Page 1

THERMAL PRINTER

TSP800II

SERIES

Hardware Manual

Page 2

Federal Communications Commission

Radio Frequency Interference

Statement

is device complies with Part 15 of FCC Rules and Industry Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions:

(1) is device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes :

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible

d'en compromettre le fonctionnement.

FCC CAUTION

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

For compliance with the Federal Noise Interference Standard, this equipment requires a shielded cable.

For RF interference suppression, if a ferrite core is provided with this device, ax it to the interface cable.

NOTE:

is equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. ese limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

CAN ICES-3 (A) / NMB-3 (A)

This equipment complies with FCC/IC radiation exposure limits set forth for an uncontrolled environment and

meets the FCC radio frequency (RF) Exposure Guidelines in Supplement C to OET65 and RSS-102 of the IC radio

frequency (RF) Exposure rules. is equipment has very low levels of RF energy that it deemed to comply without

maximum permissive exposure evaluation(MPE). But it is desirable that it should be installed and operated keeping

the radiator at least 20cm or more away from person's body (excluding extremities: hands,wrists,feet and ankles).

Cet équipement est conforme aux limites d"exposition aux rayonnements énoncées pour un environnement non

contrôlé et respecte les règles les radioélectriques (RF) de la FCC lignes directrices d'exposition dans le Supplément

C à OET65 et d"exposition aux fréquences radioélectriques (RF) CNR-102 de l"IC. Cet équipement émet une

énergie RF très faible qui est considérée conforme sans évaluation de l"exposition maximale autorisée. Cependant,

cet équipement doit être installé et utilisé en gardant une distance de 20 cm ou plus entre le dispositif rayonnant et

le corps (à l"exception des extrémités : mains, poignets, pieds et chevilles).

Page 3

Caution Symbol

These symbols are located near the thermal print head.

Because the thermal print head is hot immediately after printing, do not touch

it. Static electricity can damage the thermal print head. To protect the thermal

print head from static electricity, do not touch it.

This symbol is located near the cutter.

Never touch the cutter blade, as you could injure your ngers.

This symbol is located near the peripheral drive connector.

Do not connect this to a telephone.

Trademark acknowledgments

TSP800II: Star Micronics Co., Ltd.

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without STAR’s express

permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time of going to press.

However, should any errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

• IOS is a trademark or registered trademark of Cisco in the U.S. and other countries and is used under license.

• Android is a trademark of Google Inc.

• Windows is registered trademarks of Microsoft Corporation.

®

• The Bluetooth

word mark and logos are registered trademarks owned by the Bluetooth SIG, Inc.

©

Copyright 2009-2017 Star Micronics Co., Ltd.

Page 4

TABLE OF CONTENTS

1. Unpacking and Installation .....................................................................................................................1

1-1. Unpacking ....................................................................................................................................1

1-2. Notes about Installation ...............................................................................................................2

2. Parts Identification and Nomenclature ..................................................................................................3

3. Setup ..........................................................................................................................................................4

3-1. Connecting the Cable to the PC ...................................................................................................4

3-2. Connecting the Cable to the Printer .............................................................................................5

3-3. Connecting the Optional AC Adapter ..........................................................................................8

3-4. Turning Power On ........................................................................................................................9

3-5. Connecting to a Peripheral Unit .................................................................................................10

3-6. Loading the Paper Roll ..............................................................................................................11

3-7. Bluetooth Settings

3-8. Setup Precautions .......................................................................................................................19

4. Consumable Parts ..................................................................................................................................21

4-1. Thermal Paper Roll ....................................................................................................................21

4-2. Thermal Label Paper Roll (Tack Label Paper) ..........................................................................23

5. Control Panel and Other Functions .....................................................................................................26

5-1. Control Panel..............................................................................................................................26

5-2. Errors ..........................................................................................................................................26

6. Adjusting the Sensor ..............................................................................................................................28

6-1. Adjusting the Near End Sensor Position ....................................................................................28

6-2. PE and BM ( Paper End and Black Mark ) Sensor Adjustment .................................................30

6-3. NE (Near End) Sensor Adjustment ............................................................................................31

7. Preventing and Clearing Paper Jams ...................................................................................................32

7-1. Preventing Paper Jams ...............................................................................................................32

7-2. Removing Paper Jam .................................................................................................................32

8. Periodical Cleaning ................................................................................................................................33

8-1. Cleaning the Thermal Head .......................................................................................................33

8-2. Cleaning the Rubber Roller .......................................................................................................33

8-3. Cleaning the Sensors and the Surrounding Areas ......................................................................33

8-4. Cleaning the Paper Holder and the Surrounding Area ...............................................................33

(For

Bluetooth Interface Models only

) ........................................................14

Please access the following URL

http://www.star-m.jp/eng/dl/dl02.htm

for the latest revision of the manual.

Page 5

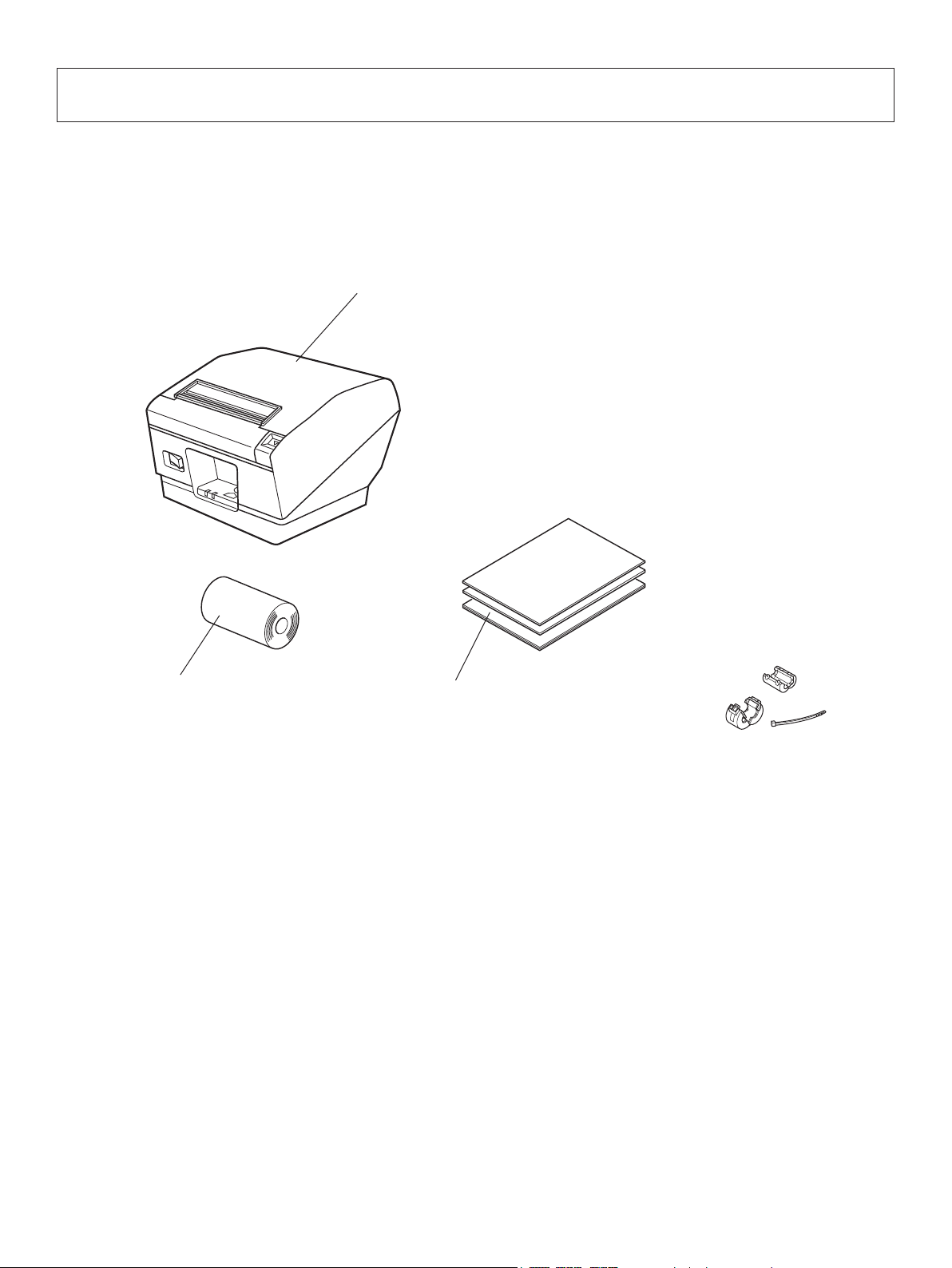

1. Unpacking and Installation

1-1. Unpacking

After unpacking the unit, check that all the necessary accessories are included in the package.

Printer

Paper roll

Setup sheets

Note

Note: The ferrite core and fastener provided with your

printer depend on your printer conguration.

Fig. 1-1 Unpacking

If anything is missing, contact the dealer where you bought the printer and ask them to supply

the missing part. Note that it is a good idea to keep the original box and all the packing materials

just in case you need to pack the printer up again and send it somewhere at a later date.

– 1 –

Page 6

1-2. Notes about Installation

1. Choose a rm, level surface where the printer will not be exposed to vibration.

2. Make sure that the printer is connected to a reliable power outlet. It should not be on the

same electric circuit as copiers, refrigerators, or other appliances that cause power spikes.

