de l’installation de cet appareil, tous les tuyaux

métallique qui entre dans les canalisations de gaz de cet appareil endommagera la vanne

AVERTISSEMENT : Toute impureté libre ou particule

résister à l’action des gaz propanes.

modérément et seulement sur les letages mâles des raccords à tuyaux. Ces composés doivent

pour déterminer si elle a la capacité nécessaire. Il ne faut utiliser le composé combiné que

dans l’appareil. S’il faut raccorder l’appareil à la tuyauterie existante, il faut vérier cette dernière

une alimentation sufsante de gaz pour répondre aux exigences d’admission de pleine puissance

La taille de la tuyauterie à gaz et la façon dont elle est installée doivent être telles qu’elle fournisse

TUYAUTERIE À GAZ

de rocher de lave. N’ a pas mettre supérieur à 5 livres de rocher par le brûleur.

approximatifment 1 couche épaisse. Ne pas couvrir les grilles avec supérieur à deux couches

basses - pas la cuisine de sommet grince. Etaler le rocher de lave également sur les grilles

Ouvert les sac de rocher de lave et le rocher d’endroit également sur les grilles internes plus

PLACEMENT DE LA ROCHE DE LAVE - CB SÉRIE

pour orientation du radiants.

de l'assemblée de la soudure du paquebot. Faites référence à la vue explosée dans ce manuel

brûleur. Installez chaque radiant sur 2 fentes du mur arrière et sur 1 épingle du mur de devant

Après que l'unité soit déballée et est installée, placez-en 1 radiant au-dessus de chaque

PLAÇANT RADIANTS - RCB SÉRIE

Page 17

15

4

initialement installé avant l’utilisation.

ait une contrainte sur l’appareil et si débranché pour le service ou le nettoyage qu’il doit être rebranché comme

équipé des roulettes et est gaz lié à un rapide relient le couplage, tout le personnel doit se rendre compte qu’il y

sûr d’utiliser des moyens approuvés de passe-ls pour protéger la connexion de ligne de gaz. Si un appareil est

mesurer 19“ longueur de tube, longueur hors-tout. Les roulettes ajoutent environ 6-1/4“ de taille à l’unité. Soyez

et un de-burr droits de découpage le mur intérieur de tube avant d’installer la roulette. La jambe de coupe devrait

facultatif. Pour d’installation la marque soigneusement et découpé le de bas de chaque jambe en utilisant une scie

Lots de roulettes: Des roulettes peuvent être utilisées avec les modèles de stand de plancher ou le stand de matériel

Vissez les jambes dans des écrous de support sur le bas

DE STAND.

OU DES JAMBES ET L'ETAGERE FOURNIES

N’INSTALLEZ PAS SANS ATTACHER ES PIEDS

MISE EN GARDE

Raidissant des supports sur 8148, 8160, et 8172 modèles seulement

d’autres appareils.

po., en vue d’un alignement exact et parfait avec

en ajustant les (4) pieds qui ont un réglage de 1-3/4

corps. L'unité doit être niveau. Équilibrer l’appareil

de stand de plancher qui doivent être vissés dans le

Ce charbroiler est assuré avec 4 pieds ou jambes

ÉQUILIBRAGE DE L’APPAREIL

Page 18

3

16

section.

L’air nécessaire à la combustion entre par le bas de l’appareil. Ne bas boucher cette

MISE EN GARDE

Les vivres pour provision de l'air adéquate doivent être fournis.

LA PROVISION DE L'AIR

aux codes locaux.

ltres ou toute autre matière combustible. L'installation du gaz d'échappement doit conformer

Une distance verticale de pas moins que 48 " seront fournis entre le sommet de l'appareil et

être installés sous un capuchon du gaz d'échappement effectif avec amme ltres insensibles.

Les grils du foyer ouverts créent beaucoup de chaleur et fumée fondamentalement et devraient

ÉPUISEZ LE BALDAQUIN

égales à ou de moins que ½ PSIG.

individuelle lors des essais de pression de la tuyauterie d’alimentation de gaz à des pressions

doivent être isolés de la tuyauterie d’alimentation du gaz en fermant sa vanne d’arrêt manuelle

en question à des pressions en dessus de ½ PSIG. Cet appareil et son régulateur de pression

débranchés de la tuyauterie d’alimentation du gaz lors des essais de pression de la tuyauterie

Cet appareil, son régulateur de pression et ses vannes d’arrêt individuelles doivent être

de l’installation nale.

exigences de gaz locales. En tout cas, il faut appeler votre société du gaz pour l’approbation

une agence d’installation qualiée. Ils doivent connaître les installations de gaz et vos

Pour votre propre protection, on vous recommande de faire installer cet appareil par

connecteur, comme indiqué dans les instructions du constructeur d’appareils.

