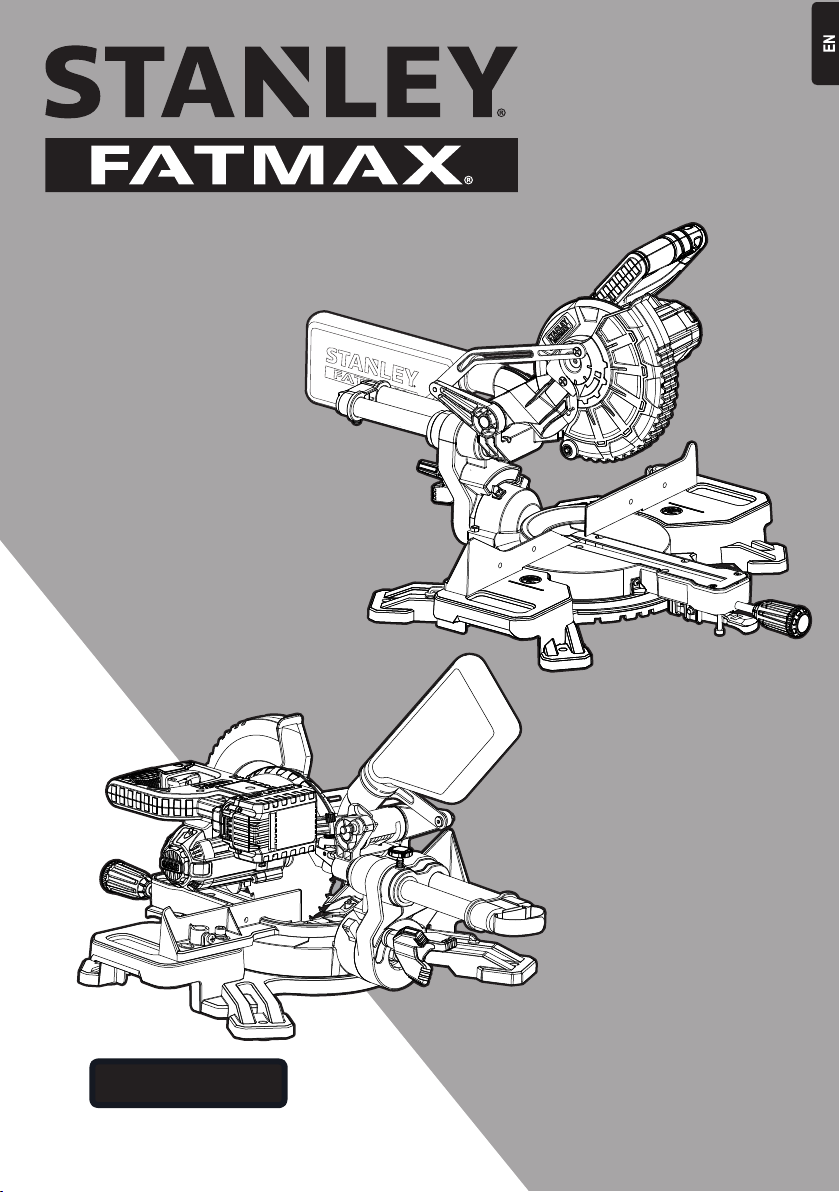

Page 1

www.stanley.eu

FMCS701

Page 2

16

15

20

2

1 17 4 14

18

10

19

12

3

13

11

11

13

3

4 1514

16

10

10

7

3

2

8 9

3

6

5

Page 3

10

10

A B

15

21

21a

15 22

Charging

Fully Charged

Hot/Cold Pack Delay

Bad Battery

C D

22

E F

15

15a

20

3

Page 4

24

25

28

26

27

G H

26

30

29

32

31

7

68

I J

11a17

12

K

4

5

L

Page 5

35

14

37

19

M

O1 O2

N

O3 O4

5

Page 6

37

19

P

Q1

Q2 R1

A

B

R2

6

R3

Page 7

36

11

S T1

36

11

T2

U1

U2 V

7

Page 8

English (Original instructions)

ENGLISH

(Original instructions)

14

38

13

13a

W

Intended use

Your Stanley Fat Max FMCS701 sliding compound mitre saw

has been designed for sawing wood, plastic and nonferrous

metal only. This tool is intended for professional and private,

non professional users.

Safety instructions

General power tool safety warnings

Warning! Read all safety warnings, instruc-

@

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below refers

to your mains operated (corded) power tool or battery operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

b. Do not operate power tools in explosive atmospheres,

c. Keep children and bystanders away while operating a

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify

tions, illustrations and specications

provided with power tool. Failure to follow

the warnings and instructions listed below may

result in electric shock, re and/or serious injury.

areas invite accidents.

such as in the presence of ammable liquids, gases

or dust. Power tools create sparks which may ignite the

dust or fumes.

power tool. Distractions can cause you to lose control.

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodied plugs

and matching outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the inuence

of drugs, alcohol or medication. A moment of inattention

while operating power tools may result in serious personal

injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or

energising power tools that have the switch on invites

accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

8

Page 9

(Original instructions)

ENGLISH

h. Do not let familiarity gained from frequent use of tools

allow you to become complacent and ignore tool

safety principles. A careless action can cause severe

injury within a fraction of a second.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e. Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the

power tools operation. If damaged, have the power

tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

h. Keep handles and grasping surfaces dry, clean and

free from oil and grease. Slippery handles and greasy

surfaces do not allow for safe handling and control of the

tool in unexpected situations.

5. Battery tool use and care

a. Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one type of

battery pack may create a risk of re when used with

another battery pack.

b. Use power tools only with specically designated

battery packs. Use of any other battery packs may create

a risk of injury and re.

c. When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys,

nails, screws, or other small metal objects, that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause burns

or a re.

d. Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally

occurs, ush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from the

battery may cause irritation or burns.

e. Do not use a battery pack or tool that is damaged or

modied. Damaged or modied batteries may exhibit

unpredictable behaviour resulting in re, explosion or risk

of injury.

f. Do not expose a battery pack or tool to re or

excessive temperature. Exposure to re or temperature

above 130 ºC may cause explosion.

g. Follow all charging instructions and do not charge the

battery pack or tool outside the temperature range

specied in the instructions. Charging improperly or at

temperatures outside the specied range may damage the

battery and increase the risk of re.

6. Service

a. Have your power tool serviced by a qualied repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

b. Never service damaged battery packs. Service of

battery packs should only be performed by the

manufacturer or authorised service providers.

Safety instructions for mitre saws

u Mitre saws are intended to cut wood or wood-like

products, they cannot be used with abrasive cut-off

wheels for cutting ferrous material such as bars, rods,

studs, etc. Abrasive dust causes moving parts such as

the lower guard to jam. Spartks from abrasive cutting will

burn the lower guard, the kerf insert and other plastic

parts.

u Use clamps to support the workpiece whenever

possible. If supporting the workpiece by hand, you

must always keep your hand at least 100 mm from

either side of the saw blade. Do not use this saw to

cut pieces that are too small to be securely clamped

or held by hand. If your hand is placed too close to the

saw blade, there is an increased risk of injury from blade

contact.

u The workpiece must be stationary and clamped or

held against both the fence and the table. Do not feed

the workpiece into the blade or cut “freehand” in any

way. Unrestrained or moving workpieces could be thrown

at high speeds, causing injury.

u Push the saw through the workpiece. Do not pull the

saw through the workpiece. To make a cut, raise the

saw head and pull it out over the workpiece without

cutting, start the motor, press the saw head down and

9

Page 10

ENGLISH

(Original instructions)

push the saw through the workpiece. Cutting on the

pull stroke is likely to cause the saw blade to climb on top

of the workpiece and violently throw the blade assembly

towards the operator.

u Never cross your hand over the intended line of cut-

ting either in front or behind the saw blade. Supporting

the workpiece “cross handed” i.e. holding the workpiece to

the right of the saw blade with your left hand or vice versa

is very dangerous.

u Do not reach behind the fence with either hand closer

than 100 mm from either side of the saw blade, to

remove wood scraps, or for any other reason while

the blade is spinning. The proximity of the spinning saw

blade to your hand may not be obvious and you may be

seriously injured.

