Page 1

CR27

HYDRAULIC

CIRCULAR SAW

Safety, OperatiOn and Maintenance

USer ManUaL

© 2011 Stanley Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

30673 6/2012 Ver. 6

Page 2

Page 3

TABLE OF CONTENTS

WARNING

IMPORTANT

SAFETY SYMBOLS ..................................................................................................................................................4

SAFETY PRECAUTIONS .......................................................................................................................................... 5

ELECTRICAL HAZARDS ..........................................................................................................................................7

TOOL STICKERS & TAGS ......................................................................................................................................10

HOSE TYPES .......................................................................................................................................................... 11

HOSE RECOMMENDATIONS ................................................................................................................................ 12

FIGURE 1. TYPICAL HOSE CONNECTIONS .....................................................................................................12

HTMA REQUIREMENTS .........................................................................................................................................13

OPERATION ............................................................................................................................................................14

FIGURE 2. CORRECT ROTATION DIRECTION .................................................................................................15

FIGURE 3. COLLET NUT & LOCKING NUT .......................................................................................................15

FIGURE 4. FLUSH CUTTING A LIMB THAT MIGHT SPLIT OR TEAR. .............................................................. 16

FIGURE 5. FLUSH CUT ....................................................................................................................................... 16

FIGURE 6. BLADE SHARPENING ...................................................................................................................... 17

FIGURE 7. FILING ANGLE ..................................................................................................................................17

FIGURE 8. SETTING CUTTER TOOTH ANGLE ................................................................................................. 18

TOOL PROTECTION & CARE ................................................................................................................................19

TROUBLESHOOTING ............................................................................................................................................20

SPECIFICATIONS ................................................................................................................................................... 21

ACCESSORIES.......................................................................................................................................................21

CR27 PARTS ILLUSTRATION ................................................................................................................................22

CR27 PARTS LIST ..................................................................................................................................................23

To ll out a Product Warranty Recording form, and for information on your warranty,

visit Stanleyhydraulic.com and select the Warranty tab.

(NOTE: The warranty recording form must be submitted to validate the warranty).

SERVICING: This manual contains safety, operation, and routine maintenance instructions. Stanley Hydraulic

Tools recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an au-

thorized and certied dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest authorized and certied dealer, call Stanley Hydraulic Tools at the number listed on the back of this

manual and ask for a Customer Service Representative.

CR27 User Manual ◄ 3

Page 4

SAFETY SYMBOLS

DANGER

WARNING

CAUTION

CAUTION

NOTICE

IMPORTANT

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicate an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided, may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and maintenance personnel.

4 ► CR27 User Manual

Page 5

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always

comply with the safety precautions given in this manual

and on the stickers and tags attached to the tool and

hose.

These safety precautions are given for your safety. Review them carefully before operating the tool and before

performing general maintenance or repairs.

Supervising personnel should develop additional pre-

cautions relating to the specic work area and local

safety regulations. If so, place the added precautions in

the space provided in this manual.

The CR27 Hydraulic Circular Saw will provide safe and

dependable service if operated in accordance with the

instructions given in this manual. Read and understand

this manual and any stickers and tags attached to the

tool and hoses before operation. Failure to do so could

result in personal injury or equipment damage.

• Operator must start in a work area without bystand-

ers. The operator must be familiar with all prohibited

work areas such as excessive slopes and dangerous terrain conditions.

• Establish a training program for all operators to en-

sure safe operation.

• Do not operate the tool unless thoroughly trained or

under the supervision of an instructor.

• Always wear safety equipment such as goggles,

ear, head protection, and safety shoes at all times

when operating the tool.

• Do not overreach. Maintain proper footing and bal-

ance at all times.

• Do not inspect or clean the tool while the hydraulic

power source is connected. Accidental engagement

of the tool can cause serious injury.

• Supply hoses must have a minimum working pres-

sure rating of 2500 psi/175 bar.

• Be sure all hose connections are tight.

• The hydraulic circuit control valve must be in the

OFF position when coupling or uncoupling the tool.

Wipe all couplers clean before connecting. Use only

lint-free cloths. Failure to do so may result in damage to the quick couplers and cause overheating of

the hydraulic system.

• Do not operate a damaged, improperly adjusted, or

incompletely assembled tool.

• Do not operate the tool at oil temperatures above

140 °F/60 °C. Operation at higher oil temperatures

can cause operator discomfort and may damage the

tool.

