Page 1

Page 2

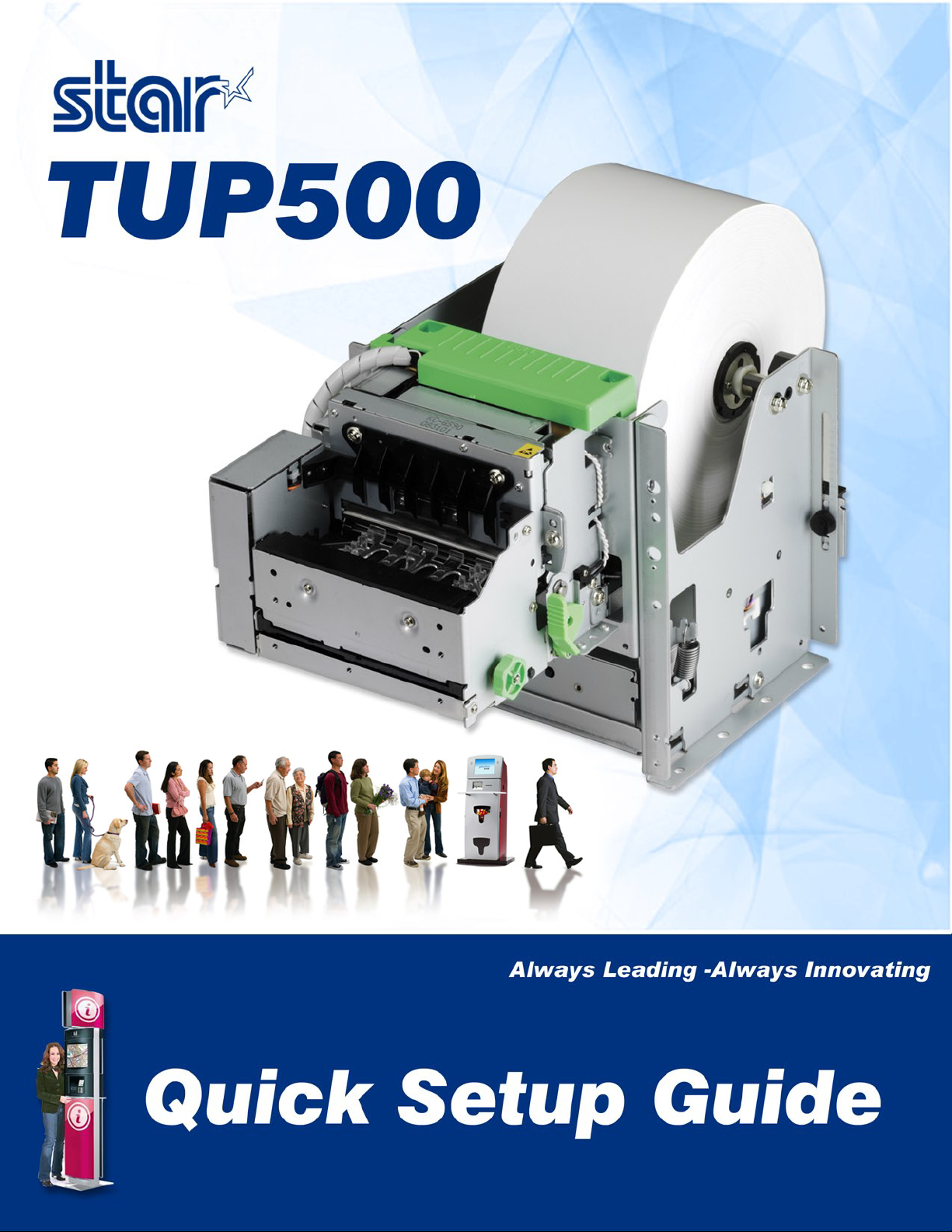

TUP500

Quick Setup Guide

Contents

a. Printer

b. Paper Shaft

c. 1” Paper Core Adapter

d. 2” Paper Core Adapter

e. Shaft Weight*

f. Interface Mounting Screws(2)*

g. Paper Core Adapter Screws(4)

