Page 1

Star

Manufacturing

International Inc.

10 Sunnen Drive

St. Louis, MO 63143

Installation

and

Operating

Instructions

Phone: (314) 781-2777

FAX: (314) 781-3636

COUNTER MODEL

POPCORN MACHINES

MODELS

49, 49D, 49SL

59, 59D, 59SL

89, 89D, 89SL

2M-8497 REV. C 1/30/90

REV.6-14-01RDB

1

Page 2

GENERAL INSTALLATION DATA

CAUTION

This equipment is designed and sold for

commercial use only by personnel trained

and experienced in its operation and is not

sold for consumer use in and around the

home nor for use directly by the general

public in food service locations. For

equipment to be used by the general

public, please contact the factory.

THOUROUGHLY INSPECT YOUR

MACHINE ON ARRIVAL

We do everything in our power to insure

delivery of your machine in perfect

condition. However there are instances in

which the unit may be damaged in transit,

in the event your unit is damaged in

transit, have the transportation company

make the necessary notations on your

freight bill or delivery receipt. Immediately

report this damage to the dealer from

whom you purchased the machine. The

dealer will advise proper handling

Instructions. If damage is not discovered

until after delivery has been made, notify

the transportation company immediately.

However, in each instance, request an

inspection report to cover whatever damage

has occured in transit.

INSTALLATION

Each machine has been properly wired

and inspected at the Factory for operation

on the Voltage and type of Current

specified on the nameplate.

CAUTION

Do not connect to any other type of

current or the machine will be seriously

damaged.

A receptacle is furnished with the 89

Series Popcorn machines. We strongly

recommend installation by a Licensed

Electrician. The guarantee of this machine

as covered by the Warranty Card does not

apply if an improper installation has been

made.

120 VOLT MACHINES

Machines with nameplate stamped 120V,

are equipped for operation on 120 Volt, 2

wire, 60 Cycle AC single phase service

and must be connected to a separate 20

Amp circuit with a 3 wire grounded,

polarized receptacle.

240 VOLT MACHINES

Machines with nameplate stamped 240V,

are equipped for operation on 240 Volt, 2

wire, 60 Cycle AC single phase service

and must be connected to a separate 15

Amp circuit with a 3 wire grounded,

polarized receptacle.

GENERAL OPERATING

INSTRUCTIONS

CAUTION

The motor air intake and exhaust holes

located on top of the machine must be

clear of any obstruction.

DO NOT COVER THESE AIR VENT HOLES

as serious damage will result.

Check to insure the installation of the

Corn Drawer before the Popping cycle is

started. See picture for location of Corn

Drawer.

With all switches in the "OFF" position,

proceed in the following sequence to Pop

Corn:

1.) Turn "ON" the Corn Warming switch.

This switch controls the Bottom heating

element, the Top heating lamp and the

Sign diplay lamps of the Sign Lighted

models.

2.) Turn "ON" the Kettle switch. This

switch controls the Kettle heating

element. The Red pilot light is provided to

indicate when the Kettle switch is "ON".

Allow six to seven minutes to pre-heat the

Kettle. The Kettle heating element is

thermostatically controlled. Thermostat

adjustments should not be necessary as it

has been preset at the factory for the

2

correct popping temperature.

Page 3

GENERAL OPERATING

INSTRUCTIONS - continued

3.) Turn "ON" the Agitator Motor switch

located at the right end of the motor

housing. This switch will function only

when the Kettle switch is in the "ON"

position. If the Kettle switch is turned

"OFF", the Motor will also stop. This Motor

should always be running when there is

corn in the Kettle. This will prevent

scorching or burning of corn.

4.) A Corn and Seasoning measuring cup

is supplied with your machine. Pour a

level measuring cup of Oil (2 ounces Models 49, 49D, 49SL, 59, 59D, 59SL and

3-1/2 ounces - Models 89, 89D, 89SL) in

Kettle. Add a level measuring cup of raw

corn (8 ounces - Models 49, 49D, 49SL,

59, 59D, 59SL and 14 ounces - Models

89, 89D, 89SL) and a Teaspoon of Popcorn

Salt. Vary the amount of salt and oil to

suit taste. If desired, salt may be added

adfter the Corn is popped.

5.) When the Corn stops popping, dump

the Kettle immediately by turning the

handle clockwise approximately 90

degrees to release latch. Recharge as

quickly as possible. Screen out unpopped

kernels over the perforated section of the

Corn pan.

6.) Turn the Kettle "OFF" when the

desired amount of popping is completed.

WARNING

Do not leave the Kettle and Motor switch

"ON" when the machine is not in use. Do

not immerse the Kettle in water or allow

water to come in contact with the Heating

element.

Popping Corn in dry kettle is not

recommended.

Do not connect machine to Direct Current,

as this unit is designed to operate on

Alternating Current only!

MAINTENANCE

Keep The Popping Unit Clean

After each popping period, wipe clean the

Kettle inside and out while it is warm.

This is important because if seasoning

and salt are not thoroughly removed, a

carbonized material will form. This

condition not only lowers popping

efficiency and causes excessive smoking,

but could damage the unit. For retaining

the high lustre on the stainless steel

Kettle shell and lids, use a non-abrasive

standard stainless steel cleaner when the

Kettle is cold. Use a damp cloth and a

warm mild soap solution to clean the glass

and clear plastic surfaces.