3. The power outlet you plan to connect to for power should be nearby and unobstructed.

4. Make sure that the printer is not exposed to direct sunlight.

5. Make sure that the printer is well away from heaters and other sources of extreme heat.

6. Do not locate the printer in a badly ventilated or dusty environment.

7. Make sure that the room where you are using the printer is not too humid.

8. Use the printer within the boundaries indicated in the environmental requirements. Even

when the ambient temperature and humidity are within the specications, avoid radical

changes in environmental conditions. The suitable operating temperature range is as follows:

Operating temperature: 5°C to 45°C

9. When disposing of the printer, obey local regulations.

– 2 –

Page 7

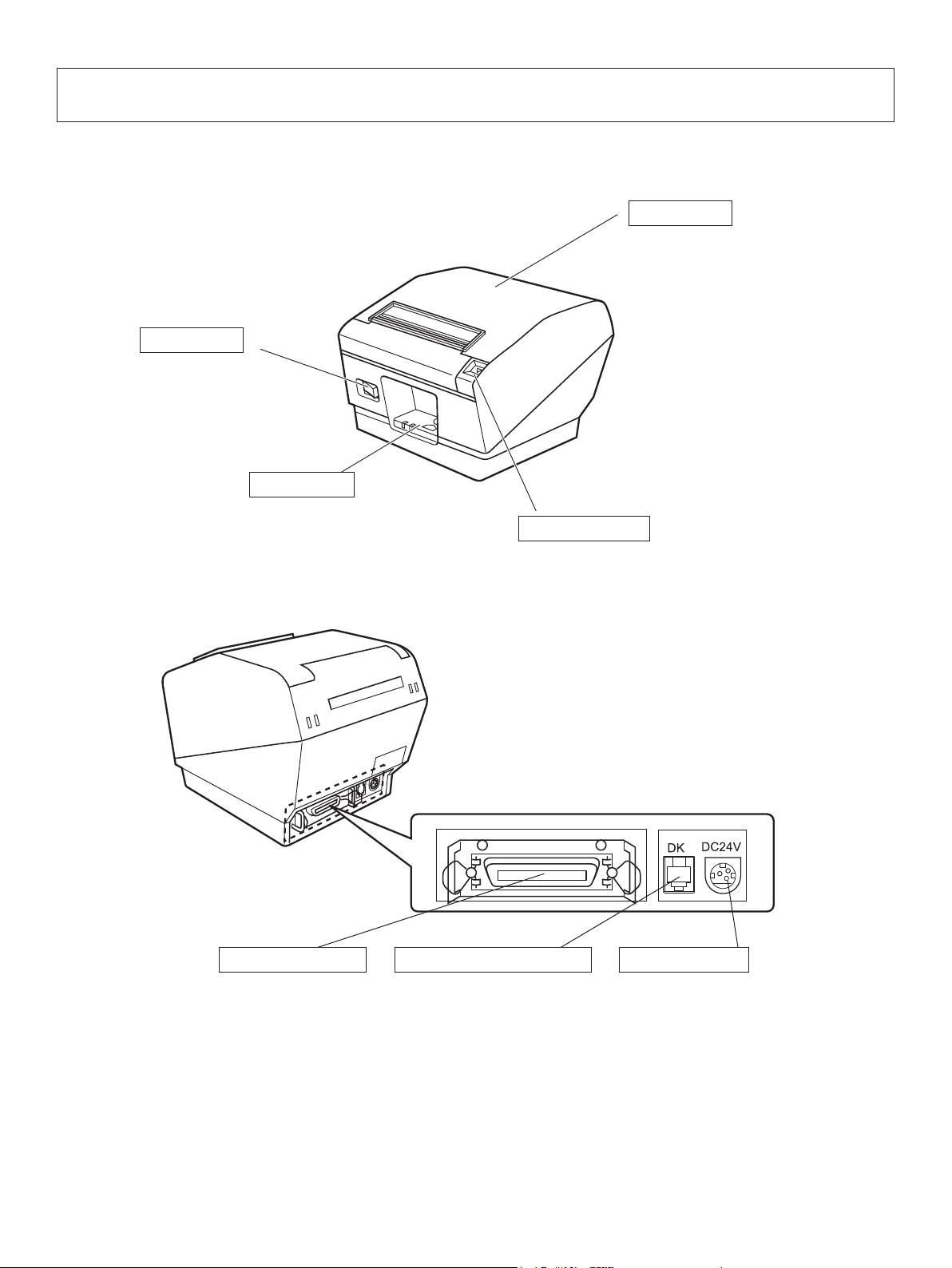

2. Parts Identication and Nomenclature

Printer cover

Open this cover to load

or replace paper.

Power switch

Used to turn on/

off power to the

printer.

Control panel

Features LED indicators to

indicate printer status and

switches to operate the printer.

Interface connector

Peripheral drive connector

Cover open lever

Push this lever in the direction of the

arrow to open the printer cover.

Power connector

For connection to a

host computer.

Connects to peripheral units

such as cash drawers, etc.

Do not connect this to a

telephone.

– 3 –

For connection of the

AC adapter.

Never unplug the

AC adapter while the

printer is on.

Page 8

3. Setup

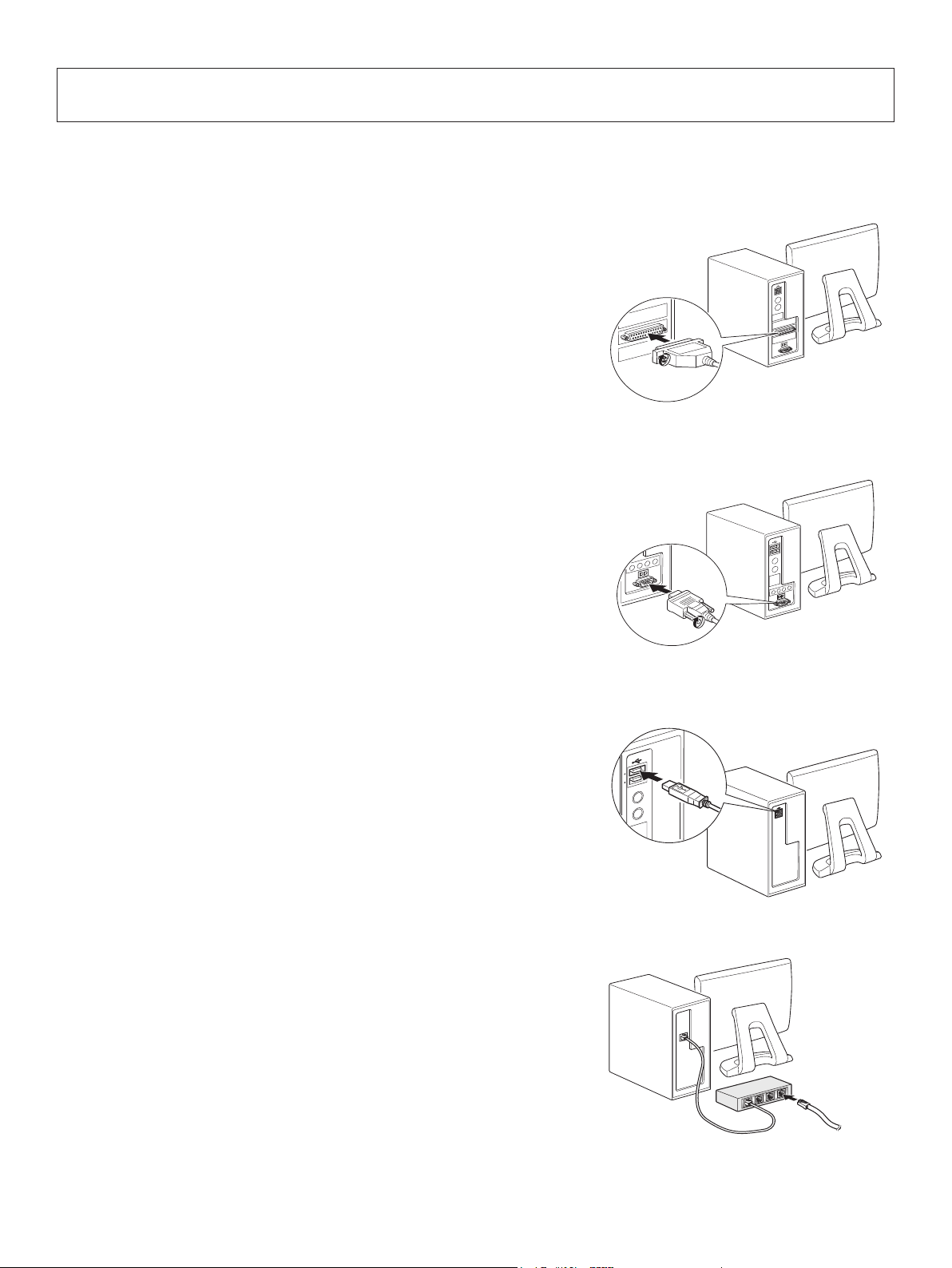

3-1. Connecting the Cable to the PC

3-1-1. Parallel Interface Cable

Connect the parallel interface cable to a parallel port

of your PC.

3-1-2. RS-232C Interface Cable

Connect the RS-232C interface cable to a RS-232C

port of your PC.

3-1-3. USB Interface Cable

Connect the USB interface cable to a USB port of

your PC.

3-1-4. Ethernet Interface cable

Connect the ethernet interface cable to a ethernet port

of your PC.

– 4 –

Page 9

3-2. Connecting the Cable to the Printer

Note that the interface cable is not provided. Please use a cable that meets specications.

