Page 1

GARDEN HOSE UTILITY PUMP

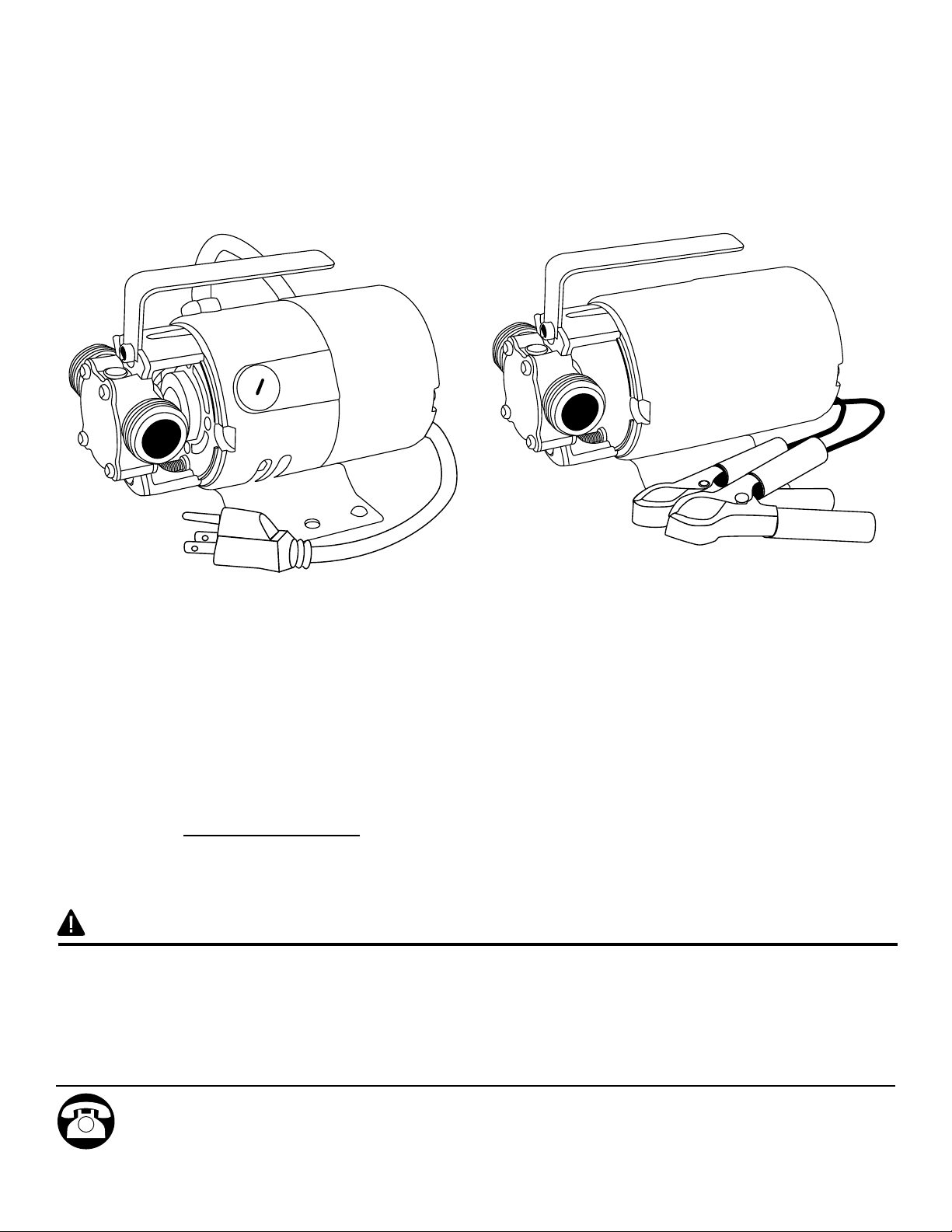

MODEL #

HPP360, HPP12V, 473707

FW0269

0313

SUPERSEDES

1012

MODEL #

HPP360, 473707

MODEL #

HPP12V

ATTACH YOUR RECEIPT HERE

Purchase Date

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install the product.

• NOTE: Pumps with the “UL” Mark and pumps with the “US” mark are tested to UL Standard UL778. CSA

certied pumps are certied to CSA Standard C22.2 No. 108. (CUS.)

Questions, problems, missing parts? Before returning to your retailer, call our customer service

department at 1-800-724-5044.

023911 B

1

Page 2

SAFETY INFORMATION SAFETY INFORMATION

DANGER

ELECTRICAL SHOCk HAzARD.

