Page 1

Star

Manufacturing

International Inc.

10 Sunnen Drive

St. Louis, MO 63143

Phone: (314) 781-2777

FAX: (314) 781-3636

COMBINATION

HOT DOG STEAMER

AND

BUNWARMER

35SS STEAMRO, JR.

Installation

and

Operating

Instructions

2M-Y6447 REV. B 4/20/99

1

Page 2

CAUTION

CAUTION

This equipment is designed and sold for

commercial use only by personnel trained and

experienced in its operation and is not sold for

consumer use in and around the home nor for

use directly by the general public in food

service locations. For equipment to be used

by the general public, please contact the

factory.

VOLTAGE

The steamer is equipped for use on the

voltage specified on the nameplate.

CAUTION

DO NOT CONNECT TO ANY OTHER

TYPE OF CURRENT OR THE

MACHINE WILL BE SERIOUSLY

DAMAGED.

INSTALLATION/OPERATION

PROCEDURE

1. Place the unit on a level surface. Pour three

to six quarts of water into the hot dog

(small) compartment. Do not overfill. (The

use of hot water will reduce pre-heat time.)

2. Place hot dogs in small compartment and

buns in the wire rack in the large

compartment. Arrange the hot dogs and

buns so that there is free circulation of

steam.

3. Turn the switch to "on" position, and set the

thermostat control on "high" until steam is

generated.

4. For normal operation set the thermostat

control in the center of the range between

"high" and "lo".

5. To control the amount of steam in the bun

compartment, use the adjustable

humidity control lever located in the bun

compartment under the center cover.

6. Keep the lids closed when not serving.

7. Add water as it becomes necessary to

maintain the water level. (Add hot water

for best results.)

DO NOT ALLOW THE UNIT TO BOIL DRY.

ADD WATER WHEN REQUIRED.

AT THE END OF EACH DAY'S

OPERATION:

1. Disconnect the lead-in cord from the outlet.

2. Remove any remaining hot dogs and buns.

3. Drain the water through the drain pipe.

4. Remove the perforated tray from the hot dog

compartment and the wire rack and steam baffle

assembly from the bun compartment. Remove

the bun tray, partition and the glass panels.

Thoroughly clean the entire unit. Stainless steel,

while corrosion resistant, should be cleaned daily

to prevent pitting.

POSSIBLE SOURCES OF TROUBLE AND

SUGGESTED REMEDIES

Evidence of condensation of the outside of the

Steamer. Cool air striking the warm surface of the

steamer may cause moisture to collect. Protect the

unit against cool drafts of air.

Casing of Hot Dogs Burst. Too much steam is being

generated. Move the thermostat control to a lower

setting.

Buns too soggy or too dry. Too much steam or too

little steam will produce this condition. Control the

amount of steam by adjusting the thermostat control

as required. Also by adjusting the humidity control

lever located in the bun compartment under the

center cover.

Some buns are better adapted for steaming than

others, with some experimentation you will find the

one best suited to your needs.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative or a

local service company for service or required

maintenance.

