Page 1

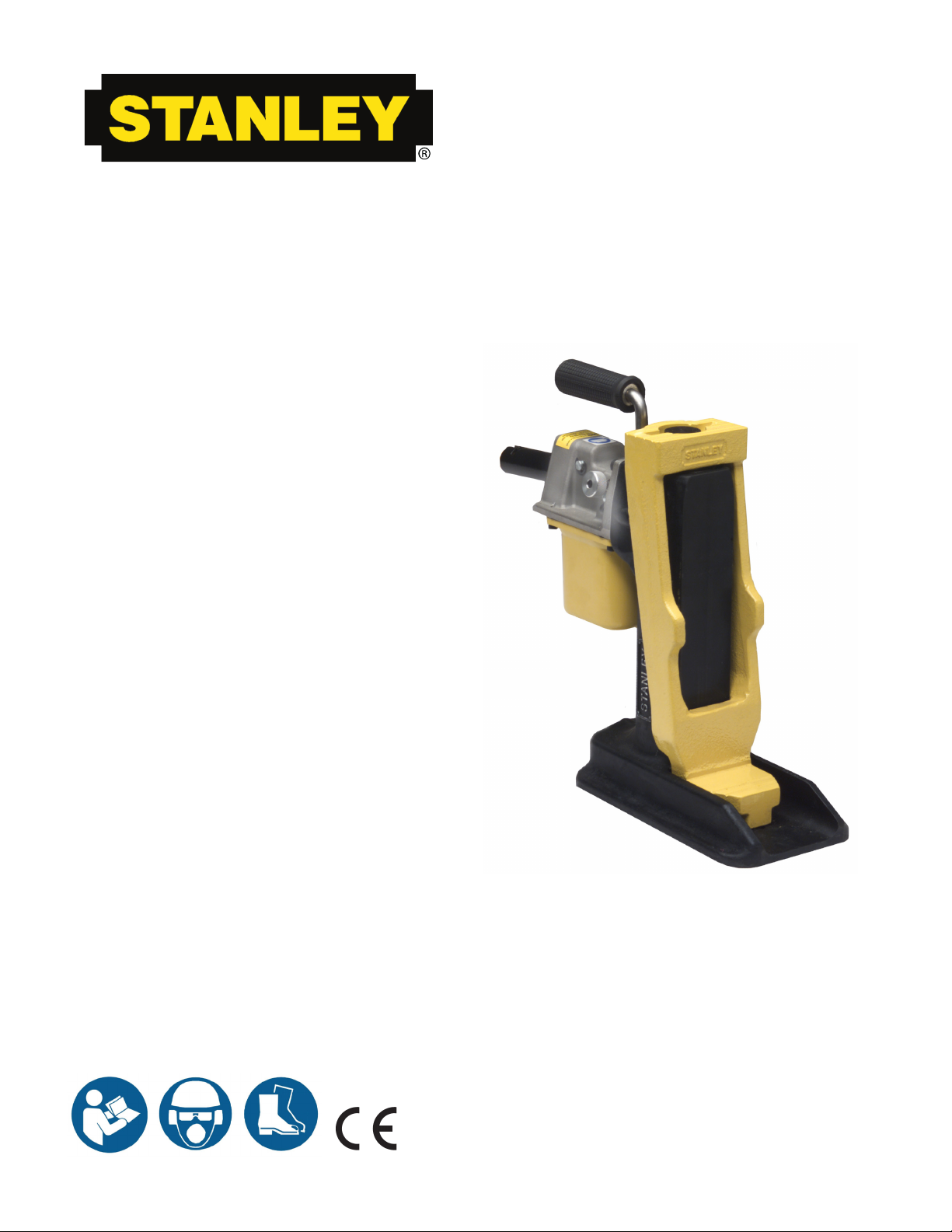

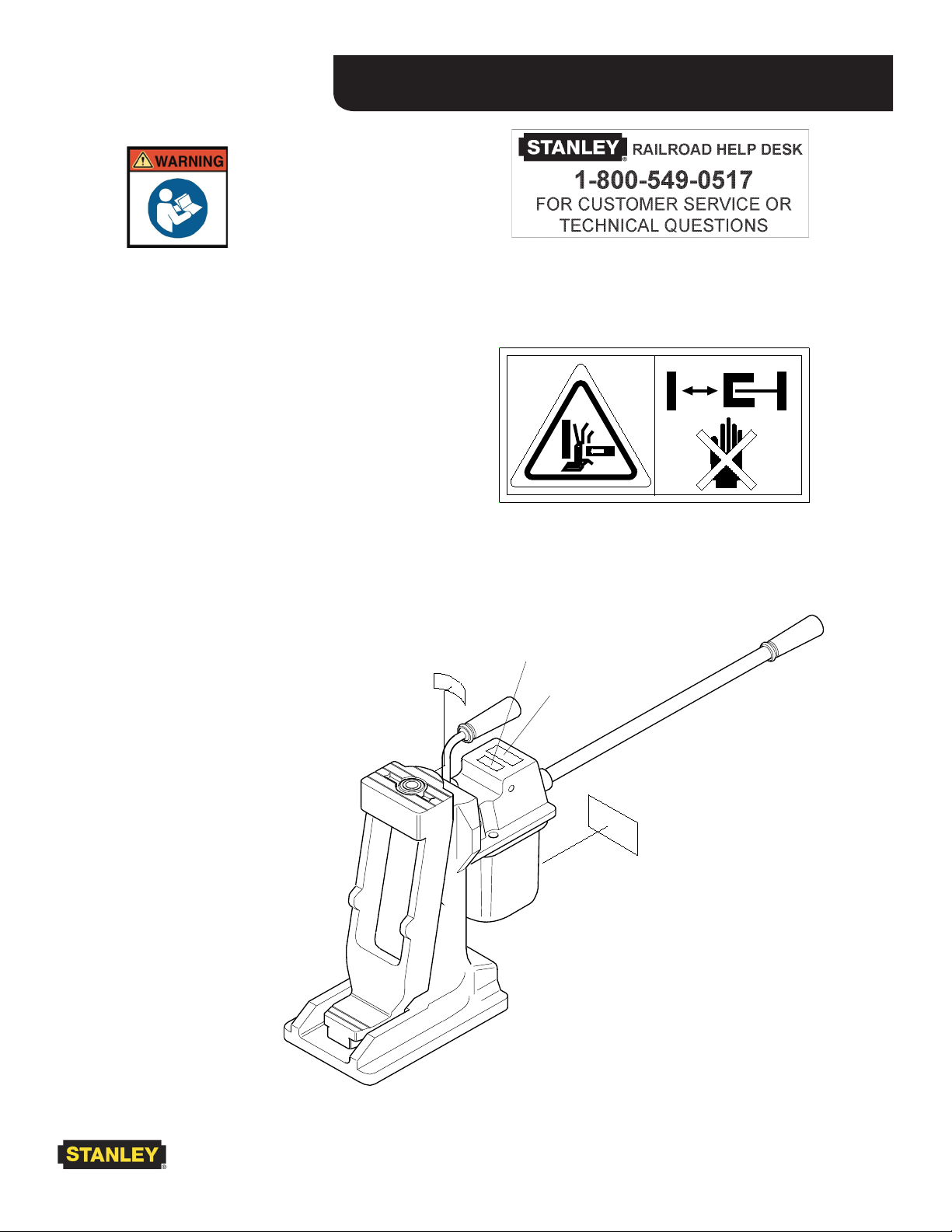

TJ10

HYDRAULIC

TRACK JACK

Safety, OperatiOn and Maintenance

USer'S ManUaL

© 2011 Stanley Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

34964 4/2013 Ver. 8

Page 2

TABLE OF CONTENTS

Declaration of Conformity ......................................................................... 3

Maintenance & Care ............................................................................ 8 - 9

General ................................................................................................ 8

Cleaning .............................................................................................. 8

Hydraulic Fluid ..................................................................................... 8

Replacing Fluid When Necessary .................................................. 8

Annual Hydraulic Fluid Change ......................................................8

Purging Air ...................................................................................... 9

Operation ........................................................................................... 10-11

Pre-Operation Instructions ................................................................. 10

Raising A Load ................................................................................... 10

Lowering A Load ................................................................................ 10

Horizontal Operation .......................................................................... 10

Safety Precautions ..............................................................................5 - 6

Tool Stickers and Tags ......................................................................... 7

Specications ......................................................................................... 12

Troubleshooting ...................................................................................... 11

Pump Assy Illustration.............................................................................14

Base Illustration & Parts List ...................................................................13

Part List....................................................................................................15

Repair Kits...............................................................................................16

Warranty..............................................................See Below or Back Cover

To ll out a Product Warranty Recording form and for information on your warranty visit

Stanleyhydraulic.com and select the Warranty tab.