*Not Pictured

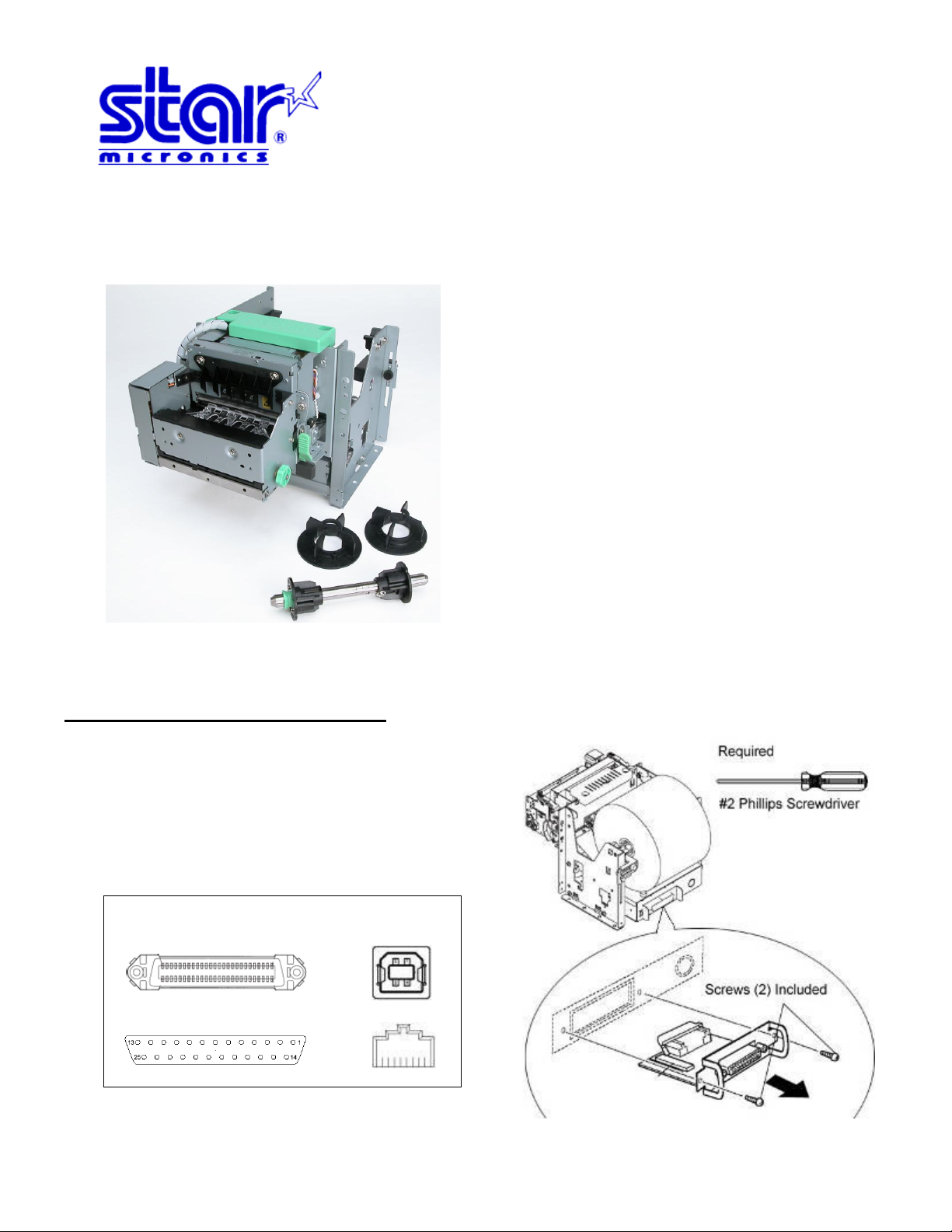

Place the interface sub-assembly into the interface

slot as shown. Take care to be sure the interface

cartridge is seated properly into its connector.

Using a #2 Phillips screwdriver, install the mounting

screws located in back of the printer.

Interface Type…

Parallel

USB

Ethernet

Serial

Thank you for choosing Star Micronics as your provider for printing solutions.

