Page 1

Notice to Installer: Instructions must remain with installation.

INSTALLATION INSTRUCTIONS

FW0519

0404

Supersedes

2/98-3

MODELS:

3CDH 3CD 412074

3CEH 3CE 433063

3CEHS 433063S

5SEH 5SE 433020

5CDH 440752

7SEH

PREINSTALLATION CHECKLIST - ALL IN STAL LA TIONS

1. Inspect your pump. Occasionally, products are dam aged during shipment. If the unit is damaged, contact your deal er

before using. Do Not remove the test plug from the pump.

2. Carefully read the literature provided to familiarize your self with specific details regarding in stal la tion and use. These

materials should be re tained for future ref er ence.

SEE BELOW FOR LIST OF WARNINGS

1. Make sure there is a prop er ly in stalled ground

fault cir cuit inter rupter (GFCI) pro tect ed cir cuit avail able. All

pumps are fur nished with pro vi sions for proper ground ing to

help pro tect you against the pos si bil i ty of electrical shock.

2. Make certain that the ground fault re cep ta cle

is with in the reach of the pump’s pow er sup ply cord DO

NOT USE AN EX TEN SION CORD. Ex ten sion cords that

are too long or too light do not de liv er sufficient volt age to

the pump mo tor. But, more im por tant, they could present a

safety haz ard if the in su la tion were to be come dam aged or

the con nec tion ends were to fall into the sump and be come

wet.

3. Make sure the pump elec tri cal sup ply cir-

cuit is equipped with fuses or cir cuit break ers of prop er

capacity. A sep a rate branch cir cuit is rec om mend ed, sized

ac cord ing the Na tional Elec tri cal Code for the cur rent shown

on the pump name plate.

4. TESTING FOR GROUND. As a safe ty mea sure,

each elec tri cal outlet should be checked for ground using

an Under writ ers Labo ra tory List ed cir cuit an a lyz er which will

in di cate if the power, neu tral and ground wires are cor rect ly

con nected to your out let. If they are not, call a qual i fied

li censed electrician.

5. Installation and checking of elec tri cal cir cuits

and hard ware should only be per formed by a qual i fied li censed

elec tri cian.

6. FOR YOUR PROTECTION, AL WAYS DIS-

CON NECT PUMP FROM ITS POWER SOURCE BE FORE

HANDLING.

7. These pumps are supplied with a 3-prong

ground ed plug to help protect you against the pos si bil i ty of

elec tri cal shock. DO NOT UN DER ANY CIR CUM STANC ES

RE MOVE THE GROUND PIN. The 3-prong plug must be

inserted in a mating 3-prong fault inter rupter re cep ta cle. If

the in stal la tion does not have such a re cep ta cle, it must be

changed to the proper type, wired, and grounded in ac cor dance with the Na tion al Elec tri cal Code and all ap pli ca ble

local codes and ordinances.

DO NOT USE FOR PUMPING OILS, GASOLINE OR ANY PETROLEUM BY-PRODUCTS.

95 N. Oak St. • Kendallville, IN 46755 • 1-800-345-9422

© Copyright 2004. All rights reserved.

SEE BELOW FOR LIST OF WARNINGS (CONTINUED)

8. RISK OF ELECTRIC SHOCK. These pumps

have not been investigated for use in swimming pool areas.

9.

the State of California to cause cancer and birth defects

or other reproductive harm.

1. Check to be sure your power source is ca-

pa ble of han dling the voltage requirements of the motor,

as indicated on the pump name plate.

2. The installation of automatic pumps with

aux il iary float switches is the re spon si bil i ty of the in stall ing

party and care should be taken that the teth ered float

switch will not hang up on the pump ing ap pa ra tus or pit

pe cu li ari ties and is se cured so that the pump will shut off.

It is rec om mended to use rigid piping and fittings and the

pit be 12" or larger in diameter.

3. These pumps are not de signed or in tend ed

to be used to handle sewage or effluent.

4. Maximum continuous operating water tem-

per a ture for stan dard mod el pumps must not ex ceed 77°F

(25°C).

5. This pump has been evaluated for use with

WATER only.

NOTE: A BATTERY BACKUP SYSTEM IS RECOMMENDED

TO PREVENT FLOODING AND/OR PROPERTY DAMAGE

IN THE EVENT OF MECHANICAL MALFUNCTION OR

POWER OUTAGE.

NOTE: Pumps with the “CSA” mark are tested to UL

standard UL778 and certified to CSA standard C22.2 No.

108.

