Page 1

HYBRID PRINTER

HSP7000 SERIES

Hardware Manual

Page 2

Federal Communications Commission

Radio Frequency Interference

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures.

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This statement will be applied only for the printers marketed in U.S.A.

FCC WARNING

Changes or modications not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

For compliance with the Federal Noise Interference Standard, this equipment requires a shielded cable.

For RF interference suppression, if a ferrite core is provided with this device, afx it to the interface cable.

Statement

The Canadian Department of Communications

Radio Interference Regulations

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

The above statement applies only to printers marketed in Canada.

Statement of

Trademark acknowledgments

HSP7000

: Star Micronics Co., Ltd.

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without

STAR’ s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All eorts have been made to ensure the accuracy of the contents of this manual at the time of

going to press. However, should any errors be detected, STAR would greatly appreciate being

informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

© Copyright 2008-2011 Star Micronics Co., Ltd.

Page 3

TABLE OF CONTENTS

1. Unpacking and Installation .....................................................................................................................1

1-1. Unpacking ....................................................................................................................................1

1-2. Choosing a place for the printer ...................................................................................................2

1-3. Removing the protective materials ..............................................................................................3

2. Parts Identication and Nomenclature ..................................................................................................4

3. Setup ..........................................................................................................................................................5

3-1. Connecting the Interface Cable to the PC ....................................................................................5

3-2. Connecting the Interface Cable to the Printer ..............................................................................7

3-3. Installing the Printer Software ...................................................................................................11

3-4. Connecting the Optional AC Adapter ........................................................................................12

3-5. Turning Power On ......................................................................................................................13

3-6. Switch Cover Installation ...........................................................................................................14

3-7. Connecting to a Peripheral Unit .................................................................................................15

3-8. Attaching the Interface Cover ....................................................................................................16

4. Loading the Ribbon Cartridge and Paper ...........................................................................................17

4-1. Loading the Ribbon Cartridge ...................................................................................................17

4-2. Loading the Paper Roll ..............................................................................................................18

4-3. Loading the Slip Paper or Validation Paper ...............................................................................20

4-4. Scanning MICR Characters .......................................................................................................21

5. Consumable Parts and AC Adapter .....................................................................................................24

5-1. Thermal Paper Roll ....................................................................................................................24

5-2. Slip Paper ...................................................................................................................................26

5-3. AC adapter (option) ...................................................................................................................27

6. Control Panel and Other Functions .....................................................................................................28

6-1. Control Panel .............................................................................................................................28

6-2. Errors ..........................................................................................................................................29

6-3. Self-Printing ...............................................................................................................................31

6-4. Cleaning Mode ...........................................................................................................................35

6-5. Sensor Adjustment .....................................................................................................................35

7. Adjusting the Near-end Sensor .............................................................................................................41

8. Preventing and Clearing Paper Jams ...................................................................................................43

8-1. Preventing Paper Jams ...............................................................................................................43

8-2. Removing Paper Jam .................................................................................................................43

8-3. Releasing a Locked Cutter .........................................................................................................45

9. Maintenance ...........................................................................................................................................46

9-1. Thermal Printer ..........................................................................................................................46

9-2. Slip Printer .................................................................................................................................47

9-3. MICR Head ................................................................................................................................47

9-4. Cleaning the Sensors and the Surrounding Area ........................................................................48

9-5. Cleaning the Paper Holder and the Surrounding Area ...............................................................48

Page 4

10. Specications ........................................................................................................................................49

10-1. General Specications ...............................................................................................................49

10-2. Auto Cutter Specications .........................................................................................................50

10-3. MICR Specications ..................................................................................................................50

10-4. External Specications ...............................................................................................................51

10-5. Interface Specications ..............................................................................................................52

10-6. Power Specs ...............................................................................................................................53

10-7. Environmental Requirements .....................................................................................................54

10-8. Reliability Specications ...........................................................................................................55

11. Dip Switch Setting ................................................................................................................................57

11-1. Parallel Interface Model .............................................................................................................58

11-2. RS-232C Interface Model ..........................................................................................................59

11-3. USB/PoweredUSB Interface Model ..........................................................................................61

11-4. Ethernet Interface Model ...........................................................................................................62

12. Parallel Interface ..................................................................................................................................64

13. RS-232C Serial Interface .....................................................................................................................65

13-1. Interface Specications ..............................................................................................................65

13-2. RS-232C Connector ...................................................................................................................66

13-3. Cable Connections .....................................................................................................................67

14. USB/PoweredUSB and Ethernet ........................................................................................................68

14-1. USB/PoweredUSB Interface Specications ..............................................................................68

14-2. Ethernet Interface Specications................................................................................................68

15. Peripheral Unit Drive Circuit .............................................................................................................69

16. Memory Switch Settings ......................................................................................................................71

Please access the following URL

http://www.star-m.jp/eng/dl/dl02.htm

for the latest revision of the manual.

Page 5

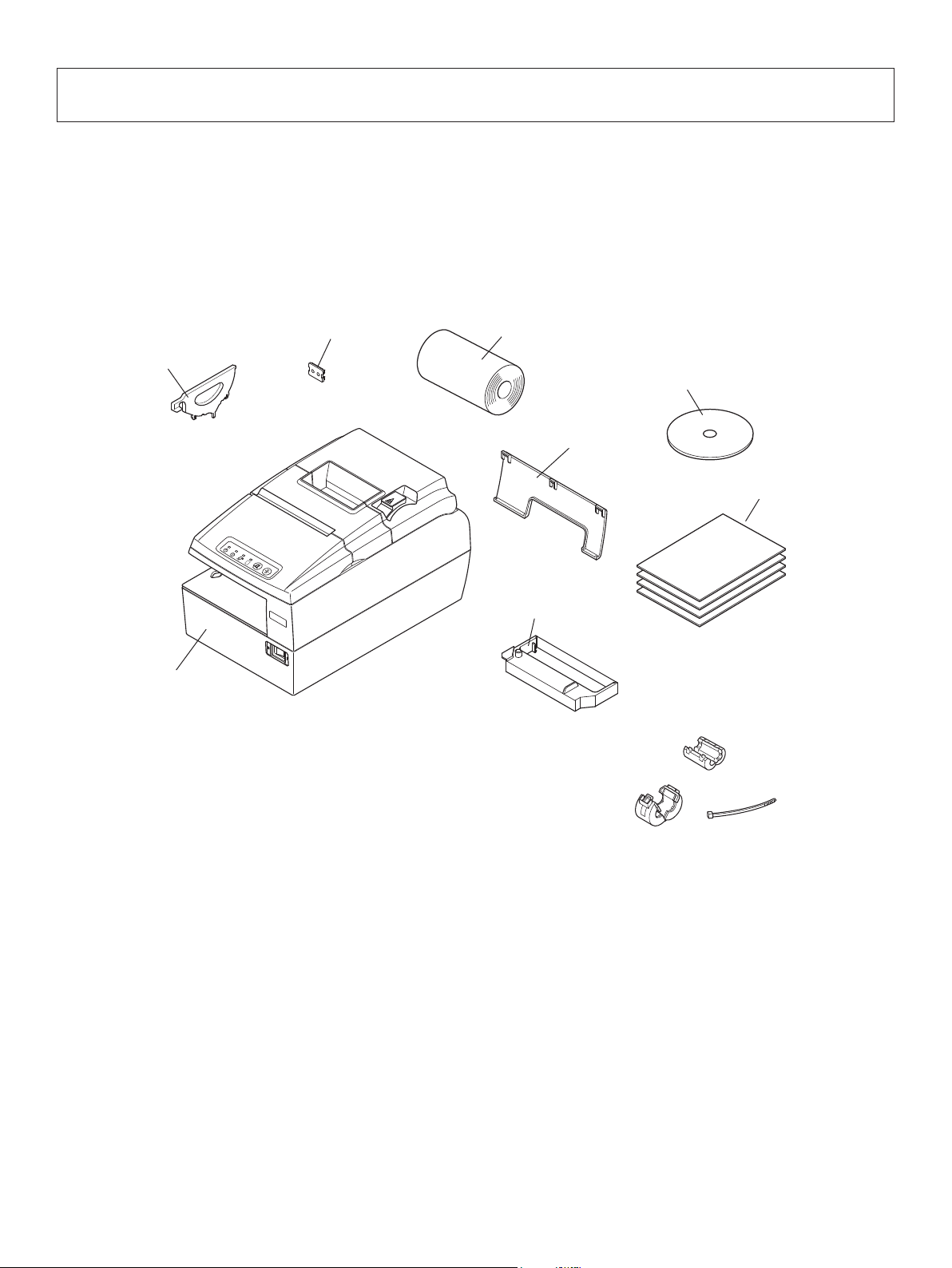

1. Unpacking and Installation

1-1. Unpacking

After unpacking the unit, check that all the necessary accessories are included in the package.

Paper guide

Printer

Switch blind

Thermal paper roll

CD-ROM

Interface cover

Setup sheets

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

Ribbon cassette

Note

Note: The ferrite core and fastener provided with your

printer depend on your printer conguration.

Fig. 1-1 Unpacking

If anything is missing, contact the dealer where you bought the printer and ask them to supply

the missing part. Note that it is a good idea to keep the original box and all the packing materials

just in case you need to pack the printer up again and send it somewhere at a later date.

– 1 –

Page 6

1-2. Choosing a place for the printer

Before actually unpacking the printer, you should take a few minutes to think about where

you plan to use it. Remember the following points when doing this.

P Choose a rm, level surface where the printer will not be exposed to vibration.

P The power outlet you plan to connect to for power should be nearby and unobstructed.

P Make sure that the printer is close enough to your host computer for you to connect

the two.

P Make sure that the printer is not exposed to direct sunlight.

P Make sure that the printer is well away from heaters and other sources of extreme heat.

P Make sure that the surrounding area is clean, dry, and free of dust.

P Make sure that the printer is connected to a reliable power outlet. It should not be on

the same electric circuit as copiers, refrigerators, or other appliances that cause power

spikes.

P Make sure that the room where you are using the printer is not too humid.

P This device employs a DC motor and switches that have an electrical contact point.

Avoid using the device in environments where silicon gas can become volatile.

PWhen disposing of the printer, obey local regulations.

WARNING

P Shut down your equipment immediately if it produces smoke, a strange odor, or unu-

sual noise. Immediately unplug the equipment and contact your dealer for advice.

P Never attempt to repair this product yourself. Improper repair work can be dangerous.

P Never disassemble or modify this product. Tampering with this product may result in

injury, re, or electric shock.

– 2 –

Page 7

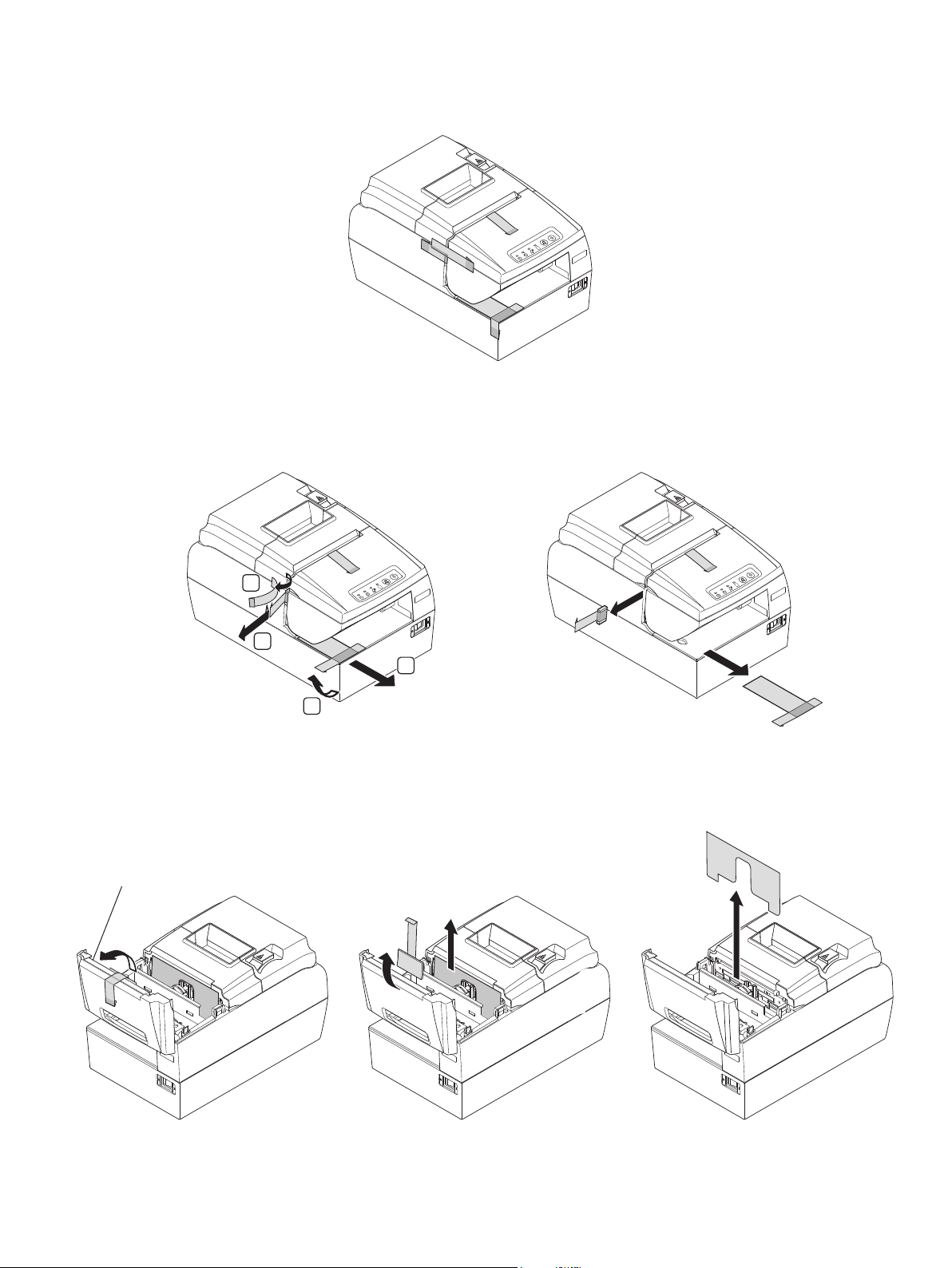

1-3. Removing the protective materials

Four protective materials are inserted into the printer to protect components during shipping.

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

Before using the printer, be sure to remove all protective materials as shown in the illustration.

(1) Remove the three tapes and pull the two protective sheets.

RELEASE

FEED

1

SLIP

PAPER OUT

ERROR

POWER

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

2

2

1

(2) Open the front cover.

Remove the tape on the front cover, and then remove the sheet.

Next, pull the protective sheet that is securing the head straight out of the unit.