Unpacking the Unit

Assembly – Installing the Interface

Page 3

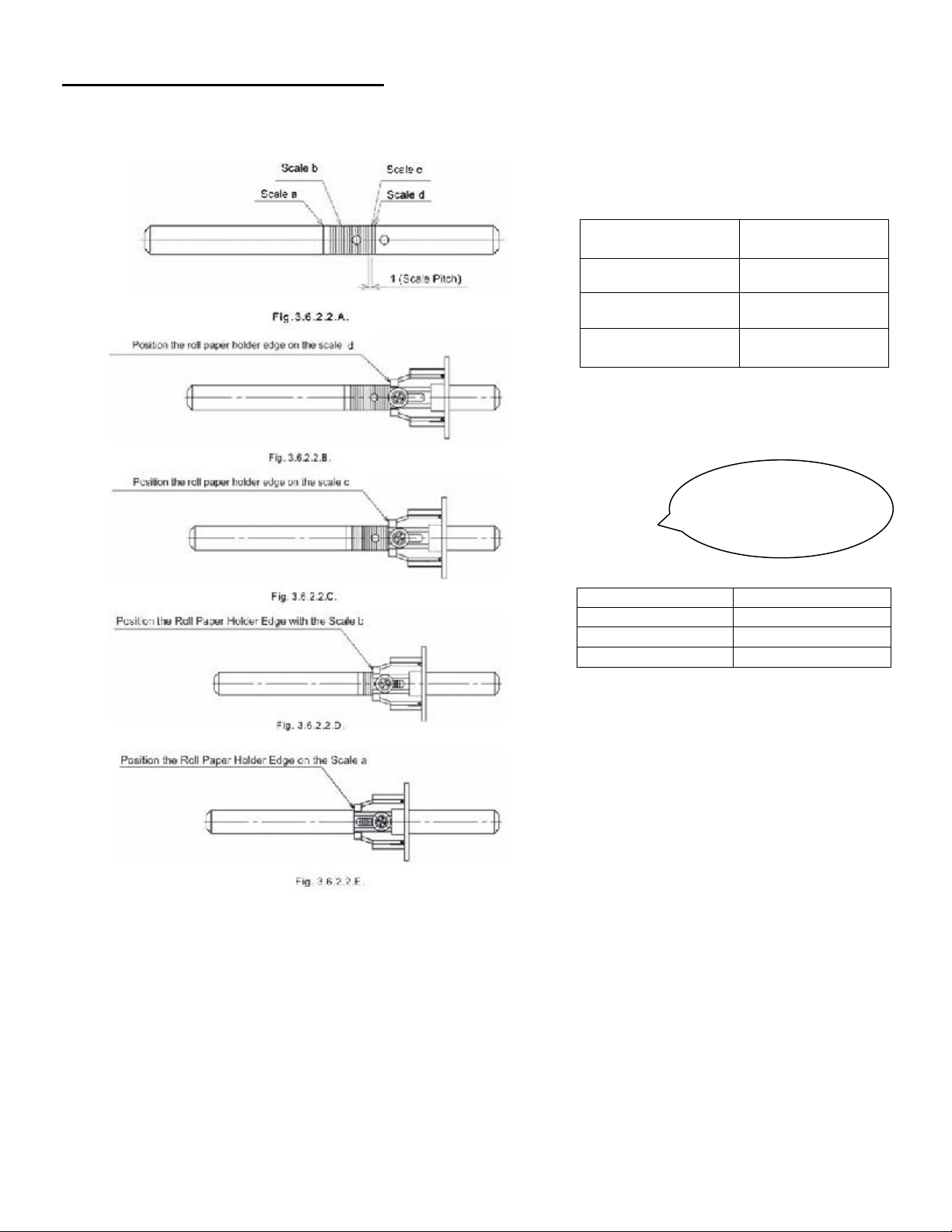

Assembly – Paper Roll Setup

The following table shows the paper roll holder

and paper core inner diameter range.

Paper roll Holder

Types

Paper Core

Diameter Ranges

Paper roll Holder (1)

25.4 mm ± 1

Paper roll Holder (2)

50.8 mm ± 1

Paper roll Holder (3)

Optional

76.2 mm ± 1

Note 1) The unit is assembled for 1 inch paper cores

when shipped from the factory. Also, it is set for a

paper width of 82.5 ±0.5 (take-up width of 83 +0.5/-1)

when the printer is shipped from the factory.