This product contains chemicals known to

SEE BELOW FOR LIST OF CAUTIONS

135816

1

Page 2

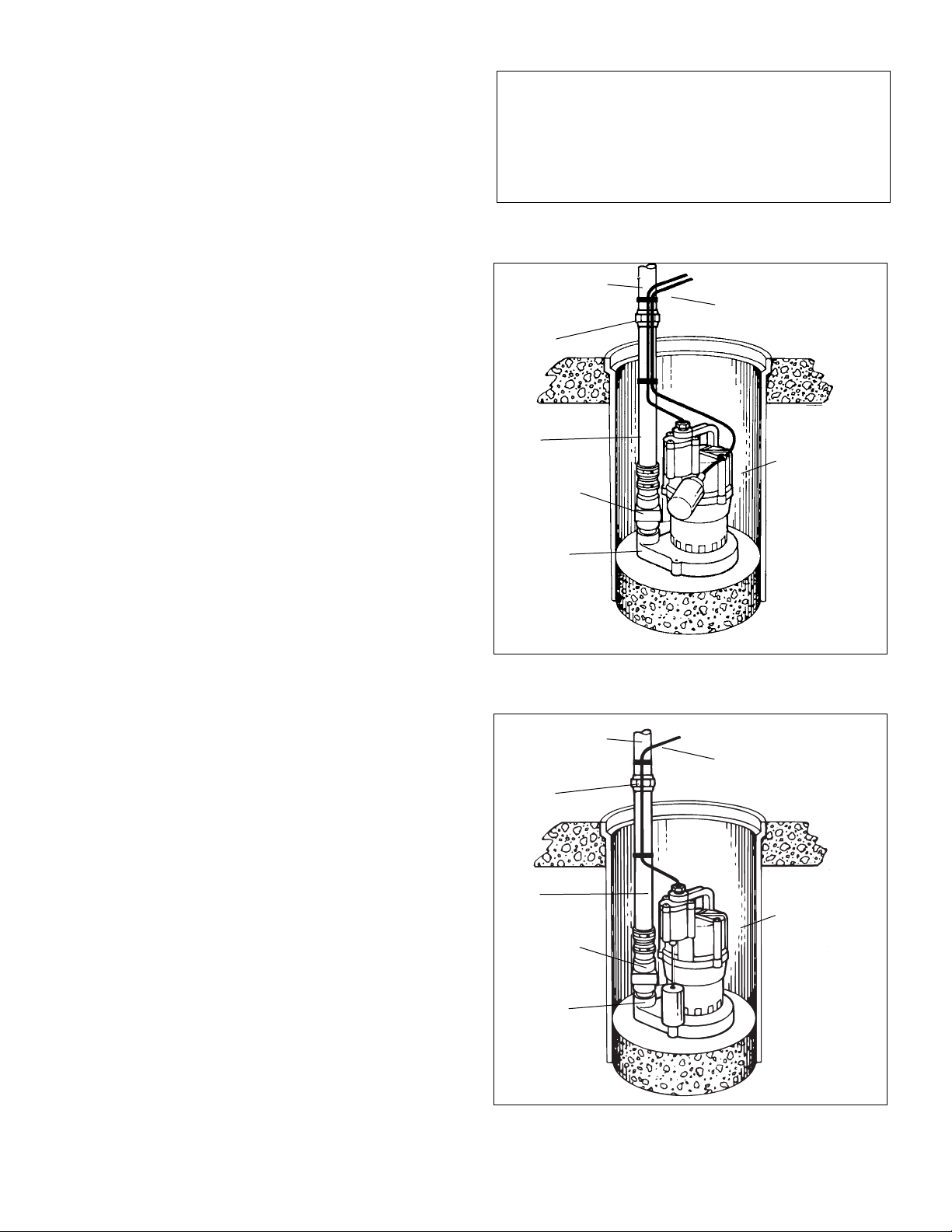

THE SUMP PIT

1. The sump pit should be large enough to prevent frequent

cycling of the pump. A sump pit of not less than 12” in

diameter and 18” deep is required. On submersible type

pumps, unit must be submerged to activate the switch.

2. The sump pit should have a hard bottom. Do not place the

pump directly on clay, earth or sand surface. Make sure

there are no small stones or gravel in the pit which may

become clogged in the pump.

3. The sump pit may be constructed of tile, concrete, steel or

plastic. Check local codes for satisfactory materials.

INSTALLATION

1. WARNING! DISCONNECT POWER AT THE MAIN

ELECTRICAL BOX BEFORE INSTALLING OR SERVICING

THE PUMP. DO NOT PLUG IN UNIT OR CHANGE FUSES

WHILE STANDING ON WET OR DAMP SURFACES,

AND DO NOT TOUCH ANY OTHER METAL SURFACES

WHILE PLUGGING IN PRODUCT OR CHANGING FUSES.

CHANGE FUSES WITH ONE HAND WHILE KEEPING

THE OTHER HAND FREE.

2. Clean any debris from the pit and set the sump pump in

place. The solid bottom of the sump will prevent clogging of

the pump from sand and dirt.

3. LOCATE THE PUMP IN THE CENTER OF THE PIT SO

THAT THE PUMP HOUSING AND ANY FLOAT CONTROL

WILL NOT COME IN CONTACT WITH THE SIDE OF THE

PIT AND CREATE OPERATIONAL PROBLEMS.

4. Connect the discharge piping and run it to the nearest sewer

or surface outlet. Sump pumps can be piped to discharge

into the house drainage system, to a dry well or splash block,

or to a storm drain, depending on local plumbing codes.

Always use a check valve when connecting discharge line

to sewer lines. The discharge piping should be as short as

possible to reduce pipe friction losses. It is recommended

that the discharge pipe diameter be equal to or larger than

the discharge size of the pump. Smaller pipe diameters will

restrict the capacity of the pump and reduce performance.

5. Always install a union in the discharge line, preferably just

above the sump pit, to allow easy removal of the pump for

cleaning or repair.

6. For installations where the piping is long, the vertical

discharge is above 7 or 8 feet, or a small sump has been

provided, use of a check valve is recommended to prevent

backflow of water into the sump and to reduce cycle

frequency.

7. DO NOT ALLOW THE CORD TO INTERFERE WITH THE

FLOAT CONTROL MOTION OR TO DRAPE OVER THE

PUMP MOTOR. With electrician’s tape, secure the cord to

the discharge pipe. This will provide protection for the cord

and make a neat installation.

8. On submersible pump models with the mechanical float

switch, first plug the float switch cord into outlet. Then plug

the power cord into float switch cord.

9. After the discharge piping is complete and the sump cleaned,

connect the pump cord to the electrical outlet and run water

into the sump to test the pump. DO NOT ATTEMPT TO

OPERATE THE PUMP WITHOUT WATER -- SEALS AND

BEARINGS COULD BE DAMAGED.

10. Fill the sump with water to the normal turn-on level and allow

the pump to remove the water to the normal control turn-off

point.

11. Install a sump cover. A cover will prevent solid matter from

falling into the sump, prevent odors, and guard against

accidental injury.

© Copyright 2004. All rights reserved.

WARNING! NEVER TOUCH THE SUMP PUMP

OR DISCHARGE PIPING WHEN THE PUMP IS

CONNECTED TO ELECTRICAL POWER AND

WATER IS PRESENT IN THE SUMP. ALWAYS

DISCONNECT THE PUMP FROM THE POWER

SOURCE BEFORE HANDLING.