Front cover

Note: That it is a good idea to keep all protective materials in case you will need to pack

the printer up again and send it somewhere at a later date.

– 3 –

Page 8

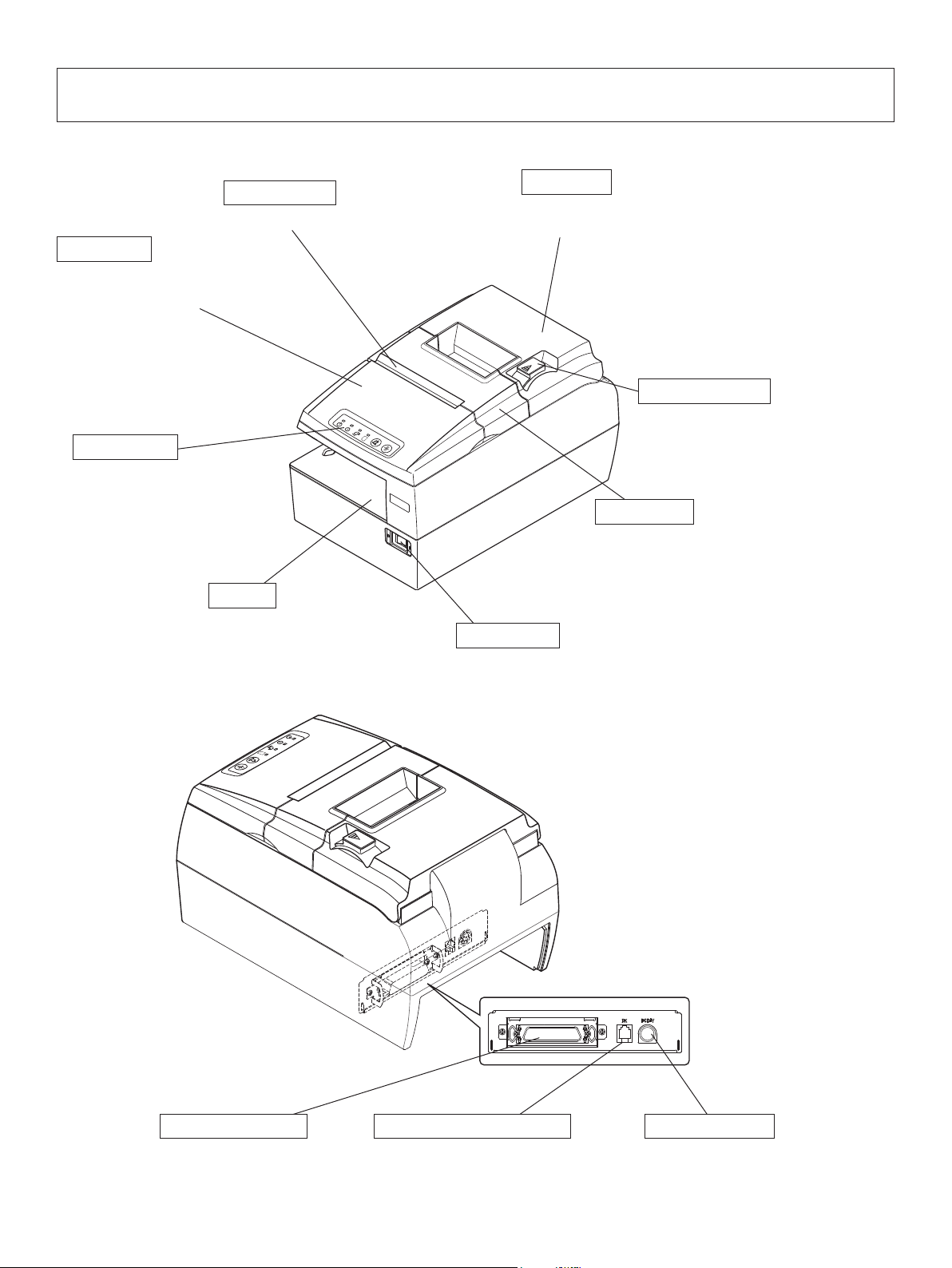

2. Parts Identication and Nomenclature

Validation slot

Insert paper here.

Front cover

Open it to replace the ribbon.

Do not open it during printing.

Control panel

Features LED indicators

to indicate printer status

and switches to operate

the printer.

Slip slot

Insert paper here.

Rear cover

Open it to replace the roll paper.

Do not open it during printing.

Cover open lever

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

Push this lever in the direction of the

arrow to open the rear cover.

Cutter cover

Open it to clear paper jam.

Do not open it during printing.

Power switch

PAPER OUT

SLIP

FEED

RELEASE

Interface connector

Used to turn on/off

power to the printer.

POWER

ERROR

Peripheral drive connector

Power connector

For connection to a

host computer.

Connects to peripheral units such

as cash drawers, etc.

Do not connect this to a telephone.

– 4 –

For connection of the AC adapter.

Never unplug the AC adapter while

the printer is on.

Page 9

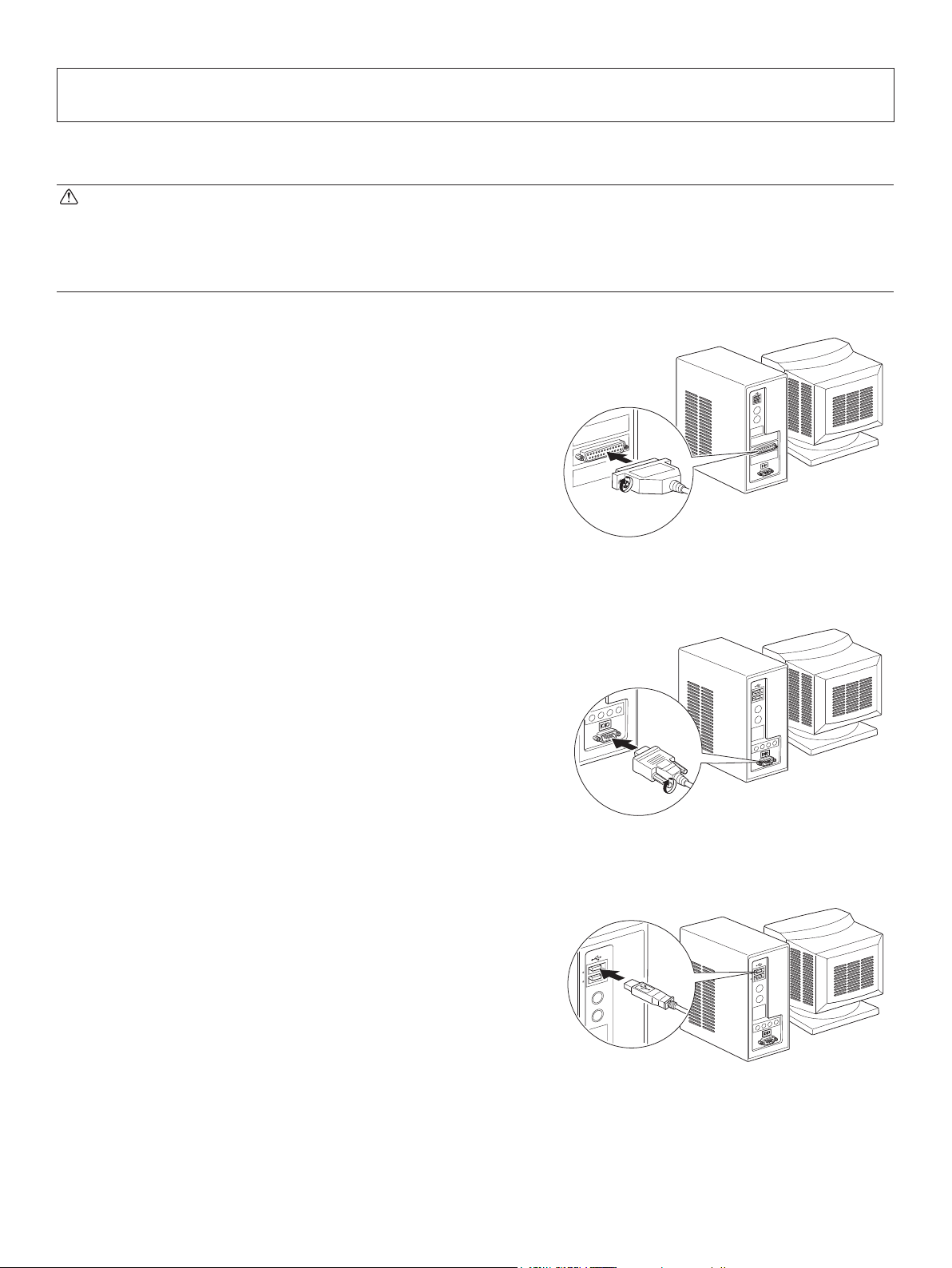

3. Setup

3-1. Connecting the Interface Cable to the PC

CAUTION

The optional USB, PoweredUSB, and LAN cables have been designed specically for this unit

(HSP7000).

Other USB, PoweredUSB, and LAN cables may not meet the EMC technical standards.

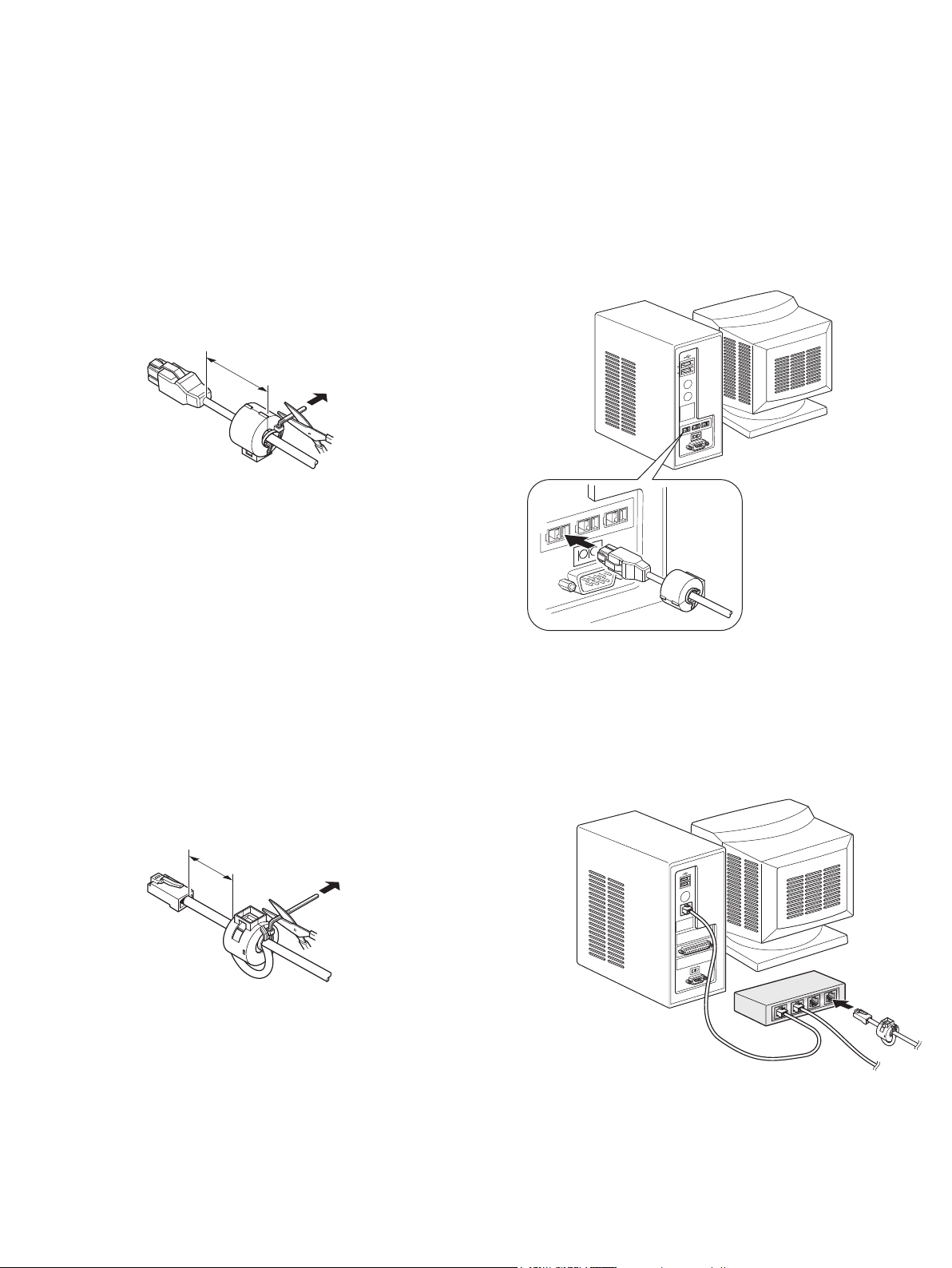

3-1-1. Parallel Interface Cable

Connect the parallel interface cable to a parallel port

of your PC.

3-1-2. RS-232C Interface Cable

Connect the RS-232C interface cable to a RS-232C

port of your PC.

3-1-3. USB Interface Cable

Connect the USB interface cable to a USB port of

your PC.

