Page 1

Star

Manufacturing

International Inc.

10 Sunnen Drive

St. Louis, MO 63143

Phone: (314) 781-2777

FAX: (314) 781-3636

2M-Y7198 Rev. F 6/28/00

Installation

and

Operating

Instructions

STAR-MAX

GAS CHARBROILER

MODELS

6015CB, 6024CB, 6036CB,

6115RCB, 6124RCB, and 6136RCB

Model 6024CB

1

Page 2

GENERAL INSTALLATION DATA

CAUTION

This equipment is designed and sold for

commercial use only by personnel trained and

experienced in its operation and is not sold for

consumer use in and around the home nor for

use directly by the general public in food service

locations. For equipment to be used by the

general public, please contact the factory.

The Star-Max series gas charbroiler is equipped

for the type of gas indicated on the nameplate

mounted on the front panel. All units are shipped

from the factory for use with natural gas. The unit

can easily be converted for use with propane gas:

see propane gas.

-IMPORTANT-

INSTALLATION: INSTALL IN NONCOMBUSTIBLE LOCATIONS ONLY! Clearance

from non-combustible construction must be 6"

from back and sides.

The installation of the Appliance must

conform to the NATIONAL FUEL GAS CODE

"ANSI Z223.1 - LATEST EDITION" AND ALL

LOCAL GAS COMPANY RULES AND

REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN

ACCORDANCE WITH THE CURRENT CAN/

CGA-B149.1 NATURAL GAS INSTALLATION

CODE OR CAN/CGA-B149.2 PROPANE

INSTALLATION CODE AND LOCAL

CODES WHERE APPLICABLE.

WARNING: Improper installation,

adjustment, alteration, service or maintenance

can cause property damage, injury or death.

Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing the equipment.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE. KEEP THE APPLIANCE AREA

CLEAR AND FREE FROM COMBUSTIBLES.

This appliance, its pressure regulator and its

individual shutoff valve must be disconnected

from the gas supply piping system during any

pressure testing of that system at test pressures

in excess of 1/2 PSIG. This appliance and its

pressure regulator must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures

equal to or less than 1/2 PSIG. For your

protection, we recommend a qualified installing

agency install this appliance. They should be

familiar with gas installations and your local gas

requirements. In any case, your gas company

should be called to approve the final installation.

In addition, there should be posted, in a

prominent location, detailed instructions to be

followed in the event the operator smells gas.

Obtain the instructions from the local gas

supplier.

LEVELING UNIT

This charbroiler is supplied with 4 feet which

must be screwed into the body. Level unit by

adjusting the (4) feet which have an adjustment of

1-3/4" for accurate and perfect line-up with other

units. CAUTION: DO NOT INSTALL

WITHOUT ATTACHING FEET - DO NOT

REMOVE FEET.

GAS INPUT TO CHARBROILER:

Models 6015CB and 6115RCB 25,000 BTU/HR

Models 6024CB and 6124RCB 50,000 BTU/HR

25,000 BTU/HR/BURNER

Models 6036CB and 6136RCB 75,000 BTU/HR

25,000 BTU/HR/BURNER

2

Page 3

GAS PIPING

Gas piping shall be of such size and so installed as

to provide a supply of gas sufficient to meet the

full gas input of the appliance. If the appliance is

to be connected to existing piping, it shall be

checked to determine if it has adequate capacity.

Joint compound (pipe dope) shall be used

sparingly and only on the male threads of the pipe

joints. Such compounds shall be resistant to the

action of L.P. gases. WARNING: Any loose dirt

or metal particles which are allowed to enter the

gas lines on this appliance will damage the valve

and affect its operation. When installing this

appliance, all pipe and fittings must be free from

all internal loose dirt.

GAS PRESSURE REGULATOR

A convertible pressure regulator is provided with

each charbroiler. It should be connected to the

inlet pipe at the rear of the unit. The gas supply is

then connected to it. It is shipped set for 6" water

column manifold pressure for use with natural

gas. Allow 6" clearance from back of unit to wall

fro servicing and installation.

CONNECTING GAS SUPPLY LINE

The gas inlet of the charbroiler is sealed at the

factory to prevent entry of dirt. Do not remove

this seal until the actual connection is made to the

gas supply line.

MANUAL SHUT OFF VALVE

A manual shut off valve should be installed

upstream from the manifold and within six feet of

the charbroiler.

