Page 1

®

®

®

®

®

GAS

GRIDDLE

MODEL

615TF, 615MF

624TF, 624MF 624TSPF, 624TCHSF

636TF, 636MF, 636TSPF, 636TCHSF

648TF, 648MF, 648TSPF, 648TCHSF

Installation and

Operation

Instructions

2M-Z16008 Rev. A 8/08/12

Page 2

SAFETY SYMBOL

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

Authorized Service Agent Listing

Model No.

Serial No.

Voltage

Purchase Date

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

2

Page 3

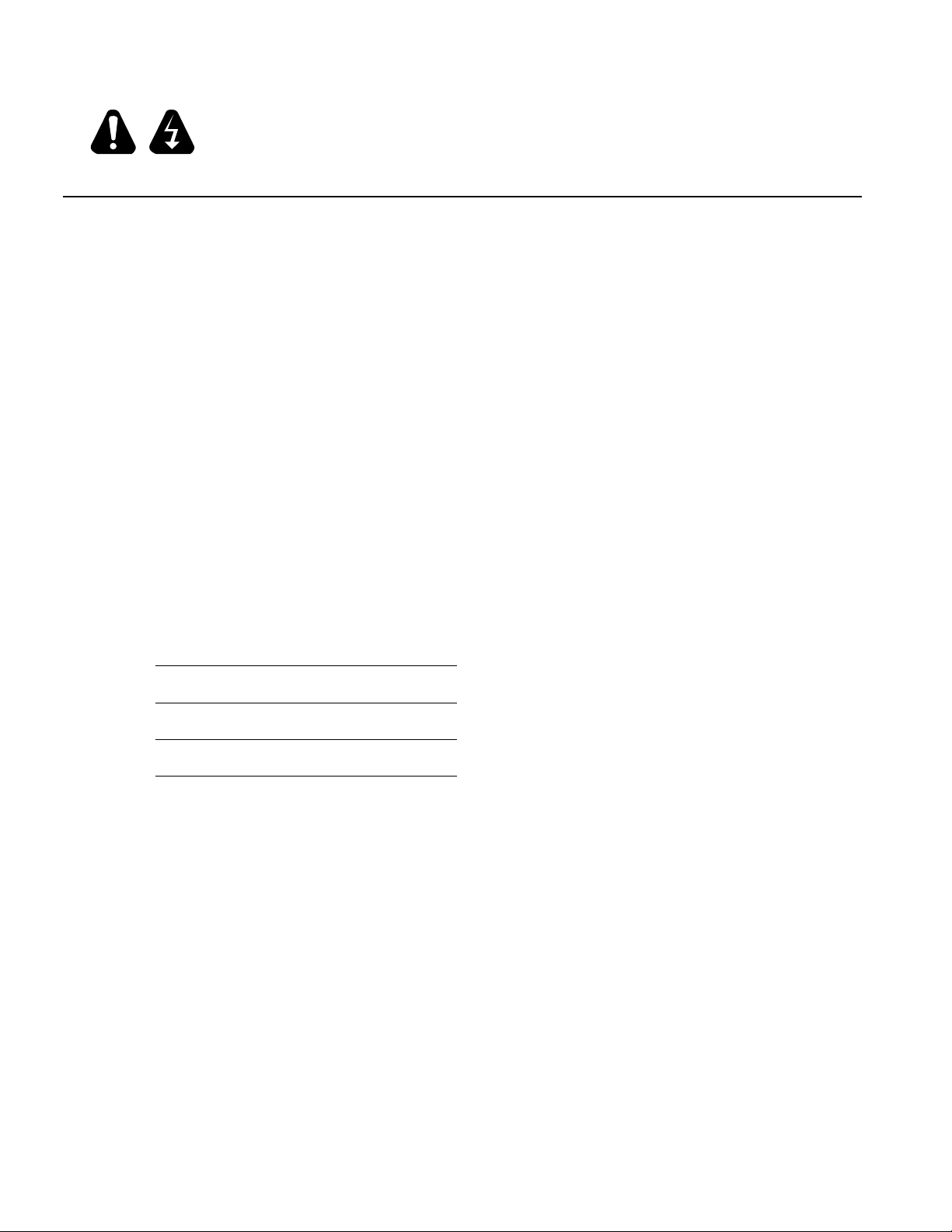

Model Control BTU Grid Area

615 1 20,000

624 2 56,600

636 3 84,900

648 4 113,200

304 sq. in

(1961 sq. cm)

498 sq in

(3213 sq. cm)

747 sq in

(4820 sq cm)

996 sq in

(6426 sq cm)

MF Manual Control

TF Thermostat Control

TSPF Thermostat & Safety Pilot Control

TCHSF Thermostat & Safety Pilot Control with Chrome Plate

SPECIFICATION

Plate

Thickness

1”

(2.54 cm)

CONTROL TYPE

Weight Dimensions

Installed Shipped Width Depth Height

83 lb

(37.6 kg)

165 lb

(74.8 kg)

247 lb

(112 kg)

330 lb

(144.7 kg)

90 lb

(4.8 kg)

175 lb

(79.4 kg)

262 lb

(118.8 kg)

350 lb

(158.8 kg)

15”

(38.1 cm)

24”

(61 cm)

36”

(91.4 cm)

48”

(122 cm)

27.75”

(70.5 cm)

15.5”

(39.4 cm)

3

Page 4

GENERAL INSTALLATION DATA

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations.

The Star-Max™ model griddles are equipped for use with the types of gas specied on the

nameplate.

All units are shipped from the factory for use with natural gas. The unit can easily be converted for

use on propane gas: See propane gas.

CAUTION

-IMPORTANT-

The installation of the Appliance should conform to the NATIONAL FUEL GAS

CODE "ANSI Z223.1 - LATEST EDITION" AND ALL LOCAL GAS COMPANY

RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE

CURRENT CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE OR

CAN/CGA-B149.2 PROPANE INSTALLATION CODE AND LOCAL CODES

WHERE APPLICABLE.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing the equipment.

For your safety, do not store or use gasoline or other ammable vapors and liquids in

the vicinity of this or any other appliance. Keep the appliance area clear and free from

combustibles.

This appliance, its pressure regulator and its individual shutoff valve must be disconnected from the

gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2

PSIG (3.45KPA).

This appliance and its pressure regulator must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 PSIG (3.45KPA). For your protection, we recommend a

qualied installing agency install this appliance. They should be familiar with gas installations and

your local gas requirements. In any case, your gas company should be called to approve the nal

installation. In addition, there should be posted, in a prominent location, detailed instructions to be

followed in the event the operator smells gas. Obtain the instructions from the local gas supplier.