Note

Roll Holder Size

Paper Thickness

1” or 25.4 mm

65 to 100 µm

2” or 50.8 mm

100 to 150 µm

3” or 76.2 mm

100 to 150 µm

“The size of the core

used is related to the

thickness of the paper

used.”

It is necessary to adjust the paper roll holder for the width of the paper you use. If the setting position is incorrect, the paper roll will

be supplied improperly to the mechanism which in turn causes paper transport problems. Thus, it is should be properly adjuste d.

Page 4

3.0.2.2. A is a reference for the paper roll holder unit paper roll shaft position. Adjust or mount the paper roll holder unit for the

core diameter and width of the paper you intend to use.

3-1 Handling 82.5 mm Paper Width

See Fig. 3.4.2.2.B for the paper roll holder setting position to handle paper widths of 82.5 ±0.5 mm.

Position the roll paper holder edge at position scale c.

See the figure to assembly at the correct position.

Note 1) The paper roll holder is assembled to that position when shipped from the factory.

3-2 Handling 79.5 mm Paper Width

See Fig. 3.4.2.2.C for the paper roll holder setting position to handle paper widths of 79 ±0.5 mm.

Position the edge of the paper roll holder at position scale c

3-3 Handling 57.5 mm Paper Width

See Fig. 3.6.2.2.D for the paper roll holder setting position to handle paper widths of 57.5 ±0.5 mm.

Position the edge of the paper roll holder at position scale b

3-4 Handling 45 mm Paper Width

See Fig. 3.6.2.2.E for the paper roll holder setting position to handle paper widths of 45 ±0.5 mm.