PROPANE GAS

This charbroiler is equipped with fixed orifice

hoods and is shipped from the factory for use

with natural gas. To convert to propane gas,

install the burner orifice hoods supplied behind

the front panel as follows:

1. Remove grill, radiants and burners.

2. Remove the burner orifice hoods and install

the orifice hoods supplied.

3. Replace the burners, radiants, and grill.

4. Set manifold pressure to (10) inch water

column. A 1/8" pipe plug on the burner manifold

can be removed for attaching a pressure gauge.

Remove the slotted, or hex-threaded plug from

the pressure regulator. Invert the plug and

re-install. The letters "LP" should now be visible

on the plug. The regulator is now set for 10"

(25.4 cm) water column.

CHECKING FOR GAS LEAKS

Soap and water solution or other material

acceptable for the purpose, shall be used in

locating gas leakage. Matches, candle flame or

other sources of ignition shall not be used for this

purpose. Check entire piping system for leaks.

PILOT LIGHTING INSTRUCTIONS

The charbroiler is equipped with standing pilots,

and should be lit immediately after the gas is

turned on.

1. Turn off main valve to unit and wait 5 minutes

to clear gas.

2. Turn off all knobs and pilot valves.

3. Turn on main valve and light all pilots.

4. Turn burner knobs to desired setting.

5. To turn burners off, turn knobs off.

SHUTTING DOWN INSTRUCTIONS

1. Turn the burner valve knobs to the off position

to turn burners off.

PILOT LIGHT REGULATION

The pilot lights on this broiler have been turned

off at the factory. Adjust pilot light flames as small

as possible, but high enough to light burner

immediately when burner valve is turned on high.

BURNER OPERATION

To ignite burners, turn burner valve knob to "HI"

position. Each burner is controlled by an

individual high-low, on-off valve. An infinite

number of broiling temperatures may be

obtained by turning the burner valve knob to any

position between high and low.

BURNER ADJUSTMENT

1. Turn burner valve knob to "HI" position.

2. Slowly decrease openings of air shutters to

give a soft blue flame having luminous tips,

then slowly increase openings to a point where

the yellow tips disappear and a hard blue flame

3

is obtained.

Page 4

EXHAUST CANOPY

Open hearth broilers inherently create a good

deal of heat and smoke and should be installed

under an efficient exhaust hood with flame proof

filters. A vertical distance of not less than 48" shall

be provided between the top of the appliance and

filters or any other combustible material.

AIR SUPPLY

Provisions for adequate air supply must be

provided.

OPERATING INSTRUCTIONS

LIGHTING

When broiler is first lit, it will smoke until the

preservation oils and impurities are burned off.

BROILING

Turn valves on and pre-heat unit on "HI" before

attempting to broil. You will have to experiment

with the grill settings and the valve settings for

your particular meat products. We recommend

that you set the grate at the full tilt position to

start with. This position allows the grease to run

down the grate into the grease tray, reducing

flare ups. Check water pans frequently and add a

sufficient amount of water when necessary. Hot

water vapors rising from the water pans and

through the combustion chamber helps reduce

flare ups. Exercise care when using your broiler.

TILTING THE GRATE

Raise or lower the grate to the next step by lifting

the grate at the back of the charbroiler where the

grate rests. Use potholders or gloves to

reposition.

ADJUSTING HEAT PATTERN

It is possible through this arrangement to have a

high heat or searing section, while having a low

heat finishing or holding section. For the searing

operation, set the valves for the section at a

position of "HI" or close to it. For holding or

finishing, set the valves closer to the "LOW"

position on the dial. You select the heat pattern

you like, and set the valves accordingly.

CLEANING

Clean regularly. Remove grate section to sink for

washing. Brush out carboned particles. Remove

and wash water pan. Wipe exterior surfaces with

detergent and a cloth. A non-abrasive cleaner can

be used on caked areas.

WATER PAN

The water pan is located at the bottom of the

unit, and is easily removed from the front of the

unit. Water should be added to the water pan and

replaced as necessary. The water pan helps

prevent flare ups and catches grease.

AIR INTAKES IN BOTTOM

Air for combustion enters from the bottom of the

unit. Do not obstruct this area.

MAINTENANCE AND REPAIRS

Contact the factory or one of its representatives

or a local service company for service or

maintenance if required.

CAUTION

CHARBROILERS ARE HOT! NEVER

ATTEMPT TO CHANGE THE GRILL

POSITION WHILE MEAT PRODUCTS

ARE COOKING. FLARE UPS CAN

OCCUR UNEXPECTEDLY. TURN OFF

CHARBROILER, AND ALLOW THE

CHARBROILER TO COOL.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

Part No. 2M-Y7198 Rev. F 6/28/00

4

Page 5

Visit our Website at: www.star-mfg.com Email: service@star-mfg.com For Fax-On-Demand Literature: (800) 807-9814

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in

which the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the

transportation company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty

status of the unit.