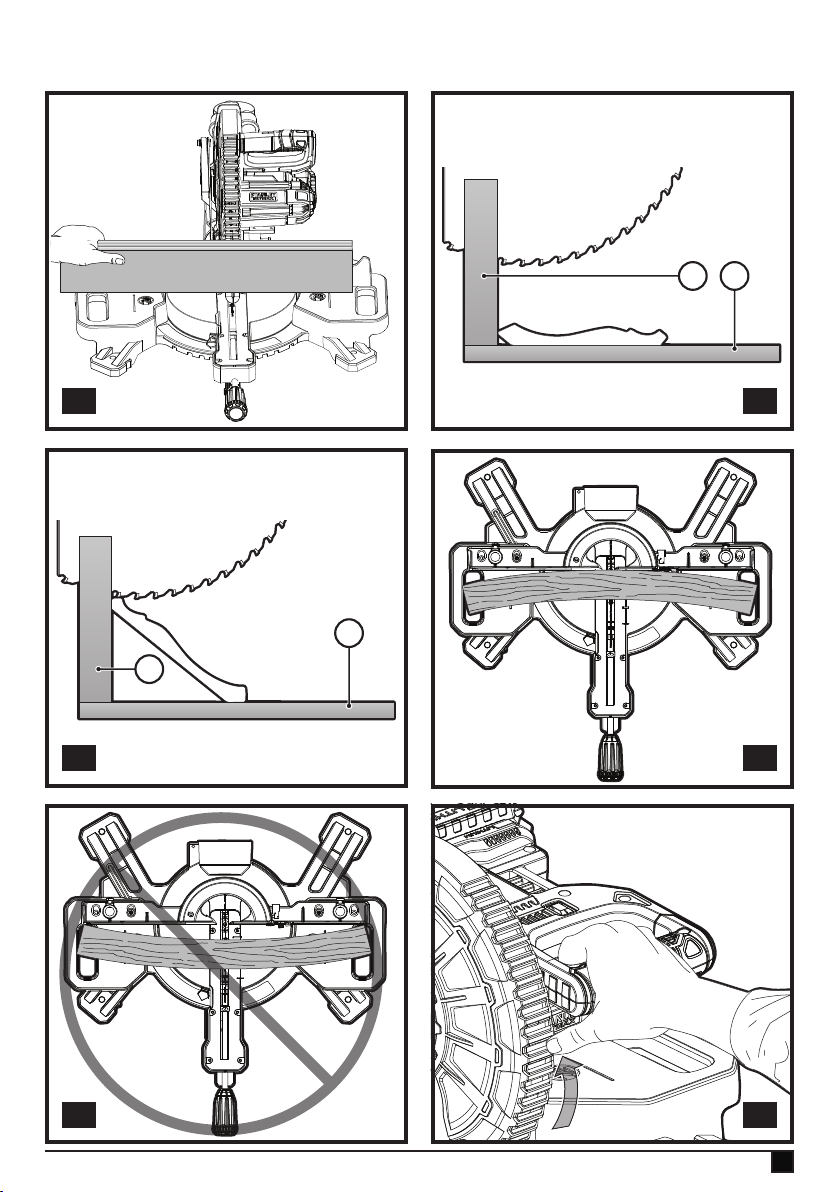

u Inspect your workpiece before cutting. If the work-

piece is bowed or warped, clamp it with the outside

bowed face toward the fence. Always make certain

that there is no gap between the workpiece, fence

and table along the line of the cut. Bent or warped

workpieces can twist or shift and may cause binding on

the spinning saw blade while cutting. There should be no

nails or foreign objects in the workpiece.

u Do not use the saw until the table is clear of all tools,

wood scraps, etc., except for the workpiece. Small de-

bris or loose pieces of wood or other objects that contact

the revolving blade can be thrown with high speed.

u Cut only one workpiece at a time. Stacked multiple

workpieces cannot be adequately clamped or braced and

may bind on the blade or shift during cutting.

u Ensure the mitre saw is mounted or placed on a level,

rm work surface before use. A level and rm work sur-

face reduces the risk of the mitre saw becoming unstable.

u Plan your work. Every time you change the bevel or

mitre angle setting, make sure the adjustable fence is

set correctly to support the workpiece and will not

interfere with the blade or the guarding system. With-

out turning the tool “ON” and with no workpiece on the

table, move the saw blade through a complete simulated

cut to assure there will be no interference or danger of

cutting the fence.

u Provide adequate support such as table extensions,

saw horses, etc. for a workpiece that is wider or

longer than the table top. Workpieces longer or wider

than the mitre saw table can tip if not securely supported.

If the cut-off piece or workpiece tips, it can lift the lower

guard or be thrown by the spinning blade.

u Do not use another person as a substitute for a table

extension or as additional support. Unstable support

for the workpiece can cause the blade to bind or the

workpiece to shift during the cutting operation pulling you

and the helper into the spinning blade.

u The cut-off piece must not be jammed or pressed by

any means against the spinning saw blade. If conned,

i.e. using length stops, the cut-off piece could get wedged

against the blade and thrown violently.

u Always use a clamp or a xture designed to properly

support round material such as rods or tubing. Rods

have a tendency to roll while being cut, causing the blade

to “bite” and pull the work with your hand into the blade.

u Let the blade reach full speed before contacting the

workpiece. This will reduce the risk of the workpiece

being thrown.

u If the workpiece or blade becomes jammed, turn the

mitre saw off. Wait for all moving parts to stop and

disconnect the plug from the power source and/or remove the battery pack. Then work to free the jammed

material. Continued sawing with a jammed workpiece

could cause loss of control or damage to the mitre saw.

u After nishing the cut, release the switch, hold the

saw head down and wait for the blade to stop before

removing the cut-off piece. Reaching with your hand

near the coasting blade is dangerous.

Additional safety instructions for mitre saws

u The intended use is described in this instruction manual.

The use of any accessory or attachment or performance

of any operation with this tool other than those recommended in this instruction manual may present a risk of

personal injury and/or damage to property.

u Do not use cracked/bent/damaged/deformed saw blades.

u Replace the kerf plate when worn.

u Do not use blades of larger or smaller diameter than

recommended. For the proper blade rating refer to the

technical data. Use only the blades specied in this

manual, complying with EN 847-1.

u Do not use High Speed Steel (HSS) saw blades.

Warning! Contact with or inhalation of dusts

@

u Do not work with material containing asbestos. Asbestos

u Wear gloves when handling saw blades and rough

u Wear hearing protection to reduce the risk of induced

u Consider using specially designed noise-reduction blades.

u Wear eye protection to reduce the risk of personal injury.

u Use the dust bag provided when sawing wood.

arising from sawing applications may endanger

the health of the operator and possible bystand-

ers. Wear a dust mask specically designed for

protection against dust and fumes and ensure

that persons within or entering the work area are

also protected.

is considered to be carcinogenic.

material (saw blades should be carried in a holder when

practicable).

hearing loss.

10

Page 11

(Original instructions)

ENGLISH

u Hold power tool by insulated gripping surfaces when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting ac-

cessory contacting a "live" wire may make exposed metal

parts of the power tool "live" and could give the operator

an electric shock

u Select the correct blade for the material to be cut.

u Do not operate the machine without the guard in position.

Do not operate the machine if the guard does not function

or is not maintained properly.

u Ensure that the arm is securely xed when performing

bevel cuts.

u Before each cut ensure that the machine is stable.

u Keep handles dry, clean and free from oil and grease.

u Keep the surrounding area of the machine well maintained

and free of loose materials, e.g. chips and off-cuts.

u Ensure the machine and the work area are provided with

adequate general or localised lighting.

u Do not allow untrained people to operate this machine.

u Ensure that the blade is mounted correctly before use.

Make sure that the blade rotates in the correct direction.

Keep the blade sharp. Follow instruction for lubricating

and changing accessories.

u Ensure the speed marked on the saw blade is at least

equal to the speed marked on the saw.

u Ensure that any spacers and spindle rings used are suit-

able for the purpose as stated by Stanley Fat Max.

u Repairs to the cut line guidance system should be carried

out by authorised repair agents or Stanley Fat Max service

staff.

u Remove the battery from the machine before carrying out

any maintenance or when changing the blade.

u Never perform any cleaning, maintenance, removal of any

off-cuts or other parts of the work piece form the cutting

area when the machine is running and the saw head is not

in the rest position.

u When possible, always mount the machine to a bench.

u Make sure all locking knobs and handles are tight before

starting any operation.

u Never use your saw without the table insert.

u Never attempt to stop the machine in motion rapidly by

jamming a tool or other means against the blade; serious

accidents can be caused unintentionally in this way.

u Before using or tting any accessory consult the instruc-

tion manual. The improper use of an accessory can cause

damage.

u Raise the blade from the table insert in the work piece

prior to releasing the on/of switch.

u Do not wedge anything against the fan to hold the motor

shaft.

u The blade guard on your saw will automatically raise when

the arm is brought down; it will lower over the blade when

the arm is raised. The guard can be raised by hand when

installing or removing saw blades or for inspection of the

saw. Never raise the blade guard manually unless the

machine is switched off.

u Check periodically that the motor air slots are clean and

free of chips.

u Never make the warning signs on the power tool unrecog-

nisable.

u Never stand on the power tool. Serious injuries could

occur when the power tool tips over or when coming in

contact with the saw blade.

u Do not take hold of the saw blade after working before it

has cooled. The saw blade becomes very hot while working.

u To avoid injury from materials being thrown, remove the

battery from saw to avoid accidental starting, and then

remove small materials.

u Before use and after any maintenance the blade guard

must be checked to ensure proper function. This test must

be performed with the saw switched off and the battery

removed. The arm must be raised and lowered to ensure

the guard covers the blade and the blade does not contact

the guard. If the guard fails to operate correctly, have your

power tool serviced by a qualied repair agent. Call Stanley Fat Max customer services for you nearest service

agent.

u This mitre saw has been designed for sawing wood,

plastic and nonferrous metal only. Do not use the saw

to cut other materials than those recommended by the

manufacturer.

u Do not take hold of the saw blade after working before it

has cooled. The saw blade becomes very hot while work-

ing.

Warning! Cutting plastics, sap coated wood,

@

and other materials may cause melted material

to accumulate on the blade tips and the body of

the saw blade, increasing the risk of the blade

overheating and binding while cutting.

Safety of others

u This charger can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning use of the appliance in a safe way and understand the

hazards involved.

u Children shall not play with the appliance. Cleaning and

user maintenance shall not be made by children without

supervision.