CAUTION

Before connecting/disconnecting the interface cable, make sure that power to the printer and

all the devices connected to the printer is turned off. Also make sure the power cable plug is

disconnected from the AC outlet.

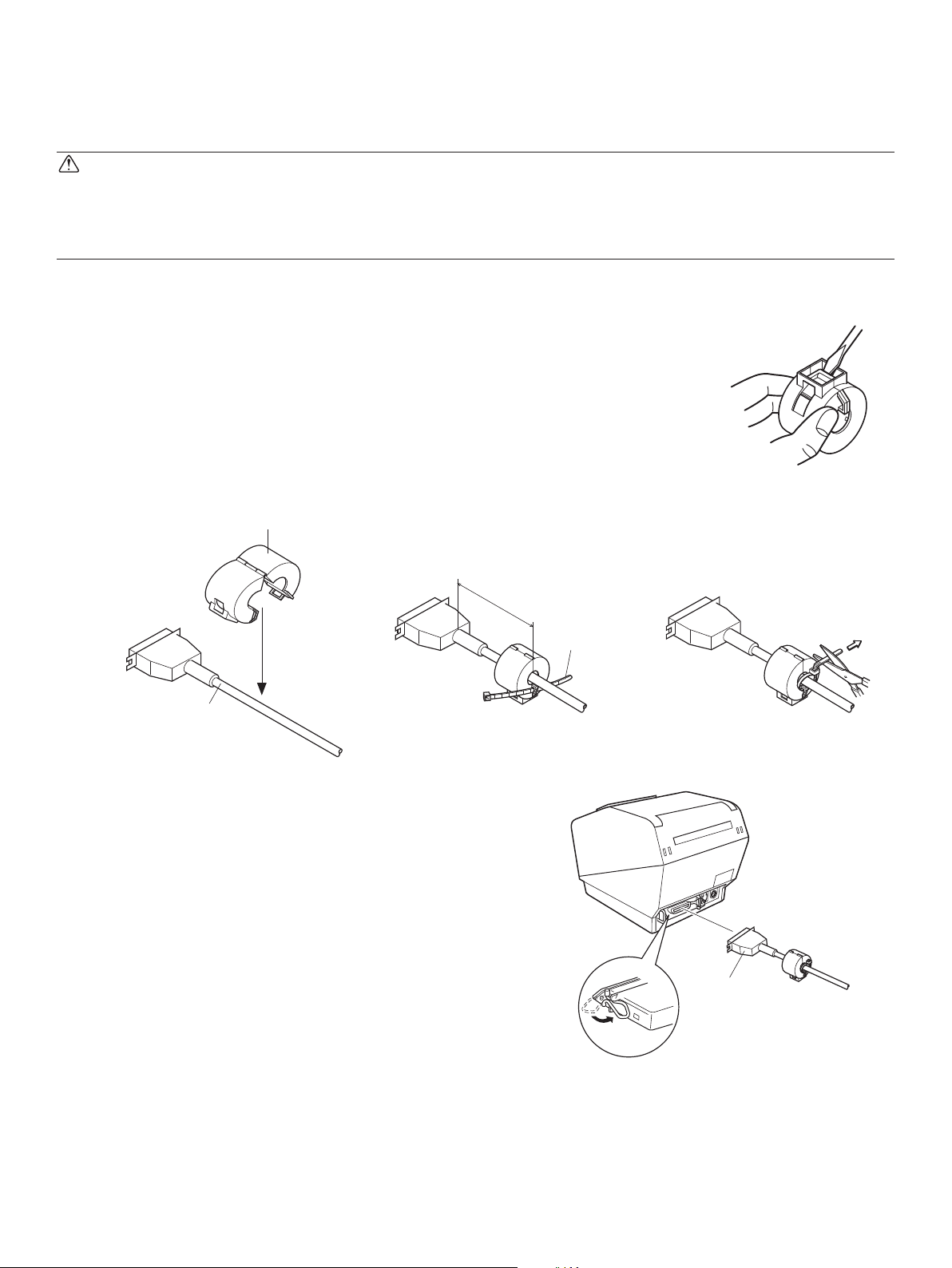

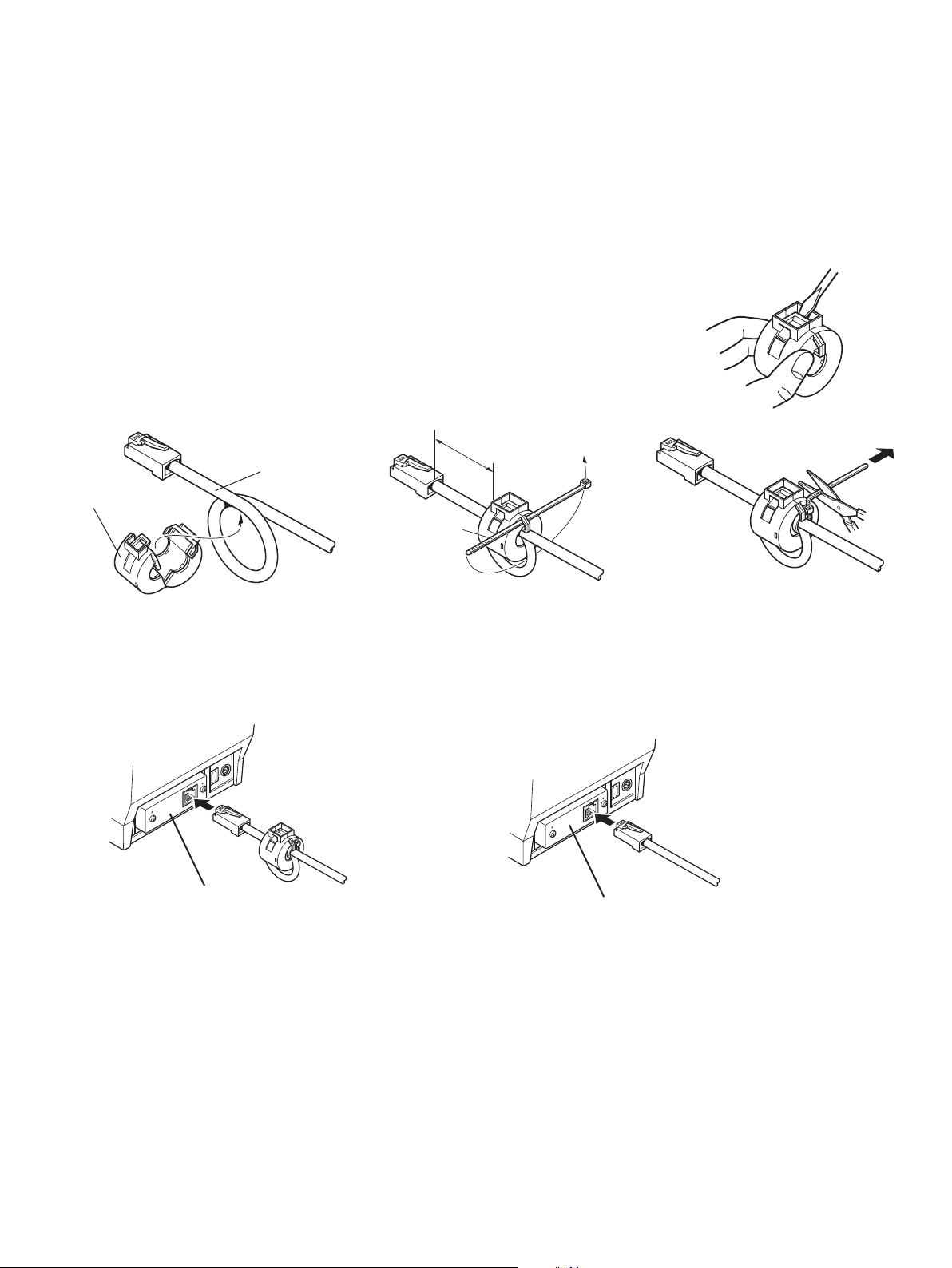

3-2-1. Parallel Interface Cable

(1) Make sure the printer is turn off.

(2) Afx the ferrite core onto the cable as shown in

the illustration.

(3) Pass the fastener through the ferrite core.

(4) Loop the fastener around the cable and lock it.

Use scissors to cut off any excess.

Ferrite core

5 cm

(maximum)

Interface cable

(5) Connect the interface cable to the connector on

the rear panel of the printer.

(6) Fasten the connector clasps.