For your safety, if you smell gas -

1. Do not touch electrical switches.

2. Extinguish any open ame.

3. Immediately call your gas company.

KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES.

CLEARANCE

For use on non-combustible countertops only.

Combustible and non-combustible material must be at least 48" (120cm) from the top of the appliance

and 6" (150mm) from the sides and back. Adequate clearance should also be provided for proper

operation and servicing.

AIR SUPPLY

Make certain not to obstruct the ow of combustion and ventilation air. Provisions for adequate air

supply must be furnished. The legs supplied with the unit must be installed. Make certain that air

intake openings in the bottom of the appliance are not obstructed. They are essential for proper

combustion and operation of the appliance.

4

Page 5

CAUTION

EXHAUST CANOPY

It is essential that facilities be provided over the griddle to carry off fumes and gases. However, the

unit should not be directly connected to a ue or stack.

LEVELING UNIT

This griddle is supplied with (4) feet which must be screwed into the legs attached to the body. Level

unit by adjusting the (4) feet which have an adjustment of 1-3/4" (43.75mm) for accurate and perfect

lineup with other units.

DO NOT INSTALL WITHOUT ATTACHING FEET - DO NOT REMOVE FEET.

GAS PIPING

Gas piping shall be of such size and so installed as to provide a supply of gas sufcient to meet

the full gas input of the appliance. If the appliance is to be connected to existing piping, it shall be

checked to determine if it has adequate capacity. Joint compound shall be used sparingly and only

on the male threads of the pipe joints. Such compounds shall be resistant to the action of LP gases.

WARNING: Any loose dirt or metal particles which are allowed to enter the gas lines on this appliance

will damage the valve and affect its operation. When installing this appliance, all pipe and ttings must

be free from loose dirt.

GAS PRESSURE REGULATOR

A convertible pressure regulator is provided with each griddle. It should be connected to the inlet pipe

at the rear of the unit. The gas supply line is then connected to it. It is shipped set for 6" (15.24cm)

water column manifold pressure for use with natural gas.

MANUAL SHUT-OFF VALVE

A manual shut-off valve should be installed upstream from the union and within 6 feet (1.829m) of this

appliance.

GAS CONVERSION

This griddle is equipped with xed orice hoods and is shipped from the factory for use on either

natural or LP gas. To convert to propane gas, install the burner orice hoods, located in the grease

drawer, (NAT orces are not included) as follows:

1. Remove front panel by removing screws located on the front and the bottom.

2. Remove the burner(s) from the orice hood(s). This is accomplished by removing the burner

mounting screw(s) and sliding the burner(s) off the hood(s).

3. Remove natural gas orice hood(s) and install the propane hood(s) furnished.

4. Reinstall burner(s).

5. Reinstall front panel.

6. Remove the slotted, or hex-threaded, plug from the pressure regulator. Invert the plug and

re-install. The letters "LP or NAT" should now be visible on the plug. LP units the regulator

is now set for 10" (25.4cm) water column, and NAT units the regulator is now set for 6"

(15.24cm) water column.

7. For LP Gas, set manifold pressure to 10" (25.4cm) water column. A 1/8" pipe plug on the

supply pipe can be removed for attaching a pressure gauge.

CONNECTING GAS SUPPLY LINE

The gas inlet of the griddle is sealed at the factory to prevent entry of dirt. Do not remove this seal

until the actual connection is made to the gas supply line.

CHECKING FOR GAS LEAKS

Soap and water solution or other material acceptable for the purpose shall be used in locating gas

leakage. Matches, candle ame, or other sources of ignition shall not be used for this purpose.

Check entire piping system for leaks.

5

Page 6

CAUTION

LIGHTING INSTRUCTIONS

When griddle is rst lit, it will smoke until the preservation oils and impurities are burned off.

1. Turn off main valve to unit and wait 5 minutes to clear gas.

2. Turn off all knobs and pilot valves.

3. Turn on main valve and light all pilots.

4. Turn burner knobs to desired setting.

5. To turn burners off, turn knobs off.

NOTE: The griddles are equipped with standing pilots and should be lit immediately after

the gas is turned on.

Pilot ames can be lit and observed through the front panel view ports. However, best access for

lighting the pilot is from the bottom of the unit just behind the center wall.

LIGHTING INSTRUCTIONS (TCHSD and TSPD SERIES)

1. Turn the control knobs to the "OFF" position.

If the gas valves have been on and gas has escaped through the burners, turn the burners

"OFF" and wait 5 minutes to clear the gas.

2. Turn the control knob to the "PILOT" position, depress and hold the knob while lighting

the pilot. Hold the knob in for 60 seconds or until the pilot stays lit. (Repeat for all burner

sections.)

3. Depress and turn the control knob to the desired temperature.

4. To turn the burners off turn the knob to the "PILOT" position.

5. To turn off all gas turn the knob to the "OFF" position. The pilots must be relit to resume

cooking settings.

PILOT LIGHT REGULATION

Adjust pilot light ames as small as possible, but high enough to light burner immediately when burner

valve is turned on high.

ADJUSTING SAFETY PILOTS (SERIES TCHSF and TSPF ONLY)

A manual pilot valve is provided on the left side of the control to adjust the pilot ame. Adjust the pilot

ame so that it is approximately 3/8 to 1/2" tall and a uniform cone shape.

BURNER ADJUSTMENT (MODELS MF ONLY)

1. Remove the front panel.

2. Turn burner valve knob to "HI" position.

3. Close the air shutter on the front of the burner to give a soft blue ame having luminous

tips and open to a point where the yellow tips disappear and a hard blue ame is obtained.

Repeat for all burners.

BURNER ADJUSTMENT (MODELS TF, TCHSF and TSPF ONLY)

1. Remove the front panel.

2. Push dial in and set thermostat of one burner to 450°F (229.9°C).

3. Close the air shutter on the front of the burner to give a soft blue ame having luminous

tips and open to a point where the yellow tips disappear and a hard blue ame is obtained.

Repeat for all burners.

BURNER OPERATION (MODELS MF)

To ignite burners, turn burner valve knob to "HI" position. Each burner is controlled by an individual

high-low, on-off valve. An innite number of temperatures may be obtained by turning the burner valve

knob to any position between high and low. For overnight shutdown, turn the valves to the "OFF"

position.

6

Page 7

CAUTION

SEASONING THE GRIDDLE HEATING SURFACE

(NON-CHROMIUM SURFACES)

Clean the griddle surface thoroughly. After the griddle has been thoroughly cleaned, it should be

seasoned to prevent food from sticking. Before using, and after each thorough scouring, season the

griddle heating surface in the following manner:

1. Turn the temperature control dial to 350°F (174.9°C).

2. Using a clean cloth, not a spatula, spread a thin lm of cooking oil over the griddle cooking

surface. This lm should remain on the hot griddle surface 1/2 hour.