Residual risks

The following risks are inherent to the use of saws:

Even with the application of the relevant safety regulations

11

Page 12

ENGLISH

(Original instructions)

and the implementation of safety devices, certain residual

risks can not be avoided. These include:

u Injuries caused by touching any rotating/moving parts.

u Impairment of hearing.

u Risk of accidents caused by the uncovered parts of the

rotating saw blade.

u Risk of injury when changing any parts, blades or acces-

sories.

u Risk of squeezing ngers when opening the guards.

u Health hazards caused by breathing dust developed when

sawing wood, especially oak, beech and MDF.

u Injuries caused by prolonged use of a tool. When using

any tool for prolonged periods ensure you take regular

breaks.

Noise

The declared noise emission values have beenmeasured in

accordance with a standard test method and may be used for

comparing one tool with another.

The declared noise emission values may also be used in a

preliminary assessment of exposure.

Warning! The noise emissions during actual use of the

power tool can differ from the declared values depending

on the ways in which the tool is used especially what kind of

workpiece is processed.

Warning! Always wear proper personal hearing protection. Under some conditions and duration of use, noise from

this product may contribute to hearing loss. Be aware of the

following factors inuencing exposure to noise:

u Use saw blades designed to reduce the emitted noise,

u Use only well sharpened saw blades, and

u Use specically designed noise-reduction saw blades.

Labels on tool

The following pictograms along with the date code are shown

on the tool:

Warning! To reduce the risk of injury, the user

must read the instruction manual.

Wear safety glasses or goggles

Wear ear protection

Wear a dust mask

This product is not to be used by children

under 16

Keep hands away from blade

12

No Hands Zone - Keep ngers and arms away

from rotational saw blades

Wear gloves when handling saw blades

Do not stare at operating lamp

Additional safety instructions for batteries and

chargers

Warning! The appliance is only to be used with the power

supply unit provided with the appliance.

Note: The tool's operating temperature range is recommended at 4 °C to 40 °C.

Batteries

u Never attempt to open for any reason.

u Do not expose the battery to water.

u Do not store in locations where the temperature may

exceed 40 °C.

u Charge only at ambient temperatures between 10 °C and

40 °C.

u Charge only using the charger provided with the tool.

u When disposing of batteries, follow the instructions given

in the section "Protecting the environment".

Do not attempt to charge damaged batteries.

p

Chargers

u Use your Stanley FatMax charger only to charge the bat-

tery in the tool with which it was supplied. Other batteries

could burst, causing personal injury and damage.

u Never attempt to charge non-rechargeable batteries.

u Have defective cords replaced immediately.

u Do not expose the charger to water.

u Do not open the charger.

u Do not probe the charger.

$

+

Electrical safety

#

u If the supply cord is damaged, it must be replaced by the

The charger is intended for indoor use only.

Read the instruction manual before use.

Your charger is double insulated; therefore no

earth wire is required. Always check that the

mains voltage corresponds to the voltage on

the rating plate. Never attempt to replace the

charger unit with a regular mains plug.

manufacturer or an authorised Stanley FatMax Service

Centre in order to avoid a hazard.

Page 13

(Original instructions)

ENGLISH

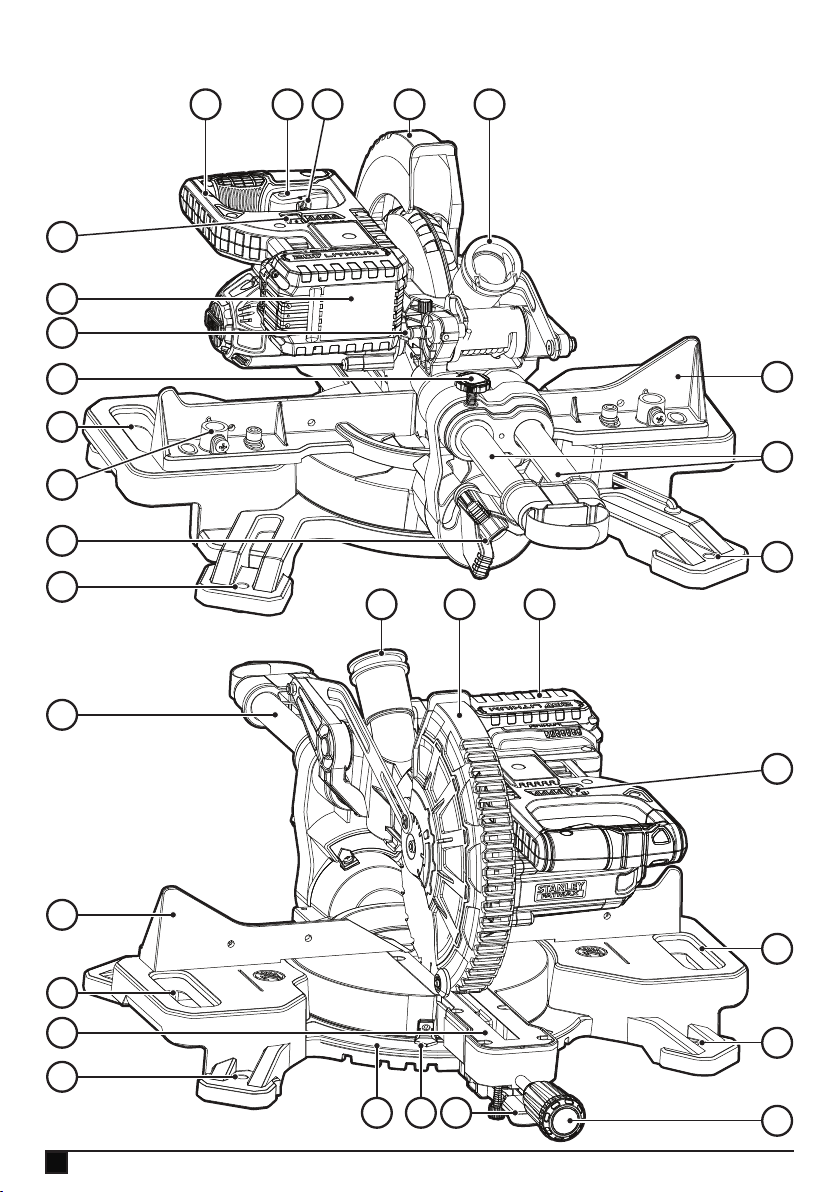

Features

This tool includes some or all of the following features.

1. Trigger switch

2. Operating handle

3. Mounting holes

4. Lower Guard

5. Mitre locking knob

6. Mitre latch button

7. Kerf plate

8. Mitre scale

9. Mitre scale indicator

10. Carry grips

11. Fence

12. Bevel lock knob

13. Rails

13a.Velcro strap

14. Dust port

15. Battery pack

16. Work light switch

17. Lock off lever

18. Rail lock screw

19. Clamp mounting hole

20. Lock down pin

Assembly (Fig. A)

Your mitre saw is part assembled in the carton.

uOpen the box and lift the saw out by using the carry grips

(10) in the base of the saw (Fig. A).

u Place the saw on a smooth, at surface such as a work-

bench or strong table.

u Examine Assembly diagram on page 2 of this manual to

become familiar with the saw and its various parts. The

section on adjustments will refer to these terms and you

must know what and where the parts are.

u The mitre locking knob (5) is not assembled for shipping.

Remove the mitre locking knob (5) from the packaging

and screw onto the saw, see gure G and J for position.

u Your saw has a built-in dust port (14) that allows either

the supplied, but not assembled, dust bag (35) or shop

vacuum system to be connected (Fig. N).

Kerf plate (Fig. J)

The kerf plate (7) is mounted to the table by 6 screws. The

kerf plate (7) height is not adjustable.

Note: If the kerf plate (7) is worn, damaged or needs to be

replaced, repairs should be carried out by authorised repair

agents or Stanley Fat Max service staff.

Lock down pin (Fig. F)

Warning! The lock down pin should be used ONLY when

carrying or storing the saw. NEVER use the lock down pin for

any cutting operation.

Note: To lift, carry and support the mitre saw during transport

use the two carrying handles (10) located on both sides of the

mitre saw base (Fig. A).

To lock the saw head in the down position, push the saw head

down, push the lock down pin (20) in and release the saw

head. This will hold the saw head safely down for transporting

the saw from place to place. To release, press the saw head

down and pull the pin out.

Warning! Always be sure that the tool is switched off and the

battery is removed from the tool before adjusting or checking

the tools function.