To remove Kettle:

Turn "OFF" the Kettle motor switches.

Disconnect the Twist Lock Cap at the end

of the Kettle conduit, turn Kettle handle

clockwise 90 degrees to unlatch the

Kettle, hold the Kettle and pull out the

hinge pin. The Kettle can now be removed

from unit. Use asbestos gloves to remove a

hot Kettle. DO NOT PLACE THE KETTLE

IN WATER, as this will damage the

electrical assembly.

To change Sign Display Lamps (on Sign

Lighted Models):

Turn "OFF" all switches. Unscrew 2 sheet

metal screws on the Rear side top (holding

switch and pilot light panel) and 4 screws

on the top. Cautiously take the top off.

Cahnge bulb(s) and reassemble the top

onto the frame. Tighten all six screws

securely. WARNING! Use only inside

Frosted Bulb. Wattage per label on the

surface of the Top Liner. By Authorized

Personnel Only.

MAINTENANCE and REPAIRS

Contact the Factory or one of its

representatives or a local Service

Company for Service or Maintenance

required.

3

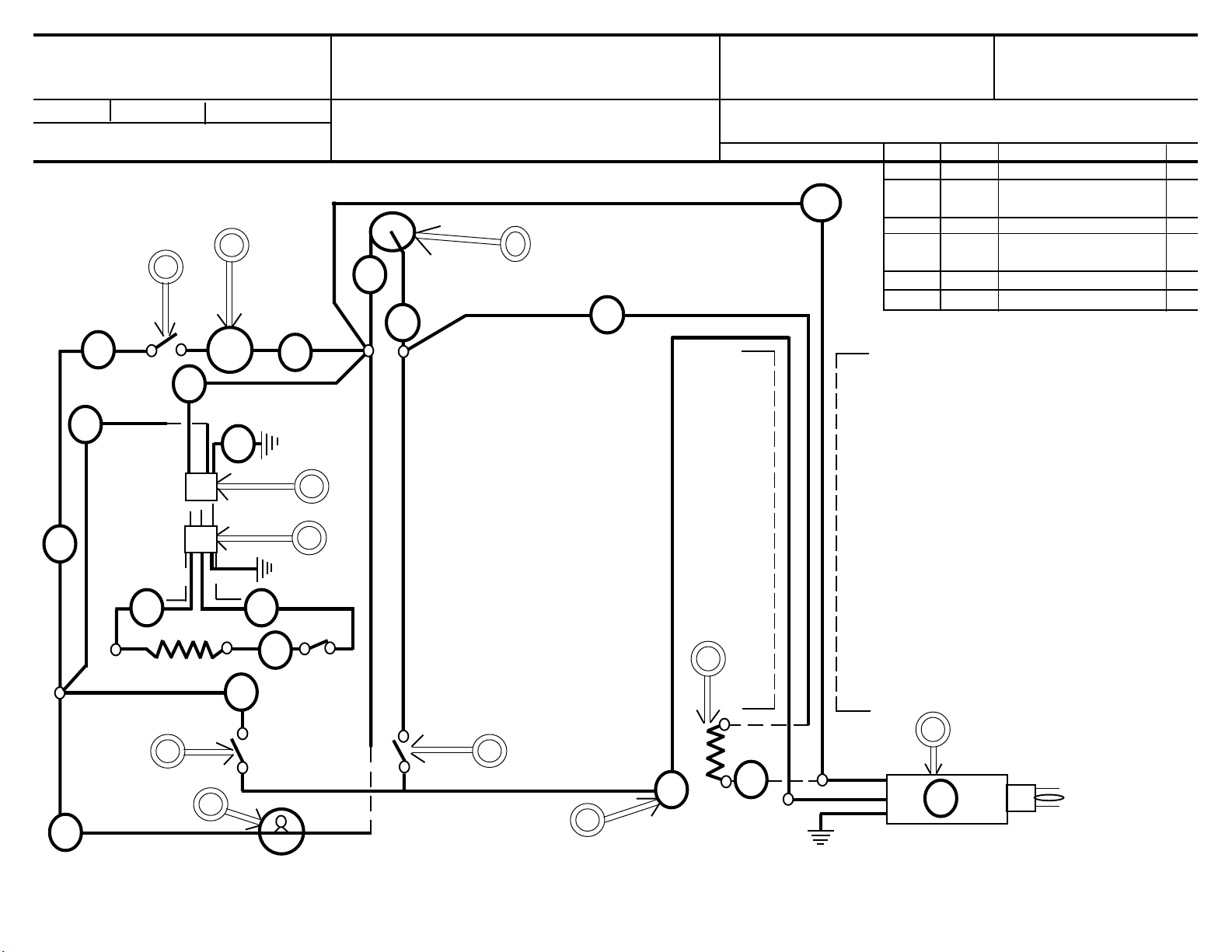