3. Remove excess oil and wipe clean.

4. Apply another lm of cooking oil over the hot cooking area for another 1/2 hour and again

remove excess oil and wipe clean. The griddle surface should now be ready for use.

Even with careful seasoning food may, to some extent, stick to the griddle cooking

surface until griddle plate is "broken in."

COOKING (MODELS TF, TCHSF and TSPF ONLY)

Set the thermostat dial knob to the temperature desired. After a short preheating period, the

thermostat will automatically maintain the selected temperature.

GREASE PAN

A grease pan is located at the front and can be removed for cleaning from the front. This pan should

be checked and emptied when necessary.

EXERCISE EXTREME CARE IN HANDLING THE GREASE PAN CONTAINING HOT

GREASE.

GRIDDLE CARE (NON-CHROMIUM AREAS)

It takes very little time and effort to keep the griddle attractive and performing at top efciency.

If grease is permitted to accumulate, it will form a gummy cake and then carbonize into a hard

substance which is extremely difcult to remove. To prevent this condition, the following suggestions

for cleanliness should be followed:

1. After each use, scrape the griddle with a scraper or exible spatula to remove excess grease

and food. A waste drawer is provided for the scrapings. If there is an accumulation of burned

on grease and food, the griddle should be thoroughly scoured and reseasoned. Use pumice

or griddle stone while the griddle is warm. DO NOT use steel wool because of the danger of

steel slivers getting into the food.

2. Daily-use a clean cloth and good non-abrasive cleaner to clean the stainless steel body of the

griddle. Wipe the polished front with a soft cloth.

3. At least once a day remove the waste drawer and wash in the same way as an ordinary

cooking utensil. The drawer is removed by pulling forward, up and out.

GRIDDLE CARE (CHROMIUM AREAS)

It takes very little time and effort to keep this Chromium griddle surface sparkling clean and

performing at top efciency. DO NOT allow grease to accumulate as it will carbonize, becoming

difcult to remove. To prevent this condition the following cleaning suggestions should be followed.

1. Remove excess oil and food regularly with a 4" (100mm) wide Razor Sharp type scraper and

wipe surface with a damp cloth.

2. Following the scraping, a damp cloth and a non-silicated, non-abrasive, non-chlorinated

cleaner such as Bon-Ami may be used to wipe surface clean, followed by wiping with clean

wet cloth.

3. Follow steps 2 and 3 from above section.

7

Page 8

Visit our Website at: www.star-mfg.com Email: service@star-mfg.com

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in

which the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the

transportation company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of

the unit.

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

LIMITED EQUIPMENT WARRANTY

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is ve (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners, abrasive pads, product identiers and

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted. Labor to replace the part is chargeable to

the customer.

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

* The Model 510FD Fryer.

* The Model 526TOA Toaster Oven.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model 518CMA & 526CMA Cheese Melter.

* The Model 12MC &

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* All QCS/RCS Series Toasters except Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

15MC & 18MCP Hot Food Merchandisers.

SERVICES NOT COVERED BY WARRANTY

PARTS WARRANTY

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16. Replacement of bulbs

17. Replacement of fuses

18. Repair of damage created during transit, delivery, &

installation OR created by acts of God

PORTABLE EQUIPMENT

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

2M-Z16008 Star-Max Gas Griddles

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

2M-4497-2 10/2010

8

Page 9

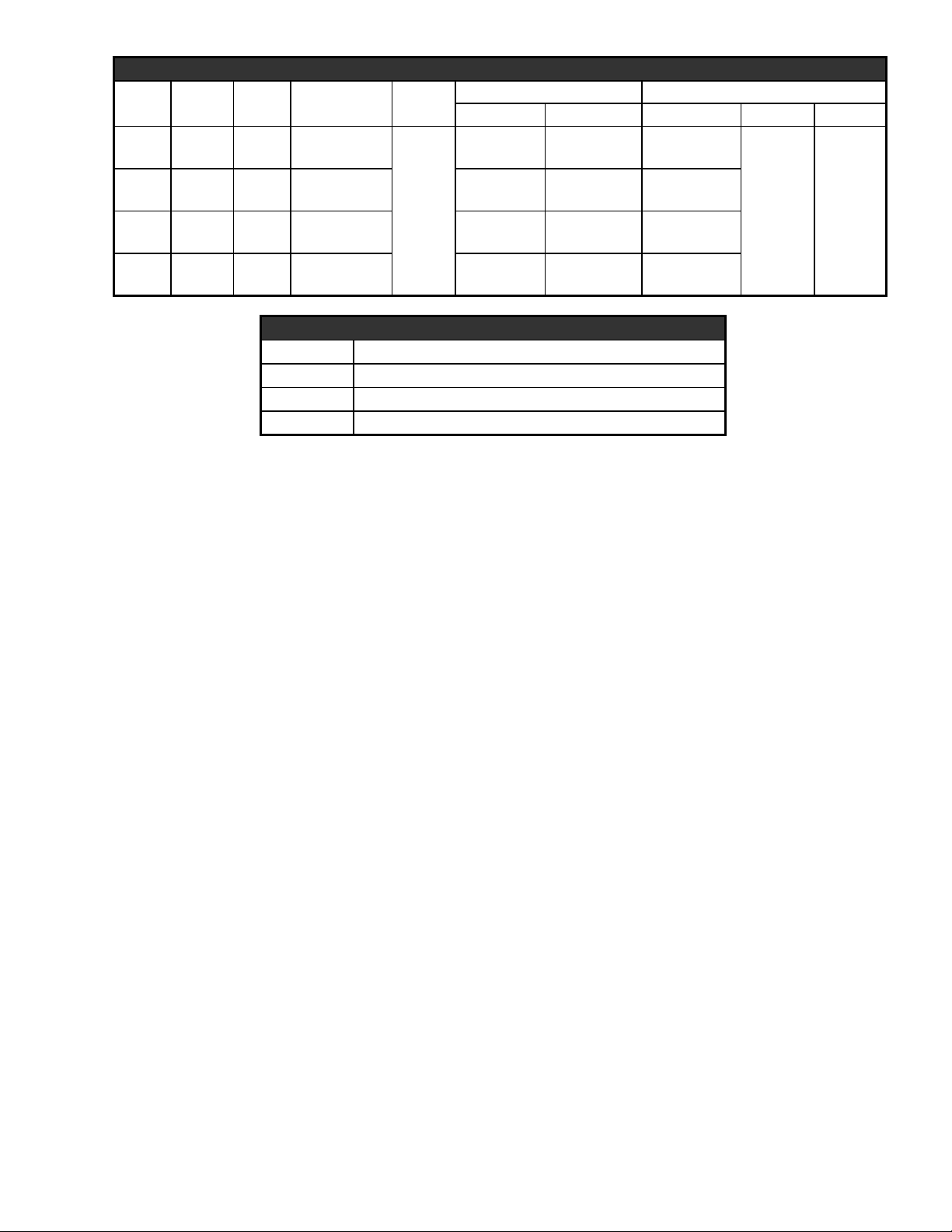

1

4

2

3

5

6

7

8

22

21

20

19

18

17

2M-Z16008 Star-Max Gas Griddles

15

16

MODEL: 624MF,624TF, 624TSPF, 624TCHSF

9

10

11

12

13

STAR MANUFACTURING INTERNATIONAL, INC.