TYPICAL INSTALLATION

SUBMERSIBLE PUMP W/FLOAT SWITCH

Piping or

flexible hose

Power cord

Union for easy

removal

Iron or plastic

pipe

Sump pit

Check valve

Discharge

TYPICAL INSTALLATION

SUBMERSIBLE PUMP W/MAGNETIC SWITCH

Piping or

flexible hose

Power cord

Union for easy

removal

Iron or plastic

pipe

Sump pit

Check valve

Discharge

IL0317

2

Page 3

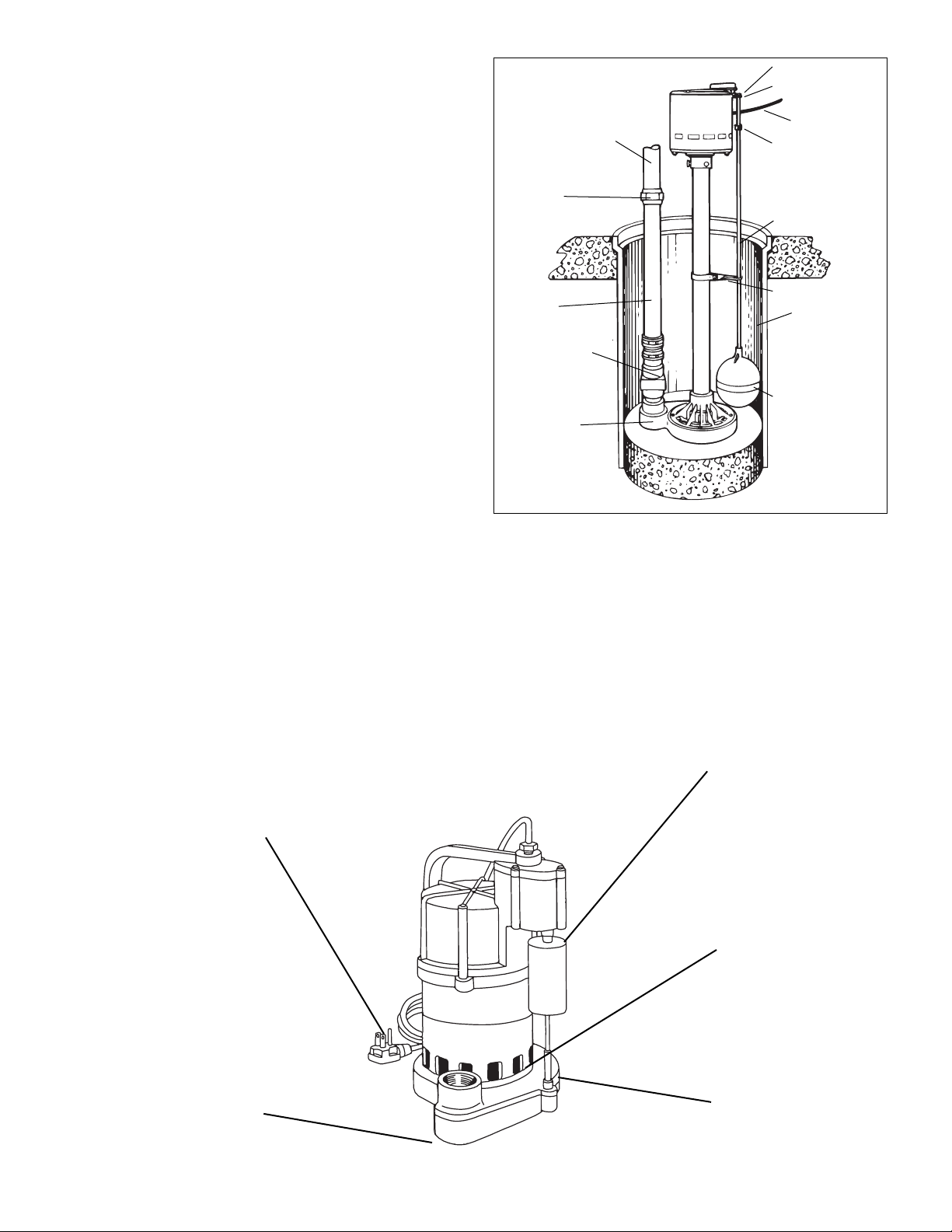

TYPICAL INSTALLATION

COLUMN SUMP PUMP

COLUMN PUMP FLOAT ASSEMBLY INSTALLATION

1. Locate float rod guide about 6” below motor. Clamp

guide to column with screw provided. DO NOT

OVERTIGHTEN!

2. Screw float onto threaded end of rod until no threads

are visible. Threads on rod will cut threads into

corrosion resistant float.

3. Insert end of float rod up through eye of rod guide.

4. Position 1st (lower) rubber rod stop approximately 8”

from the top of float rod.

5. Pass rod through eye of pump switch.

6. Slide 2nd (top) rubber rod stop flush with top of the

rod after passing through eye of switch. WARNING:

Risk of flooding. Be sure that float rod is vertical

and can move up and down freely. If float is angled or

binds, pump may not start, allowing flooding to occur.

7. With lower rod stop in this position, pump will

automatically cycle at approximately 2-1/2” off and 10-

-12” on. For faster cycling, move lower rod stop closer

to switch lever arm.

Piping or

flexible hose

Union for easy

removal

Iron or plastic

pipe

Check valve

Discharge

6

5

Power cord

4

3

1

Sump pit

2

IL0318

TROUBLESHOOTING CHECKLIST

Over 98% of all sump pumps returned to our factory are actually free from defects in material and

workmanship, and can usually be traced back to one of the below situations. Please keep this

sheet available in the unlikely event your submersible sump pump should ever need maintenance.

2. Keep top of magnet

and switch housing

1. Make sure unit is

plugged into a 115 volt

grounded outlet that will

not be turned off by a

wall switch.

NOTE: Some model

sump pumps include a

nylon screen. Lint and

other build-up should be

removed from screen area

periodically.

clean. Sometimes a film

collects from dirty sump

pits. Periodically wipe

off the top of magnet

with cloth.

3. Check for foreign

objects in the base. The

bottom plate can be

removed to clean the

impeller by taking out

the sheet metal screws

and removing the

plastic bottom cover.

5. Unit needs to be

sitting level in the pit. A

concrete block or other

material can be used to

achieve this.

4. Check for dirt, rocks,

mud or stones under

float rod. This can keep

the switch mechanism

from properly turning on

and off.

© Copyright 2004. All rights reserved.

3

Page 4

Aviso para el instalador: Las instrucciones deben permanecer con la unidad

instalada.

INSTRUCCIONES DE INSTALACIÓN

FW0519S

0404

Supersedes

2/98-3

Modelos:

3CDH 3CD 412074

3CEH 3CE 433063

3CEHS 433063S

5SEH 5SE 433020

5CDH 440752

7SEH

LISTA DE VERIFICACIÓN PREVIA A LA INSTALACIÓN

TODO TIPO DE INSTALACIÓN

1. Inspeccione su bomba. Ocasionalmente, los pro duc tos se dañan durante su transporte. Si la uni dad está dañada, co mu ní que se con su

dis tri bui dor antes de utilizarla. PRECAUCIÓN - No quite los tapones que protegen los orificios de prueba hidraúlica de la bomba.

2. Lea cuidadosamente el material impreso su mi nis tra do para familiarizarse con detalles específicos sobre la instalación y uti li za ción. Conserve

estos materiales para referencia futura.

MIRAR ABAJO PARA VER LA LISTA DE ADVERTENCIAS

1. ADVERTENCIA-Asegúrese de que haya un cir cui to pro te gi do

con in te rrup tor de circuito por pér di da a tie rra (GFCI)

co rrec ta men te instalado. To das las bom bas se en vían con

dispositivos para puesta a tierra con el fin de protegerle contra

la posibilidad de electrocución.

2. ADVERTENCIA - Asegúrese de que el re cep tá cu lo de pues ta a

tierra esté al alcance del cable de ali men ta ción eléc tri ca y NO

UTILICE UN CABLE DE EX TEN SIÓN. Los cables de extensión

de ma sia do largos o delgados no transportan su fi cien te voltaje

al motor de la bomba. Pero, más importante aún, podrían

crear un problema de se gu ri dad si se dañara su material de

aislamiento o sus extremos de co nexión cayeran en el sumidero

y se mojaran.

3. ADVERTENCIA - Asegúrese de que el cir cui to de su mi nis tro

de electricidad de la bomba esté equi pa do con fusibles o

disyuntores con capacidad ade cua da. Se re co mien da utilizar

un circuito separado con ca pa ci dad ade cua da para la corriente

indicada en la placa de iden ti fi ca ción según el Código Eléc tri co

Nacional.

4. ADVERTENCIA - PRUEBA DE PUESTA A TIERRA. Como

medida de seguridad, se debe revisar la puesta a tierra de

cada tomacorriente utilizando un ana li za dor de circuitos

aprobado por Underwriters Laboratory que indique si los cables

de potencia, neutro y tierra en su tomacorriente se encuentran

co rrec ta men te conectados. De no ser así, llame a un electricista

calificado.