Option: USB cable 1.8M TSP1 (P/N: 30729100)

– 5 –

Page 10

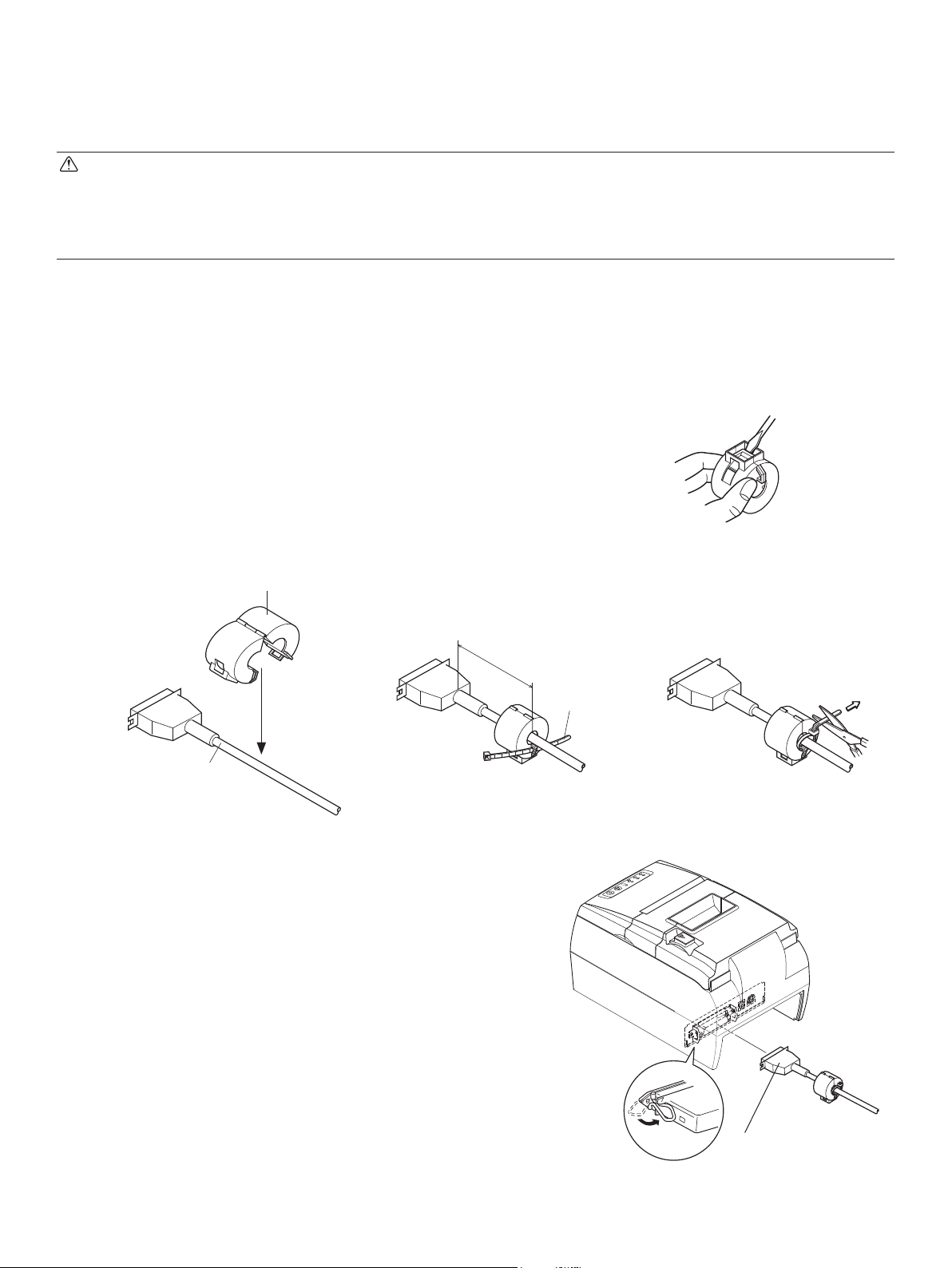

3-1-4. PoweredUSB Interface Cable

Attach the ferrite core to the PoweredUSB interface cable, and connect the cable to a PoweredUSB port of your PC.

Option: POWERED USB CABLE 1X8LNL 1.2M (P/N: 30729130)

Star Recommended PCI Card: PCI to 4 Port PoweredUSB Card (Model: 301-1150-01; manufacturer:

Digi)

Maximum 3.5 cm

Pull and cut

3-1-5. Ethernet Interface cable

Attach the ferrite core to the Ethernet interface cable, and connect the cable to an Ethernet port

of your PC.

Option: LAN cable 1.0M TSP1E (P/N: 30729200)

Maximum 3.5 cm

Pull and cut

– 6 –

Page 11

3-2. Connecting the Interface Cable to the Printer

Note that the interface cable is not provided. Please use a cable that meets specications.

CAUTION

The optional USB, PoweredUSB, and LAN cables have been designed specically for this unit

(HSP7000).

Other USB, PoweredUSB, and LAN cables may not meet the EMC technical standards.

Before connecting or disconnecting an interface cable (except when using a PoweredUSB cable),

be sure to disconnect the plug of the AC adapter power cable from the outlet.

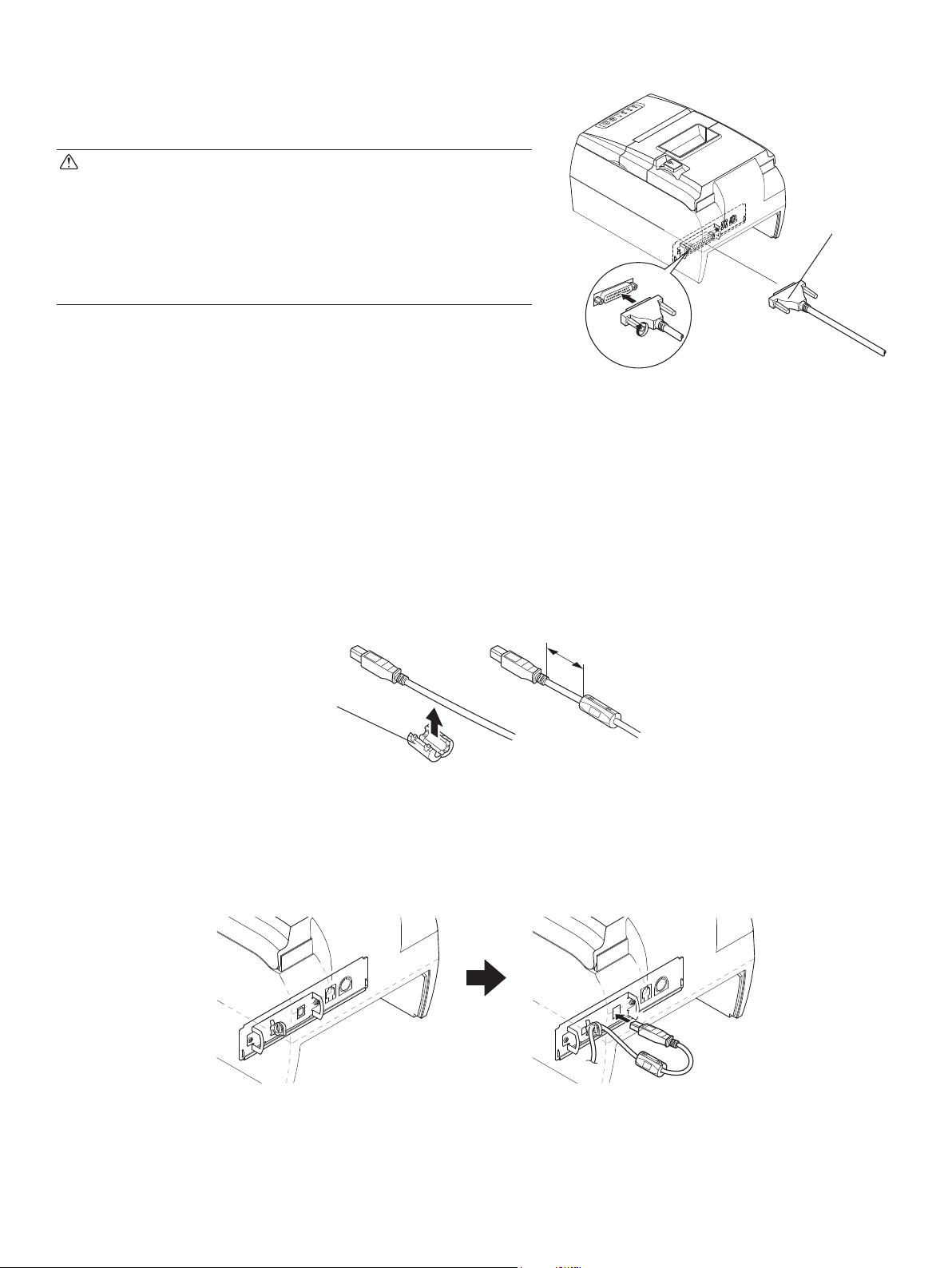

3-2-1. Parallel Interface Cable

(1) Make sure the printer is turn off.

(2) Afx the ferrite core onto the cable as shown in

the illustration.

(3) Pass the fastener through the ferrite core.

(4) Loop the fastener around the cable and lock it.

Use scissors to cut off any excess.

Ferrite core

5 cm

(maximum)

Interface cable

(5) Connect the interface cable to the connector on

the rear panel of the printer.

(6) Fasten the connector clasps.

Fastener

Pull and cut

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

– 7 –

Parallel interface

cable

Page 12

3-2-2. RS-232C Interface Cable

POWER

ERROR

PAPER OUT

(1) Make sure the printer is turn off.

SLIP

FEED

RELEASE

CAUTION

Before connecting/disconnecting the interface ca-

ble, make sure that power to the printer and all the

devices connected to the printer is turned off. Also

make sure the power cable plug is disconnected

from the AC outlet.

(2) Connect the interface cable to the connector on

the rear panel of the printer.

(3) Tighten the connector screws.

3-2-3. USB Interface Cable

Afx the ferrite core onto the USB cable as shown in the illustration below and make sure to

pass the cable through the cable support as shown in the illustration.

Option: USB CABLE 1.8M TSP1 (P/N: 30729100)

RS-232C

interface

cable

(1) Afx the supplied ferrite core onto the USB cable as shown in the illustration.

4 cm (Maximum)

Ferrite core

(2) Secure the cable with the cable hook.

(3) Insert the plug of the USB interface cable into the USB interface connector of the printer

as shown in the illustration.

– 8 –

Page 13

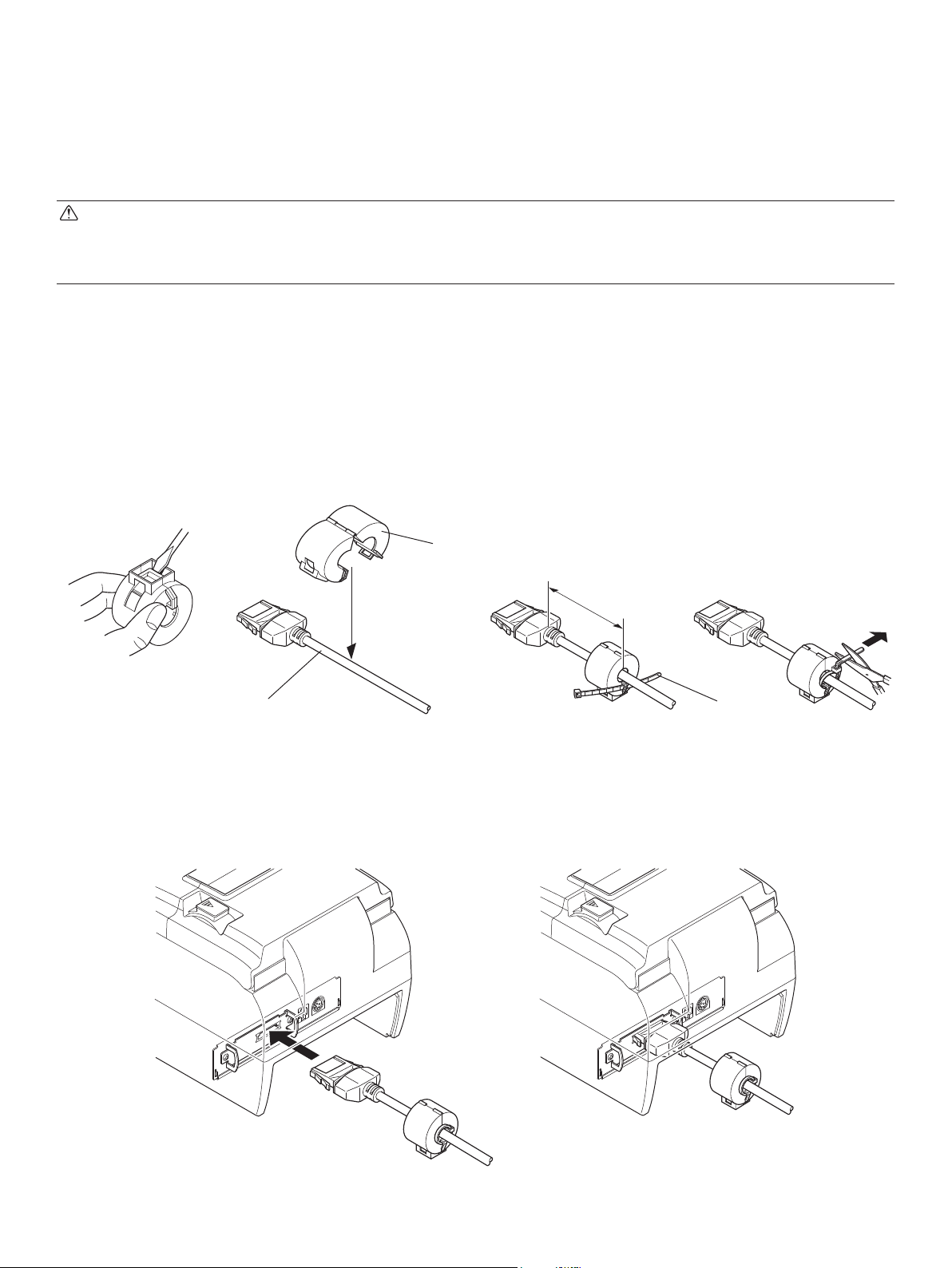

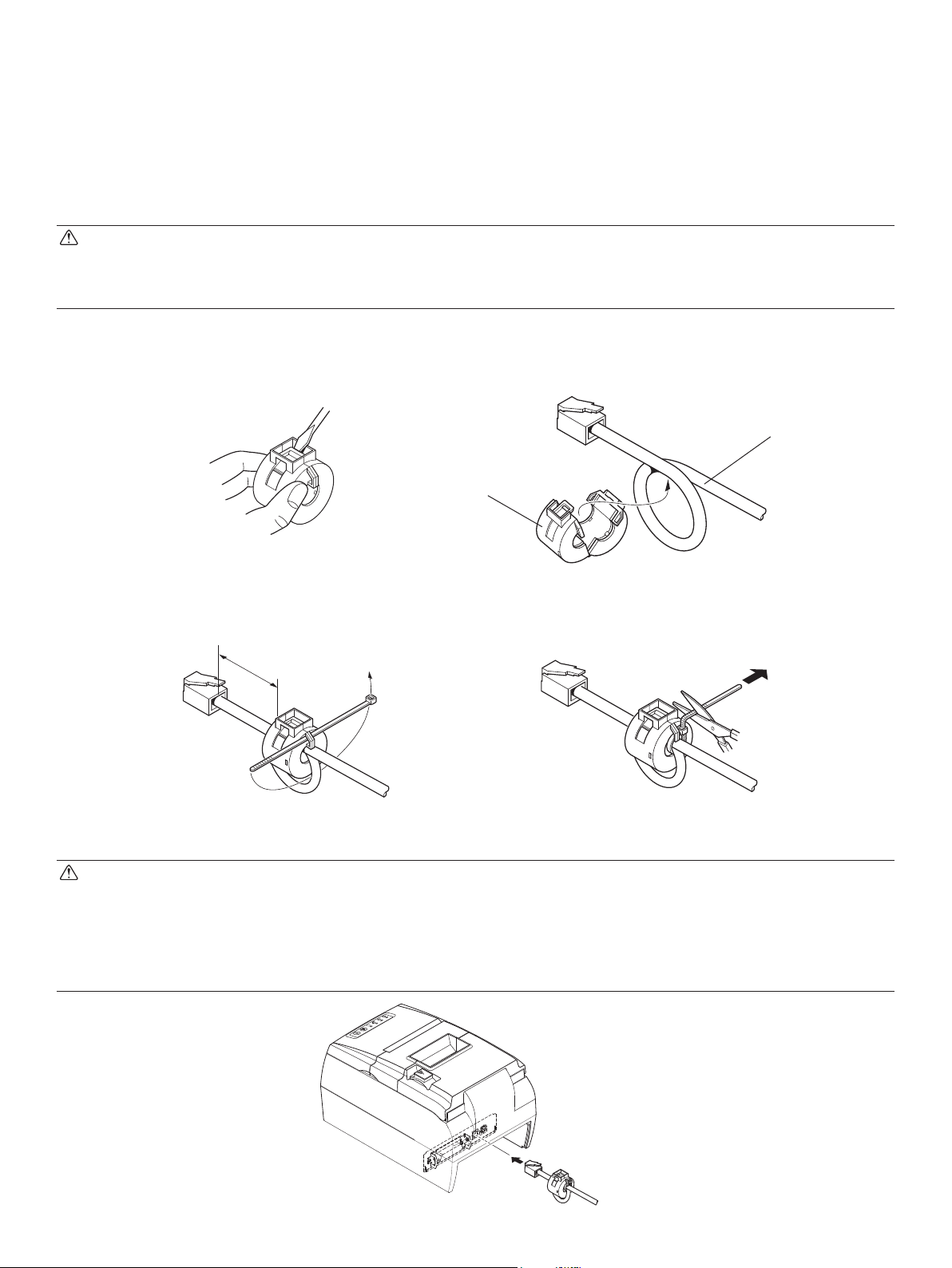

3-2-4. PoweredUSB Interface Cable

(1) Turn the power switch off.