Position the edge of the paper roll holder at position scale d

Page 5

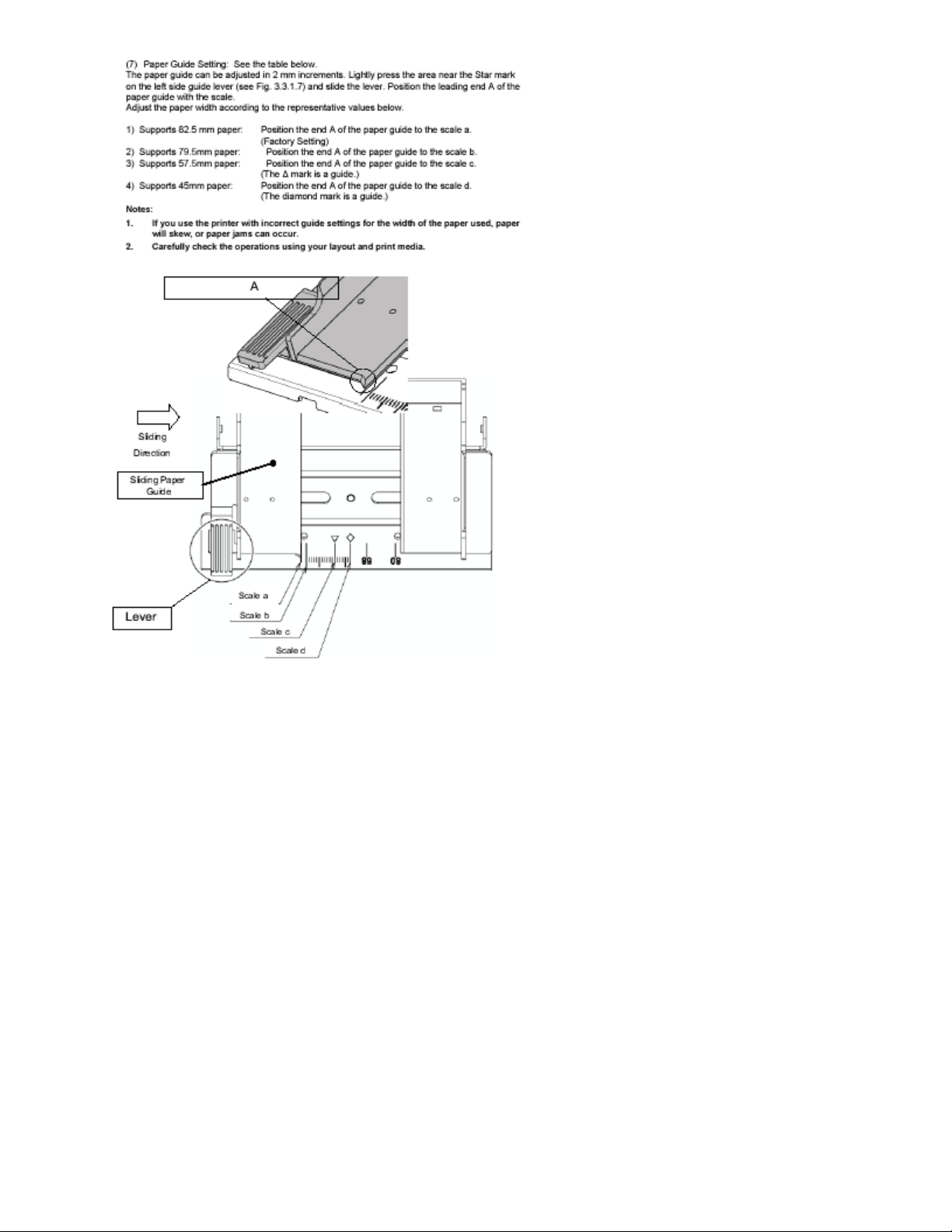

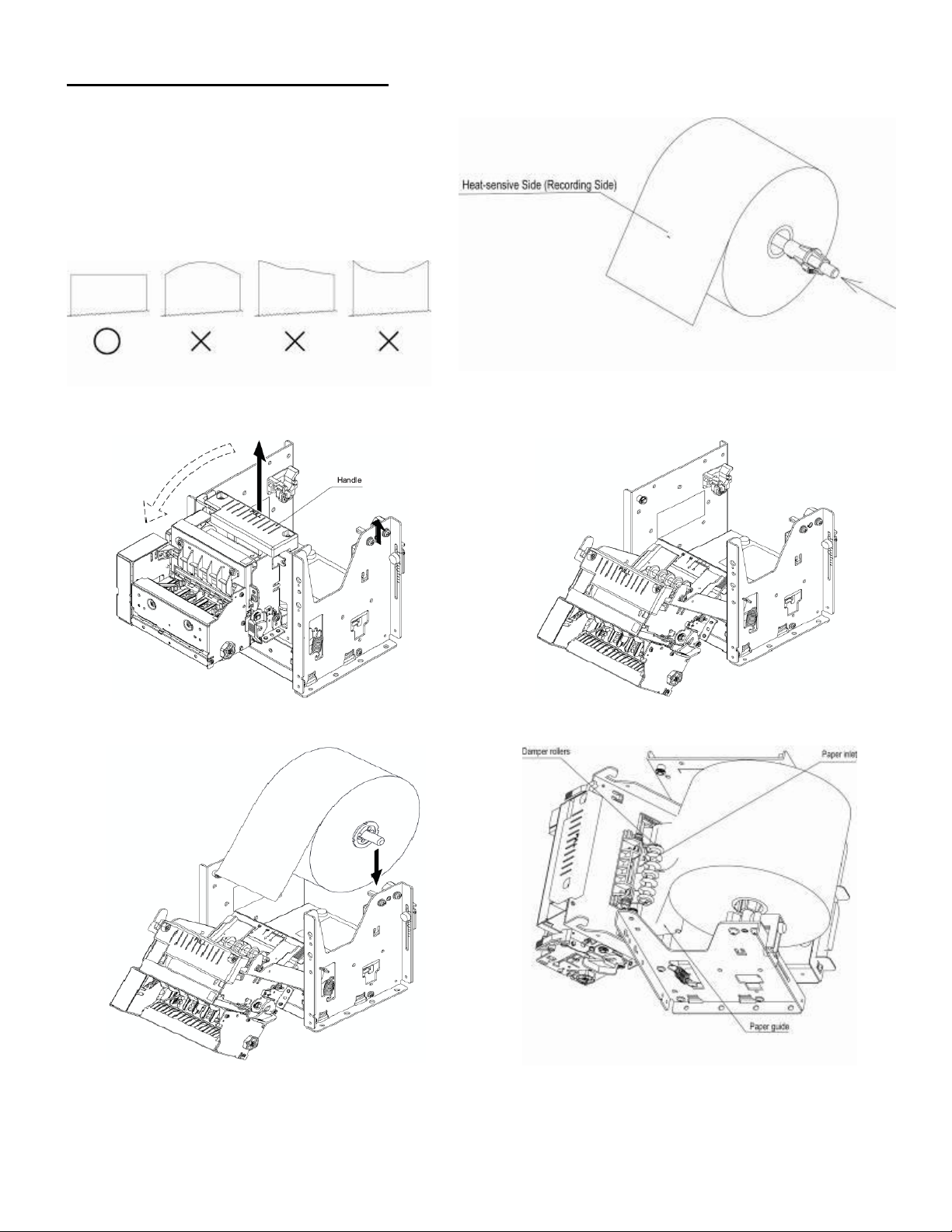

Assembly – Paper Roll Setup Continued

Once the paper roll holder is properly configured

for the roll to be used, simply insert the roll holder

into the paper core as show.

Be sure that the cut end of the paper roll is

properly cut to ensure proper paper loading.

To aid in the installation of the paper roll, the TUP500’s mechanism is hinged to the base of the printer

allowing the unit to fold open for easier access to the paper inlet path (see below)

Lift handle and pull unit forward.

In this position, it will be much easier to access the

paper inlet for loading of paper.

Position the paper roll as shown.

Slide the cut end of the paper roll into the paper inlet

being careful to feed the paper underneath the

damper rollers.

Page 6

Assembly – Connecting the Power Supply

The TUP500 requires a 24 VDC power source for proper operation. Star recommends use of the PS60A-24B

(pt. no. 30781750) universal power supply.

The PS60A-24B power supply is supplied with a US standard grounded power cord.

The printer end of the power supply cable is the mating Hoshiden connector for the TUP500. Simply connect

the Hoshiden power connection to the TUP500 by sliding back its collar and inserting the power supply’s male

connector into the matching female connector on the back of the TUP500. Finally, connect the 3-pronged

power cord to a 110-volt grounded power source.

Note: Be sure the power switch of the TUP500 is switched to the OFF position when connecting the power

supply.

Driver Installation

Driver packages are available for the following platforms:

Windows XP, 2000, VISTA, WEPOS, CE, and XP Embedded

Mac OS X

Linux

JavaPOS

1

OPOS

1. Star’s JavaPOS driver is platform independent and is compatible with any operating system that supports the Java Virtual Machine.