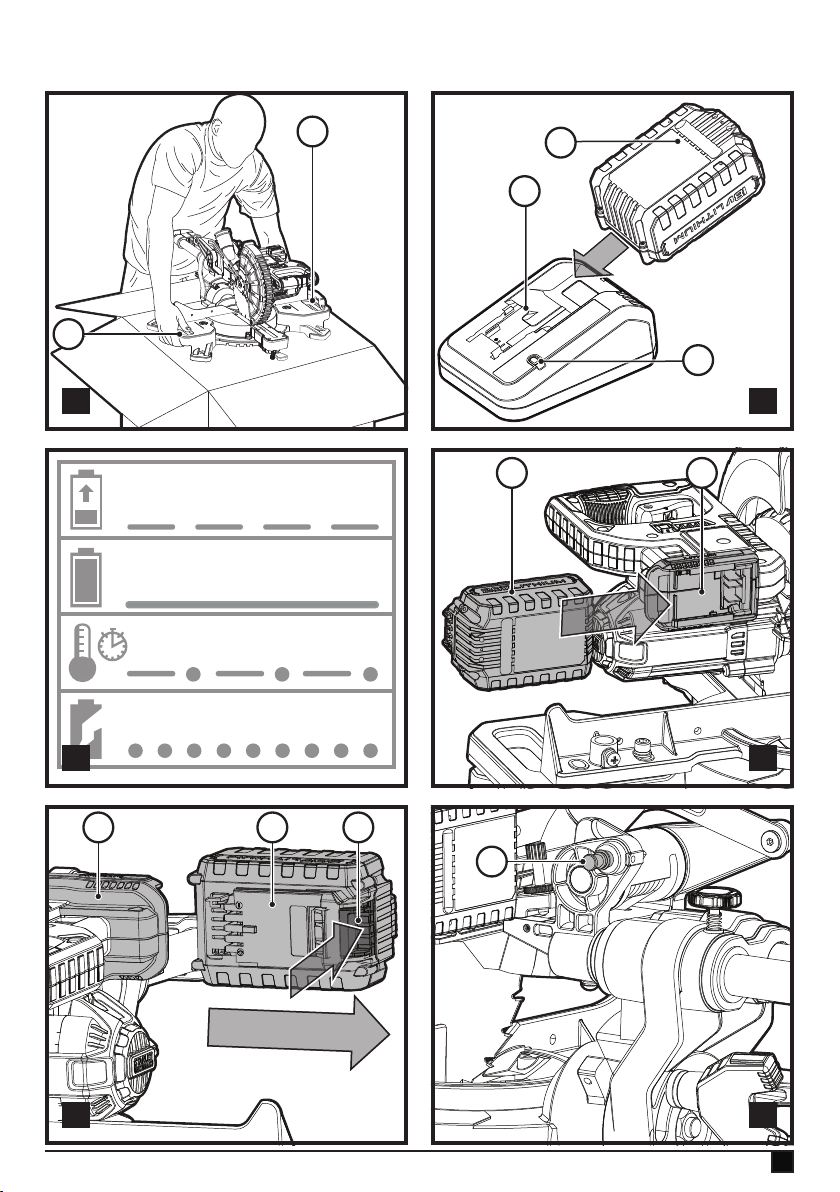

Charging a battery (g. B)

Stanley FatMax chargers are designed to charge Stanley

FatMax battery packs.

u Plug the charger (21) into an appropriate outlet before

inserting a battery pack (15).

u Insert the battery pack (15) into the charger, making sure

the battery pack is fully seated in the battery slots

(Figure B).

The LED (21a) will ash indicating that the

battery is being charged.

The completion of charge is indicated by the

LED remaining on continuously. The pack is

fully charged and may be used at this time or

left in the charger.

u Recharge discharged batteries as soon as possible after

use or battery life may be greatly diminished.

u For longest battery life, do not discharge batteries fully.

It is recommended that the batteries be recharged after

each use.

Charger diagnostics (g. C)

This charger is designed to detect certain problems that can

arise with the battery packs or the power source. Problems

are indicated by one LED ashing in different patterns.

Bad battery

The charger can detect a weak or damaged

battery. The LED ashes in the pattern indi-

cated on the label. If you see this bad battery

blink pattern, do not continue to charge the battery. Return it

to a service centre or a collection site for recycling.

Hot/cold pack delay

When the charger detects a battery that

is excessively hot or excessively cold, it

automatically starts a Hot/Cold Pack Delay,

suspending charging until the battery has normalized. After

this happens, the charger automatically switches to the Pack

13

Page 14

ENGLISH

(Original instructions)

Charging mode. This feature ensures maximum battery life.

The light ashes in the pattern indicated on the label.

Leaving the battery in the charger

The charger and battery pack can be left connected with the

LED glowing indenitely. The charger will keep the battery

pack fresh and fully charged.

This charger features an automatic tune-up mode which

equals or balances the individual cells in the battery pack to

allow it to function at peak capacity.

Battery packs should be tuned up weekly or whenever the battery no longer delivers the same amount of work. To use the

automatic tune-up mode, place the battery pack in the charger

and leave it for at least 8 hours.

Important charging notes

u Longest life and best performance can be obtained if

the battery pack is charged when the air temperature is

between 18 °C – 24 °C. DO NOT charge the battery pack

in an air temperature below +4.5 °C, or above +40 °C.

This is important and will prevent serious damage to the

battery pack.

u The charger and battery pack may become warm to the

touch while charging. This is a normal condition, and does

not indicate a problem.

u To facilitate the cooling of the battery pack after use, avoid

placing the charger or battery pack in a warm environment

such as in a metal shed or an un-insulated trailer.

u If the battery pack does not charge properly:

u Check operation of receptacle by plugging in a lamp or

other appliance;

u Check to see if receptacle is connected to a light switch

which turns power off when you turn out the lights;

u Move the charger and battery pack to a location where

the surrounding air temperature is approximately 18 °C

– 24 °C;

u If charging problems persist, take the tool, battery pack

and charger to your local service centre.

u The battery pack should be recharged when it fails to

produce sufcient power on jobs which were easily done

previously. DO NOT CONTINUE to use under these

conditions. Follow the charging procedure. You may also

charge a partially used pack whenever you desire with no

adverse effect on the battery pack.

u Foreign materials of a conductive nature such as, but

not limited to, grinding dust, metal chips, steel wool,

aluminium foil, or any buildup of metallic particles should

be kept away from charger cavities. Unplug the charger

before attempting to clean.

u Do not freeze or immerse the charger in water or any

other liquid.

Fitting and removing the battery (g. D, E)

u To t the battery (15), line it up with the receptacle on the

tool (22). Slide the battery into the receptacle and push

until the battery snaps into place.

u To remove the battery, push the battery release button

(15a) while at the same time pulling the battery out of the

receptacle as shown in gure E.

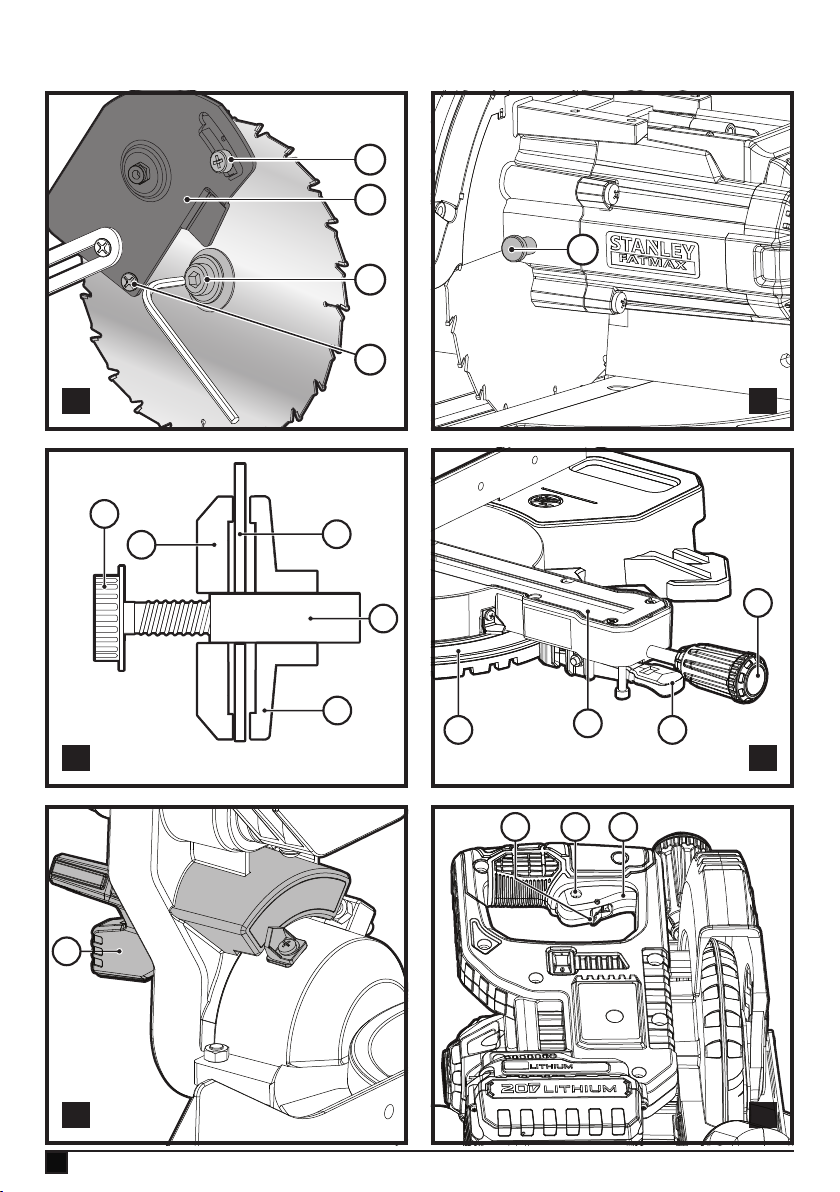

Changing or Installing a New Saw Blade

(Fig. G, H, I)

Warning! To reduce the risk of serious personal injury, turn

tool off and remove the battery pack before transporting,

making any adjustments or removing/installing attachments or

accessories. An accidental start-up can cause injury.