SK2598 REV. - 06-12-12

9

Page 10

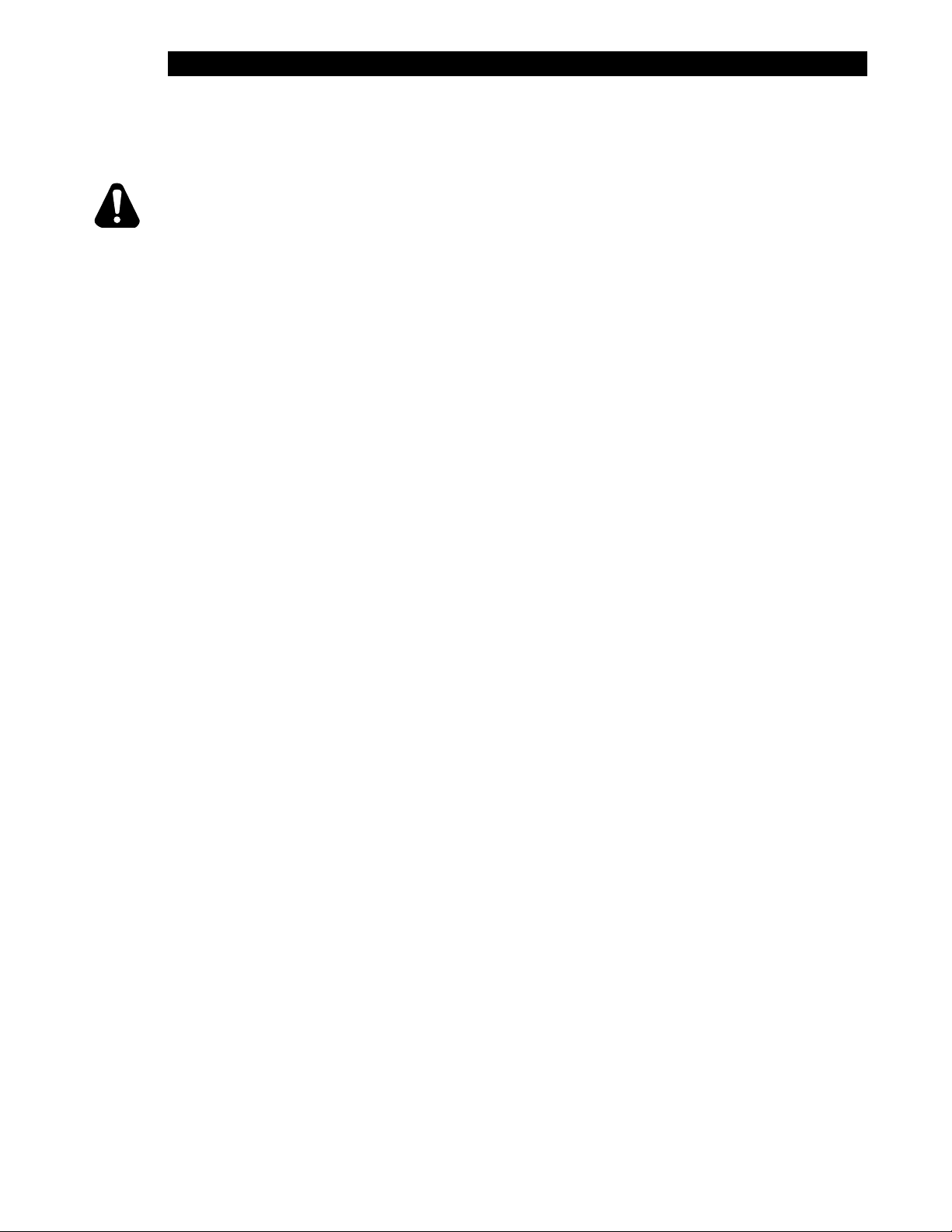

SK2599 Rev. - 6-13-2012

31

23

37

36

32

33

35

31

34

27

30

35

28

26

27

29

23

38

28

24

29

Thermostat Control

Manual Control

MODEL 624MF,624TF, 624TSPF, 624TCHSF

23

26

29

28

27

25

STAR MANUFACTURING INTERNATIONAL, INC.