Driver Software

A Product CD is not supplied with the printer in the box. Request a CD from your reseller or download and

install the latest version of the Star printer drivers at: www.starmicronics.com.

Windows Driver Installation

Windows Software Package Ver1.0: Star_TUP500_Software_Ver100_20090130.ZIP

Includes: installer, Printer Driver, Configuration Utility, OPOS, JavaPOS (for Windows)

OS: Win2K SP3, XP, Vista 32/64 (does not support configuration tool under 64bit)

Once you download the TUP500 Software package from our website at www.starmicronics.com, run the Star TUP500

installer.exe and follow the menu to proceed with the installation.

Page 7

Mac Driver Installation

CUPS driver for Mac package: starcupsdrv-3.0.0_mac_20090130.zip

Includes MAC OSX driver and manual.

OS supported: Mac OS X 10.4.11 PowerPC, Intel Mac OS X 10.5.5 Intel

Once you download the MAC OSX CUPS driver package from our website www.starmicronics.com, run the

starcupsdrv-3.0.0.pkg and follow the menu to proceed with the installation.

Linux Driver Installation

CUPS driver for Linux package: starcupsdrv-3.0.0_linux_20090130.zip

Includes Linux driver and manual.

OS supported: Red Hat Enterprise Linux 5, CentOS 5.2, OpenSUSE 11, Fedora 9, Ubuntu 8.04

Once you download the Linux CUPS driver package from our website www.starmicronics.com, run CUPS 3.0.0

and follow the menu to proceed with the installation.

JavaPOS Installation

JavaPOS for Linux package: starjavapos_linux_Ver1.9.13.ZIP

OS supported: Ubuntu 8.04, OpenSUSE 10.3, Fedora 9

JavaPOS for Mac package: starjavapos_intel_mac_Ver1.9.13.ZIP

OS supported: Mac OS X 10.5 (intel)

Once you download the TUP500 JavaPOS driver package from our website www.starmicronics.com, run the

Star JavaPOS installer and follow the menu to proceed with the installation.