Fastener

Parallel interface

cable

– 5 –

Page 10

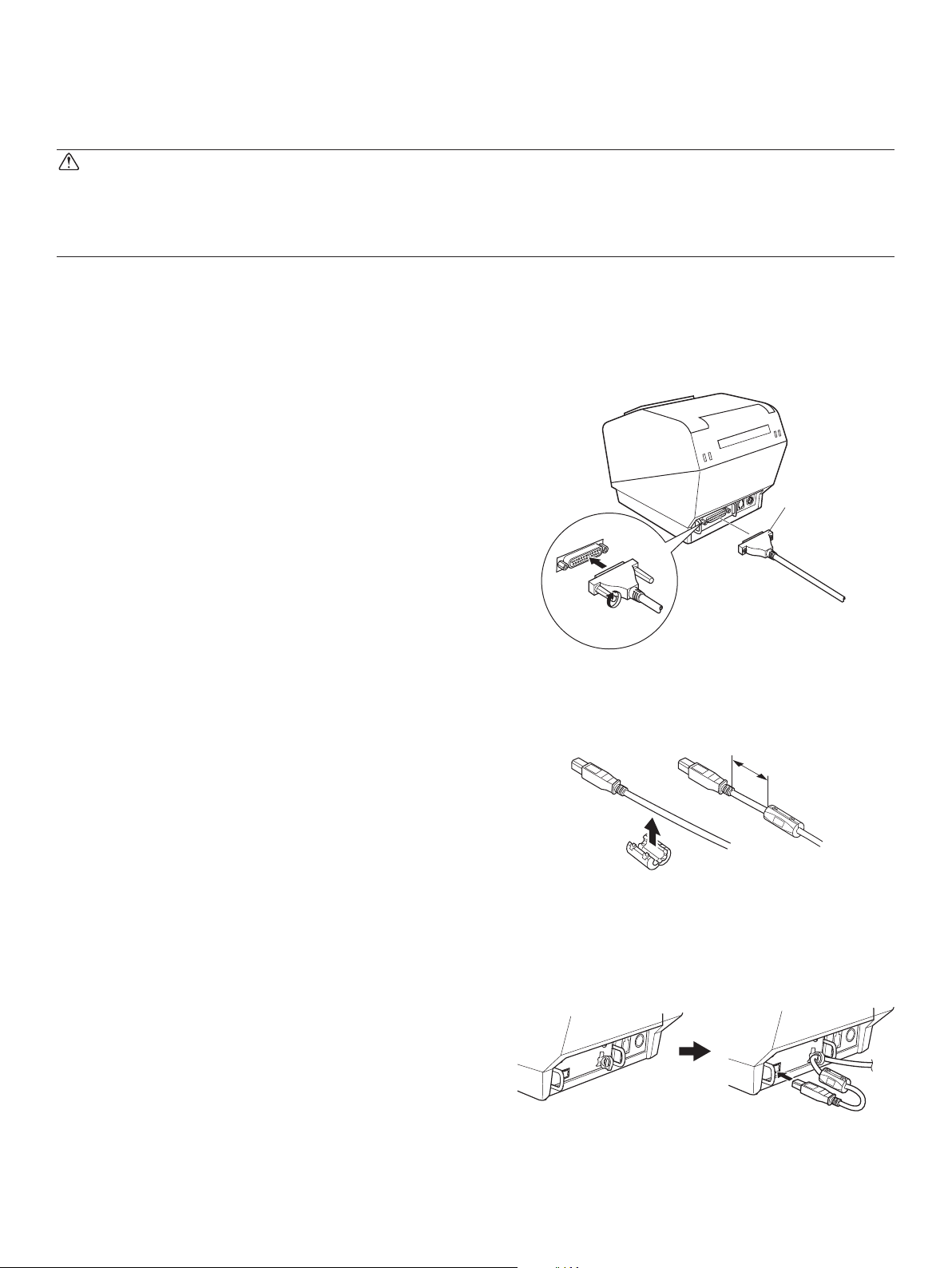

3-2-2. RS-232C Interface Cable

(1) Make sure the printer is turn off.

CAUTION

Before connecting/disconnecting the interface cable, make sure that power to the printer and

all the devices connected to the printer is turned off. Also make sure the power cable plug is

disconnected from the AC outlet.

(2) Connect the interface cable to the connector on the rear panel of the printer.

(3) Tighten the connector screws.

RS-232C

interface

cable

3-2-3. USB Interface Cable

Afx the ferrite core onto the USB cable as shown in

the illustration below and make sure to pass the cable

through the cable support as shown in the illustration.

4 cm (maximum)

– 6 –

Page 11

3-2-4. Connecting Ethernet Cable

If a ferrite core is included, install the ferrite core onto the Ethernet cable according to the following procedure to prevent electrical noise.

If a ferrite core is not included, perform steps (1) and (5) only.

When using an Ethernet cable that is 10 m or less, shielded cable is recommended.

(1) Make sure the printer is turned off.

(2) Install the ferrite core onto the ethernet cable as shown

in the illustration below.

(3) Pass the fastener through the ferrite core.

(4) Loop the fastener around the cable and lock it. Use scis-

sors to cut off any excess.

10 cm

(maximum)

Ethernet cable

Ferrite core

Fastener

(5) Connect the interface cable to the connector on the rear

panel of the printer.

Ethernet interface board

IFBD-HE05

Ethernet interface board

IFBD-HE07

Link disconnection detection feature

The Ethernet interface model is equipped with a link discon

nection detection feature. If the printer is turned on when an

Ethernet cable is not connected to it, the POWER and ERROR

lamps are simultaneously turned on and off at 2-second in

tervals to indicate the disconnection.

Be sure to connect the Ethernet cable from a PC or hub to the

printer, and then turn the printer on

– 7 –

Page 12

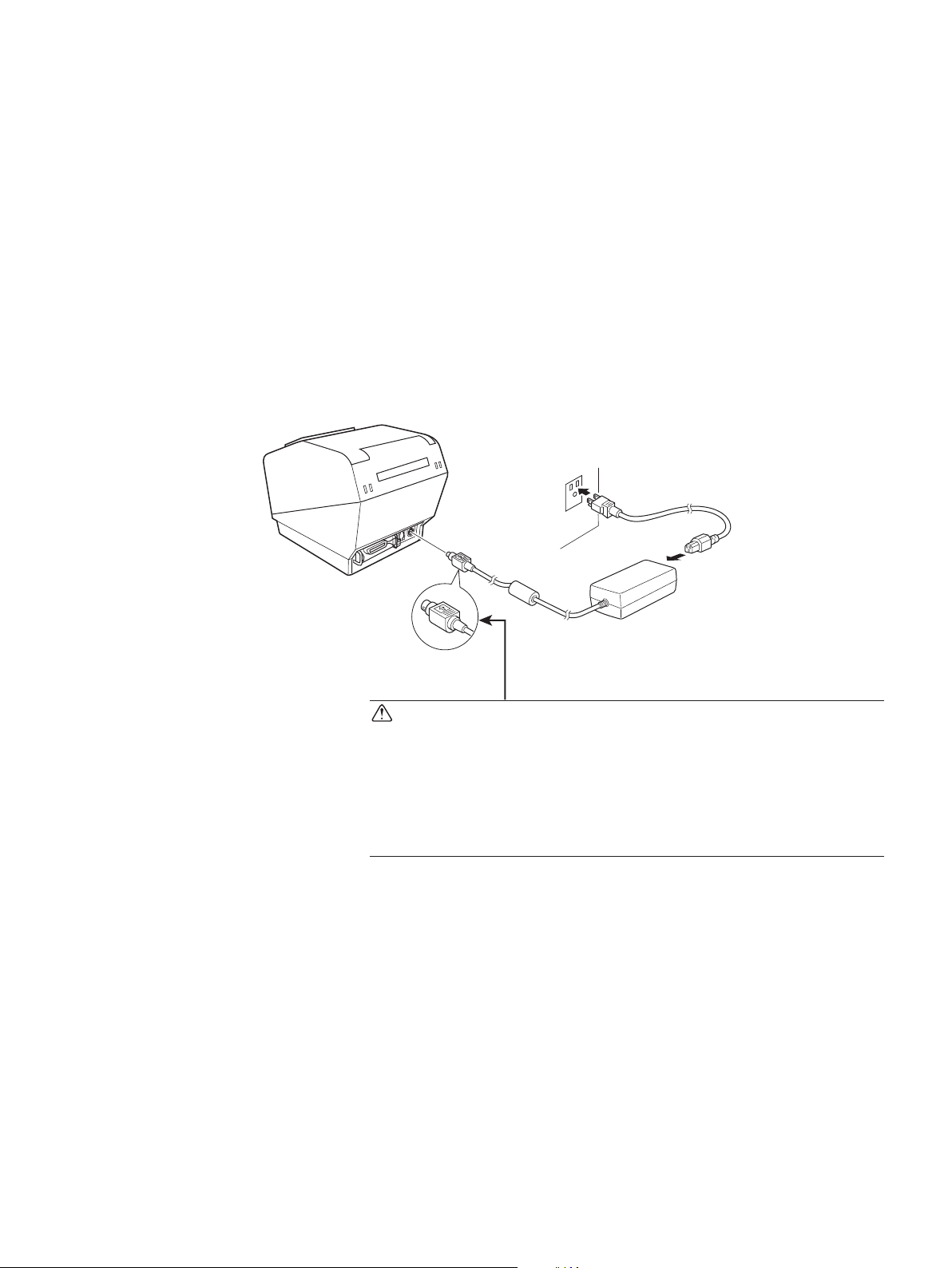

3-3. Connecting the Optional AC Adapter

Note: Before connecting/disconnecting the AC adapter, make sure that power to the printer

and all the devices connected to the printer is turned off. Also make sure the power

cable plug is disconnected from the AC outlet.

(1) Connect the AC adapter to the power cable.

Note: Use only the standard AC adapter and power cable.

(2) Connect AC adapter to the connector on the printer.

(3) Insert the power cable plug into an AC outlet.

CAUTION

When disconnecting the cable, take hold of the cable

connector to pull it out. Releasing the lock makes it easy

to disconnect the connector.

Pulling the cable excessively could cause damage to the

connector.

– 8 –

Page 13

3-4. Turning Power On

Make sure that the Power cord has been connected as described in 3-3.

Turn ON the power switch located on the front of the printer.

The POWER lamp on the control panel will light up.

Power switch

CAUTION

We recommend that you unplug the printer from the power outlet whenever you do not plan to

use it for long periods. Because of this, you should locate the printer so that the power outlet it

is plugged into is nearby and easy to access.