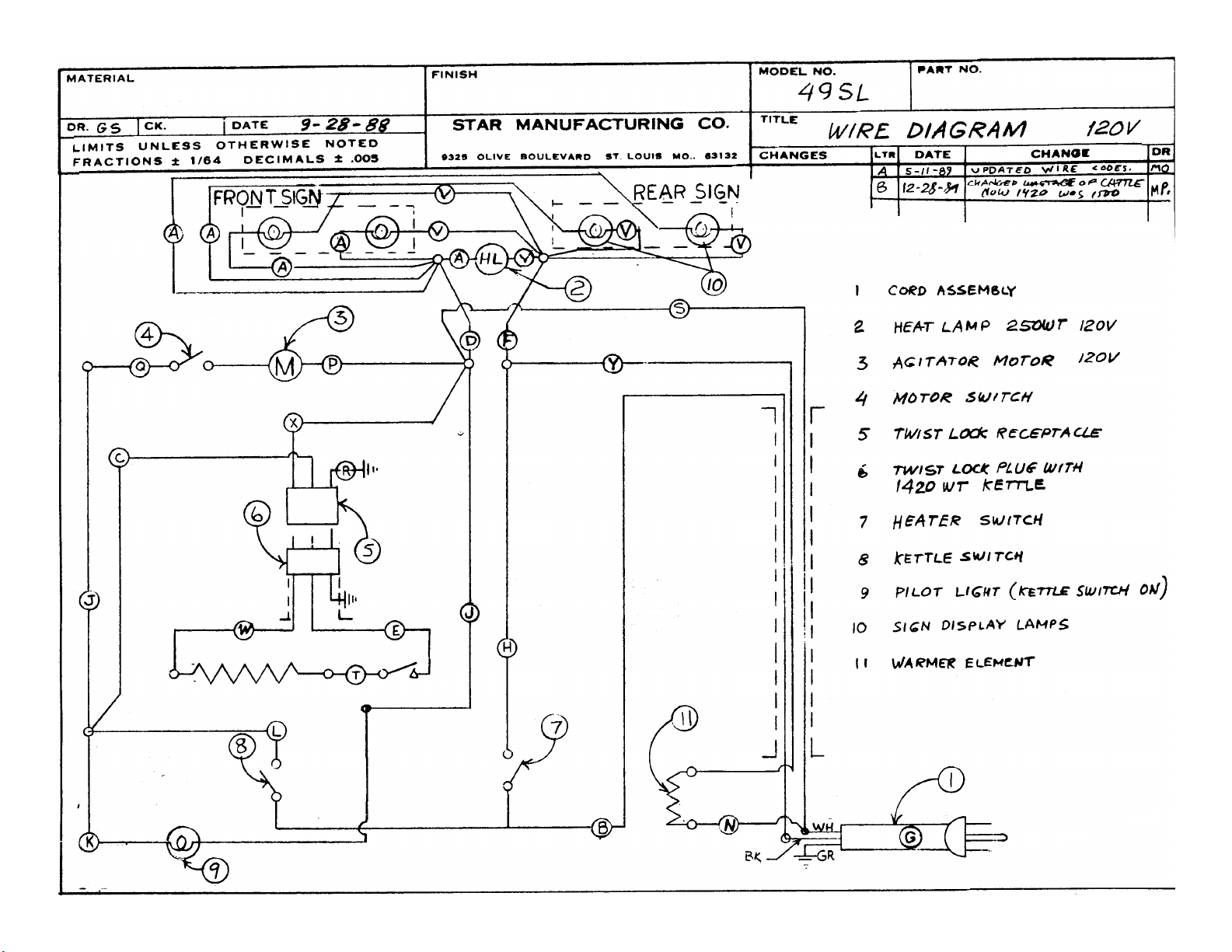

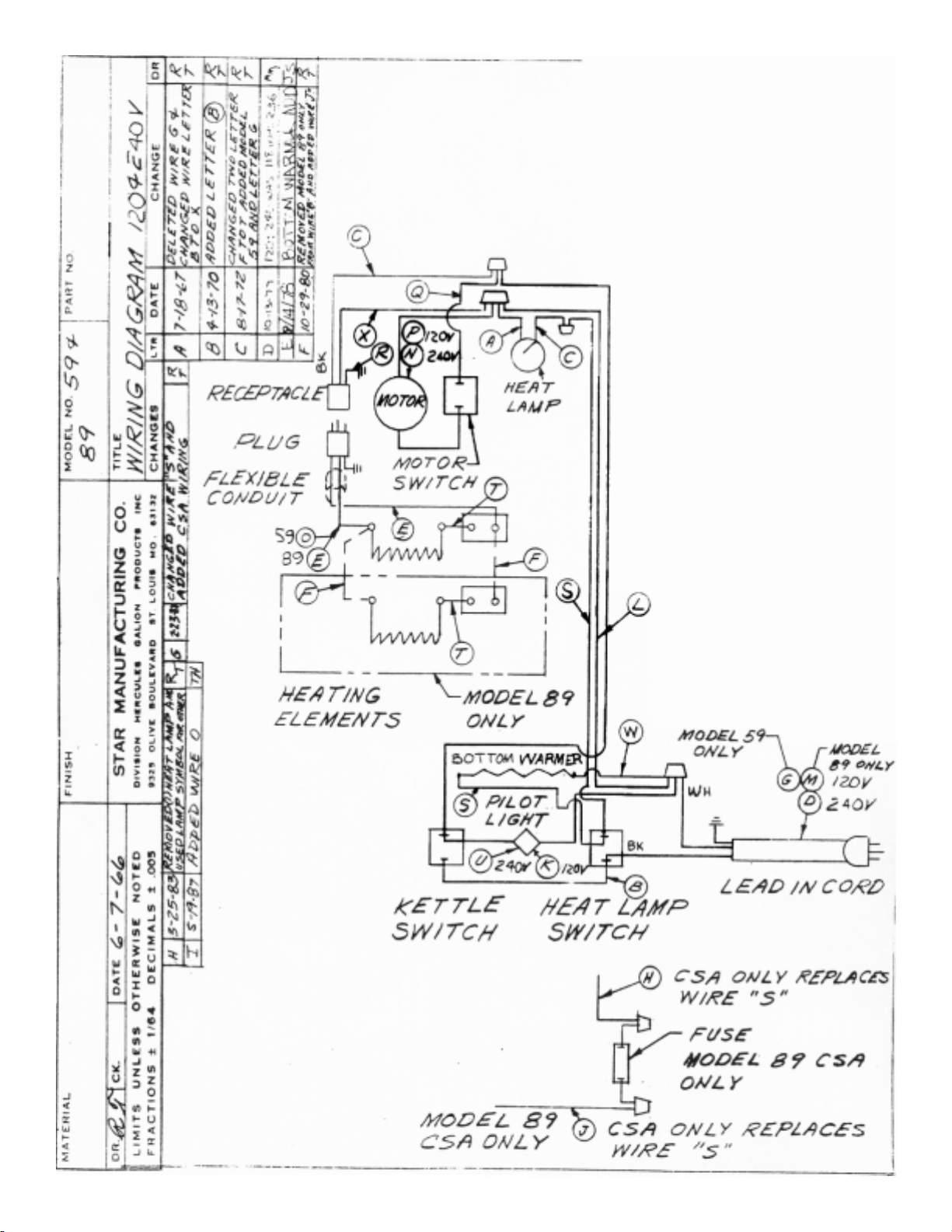

Page 4

MATERIAL

FINISH

MODEL NO. PART NO.

49, 49D

DR. PB CK. DATE 4-24-75

LIMITS UNLESS OTHERWISE NOTED

FRACTIONS +/- 1/64 , DECIMALS +/- .005

3

4

Q

M

P

X

C

BK

R

WH

5

J

W

E

6

STAR MANUFACTURING INT’L

10 SUNNEN DRIVE ST. LOUIS,MO 63143

2

A

V

Y

TITLE

WIRE DIAGRAM

CHANGES LTR DATE CHANGE DR

S

A 8-31-76 ADDED 49D MM

B 2-22-77 ADDED COLOR CODE TO JS

WIRES

C 9-14-78 ADD BOTTOM WARMER JS

D 3-25-83 SHOWED LAMP SYMBOL RT

ON HEAT LAMP

E 5-19-87 ADDED WIRE Q TH

F 5-11-89 UPDATED WIRE CODES MO

1 CORD ASSEMBLY

2 120V - 250 WATT HEAT LAMP

3 120V AGITATOR MOTOR

4 AGITATOR MOTOR SWITCH

5 TWIST LOCK RECEPTACLE

6 TWIST LOCK PLUG W/1500

WATT KETTLE

7 HEAT LAMP SWITCH

8 KETTLE SWITCH

9 SIGNAL LIGHT (KETTLE SWITCH

ON)

10 WIRE CODES

11 WARMER ELEMENT

K

T

11

(ALL WIRES ARE #16 GA CUA1 WHITE STRD)

L

1

8

9

7

BK

WH

GR

G

REV.6-14-01RDB

10

B

N

Page 5

Page 6

Page 7

Page 8