LIMITED EQUIPMENT WARRANTY

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is

limited to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited

to the repair of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below)

should be taken to the closest Star service agency, transportation prepaid.

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the JetStar series six (6) ounce popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is five (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teflon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teflon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted. Labor to replace the part is

chargeable to the customer.

SERVICES NOT COVERED BY WARRANTY

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls

16 . Replacement of bulbs

17. Replacement of fuses

18 . Repair of damage created during transit, delivery, &

installation OR created by acts of God

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

* The Model 510F Fryer.

* The Model 526TO Toaster Oven.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model CFS Series Food Steamer.

* The Model 526WO Warming Oven.

* The Model 518CM & 526CM Cheese Melter.

* The Model 12MC & 15MC & 18MCP Hot Food Merchandisers.

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model CSD & HPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 500, 11RW Series, and 11WSA Series.

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

* Heat Lamps

* Hot Cups

* Pumps

Part# 2M-4497-2 10/02 RB

Page 6

9

10

13

11

12

14

17

15

16

22

18

19

16

23

21

20

4

3

2

1

6

24

7

8

27

28

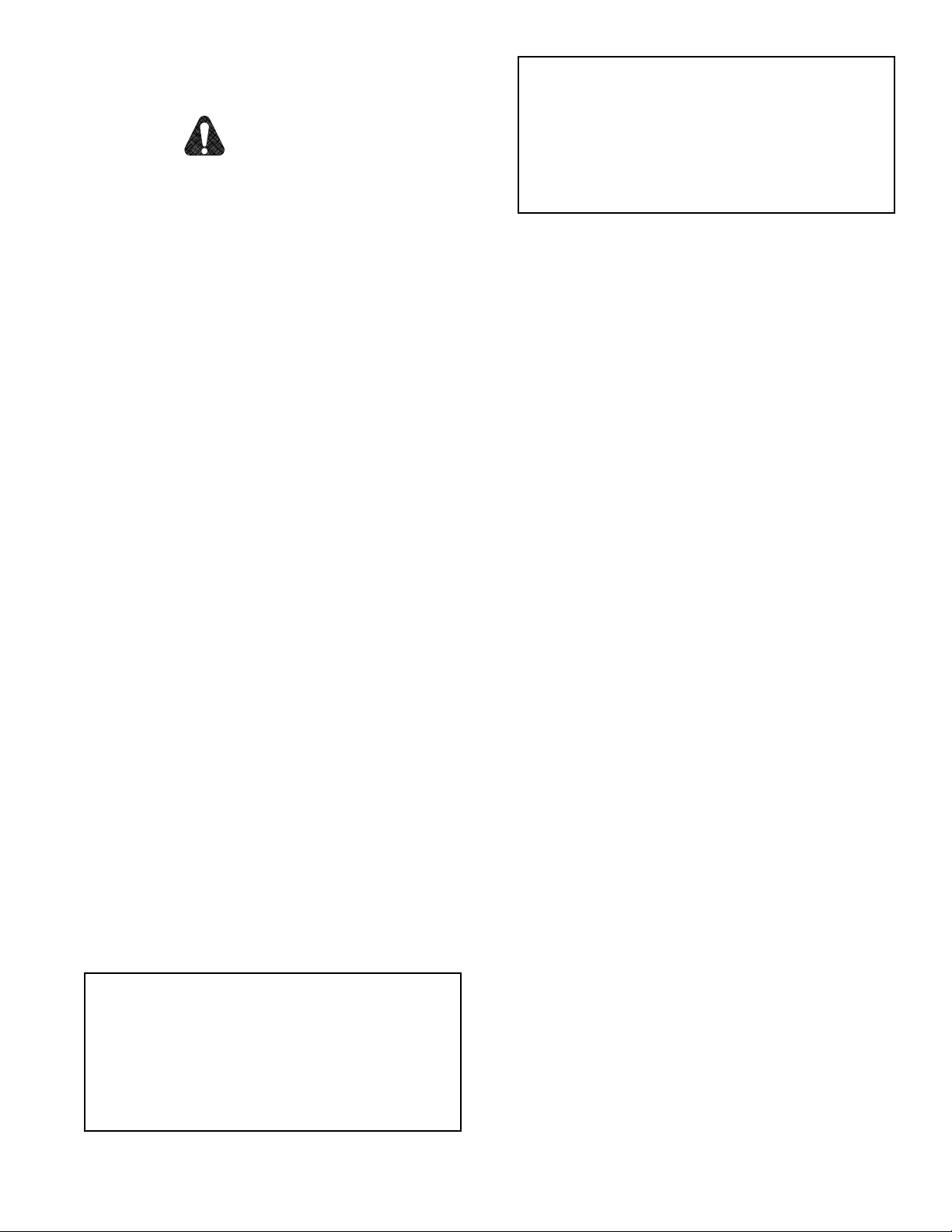

MODEL 6015CB, 6024CB, 6036CB

SK1271 REV A 8/25/06

STAR MANUFACTURING INTERNATIONAL, INC.

29

Page 7

PARTS LIST February 17, 2011, Rev. D

MODEL

6015CB, 6024CB, 6036CB Star-Max Gas Lava Rock Charbroiler-15”, 24”, 36”

Number

Key

Number