(Note: the warranty recording form must be submitted to validate the warranty).

SERVICING: This manual contains safety, and operation instructions. Stanley Hydraulic Tools

recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an authorized and certied dealer. Please read the following warning.

DANGER

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER

REPAIR OR SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE

BY AN AUTHORIZED AND CERTIFIED DEALER.

2 ► TJ10 User Manual

Page 3

DECLARATION OF CONFORMITY

Weisbeck, Andy

Directive/Standards

No.

Approved body

ASTM

B30.1-2009

Self

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

Hydraulic Tools

DICHIARAZIONE DI CONFORMITA

______________________________________________________________________

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

hereby declare that the equipment specified hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especifica a continuación:

Dichiaro che le apparecchiature specificate di seguito:

Surname and First names/Familiennname und Vornamen/Nom et prénom /Nombr e y apellido/Cognom e eno me

1. Category:

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca

3. Type/Typ/Type/Tipo/Tipo: TJ10111M, TJ10111MF, TJ10112M

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Richtlinie/Standards

Directives/Normes

Directriz/Los Normas

Direttiva/Norme

Machinery Directive

EN

EN

EN

Nr

Numéro

No

n.

2006/42/EC:2006

12100-1:2009

12100-2:2009

1492:2000+A1:2008

Stanley

Track Jack

All

Prüfung durch

Organisme agréé

Aprobado

Collaudato

Self

Self

Self

Self

5. Special Provisions: None

6. Representative in the Union: Patrick Vervier, Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

Done at/Ort/Fait à/Dado en/Fatto a Stanley Hydraulic Tools, Milwaukie, Oregon USA

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione Engineering Manager

Spezielle Bestimmungen:

Dispositions particulières:

Provisiones especiales:

Disposizioni speciali:

Date/Datum/le/Fecha/Data 3-22-11

TJ10 User Manual ► 3

Page 4

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

This safety alert and signal word indicate an imminently hazardous situation which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

This signal word indicates a potentially hazardous situation which, if not

avoided, may result in property damage or damage to the equipment.

This signal word indicates a situation which, if not avoided, may result in

damage to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and maintenance personnel.

4 ► TJ10 User Manual

Page 5

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always comply with the safety precautions given in this manual and

on the stickers and tags attached to the tool and hose.

These safety precautions are given for your safety. Review them carefully before operating the tool and before performing general maintenance or repairs.

Supervising personnel should develop additional precautions relating to the specic work area and local safety regu-

lations. If so, place the added precautions in the space provided.

GENERAL SAFETY PRECAUTIONS

• The user must be familiar with correct operation, maintenance, and use of the jack. Lack of knowledge can lead

to personal injury.

• Operator must start in a work area without bystanders. The operator must be familiar with all prohibited work

areas such as excessive slopes and dangerous terrain conditions..

• Always wear safety equipment such as goggles, gloves, head, and safety shoes at all times when operating the

tool.

• Warning: Hydraulic uid under pressure could cause skin injection injury. If you are injured by hydraulic uid,

get medical attention immediately.

• The total load lifted or supported by the jack must never exceed the rated capacity. Excess pressure can result in

personal injury. Use a jack with sufcient capacity to lift a load. Keep clear of lifted loads.

• Inspect each jack before each usage or shift to prevent unsafe conditions from developing.

• Properly support the jack.

• Do not put poorly balanced or off-center loads on the jack pad or jack. The load can tip and cause personal injury. Do not use in unstable or hazardous positions.

• The jack must be used on at surfaces to be able to carry the load correctly. The base must be completely supported. Do not push or lift on the ends of the base.

• Do not lift people, or loads with people on them.

• As the load is lifted, use blocks or cribs to guard against a falling load.

• To help prevent personal injury, do not allow personnel to go under, or work on, a load before it is properly

cribbed or blocked. All personnel must be clear of a load before lowering or lifting.

• Lift only dead weight loads. Do not add additional weight to a lifted load.

• Do not use jacks that are damaged, altered or in poor condition.

• The reservoir must have sufcient hydraulic uid to fully stroke the jack. Use only approved hydraulic uids.

• Read and understand the operating instructions in this manual, and the ASME B30.1 and EN 1494 safety code for

jacks.

• Users must ensure that all safety related decals and stickers are whole and readable. Replace those which become

unreadable.