(2) If connected to an AC adapter, pull the power cord plug from the outlet and then pull the

plug from the power connector on the printer side.

CAUTION

If connecting a PoweredUSB cable, do not connect the AC adapter because this can cause a

malfunction.

(3) Afx the ferrite core onto the cable as shown in the illustration.

Option: POWERED USB CABLE 1X8LNL 1.2M (P/N: 30729130)

(4) Pass the fastener through the ferrite core.

(5) Loop the fastener around the PoweredUSB interface cable and lock it.

Use scissors to cut off any excess.

Ferrite core

Interface cable

Maximum

3.5 cm

Fastener

(6) Connect the interface cable to the connector on the rear panel of the printer.

Pull and cut

– 9 –

Page 14

3-2-5. Connecting Ethernet Interface Cable

To protect the unit from electromagnetic interference, afx the two supplied ferrite cores to the

printer and router (hub) sides of the cable, respectively. Follow the instructions given below.

Option: LAN CABLE 1.0 M TSP1E (P/N: 30729200)

(1) Make sure the printer is turned off.

(2) Afx the ferrite core onto the Ethernet cable as shown in

the illustration below.

(3) Pass the fastener through the ferrite core.

(4) Loop the fastener around the cable and lock it. Use scis-

sors to cut off any excess.

10 cm

(maximum)

Ethernet cable

Ferrite core

Fastener

(5) Connect the interface cable to the connector on the

rear panel of the printer.

Pull and cut

Link disconnection detection feature

The Ethernet interface model is equipped with a link

disconnection detection feature.

If the printer is turned on when an Ethernet cable is not

connected to it, the POWER and ERROR lamps are

simultaneously turned on and off at 2-second intervals

to indicate the disconnection.

Be sure to connect the Ethernet cable from a PC or hub

to the printer, and then turn the printer on.

– 10 –

Page 15

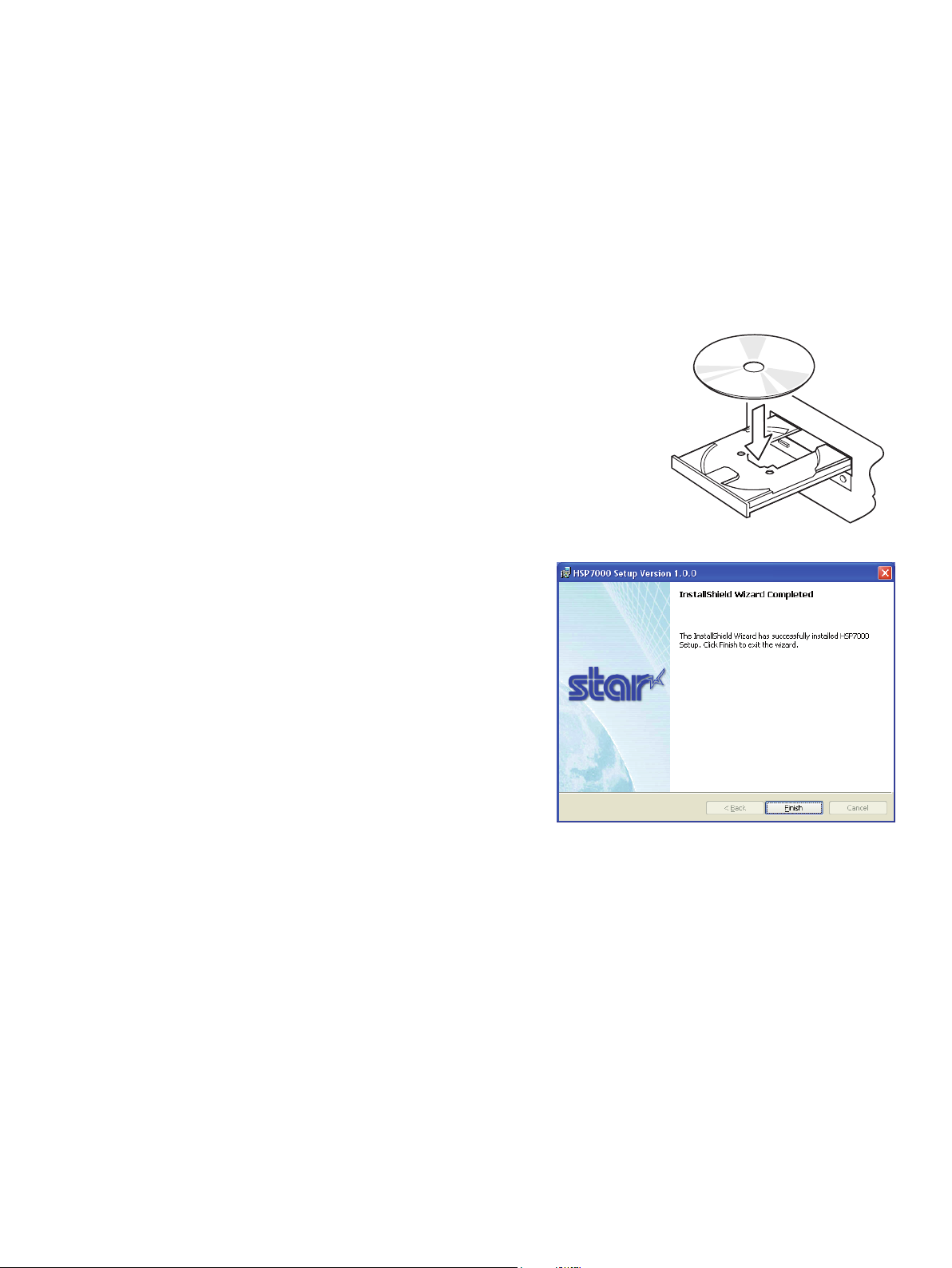

3-3. Installing the Printer Software

Here is the procedure for installing the printer driver and utility software, which are stored on

the supplied CD-ROM.

The procedure applies to the Windows operating systems shown below.

For Macintosh and Linux, refer to the software manual in the Mac folder or Linux folder of

the CD-ROM.

• Windows 2000

• Windows XP

• Windows Vista 32-Bit/64-Bit

(1) Turn ON the power to your PC to start Windows.

(2) Insert the supplied CD-ROM (Drivers and Utilities)

into the CD-ROM drive.

(3) Follow the instructions that appear on the screen.

(4) The dialog shown in the illustration indicates that

the procedure has been completed.

Click “Finish”.

The dialog that appears on the screen varies with your system. This completes the installation

of the printer software. A message will appear, prompting you to restart. Restart Windows.

For instruction on the Windows Vista 64-Bit, refer to the software manual located in the

“Documents” folders on the CD-ROM.

– 11 –

Page 16

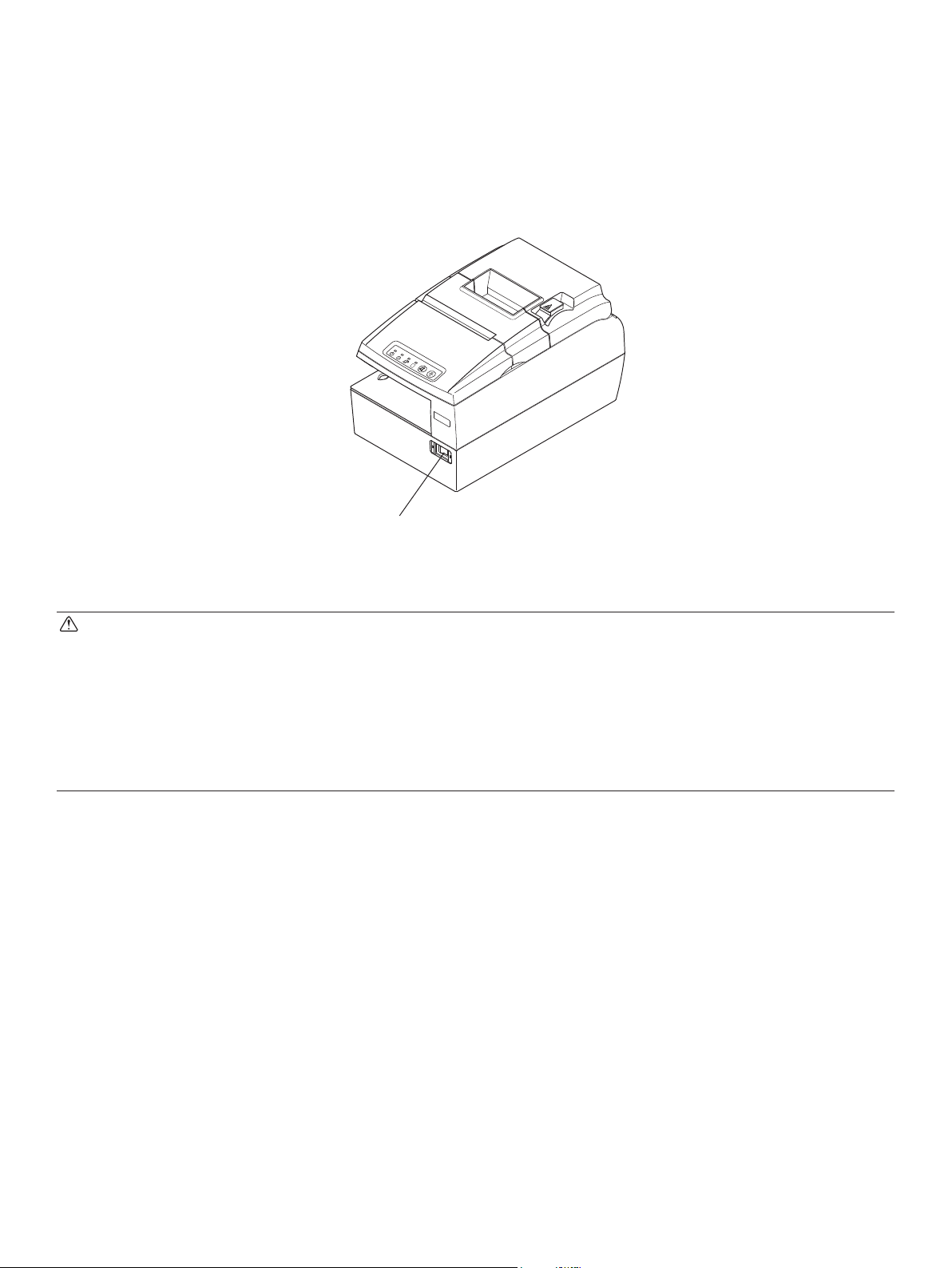

3-4. Connecting the Optional AC Adapter

Note: Before connecting/disconnecting the AC adapter, make sure that power to the printer

and all the devices connected to the printer is turned off. Also make sure the power

cable plug is disconnected from the AC outlet.

(1) Connect the AC adapter to the power cable.

Note: The optional AC adapter has been designed specically for this unit (HSP7000).

Other AC adapters may not meet the EMC technical standards.

Option: PS60A-24B

(2) Connect AC adapter to the connector on the printer.

(3) Insert the power cable plug into an AC outlet.

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

CAUTION

When disconnecting the cable, take hold of the cable

connector to pull it out. Releasing the lock makes it easy

to disconnect the connector.

Pulling the cable excessively could cause damage to the

connector.

– 12 –

Page 17

3-5. Turning Power On

Make sure that the Power cord has been connected as described in 3-4.

Turn ON the power switch located on the front of the printer.

The POWER lamp on the control panel will light up.

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

Power switch

CAUTION

We recommend that you unplug the printer from the power outlet whenever you do not plan to

use it for long periods. Because of this, you should locate the printer so that the power outlet it

is plugged into is nearby and easy to access.

When an Switch blind is afxed to the printer above the power switch, the ON/OFF marks of

the power switch may be hidden. If this occurs, remove the power cord from the outlet to turn

the printer OFF.

– 13 –

Page 18

3-6. Switch Blind Installation

It is not necessary to install the switch blind. Only install it if it is necessary for you. By installing the switch blind, the following become possible.

• Preventing the power switch from being operated by mistake.

• Ensuring that other people can not easily operate the power switch.

Install the switch blind as shown in the diagram below.

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

Switch blind

The power switch can be turned ON (

|

pen etc.) in the holes in the switch blind.

CAUTION

We recommend that you unplug the printer from the power outlet whenever you do not plan to

use it for long periods. Because of this, you should locate the printer so that the power outlet it

is plugged into is nearby and easy to access.

) and OFF (O) by inserting a narrow instrument (ball

– 14 –

Page 19

3-7. Connecting to a Peripheral Unit

You can connect a peripheral unit to the printer using a modular plug.

See “15. Peripheral Unit Drive Circuit” for details about the type of modular plug that is required. Note that this printer does not come with a modular plug or wire, so it is up to you to

obtain one that suits your needs.

CAUTION

Make sure that the printer is turned off and unplugged from the AC outlet and that the computer

is turned off before making connections.

(1) Make sure the printer is turned off.

(2) Afx the ferrite core onto the peripheral drive cable as shown below.