Old Style Hinge Bracket = N/A

Use C3-Y2611 + C3-Y2612 instead

Long Jumper

2C-9617

8 Oz. Kettle

49 Series

59 Series

Page 9

PARTS LIST January 22, 2014

Model: 49 & 59 Kettle Series Popcorn Machines

Fig No Part Number Qty Description Application

C3-49009 NLA 1

1-31

1 2F-8351 1 CASTING KETTLE 8 oz

2 C3-8605 1 JUMPER LONG

3 2T-6213 1 THERMOSTAT, 550V B-200 1/4 TURN CLOWISE = 30°F RISE

4

5

7 C3-59024 1 ELEMENT CLAMP ASSY

8 2C-1810 3 WASHER 3/16 STL NP

9 2C-1512 3 SCREW 10-24X3/8 RHP STL

13 C3-Y4053 1 INSULATION MANNINGLAS

14 2C-8569 1 SCREW 1/4-20X2 ST SET

15-19 C3-59007 NLA 1 KETTLE HANDLE ASSY #4936652, #5916854 & BELOW

15 2P-8880 1 SPRING-HANDLE TORSION

16 2A-8838 1 ROD, HANDLE PLATED

17 2R-8293, NLA 1 HANDLE HARDWOOD BLACK

18 2C-1811 1 WASHER 1/4 STL

19 2C-2581 2 NUT 1/4-20 BR ACORN NP

24 2C-9607 1 SCREW-ADJUST SG1508 #4936652, #5916854 & BELOW

25 2A-5401 1 PIN-COTTER 3/32DX3/4 SS #4936652, #5916854 & BELOW

C3-49084 NLA 1 240V (49 & 59 SERIES)

C3-59025 NLA 1 120V (59& 59D SERIES)