TJ10 User Manual ► 5

Page 6

SAFETY PRECAUTIONS

GENERAL SAFETY PRECAUTIONS CONTINUED:

• Never use extreme heat to disassemble a hydraulic ram or cylinder. Metal fatigue can lead to unsafe conditions.

• Be aware of possible "pinch points" of the jack, and stay clear to avoid personal injury.

• When lifting with the edge of the lifting toe, place a wedge between the load and the top of the lifting toe to

avoid bending the cylinder column.

• Carry the jack only by the carrying handle. Make sure the jack is in the fully lowered position.

• End users must be trained in the proper use of the jack..

• Remove operating levers when not in use to avoid accidental dislocation of the jack, and reduce the tripping

hazard.

• Make sure all personnel are clear of the load before lifting or lowering.

• DO NOT use extenders unless authorized by a qualied person.

• Never use this tool when working around electried rail unless it is de-energized or you have been properly

trained to work on electried rail. If you are not sure the rail is live or not, you must treat it as being live and

dangerous to life.

6 ► TJ10 User Manual

Page 7

WARNING DECAL - P/N 28788

(Shown smaller than actual size)

Indicates that users should read

the manual before using the

product.

The following information is found on the base

of the Track Jack.

• ModelNumber

• Capacity

• MaximumPressure

• Date

TOOL STICKERS AND TAGS

RAILROAD HELP DESK - P/N 25610

CRUSH HAZARD - P/N 31064

P/N 31064

STICKER LOCATIONS

P/N 28788

P/N 25610

P/N 05152

TJ10 User Manual ► 7

Page 8

MAINTENANCE & CARE

GENERAL PROTECTION

Store the Track Jack in an upright position, in a place

where it is protected from the elements, abrasive dust,

and damage.

Use only recommended repair and replacement parts

and materials specied in the Parts List section of this

manual.

Do not use the jack for applications it was not designed

for.

Use the carrying handle to transport the Track Jack from

location to location. Do not carry the Track Jack by

inserting the jack handle in the socket.

CLEANING

Establish a routine to keep the jack as free from dirt as

possible – daily, or at each shift change, for example.

Jacks exposed to rain, sand, or grit-laden air should be

cleaned prior to each use.

Exposed screw threads should be cleaned and re-lubricated as necessary.

ADDING FLUID WHEN NEEDED

A jack that is low on hydraulic uid can lift a full load,

but not to the full lift height. As the reservoir begins to

run dry, the lever socket becomes very easy to pump,

and the jack stops lifting. To add oil:

1. Fully retract the plunger.

2. Remove the ll plug.

3. Fill the reservoir with new, clean uid (use ISO#15

Hydraulic Fluid) to a level 1/8 inch below the bottom of the ll plug hole.

WARNING

Do not overll or underll the reservoir

as this may damage the jack.

ANNUAL FLUID CHANGE

Regardless of usage, the Track Jack hydraulic uid

should be changed annually to ensure proper operation

of the jack. To drain the uid:

Keep the cylinder clean at all times. Keep the piston

retracted when not in use.

Operating lever and load-bearing surfaces should be

free of slippery material or uids.

Keep tool labels and stickers legible.

HYDRAULIC FLUID

The Track Jack holds approximately 28 ounces/820 cc

cubic inches of hydraulic uid in its reservoir.

DANGER

DO NOT USE BRAKE FLUID OR OTHER

NON-APPROVED SUBSTITUTE FLUIDS.

LIGHTER WEIGHT FLUIDS MAY CAUSE

THE JACK TO FAIL UNDER LOAD.

8 ► TJ10 User Manual

1. Thoroughly clean the area around the ll plug.

2. Remove the ll plug and lay the Track Jack on its

back to allow the uid to drain from the ll hole into

an appropriate receptacle.

3. Dispose of the used hydraulic uid in accordance

with Environmental Protection Agency regulations.

4. Make sure dirt or other contaminants do not enter

the reservoir while the ll plug is removed. When

drained, check the uid for contaminants. If the

uid appears gritty or dirty, ush the reservoir with

clean hydraulic uid before relling.

5. Rell the reservoir with the recommended hydraulic

uid. Stand the jack upright, and with the piston

fully retracted, ll the reservoir until the uid level

is 1/8 inch below the bottom of the ll plug.

6. Before returning the jack to service, fully extend the

piston without a load by pumping the pump handle

without the long extension handle. If the uid level

is correct, the pump handle will become almost impossible to pump by hand as the piston reaches full

extension. Replace the plug.

Page 9

7. It may be necessary to bleed air out of the cylinder.

See instructions below for purging air.