Removing the Blade

u Remove battery pack (15) from the saw.

u Raise the arm to the upper position and raise the lower

guard (4) as far as possible.

u Loosen, but do not remove the guard bracket front screw

(24) until the bracket (25) can be raised far enough to

access the blade screw (26). Lower guard will remain

raised due to the position of the guard bracket screw.

u Depress the spindle lock button (28) while carefully rotat-

ing the saw blade (29) by hand until the lock engages.

u Keeping the button depressed, use the other hand and the

hex side of the wrench provided to loosen the blade screw

(26). (Turn clockwise, left-hand threads.)

u Remove the blade screw (26) using the hex side of the

wrench provided, the outer clamp washer (30) and blade

(29). The inner clamp washer (31) may be left on the

spindle (32).

Installing a Blade

u Remove battery pack (15) from the saw.

u With the arm raised, the lower guard (4) held open and

the guard bracket (25) raised, place the blade (29) on the

spindle (32) and against the inner blade clamp (31) with

the teeth on the blade pointing in the direction of rotation

as marked on the saw.

u Assemble the outer clamp washer (30) onto the spindle

(32).

u Install the blade screw (26) and, engaging the spindle lock

(28), tighten the screw (26) rmly with wrench provided

(turn counterclockwise, left-hand threads).

u Return the guard bracket (25) to its original full down posi-

tion and rmly tighten the guard bracket screw (24) to hold

bracket in place.

Cut line guidance system

Warning! Do not stare into work light. Serious eye injury could

result.

14

Page 15

(Original instructions)

ENGLISH

Note: The battery must be charged and connected to the

mitre saw.

The cut line guidance system can only be turned On or Off by

the work light switch (16).

To cut through an existing pencil line on a piece of wood, turn

on the cut line guidance system using the work light switch

(16) (not with the main trigger), then pull down on the operating handle (2) to bring the saw blade close to the wood.

The shadow of the blade will appear on the wood. This

shadow line represents the material that the blade will remove

when performing a cut.

To correctly locate your cut to the pencil line, align the pencil

line with the edge of the blade’s shadow. Keep in mind that

you may have to adjust the mitre or bevel angles in order to

match the pencil line exactly.

Your saw is equipped with a battery fault feature. The work

light begins to ash when the battery is near the end of its

useful charge, or when the battery is too hot. Charge the battery prior to continuing cutting applications. Refer to charging

procedure under Important safety instructions for battery

packs for battery charging instructions.

Mitre control (Fig. J)

The mitre lock knob (5) and mitre latch button (6) allow you

to mitre your saw to 47° right and 47° left. The mitre latch will

automatically locate at 0˚, 15˚, 22.5˚, 31.6˚ and 45˚ both left

and right. To mitre the saw, unlock the mitre lock mechanism

by turning the mitre lock knob (5) anti clockwise to unlock and

clockwise to lock. Pull the mitre latch button (6) up, and set

the mitre angle desired on the mitre scale (8). Lock the mitre

lock knob (5) by turning clockwise.

Bevel Lock Knob (Fig. K)

The bevel lock allows you to bevel the saw 48° to the left.

To adjust the bevel setting, turn the bevel lock knob (12)

counterclockwise to loosen. To tighten, turn the bevel lock

knob clockwise.

Caution! Pinch hazard. Be sure to tighten bevel lock knob

before adjusting overrides.

Trigger Switch (Fig. L)

To turn the saw on, push the lock-off lever (17) to the left,

then depress the trigger switch (1). The saw will run while

the switch is depressed. Allow the blade to spin up to full

operating speed before making the cut. To turn the saw off,

release the switch. Allow the blade to stop before raising the

saw head. There is no provision for locking the switch on. A

hole (1a) is provided in the trigger for insertion of a padlock to

lock the switch off.

Your saw is not equipped with an automatic electric blade

brake, but the saw blade should stop within 5 seconds of trig-

ger release. This is not adjustable. If the stop time repeatedly

exceeds 5 seconds, have the tool serviced by an authorised

Stanley FatMax service centre.

Always be sure the blade has stopped before removing it from

the kerf.

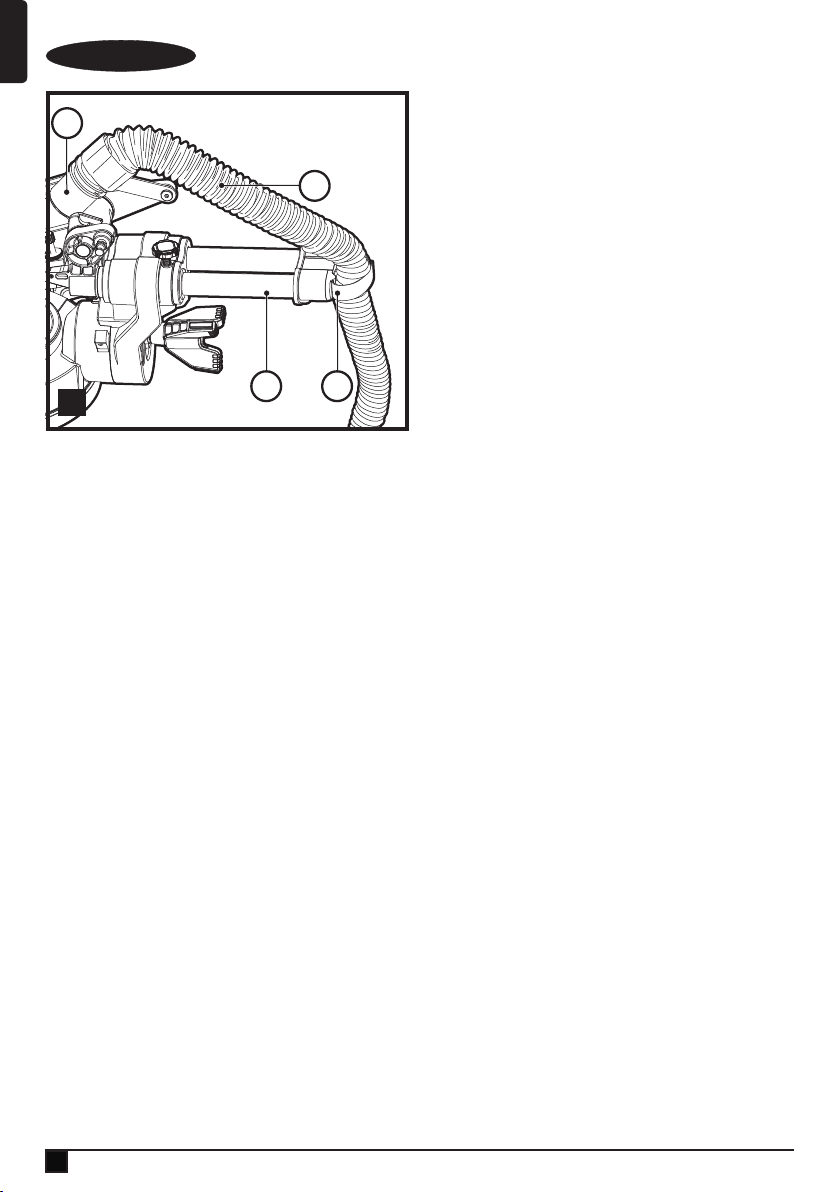

Dust Extraction (Fig. M)

Warning! To reduce the risk of serious personal injury, turn

tool off and remove the battery pack before transporting,

making any adjustments or removing/installing attachments or

accessories. An accidental start-up can cause injury.

Your saw has a built-in dust port (14) that allows either the

supplied dust bag (35) or a shop vacuum system to be

connected.

To attach the dust bag

u Fit the dust bag (35) to the dust port (14) as shown in

Figure M.

u A vacuum tube (38 - not provided) can be tted to the dust

port (14) rather than the dust bag (35). This can be done

by tting your vacuum tube (38) in place of the dust bag

(35), see gure M.

u Use the velcro strap (13a) to hold your vacuum tube (38)

clear from the sliding rails (13) whilst operating the saw.

Note: The velcro strap (13a) is not a carrying handle and

should not be used to move or transport the saw.

To empty the dust bag

uRemove dust bag (35) from the saw and gently shake or

tap the dust bag to empty.

u Reattach the dust bag back onto the dust port (14).

You may notice that all the dust will not come free from the

bag. This will not affect cutting performance but will reduce

the saw's dust collection efciency. To restore your saw's dust

collection efciency, depress the spring inside the dust bag

when you are emptying it and tap it on the side of the trash

can or dust receptacle.

Warning! Never operate this saw unless the dust bag is in

place. Wood dust may create a breathing hazard.

Cutting with your saw

If the slide feature is not used, ensure the saw head is

pushed back as far as possible and the rail lock screw (18) is

tightened. This will prevent the saw from sliding along its rails

as the workpiece is engaged.

Note: DO NOT CUT FERROUS METALS OR MASONRY

WITH THIS SAW (NON FERROUS METALS CAN BE CUT

BY THIS SAW. Do not use any abrasive blades.

Note: Refer to guard actuation and visibility in the adjustments

section for important information about the lower guard before

cutting.

15

Page 16

ENGLISH

(Original instructions)

Crosscuts (g. N)

A crosscut is made by cutting wood across the grain at any

angle. A straight crosscut is made with the mitre arm at the

zero degree position. Set and lock the mitre arm at zero, hold

the wood rmly on the table and against the fence. With the

rail lock screw (18) tightened, turn on the saw by squeezing

the trigger switch (1).