10

2M-Z16008 Star-Max Gas Griddles

Page 11

PARTS LIST June 13, 2012, Rev -

Model: 615, 624, 636, 648 Star-Max Gas Griddles

Fig No Part No Qty Description Application

1

2

3 G5-Z4817 1 FLUE DIVIDER ALL 636, 648

4

5 G3-Z5945 2 SIDE PANEL ALL

6 G3-624302 1 SIDE LINER ASSEMBLY LEFT ALL

7

8 G3-624303 1 SIDE LINER ASSY RIGHT ALL

9

10 2A-Z5942 4 FOOT ALL

11 2C-8823 Various SCREW #8 x 3/8 ALL

12 G3-Z6036 2 DRAWER SLIDE ALL

13 G3-Y7046 1 GREASE DRAWER ALL

2M-Z16008 Star-Max Gas Griddles

15

16

G3-615315

G3-615316 615TF

G3-624320 624MF

G3-624321 624TCHSF

G3-624322 624TF, 624TSPF

G3-624323 DIVIDED PLATE ASSEMBLY 624MF-DIV

G3-636316

G3-636317 636TCHSF

G3-636318 636TF, 636TSPF

G3-648320 648MF

G3-648321 648TCHSF

G3-648322 648TF, 648TSPF

G3-648323 648TF-TFR

G3-648324 648TF-TFL

G3-615304

G3-624304 ALL 624, 636, 648

G3-Z5906

G5-Z4812 624MF, 624TF, 624TSPF, 624TCHSF

G5-Z4813 636MF, 636TF, 636TSPF, 636TCHSF

G5-Z4814 648MF, 648TF, 648TSPF, 648TCHSF

G3-Z5951

G3-Z5953 624MF, 624TF, 624TSPF, 624TCHSF

G3-Z5955 636MF, 636TF, 636TSPF, 636TCHSF

G3-Z5957 648MF, 648TF, 648TSPF, 648TCHSF

G3-Z5909

G3-Z5919 624MF, 624TF, 624TSPF, 624TCHSF

G3-Z5929 636MF, 636TF, 636TSPF, 636TCHSF

G3-Z5939 648MF, 648TF, 648TSPF, 648TCHSF

2M-Z15449

2M-Z15450 LABEL GAS T-STAT LG 615TF / 624TF / 636TF / 648TF

2M-Z16011 2/3/4

G3-Z15791

I4-Z15484 KNOB ASSY LG GAS KEYB

1/2/3/4

1/2/3/4

2/3/4

GRIDDLE PLATE ASSEMBLY

1

GRIDDLE PLATE ASSEMBLY

1 CHUTE ASSEMBLY

1 FLUE

1 REAR PANEL

1 BOTTOM

KNOB LABEL MAN LG 615MF / 624MF / 636MF / 648MF

KNOB LABEL GAS-TSTAT

PILOT

KNOB ASSY LG GAS KEYR 615TF / 624TF / 636TF / 648TF

615MF

636MF

ALL 615

615MF, 615TF

615MF, 615TF

615MF,615TF

624TSPF/ 624TCHSF/ 636TSPF/ 636TCHSF/

648TSPF/ 648TCHSF

615MF / 624MF / 636MF / 648MF

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 1

INCLUDE MODEL AND SERIAL NUMBER OF 3

Some items are included for illustrative purposes only and in certain instances may not be available.

Star International Holdings, Inc. Company

11

Page 12

PARTS LIST June 13, 2012, Rev -

Model: 615, 624, 636, 648 Star-Max Gas Griddles

Fig No Part No Qty Description Application

17 2M-Z15804 1 STAR-MAX LOGO ALL

G3-Z15797

G3-Z15798 615TF

G3-Z15799 624MF

G3-Z15806 624TF, 624TSPF, 624TCHSF

18

G3-Z15807 636MF

G3-Z15808 636TF, 636TSPF, 636TCHSF

G3-Z15809 648MF

G3-Z15810 648TF, 648TSPF, 648TCHSF

19 2C-8477 3 CLIP .125 PO STL PHOS ALL

20 G3-Z5946 1/2/3/4 BURNER COVER ALL 615 / 624 / 636 / 648

G3-Z5905

G3-Z5915 624MF, 624TF, 624TSPF, 624TCHSF

21

G3-Z5925 636MF, 636TF, 636TSPF, 636TCHSF

G3-Z5935 648MF, 648TF, 648TSPF, 648TCHSF

22 2F-Z5949 1/2/3/4 BURNER ALL 615 / 624 / 636 / 648

2K-Z5960

2K-Z5961 615TF

2K-Z5962 624MF, 624MFS

2K-Z5963 624TF, 624TSPF, 624TCHSF

23

2K-Z5964 636MF, 636MFS

2K-Z5965 636TF, 636TSPF, 636TCHSF

2K-Z5966 648MF, 648MFS

2K-Z5967 648TF, 648TSPF, 648TCHSF

2J-Z0792

24

H3-Z4557 REGULATOR-GAS 3/4 NPT LP LP UNITS

25 2V-Y8832 1/2/3/4 VALVE-MANUAL GAS 615MF / 624MF / 636MF / 648MF

26 2V-Z6647 1/2/3/4 PILOT BURNER

27 2V-6671 1/2/3/4 PILOT VALVE ALL 615 / 624 / 636 / 648

28 2P-1453

2A-Y1255 2/3/4 ORIFICE PROPANE 624 / 636 / 648 LP

29

2A-Z4930 1/2/3/4 ORIFICE #41, NAT 624 / 636 / 648 NAT

30 2K-Z5968 2/3/4 FITTING 1/4 MPT X 3/8 CC

31 2K-Z4921

32 2K-Z6081 2/3/4 PILOT TUBE

1 FRONT PANEL

1 CENTER WALL

1 MANIFOLD

PRESSURE REGULATOR NAT UNITS

1

1

PIPE PLUG

3/4/5

2/3/4

1/2/3/4 615TF / 624TF / 636TF / 648TF

BURNER TUBE

615MF

615MF, 615TF

615MF

615MF / 624MF / 636MF / 648MF

615TF / 624TF / 636TF / 648TF

615MF, 624MF, 636MF, 648MF

615TF, 624TF, 636TF, 648TF

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

2M-Z16008 Star-Max Gas Griddles

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 2

INCLUDE MODEL AND SERIAL NUMBER OF 3

Some items are included for illustrative purposes only and in certain instances may not be available.

Star International Holdings, Inc. Company

12

Page 13

PARTS LIST June 13, 2012, Rev -

Model: 615, 624, 636, 648 Star-Max Gas Griddles

Fig No Part No Qty Description Application

33 2J-Z0804 2/3/4 THERMOCOUPLE-PILOT

34 G3-Z6124 2/3/4 PILOT BRACKET

1/2/3/4

35 2A-9369

36 2K-Y7111 1/2/3/4 ELBOW 1/4 MBT X 3/8 CC 615TF / 624TF / 636TF / 648TF

2T-Y7590

37

2T-Z4293 THERMOSTAT

38 2J-Z5959 2/3/4 COMBINATION CONTROL

2/3/4

1/2/3/4

ORIFICE FITTING

STEM-T-STAT

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

615TF / 624TF / 636TF / 648TF

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

615TF / 624TF / 636TF / 648TF

624TSPF / 636TSPF / 648TSPF

624TCHSF / 636TCHSF / 648TCHSF

2M-Z16008 Star-Max Gas Griddles

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 3

INCLUDE MODEL AND SERIAL NUMBER OF 3

Some items are included for illustrative purposes only and in certain instances may not be available.

Star International Holdings, Inc. Company

13

Page 14

7

14

5. Négligence dans l’entretien régulier journalier sur la surface en chrome.

surface chromée.

ou autres produits nettoyants qui pourraient abîmer et compromettre les prestations de la

4. Utilisation de tout produit chimique ou solution nettoyante abrasive, brique de gril, pierre, tamis

causer un détachement ou éclatement de la surface.