8. Inspect the jack for leaks, cracks, or other damage.

DANGER

Immediately take out of service any

jack that appears to be damaged or

PURGING AIR

Air trapped within the jack hydraulic system can be

removed by performing the following steps.

leaking.

MAINTENANCE & CARE

1. Make sure the plunger is fully retracted.

2. Pry out the cap on top of the unit.

3. Loosen (Do Not Remove) the capscrew under the

cap located in the top of the plunger.

4. Place the jack in a suitable xture to prevent the

extension of the plunger while purging air.

DANGER

The xture used to prevent extension

of the plunger while purging air must

be able to withstand the full ten ton

force of the jack.

5. Add hydraulic uid to the reservoir if necessary. See

instructions above for adding uid.

6. Pump the handle until oil comes up through the

thread area of the capscrew in the plunger.

7. Tighten the socket head capscrew to 10-12 ft.

lbs./14-16 Nm.

8. Top off the reservoir with hydraulic uid. NOTE:

Make sure the plunger is fully retracted before lling

the reservoir.

TJ10 User Manual ► 9

Page 10

OPERATING INSTRUCTIONS

DANGER

MAKE SURE THAT ALL PERSONNEL ARE CLEAR

OF THE LOAD BEFORE ATTEMPTING TO RAISE

OR LOWER THE JACK. SERIOUS INJURY OR

DEATH COULD RESULT FROM THE IMPROPER

USE OF THIS TOOL.

PREOPERATION PROCEDURES

Before putting a new Track Jack into initial service,

or after an extended period of being unused, perform

a visual inspection for bent, broken, cracked, missing

or worn components. Ensure the hydraulic uid and

lubricant level is correct. Fully extend and retract the

jack without a load to ensure that the jack is primed and

operating properly.

RAISING A LOAD

1. Before using the Track Jack, make sure that it is set

on a rm surface capable of bearing the intended

load.

WARNING

Use only the recommended length jack

handle. DO NOT use longer handles or

extenders.

5. Remove the jack handle from the handle socket once

the load reaches its desired height.

6. Crib or block the load to prevent accidently dropping the load.

LOWERING A LOAD

1. Make sure all personnel are clear of the load.

2. Remove cribbing or blocking if used.

3. Open the release valve by turning it counterclockwise (open slowly).

DANGER

2. Make sure the release valve is closed, by turning it

clockwise until it is hand tight.

DANGER

Overtightening the release valve can damage

the valve seat. DO NOT use pliers or wrenches

to tighten the release valve.

3. Pump the handle by hand until the toe lift or head

lift plate rises to and engages the load.

DANGER

Make certain that the lifting toe is fully

engaged on the load, and the entire jack is

stable, before proceeding further.

4. Insert the jack handle fully into the handle socket

and pump until the desired lift has been obtained.

Lowering speed is controlled by opening the

release valve more or less. DO NOT open the

valve more than two full turns.

4. When the load reaches the desired level, close the

release valve by turning it clockwise until it is hand

tight.

HORIZONTAL OPERATION

The Track Jack can also be used horizontally to separate

two items, as long as it is placed with the handle socket

facing upwards.

1. Place the Track Jack base against the largest, heaviest, or otherwise least moveable of the two items.

2. Close the release valve by turning it clockwise until

hand tight.

3. Pump the handle socket by hand until the lifting toe

or the head of the lifting toe rmly engages the more

moveable of the two items.