C3-Y2611 1 BRACKET-KETTLE HINGE CP

C3-Y2612 1 BRACKET-KETTLE PLATED

2C-1589 2 SCREW, MACHINE

2C-Y1221 2 BOLT 1/4-20X1/2 HEX STL NP

KETTLE ASSY COMPLETE

120V (49 & 59 SERIES)

15-19 C3-49014 1 HANDLE AND ROD ASSY COMPLETE

2A-2100 1 PIN-GROOVE 1/80X5/8 ST

2A-Y5377 1 ROD-HANDLE-PLATED

2R-09-WB-0027 1 HANDLE BLACK 3/8-16

2B-Y6139 1 CLIP-HANDLE

2P-8880 1 SPRING-HANDLE TORSION

24 2V-Y5379 1 RETAINER

25 C3-Y5378 1 CAM

20-23 C3-59052 1 KETTLE CONDUIT W/WIRES

20 C3-59029 1 KETTLE LEAD WIRE ASSY

21 2P-8354 1 CAP-TWIST LOCK L5-15P

22 2E-8355 1 CONDUIT, FLEXIBLE - 14”

23

26

27 2C-2559 1 NUT 10-24 ACHD BR NP

31

2E-1177 1 CONNECTOR 3/8 TB#266

2K-3831 1 BUSHING-7/16 ODX-028

C3-59051 1 KETTLE SHELL ASSY OLD STYLE 49 & 59

2C-Y3166 1 WASHER

2C-1494 1 SCREW 8-32X1/2 RHP STL NP

2N-Y5592 1 ELEMENT 1420 WATTS/9.6 OHMS 120V

2N-Y5593 1 ELEMENT 1420 WATTS/40 OHMS 240V

Page 10

Short Jumper

Long Jumper

Old Style Hinge Bracket = N/A

Use C3-Y2611 + C3-Y2612 instead

Short Jumper

Old Style Element Clamps = N/A

Use C3-Y3140 instead

Long Jumper

14 Oz. Kettle

89 Series

Page 11

PARTS LIST EFFECTIVE 11-11-03 rb

01/15/2014 BBE

MODEL 89 Series Machines

Key

Number

Part

Number

Number

Per

Unit

Description

14 Oz. Kettle Assembly

1-31 C3-89002 1 KETTLE ASSEMBLY COMPLETE - 120V (#8909159 & BELOW)

N/A - Use C3-89011 + C3-Y2612 instead

C3-89011 1 KETTLE ASSEMBLY COMPLETE - 120V (

(10 Lbs shipping weight)

C3-89009 1 KETTLE ASSEMBLY COMPLETE - 240V (#8909160 & ABOVE)

1 2F-8395 1 KETTLE CASTING (Sand Cast Material)

2 C3-8605 2 KETTLE JUMPER - LONG

3 2T-6213 2 THERMOSTAT (1/4 turn clockwise = 30

4 C3-8283 1 KETTLE HINGE BRACKET (#8909159 & BELOW)

N/A - Use C3-Y2611 + C3-Y2612 instead

C3-Y2611 1 KETTLE HINGE BRACKET (

5 2C-1589 2 MACHINE SCREW (1/4-20 x 1/2 Flat Head)

2C-Y1221 2 MACHINE SCREW (1/4-20 x 1/2 Hex Head)

6 C3-8690 2 KETTLE JUMPER - SHORT

7 C3-8568 1 THERMOSTAT CLAMP

8 2C-1810 9 BURR

9 2C-1512 7 SCREW (10-24 x 3/8)

10 C3-8951 1 THERMOSTAT CLAMP

11 2C-1515 2 SCREW (10-24 x 3/4)

13 C3-Y4053 1 KETTLE INSULATION

14 2C-8569 1 STUD (1/4-20 x 2)

#8909160 & ABOVE)

#8909160 & ABOVE)

0

F rise)

15-19, C3-59007 1 KETTLE HANDLE ASSEMBLY COMPLETE

24,25 (#8923059 & BELOW)

15 2P-8880 1 KETTLE HANDLE SPRING

16 C3-8838 1 KETTLE ROD HANDLE w/PIN

17 2R-8293 1 KETTLE HANDLE (wood)

18 2C-1811 1 BURR (1/4)

19 2C-2581 2 ACORN NUT (1/4-20)

24 2C-9607 1 SCREW - ADJUSTING

25 2A-5401 1 COTTER KEY

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED

INCLUDE MODEL AND SERIAL NUMBER

PAGE

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

1 OF 2

Page 12

PARTS LIST EFFECTIVE 11-11-03 rb

MODEL 89 Series Machines

Key

Number

Part

Number

Number

Per

Unit

Description

14 Oz. Kettle Assembly

15-19, C3-49014 1 KETTLE HANDLE ASSEMBLY COMPLETE

24,25 (#8923060 & ABOVE)