5. ADVERTENCIA - La instalación y revisión de los cir cui tos

eléctricos y componentes físicos sólo debe ser efec tua da por

un electricista calificado.

6. ADVERTENCIA - PARA SU PROTECCIÓN, DESENCHUFE

SIEMPRE LA BOMBA DE SU FUEN TE DE ALI MEN TA CIÓN

ELÉCTRICA ANTES DE MANIPULARLA.

7. ADVERTENCIA - Estas bombas se suministran con un enchufe

de puesta a tierra de 3 clavijas para ayudar a protegerle contra

la posibilidad de elec tro cu ción. NO RETIRE BAJO NIN GU NA

CIR CUNS TAN CIA LA CLA VI JA DE PUES TA A TIERRA. El

enchufe de 3 clavijas se debe insertar en un re cep tá cu lo de

in te rrup ción de fallas de 3 clavijas. Si la ins ta la ción no cuenta

con este tipo de receptáculo será necesario instalar uno

adecuado, el cual debe estar cableado y puesto a tierra según

el Código Eléctrico Nacional y todos los códigos y or de nan zas

que apliquen.

NO SE UTILICE PARA BOMBEAR ACEITES, GA SO LI NA O PRODUCTOS DERIVADOS DEL PE TRÓ LEO

95 N. Oak St. • Kendallville, IN 46755 - EE.UU. • 1-800-345-9422

© Reservados todos los derechos.

© Copyright 2004. All rights reserved.

MIRAR ABAJO PARA VER LA LISTA DE ADVERTENCIAS

8.

ha sido investigada para uso en áreas de piscinas

9.

ADVERTENCIA: Este producto contiene sustancias

químicas que de acuerdo al estado de California pueden

causar cancer y defectos de nacimiento u otros daños en la

reproducción.

MIRAR ABAJO PARA VER LA LISTA DE PRECAUCIONES

1. PRECAUCIÓN - Asegúrese de que su fuente de ali men ta ción

eléctrica pueda suministrar el voltaje que requiere el motor,

según indica la placa de identificación de la bomba.

2. PRECAUCIÓN - El instalador tiene la res pon sa bi li dad de

instalar bombas automáticas con in te rrup tor de flotador

auxi liar y debe tener cuidado de que el interruptor de

flotador cautivo no se trabe con el aparato de bombeo o

las pe cu lia ri da des del foso y esté asegurado para que la

bomba se pueda apagar. Se recomienda utilizar tubería y

accesorios rígidos y un foso de 30,5 cm (12") de diámetro o

mayor.

3. PRECAUCIÓN - Estas bombas no están diseñadas para

ser utilizadas con aguas negras o efluentes.

4. PRECAUCIÓN - Esta bomba ha sido evaluada únicamente

para el uso con AGUA.

5. PRECAUCIÓN - La temperatura de operación continua

máxima de los modelos de bombas estándar no debe ser

mayor de 25°C (77ºF).

NOTA: Se recomienda utilizar un sistema de baterías de

respaldo para impedir las inundaciones y/o el daño a las

propiedades si se produce un malfuncionamiento mecánico

o se corta la alimentación eléctrica de la red de distribución

del servicio eléctrico.

Aviso: Las bombas con la marca CSA han side probadas

de acuerdo al estandard UL778. Las bombas “Certificadas”

estan certificad de acuerdo al estandard CSA C22.2 No.

108.

4

Peligro de choque eléctrico. Esta bomba no

Page 5

EL POZO DEL SUMIDERO

1. El pozo del sumidero debe ser bastante grande para evitar

frecuente movimiento por ciclos de la bomba. Un pozo del

sumidero debe ser por lo menos 12ý den diámetro por

18ý de profundidad. En las bombas tipo sumergible, es

necesario sumergirlas para activar el interruptor.

2. El fondo del pozo del sumidero debe ser firme. No coloque

la bomba directamente en una superficie de arena, tierra o

arcilla. Verifique que no hay piedras ni arena gruesa en el

pozo que pueden atascar el bomba.

el sumidero, conecte el cordón de la bomba al toma de

corriente y llene el sumidero con un poco de agua para

probar la bomba. NO TENTE OPERAR LA BOMBA SIN

AGUA PORQUE PODRÍA CAUSAR DAÑOS A LOS

SELLOS Y COJINETES.

10. Llene el sumidero con agua hasta el nivel de arrancar y

deje que la bomba remueva el agua hasta llegar al nivel

normal de control de apagar.

11. Instale una cubierta del sumidero. Una cubierta evitará

que caigan partículas sólidas para dentro del sumidero,

evitará olores malos, y guardará contra daños personales

accidentales.

3. La construcción del pozo del sumidero puede ser de

tubo de albañil, concreto, acero o plástico. Verifique los

reglamentos locales para materiales adecuados.

INSTALACIÓN

1. ¡ADVERTENCIA! DESCONECTE LA FUERZA ELÉCTRICA

EN LA CAJA PRINCIPAL DE LA FUERZA ANTES DE

INSTALAR O HACER SERVICIOS A LA BOMBA. NO

ENCHUFE LA UNIDAD NI CAMBIE LOS FUSIBLES

AL ESTAR DE PIE EN UNA SUPERFICIE HÚMEDA O

MOJADA Y NO TOQUE EN NINGUNA OTRA SUPERFICIE

DE METAL AL ENCHUFAR EL PRODUCTO O AL

CAMBIAR FUSIBLES. HAGA ESTA OPERACIÓN CON

UNA MANO DEJANDO LA OTRA LIBRE.

2. Limpie cualquier desecho del pozo del sumidero y coloque

la bomba en su lugar correcta. El fondo sólido del pozo

del sumidero evitará obstrucción de la bomba por arena y

tierra.

Para la instalación de una bomba de columna, acople el

flotante según las instrucciones de la página 3 antes de continuar.

3. COLOQUE LA BOMBA EN EL CENTRO DEL POZO PARA

QUE SU CAJA Y EL CONTROL FLOTANTE NO ENTREN

EN CONTACTO CON EL LADO DEL POZO CRIANDO

PROBLEMAS OPERACIONALES.

4. Conecte la tubería de descarga y recorrala a la alcantarilla

o la salida en la superficie más cercanas. Se puede entubar

las bombas del sumidero para descargar en el sistema

de drenage de la casa, en un pozo seco o bloque de

salpicadura, o en un desagüe de agua pluvial dependiendo

de los relamentos de fontaneria locales. SIEMPRE USE

UNA VÁLVULA DE RETENCIÓN AL CONECTAR EL TUBO

DE DESCARGA A LOS TUBOS DE ALCANTARILLA.

La tubería de descarga debe ser la más curta posible

para disminuir la pérdida de frección en las tuberías. Se

recomienda que el diámetro de la tubería de descarga

sea igual o mayor del tamaño de descarga de la bomba.