10 ► TJ10 User Manual

Page 11

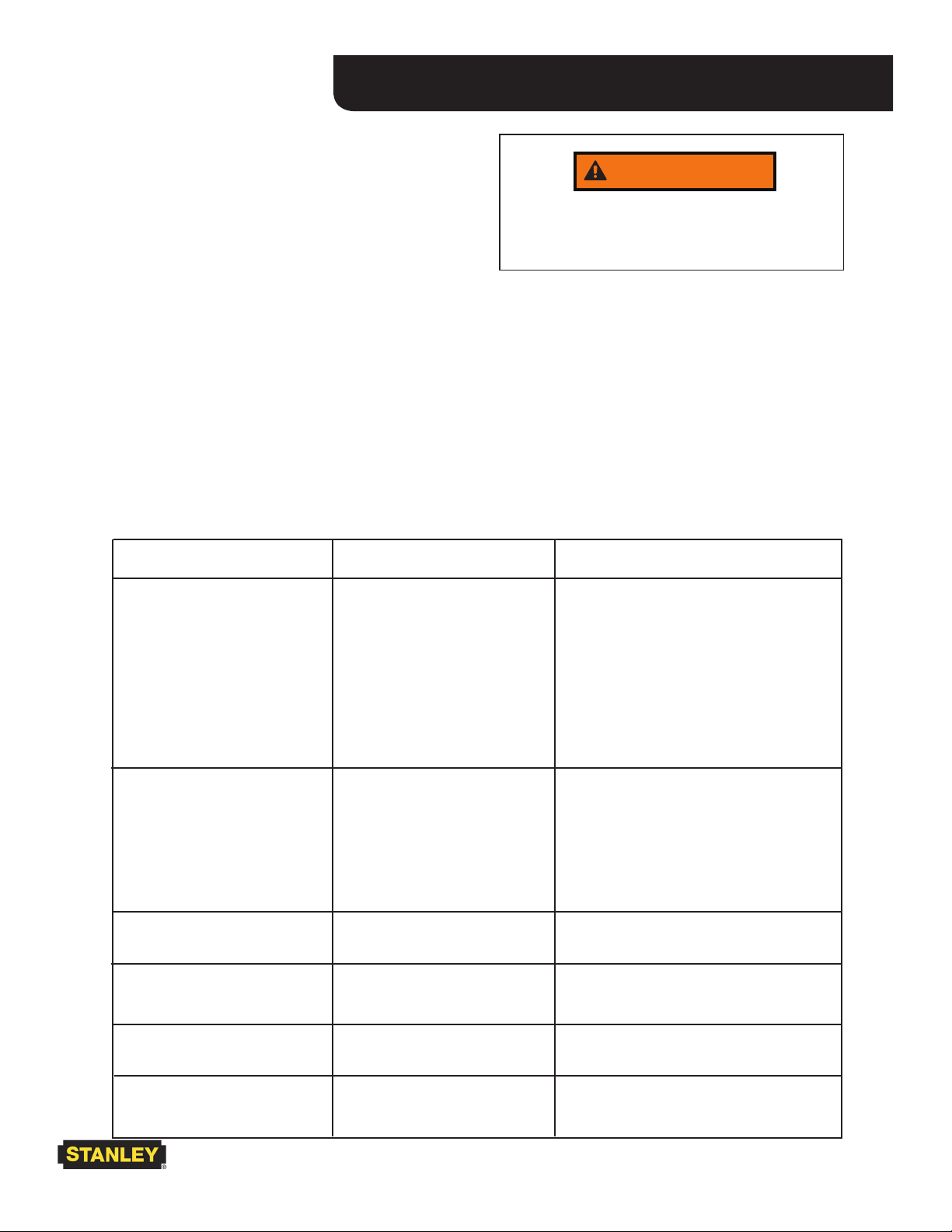

TROUBLESHOOTING

4. Make sure personnel are clear of all items being

jacked before attempting to move anything.

WARNING

5. Insert the jack handle into the handle socket and

pump until the desired separation has been obtained.

6. Remove the jack handle from the socket once the

moveable load reaches its desired separation.

7. To free the jack, open the release valve by turning it

counterclockwise. When the lift plate is clear, close

the release valve.