Status Monitor Tool

Status Monitor Ver1.0 package: Star_TUP500_StatusMonitor_Ver100_20090130.ZIP

Includes TUP500 Status tool, (via Printer LM, StariO) including SDK.

StariO: Ver1.2.0.0

OS: Win2K SP3, XP, Vista 32bit

Page 8

Installing the TUP500 Printer Driver

For USB installations:

Once the TUP500 Installer.exe is installed and you plug the printer in, the driver will Plug and Play and automatically

install the driver and show up in Printers & Faxes.

For Parallel installations:

Click on Start Menu/All Programs/Star Micronics/TUP500/Utility/Add Printer Wizard (TUP500)

Continue following the Wizard to install the driver.

Printer configuration:

Open the driver properties and notice a TUP500 Config tab.

Page 9

Just click on the TUP500 Config tab and click on Launch Configuration Utility.

The utility will allow you to:

1) Configure specific printer settings like print speed, print density, paper width, snout control (bezel) and

fonts, etc..

2) Load graphics into the internal printer memory

3) Perform print tests

4) Setup your Ethernet interface

5) Configure OPOS and JavaPOS driver for Windows

Page 10

Configuring Ethernet

In the configuration utility on the left side, click on Ethernet I/F Setup.

Then click on Search LAN for Printers and your printer should show up and display a temporary IP address.

To configure the printer with a Static IP address, click on Change TCP/IP Setting and follow the instructions on the screen

to make the IP Static.

Page 11

Configuring OPOS

For USB installations – put Dip Switch #5 OFF to put the printer in vendor class mode.

Launch the configuration application through the driver properties and click on OPOS on the left side

Click on Add New on the right side. Select your Port and click OK.

To test communication, click on Check Health.

Page 12

Configuring JavaPOS

In the configuration utility on the left side, click on JavaPOS and click on Add New on the right side.

Select your printer port and click OK. Click on Check Health and it will prompt you to save your .xml file. This is

a one time message, select any location. A small test will print out confirming communication.

Page 13

Checking Status

If you implement the language monitor method to determine status, you will need to enable the status

monitor.

Put a check mark next to Background status: Enable and click OK

Page 14

Other Utilities available

Status monitor tool

Page 15

Testing – Printing a Printer Self-Test Page

To print a printer self-test, simply follow the steps

listed below.

1. Turn the printer’s power switch to the OFF

position

2. Press and hold the paper feed switch (SW1)

3. Turn the printer’s power switch to the ON

position

4. Release the paper feed switch (SW1)

NOTE: In order to print a self-test page, the printer

must be properly loaded with paper and must have its

power supply connected to a live power source.

The TUP500, like all Star printers, has a built-in diagnosis printout that can be manually printed to check the

printer’s current configuration. This “Self-Test” page also allows the user to confirm that the printer is in fact

operating properly.

Additional Documentation

This “Quick Setup Guide” is a condensed summary of the information available from all of the manuals

available on our website www.starmicronics.com excluding Technical Manual. Listed below are the manuals

available for the TUP500

TUP500 Specification Manual (TUP500sm.pdf) – This manual provides detailed specification for the

configuration and use of the TUP500. Also included are dimensional drawings, electrical specifications, usage

examples and ideal operating environment specifications.

TUP500 Installation Manual (TUP500im.pdf) – This manual provides details instructions for installing the shaft

weight. The proper installation of this weight ensures proper paper feed and looping functionality of the

TUP500’s document presenter.

TUP500 Technical Manual (TUP500tm.pdf) – This manual is designed as a technical reference for periodic

inspection and maintenance of the TUP500 series printers. Users of this manual should possess a technical

aptitude that is typical of service personnel. This manual is not intended for the general user.

Line Mode Programmer’s Manual (lindemodepm.pdf) – This reference manual provides the command

specification for Star Line Mode for all thermal line printers from Star. It provides detailed commands and

examples for controlling Star printers directly by command, without drivers.

Page 16

Loading...

Loading...