3. Utilisation erronée de tout instrument ou outil qui raye ou entaille la surface, ce qui pourrait

ajustement de dérivation dans le manuel d’instructions fourni avec l’appareil.)

conséquences une surchauffe de l’appareil et une décoloration de la surface chromée. (Voir

2. Ajustements de dérivation non effectués adéquatement sur les appareils à gaz, ce qui a pour

1. Installation inappropriée.

situations suivantes:

surface chromée a été utilisée de manière erronée, a fait l’objet d’un usage abusif ou a été sujette aux

Manufacturing International Incorporated ou l’un de ses représentants autorisés détermine que la

de fabrication au propriétaire initial, depuis la date d’installation. Cette garantie limitée est nulle si Star

d’origine. Tous les grils Chrome-Max™ sont garantis pendant une période de cinq ans contre les vices

able et il ne nécessite qu’un entretien minimum pour maintenir la surface chromée dans son état

Votre gril Chrome-Max™ a été conçu de manière à vous donner de nombreuses années de cuisson

EXCLUSIONS DE LA GARANTIE LIMITÉE SUR LE GRIL CHROME-MAX™

5. Une utilisation abusive de la surface annule la garantie.

4. Ne jamais utiliser de nettoyant liquide commercial sur la surface du gril.

3. Ne jamais utiliser de laine d’acier.

2. Ne jamais frapper la surface du gril avec un instrument aflé ou un bord de spatule.

1. Ne jamais utiliser de pierre ponce, de pierres à gril ou d’abrasifs sur la surface.

3. Suivre les étapes 2 et 3 de la section Entretien du gril (surfaces non chromées).

surface. Il suft ensuite d’essuyer avec un chiffon propre humide.

et un nettoyant non chloré, non abrasif et non silicatisé, tel que le Bon Ami, pour nettoyer la

2. Suite au raclage, pour le nettoyage de la n de la journée, on peut utiliser un chiffon humide

rasoir de 100 mm (4 po) de large, et essuyer la surface à l’aide d’un chiffon humide, si désiré.

1. Enlever l’excédent d’huile et d’aliments régulièrement avec une raclette de type lame à

devraient être suivies:

carbonisée et difcile à enlever. Pour prévenir cette situation, les mesures de nettoyage suivantes

et maintenir ses prestations optimales. NE PAS laisser la graisse s’accumuler car elle deviendra

Il faut très peu de temps et d’efforts pour garder la surface de ce gril en chrome industriel étincelante

GARDE

MISE EN

ENTRETIEN DU GRIL (SURFACES CHROMÉES)

Page 15

6

15

de cuisson ordinaire. Le tiroir s’enlève en tirant vers l’avant, le haut et l’extérieur.

3. Au moins une fois par jour, retirer le tiroir à déchets et laver de la même façon qu’un ustensile

en acier inoxydable du gril. Essuyer le devant poli à l’aide d’un chiffon doux.

2. Tous les jours - utiliser un chiffon propre et un bon nettoyant non abrasif pour nettoyer le corps

aliments.

Ne pas utiliser de laine d’acier en raison du risque que des éclats d’acier pénètrent dans les

puis reconditionné. Utiliser une pierre ponce ou une pierre à gril pendant que le gril est chaud.

gras et les aliments deviennent excessivement calcinés, le gril doit être récuré soigneusement,

l’excédent de graisse et d’aliments. Un récipient à déchets est prévu pour les raclures. Si le

1. Après chaque usage, racler le gril à l’aide d’une raclette ou d’une spatule exible pour enlever

mesures suivantes de propreté devraient être suivies:

en une substance dure qui est extrêmement difcile à enlever. Pour prévenir cette situation, les

Si on la laisse s’accumuler, la graisse forme une agglutination gommeuse pour ensuite se carboniser

Il faut très peu de temps et d’efforts pour garder le gril attrayant et maintenir des prestations optimales.

ENTRETIEN DU GRIL (SURFACES NON CHROMÉES)

GARDE

GRAISSE CHAUDE.

REDOUBLER DE PRUDENCE EN MANIANT LE BAC À GRAISSE CONTENANT DE LA

MISE EN

vérié et vidé au besoin.

Le bac à graisse, situé à l’avant, peut être enlevé depuis l’avant pour le nettoyage. Ce bac doit être

BAC À GRAISSE

préchauffage, le thermostat maintient automatiquement la température choisie.

Mettre le bouton du cadran du thermostat à la température désirée. Après une brève période de

CUISSON (MODÈLES TD, TCHSD et TSPD SEULEMENT)

surface de cuisson jusqu’à ce que la plaque du gril soit "rodée".

Même avec un conditionnement soigné, les aliments peuvent, dans une certaine mesure, adhérer à la

devrait maintenant être prête à usage.

autre demi-heure, puis retirer à nouveau l’excédent de graisse et essuyer. La surface du gril

4. Appliquer une autre pellicule d’huile de cuisson sur la surface de cuisson chaude pendant une

3. Enlever l’excédent de graisse et essuyer.

une demi-heure sur la surface chaude du gril.

cuisson ou de matière grasse sur la surface de cuisson du gril. Cette pellicule doit demeurer

2. À l’aide d’un chiffon propre, et non d’une spatule, étendre une pellicule mince d’huile de

1. Tourner le cadran de contrôle de température à 174.9oC (350oF).

la surface chauffante du gril de la manière suivante:

empêcher les aliments de coller. Avant usage et après chaque nettoyage en profondeur, conditionner

Nettoyer soigneusement la surface du gril. Une fois bien nettoyé, le gril devrait être conditionné pour

NON CHROMÉES)

CONDITIONNEMENT DE LA SURFACE CHAUFFANTE DU GRIL (SURFACES

durant la nuit, tournez les valves à la position de "OFF."

températures en tournant le bouton du robinet du brûleur à une position entre haut et bas. Pour l'arrêt

est commandé par un robinet individuel haut-bas, marche-arrêt. On peut obtenir un nombre inni de

Pour allumer les brûleurs, tourner le bouton du robinet du brûleur à la position "HI." Chaque brûleur

FONCTIONNEMENT DES BRÛLEURS (MODÈLES MD et MDS SEULEMENT)

dure est obtenue. Répéter pour tous les brûleurs.

lumineuses et ouvrir jusqu’à un point où les pointes jaunes disparaissent et une amme bleue

3. Fermer le volet d’air de manière à donner une amme bleue douce ayant des pointes

2. Pousser le cadran vers l’intérieur et mettre le thermostat d’un brûleur à 229.9oC (450oF).

1. Enlevez le panneau avant.

AJUSTEMENT DES BRÛLEURS (MODÈLES TD, TCHSD et TSPD SEULEMENT)

Page 16

5

16

dure est obtenue. Répéter pour tous les brûleurs.

lumineuses et ouvrir jusqu’à un point où les pointes jaunes disparaissent et une amme bleue

3. Fermer le volet d’air de manière à donner une amme bleue douce ayant des pointes

2. Tourner le bouton du robinet du brûleur à la position "HI."

1. Enlevez le panneau avant.

AJUSTEMENT DES BRÛLEURS (MODÈLES MF SEULEMENT)

une forme uniforme de cône.

amme pilote. Ajustez la amme pilote de sorte qu'elle soit approximativement 3/8 à 1/2" grands et

Une soupape de commande manuelle est fournie du côté gauche de la commande pour ajuster la

SEULEMENT)

AJUSTEMENT DES LAMPES PILOTES DE SÛRETÉ (SÉRIES TCHSF ET TSPF

allumer le brûleur immédiatement lorsque le robinet du brûleur est ouvert à réglage élevé.