PART NO. 2M-Y6447 REV. B 4/30/99

2

Page 3

Page 4

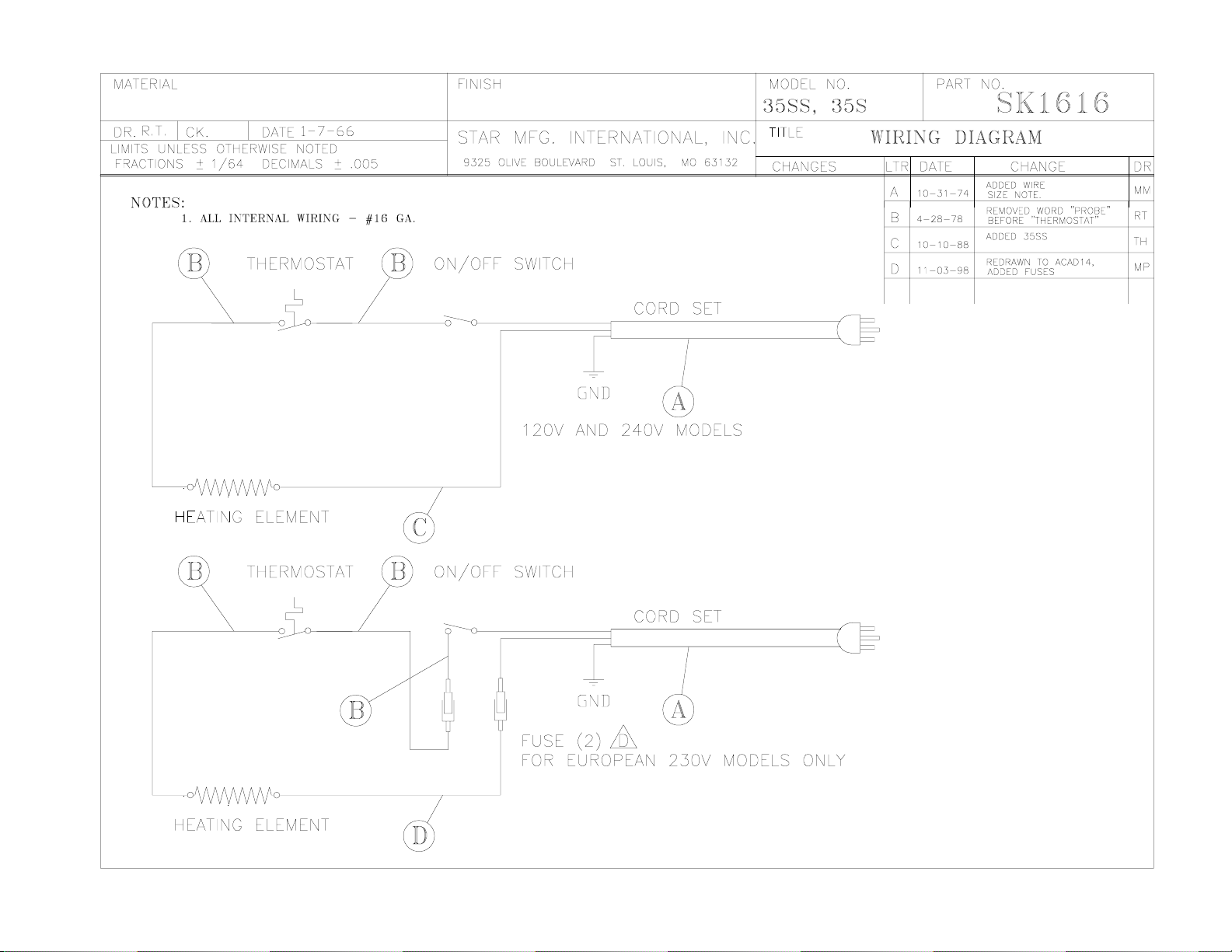

STAR MANUFACTURING INTERNATIONAL, INC.

SK1307

REV. B 05-21-03

HOT DOG STEAMER

35SSC

1

3

2

5

6

8

7

9

10

11

12

13

17

14

15

24

25

18

19

20

22

23

27

16

21

26

30

29

28

4

hot dogs

delicious

Page 5

PARTS LIST January 26, 2012, Rev B

(2C-1493 = Screw)

Z6694

Z0872

3

2

A3

A3

MODEL

35SS Jr. Hot Dog Steamer & Bunwarmer

(#35179415 & UP)

Fig No. Part No Qty Description Application

1 2R-Z0872 2 KNOB

2 A3-35319 2 END LID ASSEMBLY (INCLUDES KNOB)

3 A3-Y6558 1 COVER - CENTER

4 A3-Z6694 1 BUN BASKET 35SSC

5 A3-35312 1 HUMIDITY CONTROL ASSEMBLY

6 A3-Y6388 1 TRAY - BUN

7 A3-Y6384 1 PARTITION

8 A3-Y6383 1 TRAY - HOT DOG

9

10 2I-Y6404 2 O’RING (ELEMENT)

11 2T-Y6369 1 THERMOSTAT

12 2R-Y6353 1 KNOB - THERMOSTAT

13 2E-Y6144 1 SWITCH

14 A3-35219 1 CAP AND CHAIN ASSY (GASKET INCLUDED)

15 2I-Z13053 1 GASKET - CAP AND CHAIN

16

17 2K-7889 1 BUSHING - CORD

18 2A-Y3405 4 FOOT (2P-Y3404 = Plug, 2C-8317 = Screw)

19

20 PS-35311 1 BODY ASSEMBLY

21

22 A3-Y6391 2 RAIL - BASE

23 A3-Y6395 1 RAIL - BASE

24 2M-Y6402 1 COVER PLATE

25 2C-Y6403 1 JAM NUT

26 2M-Y6512 1 SIGN - HOT DOGS FRONT (2”)

27 2M-Y6513 1 SIGN - HOT DOGS REAR (CUSTOMER) (3”)

28 2E-Z2145 2 FUSEHOLDER

30

NI

2N-Y6366

2N-Z2796 ELEMENT 1000W 240V

A3-35321

A3-35314 CORD ASSY 120V

A3-35313 CORD ASSY 240V

2Q-Y6393 2 GLASS - PLATE (8 1/4” x 17 3/4” x 1/8” DBL STRENGTH)

REPLACEMENT GLASS MUST BE PURCHASED LOCALLY

A3-35316

A3-35322 CONTROL PANEL ASSEMBLY ON 230V CE MODEL

2E-Z2148 2 FUSE 5A 250V

PS-35225 HOT DOG JUICE TRAY W/RACK (OPTIONAL)

PS-35217 HOT DOG JUICE TRAY ONLY (OPTIONAL)

PS-35218 HOT DOG JUICE RACK ONLY (OPTIONAL)

1

1

1

ELEMENT 1000W 120V

CORD ASSY 230V CE

CONTROL PANEL ASSEMBLY ON 120V & 240V MODEL

Older units utilize A2-178023,

drawing follows

230V CE Models (Not Shown)29 2E-Z2146 2 FUSEHOLDER

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 1

INCLUDE MODEL AND SERIAL NUMBER OF 1

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 6

8A-35T (HDJT, Hot Dog Juice Tray)

contains both Rack & Pan

A3-35109, Pan

Assembly

A3-35218, Rack

Assembly

Page 7

Page 8

Page 9

Loading...

Loading...