Peripheral drive cable

Ferrite core

(3) Pass the fastener through the ferrite core.

(4) Loop the fastener around the peripheral drive cable and lock it.

Use scissors to cut off any excess.

3.5 cm (maximum)

Pull and cut

(5) Connect the peripheral drive cable to the connector on the rear panel of the printer.

CAUTION

Do not connect a telephone line into the peripheral drive connector. Failure to observe this may

result in damage to the printer.

Also, for safety purposes, do not connect wiring to the external drive connector if there is a

chance it may carry peripheral voltage.

POWER

ERROR

PAPER OUT

SL

IP

FEED

RELE

ASE

– 15 –

Page 20

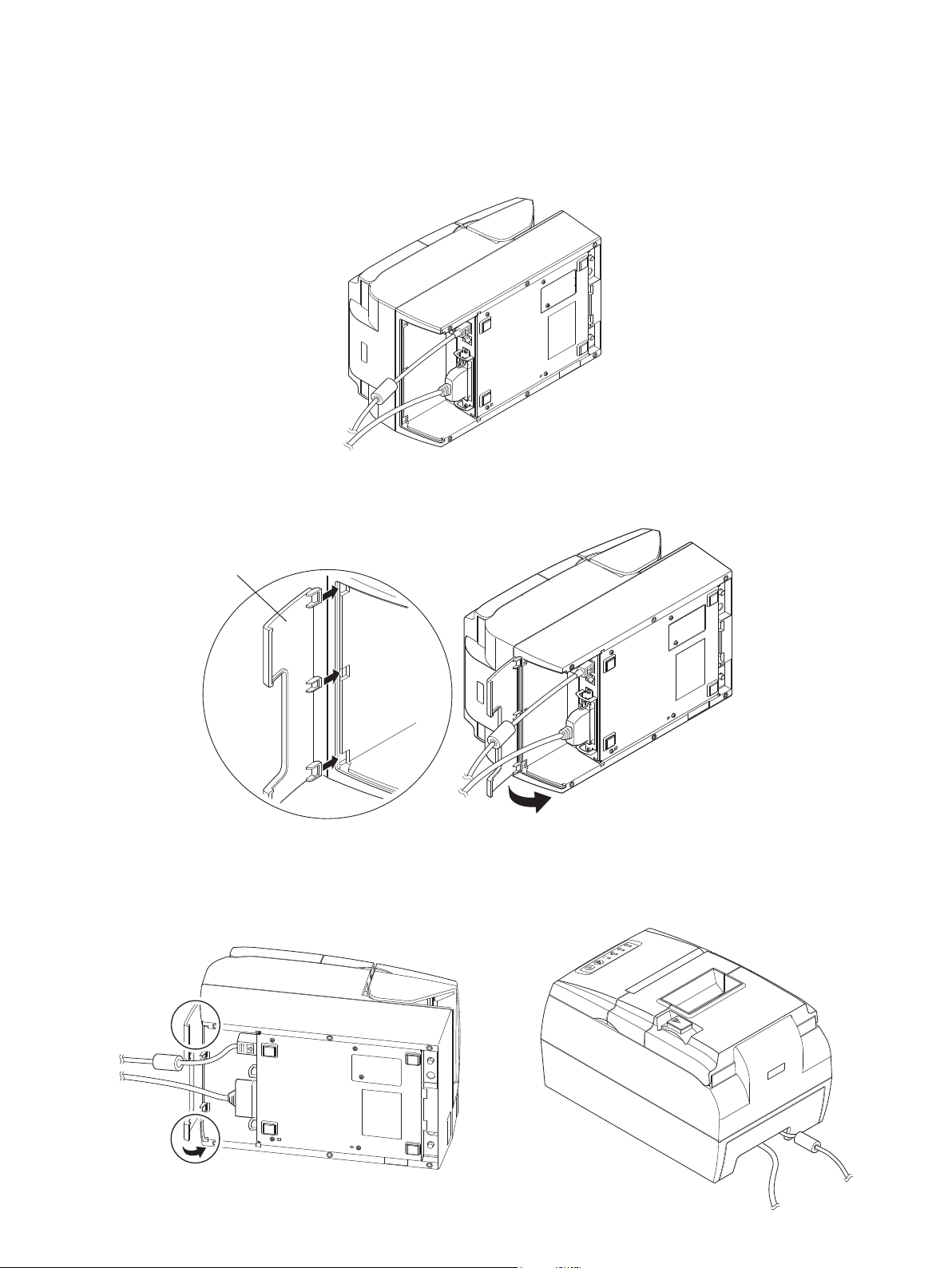

3-8. Attaching the Interface Cover

It is not necessary to attach the interface cover. Only attach it if it is necessary for you.

Attach the interface cover as shown in the illustration.

(1) Place the printer as shown below.

(2) Install the interface cover by aligning the tabs on the interface cover with the grooves in

the printer case.

Interface cover

(3) Place the AC cable and the interface cable in the cutout of the interface cover. Then, install

the interface cover until the both ends of the interface cover click into place.

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

– 16 –

Page 21

4. Loading the Ribbon Cartridge and Paper

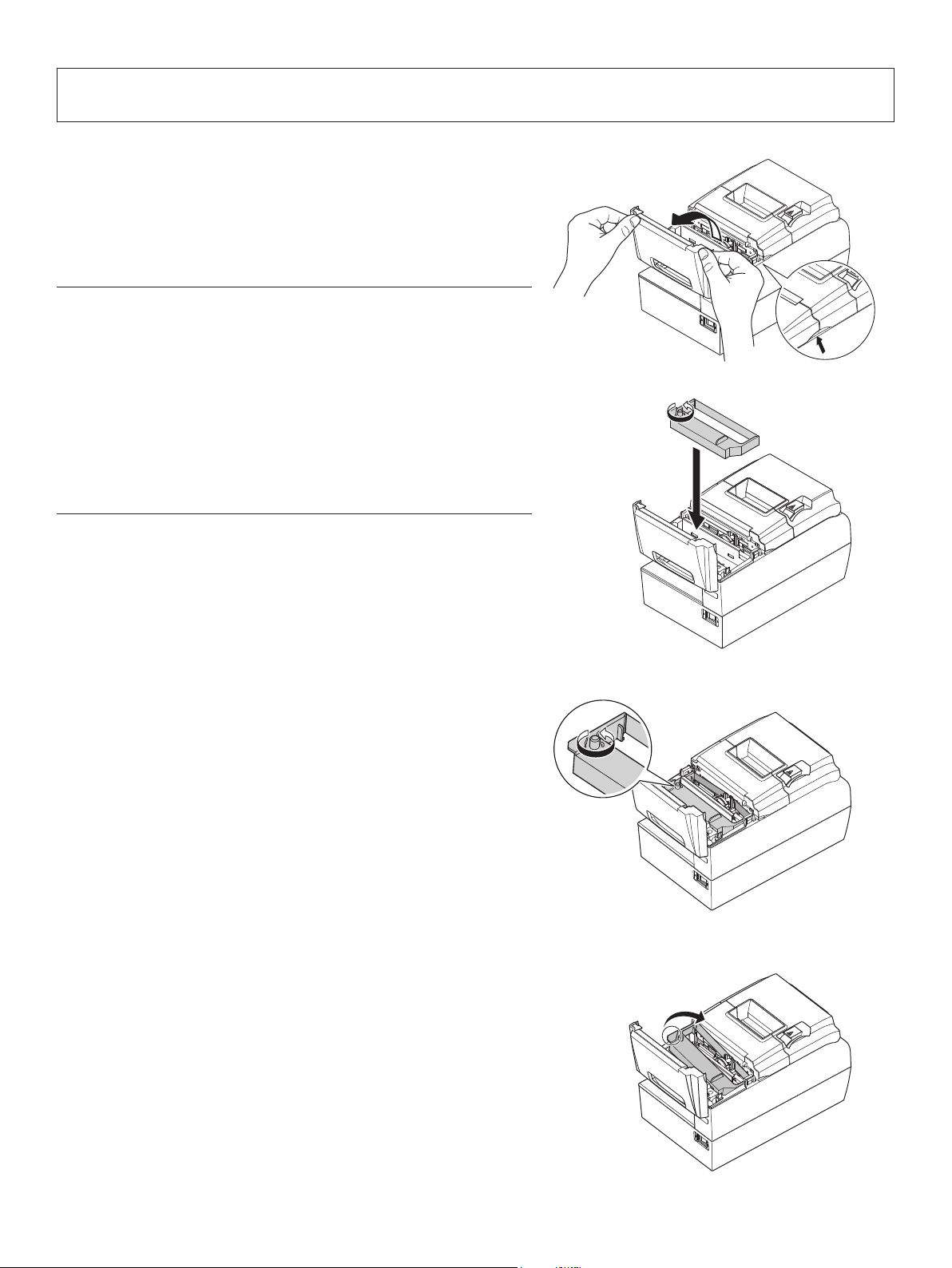

4-1. Loading the Ribbon Cartridge

(1) Turn off power to the printer.

(2) Open the front cover by holding the nger grips

on both ends of the cover and lifting it up.

Important!

1. Do not touch the print head immediately after

printing as it can be extremely hot.

2. Do not touch the cutter blade.

· There is a cutter inside the paper outlet slot.

Not only should you not put your hand in the

paper outlet slot while printing is in progress,

never put your hand into the outlet even when

printing is not in progress.

(3) Place the ribbon cartridge in the direction shown

in the gure and press it down to load it. If loading

of the ribbon cartridge is not satisfactory, press

down the cartridge while rotating the ribbon feed

knob in the direction of the arrow.

(4) Turn the ribbon feed knob of the ribbon cartridge

in the direction of the arrow to remove slack in

the ribbon.

(5) Close the front cover.

Note: When removing the ribbon cartridge, raise

the nger grip as shown in the gure.

– 17 –

Page 22

4-2. Loading the Paper Roll

4-2-1. Using 79.5 mm Width Paper Roll

Be sure to use roll paper that matches the printer’s specication.

When using a paper roll with an 57.5 mm width, install the paper guide as described on the

following page.

(1) Push the cover open lever, and open the printer

cover.

(2) While observing the direction of the roll, set the

paper roll into the hollow, and pull on the leading

edge of the paper toward you.

CAUTION

Do not pull out the end of the paper diagonally,

as it will cause the paper to become jammed or

skewed.

Paper roll

ERROR

PAPER

OUT

SLI

P

FEED

RE

LEASE

Cover open lever

ERROR

PAPER OUT

SLIP

FEED

RELEASE

ERROR

PAPER OUT

SLIP

FEED

RELEASE

(3) Push down both sides of the printer cover to

close.

Note: Make sure that the printer cover is securely

closed.

(4) If the printer cover is closed after turning on the

power, the cutter operates automatically and the

front end of the paper is cut.

– 18 –

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

Page 23

4-2-2. Using 57.5/75.5 mm Width Paper Roll

When using a paper roll with 57.5 or 75.5 mm width, install the supplied paper guide on the

printer.

To change the effective print width (roll paper width), change the setting at memory switch

conguration Utility. For details on the setting of the memory switches, refer to the software

manual located in the “Documents” folders on the CD-ROM.

(1) Install the roll paper guide in the unit as illustrated below.

To use a 75.5 mm width paper roll, align the roll paper guide in hole [1], and to use a 57.5

mm width paper roll, align it in hole [2].

Paper guide

[1]

[2]

POWER

ERROR

PAPE

R

OUT

SLIP

FEED

RELEASE

(2) Install the roll paper guide in the unit by aligning it with the holes and grooves as illustrated

below.

Note: After using a paper roll with a width of 57.5 mm, do not change to a paper roll with

a width of 79.5 or 75.5 mm. (This is because the printer head has deteriorated as a

result of a portion of the head having been in direct contact with the platen.)

After using a paper roll with a width of 75.5 mm, do not change to a paper roll with

a width of 79.5 mm. for same reason.

– 19 –

Page 24

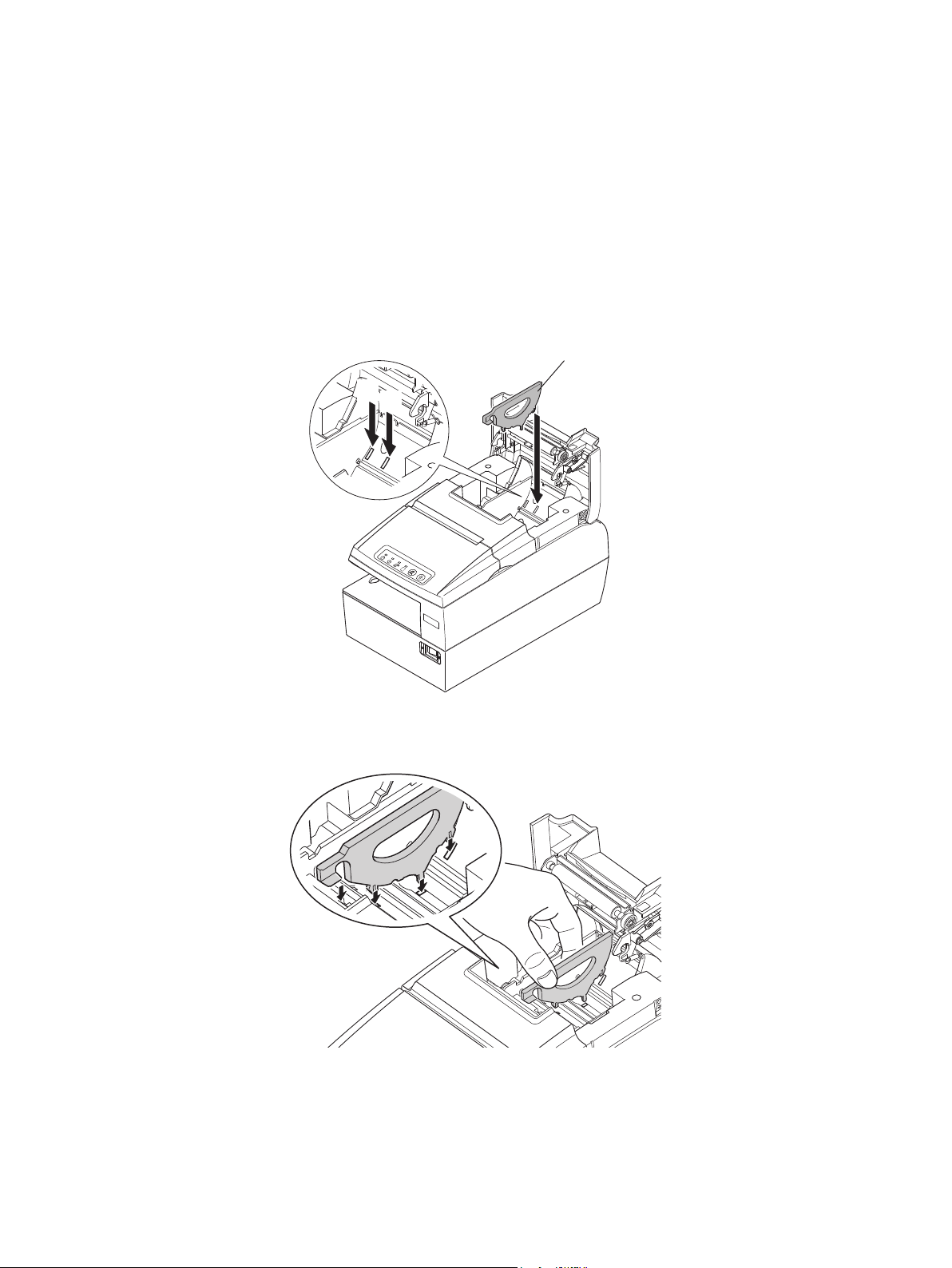

4-3. Loading the Slip Paper or Validation Paper

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

Before starting printing, make sure the ribbon cassette is placed in the printer. (See “4-1. Loading the Ribbon Cartridge” for details.)