Mettre les ammes de veille à un réglage aussi bas que possible, mais sufsamment élevé pour

AJUSTEMENT DES FLAMMES DE PILOTES

allumées encore an de cuire.

5. Pour arrêter le gaz, tournez le bouton à la position de "OFF." Les pilote lampes doivent être

4. Pour tourner les brûleurs arrêtent le bouton à la position "PILOTE."

3. Tenez et tournez le bouton de commande à la température désirée.

s'est allumé. (Répétition pour toutes les sections de brûleur.)

allumant le pilote. Tenez le bouton dedans pendant 60 secondes ou jusqu'aux séjours pilotes

2. Tournez le bouton de commande à la position "PILOTE", enfoncez et tenez le bouton tout en

brûleurs et attendez 5 minutes pour dégager le gaz.

Si les clapets à gaz ont été allumés et le gaz s'est échappé par les brûleurs, tournez "OFF"

GARDE

MISE EN

1. Tournez les boutons de commande à la position de "OFF."

INSTRUCTIONS D’ALLUMAGE (SÉRIES TCHSZ ET TSPZ)

allumer la lampe pilote est du fond de l'unité juste derrière le mur central.

La amme pilote peut être allumée et vue par le panneau avant. Cependant, le meilleur accès pour

allumés immédiatement après ouverture du gaz.

REMARQUE: Les grils sont équipés de lampes de veille permanentes et doivent être

5. Pour fermer les brûleurs, tourner les boutons à la position d’arrêt.

4. Tourner les boutons de brûleur au réglage désiré.

3. Ouvrir la vanne principale et allumer toutes les ammes de veille.

2. Fermer tous les boutons et les robinets des ammes de veille.

du gaz.

1. Fermer la vanne d’alimentation principale à l’appareil et attendre 5 minutes jusqu’à disparition

impuretés soient complètement brûlées.

Au premier allumage, le gril émettra de la fumée jusqu’à ce que les huiles de préservation et les

GARDE

MISE EN

INSTRUCTIONS D’ALLUMAGE

chèque système de la tuyauterie entier pour les fuites.

gaz. Égaux, amme de la bougie ou autres sources d'ignition ne seront pas utilisées pour ce but. Le

Savon et solution de l'eau ou autre matière acceptable pour le but, sera utilisé dans localiser la fuite du

VÉRIFIER POUR LES FUITES DU GAZ

jusqu'à ce que le réel rapport soit fait à la ligne de la provision du gaz.

L'entrée du gaz du grils est scellée à l'usine pour prévenir entrée de saleté. N'enlevez pas ce cachet

LA RELIANT LIGNE DE LA PROVISION DU GAZ

Page 17

17

4

la boîte de la pipe de la provision que soit enlevé pour attacher une jauge de pression.

7. Mettez la diverse pression à 25.4 cm (10 po) eau la colonne. Un 1/8 " bouchon de la pipe sur

régulateur est maintenant mis pour 25.4 cm (10 po) colonne de l'eau.

bouchon et le ré installe. Les lettres " LP " devrait être maintenant visible sur le bouchon. Le

6. Enlevez les emboîté, ou sort - enlé, bouchez de le régulateur de la pression. Inversez le

5. Remettre le tableau avant en place.

4. Remettre le(s) brûleur(s) en place.

3. Retirer le(s) capot(s) de gaz naturel et poser le(s) capot(s) de propane fourni(s).

brûleur et en se glissant les brûleurs des capots.

2. Retirer le(s) brûleur(s) du(des) capot(s). Ceci est accompli en enlevant les vis de support de

1. Retirer le tableau de commande en enlevant les vis situées à l’avant et en bas.

graisse, comme suit:

convertir au gaz du propane, installez les capuchons de l'orice du brûleur, localisés dans le tiroir de la

Ce gril est équipé de capots xes et est expédié de l’usine pour usage sur le gaz naturel. Pour

GAZ PROPANE

appareil.

Un robinet d’arrêt manuel doit être posé en amont du raccord et à moins de 1.829 m (6 pieds) de cet

ROBINET D’ARRÊT MANUEL

naturel.

transporté résolu pour 15.24cm (6 po) colonne de l'eau diverse pression pour usage avec le gaz

à la pipe d'entrée à l'arrière de l'unité. La ligne de la provision du gaz est reliée à lui alors. Il est

Un régulateur de la pression convertissable est fourni chaque plaque chauffante. Il devrait être relié

LE RÉGULATEUR DE LA PRESSION DU GAZ

tuyaux et raccords sont exempts de saleté lâche.

abîmera le robinet et affectera son fonctionnement. En installant cet appareil, s’assurer que tous les

particule lâche de saleté ou de métal qu’on laisse pénétrer dans la canalisation de gaz de cet appareil

Ces mastics devront être résistants à l’action des gaz de propane liquéé. MISE EN GARDE: Toute

Du mastic à joints doit être utilisé modérément et uniquement sur les lets mâles des joints de tuyau.

raccordé à une canalisation existante, il faut la vérier pour déterminer si sa capacité est adéquate.

nement de gaz sufsant pour répondre aux besoins de gaz de l’appareil. Si l’appareil doit être

La canalisation de gaz doit être de dimensions et installée de manière à assurer un approvision-

CANALISATION DE GAZ

NE PAS INSTALLER SANS POSER LES PIEDS - NE PAS RETIRER LES PIEDS.

d’un alignement exact et parfait avec les autres unités.

l’appareil à niveau en ajustant les quatre pieds qui ont un ajustement de 43.75 mm (1 3/4 po) en vue

Ce gril est pourvu de quatre pieds qui doivent être vissés dans les montants xés au corps. On met

GARDE

MISE EN

UNITÉ DE MISE À NIVEAU

cheminée.

gaz. Cependant, l’appareil ne doit pas être raccordé directement à un conduit d’évacuation ou à une

Il est essentiel de prendre des mesures au-dessus du gril pour l’échappement des fumées et des