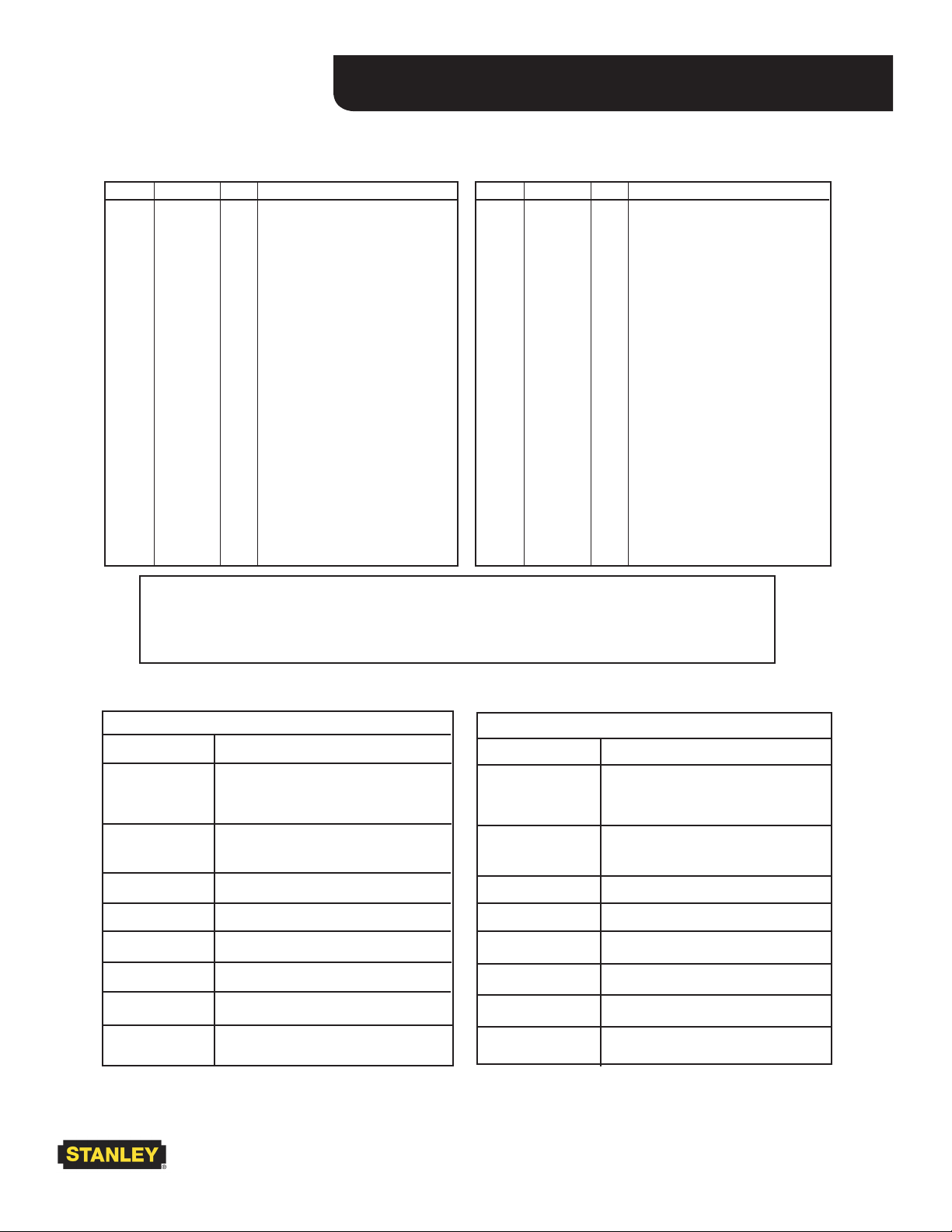

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

Because the Track Jack can be used for many different applications, this information is general in nature

anddoesnotaddressspecicuses.

NEVER LIFT OR LOWER A LOAD HEAVIER THAN

THE LOAD RATING OF THE JACK. DAMAGE

TO THE JACK OR LOAD COULD RESULT FROM

IMPROPER USE OF THIS TOOL.

PUMPING HANDLE

A pumping handle is included with the Track Jack is designed with a 4:1 safety factor. DO NOT use the pumping handle for any other purpose. DO NOT substitute

other material for use as a pumping handle.

PROBLEM CAUSE CORRECTION

Jack will not raise

Jack raises but will not hold Release valve ball not seat-

Jack only raises part way Hydraulicuidlevelislow Addhydraulicuid

Jackleakshydraulicuid Seal failure Havejackservicedbyaqualied

A) Release valve not closed

B) Release valve ball not

seating properly

C) Seal failure Havejackservicedbyaqualied

ing properly

Relief valve set too low or

Malfunctioning

Seal failure Havejackservicedbyaqualied

Close the valve

Havejackservicedbyaqualied

technician

technician

Havejackservicedbyaqualied

technician

technician

technician

Jack retracts slowly Air in the hydraulic system Purge air from the hydraulic system

Jack raises, but pulses and

hesitates

Air in the hydraulic system Purge air from the hydraulic system

TJ10 User Manual ► 11

Page 12

SPECIFICATIONS

Performance

MaximumLift ........................................................................................................................ 8.9 in. /226 mm

MaximumLoad .................................................................................................................... 10 tons/9070 kg

Pump Displacment ...............................................................................46 cu. in/7.5 cc stroke, single speed

Advance rate per stroke ..........................................................................................................14 in./3.6 mm

Pressure at rated load .............................. 7300 psi/500 bar Model TJ10, (7150 psi/493 bar Model TJ10M)

Maximumpumphandleeffort ...................................................................................................80 lbs./355 N