When the saw comes up to speed (about 1 second) lower

the arm smoothly and slowly to cut through the wood. Let the

blade come to a full stop before raising arm.

When cutting anything larger than a 2 x 4 (51 x 102), use an

out-down-back motion with the rail lock screw (18) loosened.

Pull the saw out, toward you, lower the saw head down toward

the work piece, and slowly push the saw back to complete the

cut. Do not allow the saw blade to contact the top of the work

piece while pulling out. The saw may run toward you, possibly

causing personal injury or damage to the work piece.

Warning! Always use a work clamp to maintain control and

reduce the risk of work piece damage and personal injury, if

your hands are required to be within 6" (152 mm) of the blade

during the cut.

Note! The rail lock screw (18) must be loose to allow the saw

to slide along its rails.

Mitre crosscuts are made with the mitre arm at some angle

other than zero.

This angle is often 45º for making corners, but can be set

anywhere from zero to 47º left or 47° right. Make the

cut as described above.

When performing a mitre cut on work pieces wider than a 2

x 6 that are shorter in length, always place the longer side

against the fence (Fig. O).

To cut through an existing pencil line on a piece of wood,

match the angle as close as possible. Cut the wood a little too

long and measure from the pencil line to the cut edge to deter-

mine which direction to adjust the mitre angle and recut. This

will take some practice, but it is a commonly used technique.

Bevel cuts

A bevel cut is a crosscut made with the saw blade leaning at

an angle to the wood. In order to set the bevel, loosen the

bevel lock knob (12), and move the saw to the left as desired.

Once the desired bevel angle has been set, tighten the bevel

lock rmly. Bevel angles can be set from 3º right to 48º left.

Quality of cut

The smoothness of any cut depends on a number of variables.

Things like material being cut, blade type, blade sharpness

and rate of cut all contribute to the quality of the cut. When

smoothest cuts are desired for moulding and other precision

work, a sharp (60 tooth carbide tip) blade and a slower, even

cutting rate will produce the desired results.

16

Ensure that the material does not move or creep while cutting;

clamp it securely in place.

Always let the blade come to a full stop before raising arm. If

small bres of wood still split out at the rear of the work piece,

stick a piece of masking tape on the wood where the cut will

be made. Saw through the tape and carefully remove tape

when nished.

For varied cutting applications, refer to the list of recommend-

ed saw blades for your saw and select the one that best ts

your needs. Refer to Saw Blades under Optional Accessories.

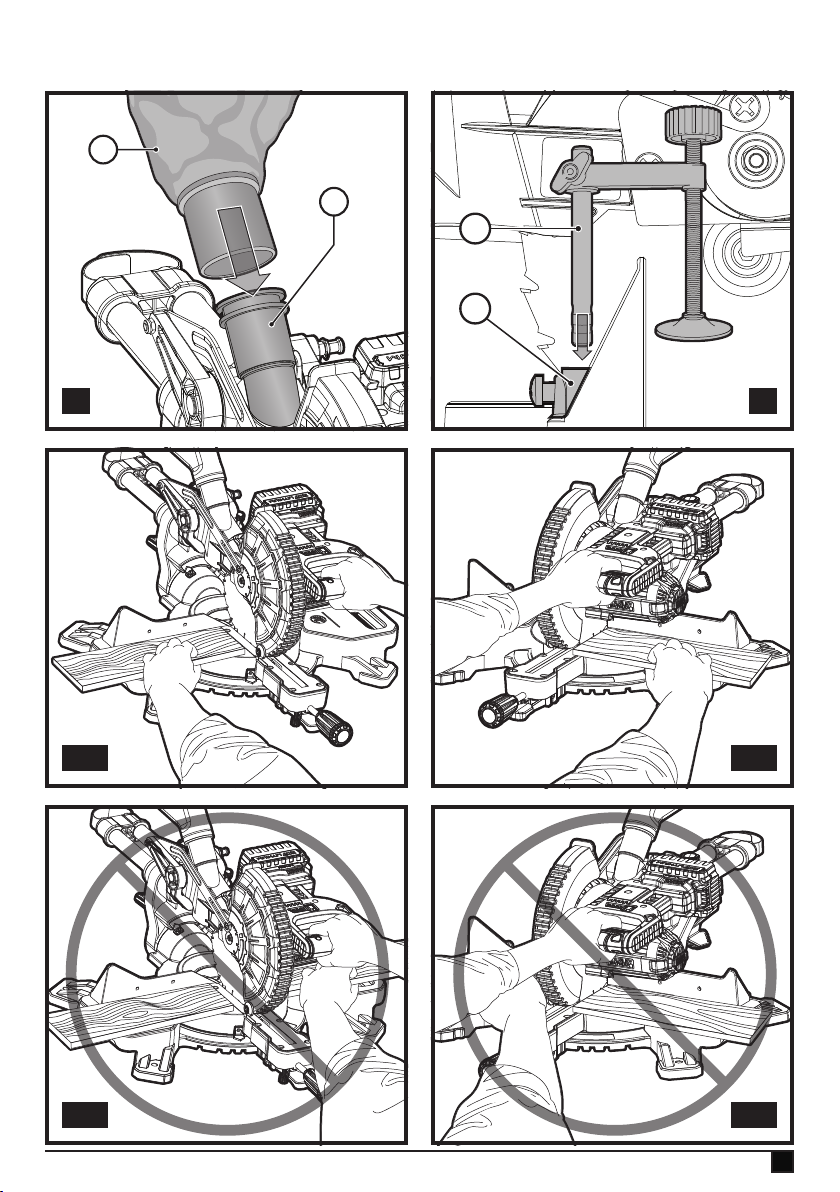

Body and hand position (g. O1–O4)

Proper positioning of your body and hands when operating the

mitre saw will make cutting easier, more accurate and safer.

Never place hands near cutting area. Place hands no closer

than 6" (152 mm) from the blade. Hold the work piece tightly

to the table and the fence when cutting. Keep hands in position until the trigger has been released and the blade has

completely stopped.

ALWAYS MAKE DRY RUNS (UN-POWERED) BEFORE

FINISH CUTS SO THAT YOU CAN CHECK THE PATH OF

THE BLADE. DO NOT CROSS HANDS, AS SHOWN IN

FIGURE O3.

Keep both feet rmly on the oor and maintain proper balance. As you move the mitre arm left and right, follow it and

stand slightly to the side of the saw blade. Sight through the

guard louvres when following a pencil line.

Clamping the work piece

Warning! To reduce the risk of serious personal injury, turn

tool off and remove the battery pack before transporting,

making any adjustments or removing/installing attachments or

accessories. An accidental start-up can cause injury.

Warning! A work piece that is clamped, balanced and secure

before a cut may become unbalanced after a cut is completed.

An unbalanced load may tip the saw or anything the saw is

attached to, such as a table or workbench. When making a

cut that may become unbalanced, properly support the work

piece and ensure the saw is rmly bolted to a stable surface.

Personal injury may occur.

Warning! The clamp foot must remain clamped above the

base of the saw whenever the clamp is used. Always clamp

the work piece to the base of the saw – not to any other part

of the work area. Ensure the clamp foot is not clamped on the

edge of the base of the saw.

Warning! Always use a work clamp to maintain control and

reduce the risk of work piece damage and personal injury, if

your hands are required to be within 6" (152 mm) of the blade

during the cut. If you cannot secure the work piece on the

table and against the fence by hand (irregular shape, etc.), or

Page 17

(Original instructions)

ENGLISH

your hand would be less than 6" (152 mm) from the blade, a

clamp or other xture must be used.

Use the material clamp provided with your saw. To purchase

a material clamp, contact your local retailer or Stanley FatMax

service centre.

Other aids such as spring clamps, bar clamps or C-clamps

may be appropriate for certain sizes and shapes of material.

Use care in selecting and placing these clamps. Take time to

make a dry run before making the cut.