Insert the paper as follows:

(1) Turn the printer power switch ON.

(2) Insert the paper as illustrated below. Facing the printer, insert the paper straight, while

sliding the right end of the paper against the right end of the slip paper slot. Alternatively,

insert the paper straight from the top.

Note: Sliding the paper diagonally can cause a paper jam. If the paper gets jammed, press

the RELEASE button to remove the paper. Then, insert the paper again.

(See “8-2. Removing Paper Jam” for details.)

Inserting Slip Paper

RELEASE

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

FEED

SLIP

PAPER OUT

ERROR

POWER

Inserting Validation Paper

2

1

1

2

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

(3) When the printer detects a paper, it automatically feeds the paper and starts printing.

(4) After completing printing, the printer will automatically release the paper.

Note: Be sure to use a type of paper that matches the printer’s specications. (See “5-2-1.

Specications”.) Do not use paper that is curled, kinked, wrinkled, warped, or

torn.

– 20 –

Page 25

4-4. Scanning MICR Characters

The insertion direction for MICR paper varies according to the model.

HSP7543 (no MICR scanning head): MICR characters cannot be scanned.

HSP7643 (MICR scanning head installed above):

Insert the MICR paper with the MICR characters facing

up.

HSP7743 (MICR scanning head installed below):

Insert the MICR paper with the MICR characters facing

down.

Insert a MICR paper as follows:

(1) Turn the printer power switch ON.

(2) Make sure the SLIP lamp is ashing.

As you face the printer, insert the paper straight, while sliding the right end of the MICR

(3)

paper against the right end of the slip paper slot.

Note: Sliding the paper diagonally can cause a paper jam.

If the paper gets jammed, press the RELEASE button to remove the paper. Then,

insert the paper again. (See “8-2. Removing Paper Jam” for details.)

(4) When the MICR paper reaches the scanning position, the SLIP lamp will turn ON.

<Direction of MICR Paper on HSP7643>

100

P L E

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

10 0

Scanning

characters

S A M P L E

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

<Direction of MICR Paper on HSP7743>

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

Scanning

characters

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

– 21 –

Page 26

Notes:

1) For MICR scanning, do not place the printer near devices that generate magnetism or

in an area that can expose the printer to shocks or vibration. Placing the printer in such

areas can negatively affect its scanning performance. Before putting the printer into

actual operation, verify the printer’s scanning performance by performing trial scans

at its installed location.

2) Use at MICR paper that is not curled, kinked, wrinkled, warped, or torn. Otherwise,

the ink ribbon could become abraded or soiled, or it could cause a paper jam.

3) Do not use MICR paper with clips, staples, or debris attached to it. Otherwise, it could

damage the MICR scanning head, in addition to causing a paper jam.

Caution Symbol

This symbol is placed near the slip print head to indicate that it may be hot.

Never touch the slip print head immediately after the printer has been used. Let the

print head cool for a few minutes before touching it.

This symbol is placed near the thermal print head to indicate that it may be hot.

Never touch the thermal print head immediately after the printer has been used. Let

the print head cool for a few minutes before touching it. Observe the precautions

for handling electrostatic sensitive devices.

This symbol is placed near the cutter.

Never touch the cutter blade, as you could injure your ngers.

This symbol is placed near the peripheral drive connector.

Do not connect this to a telephone.

WARNING

P Shut down your equipment immediately if it produces smoke, a strange odor, or unusual

noise. Immediately unplug the equipment and contact your dealer for advice.

P Never attempt to repair this product yourself. Improper repair work can be dangerous.

P Never disassemble or modify this product. Tampering with this product may result in injury,

re, or electric shock.

P Do not touch the cutter blade.

• There is a cutter inside the paper outlet slot. Not only should you not put your hand in the

paper outlet slot while printing is in progress, never put your hand into the outlet even

when printing is not in progress.

• The printer cover can be opened when replacing the paper. However, since the cutter

blade is on the inside of the printer cover, be careful not to place your face or hands too

close to the cutter blade.

P During and immediately after printing, the area around the print head is very hot. Do not

touch it, as you could be burned.

P Since working on the cutter may be dangerous, be sure to turn off the printer rst.

– 22 –

Page 27

CAUTION

P We recommend that you unplug the printer from the power outlet whenever you do not plan

to use it for long periods. Because of this, you should locate the printer so that the power

outlet it is plugged into is nearby and easy to access.

P If the voltage shown on the label on the of your printer does not match the voltage for your

area, contact your dealer immediately.

P Make sure that the printer is turned off and unplugged from the AC outlet and that the

computer is turned off before making connections.

P Do not connect a telephone line into the peripheral drive connector.

Failure to observe this may result in damage to the printer.

Also, for safety purposes, do not connect wiring to the external drive connector if there is

a chance it may carry peripheral voltage.

P Do not operate the open lever while pressing on the rear cover with your hand.

P Do not pull the open lever and open the rear cover when printing is in progress or when

the auto cutter is operating.

P Do not pull out paper while the rear cover is closed.

P If liquids, foreign objects (coins and paper clips), and so on enter the printer, turn off the

printer, unplug it from the AC outlet, and contact your dealer for advice.

Continued use could cause a short circuit, which may result in re or electric shock.

P The heating element and the driver IC of the thermal head are easily damaged. Do not touch

them with metal objects, sandpaper, etc.

P Printing quality may suffer if the thermal head heating element becomes soiled by being

touched with your hands. Do not touch the thermal head heating element.

P There is a risk of damage to the driver IC of the thermal head from static electricity. Never

directly touch the IC.

P The printing quality and working life of the thermal head cannot be guaranteed if any ther-

mal paper other than that recommended is used. In particular, thermal paper containing

+

, K+, C1-] may drastically reduce the working life of the thermal head. Please exercise

[Na

caution.

+

The use of paper with a maximum ion density of Na

ppm is recommended.

P Do not operate the printer if there is moisture on the front surface of the head from conden-

sation, etc.

500 ppm, K+ 150 ppm, and Cl– 300

Notes on Using the Auto Cutter

P To print after a cut, feed 1 mm (8-dot line) or more of paper.

P If the cutter is not in its home position after an error, rst eliminate the cause of the error;

then, turn the power back ON.

P A margin of 5 mm or more is recommended from the end of the printed area to the cutting

position.

P Do not attempt to remove the paper during a cut, as this can cause a paper jam.

– 23 –

Page 28

5. Consumable Parts and AC Adapter

Use paper that meets the specications.

5-1. Thermal Paper Roll

5-1-1. Paper roll specication

(1) Thickness: Normal paper 65~85 µm (excluding Mitsubishi HiTec F5041)

Label paper 65~150 µm (cutter is not supported)

(2) Width: General thermal paper 79.5±0.5 mm (57.5±0.5 mm/75.5±0.5 mm

when the paper roller holder is used)

Label paper 76.5 ± 0.5 mm

(3) Outer roll diameter: ø83 mm or less

Take up paper roll width: 80

(4) Core outer/inner diameter:

Paper type Core outer Core inner

Normal paper: ø18±1 mm ø12±1 mm

Label paper: ø32±1 mm ø25.4±1 mm

(5) Printed surface: Outer edge of roll * Do not use an inner wrapped roll paper.

+0.5

mm or (58

-1

holder is used)

+0.5

mm/76

-1

+0.5

mm when the paper roller

-1

CAUTION

1) Do not glue or tape the roll paper and shaft core together.

2) Do not use paper rolls that have the tail end folded.

3) The trailing edge should not be folded.

– 24 –

Page 29

5-1-2. Effective Print Width

Paper Width

(mm)

Right / Left Margin (mm) Effective Print Width

(mm)

79.5 ± 0.5 3.75 72 48

75.5 ± 0.5 3.75 68 45

57.5 ± 0.5 Left 2.75, Right 3.75 51 34

Label Width

(mm)

76.5 ± 0.5 2 72 48

Right / Left Margin (mm) Effective Print Width

(mm)

Left Margin Right MarginEffective Print Width

Number of Print Columns (12 × 24 Font)

Number of Print Columns (12 × 24 Font)

Paper Width

– 25 –

Page 30

5-2. Slip Paper

5-2-1. Specications

(1) Width: 68 ~ 230 mm

(2) Length: 75 ~ 297 mm

(3) No. of copies: original + 3 copies

(4) Total thickness: 1 sheet 0.09 ~ 0.15 mm (up to A4 portrait)

0.09 ~ 0.20 mm (up to A6 portrait)

4 sheets 0.09 ~ 0.31 mm

(5) Copy slippage: 1.5 mm or less per 15 lines (between original and bottom-

most paper)

(6) Adhesive: top-bound = good; right-bound = acceptable;

left-bound = acceptable; bottom-bound = unacceptable

Note: Be particularly careful with paper that has adhesive on the left end because it might

feed diagonally.

Note:

1) Do not use paper that is curled, kinked, wrinkled, warped, or torn.

2) Do not use paper that has holes in the positions shown below, and do not print on the

back of paper that has low reectance, because they can cause the paper sensor to

operate improperly.

37 mm

27 mm

8 mm

: Holes not allowed

: Printing not allowed on pa-

per with holes or reectance

below 40%

Paper feed

direction

3) The copying performance of the printer is greatly affected by the ambient temperature.

Therefore, print under the conditions described below.

Number of copies Ambient temperature

Original + 3 copies 10 ~ 40°C

Original + 1 copy 5 ~ 45°C

– 26 –

Page 31

5-2-2. Slip Printing Area

The printing position is as shown in the diagram below.

5

Paper feed roller (rear)

Paper stop position

Paper feed roller (front)

Paper feed direction

TOF sensor

3.1

First line printing

COF sensor

Last line printing

85.4

13.5 13.529.5

13.5

29.5

BOF sensor

31.8

32.6

13.5

15.1

15.1

5.6

59.1 16.3

14.811

1.9

Approx. 83.5

28.2

18.4

Minimum

(unit: mm)

5-2-3. Validation Printing Range

150 (Min)

5.6

53 (Max)

18.4 (Min)

(unit: mm)

68 (Min)

36.1

33

(printable area)

85.4

3.1

5-3. AC adapter (option)

Note: The optional AC adapter has been designed specically for this unit (HSP7000).

Other AC adapters may not meet the EMC technical standards. In addition, use of

other AC adapters may result in damage to the printer, re or electric shock.

Model name: PS60A-24B

Input: 90 to 264 V AC, 50/60 Hz

Output: DC24 V ±5%, 2.0 A (5.0 A Load 10 sec. Max.)

– 27 –

Page 32

6. Control Panel and Other Functions

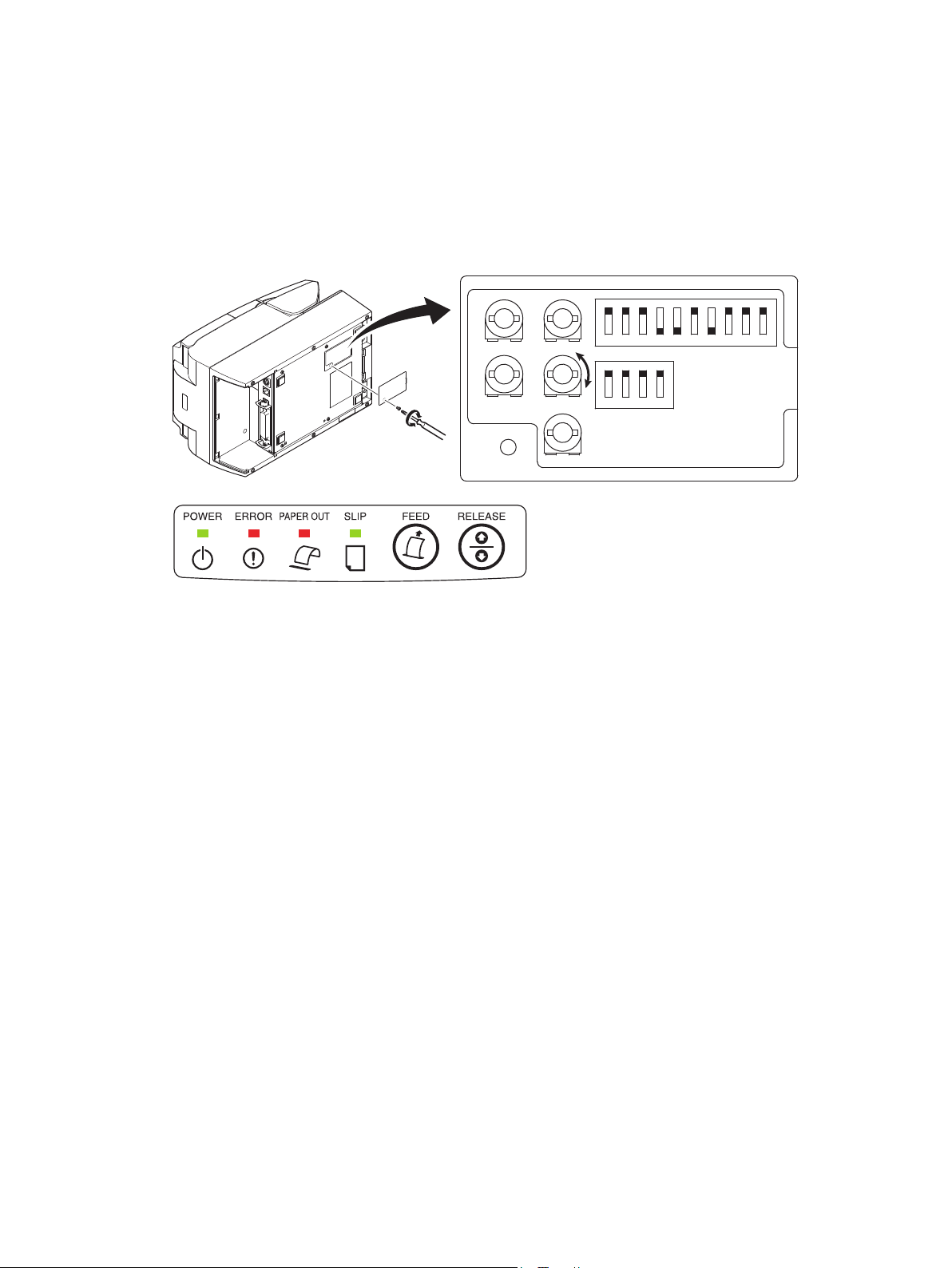

6-1. Control Panel

1 POWER Lamp (Green)

2 ERROR Lamp (Red)

3 PAPER OUT Lamp (Red)

4 SLIP Lamp (Green)

5 FEED Button 6 RELEASE Button

1 POWER Lamp (Green)

Lights when the printer is online.