When an Switch blind is afxed to the printer above the power switch, the ON/OFF marks of

the power switch may be hidden. If this occurs, remove the power cord from the outlet to turn

the printer OFF.

– 9 –

Page 14

3-5. Connecting to a Peripheral Unit

You can connect a peripheral unit to the printer using a modular plug. See “Modular plug” on

page 53 for details about the type of modular plug that is required. Note that this printer does

not come with a modular plug or wire, so it is up to you to obtain one that suits your needs.

CAUTION

Make sure that the printer is turned off and unplugged from the AC outlet and that the computer

is turned off before making connections.

(1) Connect the peripheral drive cable to the connector on the rear panel of the printer.

CAUTION

Do not connect a telephone line into the peripheral drive connector. Failure to observe this may

result in damage to the printer.

Also, for safety purposes, do not connect wiring to the external drive connector if there is a

chance it may carry peripheral voltage.

– 10 –

Page 15

3-6. Loading the Paper Roll

Be sure to use paper roll that matches the printer’s specication.

1 Push the cover open lever and open the printer

cover.

For the RX model:

Turn the key under the cover open lever so that the

lock is "OPEN." Then, push down on the cover

open lever and open the printer cover.

The key cannot be removed when the lock is

"OPEN." Before you remove the key, turn it so

that the lock is in the "CLOSE" position.

Cover open lever

OPEN

Paper roll

Tension bar

2 Set the paper roll in the direction as shown, and

pull on the leading edge of the paper towards you.

CLOSE

Note: Make sure not to pass the paper under the

tension bar. In the following condition,

remove the tension bar unit in accordance

with the procedure described in paragraphs

3-6-1:

• Paper thickness between 100 μm and 150

μm

Note: When using a paper roll with an 79.5 mm

width, attach the paper roll holder in accordance with the procedure described in

paragraph 3-6-2.

3 Push both sides as shown in order to close the

printer cover.

Note: When closing the printer cover, make sure

both sides close rmly, not just one side.

– 11 –

Page 16

3-6-1. Removing the Tension Bar

When using thermal paper roll, the tension bar unit may or may not be necessary, depending

on the paper thickness. If the tension bar unit is unnecessary, remove it in accordance with the

procedure indicated below. The tension bar unit is unnecessary when using thermal label paper

roll (tack label paper).

Paper thickness

between 65 μm and 100 μm

Paper thickness

between 100 μm and 150 μm

Horizontal

Necessary

Unnecessary

Needed Optional

Vertical Kit

Needed Optional

Wall-mount Kit

Use a at head screwdriver as shown to remove the clips

at both ends of the tension bar. Then, remove the tension

bar unit.

– 12 –

Page 17

3-6-2. Removing the Paper Roll Holder

When using a paper roll with an 79.5 mm width, install the paper roll holder into the groover

as shown. When you change the effective print width (paper roll width), change the printer

utility’s memory switch setting.

For details, see the printer utility help.

Note: After using a paper roll with a width of 79.5 mm, do not change to a paper roll with

a width of 115.5 mm. This is because the printer head has deteriorated as a result of

a portion of the head having been in direct contact with the rubber roller.

Paper roll holder

– 13 –

Page 18

3-7. Bluetooth Settings

PAIR buttonRST button

(For

Bluetooth Interface Models only

)

<

LED

>

Indicates the status of the Bluetooth interface.

Green (on): Not connected.

Green (ashing): Ready to start pairing.

PAIRRST

LED

Blue (on): Connected.

Purple (ashing): Auto connection ON.

Pair the printer with the master device by following the procedure below.

Compatibility list: http://www.star-m.jp/prjump/000031.html

3-7-1. Pairing using SSP (Simple Secure Pairing) [Default]

(1) Working on the master device, tap [Settings] and set [Bluetooth] to ON.

<

iOS > < Android >

(2) After turning the printer's power switch on, press and hold the PAIR button on the rear

interface of the printer for 5 seconds or more, and then release it. The LED will ash green.

PAIR button

PAIR

RST

PAIR

RST

Flashing green LED

(3) Pairing will be possible for 60 seconds from when the LED begins ashing green.

During this time, execute "Search for devices" from the master device and tap the relevant

device from the displayed list.

Device name: Star Micronics (default)

(4) In an iOS device, after pairing, the LED will automatically begin flashing blue, and the

printer will be automatically connected. In an Android device, the LED turns blue only

while data is sent.

(5) Connect to the printer from the master device application and perform printing. If the

printing is successful, the pairing process has been completed.

– 14 –

Page 19

Note: e printer performs various processes immediately aer connecting to or disconnecting from a master

device.

Please wait approximately 0.1 seconds aer connecting, and approximately 0.5 seconds aer disconnecting,

before beginning communications with the printer.

3-7-2. Pairing using PIN code

Enter the following information in the master device if it does not support SSP, or when otherwise necessary.

PIN: 1234 (default)

Device name: Star Micronics (default)

It is recommended that you change the PIN code for greater security.

For details regard changing the PIN code, please see the “Software Manual -Star Bluetooth Utility- ”.

3-7-3. Auto Connection Function (iOS only)

Each time the wireless connection is disconnected while communicating with upper-level iOS devices including iPad over

Bluetooth, it is necessary to move back to the Bluetooth setting screen in the upper-level iOS device and tap the desired

printer name again to build a connection. is is an iOS specication.

In order to save this labor, this printer is equipped with the Auto Connection function that automatically requests a con-

nection from an upper-level iOS device that was connected to the printer last time.

e default setting of this function may dier according to the printer model you are using.

Conrm the default settings for your printer, as well as the use examples for ON/OFF settings, and then make the settings

to match your purpose.

You can also check the current ON/OFF setting by performing self-printing.

< Conrmation procedure by self-printing >

(1) While the printer cover is closed, hold down the FEED button on the

operation panel, and then turn on the power switch.

(2) Self-printing starts and the settings for F/W version, DIP switch,

memory switch, and so on are printed.

Subsequently the interface information is printed and nally the cur-

rent ON/OFF settings are printed.

Caution: If "Auto Connection function" is set to ON when using devices other than iOS, a Bluetooth communi-

cation with the printer may fail. To use devices other than iOS, such as the Android/Windows devices,

make sure you turn o the "Auto Connection" function before using the printer.

For information on how to set up this function, see "3-7-4. Setting up Auto Connection".

– 15 –

Page 20

See the table below for details of Auto Connection setting.

Auto Connection ON Auto Connection OFF

Reconnecting without

changing the master device

Changing the connected

master device

Example (recommended) When connecting directly to

After the printer is turned

on, it automatically connects

to the last master device that

was connected.

Disconnect the Bluetooth

connection in such a way as

to turn OFF the power to the

upper-level device automatically connected.

Then, establish a pairing

with a desired master device.

the printer from one master

device.

After turning on the printer,

tap this printer's name on

the Bluetooth settings screen

on the master device.

After turning on the printer,

establish a pairing with a

desired master device.

When using the printer with

multiple master device.

– 16 –

Page 21

3-7-4. Setting up Auto Connection

u

Setting up from the Main Unit for the TSP800II

Note: e following procedure explains how to change the Auto Connection function setting from ON to OFF.

If you want to change it from OFF to ON, please follow the same procedure.

(1) When paper is loaded in the printer and it is turned on, the [POWER] LED(green) on

the front of the printer turns on.

(2) If you hold down the [RST] button on the back of the printer for at more than ve seconds,

initial operations are performed in the same way as when the power is turned on, and the

LEDs on the front of the printer ash. If you press the [RST] button when the printer is

placed upright, place it horizontally again while the LED is ashing.

PAIR

RST

PAIR

RST

RST button

(3) The following information is printed. After that, turn the printer off and then back

on again to set "Auto Connection" to OFF.

< Current Setting >

Auto Connection : OFF

To enable this setting, turn

Printer Power OFF and turn ON.

(4) To make sure "Auto Connection" is set to OFF correctly, perform self-printing as

described in "3-7-3. Conrmation procedure by self-printing”.

u

Setting from the Software

After pairing your device and the TSP800II, change "Auto Connection" in the following

application provided by our company.

iOS: Download "Star Setting Utility" from the following Web site.

l

http://www.star-m.jp/prjump/000003.html

Android: Download "Star Setting Utility" from the following Web site.

l

http://www.star-m.jp/prjump/000004.html

Windows: Download "Star Bluetooth Utility" from the following Web site.

l

http://www.star-m.jp/prjump/000006.html

– 17 –

Page 22

3-7-5. Resetting Bluetooth Settings

The following procedure explains how to initialize settings that you have changed such as

the PIN code, device name, and so on.

(1) While inserting a thin object such as the tip of a pen and holding down the RST button on

the rear of the printer, turn on the printer's power switch. The POWER LED (green) and the

ERROR LED (red) on the front of the printer start flashing.

(2) Hold down the

RST button for 4 seconds or more

RST button

PAIR

RST

PAIR

RST

Hold down for 4 seconds or more

(note 1), and then release it.

(3) After you release the RST button, if the LED stops flashing and the POWER LED remains lit

green within 12 seconds, initialization is complete. If the LED continues to flash for longer than

12 seconds after releasing the RST button, this indicates that initialization was not successful.

Turn off the printer's power and then try again from step 1.

(4) Turn off the printer's power switch and delete the pairing setup with the higher ranked device.

Note 1: In step 2, if you do not hold down the RST button for long enough, initialization will not complete correctly.