HOTTE D’ÉCHAPPEMENT

l’appareil.

pas obstruées. Elles sont essentielles à une bonne combustion et au fonctionnement approprié de

doivent être installées. S’assurer que les ouvertures d’admission d’air au bas de l’appareil ne sont

doivent être prises pour obtenir un approvisionnement d’air adéquat. Les jambes fournies avec l’unité

S’assurer de ne pas obstruer l’écoulement d’air de ventilation et de combustion. Des mesures

APPROVISIONNEMENT D’AIR

Page 18

3

18

réparations.

côtés et de l’arrière. Un dégagement adéquat doit également être prévu pour le fonctionnement et les

combustibles doivent être à au moins 120 cm (48 po) du dessus de l’appareil et à 150 mm (6 po) des

Pour usage uniquement sur les comptoirs non combustibles. Les matières combustibles et non

DÉGAGEMENT

TENEZ TOUT COMBUSTIBLE À L’ÉCART DE L’APPAREIL.

3. Appelez immédiatement compagnie de gaz.

2. Éteignez toute amme nue.

1. Ne touchez pas aux interrupteurs électriques.

Si vous sentez une odeur de gaz -

fournisseur de gaz local.

dans l’hypothèse où l’opérateur sent une odeur de gaz. On peut se procurer les instructions auprès du

votre compagnie de gaz. En outre, on doit apposer, bien en vue, des instructions détaillées à suivre

exigences de votre localité pour le gaz. L’installation dénitive doit être soumise à l’approbation de

cet appareil à une agence d’installation qualiée. Celle-ci doit connaître les installations au gaz et les

à 3.45 kPa (0.5 lb/po2). Pour votre protection, nous vous recommandons de coner l’installation de

de pression du système d’approvisionnement en gaz à des pression d’essai égales ou inférieures

du système d’alimentation en gaz en fermant son robinet d’arrêt manuel individuel durant tout essai

d’essai de plus de 3.45 kPa (0.5 lb/po2). Cet appareil et son régulateur de pression doivent être isolés

système d’approvisionnement en gaz durant tout essai de pression de ce système à des pressions

Cet appareil, son régulateur de pression et son robinet d’arrêt individuel doivent être débranchés du

DE TOUT AUTRE APPAREIL. TENIR TOUT COMBUSTIBLE À L’ÉCART DE L’APPAREIL.

D’AUTRES VAPEURS ET LIQUIDES INFLAMMABLES À PROXIMITÉ DE CET APPAREIL OU

POUR VOTRE SÉCURITÉ, NE PAS CONSERVER NI UTILISER DE L’ESSENCE OU

de réparer l’équipement.

attentivement les instructions d’installation, d’utilisation et d’entretien avant d’installer ou

l’entretien peuvent causer des dommages matériels, des blessures ou la mort. Lire

Des erreurs lors de l’installation, du réglage, de l’altération, des réparations ou de

GARDE

MISE EN

GARDE

MISE EN

GARDE

MISE EN

ÉCHÉANT.

INSTALLATION AU PROPANE CAN/CGA-B149.2 ET AUX CODES LOCAUX, LE CAS

D’INSTALLATION AU GAZ NATUREL CAN/CGA-B149.1 OU AU CODE DE

AU CANADA, L’INSTALLATION DOIT ÊTRE CONFORME AU CODE COURANT

TOUTES LES RÈGLES ET RÉGLEMENTATIONS DE LA COMPAGNIE DE GAZ LOCALE.

COMBUSTIBLE "ANSI Z223.1 - TOUTE DERNIÈRE ÉDITION" DES ÉTATS-UNIS ET À

L’installation de l’appareil doit se conformer au CODE NATIONAL DE GAZ

-IMPORTANT-

être converti pour usage avec le propane: voir gaz propane.

Tous les appareils sont expédiés de l’usine pour usage avec le gaz naturel. L’appareil peut facilement

signalétique.

Les grils modèle Star-Max™ sont équipés pour usage avec les types de gaz précisés sur la plaque

par le grand public.

service alimentaire. Prière de se mettre en contact avec l’usine pour l’équipement devant être utilisé

dans et autour de la maison ni pour usage directement par le grand public dans les établissements de

et expérimentés sur son usage, et il ne doit pas être vendu pour utilisation par des consommateurs

Cet équipement est conçu et vendu pour usage commercial seulement par des employés formés

GARDE

MISE EN

DONNÉES GÉNÉRALES D’INSTALLATION

Page 19

Courriel : Service@star-mfg.com

Site web : www.star-mfg.com

19

2

Date d’achat

Voltage

Pour une liste mise à jour voir :

Ou

Voir la liste pourvue avec l’appareil

Agent de service autorisé

AVIS

N° de série

N° de modèle

rapide. Entrez l’information requise ci-dessous pour référence rapide.

le numéro de modèle, le numéro de série, le voltage et la date d’achat pour un service plus

Contactez votre détaillent local pour les réparations ou l’entretien requis. Assurez-vous d’avoir

ENTRETIEN ET RÉPARATIONS

l’utilisateur assume tous les risques en relation avec telle utilisation.

suite de l’utilisation des spécifi cations. En utilisant le renseignement pourvu,

ou les omissions dans le renseignement pourvu ou les conclusions tirées à la

fournir le renseignement correct, STAR n’est pas responsable pour les erreurs

de changer sans préavis. Quoique STAR Manufacturing exerce la bonne foi de

et régulations, les spécifi cations contenues dans ce manuel sont susceptibles

Dû aux modifi cations périodiques de dessins, méthodes, procédures, règles

l’équipement acheté préalablement.

les changements, améliorations, ajouts ou remplacements correspondants pour

sans préavis. Ces changements ne donnent pas le droit à l’acheteur d’obtenir

Star se réserve le droit de changer les spécifi cations et la conception du produit

ricant de toute responsabilité.

L’utilisation de toute pièce autre que les pièces d’origine STAR dégage le fab-

CONSERVEZ CE MANUEL POUR RÉFÉRENCE FUTURE

dans le manuel qui accompagne l’appareil.

instructions d’utilisation ou d’entretien importantes contenues

Ces symboles sont utilisés pour souligner à l’utilisateur les

SYMBOLE DE SÉCURITÉ

Page 20

20

®

®

®

2M-Z16008 Rev. A 8/08/12

et d’opération

d’installation

Instructions

615TF, 615MF

MODEL

648TF, 648MF, 648TSPF, 648TCHSF

636TF, 636MF, 636TSPF, 636TCHSF

624TF, 624MF, 624TSPF, 624TCHSF

GRILS A GAZ

®

Loading...

Loading...