Diámetros menores de tubería restringirán la capacidad de

la bomba y bajarían el rendimiento.

5. Siempre instale una unión en el tubo de descarga, de

preferencia un poxo arriba del pozo del sumidero, para

permitir una remoción fácil de la bomba para su limpieza y

mantenimiento.

6. En las instalaciones donde la tubería es larga, la descarga

es superior a siete u ocho pies, o una bomba pequeña ha

sido proporcionada, se recomienda la utilización de una

válvula de retención para evitar contraflujo de agua dentro

del sumidero y reducir la frecuencia de ciclo.

7. NO PERMITA QUE EL CORDÓN INTERFIERA CON

EL MOVIMIENTO DEL CONTROL FLOTANTE NI QUE

CUELGUE SOBRE EL MOTOR DE LA BOMBA. Usando

cinta aislante de electricista, fije el cordón al tubo de

descarga. Esto proporcionará protección al cordón y dejará

una instalación ordenada.

8. En los modelos de bomba con Interruptor Flotante Mecánico

primero enchufe el cordón del interruptor flotante en el toma

de corriente. Después enchufe el cordón de fuerza en el

cordón del interruptor flotante.

9. Después de completar la tubería de descarga y de limpiar

© Copyright 2004. All rights reserved.

© Reservados todos los derechos.

¡ADVERTENCIA! NUNCA TOQUE EN LA

BOMBA DE SUMIDERO NI EN LA TUBERÍA

DE DESCARGA CUANDO LA BOMBA ESTÁ

CONECTADA A LA CORRIENTE ELÉCTRICA

Y CUANDO AGUA ESTÁ EN EL SUMIDERO.

SIEMPRE DESCONECTE LA BOMBA DE

LA CORRIENTE ELÉCTRICA ANTES DE

TOCARLA.

INSTALACIÓN DE LA BOMBA CON MODELOS

DE INTERRUPTORES FLOTANTES MANUAL O

AUTOMÁTICO

Tubo o

manguera

flexible

Unión para

remoción Fácil

Tubo de hierro

o de plástico

Válvula de

retención

Descarga

5

Cordón

electrico

Pozo del

sumidero

Page 6

INSTALACIÓN DE LA BOMBA CON MODELOS

DE INTERRUPTORES FLOTANTES MECÁNICOS

Tubo o

manguera

flexible

Unión para

remoción Fácil

Tubo de hierro

o de plástico

Válvula de

retención

Cordón

electrico

Pozo del

sumidero

5. Haga pasar la varilla a través del ojo del conmutador de la

bomba.

6. Deslice el segundo tope de varilla de caucho (superior) de

modo que quede a ras con la parte superior de la varilla,

después de pasar a través del ojo del conmutador.

ADVERTENCIA: Riesgo de inundación. Cerciórese de

que la varilla del flotante esté en posición vertical y de que

se pueda mover libremente hacia arriba y hacia abajo. Si

el flotante está inclinado o no se mueve libremente, es

posible que impida el arranque de la bomba y produzca una

inundación.

7. Con el tope de varilla inferior en esta posición, la bomba se

apaga automáticamente a aproximadamente 6 centímetros

(2 1/2 pulgadas) y se encenderá automáticamente entre

aproximadamente 25 y 30 centímetros (10 y 12 pulgadas).

Para lograr un encendido y apagado más frecuentes,

acerque el tope de la varilla inferior al brazo de palanca del

conmutador.

Descarga

IL0317

INSTALLATIÓN DE BOMBA DE SUMIDERO CON

COLUMNA

6

5

Cordón

electrico

Tubo o

manguera

flexible

Unión para

remoción Fácil

Tubo de hierro

o de plástico

Válvula de

retención

Descarga

INSTALACIÓN DEL CONJUNTO DE FLOTANTE DE LA

BOMBA DE COLUMNA

1. Ubique la guía de la varilla del flotante a aproximadamente

unos 15 centímetros (6 pulgadas) por debajo del motor. Fije

la guía a la columna mediante el tornillo provisto. NO LO

APRIETE EXCESIVAMENTE.

2. Enrosque el flotante por el lado roscado de la varilla hasta

que deje de verse la rosca de la varilla. La rosca de la

varilla penetrará en la superficie del flotante resistente a la

corrosión.

3. Inserte el extremo de la varilla del flotante a través del ojo

de la guía de la varilla.

4. Coloque el primer tope de varilla de caucho (inferior) a

aproximadamente 20 centímetros (8 pulgadas) de la varilla

del flotante.

4

3

1

2

IL0318

Pozo del

sumidero

© Reservados todos los derechos.

© Copyright 2004. All rights reserved.

DETECCIÓN DE FALLAS

Más de 98% de todas las bombas de sumidero devueltas a

nuestra fábrica no tienen defectos en materiales ni en mano

de obra, y la causa del problema normalmente es una de las

situaciones supradichas.

NOTA: Algunos

modelos de

bombas de

sumidero vienen

con una criba

de nylon. Es

necesario remover

periodicamente

hilas y otras

acumulaciones.

Asegúrese de que

la bomba esté

enchufada en un

tome de corriente

con 115 voltios~

de tierra eléctrica

que no puede ser

desconectado por

un interruptor de

pared.

La bomba tiene que estar colocada de

forma nivelada en el pozo. Se puede

usar un bloque de concreto u otro

material para lograr esto.

6

Mantanga

limpia la parte

arriba del imán

y la caseta

del interruptor.

De vez en

sumidero

sucios. Hay

que limpiar

la parte de

arriba de imán

periodicamente.

Verifique si

hay partículas

ajenas en

las base.

El plato del

fondo puede

ser removido

para limpiar

el impulsor al

destornillar

los tornillos de

chapa metalica

y removiendo

la cubierta

de plástico el

fondo.

Verifique si hay

tierra, piedras, lodo,

o rocas debajo de la

barra flotante. Esto

podria impedir que

el mecanismo del

interruptor funcione

correctamente.

Page 7

Avis à l’installateur – Ces instructions doivent accompagner l’installation.

INSTRUCTIONS D’INSTALLATION

FW0519F

0404

Supersedes

2/98-3

Modèles

3CDH 3CD 412074

3CEH 3CE 433063

3CEHS 433063S

5SEH 5SE 433020

5CDH 440752

7SEH

VÉRIFICATIONS AVANT L’INSTALLATION

TOUTES LES INSTALLATIONS

1. Inspecter la pompe. De temps en temps, des produits sont endommagés en cours d’expédition. Si une pompe est endomma-

gée, contacter le distributeur avant utilisation. Ne PAS enlever le bouchon test de la pompe.

2. Il faut lire avec soin les brochures fournies, afin de se familiariser avec les détails spécifiques concernant l’installation et

l’utilisation. Il faut garder ces brochures pour référence ultérieure.

ADVERTISSEMENT

VOIR PLUS BAS POUR LA LISTE DES AVERTISSEMENTS

1. Vérifier que le circuit est correctement protégé par un dis-

joncteur différentiel (GFCI). Toutes les pompes sont fournies

avec la possibilité de mise à la terre pour protéger contre les

risques de choc électrique.