This pump is non-submersible. Keep the motor dry at all times. Do not wash the motor. Do not immerse. Protect the

motor from wet weather. Do not allow any part of cord or receptacle ends to sit in water or in damp locations. Failure to

follow these warnings will result in death or serious injury and/or property damage.

FIRE/EXPLOSION HAzARD.

Pump only clear water. Do not pump ammable or explosive uids such as gasoline, fuel oil, kerosene, etc. Do not use

in a ammable and/or explosive atmosphere. Failure to follow these warnings could result in death or serious injury and/

or property damage.

RISk OF ELECTRIC SHOCk.

These pumps have not been investigated for use in swimming pool areas.

wARNING

ELECTRICAL SHOCk ALERT.

Before installing this product, have the electrical circuit checked by an electrician to ensure proper grounding.

ELECTRICAL SHOCk ALERT.

All wiring should be performed by a qualied electrician.

ELECTRICAL SHOCk ALERT.

Connect Models HPP360 and 473707 to a properly-grounded 115 volt circuit equipped with a Ground fault Circuit

iInterrupter (GFCI) device.

ELECTRICAL SHOCk ALERT.

Do not handle pump or pump motor with wet hands or when standing on a wet or damp surface or in water.

ELECTRICAL SHOCk ALERT.

Protect pump from extreme heat, cold and humidity. This unit is not waterproof and is not intended to be used in showers,

saunas, or other potentially wet locations. The motor is designed to be used in a clean, dry location with access to an

adequate supply of cooling air. Ambient temperature around the motor should not exceed 104°F (40°C). For outdoor

installations, motor must be protected by a cover that does not block airow to and around the motor. This unit is not

weatherproof, nor is it able to be submersed in water or any other liquid. Do not use in or near swimming pool or spa.

ELECTRICAL SHOCk ALERT.

BE CERTAIN the pump power source is disconnected before installing or servicing pump.

ELECTRICAL SHOCk ALERT.

In any installations where property damage and/or personal injury might result from an inoperative or leaking pump due to

power outages, discharge line blockage, or any other reason, a backup system(s) should be used. In order to safely use

this product, familiarize yourself with this pump.

CAUTION

PERSONAL INJURY OR PRODUCT DAMAGE MAY RESULT

Models HPP360 and 473707 operate on 115 volts. Make certain that the power source conforms to the requirements of

your equipment.

PRODUCT DAMAGE MAY RESULT

This pump is not designed to handle salt water, brine, laundry discharge or any other liquid that may contain caustic

chemicals and/or foreign materials.

PRODUCT DAMAGE MAY RESULT

The maximum temperature of the pumped liquid must not exceed 130°F (54°C). The minimum allowable temperature is

40°F (4°C).

PRODUCT DAMAGE MAY RESULT

Be sure the water source and piping are clear of sand, dirt and scale. Debris will clog the pump and void the warranty.

PRODUCT DAMAGE MAY RESULT

Failure to protect the pump and piping from freezing will cause damage and void the warranty.

PRODUCT DAMAGE MAY RESULT

Do not run pump dry. Impeller and seal damage will result.

PERSONAL INJURY MAY RESULT

Release all pressure within the system before servicing any component. Provide a means of pressure relief for

installations where the discharge line can be shut off or obstructed.

PROPERTY DAMAGE MAY RESULT

Drain all liquids from the system before servicing.

PERSONAL INJURY AND/OR PROPERTY DAMAGE MAY RESULT

Secure the discharge line before starting the pump. An unsecured discharge line will whip, possibly causingi personal

injury and/or property damage.

PERSONAL INJURY MAY RESULT

Do not touch motor while operating pump. Motor is designed to operate at high temperatures.

PACkAGE CONTENTS

Description Quantity

Pump 115V or 12V 1

Inlet Hose 1

Puddle Vac 1

ELECTRICAL SHOCk ALERT.

Protect electrical cord from sharp objects, hot surfaces, oil and chemicals. Avoid kinking the cord. Replace or repair

damaged or worn cords immediately.

PERSONAL INJURY ALERT.

Models HPP360 and 473707 are equipped with an automatic resetting thermal protector and may restart unexpectedly.

Refer to troubleshooting.

CHEMICAL ALERT.

This product contains chemicals known to the state of California to cause cancer and birth defects or other reproductive

harm.

2 3

MODEL #

HPP360 / 473707

MODEL #

HPP12V

Page 3

PREPARATION

PRIMING AND STARTUP

Before beginning installation of product, make sure all parts are present. Compare parts with package contents

list. If any part is missing or damaged, do not attempt to assemble the product.

Estimated Installation Time: 5 minutes

No tools required for assembly.

INSTALLATION INSTRUCTIONS

NOTE: Pump depends on the liquid owing through it for

lubrication. DO NOT RUN THE PUMP DRY!