Describes various errors in combination with other lamps.

2 ERROR Lamp (Red)

Lights when the cover is open.

Describes various errors in combination with other lamps.

3 PAPER OUT Lamp (Red)

Describes the condition of the roll paper.

Describes various errors in combination with other lamps.

4 SLIP Lamp (Green)

Describes the condition of the slip paper when SLIP is selected.

Describes various errors in combination with other lamps.

5 FEED Button

While the printer is online, feeds the roll paper.

6 RELEASE Button

Releases the slip paper.

– 28 –

Page 33

6-2. Errors

(1) Recoverable errors

Error Description POWER

Lamp

Thermal head high

temperature detection error

Impact head high

temperature detection error

Roll paper near-end

detection

Thermal (rear) cover

open error

Slip (front) cover

open error

Thermal paper out

or jam error

Slip paper jam/TOF/

BOF/COF error

Cutter error (cutting

error)

Link disconnection

detection*1

Flashes at

2 second

intervals.

Flashes at

2 second

intervals.

ON OFF Flashes at

ON ON — OFF Recovered by closing the

ON ON — ON Recovered by closing the

ON OFF Flashes at

ON OFF — Flashes at

OFF Flashes at

Flashes at

2 second

intervals.

ERROR

Lamp

OFF OFF OFF Automatically recovered

OFF OFF ON Automatically recovered

0.5 second

intervals

Flashes at

2 second

intervals.

PAPER

OUT

Lamp

4 second

intervals.

1 second

intervals

OFF OFF Recovered when the cutter

— — Connect an Ethernet cable.

SLIP

Lamp

OFF Indicates that the end of the

OFF Recovered by loading a

0.25 second intervals

Recovery Conditions

after the thermal head has

cooled.

after the impact head has

cooled.

roll paper is approaching.

Recovered by loading a

new paper roll and closing

the rear cover.

thermal (rear) cover.

slip (front) cover.

paper roll or clearing the

paper jam, reloading the

paper roll, and closing the

rear cover.

Recovered by loading

paper or clearing the

paper jam, reloading the

paper, and closing the rear

cover.

returns to its home position

after the power is turned

OFF and then ON. (See

notes 1 and 2)

For details, see section

3-2-5, "Ethernet Interface

Cable."

*1 Ethernet interface model only

Note:

1) If the cutter doesn’t return to the home position or doesn’t perform the initial movement, it cannot be recovered. See “8-3. Releasing a Locked Cutter” for details.

2) If the paper is jammed, turn the power off, clear the jammed paper, then turn the power

ON.

See “8-2. Removing Paper Jam” for details.

– 29 –

Page 34

2) Non-recoverable errors

Error Description POWER

Lamp

RAM error OFF Flashes at

EEPROM error OFF Flashes at

Flash memory error

Clamp error OFF Flashes at

Validation color OFF Flashes at

Thermal head error OFF Flashes at

Impact head error OFF Flashes at

Home position error

Power voltage error

OFF Flashes at

OFF Flashes at

OFF Flashes at

ERROR

Lamp

0.5 second

intervals

1 second

intervals

2 second

intervals

0.5 second

intervals

0.5 second

intervals

1 second

intervals

1 second

intervals

1 second

intervals

2 second

intervals

PAPER

OUT

Lamp

Flashes at

0.5 second

intervals

Flashes at

1 second

intervals

Flashes at

2 second

intervals

OFF ON This is not a recoverable

Flashes at

0.5 second

intervals

OFF OFF This is not a recoverable

OFF ON This is not a recoverable

Flashes at

1 second

intervals

Flashes at

2 second

intervals

SLIP

Lamp

Flashes at

0.5 second

intervals

Flashes at

1 second

intervals

Flashes at

2 second

intervals

ON This is not a recoverable

ON This is not a recoverable

OFF This is not a recoverable

Recovery Conditions

This is not a recoverable

error.

This is not a recoverable

error.

This is not a recoverable

error.

error.

error.

error.

error.

error.

error.

Note:

1) If a non recoverable error occurs, turn the power OFF immediately.

2) When Power supply error occurs, there is a possibility that the power supply unit has

a trouble.

For other non recoverable errors, please consult the dealer for repairs.

– 30 –

Page 35

6-3. Self-Printing

6-3-1. Test Printing

• Thermal paper roll

(1) Place a paper roll on the printer.

(2) With the rear cover closed, turn the power switch ON while keeping the FEED button

depressed.

(3) The printer will run a test print in the following order: version number, DIP switch

settings, memory switch settings, etc.

After the test print is completed, the printer will revert to the normal mode.

• Slip paper

(1) With the front cover closed, turn the power switch ON while keeping the RELEASE

button depressed.

(2) Insert a paper into the slip slot. The printer will automatically feed the paper; then, it

will run a test print.

The printer will run a test print in the following order: version number, DIP switch

settings, memory switch settings, etc.

After completing the test print, the printer will release the paper and revert to the

normal mode.

– 31 –

Page 36

6-3-2. Hexadecimal Dump Mode

(1) Place the thermal paper roll on the printer.

Open the rear cover, then turn the power on while holding the FEED button.

(2) When the rear cover is closed, “*** HEX DUMP PRINTING ***” is printed, and the

printer enters the Hexadecimal Dump Mode.

(3) Each of the signals sent from the computer to the printer will be printed out in hexadecimal

code.

This function allows you to check if a control code sent to the printer by the program being

used is correct or not.

(4) The nal line is not printed if its data is less than one full line. However, if the FEED but-

ton is pushed, the nal line is printed. To turn off the mode, it is necessary to turn off the

printer completely.

– 32 –

Page 37

6-3-3. Impact Head Printing Dot Alignment Adjustment Mode

(1) With the front cover open, turn the power ON while keeping the RELEASE button

pressed.

(2) Close the front cover and place the paper in the printer. Then, the printer will print “Dot

Alignment Adjust Mode” and enter the impact head dot alignment adjustment mode. The

printer will continue printing a total of 22 patterns of dot alignment adjustments as shown

below. The patterns are staggered in 1/8-dot increments.

The printed line above each pattern shows a number between 1 and 23 and its setting value

(Lv.xx). The pattern preceded by a “*” mark indicates the present setting value.

(3) As shown below, the adjustment patterns that are printed consist of a three-dot bar each

at the top and bottom for the forward pass, and a three-dot bar in the middle for the backward pass. Check the patterns visually and select a pattern with the three bars forming the

straightest line.

Forward pass

Backward pass

Forward pass

Improper

correction

Optimal

correction

Improper

correction

(4) To set up a pattern, press the RELEASE button as many times as the number (1 to 23) of

the desired pattern. In the process, a buzzer will make a short sound (0.1 second) with each

pressing of the RELEASE button.

– 33 –

Page 38

(5) Repeat step (4). At the pattern number that you wish to accept, keep the RELEASE but-

ton depressed (approx. 2 seconds) until the buzzer makes a long (0.5 second) sound. This

completes the acceptance of the setting.

Example: To accept the No. 4 setting, short-press the RELEASE button three times. At

the fourth time, keep the RELEASE button depressed.

Note: If you press the RELEASE button 24 or more times, it will exceed the available range

of settings. This will cause the warning buzzer (0.1 second) to sound four times, and

will delete the number of pressings of the button. Go back to step (4) to resume the

setup process.

(6) If you do not nd an optimal correction pattern among the printed patterns, perform the

“Backward” or “Forward” operation as indicated in No. 1. These operations will allow

you to make printing pattern adjustments with a greater range of dot corrections. After

performing steps (1) to (3), perform the respective operations as follows:

For a “Backward” operation, keep the RELEASE button depressed (approx. 2 seconds)

until the buzzer makes a long (0.5 second) sound.

→ The printer will release the paper with a printing pattern in which the backward pass

is corrected rightward of the current printing pattern.

For a “Forward” operation, keep the RELEASE button depressed until the buzzer makes

a long (0.5 second) sound. Then, continue pressing and holding (approx. 4 seconds) the

RELEASE button until the buzzer makes a short (0.1 second) sound and another long (0.5

second) sound.

→ The printer will release the paper with a printing pattern in which the backward pass

is corrected leftward of the current printing pattern.

(7) The printer will write the setting value, which you have accepted, on the nonvolatile memory.

For conrmation, the printer will print out ve patterns (which includes the setting value

that you have accepted, as well as the preceding and succeeding patterns) and an “Adjust

Completed” message.

This is followed by the release of the paper and the resetting of the printer.

Note: During the period between the time you accepted the setting value and the printer

starts to print as described above, the printer will write the setting value on the

memory. Never turn the power OFF or reset the printer during this period. Doing so

will corrupt the dot adjustment settings as well as other settings.

If you make a mistake in the settings, do not turn the power OFF in the middle of

the process. Instead, wait until the printer completes the nal reset and start the dot

adjustment mode from the beginning.

– 34 –

Page 39

6-4. Cleaning Mode

Perform the following procedure to enter the cleaning mode. See “9-3. MICR Head” in

“9. Maintenance” for details on cleaning the MICR head.

(1) With the rear cover closed, turn the power switch ON while keeping both the FEED button

and RELEASE button depressed.

(2) Insert the cleaning sheet. Cleaning starts.

(3) The printer is reset when the cleaning is complete.

6-5. Sensor Adjustment

This printer is equipped with the following ve

paper sensors:

• PE (Paper End) Sensor

Detects whether a roll paper is loaded on the

printer.

• NE (Near End) sensor

Detects whether the roll paper is nearing its

end.

• BOF (Bottom of Feed) Sensor

Detects whether a slip paper is placed on the

printer.

BOF Sensor

• COF (Center of Feed) Sensor

Detects the feed position for printing on a slip

of paper.

• TOF (Top of Feed) Sensor

Detects the top of feed of a slip paper.

The aforementioned sensors can be adjusted as follows.

PE Sensor

COF Sensor

NE Sensor

TOF

Sensor

6-5-1. PE Sensor Adjustment Mode

(1) Make sure the printer power is turned OFF.

(2) Open the rear cover and set a paper roll in place, thus setting the printer in the “paper

present” state.

ERROR

P

APER

OUT

SLI

P

FEED

RE

LEASE

(3) Undo the screws and remove the DIP switch cover from the bottom of the printer.

(4) Using the tip of a ballpoint pen or a similar object, set the DIP switches as follows: DIPSW1-4

OFF, DIPSW1-5 ON, DIPSW1-6 OFF, DIPSW1-7 and DIPSW1-8 ON. Turn the printer

power ON.

The lamps on the control panel will ash, and the printer will enter the sensor adjustment

mode.

– 35 –

Page 40

(5) Using a small slot screwdriver, turn VR1 as shown below, and adjust it so that all the lamps

are lit: POWER lamp (green: constant ON), ERROR lamp (red), PAPER OUT lamp (red),

and SLIP lamp (green).

VR1

VR2

VR3

VR4

VR5

1 2 3 4 5 6 7 8 9

1 2 3 4

10

(6) Turn the printer power OFF, and restore the DIP switches DIPSW1-4, DIPSW1-5, DIPSW1-6,

DIPSW1-7, and DIPSW1-8 to their original settings.

6-5-2. NE Sensor Adjustment Mode

(1) Make sure the printer power is turned OFF.

(2) Open the rear cover and remove the paper roll, thus setting the printer in the “paper absent”

state.

ERROR

PAPER OUT

SLIP

FEED

RELEASE

(3) Undo the screws and remove the DIP switch cover from the bottom of the printer.

(4) Using the tip of a ballpoint pen or a similar object, set the DIP switches as follows:

DIPSW1-4, DIPSW1-5 and DIPSW1-6 OFF, and DIPSW1-7 and DIPSW1-8 ON. Turn

the printer power ON.

The lamps on the control panel will ash, and the printer will enter the sensor adjustment

mode.

– 36 –

Page 41

(5) Using a small slot screwdriver, turn VR2 as shown below, and adjust it so that all the lamps

are lit: POWER lamp (green: constant ON), ERROR lamp (red), PAPER OUT lamp (red),

and SLIP lamp (green).

VR1

VR2

VR3

VR4

VR5

1 2 3 4 5 6 7 8 9

1 2 3 4

10

(6) Turn the printer power OFF, and restore the DIP switches DIPSW1-4, DIPSW1-5, DIPSW1-6,

DIPSW1-7, and DIPSW1-8 to their original settings.

6-5-3. BOF Sensor Adjustment Mode

(1) Make sure the printer power is turned OFF.

(2) Set the slip slot in the “paper absent” state.

(3) Undo the screws and remove the DIP switch cover from the bottom of the printer.

(4) Using the tip of a ballpoint pen or a similar object, set the DIP switches as follows: DIPSW1-4

OFF, DIPSW1-5 and DIPSW1-6 ON, DIPSW1-7 OFF, and DIPSW1-8 ON. Turn the printer

power ON.

The lamps on the control panel will ash, and the printer will enter the sensor adjustment

mode.

(5) Using a small slot screwdriver, turn VR3 as shown below, and adjust it so that all the lamps

are lit: POWER lamp (green: constant ON), ERROR lamp (red), PAPER OUT lamp (red),

and SLIP lamp (green).

VR1

VR2

– 37 –

VR3

VR4

VR5

1 2 3 4 5 6 7 8 9

1 2 3 4

10

Page 42

(6) Turn the printer power OFF, and restore the DIP switches DIPSW1-4, DIPSW1-5, DIPSW1-6,

DIPSW1-7, and DIPSW1-8 to their original settings.

6-5-4. COF Sensor Adjustment Mode

(1) Make sure the printer power is turned OFF.

(2) Insert a slip paper to set the printer in the “paper present” state.

To do so, open the front cover as shown below and insert the paper diagonally from the

left.

Set the paper straight while pressing on the platen. Then, close the front cover.

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

(3) Undo the screws and remove the DIP switch cover from the bottom of the printer.