For F/W Ver2.0, Ver3.0a, and Ver3.0b interfaces

In step 2, you need to hold down the RST button for 8 seconds or more.

Also, aer nishing steps 1 to 3, to check that initialization was completed correctly, perform self-printing.

If the second sheet (*** Bluetooth Information ***) is not printed, initialization has not been completed correctly. If this happens, turn o the printer's power, and then try again from step 1.

(You can check the rmware version from the self-printing results. See page 15 for the self-printing procedure.)

2: Do not turn o the printer during initialization; otherwise initialization will not complete correctly.

3: If initialization is not completed correctly, turn o the printer's power and then try again from step 1.

– 18 –

Page 23

3-8. Setup Precautions

Caution Symbol

These symbols are located near the thermal print head.

Because the thermal print head is hot immediately after printing, do not touch

it. Static electricity can damage the thermal print head. To protect the thermal

print head from static electricity, do not touch it.

This symbol is located near the cutter.

Never touch the cutter blade, as you could injure your ngers.

This symbol is located near the peripheral drive connector.

Do not connect this to a telephone.

WARNING

l

If you notice smoke or strange odors coming from this product, turn the power switch off immediately,

and remove the power cord from the AC outlet. For repairs, contact the dealer that you bought the product from.

l

Never attempt to repair the product yourself. Doing so can be dangerous.

l

Never disassemble or modify the product. Doing so may result in injury, re, or electric shock.

l

On models that have cutters or tear bars, do not touch the cutter blade or the tear bar.

-

There is a cutter or tear bar inside the paper outlet slot. Never put your hand in the slot regardless of

whether or not the printer is in operation.

-

You must open the printer cover to replace paper. However, because the cutter blade or tear bar is located inside of the cover, be careful not to bring your face and hands too close to the blade or tear bar

when the cover is open.

l

During and immediately after printing, the area around the print head is very hot. Don’t touch it because

you could be burned.

l

Be sure to turn off the printer before performing maintenance on the cutter. Failing to do so is dangerous.

CAUTION

l

We recommend that you unplug the printer from the power outlet whenever you do not plan to use the

printer for long periods.

Because of this, you should locate the printer so that the power outlet it is plugged into is nearby and easy

to access.

l

If an AC cord set is supplied with the product, the power cord that is included has been specially designed

for the product.

l

Make sure that the printer and the PC are turned off and unplugged from their AC outlets before you

make connections.

l

Do not connect a telephone line to the peripheral drive connector, which is used for devices such as cash

drawers. Doing so may cause the printer to malfunction. Also, for safety purposes, do not connect a wire

that may carry excessive voltage to the peripheral drive connector.

– 19 –

Page 24

l

Do not open the printer covers while the printer is printing or cutting.

l

Do not pull out paper when the printer cover is closed.

l

If liquid or foreign objects (such as coins and paper) enter the inside of the printer, turn the power switch

off, disconnect the power cord from the AC outlet, and consult the dealer that you bought the product from.

Continuing to use the printer may lead to a short-circuit, which may cause electric shock or re.

l

The heating element and the driver IC of the thermal print head are easily damaged. Do not touch them

with metal objects, sandpaper, etc.

l

Do not touch the thermal print head heating element. Doing so may make it dirty, which will decrease the

printing quality.

l

Static electricity can damage the driver IC and other components of the thermal print head. Avoid touch-

ing it directly.

l

Do not operate the printer if there is moisture (which has been caused by condensation or another factor)

on the front surface of the head.

l

The printing quality and the thermal print head’s service life cannot be guaranteed if paper other than the

recommended paper is used.

In particular, thermal paper containing Na+, K+, or C1- may drastically reduce the service life of the

thermal print head.

We recommend that you use paper with the following maximum ion densities: 500 ppm of Na+, 150 ppm

of K+, and 300 ppm of Cl-.

For details on recommended thermal paper, see the following webpage.

http://www.starmicronics.com/support/

CAUTION

Wireless Communication

l

Do not use the device where using wireless devices is prohibited or may cause interference or danger.

l

The radio waves generated by the device may interfere with the operation of electronic medical devices.

If you are using any electrical medical device, contact its manufacturer for the restrictions on the use of

the device.

l

Security functionality for Bluetooth is installed in this product. Congure the security settings according

to the manual (available on the Star Micronics website) to reduce the risk of security issues.

l

This device supports Bluetooth.

Since this functionality may be limited by local regulations, rst review the radio laws specic to the

country in which the product will be used.

l

Below is a list of laws this device has been approved by. As Star Micronics is committed to constant in-

novation, revisions may be made without an announcement. Access the Star Micronics website for the

latest listing of approvals.

l

Please refer to Star Micronics website for the latest information and manuals.

– 20 –

Page 25

4. Consumable Parts

When consumable parts have run out, use those specied in the table below.

Note: Access the following URL for the information of the recommended paper.

http://www.star-m.jp/eng/dl/dl02.htm

Make sure that the AC adapter specied in the table is used.

Use of consumable parts or AC adapter which are not specied in the table may result in damage to the printer, re or electric shock.

4-1. Thermal Paper Roll

(1) Paper roll specication

Width: 111.5±0.5 mm or 79.5±0.5 mm

Outer roll diameter: ø100 mm or less

Take up paper roll width: 112

Thickness: 65~150 µm (when using 115.5 mm width paper)

65~85 µm (when using 79.5 mm width paper)

Core outer/inner diameter

Paper thickness Core outer Core inner

65~75 µm ø18±1 mm ø12±1 mm

65~75 µm ø32±1 mm ø25.4 mm

75~150 µm ø32±1 mm ø25.4 mm

Printed surface: Outer edge of roll

Tail end handling: Do not use paste or glue to secure the paper roll or its core.

Do not fold the tail end of the paper.

+0.3

mm or 80

-1

+0.5

-1

mm

– 21 –

Page 26

(2) Effective Print Width

Paper Width

(mm)

Right / Left Margin (mm) Effective Print Width

(mm)

115.5 ± 0.5 4 104 69

79.5 ± 0.5 4 72 48

Left Margin Right MarginEffective Print Width

Paper Width

Number of Print Columns

(12 × 24 Font)

– 22 –

Page 27

4-2. Thermal Label Paper Roll (Tack Label Paper)

(1) Label paper specication

Backing paper width: 110±0.5 mm

Outer roll diameter: ø100 mm or less

Take up paper roll width: 112

Thickness: Max. 150 μm

Core outer/inner diameter: core inner diameter ø25.4±1 mm/core outer diameter

Printed surface: Outer edge of roll

Tail end handling: Do not use paste or glue to secure the paper roll or its

Do not fold the tail end of the paper.

(2) Effective Print Width

+0.3

mm

-1

ø32±1 mm

core.

Paper Width

(mm)

105 ± 0.5 5 95 63

Right / Left Margin (mm) Effective Print Width

(mm)

Number of Print Columns

(12 × 24 Font)

– 23 –

Page 28

• Detailed Diagrams of Recommended Tack Label Specications

Tack label

ø100 MAX

ø32 ± 1

ø25.4 ± 1

+1.5

110

-1.0

(Rolled dimension)

Release paper

(backing paper)

Base material

(label paper)

30 ±1 – 295 ±3

(Label length)

Printing direction

Black mark (back

of diagram)

PCS: 0.90 minimum

+1.0

-0.8

1

5 ± 1.0

15 MIN

35 – 300

(Black mark pitch)

• Detailed Diagram of Effective Printing Range

95 (effective printing width:

63 characters with font A)

5 (Left margin) 3 (Right margin)

Dot numbers 39 – 598

Paper tube

5 ± 1

(2.5)

105 ± 0.5

2.5 ± 0.5

Effective printing range

(Label width)

110 ± 0.5

(Backing paper width)

3 (Top margin)

* Minimum settable top margin when

3 (Bottom

margin)

paper is fed using back-feed.

105 ± 0.5 (Label width)

110 ± 0.5 (Backing paper width)

– 24 –

30 – 295 (Label length)

35 – 300 (Black mark pitch)

24 – 289 (Effective printing length)

(2.5)2.5 ± 0.5

Page 29

• Cut Position / Printing Line / Black Mark Sensor’s Positional Relationship

Effective printing range

2.5

5

Cut position

2.5

Approx. 14Approx. 14

Printing line

Black mark sensor

• Min. Label Pitch / Cut Position / Printing Line / Black Mark Sensor’s Positional Relationship

Effective printing range

(35)

30 ± 1

5 ± 1

24

Approx. 14

Approx. 14

Cut position

Printing line

Black mark sensor

– 25 –

Page 30

5. Control Panel and Other Functions

5-1. Control Panel

1 POWER lamp (Green LED)

When the printer is online, power lamp

is ON and ERROR lamp is OFF.

2 ERROR lamp (Red/Orange LED)

Indicates various errors in combination

with POWER lamp.

3 FEED button

2 ERROR lamp (Red/Orange LED)

1 POWER lamp (Green LED)

5-2. Errors

1) Recoverable errors

Error Description POWER Lamp ERROR Lamp Recovery Conditions

Head high temperature

detection

Cover open error ON ON (Red) Automatically recovered by

Paper out error ON ON (Orange) Automatically recovered by

Paper near end ON Flashes orange

Black mark paper size

error

Paper cut error OFF Flashes red lamp

Link disconnection detection*1

Flashes at 0.5-second intervals

ON ON (Orange) Recovered by loading a new pa-

Flashes at 2-second

intervals

3 FEED button

Press the FEED button to feed paper

roll.