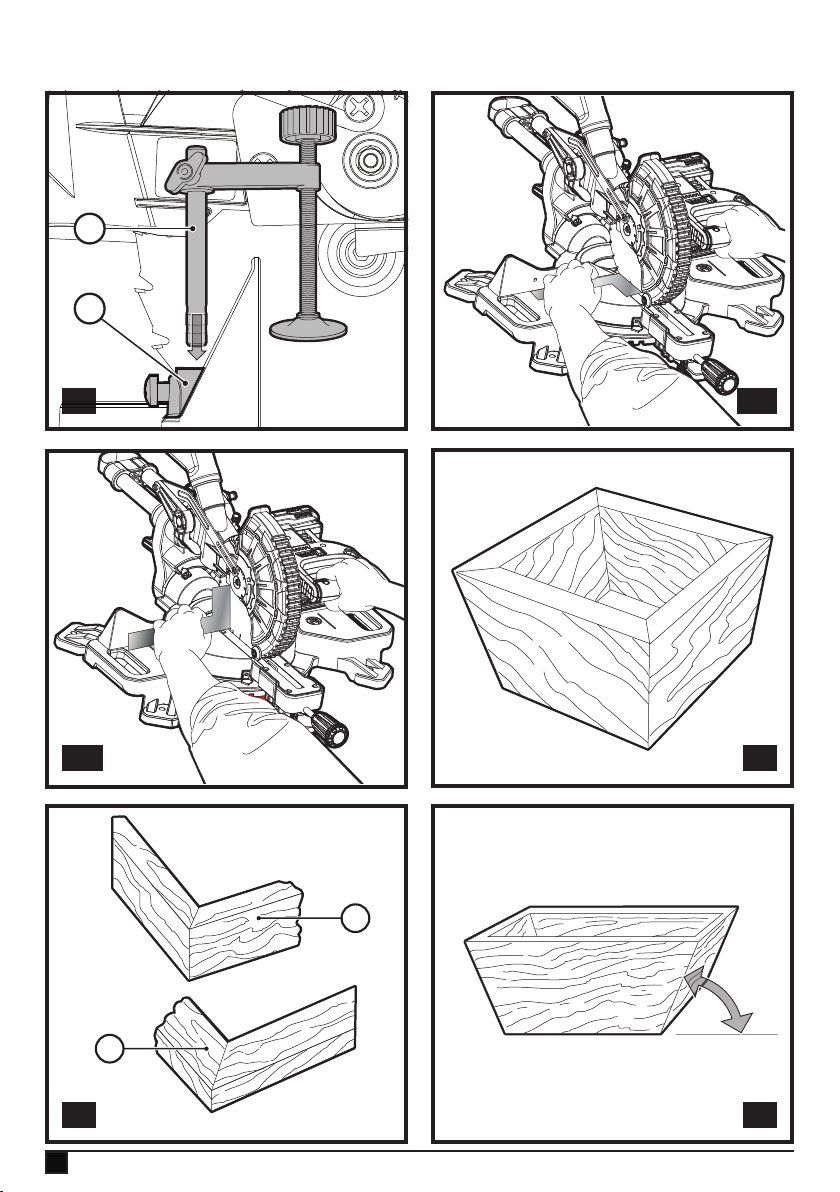

To install clamp (g. P)

u Insert the clamp (37) into the hole (19) behind the fence.

The clamp should be facing toward the back of the mitre

saw. The groove on the clamp rod should be fully inserted

into the base. Ensure this groove is fully inserted into the

base of the mitre saw. If the groove is visible, the clamp

will not be secure.

u Rotate the clamp 180º toward the front of the mitre saw.

u Loosen the knob to adjust the clamp up or down, then use

the ne adjust knob to rmly clamp the work piece.

Note: Place the clamp on the opposite side of the base when

bevelling. ALWAYS MAKE DRY RUNS (UN-POWERED) BEFORE FINISH CUTS TO CHECK THE PATH OF THE BLADE.

ENSURE THE CLAMP DOES NOT INTERFERE WITH THE

ACTION OF THE SAW OR GUARDS.

Adjustments

Your mitre saw is fully and accurately adjusted at the factory at

the time of manufacture. If readjustment due to shipping and

handling or any other reason is required, follow the instruc-

tions below to adjust your saw.

Once made, these adjustments should remain accurate. Take

a little time now to follow these directions carefully to maintain

the accuracy of which your saw is capable.

Mitre scale adjustment (g. Q1)

Lock the arm in the down position. Unlock the mitre lock

knob (5) and swing the mitre arm until the mitre latch button

(6) locks it at the 0° mitre position. Do not lock the mitre lock

knob. Place a square against the saw’s fence and blade,

as shown. (Do not touch the tips of the blade teeth with the

square. To do so will cause an inaccurate measurement.) If

the saw blade is not exactly perpendicular to the fence, loosen

and move the material fence until the blade is perpendicular

to the fence, as measured with the square. Pay no attention to

the reading of the mitre pointer at this time.

Bevel square to table adjustment (Fig. Q2)

To align the blade square to the table, lock the arm in the

down position with the lock down pin (20). Place a square

against the blade, ensuring the square is not on top of a tooth.

Loosen the bevel lock knob (5) and ensure the arm is rmly

against the 0° bevel stop. Rotate the 0° bevel adjustment

screw with the 1/2" (12.7 mm) socket (not provided) as neces-

sary so that the blade is at 0° bevel to the table, as measured

with the square.

Guard actuation and visibility (Fig. V)

Warning! Pinch hazard. To reduce the risk of injury, keep

thumb underneath the operating handle when pulling the

handle down. The lower guard will move up as the operating

handle is pulled down, which could cause pinching.

The lower guard (4) on your saw has been designed to automatically uncover the blade when the arm is brought down

and to cover the blade when the arm is raised.

Before each use or after making adjustments, cycle the arm

(un-powered) and make sure the guard opens smoothly and

closes fully. It should not contact the blade. With the arm

up, raise the guard (un-powered) as shown in Figure V and

release. The guard should fully close rapidly.

Do not operate the saw if the guard does not move freely and

fully close rapidly. Never clamp or tie the guard in an open

position when operating the saw.

The guard can be raised by hand when installing or removing

saw blades or for inspection of the saw.

NEVER RAISE THE LOWER GUARD MANUALLY UNLESS

THE BLADE IS STOPPED.

Note: Certain special cuts of large material will require that

you manually raise the guard. Refer to cutting large material

under special cuts.

The front section of the guard is louvred for visibility while

cutting. Although the louvres dramatically reduce ying debris,

they are openings in the guard and safety glasses should

be worn at all times.

Rail Guide

Periodically check the rails (13) for any play or clearance. The

rails can be cleaned with a dry clean cloth.

Cutting Picture Frames, Shadow Boxes And Other

Four-Sided Projects (Fig. R1, R2)

To best understand how to make the items listed here, we

suggest that you try a few simple projects using scrap wood

until you develop a “feel” for your saw.

Your saw is the perfect tool for mitreing corners like the one

shown in Figure R1. Sketch A in Figure R2 shows a joint made

by using the bevel adjustment to bevel the edges of the two

boards at 45º each to produce a 90º corner. For this joint the

mitre arm was locked in the zero position and the bevel ad-

justment was locked at 45º. The wood was positioned with the

broad at side against the table and the narrow edge against

the fence. The cut could also be made by mitreing right and

left with the broad surface against the fence.

17

Page 18

ENGLISH

(Original instructions)

Cutting trim moulding and other frames (g. R2)

Sketch B in Figure R2 shows a joint made by setting the mitre

arm at 45º to mitre the two boards to form a 90º corner. To

make this type of joint, set the bevel adjustment to zero and

the mitre arm to 45º. Once again, position the wood with the

broad at side on the table and the narrow edge against the

fence.

Figures R1 and R2 are for four-sided objects only.

As the number of sides changes, so do the mitre and bevel

angles. The chart below gives the proper angles for a variety

of shapes.

Examples

Number of Sides Mitre or Bevel Angle

4 45°

5 36°

6 30°

7 25.7°

8 22.5°

9 20°

10 18°

The chart assumes that all sides are of equal length. For a

shape that is not shown in the chart, use the following formula:

180º divided by the number of sides equals the mitre (if the

material is cut vertically) or bevel angle (if the material is cut

laying at).

Cutting compound mitres (g. R3)

A compound mitre is a cut made using a mitre angle and a

bevel angle at the same time. This is the type of cut used to

make frames or boxes with slanting sides like the one shown

in gure R3.

Note: If the cutting angle varies from cut to cut, check that

the bevel lock knob and the mitre lock handle are securely

locked. These must be locked after making any changes in

bevel or mitre. The chart at the end of this manual (Table 1)

will assist you in selecting the proper bevel and mitre settings

for common compound mitre cuts. To use the chart, select the

desired angle A (Fig. R3) of your project and locate that angle

on the appropriate arc in the chart. From that point follow the

chart straight down to nd the correct bevel angle and straight

across to nd the correct mitre angle.

Set your saw to the prescribed angles and make a few trial

cuts. Practice tting the cut pieces together until you develop

a feel for this procedure and feel comfortable with it.

Example: To make a 4-sided box with 26º exterior angles

(Angle A, Fig. R3), use the upper right arc. Find 26° on the arc

scale. Follow the horizontal intersecting line to either side to

get mitre angle setting on saw (42°). Likewise, follow the

18

vertical intersecting line to the top or bottom to get the bevel

angle setting on the saw (18°). Always try cuts on a few scrap

pieces of wood to verify the settings on the saw.

Cutting base moulding (g. S)

Straight 90º cuts:

Position the wood against the fence and hold it in place as

shown in Figure S. Turn on the saw, allow the blade to reach

full speed and lower the arm smoothly through the cut.

Cutting base moulding up to 3.5" (90 mm) high

vertically against the Fence

Position material as shown in Figure S. All cuts should be

made with the back of the moulding against the fence and with

the bottom of the moulding against the table.

Inside Corner Outside Corner

Left Side

Right Side

Mitre left 45°

Save left side of cut

Mitre right 45°

Save right side of cut

Mitre right 45°

Save left side of cut

Mitre left 45°

Save right side of cut

Material up to 3.5" (90 mm) can be cut as described above.

Cutting crown moulding

In order to t properly, crown moulding must be compound

mitred with extreme accuracy.

The two at surfaces on a given piece of crown moulding are

at angles that, when added together, equal exactly 90°. Most,

but not all, crown moulding has a top rear angle (the section

that ts at against the ceiling) of 52° and a bottom rear angle

(the part that ts at against the wall) of 38°.

Your mitre saw has special preset mitre detent points at 31.6°

left and right for cutting crown moulding at the proper angle.

There is also a mark on the bevel scale at 33.8°.

The Bevel Setting/Type of Cut chart gives the proper settings

for cutting crown moulding. (The numbers for the mitre and

bevel settings are very precise and are not easy to accurately

set on your saw.) Since most rooms do not have angles of

precisely 90°, you will have to ne tune your settings anyway.