être installé avec des moyens retenants de garder contre la transmission de la contrainte au

à un dispositif rapide étant conforme à la norme ANSI Z21.41 ou au CAN1-6.9. Il doit également

roulettes fournies, un connecteur étant conforme à la norme ANSI Z21.69 ou au CAN/CGA-6.16 et

NOTIFICATION: Quand cet appareil est installé avec des roulettes, il doit être installé avec les

CAS ÉCHÉANT.

D’INSTALLATION AU PROPANE CAN/CGA-B149.2 ET AUX CODES LOCAUX, LE

D’INSTALLATION AU GAZ NATUREL CAN/CGA-B149.1 OU AU CODE

AU CANADA, L’INSTALLATION DOIT ÊTRE CONFORME AU CODE COURANT

GAZ LOCALE.

ET À TOUTES LES RÈGLES ET RÉGLEMENTATIONS DE LA COMPAGNIE DE

COMBUSTIBLE "ANSI Z223.1 - TOUTE DERNIÈRE ÉDITION" DES ÉTATS-UNIS

L’installation de l’appareil doit se conformer au CODE NATIONAL DE GAZ

est recommandés du dos de l’unité.

la construction de non-combustible doit être 3“ minimum dos et côtés. Pour entretenir, 6“

NE L’INSTALLER QUE DANS UN ENDROIT NON COMBUSTIBLE ! Le dégagement avec

avant l’éclairage.

Soyez sûr d’enlever tout le matériel de papier de protection et d’emballage à partir de l’unité

-IMPORTANT-

propane : voir le gaz propane.

l’utilisation au gaz naturel. Il est facile de convertir l’appareil en vue de l’utilisation au gaz

constructeur montée sur le panneau avant. Tous les appareils sont expédiés de l’usine pour

Le barbecue de la série Ultra-Max est équipé pour le type de gaz indiqué sur la plaque du

du public dans les endroits de pique-nique.

formé et sachant l’utiliser et il n’est pas vendu pour l’utilisation à la maison, ni pour l’usage

Cet équipement n’est conçu et vendu que pour l’utilisation commerciale par le personnel

MISE EN GARDE

DONNÉES GÉNÉRALES D’INSTALLATION

Page 19

2

17

plus rapide.

questions qui peuvent se poser. Veuillez avoir votre numéro et numéro de série de type pour un service

Star (1-800-807-9054) disponible pendant des heures de travail normales pour répondre à toutes les

Référez-vous à la liste autorisée de centre commercial équipée d'unité. Le service SVP de service de

Entrez en contact avec votre agent autorisé local de service pour le service ou l'entretien requis.

ENTRETIEN ET RÉPARATIONS

correspondants pour l’équipement précédemment acheté.

aux améliorations, aux additions ou aux remplacements

telles révisions ne ont pas droit l’acheteur aux changements,

conception de produits sans communication préalable. De

Star se réserve le droit de changer des caractéristiques et la

NOTIFICATION

responsabilité.

par usine véritable de Star soulage le fabricant de toute la

Employer n’importe quelle partie autre que les pièces fournies

NOTIFICATION

MAINTENEZ CE MANUEL POUR LA FUTURE RÉFÉRENCE

accompagnant l’appareil.

instructions importantes de fonctionnement et d’entretien du manuel

Ce symbole est prévu pour alerter l’utilisateur à la présence des

SYMBOLE DE SÛRETÉ

Page 20

18

fournisseur local de gaz.

sent le gaz. Obtenez les instructions du

détaillées d’être suivi en cas que l’opérateur

emplacement en avant, des instructions

En outre, là devrait être signalé, dans un

d’installer et utiliser cet appareil.

aéré. Référez-vous aux instructions avant

et utilisé seulement dans l’espace bieninstallé selon des règlements actuels

AVERTISSEMENT: Cet appareil sera

appareil.

proximité de ceci ou d’aucun autre

vapeurs ou liquides inflammables à

ou n’utilisez pas l’essence ou d’autres

POUR VOTRE SÛRETÉ: N’enregistrez pas

d’installer ou entretenir ce matériel.

et d’entretien complètement avant

les instructions d’installation, d’opération

matériels, des dommages ou la mort. Lisez

l’entretien peuvent causer des dégats

le réglage, le changement, le service ou

AVERTISSEMENT: L’installation inexacte,

et d’opération

d’installation

Instructions

8048CB, 8060CB, et 8072CB

8024CB, 8036CB,

MODELES

ULTRA-MAX

8124RCB, 8136RCB

MODELES

Fax: (314) 781-2714

Phone: (314) 678-6303

St. Louis, MO 63143

10 Sunnen Drive

International Inc.

Manufacturing

Star

BARBECUE A GAZ ROCHE DE LAVE

8148RCB, 8160RCB, et 8172RCB

BARBECUE A GAZ RAYONNANT ULTRA-MAX

2M-Z7906 Rev. B 5/9/06

Loading...

Loading...