OFF Automatically recovered after

the print head has cooled.

closing the printer cover.

loading a new paper roll, then

closing the printer cover.

Indicators show that the paper

lamp at 1 second

intervals

at 0.125 second

intervals

Flashes at 2-second intervals

end is approaching, but the

printer continues to print.

per roll, then closing the printer

cover.

Recovered if the cutter returns to

the home position after turning

the power OFF and ON. (See

Notes 1 and 2.)

Connect an Ethernet cable. For

details, see section 3-2-4, "Con-

necting Ethernet Cable."

*1 Ethernet interface model only

Note:

1) If the cutter doesn’t return to the home position or doesn’t perform the initial movement, it cannot be recovered.

2) If the paper is jammed, turn the power off, clear the jammed paper, then turn the power

ON.

– 26 –

Page 31

2) Non-recoverable errors

Error Description POWER Lamp ERROR Lamp

Flash access error OFF Flashes Orange

lamp at 0.5-second intervals

EEPROM error OFF Flashes

Red lamp at

0.75-second

intervals

SRAM error OFF Flashes Orange

lamp at 1-second intervals

Head thermistor error OFF Flashes Red

lamp at 1.5-second intervals

Power voltage error OFF Flashes Orange

lamp at 2-second intervals

Recovery Conditions

This is not a recoverable error.

This is not a recoverable error.

This is not a recoverable error.

This is not a recoverable error.

This is not a recoverable error.

Note:

1) If a non recoverable error occurs, turn the power OFF immediately.

2) When Power supply error occurs, there is a possibility that the power supply unit has

a trouble.

For other non recoverable errors, please consult the dealer for repairs.

– 27 –

Page 32

6. Adjusting the Sensor

This printer is equipped with the following two paper sensors:

PE / BM sensor

• PE and BM (Paper End and Black Mark) Sensor

Detects whether a roll paper is loaded in the printer.

In addition, detects the Black Mark that is pre-printed

NE sensor

on the paper’s print side.

• NE (Near End) sensor

Detects whether the roll paper is nearing its end.

6-1. Adjusting the Near End Sensor Position

Use the following procedure to adjust the near-end sensor so it is compatible with the size of

paper roll you are using.

However, for vertical or wall-mount use, keep the adjuster xed to level 3, without changing

its position.

1 Open the printer cover.

2 Determine the diameter of the paper roll you are using and nd the required setting in the

table below.

3 Insert the tip of a ballpoint pen or similar object into the hole of the adjuster, and then push

and side the adjuster to the desired setting.

When changing the setting, make sure that the position of the hole is aligned with the align-

ment mark indicated by the arrow.

(Level 1)

(Level 2)

(Level 3)

Near-end sensor (vertical / wall-mount layout)

(Level 3)

(Level 2)

(Level 1)

Near-end sensor (horizontal layout)

– 28 –

Page 33

Adjustment value according to the paper you are using

Paper thick-ness

(µm)

65 ø23 ø27 ø31 2.5 4.9 7.7

75 2.1 4.2 6.7

Paper thick-ness

(µm)

65 ø36 ø40 ø44 2.8 6.4 10.4

75 2.4 5.5 9.0

85 2.1 4.9 7.9

95 1.9 4.4 7.1

105 1.7 4.0 6.4

130 1.4 3.2 5.2

150 1.2 2.8 4.5

When using the paper roll with a core whose inside diameter (A):ø12, outside diameter

(B):ø18

Detected diameter (C)

(Approx. mm)

Level 1 Level 2 Level 3 Level 1 Level 2 Level 3

When using the paper roll with a core whose inside diameter (A): ø25.4, outside diameter (B):ø32

Detected diameter (C)

(Approx. mm)

Level 1 Level 2 Level 3 Level 1 Level 2 Level 3

Remained paper length

(Approx. m)

Remained paper length

(Approx. m)

C

B

A

Paper roll core

Note:

1) The adjuster is factory-set at level 1 on the horizontal

layout and level 3 on the vertical/wall-mount layout.

2) The detected diameter and remained paper length

given above are calculated values, and there may be

some variances depending on the rolled state of the

paper or the actual mechanism.

3) If thick paper is used (paper thickness between 100

μm and 150 μm), the paper roll may loosen and cause

variances in the detected values. Therefore, set the

adjustor to Level 3 for horizontal layout.

4) The near end sensor doesn't correspond to the thermal

C

label paper roll (tack label paper).

– 29 –

Page 34

6-2. PE and BM ( Paper End and Black Mark ) Sensor Adjustment

The sensitivity of the sensor is calibrated at the factory, so sensor adjustment is not necessary

under ordinary conditions. However, you may need to make adjustments when using nonrecommended paper or when the surrounding environment prevents the sensor from working

properly.

1 Make sure that the printer is turned OFF.

2 Open the printer cover, load the roll paper, and set the printer to the "paper present" state.

3 Remove the screw from the DIP switch cover on the bottom of the printer. Then take off

the DIP switch cover, as shown in the illustration below.

4 Using the tip of a ballpoint pen or a similar tool, set the DIP switches as follows:

DIP SW1-4 OFF, DIP SW1-5 ON, DIP SW1-6 ON, and DIP SW1-7 ON. Turn the printer

power ON. The lamps on the control panel will ash, and the printer will enter the sensor

adjustment mode.

5 Using a small slot screwdriver, turn VR3 as shown below, and adjust it so that the green

POWER LED and the red ERROR LED light.

6 Turn the printer power OFF, and restore the following DIP switches to their original set-

tings: DIP SW1-4, DIP SW1-5, DIP SW1-6, and DIP SW1-7.

Paper roll

DSW 2 DSW 1

9

10

VR 2

1 2 3 4 5 6 7 8 1 2 3 4

OFF

ON

VR 1VR 3

Power switch

Power lamp

ERROR

POWER

ERROR lamp

– 30 –

FEED

Page 35

6-3. NE (Near End) Sensor Adjustment

The sensitivity of the sensor is calibrated at the factory, so sensor adjustment is not necessary

under ordinary conditions. However, you may need to make adjustments when using nonrecommended paper or when the surrounding environment prevents the sensor from working

properly.

1 Make sure that the printer is turned OFF.

2 Open the printer cover, remove the roll paper and set the printer to the "paper absent" state.

3 Remove the screw from the DIP switch cover on the bottom of the printer. Then take off

the DIP switch cover, as shown in the illustration below.

4 Using the tip of a ballpoint pen or a similar tool, set the DIP switches as follows:

DIP SW1-4 OFF, DIP SW1-5 OFF, DIP SW1-6 ON, and DIP SW1-7 ON. Turn the printer

power ON. The lamps on the control panel will ash, and the printer will enter the sensor

adjustment mode.

5 Use a small slot screwdriver to turn VR2 clockwise as far as it will go. If the POWER LED

lights, go to step 6. If the POWER LED does not light, turn VR2 so that both the ERROR

LED and the POWER LED light.

6 Turn the printer power OFF, and restore the following DIP switches to their original set-

tings: DIP SW1-4, DIP SW1-5, DIP SW1-6, and DIP SW1-7.

Paper roll

Power switch

DSW 2 DSW 1

9

10

VR 2

1 2 3 4 5 6 7 8 1 2 3 4

OFF

ON

VR 1VR 3

Power lamp

ERROR

POWER

ERROR lamp

– 31 –

FEED

Page 36

7. Preventing and Clearing Paper Jams

7-1. Preventing Paper Jams

The paper should not be touched during ejection and before it is cut.

Pressing or pulling the paper during ejection may cause a paper jam, paper cutting failure or

line feed failure.

7-2. Removing Paper Jam

If a paper jam occurs, clear it as described below.

(1) Set the power switch to off to turn off power to the printer.

(2) Push the lever toward you to open the printer cover.

(3) Remove the jammed paper.

Note 1: To prevent parts such as the thermal head or the rubber roller from damage or

deformation, do not forcibly pull on the paper with the printer cover closed.

Note 2: If label paper gets jammed, the glue from the labels could stick to the parts. If this

occurs, make sure to wipe them clean of the glue.

(4) Position the paper roll straight and close the printer cover gently.

Note 1: Make sure that the paper is positioned straight. If the printer cover is closed with

the paper skewed, a paper jam may result.

Note 2: Lock the printer cover by pressing down on the sides. Do not try to close it by

pressing down on the centre. The cover may not lock properly.

(5) Set the power switch to on to turn on power to the printer. Make sure that the ERROR LED

is not lit.

Note: While the ERROR LED is lit, the printer will not accept any commands such as the

print command, so make sure that the printer cover is locked properly.

– 32 –

Page 37

8. Periodical Cleaning

Printed characters may become partially unclear due to accumulated paper dust and dirt. To

prevent such a problem, paper dust collected in the paper holder and paper transport section

and on the surface of the thermal head must be removed periodically.

Such cleaning is recommended to be carried out once six month or one million lines. If the

printer uses label paper, clean it on a monthly basis or after printing approximately 200,000 lines.

8-1. Cleaning the Thermal Head

To remove the dark paper dust that has accumulated on the thermal head surface, wipe it clean

with cotton swab (or soft cloth) dipped in alcohol (ethanol, methanol, or isopropyl alcohol). If

the printer uses label paper, wipe it clean of the glue that may have accumulated.

Note 1: The thermal head is easily damaged, so clean it with a soft cloth, taking care not

to scratch it.

Note 2: Do not attempt to clean the thermal head immediately after printing, when the

thermal head is hot.

Note 3: Beware of the risk of damaging the thermal head as a result of static electricity

that may be created during cleaning.