2. Vérifier que la prise à fuite de terre est à portée du cordon

de la pompe. IL NE FAUT PAS UTILISER DE RALLONGE.

Les rallonges qui sont trop longues ou de capacité trop faible

ne peuvent pas fournir la tension nécessaire au moteur de la

pompe. Mais, encore plus important, elles peuvent être dangereuses si l’isolant devient endommagé ou si les extrémités

avec branchement tombent dans le puisard et deviennent

mouillées.

3. Vérifier que le circuit d’alimentation de la pompe est

équipé d’un fusible ou disjoncteur de capacité appropriée. Il est recommandé d’utiliser un circuit séparé de

capacité correspondant à l’intensité montrée sur la plaque

d’identification de la pompe, conformément au code na tion al

d’électricité.

4. ESSAI DE TERRE. Comme mesure de sécurité, il faut vérifier que chaque prise de cou rant est à la terre, en utilisant un

analyseur de circuit sur la liste de Un der writ ers Lab o ra to ry

qui indique si les fils de phase, de neutre et de terre sont

correctement branchés. S’ils ne sont pas branchés correctement, appeler un électricien qualifié.

5. L’installation et l’inspection du système électrique doivent

être faites par un électricien qualifié.

6. COMME PRÉCAUTION DE SÉCURITÉ, IL FAUT

TOUJOURS DÉBRANCHER L’ALIMENTATION

ÉLECTRIQUE AVANT TOUTE INTERVENTION.

7. Ces pompes sont équipées d’une fiche à trois broches

avec mise à la terre. IL NE FAUT JAMAIS ENLEVER LA

BROCHE DE TERRE. La fiche à trois broches doit être

branchée dans une prise à trois fils à disjoncteur différentiel. Si l’installation n’a pas une telle prise de courant, il faut

en faire installer une de type approprié, conformément au

code national d’électricité et aux réglementations et codes

locaux.

VOIR PLUS BAS POUR LA LISTE DES AVERTISSEMENTS

8.

9.

1. PRUDENCE – Vérifier que la tension de l’alimentation cor-

2. PRUDENCE – L’installation de pompes automatiques avec

3. PRUDENCE – Ces pompes ne sont pas conçues pour le

4. PRUDENCE – Cette pompe a été évaluée pour utilisation

5. PRUDENCE – La température maximale de service pour

REMARQUE : IL EST CONSEILLÉ D’UTILISER UN SYS-

REMARQUE : Les pompes avec annotations “CSA” sont

ADVERTISSEMENT

pas été testée pour être utilisée près de piscines.

AVERTISSEMENT: Ce produit contient des produits chi-

miques dont l’état de la Californie a déterminer comme

étant la cause de cancer et de déficiences à la naissance

ou autres dommages reproductifs.

VOIR PLUS BAS POUR LA LISTE DES MISES EN GARDE

re spond à celle du moteur qui est indiquée sur la plaque

d’identification de la pompe.

des interrupteurs auxiliaires à flotteur est la responsabilité

de l’utilisateur qui doit s’assurer que l’interrupteur à flotteur

avec un fil de retenue n’accroche pas le dispositif de pompage ni les aspérités du puisard et qu’il est correctement

attaché pour que la pompe s’arrête. Il est recommandé

d’utiliser des tuyaux et des raccords rigides et d’avoir un

puisard d’au moins 30,5 cm (12 po) de diamètre.

pompage des eaux d’égout ou des effluents.

uniquement avec de l’EAU.

les pompes de modèle standard ne doit pas dépasser 25°C

(77ºF).

TÈME D’ALIMENTATION DE SECOURS À BATTERIE

AFIN D’ÉVITER UNE INONDATION ET DES DÉGÂTS

MATÉRIELS EN CAS D’INCIDENT MÉCANIQUE OU DE

PANNE D’ÉLECTRICITÉ.

vérifiées d’après lanorme UL778. Les pompes certifiées

CSA sont vérifiées d’après la norme C22.2 no. 108.

ADVERTISSEMENT

Risque de choc électrique. Cette pompe n’a

NE PAS UTILISER POUR LE POMPAGE D’HUILES, D’ESSENCE NI DE SOUS-PRODUITS PÉTROLIERS.

95 N. Oak St. · Kendallville, IN 46755, É.-U. · 1-800-345-9422

© Tous droits réservés.

© Copyright 2004. All rights reserved.

7

Page 8

INSTRUCTIONS POUR POMPES DE PUISARD IMMERGÉES

ET POMPES SUR COLONNE

LE PUISARD

1. Le puisard doit être suffisamment grand pour empêcher une

fréquence élevée de cycles marche-arrêt de la pompe. Il doit

mesurer au moins 30 cm de diamètre et 46 cm de profondeur. Les pompes immergées doivent baigner entièrement

dans le liquide pour que l’interrupteur s’actionne.

2. Le fond du puisard doit être dur. Ne montez pas la pompe

directement sur un sol d’argile, de terre ou de sable.

Assurez-vous de l’absence de petites pierres ou de gravier

qui pourraient se coincer dans la pompe.

3. Le puisard peut être construit au moyen de dalles, en béton,

en acier ou en plastique. Consultez le code local en vigueur

pour connaître les matières qui conviennent.

INSTALLATION

1. AVERTISSEMENT! COUPEZ L’ALIMENTATION

AU NIVEAU DU COFFRET ÉLECTRIQUE AVANT

L’INSTALLATION OU L’ENTRETIEN DE LA POMPE.

NE BRANCHEZ PAS LA POMPE ET NE REMPLACEZ

PAS LES FUSIBLES EN VOUS TENANT SUR UN

SOL MOUILLÉ OU HUMIDE, OU EN TOUCHANT UNE

SURFACE MÉTALLIQUE. REMPLACEZ LES FUSIBLES

D’UNE MAIN TOUT EN GARDANT L’AUTRE LIBRE.

2. Retirez tous les débris du puisard et mettez la pompe en

place. Le fond plein de la pompe empêche le sable et la

boue de la colmater. NOTA : Lors de l’installation d’une

pompe de puisard, fixer le flotteur selon les indications de la

page 3 avant de continuer.

3. PLACEZ LA POMPE AU CENTRE DU PUISARD DE SORTE

QUE LE CORPS DE POMPE ET L’INTERRUPTEUR À

FLOTTEUR NE PUISSENT ENTRER EN CONTACT AVEC

LA PAROI DU PUISARD ET PROVOQUER DES ANOMALIES DE FONCTIONNEMENT.

4. Raccordez la conduite de refoulement et faites-la courir

jusqu’à la prise d’égout ou de surface la plus proche. La

conduite de refoulement des pompes de puisard peut

déboucher, selon les codes de plomberie locaux, dans le

résau d’égout de la maison, dans un puits sec ou une culière

ou dans un collecteur d’eaux pluviales. Pour les raccordements de conduite de refoulement aux canalisations d’égout,

il faut toujours monter un clapet antiretour. La conduite de

refoulement doit être la plus courte possible, pour réduire au

minimum les pertes de charge par frottement. Il est recommandé d’employer un tuyau de diamètre égal ou supérieur

à celui de l’orifice de refoulement de la pompe. Un tuyau de

plus petit diamètre aura pour effet de réduire le débit et le

rendement de la pompe.