Dimensions and Weight

Baseplate Size..............................................................................................................6x11in./15x28cm

Lift Toe Width and Depth .............................................................................................2-1/2x3/63x76mm

Height (retracted) ..........................................14.5 in//37 cm Model TJ10, (14.75 in/37.5 cm Model TJ10M)

extended ......................................................23.4 in./59 cm Model TJ10, (23.56 in/60 cm Model TJ10M)

Net Weight (less oil) .................................................. 43 lb/20 kg Model TJ10, (44 lb/20 kg Model TJ10M)

Lever Bar Length ..................................................................................................................... 36 in./ 80 cm

Hydraulic Requirements

Reservoir Capacity .................................................................................................................. 28 oz/820 cc

Recommended Fluid ................................................................................................ISO #7 Hydraulic Fluid.

Standards ................................................................................................................. ASME B30.1, EN 1494

NOTE:Weights,dimensionsandoperatingspecicationslistedonthissheetaresubjecttochangewithoutnotice.Wherespecicationsarecriticaltoyourapplication,pleaseconsultthefactory.

12 ► TJ10 User Manual

Page 13

BASE ILLUSTRATION

TJ10 User Manual ► 13

Page 14

PUMP ASSY ILLUSTRATION

14 ► TJ10 User Manual

NOTE: Item descriptions which

are preceded by a item number

may be ordered individually.

NOTE: Item descriptions which are

preceded by a symbol are only available

in their respective repair kits.

Manifold Assembly P/N-34873

Includes all items shown except

pump handle 34870.

Page 15

PARTS LIST

TJ10 *TJ10M

ITEM P/N QTY DESCRIPTION

1 52805 1 Cap

16 65924 1 Pumping Handle

28 01219 2 Pipe Plug

29 10888 4 Capscrew

40 34849 1 Relief Valve Assy

46 56629 1 Manifold

49 00769 4 Capscrew

50 31064 1 Sticker, Crush Hazard

52 05152 1 Sticker, Stanley Log

56 28788 1 Sticker, Manual Composite

57 25610 1 Sticker, Help Desk

59 34852 1 Piston

ITEM P/N QTY DESCRIPTION

1 52805 1 Cap

3 52806 1 Lifting Toe

6 52807 1 Stop Ring

11 52809 1 Plunger

14 52812 1 Base, (Model TJ10111M)

16 52813 1 Pumping Handle

28 01219 2 Pipe Plug

29 56518 4 Capscrew

38 52824 1 Seat Assy

40 52827 1 Relief Valve Assy

46 52830 1 Manifold

49 56521 4 Capscrew

50 31064 1 Sticker, Crush Hazard

52 05152 1 Sticker, Stanley Logo

56 28788 1 Sticker, Manual Composite

57 25610 1 Sticker, Help Desk

58 56601 1 Base (Narrow), (Model

TJ10112M)

59 52819 1 Piston

NOTE: When ordering parts make sure to check the (Model Number)

on your track jack to distinguish between a TJ10 and TJ10M*.

KITS FOR MODEL TJ10111 & TJ10112 ONLY

P/N DESCRIPTION

56629 Manifold Assy

34872 Cylinder Repair Kit

34858 Carry Handle Repair Kit

34851 Reservoir Repair Kit

34853 Beam & Piston Repair Kit

34848 Pump Repair Kit

34845 Release Valve Repair Kit

* KITS FOR MODEL TJ10111M & TJ10112M ONLY

P/N DESCRIPTION

56629 Manifold Assy

56528 Spring Kit

56522 Cylinder Repair Kit

56523 Carry Handle Repair Kit

56524 Reservoir Repair Kit

56525 Beam & Piston Repair Kit

56526 Pump Repair Kit

56527 Release Valve Repair Kit

* "M" Models Begin With S/N 5000.

TJ10 User Manual ► 15

Page 16

REPAIR KITS

16 ► TJ10 User Manual

Page 17

NOTES

TJ10 User Manual ► 17

Page 18

Stanley Hydraulic Tools

3810 SE Naef Road

Milwaukie, OR 97267-5698 USA

Phone: (503) 659-5660

Fax:(503)652-1780

www.stanleyhydraulic.com

Copyright© 2009 The Stanley Works

To ll out a Product Warranty Recording form and for information on your warranty visit

Stanleyhydraulic.com and select the Warranty tab.

(Note: the warranty recording form must be submitted to validate the warranty).

Loading...

Loading...