2A-2100 1 PIN - GROOVE

2A-Y5377 1 KETTLE ROD HANDLE

2R-Y5375 1 KETTLE HANDLE

2C-Y5376 1 CLIP - LATCH HANDLE

2P-8880 1 KETTLE HANDLE SPRING

2V-Y5379 1 RETAINER / SPACER

C3-Y5378 1 CAM

20-23 C3-59052 1 KETTLE CONDUIT COMPLETE

20 C3-59029 1 KETTLE LEAD WIRE ASSEMBLY (2 wire set w/terminals)

2C-9617 2 WIRE TERMINAL

2I-5062 15 INSULATOR BEAD

21 2P-8354 1 MALE TWIST-LOC PLUG

22 C3-8355 1 KETTLE CONDUIT

C3-Y3045 1 GROUND STRAP

23 2E-1177 1 SQUEEZE CONNECTOR

2K-3831 1 BUSHING (for conduit)

(plastic)

(w/wires & twist-loc plug)

26 C3-59051 1 KETTLE SHELL W/WASHER

(#8923059 & BELOW) (needs C3-49014 HANDLE also)

2C-Y3166 1 WASHER (1” x 1/4”)

2C-1494 1 SCREW (holds shell to casting)

27 2C-2559 1 ACORN NUT (10-24)

28,29 C3-Y3140 2 NEW STYLE ELEMENT CLAMP (use qty. 3 each of Key #8 & #9)

8 2C-1810 3 BURR

9 2C-1512 3 SCREW

30 2N-Y5594 1 KETTLE ELEMENT - 120V (300W/ 40 ohms) (SMALL) (blue dot)

2N-Y5595 1 KETTLE ELEMENT - 240V (300W/ 40 ohms) (SMALL) (red dot)

31 2N-Y5592 1 KETTLE ELEMENT - 120V (1500W/ 9.6 ohms) (blue dot)

2N-Y5593 1 KETTLE ELEMENT - 240V (1500W/ 9.6 ohms) (red dot)

(Element design was changed in 6/87)

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED

INCLUDE MODEL AND SERIAL NUMBER

PAGE

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

2 OF 2

Page 13

Hi-Temp Wire = 1N-E2052

Right Hinge w/Pin = C3-59019

Screw = 2C-1646

Left Hinge w/Pin = C3-59020

Screw = 2C-1646

Left Leaf Hinge Long = C3-8279

Screw = 2C-1512 (10-24x3/8)

Nut = 2C-2559

Motor Support Assy.

C3-59003

Right Leaf Hinge Long = C3-8278

Screw = 2C-1512 (10-24x3/8)

Nut = 2C-2559

New Style Hinge Bracket

C3-Y2612

Page 14

PARTS LIST April 7, 2010,

8 oz. & 14 oz. Machines Parts

49, 59, 89 Series Machines

Key

Number

1 C3-Y6683 1 KETTLE & LID SUPPORT

2 C3-59011 1 RIGHT KETTLE LID ASSEMBLY W/HANDLE N/A - No replacement

2R-1272 1 KNOB - KETTLE LID

2C-1506 1 SCREW (not shown)

3 2P-Y6231 1 BEARING ASSEMBLY (PLASTIC)

4 C3-59012 1 LEFT KETTLE LID ASSEMBLY

5-13 C3-59053 1 KETTLE LATCH ASSEMBLY COMPLETE

5 C3-Y1470 1 KETTLE LATCH

6 C3-2806 1 KETTLE LATCH SPRING

7 2C-1505 2 SCREW (10-24x3/8)

2C-1827 2 WASHER-SHAKE (#10) (not shown)

8 2C-1557 1 SCREW (10-24x1-1/2)

9 2C-2559 2 ACORN NUT (10-24)

10 2C-2555 1 ACORN NUT (8-32)

11 2C-1493 1 SCREW (8-32x3/8)

2C-1825 1 WASHER-SHAKE (#8) (not shown)

12 C3-8313 1 KETTLE LID PIN SPRING

13 C3-2803 1 HINGE LATCH

14 C3-Y2612 1 KETTLE HINGE MOTOR HOUSING (#5909527 & UP)

15 2E-8343 1/3 SWITCH-TOGGLE (QTY.1 ON 59D & 89D ONLY for motor)

(QTY.3 ON #4942396, #5917564, #8926996 & ABOVE)

2E-Y6144 3 SWITCH-ROCKER (#4936951 TO #4942395) (not shown)

(#5916883 TO #5917563)

(#8923915 TO #8926995)

2E-3966 2 SWITCH-ROTARY (59D & 89D ONLY for kettle & lights) (not shown)

2R-7886 2 KNOB-ROTARY SWITCH (not shown)

16 C3-59004 1 MOTOR COVER ASSEMBLY

17 PS-49116 1 MOTOR W/GEAR BOX & LEAD WIRES (120V)

C3-59050 1 MOTOR W/GEAR BOX & LEAD WIRES (240V)

17a 2A-9556 NLA 1 MOTOR GEAR W/SHAFT (#5900 imprinted) (PLASTIC)

17b 2A-9557 1 MOTOR GEAR (#5318 imprinted) (METAL)

17c 2A-Y1265 1 MOTOR GEAR - SMALL (PLASTIC)

2I-H6579 4 MOTOR GROMMETS (not shown)

18 C3-8263 1 KETTLE HINGE PIN

19 2A-Y6694 1 HAIRPIN

(#4945475, #59118062, #8928211 & BELOW)

20 2A-7939 1 AGITATOR SHAFT

21 2A-Y1555 1 UNIVERSAL

22 2A-5401 1 COTTER PIN

23 2B-8317 4 AGITATOR BLADE (SPRING)(49 & 59 SERIES) (4” LONG)