5. Montez toujours un raccord-union dans la conduite de

refoulement, de préférence juste au-dessus du puisard, pour

faciliter le retrait de la pompe pour l’entretien ou les réparations.

6. Dans les installations où la conduite est longue, la tuyauterie

de refoulement verticale de plus de 2,1 à 2,4 mètres, ou que

la pompe de puisard est peu puissante, il est recommandé

de monter un clapet antiretour servant à empêcher le retour

de l’eau dans le puisard et à réduire la fréquence de cycle

de la pompe.

7. FAITES COURIR LE CORDON D’ALIMENTATION DE

SORTE QU’IL NE PUISSE PAS NUIRE AU MOUVEMENT

DE L’INTERRUPTEUR À FLOTTEUR OU S’ENROULER

© Copyright 2004. All rights reserved.

© Tous droits réservés.

AUTOUR DU MOTEUR DE POMPE. Avec du ruban isolant,

fixez fermement le cordon à la conduite de refoulement. Le

cordon est ainsi protégé et l’installation a un aspect soigné.

8. Pour les modèles de pompes immergées à interrupteur à

flotteur branchez d’abord le cordon de l’interrupteur dans la

prise de, courant puis la fiche de la pompe dans celle du

cordon d’interrupteur, à flotteur.

9. Après avoir monté la conduite de refoulement et nettoyé

le puisard, branchez le cordon de la pompe dans la prise

secteur et verser de l’eau dans le puisard pour essayer

la pompe. NE FAITES PAS FONCTIONNER LA POMPE

À SEC, SOUS PEINE D’ENDOMMAGER LES JOINTS

D’ÉTANCHÉITÉ ET LES ROULEMENTS.

10. Remplissez le puisard d’eau jusqu’au niveau de démarrage

normal et laissez la pompe retirer l’eau jusqu’au niveau

d’arrêt normal.

11. Posez le couvercle de puisard, pour empêcher les solides

de tomber dans le puits et les odeurs de s’échapper, et pour

réduire les risques de blessures accidentelles.

AVERTISSEMENT : NE TOUCHEZ JAMAIS À LA

POMPE OU À LA TUYAUTERIE DE REFOULEMENT

LORSQUE L’APPAREIL EST SOUS TENSION ET QUE

LE PUISARD CONTIENT DE L’EAU. DÉBRANCHEZ

TOUJOURS LA POMPE DE LA PRISE DE COURANT

AVANT D’Y TRAVAILLER.

INSTALLATION D’UNE POMPE À INTERRUPTEUR À

FLOTTEUR

Tuyauterie

rigide ou

flexible

Raccord-union

simplificant la

dépose

Tuyau en fer

ou en plastique

Clapet

antiretour

Refoulement

8

Cordon

d’alimentation

électrique

Puisard

Page 9

UNE POMPE À INTERRUPTEUR MAGNÉTIQUE

Tuyauterie

rigide ou

flexible

Raccord-union

simplificant la

dépose

Tuyau en fer

ou en plastique

Clapet

antiretour

Refoulement

Cordon

d’alimentation

électrique

IL0317

INSTALLATION D’UNE POMPE

SUR COLONNE

6

5

Tuyauterie

rigide ou

flexible

Raccord-union

simplificant la

dépose

Tuyau en

fer ou en

plastique

Clapet

antiretour

4

Puisard

Cordon

d’alimentation

électrique

3

1

Puisard

2

affleurant le haut de la tige après l’avoir passée dans l’oeillet

du commutateur. AVERTISSEMENT : Risque d’inondation.

S’assurer que la tige flotteur est verticale et peut se déplacer

librement de haut en bas. Si le flotteur est incliné ou se

coince, il est possible que la pompe ne démarre pas et

qu’une inondation se produise.

7. Avec la butée inférieure de la tige à cette position, la pompe

s’arrête automatiquement à environ 2,5 po (6 cm) du fond et

démarre entre 10 et 12 po (25 et 30 cm). Pour un démarrage

plus rapide, déplacer la butée inférieure plus près du levier

du commutateur.

AIDE-MÉMOIRE DE DÉPANNAGE

Plus de 98 % des pompes de puisard qui nous sont retournées

ne souffrent d’aucun défaut de matière ou de fabrication. Le plus

souvent, une des situations décrites ci-dessus est à l’origine de

l’anomalie de fonctionnement. Veuillez donc conserver le présent

aide-mémoire au cas, peu probable, où votre pompe de puisard

immergée nécessiterait un.

REMARQUE : Certains modèles de pompes

de puisard sont munis d’un filtre en nylon. Ce

filtre doit être débarrassé à intervalles réguliers

de la peluche et autres matières qui s’y sont

accumulées.

Assurez-vous

que l’appareil est

branché dans une

prise secteur 115V

mise à la terre et

que l’alimentation

électrique ne peut

pas être coupée

par un interrupteur

mural.

Gardez propre

les dessus

de l’aimant

et le boîtier

interrupteur.

Il arrive qu’il

s’y forme une

mince couche

de saleté en

provenance du

puisard. Essuyez

le dessus de

l’aimant avec

un chiffon à

intervalles

réguliers.

Vérifiez qu’il n’y

a pas de corps

étrangers dans le

socle. Pour enlever

la plaque inférieure

et nettoyer la roue,

défaites les vis

pour tôle et retirez

le couvercle en

plastique.

Refoulement

IL0318

INSTALLATION DE L’ENSEMBLE FLOTTEUR POMPE DE

PUISARD

1. Installer la tige guide du flotteur à environ 6 po (15 cm) sous

le moteur. Fixer la tige guide à la colonne avec la vis incluse.

NE PAS TROP SERRER!

2. Visser le flotteur sur le bout fileté de la tige jusqu’à ce que

les filets soient tous utilisés. Le flotteur anticorrosion est

fileté par les filets sur la tige.

3. Insérer l’extrémité de la tige flotteur dans l’oeillet sur la tige

guide.

4. Placer la première butée (inférieure) en caoutchouc à

environ 8 po (20 cm) du haut de la tige flotteur.

5. Enfiler la tige dans l’oeillet sur le commutateur de la pompe.

6. Placer la deuxième butée (supérieure) en caoutchouc

© Copyright 2004. All rights reserved.

L’appareil doit reposer de niveau dans le

puisard. Servez-vous d’un bloc en béton

ou d’un autre matériau analogue pour

mettre la pompe bien à l’horizontale.

9

Assurez-vous que la

présence de saleté, de

boue ou de pierres sous

la tige de flotteur ne gêne

pas le fonctionnement du

mécanisme de marchearrêt de la pompe.