Note 4: Turn the power ON only after the alcohol has dried completely.

8-2. Cleaning the Rubber Roller

Use a dry, soft cloth to wipe off the dust that may have accumulated on the rubber roller.

8-3. Cleaning the Sensors and the Surrounding Areas

Clean the sensors (mainly the reector type sensors) of debris, dust, paper particles, glue, etc.

that may have accumulated.

8-4. Cleaning the Paper Holder and the Surrounding Area

Clean the paper holder of debris, dust, paper particles, glue, etc. that may have accumulated.

Sensors

Thermal head

Rubber roller

– 33 –

Page 38

English:

Deutsch:

[German]

Svenska:

[Swedish]

Español:

[Spanish]

Português:

[Portuguese]

Français:

[French]

Suomi:

[Finnish]

Italiano:

[Italian]

Dansk:

[Danish]

Nederlands:

[Dutch]

Eesti:

[Estonian]

Ελληνική:

[Greek]

Hereby, STAR MICRONICS CO.,LTD. declares that this Wireless

Device is in compliance with the essential requirements and

other relevant provisions of Directive 1999/5/EC.

Hiermit erklärt STAR MICRONICS CO.,LTD., dass sich das Gerät

Wireless Device in Übereinstimmung mit den grundlegenden

Anforderungen und den übrigen einschlägigen

Bestimmungen der Richtlinie 1999/5/EG bendet.

Härmed intygar STAR MICRONICS CO.,LTD. att denna

Wireless Device står I överensstämmelse med de väsentliga

egenskapskrav och övriga relevanta bestämmelser som

framgår av direktiv 1999/5/EG.

Por medio de la presente STAR MICRONICS CO.,LTD. declara

que el Wireless Device cumple con los requisitos esenciales y

cualesquiera otras disposiciones aplicables o exigibles de la

Directiva 1999/5/CE.

STAR MICRONICS CO.,LTD. declara que este Wireless Device

está conforme com os requisitos essenciais e outras

disposições da Directiva 1999/5/CE.

Par la présente STAR MICRONICS CO.,LTD. déclare que l'appareil

Wireless Device est conforme aux exigences essentielles et

aux autres dispositions pertinentes de la directive 1999/5/CE.

STAR MICRONICS CO.,LTD. vakuuttaa täten että Wireless

Device tyyppinen laite on direktiivin 1999/5/EY oleellisten

vaatimusten ja sitä koskevien direktiivin muiden ehtojen

mukainen.

Con la presente STAR MICRONICS CO.,LTD. dichiara che questo

Wireless Device è conforme ai requisiti essenziali ed alle altre

disposizioni pertinenti stabilite dalla direttiva 1999/5/CE.

Undertegnede STAR MICRONICS CO.,LTD. erklærer herved, at

følgende udstyr Wireless Device overholder de væsentlige

krav og øvrige relevante krav i direktiv 1999/5/EF.

Hierbij verklaart STAR MICRONICS CO.,LTD. dat het toestel

Wireless Device in overeenstemming is met de essentiële

eisen en de andere relevante bepalingen van richtlijn 1999/5/

EG.

Käesolevaga kinnitab STAR MICRONICS CO.,LTD. seadme

Wireless Device vastavust direktiivi 1999/5/EÜ põhinõuetele

ja nimetatud direktiivist tulenevatele teistele asjakohastele

sätetele.

ΜΕ ΤΗΝ ΠΑΡΟΥΣΑ STAR MICRONICS CO.,LTD. ΔΗΛΩΝΕΙ ΟΤΙ

Wireless Device ΣΥΜΜΟΡΦΩΝΕΤΑΙ ΠΡΟΣ ΤΙΣ ΟΥΣΙΩΔΕΙΣ

ΑΠΑΙΤΗΣΕΙΣ ΚΑΙ ΤΙΣ ΛΟΙΠΕΣ ΣΧΕΤΙΚΕΣ ΔΙΑΤΑΞΕΙΣ ΤΗΣ

ΟΔΗΓΙΑΣ 1999/5/EK.

Slovensky:

[Slovak]

Slovensko:

[Slovenian]

Česky:

[Czech]

Magyar:

Hungarian

[

Български:

[Bulgarian]

Polski:

[Polish]

Malti:

[Maltese]

Latviski:

[Latvian]

Lietuvių :

[Lithuanian]

Norsk :

[Norwegian]

Română :

[Romanian]

Hrvatski :

[Croatian]

STAR MICRONICS CO.,LTD. týmto vyhlasuje, že Wireless Device

spĺňa základné požiadavky a všetky príslušné ustanovenia

Smernice 1999/5/ES.

STAR MICRONICS CO.,LTD. izjavlja, da je ta Wireless Device

v skladu z bistvenimi zahtevami in ostalimi relevantnimi

določili direktive 1999/5/ES.

STAR MICRONICS CO.,LTD. tímto prohlašuje, že tento Wireless

Device je ve shodě se základními požadavky a dalšími

príslušnými ustanoveními smernice 1999/5/ES.

Alulírott, STAR MICRONICS CO.,LTD. nyilatkozom, hogy

]

a Wireless Device megfelel a vonatkozó alapvetõ

követelményeknek és az 1999/5/EK irányelv egyéb

elõírásainak.

това Безжично устройство е в съответствие със

задължителните изисквания и другите приложими

разпоредби на Директива 1999/5/EO.

Niniejszym STAR MICRONICS CO.,LTD. oświadcza, że

Wireless Device jest zgodny z zasadniczymi wymogami

oraz pozostałymi stosownymi postanowieniami Dyrektywy

1999/5/WE.

Hawnhekk, STAR MICRONICS CO.,LTD., jiddikjara li dan

Wireless Device jikkonforma mal-ħtiġijiet essenzjali u ma

provvedimenti oħrajn relevanti li hemm d-Dirrettiva 1999/5/

KE.

Ar šo STAR MICRONICS CO.,LTD. deklarē, ka Wireless Device

atbilst Direktīvas 1999/5/EK būtiskajām prasībām un citiem ar

to saistītajiem noteikumiem.

Šiuo STAR MICRONICS CO.,LTD. deklaruoja, kad šis Wireless

Device atitinka esminius reikalavimus ir kitas 1999/5/EB

Direktyvos nuostatas.

STAR MICRONICS CO.,LTD. erklærer herved at utstyret Wireless

Device er i samsvar med de grunnleggende krav og øvrige

relevante krav i direktiv 1999/5/EF.

Prin prezenta STAR MICRONICS CO., LTD. declară că acest

dispozitiv este conform cu cerinţele esenţiale și alte prevederi

relevante ale directivei 1999/5/CE.

Ovime Star Micronics CO., LTD. Izjavljuje da je bežični uređaj

u skladu s osnovnim zahtjevima i drugim važnim odredbama

direktive 1999/5/EZ.

Italia: l’uso pubblico è soggetto ad autorizzazione generale da parte del rispettivo provider di servizi.

Norge: Dette avsnittet gjelder ikke det geograske området innenfor en radius på 20 km fra sentrum av Ny-Ålesund.

is statement will be applied only for the printers marketed in Europe.

Page 39

y

,

STAR MICRONICS CO.,LTD. Head Office

20-10 Nakayoshida, Suruga-ku, Shizuoka-shi, Shizuoka, 422-8654, Japan

Tel. + 81-54-263-1111 Fax. + 81-54-263-1057

STAR Quality Technical Center

18-12 Nakayoshida, Suruga-ku, Shizuoka-shi, Shizuoka, 422-8001, Japan

Tel. + 81-54-263-1303 Fax. + 81-54-263-6650

Declaration of Conformity

We declare, under our solo r esponsibility, that the product to which this declaration

relates complies with the provisions of following European Direct ives:

1999/5/EC

2014/30/EU

2014/35/EU

2011/65/EU , 2015/863

harmonised standard

RADIO : EN 300 328 V1.9.1:2015

EMC : EN 301 489-1 V1.9.2:2011

EN 301 489-17 V2.2.1:2012

EN 55032:2012 Class B (CISPR 32:ed1.0-2012)

EN 61000-3-2:2014 (IEC 61000-3-2:2014)

EN 61000-3-3:2013 (IEC 61000-3-3:2013)

EN 55024:2010 (CISPR 24:ed2.0-2010)

SAFETY : EN 60950-1:2006 / A2:2013

EN 62311:2008

EN 62479:2010

ENVIRONMENT: EN 50581:2012

Manufacturer’s Name

Manufacturer’s Address

Star Micronics Co.,Ltd.

20-10 Naka

oshida, Suruga-ku, Shizuoka-shi

Shizuoka 422-8654 Japan

Importer’s Name

Importer’s Address

Type of Equipment

Model Name

Ref. Radio Report No.

Ref. EMC Report No.

Star Micronics Europe Ltd.

Star House, Peregrine Business Park, Gomm Road,

High Wycombe, Bucks. HP13 7DL, U.K.

Thermal Printer

TSP800

F161591E1, F161591E2

F111592E1 ,

92-152-EMC , 91-113-EMC , 91-002-16-EMC , 90-050-EMC

Ref. Safety Cert. No.

91-113-Safety ,

73507094 Rev.2,3,4,5 , S161188E1

Ref. Environ. Report No.

Place (Signature)

High Wycombe - U.K.

Date (Full Name)

Year of 1st CE mark (Position)

TSP800-RoHS-02

13-02-2017 David Pearce

'00 Technical Director

Page 40

URL: http://www.star-m.jp/eng

Rev. 1.6

Loading...

Loading...