2B-8319 4 AGITATOR BLADE (SPRING)(89 SERIES) (4-1/4” LONG)

24 C3-8318 1 AGITATOR COLLAR

25 2C-6170 2 SET SCREW (8-32)

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

1

4

Star International Holdings, Inc. Company

Page 15

PARTS LIST April 7, 2010,

8 oz. & 14 oz. Machines Parts

49, 59, 89 Series Machines

Key

Number

20-25 C3-59057 1 AGITATOR ASSEMBLY COMPLETE (49 & 59 SERIES)

(TO UPDATE/UPGRADE - #4945475, #59118062 & BELOW)

20-25 C3-89006 1 AGITATOR ASSEMBLY COMPLETE (89 SERIES)

(TO UPDATE/UPGRADE - #8928211 & BELOW)

20 2A-Y7683 1 AGITATOR SHAFT (4-7/16” LONG)

20 2A-Y7217 1 AGITATOR SHAFT (5-7/16” LONG)

2C-Y6508 1 GROOVE - PIN (not shown)

21 2A-Y1555 1 UNIVERSAL

22 2A-Y6694 1 CLIP - SHAFT

23 2B-Y7218 1 AGITATOR BLADE (49 & 59 SERIES) (8-1/4” LONG)

2B-Y7219 1 AGITATOR BLADE (89 SERIES) (8-3/4” LONG)

24 2A-Y6207 1 AGITATOR COLLAR

25 2C-6170 2 SET SCREW (8-32)

20-25 C3-49502 1 AGITATOR ASSEMBLY COMPLETE (49 & 59 SERIES)

(#4945476, #59118063 & ABOVE) N/A-USE C3-59057 Instead

C3-89502 1 AGITATOR ASSEMBLY COMPLETE (89 SERIES)

(#8928212 & ABOVE) N/A-USE C3-89006 Instead

26 2S-Y2238 1 WARMER LAMP (120V, 250W)

2S-Y1508 1 WARMER LAMP - RED (120V, 250W) (used on 49D only)

27-29 C3-Y7940 1 CORN DRAWER ASSEMBLY (not as shown)

29 2R-4391 1 HANDLE

2R-Z0872 1 KNOB (not shown)

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

CUSTOMER’S VIEW, NOT SERVER’S

30-33 C3-49011 1 RIGHT DOOR COMPLETE (49)

C3-49052 1 RIGHT DOOR COMPLETE (49D) (#4905055 & BELOW)

N/A-No replacement

C3-49065 1 RIGHT DOOR COMPLETE (49D) (#4905056 & ABOVE)

C3-59069 1 RIGHT DOOR COMPLETE (59 & 89 SERIES, 89W) N/A-No replacement

30 C3-49068 2 DOOR HINGE ASSEMBLY-RIGHT (49D) (#4905056 & ABOVE)

C3-59054 2 DOOR HINGE ASSEMBLY-RIGHT

31 C3-Y2713 1 STRIKE - MAGNETIC LATCH

32 2R-1272 1 KNOB - DOOR (2C-1506 = SCREW)

33 C3-Y2730 2 DOOR - PLEXIGLASS (49) (15” x 9-1/2” W/2 holes)

C3-Y2979 2 DOOR - PLEXIGLASS (49D) (#4905056 & ABOVE)

(15” x 9-1/2” W/3 holes)

C3-Y2729 2 DOOR - PLEXIGLASS (59 & 89 SERIES, 89W)

(15” x 13” W/2 holes) N/A-No replacement

2M-Y1755 1 INSTRUCTIONS - CLEAR (not shown)

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

2

4

Star International Holdings, Inc. Company

Page 16

PARTS LIST April 7, 2010,

8 oz. & 14 oz. Machines Parts

49, 59, 89 Series Machines

Key

Number

CUSTOMER’S VIEW, NOT SERVER’S

31-34 C3-49012 1 LEFT DOOR COMPLETE (49)

C3-49053 1 LEFT DOOR COMPLETE (49D) (#4905055 & BELOW)

N/A-No replacement

C3-49066 1 LEFT DOOR COMPLETE (49D) (#4905056 & ABOVE)

C3-59070 1 LEFT DOOR COMPLETE (59 & 89 SERIES, 89W)

N/A-No replacement

31 C3-Y2713 1 STRIKE - MAGNETIC LATCH

32 2R-1272 1 KNOB - DOOR (2C-1506 = SCREW)

34 C3-49069 2 DOOR HINGE ASSEMBLY-LEFT (49D) (#4905056 & ABOVE)

C3-59055 2 DOOR HINGE ASSEMBLY-LEFT

2M-Y1755 1 INSTRUCTIONS - CLEAR (not shown)

35,36 2Q-Y2608 3 GLASS (49 SERIES) (PURCHASE LOCALLY, if possible) (ALL SIDES)

(24-5/8 x 19-5/8 x 1/8 double strength)

35 2Q-8344 1 FRONT GLASS (59 & 89 SERIES, 89W)

(PURCHASE LOCALLY, if possible)

(26-5/8 x 24-5/8 x 1/8 double strength)

2Q-Y2912 1 FRONT GLASS (89T, TIFFANY)

2M-Y2737 1 SIGN - FRONT GLASS (89P, PATRIOT)