Instructions for cutting crown moulding laying at

and using the compound features

u Lay the moulding with broad back surface down at on

saw table (36) (g. T1).

u The settings below are for all Standard crown moulding

with 52° and 38° angles.

Page 19

(Original instructions)

ENGLISH

Bevel Setting Type Of Cut

LEFT SIDE, INSIDE CORNER:

33.8°

33.8°

33.8°

33.8°

1. Top of moulding against fence

2. Mitre table set right 31.62°

3. Save left end of cut

RIGHT SIDE, INSIDE CORNER:

1. Bottom of moulding against fence

2. Mitre table set left 31.62°

3. Save left end of cut

LEFT SIDE, OUTSIDE CORNER:

1. Bottom of moulding against fence

2. Mitre table set left 31.62°

3. Save right end of cut

RIGHT SIDE, OUTSIDE CORNER:

1. Top of moulding against fence

2. Mitre table set right 31.62°

3. Save right end of cut

Note: When setting bevel and mitre angles for all compound

mitres, remember that the angles presented for crown

mouldings are very precise and difcult to set exactly. Since

they can easily shift slightly and very few rooms have exactly

square corners, all settings should be tested on scrap

moulding.

Alternative method for cutting crown moulding

Place the moulding at an angle between the fence (11) and

the saw table (36), with the top side of the moulding on the

table and the bottom side of the moulding on the fence as

shown in gure T1.

The advantage to cutting crown moulding using this method

is that no bevel cut is required. Minute changes in the mitre

angle can be made without affecting the bevel angle. This

way, when corners other than 90º are encountered, the saw

can be quickly and easily adjusted for them.

Instructions for cutting crown moulding angled

between the fence and base of the saw for all cuts

This saw can cut up to 9/16" (14 mm) x 3-5/8" (92 mm) crown

moulding nested.

u Angle the moulding so the bottom of the moulding (part

which goes against the wall when installed) is against the

fence (11) and the top of the moulding is resting on the

saw table (36), as shown in gure T2.

u The angled “ats” on the back of the moulding must rest

squarely on the fence and saw table (36).

Inside Corner Outside Corner

Left Side

Right Side

Mitre right at 45°

Save right side of cut

Mitre left at 45°

Save left side of cut

Mitre left at 45°

Save right side of cut

Mitre right at 45°

Save left side of cut

Bowed material (g. U1, U2)

When cutting bowed material always position it as shown in

gure U1 and never like that shown in gure U2. Positioning

the material incorrectly will cause it to pinch the blade near

the completion of the cut.

Cutting round material

Rounded material should be clamped or held rmly to the

fence to keep It from rolling. This is extremely important when

making angle cuts.

Cutting large material (g. V)

Occasionally you will encounter a piece of wood a little too

large to t beneath the lower guard. To clear the guard over

the wood, with the saw off and your right hand on the operating handle, place your right thumb outside of the upper portion

of the guard and roll the guard up just enough to clear the

wood, as shown in gure V. Release the guard prior to starting

the motor. The guard mechanism will function properly during

the cut. Only do this when necessary.

NEVER TIE, TAPE, OR OTHERWISE HOLD THE GUARD

OPEN WHEN OPERATING THIS SAW.

Maintenance

Warning! To reduce the risk of serious personal injury, turn

tool off and remove the battery pack before transporting,

making any adjustments or removing/installing attachments or

accessories. An accidental start-up can cause injury.

Warning! To reduce the risk of serious personal injury, DO

NOT touch the sharp points on the blade with ngers or hands

while performing any maintenance.

DO NOT use lubricants or cleaners (particularly spray or

aerosol) in the vicinity of the plastic guard. The polycarbon-

ate material used in the guard is subject to attack by certain

chemicals.

u All bearings are sealed. They are lubricated for life and

need no further maintenance.

u Periodically clean all dust and wood chips from around

AND UNDER the base and the rotary table. Even though

slots are provided to allow debris to pass through, some

dust will accumulate.

u The brushes are designed to give you several years of

use. If they ever need replacement, return the tool to the

nearest service centre for repair.

Special Cuts

Never make any cut unless the material is secured on the

table and against the fence.

19

Page 20

ENGLISH

(Original instructions)

Troubleshooting

Problem Possible Cause Solution

Install battery. Refer to Installing

and Removing Battery Pack.

Charge battery. Refer to Charging

Procedure.

Have brushes replaced by

authorised service centre.

Replace blade. Refer to Changing

or Installing a New Saw Blade.

Turn blade around. Refer to

Changing or Installing a New Saw

Blade.

Remove blade and clean with

coarse steel wool and turpentine or

household oven cleaner.

Change the blade type.

Charge battery. Refer to Charging

Procedure.

Tighten all mounting hardware.

Refer to Bench Mounting

Reposition on at level surface.

Replace blade. Refer to Changing

or Installing a New Saw Blade.

Check and adjust. Refer to Mitre

Scale Adjustment under

Adjustments.

Check and adjust. Refer to Mitre

Scale Adjustment under

Adjustments.

Check and adjust fence. Refer to

Bevel Square to Table Adjustment

under Adjustments.

Clamp work piece securely to fence

or glue 120 grit sandpaper to fence

with rubber cement.

Take to authorised service centre.

Refer to Bowed Material under

Special Cuts.

Saw will not

start.

Saw makes

unsatisfactory

cuts.

Work light is

ashing.

Machine

vibrates

excessively.

Does not

make accurate

mitre cuts.

Material

pinches blade.

Battery not installed.

Battery not charged.

Brushes worn out

Dull blade.

Blade mounted

backwards.

Gum or pitch on

blade.

Incorrect blade for

work being done.

Battery not charged

Saw not mounted

securely to stand or

work bench.

Stand or bench on

uneven oor.

Damaged saw

blade.

Mitre scale not

adjusted correctly.

Blade is not square

to fence.

Blade is not

perpendicular to

table.

Work piece moving

Kerf plate worn or

damaged.

Cutting bowed

material.

Protecting the environment

Separate collection. Products and batteries marked

with this symbol must not be disposed of with normal

Z

household waste.

Products and batteries contain materials that can be recovered or recycled reducing the demand for raw materials.

Please recycle electrical products and batteries according to

local provisions. Further information is available at

www.2helpU.com

Technical data

FMCS701 (H1)

Voltage V 18

Speed /min 3,800

Blade outer diameter mm 190

Bore diameter mm 16

Blade max. kerf mm 1.8

Weight without battery kg 10

Blade thickness mm 1.0

Mitre (max. positions) ° 47

Bevel (max. positions) ° 47

0 deg. mitre

45 deg. mitre right

45 deg. mitre left

45 deg. bevel left

Charger 905998** typ. 1 906086** typ. 1

Input voltage V

Output voltage V

Output current A 1 2

Approx. charge time Mins 90 - 240 45 - 120

Battery FMC689L FMC687L FMC688L

Voltage V

Capacity Ah 1.5 2.0 4.0

Type Li-Ion Li-Ion Li-Ion

horizontal mm 50 x 216

vertical mm 90 x 15

horizontal mm 50 x 152

vertical mm 90 x 15

horizontal mm 50 x 152

vertical mm 90 x 15

horizontal mm 50 x 152

vertical mm 50 x 15

AC

DC

DC

Level of sound pressure according to EN 62841:

LpA (sound pressure) 83.0 dB(A), Uncertainty (K) 3 dB(A)

LWA (sound power) 94.5 dB(A), Uncertainty (K) 3 dB(A)

230 230

18 18

18 18 18

EC declaration of conformity

MACHINERY DIRECTIVE

%

FMCS701 Sliding Compound Mitre Saw

Stanley Europe declares that these products described under

"technical data" are in compliance with:

EN62841-1:2015, EN62841-3-9:2015+A11:2017

20

Page 21

These products also comply with Directive

2006/42/EC, 2014/30/EU and 2011/65/EU.

For more information, please contact Stanley Fat Max at the

following address or refer to the back of the manual.

The undersigned is responsible for compilation of the

technical le and makes this declaration on behalf of

Stanley Fat Max.

Ray Laverick

Engineering Director

Stanley Fat Max Europe, 210 Bath Road, Slough,

Berkshire, SL1 3YD

United Kingdom

28/06/2018

Guarantee

Stanley Europe is condent of the quality of its products and

offers consumers a 12 month guarantee from the date

of purchase. This guarantee is in addition to and in no way

prejudices your statutory rights. The guarantee is valid within

the territories of the Member States of the European Union

and the European Free Trade Area.

To claim on the guarantee, the claim must be in accordance

with Stanley Fat Max Terms and Conditions and you will need

to submit proof of purchase to the seller or an authorised repair agent. Terms and conditions of the Stanley Europe 1 year

guarantee and the location of your nearest authorised repair

agent can be obtained on the Internet at www.2helpU.com, or

by contacting your local Stanley Europe ofce at the address

indicated in this manual.

Please visit our website www.stanley.eu/3 to register

your new Stanley Fat Max product and receive updates on

new products and special offers.

(Original instructions)

ENGLISH

21

Page 22

22

Page 23

23

Page 24

N558257 REV-01

United Kingdom

Stanley Fat Max Tel. 01753 511234

210 Bath Road Fax 01753 572112

Slough, Berkshire SL1 3YD www.stanleytools.co.uk

06/2018

Loading...

Loading...