– 38 –

Page 43

(4) Using the tip of a ballpoint pen or a similar object, set the DIP switches as follows: DIPSW1-4

and DIPSW1-5 OFF, DIPSW1-6 ON, DIPSW1-7 OFF, and DIPSW1-8 ON. Turn the printer

power ON. The lamps on the control panel will ash, and the printer will enter the sensor

adjustment mode.

(5) Using a small slot screwdriver, turn VR4 as shown below, and adjust it so that all the lamps

are lit: POWER lamp (green: constant ON), ERROR lamp (red), PAPER OUT lamp (red),

and SLIP lamp (green).

VR1

VR2

VR3

VR4

VR5

1 2 3 4 5 6 7 8 9

1 2 3 4

10

(6) Turn the printer power OFF, and restore the DIP switches DIPSW1-4, DIPSW1-5, DIPSW1-

6, DIPSW1-7, and DIPSW1-8 to their original settings.

6-5-5. TOF Sensor Adjustment Mode

(1) Make sure the printer power is turned OFF.

(2) Insert a slip paper to set the printer in the “paper present” state.

To do so, open the front cover and insert the paper diagonally from the left. Set the paper

straight while pressing on the platen. Then, close the front cover.

See the illustration under “6-5-4. COF Sensor Adjustment Mode” for instructions on how

to set the paper in place.

(3) Undo the screws and remove the DIP switch cover from the bottom of the printer.

(4) Using the tip of a ballpoint pen or a similar object, set the DIP switches as follows: DIPSW1-4

OFF, DIPSW1-5 ON, DIPSW1-6 and DIPSW1-7 OFF, and DIPSW1-8 ON. Turn the printer

power ON. The lamps on the control panel will ash, and the printer will enter the sensor

adjustment mode.

– 39 –

Page 44

(5) Using a small slot screwdriver, turn VR5 as shown below, and adjust it so that all the lamps

are lit: POWER lamp (green: constant ON), ERROR lamp (red), PAPER OUT lamp (red),

and SLIP lamp (green).

VR1

VR2

VR3

VR4

VR5

1 2 3 4 5 6 7 8 9

1 2 3 4

10

(6) Turn the printer power OFF, and restore the DIP switches DIPSW1-4, DIPSW1-5, DIPSW1-6,

DIPSW1-7, and DIPSW1-8 to their original settings.

– 40 –

Page 45

7. Adjusting the Near-end Sensor

Use the following procedure to adjust the near-end sensor so it is compatible with the size of

paper roll you are using.

(1) Open the rear cover.

(2) Determine the diameter of the paper roll you are using and nd the required setting in the

table on the next page.

(3) Insert the tip of a ballpoint pen or similar object into the hole of the adjuster, and then push

and slide the adjuster to the desired setting.

When changing the setting, make sure that the position of the hole is aligned with the align-

ment mark indicated by the arrow.

– 41 –

(Level 1) (Level 2)

Page 46

Adjustment value according to the paper you are using

Paper

Thickness

(μm)

65 Approx.

85 Approx.

B

A

Detected diameter (C)

C

ø12 (A) inner diameter / ø18 (B) outer di-

ameter core roll paper

Remaining paper

(mm)

Level 1 Level 2 Level 1 Level 2

Approx.

ø23

ø23

ø26

Approx.

ø26

length (m)

Approx.

2.5

Approx.

1.9

Approx.

4.3

Approx.

3.2

Notes:

1) The adjuster is factory-set at level 1.

2) The detected diameter and remained paper length

given in the table are calculated values, and there

are some variances depending on the rolled state of

the paper, the actual mechanism, or the printing pattern.

3) If thick paper is used (paper thickness 80 μm or

greater), the paper roll may loosen and cause variances in the detected values. Therefore, setting the

adjuster to Level 2 is recommended.

Paper roll core

C

– 42 –

Page 47

8. Preventing and Clearing Paper Jams

8-1. Preventing Paper Jams

8-1-1. Roll paper

While placing a roll paper on the printer, do not pull out the end of the paper diagonally.

Also, do not touch the roll paper while it is printing, releasing, or before completing cutting. If

you hold or pull the paper with your hands while the paper is being released, it could cause the

paper to jam, cut improperly, or place a line break improperly.

8-1-2. Slip paper

Do not use paper that is curled, kinked, wrinkled, warped, or torn.

While loading the paper, place it straight.

Also, do not touch the paper while it is printing or is being released.

If you hold or pull the paper with your hands while the paper is being released, it could cause

the paper to jam, cut improperly, or place a line break improperly.

8-2. Removing Paper Jam

If a paper jam occurs, clear it as described below.

8-2-1. Roll paper

(1) Set the power switch to off to turn off power to the printer.

(2) Push the lever toward you to open the printer cover.

(3) Remove the jammed paper.

Note: To prevent parts such as the thermal head or the rubber roller from damage or

deformation, do not forcibly pull on the paper with the printer cover closed.

(4) Position the paper roll straight and close the printer cover gently.

Note:

1) Make sure that the paper is positioned straight. If the printer cover is closed with the

paper skewed, a paper jam may result.

2) Lock the printer cover by pressing down on the sides. Do not try to close it by pressing

down on the centre. The cover may not lock properly.

(5) Set the power switch to on to turn on power to the printer. Make sure that the ERROR lamp

is not lit.

Note: While the ERROR lamp is lit, the printer will not accept any commands such as the

print command, so make sure that the printer cover is locked properly.

– 43 –

Page 48

8-2-2. Slip paper

Press the RELEASE button on the control panel in order to auto-release the paper.

If the paper cannot be removed by performing an auto-release, open the front cover, push the

point A or B on the platen, and remove the paper.

A

B

Thermal head

POWER

ERROR

PAPER OUT

SLIP

FEED

RELEASE

Caution Symbol

This symbol is placed near the slip print head to indicate that it may be hot.

Never touch the slip print head immediately after the printer has been used. Let the

print head cool for a few minutes before touching it.

This symbol is placed near the thermal print head to indicate that it may be hot.

Never touch the thermal print head immediately after the printer has been used. Let

the print head cool for a few minutes before touching it. Observe the precautions

for handling electrostatic sensitive devices.

This symbol is placed near the cutter.

Never touch the cutter blade, as you could injure your ngers.

This symbol is placed near the peripheral drive connector.

Do not connect this to a telephone.

– 44 –

Page 49

8-3. Releasing a Locked Cutter

If the auto cutter locks up, set the power switch to OFF to turn off the printer, and then set the

power switch to ON to turn the printer back on. A typical locked cutter will be restored when

you restart the printer.

If restarting the printer does not release the locked cutter, follow the steps below.

WARNING

Since working on the cutter may be dangerous, be sure to turn off the printer rst.

(1) Turn the printer off and unplug the power cord

from the AC outlet.

(2) Open the front cover, and then the cutter cover.

(3) Remove any jammed paper.

Note: Be careful not to damage the printer while

removing any jammed paper.

Since the thermal print head is particularly

sensitive, be sure not to touch it.

(4) Insert a Philips screwdriver into the manual op-

eration hole on the side of the cutter, and turn it

in the direction of the arrow shown on the right

until the rear cover is opened.

(5) Open the rear cover, clear the paper jam, reload

the paper, and close the rear cover.

(6) Install the cutter cover and the front cover, and

turn the power switch ON.

Cutter cover

Front cover

Auto cutter

– 45 –

Page 50

9. Maintenance

Printed characters may become partially unclear due to accumulated paper dust and dirt.

To prevent such a problem, perform periodic maintenance, such as removing the paper dust in

the paper transport section and on the surface of the thermal head.

CAUTION

Turn the printer’s power switch OFF before performing maintenance.

9-1. Thermal Printer

Cleaning is recommended to be carried out once every six months or one million lines for general thermal paper and once every month or 200,000 lines for label paper.

9-1-1. Cleaning the Thermal Head

To remove the dark paper dust that has accumulated on the thermal head surface, wipe it clean

with cotton swab (or soft cloth) dipped in alcohol (ethanol or methanol, or alcohol).

Note :

1) The thermal head is easily damaged, so clean it with a soft cloth, taking care not to

scratch it.

2) Do not attempt to clean the thermal head immediately after printing, when the thermal

head is hot.

3) Beware of the risk of damaging the thermal head as a result of static electricity that

may be created during cleaning.

4) Turn the power ON only after the alcohol has dried completely.

9-1-2. Cleaning the Platen Rubber Roller

Use a dry, soft cloth to wipe off the dust that may have accumulated on the rubber roller.

Rotate the platen to clean the entire surface.

Thermal head

FEED

RELEASE

POWER

ERROR

PAPER OUT

SLIP

Rubber roller

– 46 –

POWER

ERROR

PAPE

R

OUT

SLIP

FEED

RE

LEASE

Page 51

9-2. Slip Printer

Cleaning is recommended to be carried out once every six months or one million lines.

9-2-1. Cleaning the Impact Platen

Use a dry, soft cloth to gently wipe off the paper particles that may have accumulated on the

surface.

9-2-2. Cleaning the Rubber Roller

Use a dry, soft cloth to wipe off the dust that may have accumulated on the rubber roller.

Rotate the rubber roller to clean the entire surface.

Rubber roller

9-3. MICR Head

Cleaning is recommended to be carried out using the following procedure once every year or

70,000 passes.

* The HSP7543 (no MICR scanning head) does not have a scanning head; therefore, this

cleaning is unnecessary.

(1) With the rear cover closed, turn the power switch ON while keeping both the FEED button

and RELEASE button depressed.

(2) Insert the cleaning sheet. Cleaning starts.

RELEASE

FEED

SLIP

PAPER OUT

ERROR

POWER

– 47 –

Page 52

Use the following specied cleaning sheet.

Star Recommended Cleaning Sheet: PRESAT brand “CHECK READER CLEANING

CARD”

(3) The printer is reset when the cleaning is complete.

9-4. Cleaning the Sensors and the Surrounding Area

Clean the sensors (particularly the reection sensors) of debris, dust, paper particles, etc.

Cleaning is recommended to be carried out once every six months or one million lines.

Sensors

POWER

ERROR

PAPE

R OUT

SLIP

FEED

RE

LEASE

If the dust that accumulates in these

areas enters inside the printer, it can

cause a sensor failure.

COF Sensor

TOF Sensor

PE Sensor

9-5. Cleaning the Paper Holder and the Surrounding Area

Clean the paper holder of debris, dust, paper particles, glue, etc. that may have accumulated.

Cleaning is recommended to be carried out once every six months or one million lines.

– 48 –

Page 53

10. Specications

10-1. General Specications

10-1-1. Thermal Printer

(1) Printing method Direct line thermal printing (thermal type)

(2) Print speed Max. 2000 dots/sec. (250 mm/sec.) (normal type paper)

(3) Dot density 203 dpi: 8 dots/mm (0.125 mm/dot)

(4) Printing width Max. 72 mm

(5) Number of print columns Max. 48 columns (12 × 24 font)

Max. 64 columns (9 × 24 font)

Max. 36 columns (16 × 24 OCRB font)

Max. 24 columns (24 × 24 kanji font)

(6) Paper feed method Friction feed

Feed pitch 0.125 mm

(7) Paper roll See “5-1. Thermal Paper Roll” in “5. Consumable Parts

and AC Adapter” for details.

Paper width:

General thermal paper: 79.5 ± 0.5, 75.5 ± 0.5,

57.5 ± 0.5 mm

Label paper: 76.5 ± 0.5 mm

Roll diameter: ø83 mm or less

(8) Noise Approx. 56 dB

10-1-2. Slip Printer

(1) Print method: Serial dot impact

(2) Print head: 9-pin

(3) Print direction: both

(4) Print speed: 4.8 columns/sec. (7 × 9 font, continuous ANK 40 columns

printing)

(5) Font type: ○ STAR line mode

(1-byte)

Alphanumeric (ANK) 95 characters

Expanded graphics 128 characters × 40 page

International characters 46 characters

(2-byte)

Kanji (JIS level 1) 3,489 characters

Kanji (JIS level 2) 3,390 characters

Special symbols 83 characters

1-byte kanji 282 characters

– 49 –

Page 54

○ ESC/POS mode

(1-byte)

Alphanumeric (ANK) 95 characters

Expanded graphics 128 characters × 9 pages

International characters 37 characters

(2-byte)

Kanji (JIS level 1) 3,489 characters

Kanji (JIS level 2) 3,390 characters

Special symbols 83 characters

(6) Font conguration: 7 (half dot) × 9 or 5 × 9

(7) Print width: 85.4 mm

(8) Print columns: 60 columns (7 × 9 font)

45 columns (5 × 9 font)

(9) Paper feed method: Friction feed

Feed pitch min. 0.176 mm (1/144 inch)

(10) Paper feed speed: max. 141 mm/sec.

(11) Ink ribbon: Type Cartridge cassette

Color Black

Material Nylon #40 denier

(12) Paper specications: See “5-2. Slip Paper” in “5. Consumable Parts and AC

Adapter” for details.

10-2. Auto Cutter Specications

(1) Cutting Modes Partial cut (leaves one uncut portion in center of paper)

(2) Cutting Duty Min. 3 seconds/cut

(3) Thickness of paper 0.065 ~ 0.085 mm

10-3. MICR Specications

(1) Read width: 8.1 mm

(2) Read characters: ISO 1004: E-13B/CMC-7

(3) Read rate: 98% or more

(4) MICR character non-scannable area:

100

SAMPLE

40mm

Blank area

* The HSP7543 (no MICR scanning head) does not have a MICR character scanning func-

tion; therefore, the above specications do not apply.

– 50 –

Page 55

10-4. External Specications

(1) External dimensions: 186 mm (width) × 296 mm (depth) × 177 mm (height)

(2) Weight: 4.6 kg (without roll paper)

18 6

29 6

17 7

(unit: mm)

– 51 –

Page 56

10-5. Interface Specications

Selectable interface card type

• Parallel: Amphenol 36 pin

Conforming to IEEE 1284 (compatibility mode, nibble

mode)

• Serial RS-232C: D-SUB25 pin

• USB: Type B

• Ethernet: RJ-45

• PoweredUSB: FCI 69913-104LF (1x8 right-angle type)

Type B connector:

DUSB-BRA42-T11 (D2)-FA (manufacturer: DDK)

Pin number Signal name Function

1 VBUS USB power pin (+5V DC)

2 D- Serial data 3 D+ Serial data +

4 GND Signal ground

2 1

3 4

PoweredUSB connector:

69913-104LF (manufacturer: FCI)

Pin number Signal name Function

1 F-GND Frame ground

2 +24V +24V DC

3 GND Signal ground

4 D+ Serial data +

5 D- Serial data 6 VBUS USB power pin (+5V DC)

7 +24V +24V DC

8 F-GND Frame ground

8

1

– 52 –

Page 57

10-6. Power Specs

10-6-1. Standard Mode (option: PS60A-24B)