1. Mount pump solidly on a stable platform. Pump should

be located so that the water source is within reach of

supplied 6 ft. inlet hose.

2. Check the washer in the inlet tting of pump to make sure

it is air tight. If this leaks, pump will not operate. Install inlet

hose on the inlet side of pump. Make sure all connections

are tight.

Install a 5/8 in. outlet hose (not included) on the outlet

side of pump. Outlet hose should be as short as possible

and no longer than 25 ft. The inlet hose must reach below

the surface of the water and the outlet hose must be kept

above water.

1

Outlet Inlet

2

Outlet Hose

3 ft. Max.

Vertical

Water Source

4a. For models HPP360 and 473707, plug the cord into a

3-wire, 115 volt, 60Hz grounded A/C outlet protected by

a ground-fault circuit-interruptor. Pump will deliver 350

gallons per hour with an unrestricted discharge line. If the

discharge line is restricted or raised, pump will pump less

water.

4b. For model HPP12V, attach red battery clip to positive

terminal and black battery clip to negative terminal of a

fully charged battery.

5. To reduce friction, do not coil or kink the hoses. When

pumping from a well or stream, raise the inlet hose a few

inches off the bottom to avoid pumping in debris which

can damage the pump.

4a

Discharge

Water

4b

5

Discharge

Water

Outlet Hose

Red

Battery

Clip

Water

Source

Outlet Hose

Positive

Terminal

Water

Source

Black Battery

Clip

Negative

Terminal

Battery

PRIMING AND STARTUP

3. To prime pump, ll the pump cavity through inlet to wet

impeller. Connect supplied 6 ft. inlet hose and submerge

below surface of water. Turn on pump.

4 5

3

Outlet

Inlet

Outlet Inlet

Water Source

6. This unit is shipped with a puddle vac accessory which

allows it to remove water from at surfaces. After

attaching inlet hose in step 2, screw the puddle vac onto

the end of the inlet hose and place it on the surface to be

pumped.

CAUTION: Before water is completely gone, unplug the

pump. DO NOT RUN PUMP DRY!

Water

Source

6

Page 4

INSTALLATION INSTRUCTIONS

CARE AND MAINTENANCE

7. If pump does not start to pump water within 30 seconds,

unplug and re-check the installation and plumbing as

follows.

- Check to be sure pump is located so that the water

source is within reach of supplied 6 ft. inlet hose.

- Check to be sure all inlet connections are air and water-

tight and inlet hose is as short as possible.

- Check to be sure inlet hose is below the surface of the

water source.

- Check to be sure the outlet hose is less than 25 ft. in

length and is above the surface of the outlet water.

CARE AND MAINTENANCE

1. Always drain pump when not in use. If pump is going to be

out of use for a month or longer, ush with fresh water and

remove face plate cover. Remove impeller, clean inside

pump cavity and apply a generous coating of petroleum jelly

(not included) to the inside of the cavity and the impeller

before replacing the impeller. The pump should be checked

frequently for proper operation. If anything has changed

since the pump was new, it should be repaired or replaced.

CAUTION: Only qualied electricians should repair this unit.

Improper repair and/or assembly can cause electrical shock

hazard.

2. How to Replace Brushes (115V pump only)

NOTE: Motor brushes (not included) are normal wear items and

must be replaced periodically.

- Be sure pump is disconnected from power source.

- Unscrew brush cap located along the side of the motor.

Remove brush and spring and spring cover by pulling them

straight out of the brush holder.

- Install new brush and spring assembly (not included), keeping

the new brush curvature aligned the same as the previous

brush.

- Replace cap.

7

Outlet Inlet

1

2

Spring

Brush

Cap

Water Source

Spring

Brush

Cap

Brush

Cap

3 ft. Max.

Vertical

3. How to Replace Impeller

NOTE: Replace the impeller when it has been worn or

damaged by foreign objects, improper liquid or running dry.

- Remove four face plate screws, face plate and gasket.

- Remove damaged or worn impeller.

- Clean the inside of the pump cavity and remove any foreign

materials that might prevent the impeller from moving easily.

- Apply petroleum jelly to the inside of the pump cavity and the

outside of the new impeller (not included).

- Align the at on the new impeller with the at on the motor

shaft. Push into place while twisting blades in a clockwise

direction.

- Place new gasket on pump cavity face, align holes and

replace cover. Tighten all four screws evenly and snugly.

3

Face Plate

Screws (4)

Pump Cavity

Impeller

Gasket

Face Plate

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Pump will not

prime or retain

prime after

operating.