36 2Q-8345 2 SIDE GLASS (59 & 89 SERIES, 89W)

(PURCHASE LOCALLY, if possible)

(22-5/8 x 24-5/8 x 1/8 double strength)

2Q-Y2913 2 SIDE GLASS (89T, TIFFANY)

2M-Y2738 2 SIGN - SIDE GLASS (89P, PATRIOT)

37 2I-Z0160 6 GLASS CHANNEL (UPRIGHT) (Will need to be cut to 24-11/16”)

38 2I-Z0160 2 GLASS CHANNEL (SIDE, BOTTOM) (59 & 89 SERIES, 89W)

(Will need to be cut to 21-13/16”)

39 2I-Z0160 1 GLASS CHANNEL (FRONT, BOTTOM) (59 & 89 SERIES, 89W) (25-3/8”)

2I-Y2609 3 GLASS CHANNEL (BOTTOM) (49 SERIES)

40 C1-S7515 1 LEAD IN CORD - 120V (49 SERIES)

C3-49094 1 LEAD IN CORD - 240V (49 SERIES)

C3-59022 1 LEAD IN CORD - 120V (59 SERIES)

C3-89008 1 LEAD IN CORD - 120V (89 SERIES)

C3-59023 1 LEAD IN CORD - 240V (59 & 89)

C3-89001 1 LEAD IN CORD - 120V (59D, 59SL, 89D, 89SL)

C3-59036 1 LEAD IN CORD - 240V (59D, 59SL, 89D, 89SL)

2K-Y2968 1 BUSHING - STRAIN RELIEF (120V)

2K-Y2967 1 BUSHING - STRAIN RELIEF (240V)

2E-8715 1 FEMALE WALL RECEPTACLE (120V only)

41 C3-49003 1 TOP ASSEMBLY (49) N/A-No replacement

C3-49054 1 TOP ASSEMBLY (49D, #4905055 & BELOW)

C3-49067 1 TOP ASSEMBLY (49D, #4905056 & ABOVE)

C3-59014 1 TOP ASSEMBLY (59 & 89) N/A-No replacement

C3-59015 1 TOP ASSEMBLY (59D & 89D) (less sign) N/A-No replacement

C3-59110 1 TOP ASSEMBLY (89SL)

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

3

4

Star International Holdings, Inc. Company

Page 17

PARTS LIST April 7, 2010,

8 oz. & 14 oz. Machines Parts

49, 59, 89 Series Machines

Key

Number

42,43 2C-9788 1 MAGNET & BRACE

44 2E-T1042 1 FEMALE TWIST LOCK RECEPTACLE

45 C3-59035 1 PILOT LIGHT ASSEMBLY - 120V (49, 59, 89, 89W )

C3-59034 1 PILOT LIGHT ASSEMBLY - 240V (49, 59, 89 )

C3-59047 1 PILOT LIGHT ASSEMBLY - 120V (49D, 59D, 89D)

C3-59048 1 PILOT LIGHT ASSEMBLY - 240V (49D, 59D, 89 D) N/A-No replacement

46 2E-Y5921 1 SOCKET - LAMP

C3-Y6129 1 CLIP

C3-Y4526 1 LAMPSHIELD (49 & 59 SERIES)

C3-Y4122 1 LAMPSHIELD (89 SERIES)

47 C3-8725 1 COVER - CONTROL (59, 89) (not shown)

C3-8386 1 COVER - CONTROL (59D, 89D) (not shown)

C3-Y2614 1 COVER - CONTROL (49 SERIES) (not shown) (alias SWITCHPLATE)

48 C3-49106 1 FRONT LOWER DOOR ASSEMBLY (49 SERIES)

C3-59106 1 FRONT LOWER DOOR ASSEMBLY (59 & 89 SERIES)

C3-89058 1 FRONT LOWER DOOR ASSEMBLY (89W)

2A-Y3405 4 FOOT

2M-Y6459 1 DECAL “FRESH POPPED POPCORN” (59, 89) N/A-No replacement

2M-Y2632 1 DECAL - SWITCHES, “KETTLE & WARMER”

2M-Y6306 1 DISPLAY SIGN (49SL) (back) N/A-No replacement

2M-Y6307 1 DISPLAY SIGN (49SL) (front) N/A-No replacement

2M-8506 1 DISPLAY SIGN (59D, 89D) N/A-No replacement

2M-Y6453 1 DISPLAY SIGN (49)

C3-Y2721 1 DISPLAY SIGN (49D) (woodgrain design) N/A-No replacement

2M-Y2062 1 DISPLAY SIGN (89W)

2M-Y6460 2 DISPLAY SIGN (89SL) N/A-No replacement

2S-8373 2 DISPLAY LAMP (59D, 89D) N/A-No replacement

C3-Y2722 1 RETAINER BOTTOM (for sign)

2N-8396 1 WARMER ELEMENT - 120V (not shown)

2N-8397 1 WARMER ELEMENT - 240V (not shown)

C3-8334 1 CORN SCOOP - METAL (not shown)

2L-Y4640 1 CORN CUP (3/4 cup) (not shown)

2L-Y4639 1 OIL CUP (1/4 cup) (not shown)

Part

Number

MODEL

Number

Per

Unit

Description & Model Designation

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star International Holdings, Inc. Company

4

4

Loading...

Loading...