Page 10

TECHNICAL - USEFUL INFORMATION

ELECTRIC POWER

AC = Alternating Current Power

DC = Direct Current

E = Volts = Electrical Voltage (Similar to head)

I = Amperes = Electrical Current (Similar to rate of

W = Watts = Electrical Power (Similar to head capacity)

KW = Kilowatts = 1000 Watts

Apparent Power = Volts x Amperes = Voltamperes

Apparent Power = EI

Useful Power = EI x PF

TO FIND CAPACITY OF A TANK OR CISTERN

Diameter of

Tank in Feet

Squared

x .7854 x

fl ow)

Height of

Tank in Feet

x 7.48 =

Capacity in

U.S. Gallons

WHEN YOU KNOW YOU CAN FIND IF YOU MULTIPLY BY

Length

Inches (in) Millimeters (mm) 25.4

Inches (in) Centimeters (cm) 2.539 3

Feet (ft) Meters (m) 0.304 8

Yards (yd) Meters (m) 0.914 4

Miles (statute) (mi) Kilometers (km) 1.609 344

Liquid Volume

Ounces (oz) Milliliters (ml) 29.574

Pints (pt) Liters (l) 0.473 2

Quarts (qt) Liters (l) 0.946 3

Gallons (gal) Liters (l) 3.785 412

3

Lb/Foot

Lb/Gal (lb/gal) Kilogram/Meter

(lb/ft3) Kilogram/Meter

FW0552

HORSEPOWER

1 H.P. Equals . . .

.746 Kilowatts or 746 watts

33,000 ft. lbs. per minute

550 ft. lbs. per second

0903

Supersedes

Original

HEAD

1 Pound Per Square Inch (P.S.I.)

1 Foot of Water

1 Inch of Mercury (or Vacuum) 1.132 ft. of water

1 Kilogram Per Square Centimeter 14.22 lb. per sq. in

1 Atmosphere (at sea level)

1 Meter of Water 3.28 ft. of water

3

3

(kg/m3) 16.018 46

(kg/m3) 119.826 4

2.31 ft. head of water

2.04 in. mercury

0.07 kg. per sq. cm.

0.433 lb. per sq. in

.885 in. mercury

14.7 lb. per sq. in.

34.0 ft. of water

10.35 m. of water

RENSEIGNEMENTS TECHNIQUES UTILES

ALIMENTATION ÉLECTRIQUE

CA = Courant alternatif

CC = Courant continu

E = Volts = Tension électrique (semblable à la hydrostatique)

I = Ampères = Courant électrique (semblable au débit

W = Watts = Puissance électrique (semblable au produit de la

KW = Kilowatt = 1000 watts

Puissance apparente = Volts x ampères = Voltampères

Puissance apparente = EI

Puissance utile W = EI x FP

AVEC CES TAILLES OBTENEZ CELLES-CI EN MULTIPLIANT PAR

Longueur

Pouce (po) Millimètre (mm) 25,4

Pouce (po) Centimètre (cm) 2,539 3

Pied (pi) Mètre (m) 0,304 8

Verge (vge) Mètre (m) 0,914 4

Mile (terrestre) (mi) Kilomètre (km) 1,609 344

Volume (liquide) É. -U.

Once (oz) Millilitre (mL) 29,574

Chopine (chop) Litre (L) 0,473 2

Pinte (pte) Litre (L) 0,946 3

Gallon (gal) Litre (L) 3,785 412

Livre/pi

Livre/gallon (lb/gal) Kilogramme/m

pression hydrostatique par le débit)

POUR TROUVER LA CAPACITÉ D’UN RÉSERVOIR OU D’UNE CITERNE :

Diamètre du réservoir

en pieds carrés

3

(lb/pi3) Kilogramme/m

x 0,7854 x

Hauteur du

réservoir en pieds

3

3

PUISSANCE EN HP

1 HP est égal à

0,746 kilowatt ou 746 W

33 000 pi.lb par minute

550 pi.lb par seconde

HYDROSTATIQUE

1 livre par pouce carré (lb/po3)

1 pied d’eau

1 pouce de mercure (ou vide) 1,132 pi d’eau

1 kilogramme par centimètre carré 14,22 lb/po

1 atmosphère (au niveau de la mer)

1 metre d’eau 3,28 pi d’eau

x 7,48

(kg/m3) 16,018 46

(kg/m3) 119,826 4

Capacité en gallons

américains

2,31 po hauteur d’eau

2,04 po hauteur de mercure

0,07 kg par cm

0,433 lb/po

0,885 po de mercure

14,7 lb po

34 pi d’eau

10,35 m d’eau

2

2

2

2

Page 11

INFORMACIÓN TÉCHICA y ÚTIL

FUERZA ELÉCTRICA

AC = Corriente Alterna

DC = Corriente Directa

E = Voltios ~ = Presión Eléctrica (parecida con carga)

I = Amperios = Corriente Eléctrica (parecida con rapidez

W = Vatios = Fuerza Eléctrica (parecida con carga)

KW = Kilovatios = 1000 Vatios

Fuerza Aparente = Voltios x amperios = Voltamperios

Fuerza Aparente = EI

Potencia Util W = EI x FP

de flujo)

PARA ENCONTRAR LA CAPACIDAD DE UN TANQUE O CISTERNA:

Diámetro del Tanque

en pies cuadrado

x .7854 x

Altura del

Tanque en pies

x 7.48 =

Capacidad en U.S.

Galones

CUANDO UD. SABE UD. PUEDE ENCONTRAR SI MULTIPLICA POR

Longitud

Pulgadas (in) Milímetros (mm) 25.4

Pulgadas (in) Centímetros (cm) 2.539 3

Pies (ft) Metros (m) 0.304 8

Yardas (yd) Metros (m) 0.914 4

Millas (milla térrestre) (mi) Kilometros (km) 1.609 344

Volumen Líquido

Onzas (oz) Milímetros (ml) 29.574

Pintas (pt) Litros (l) 0.473 2

Quartos (qt) Litros (l) 0.946 3

Galones (gal) Litros (l) 3.785 412

Libras/pies

Libras/galones (lb/gal) Kilos/Metros

3

(lb/ft3) Kilos/Metros

3

3

POTENCIA (HP)

1 HP =

.746 Kilovatios o 746 Vatios

33,000 pies libras por minuto

550 pies libras por segundo

CARGA HIDROSTÁTICA

1 P.S.I. 2.31 carga hidrostatica

1 Pie de Agua 0.433 P.S.I.

1 Pulgada de Mercurio (o vacio) 1.132 pies de agua

1 Kilograma por Cm

1 Atmosfera (nivel del mar) 14.7 P.S.I.

1 Metro de Agua 3.28 pies de agua

(kg/m3) 16.018 46

(kg/m3) 119.826 4

2

2.04 pulgadas de mercurio

0.07 kilogramas por cm

.885 pulgadas de mercurio

14.22 P.S.I.

34.0 pies de agua

10.25 metros de agua

2

Loading...

Loading...