1. Pump won’t prime. 1. See priming instructions on page 6.

2. Suction lift too high. 2. Move pump closer to water source.

3. Hose kinked. 3. Straighten hose.

4. Hose fitting not tight on inlet. 4. Tighten fitting.

5. Air leak in suction hose. 5. Repair or replace hose.

Pump runs

but no water is

discharged.

1. Hose kinked. 1. Straighten hose.

2. Pump is not primed. 2. See priming instructions on page 6.

3. Defective impeller. 3. Replace impeller.

4. Suction lift too high. 4. Move pump closer to water source.

5. Discharge height too great. 5. Reduce discharge height.

6. Clogged inlet. 6. Clean inlet.

Motor runs too

hot.

1. Voltage incorrect. 1. Connect to 115 volt outlet.

2. Restricted discharge hose. 2. Increase hose diameter to 3/4 in.

3. Impeller damaged. 3. Replace impeller.

4. Liquid too viscous. 4. Reduce viscosity of liquid.

5. Plugged or kinked discharge. 5. Clean and straighten hose.

6. Insufficient air flow on motor. 6. Make sure ample fresh air is available

at the motor.

Flow rate is low. 1. Hose kinked. 1. Straighten hose.

2. Clogged impeller. 2. Clear obstruction.

3. Worn impeller. 3. Replace impeller.

4. Excessive length of hose. 4. Reduce length of inlet and outlet hose.

Pump will not

run.

1. No power. 1. Verify that unit is plugged into 115 volt

outlet.

2. Impeller jammed. 2. Clean pump cavity and impeller.

3. Motor overheated. 3. Motor has automatic thermal protector.

Wait fifteen minutes for motor to cool.

6 7

Page 5

REPLACEMENT PARTS

KH71

KH72 (set of 2)

Brush

Assembly

Impeller

Gasket

Part # Description

KH71 Gasket & impeller kit for HPP360, 473707 & HPP12V

KH72 Brush kit for HPP360, 473707

023754 Pump Head Kit (Includes face plate, seal, impeller and pump head)

LIMITED wARRANTY

This product is warranted for one year from the date of

purchase or two years from the date of manufacture,

whichever occurs rst. Subject to the conditions hereinafter

set forth, the manufacturer will repair or replace to the

original consumer, any portion of the product which proves

defective due to defective materials or workmanship. To

obtain warranty service, contact the dealer from whom the

product was purchased. The manufacturer retains the sole

right and option to determine whether to repair or replace

defective equipment, parts or components. Damage due

to conditions beyond the control of the manufacturer is not

covered by this warranty.

THIS WARRANTY WILL NOT APPLY: (a) To defects

or malfunctions resulting from failure to properly install,

operate or maintain the unit in accordance with printed

instructions provided; (b) to failures resulting from abuse,

accident or negligence or use of inappropriate chemicals or

additives in the water; (c) to normal maintenance services

and the parts used in connection with such service;

(d) to units which are not installed in accordance with

normal applicable local codes, ordinances and good trade

practices; and (e) the unit is used for purposes other than

for what it was designed and manufactured.

Brush

Assembly

THE WARRANTY PROVIDED HEREIN IS IN LIEU OF ALL

OTHER EXPRESS WARRANTIES, AND MAY NOT BE

EXTENDED OR MODIFIED BY ANYONE. ANY IMPLIED

WARRANTIES SHALL BE LIMITED TO THE PERIOD

OF THE LIMITED WARRANTY AND THEREAFTER ALL

SUCH IMPLIED WARRANTIES ARE DISCLAIMED AND

EXCLUDED. THE MANUFACTURER SHALL NOT, UNDER

ANY CIRCUMSTANCES, BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES, SUCH

AS, BUT NOT LIMITED TO DAMAGE TO, OR LOSS

OF, OTHER PROPERTY OR EQUIPMENT, LOSS OF

PROFITS, INCONVENIENCE , OR OTHER INCIDENTAL

OR CONSEQUENTIAL DAMAGES OF ANY TYPE OR

NATURE. THE LIABILITY OF THE MANUFACTURER

SHALL NOT EXCEED THE PRICE OF THE PRODUCT

UPON WHICH SUCH LIABILITY IS BASED.

This warranty gives you specic legal rights, and you may

have other rights which vary from state to state. Some

states do not allow limitations on duration of implied

warranties or exclusion of incidental or consequential

damages, so the above limitations may not apply to you.

WARRANTY VALID IN CANADA AND MEXICO.

RETURN OF WARRANTED COMPONENTS: Any item

to be repaired or replaced under this warranty must be

returned to the manufacturer at Kendallville, Indiana or

such other place as the manufacturer may designate,

freight prepaid.

8

Loading...

Loading...