1 2R-8229 2/4/6 SHIELD KNOB 6015CB/6024CB/6036CB

2 2R-9364 1/2/3 KNOB-CONTROL 6015CB/6024CB/6036CB

3 2R-9193 1/2/3 INDICATOR BUTTON 6015CB/6024CB/6036CB

4 2M-Y9495 1 FACEPLATE 6015CB

2M-Y9479 1 FACEPLATE 6024CB

2M-Y9480 1 FACEPLATE, LEFT 6036CB

2M-Y9481 1 FACEPLATE, RIGHT 6036CB

5 G3-Y7152 1 FRONT PANEL 6015CB

G3-Y7016 1 FRONT PANEL 6024CB

G3-Y7014 1 FRONT PANEL 6036CB

6 H3-T1026 1 GREASE DRAWER 6015CB

H3-Y7045 1 GREASE DRAWER 6024CB

H3-Y7044 1 GREASE DRAWER 6036CB

7 G3-Y7047 2 SLIDE DRAWER

8 2A-Z0314 4 LEG

9 2F-Y8831 1 GRATE 3” 6015CB

10 2F-Y8830 2/4/6 GRATE 6” 6015CB/6024CB/6036CB

11 2F-Y7193 1/2/3 LAVA ROCK 2” 8 LBS. 6015CB/6024CB/6036CB

12 2F-Y7141 1 GRATE LAVA ROCK 15” 6015CB, 6036CB

13 2F-Z3273 2 GRATE LAVA ROCK 10.5” 6024CB, 6036CB

14 H3-624086 1/2/3 BURNER GUARD ASSEMBLY 6015CB/6024CB/6036CB

(AS PICTURED)

15 2F-Y7052 1/2/3 BURNER ASSEMBLY (AS PICTURED) 6015CB/6024CB/6036CB

(EFFECTIVE 1/92)

16 2A-Y6694 1/2/3 CLIP 6015CB/6024CB/6036CB

17 G3-624038 1 GUARD WELD ASSEMBLY 6015CB

G3-624037 1 GUARD WELD ASSEMBLY 6024CB

G3-624039 1 GUARD WELD ASSEMBLY 6036CB

18 2P-1453 1 PLUG-PIPE

19 2V-6671 1/2/3 VALVE-PILOT 6015CB/6024CB/6036CB

20 2V-Y8832 1/2/3 VALVE-BURNER 6015CB/6024CB/6036CB

21 2J-Y8838 1/2/3 HOOD BURNER NAT. #45 6015CB,/6024CB/6036CB

2J-Y7136 1/2/3 HOOD BURNER LP. #53 6015CB/6024CB/6036CB

22 G3-Y7355 1/2/3 TUBE-PILOT 6015CB/6024CB/6036CB

23 G3-Y7356 1/2/3 PILOT BRACKET 6015CB/6024CB/6036CB

24 2K-Y7123 1 INLET PIPE

25 G3-Y7252 1 INLET PIPE SUPPORT

26 2J-Y7589 1 PRESSURE REGULATOR

27 H3-Y7569 1/2/3 COVER, BURNER BACK

28 H3-Y7570 1/2/3 COVER, BURNER FRONT

NI H3-Y7095 1/2/3 Bracket Burner

Part

Number

Per

Unit

Description and Model Designation

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 8

STAR MANUFACTURING

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(800) 807-9054 (314) 781-2777

Parts & Service (800) 807-9054

www.star-mfg.com

Loading...

Loading...