• To avoid personal injury or equipment damage, all

tool repair, maintenance and service must only be

performed by authorized and properly trained personnel.

• Do not exceed the rated limits of the tool or use the

tool for applications beyond its design capacity.

• Always keep critical tool markings, such as labels

and warning stickers legible.

• Always replace parts with replacement parts recommended by Stanley Hydraulic Tools.

• Check fastener tightness often and before each use

daily.

• Do not wear loose tting clothing when operating the

tool.

• Keep all parts of your body away from the rotating

saw blade.

• Keep the saw blade off all surfaces when starting

the circle saw.

• Do not reverse saw blade rotation direction by

changing uid ow direction.

• Without the use of non-conductive accessories, this

tool is not for use near energized electric lines. Failure to comply with this warning could result in serious personal injury.

• Never cock, jam or wedge the saw blade during operation.

• Eye injury and cutting or severing of body parts is

possible if proper procedures are not followed.

CIRCULAR SAW SPECIFIC SAFETY

PRECAUTIONS

• Do not rely exclusively upon the safety devices built

into the saw. As a circle saw user, several steps

must be taken to keep your cutting jobs free from

accident or injury.

• Ensure the saw blade is correctly mounted and

tightened before each use.

• Keep a good rm grip on the pole saw with both

hands. Place your right hand on the rear handle and

your left hand on the outer tube assembly when op-

erating. Use a rm grip with your thumbs and ngers

encircling the saw handle and outer tube assembly.

A rm grip helps keep control of the saw. Do not let

go.

CR27 User Manual ◄ 5

Page 6

SAFETY PRECAUTIONS

• Ensure that the direction of rotation of the saw blade

is as prescribed in this manual.

• Cut at the rated operating speeds (gpm).

• Operate the saw at “no load” for 30 seconds in a

safe position and ensure there is no excessive vibration or other defects detected. If considerable vibration or other defects are detected, stop operation

of the tool immediately and determine the cause. Do

not use the tool until the defect is corrected.

• If the tool is dropped with a saw blade installed, the

saw blade should be examined.

• Make sure you’re well rested and mentally alert before operating the saw.

• Do not start cutting until you have a clear work area,

secure footing and a planned drop area for falling

branches.

• Keep all parts of the body away from the saw during

operation.

• Carry the saw with the unit de-energized.

• Do not operate a pole saw that is damaged, improp-

erly adjusted or not completely and securely assembled. Make sure the saw blade stops moving when

the control trigger is released.

• Use extreme caution when cutting small branches.

Twigs may catch the saw blade and be whipped toward the operator or pull the operator off balance.

• Only use saw blades manufactured by Stanley Hydraulic Tools. Stanley assumes no responsibility for

failure in equipment, accidental damage or accidental injury as a result of the use of saw blades not

manufactured by Stanley Hydraulic Tools.

• Always assure the saw blade is sharp. Do not try to

use the tool with a dull saw blade.

• Keep the handle dry, clean and free of hydraulic

uid.

• When using tools near energized transmission lines,

make sure to use only hoses labeled and certied

non-conductive.

• Turn off the power unit or move the hydraulic control

valve to neutral before setting the pole saw down.

• Know the location of buried or covered electrical

services before starting work.

• To avoid personal injury or equipment damage, all

tool repair, maintenance and service must only be

performed by authorized and properly trained per-

sonnel.

6 ► CR27 User Manual

Page 7

ELECTRICAL HAZARDS

The following guidelines must be followed to prevent

accidental contact with overhead electrical conductors

and/or communication wires and cables. (Ref. ANSI

Z133.1-1982)

All overhead conductors and all communications wires

and cables are considered to be energized with potentially fatal voltages and must never be touched either directly or indirectly. Accidental contact with any overhead

conductors or communication wires and cables can result in death or serious injury.

A close inspection shall be made by the tool operator and by the tool operator’s supervisor to determine

whether an electrical conductor passes through the tree

or passes within reaching distance of the tool operator.

Only qualied tool operators shall be assigned to the

work if an electrical hazard exists.

A second qualied tool operator must be within normal

voice communication during line clearing operations

aloft when the tool operator approaches closer than 10

feet (3 m) to any conductor or electrical apparatus energized in excess of 750 volts, or when roping is required

to remove the branches or limbs.

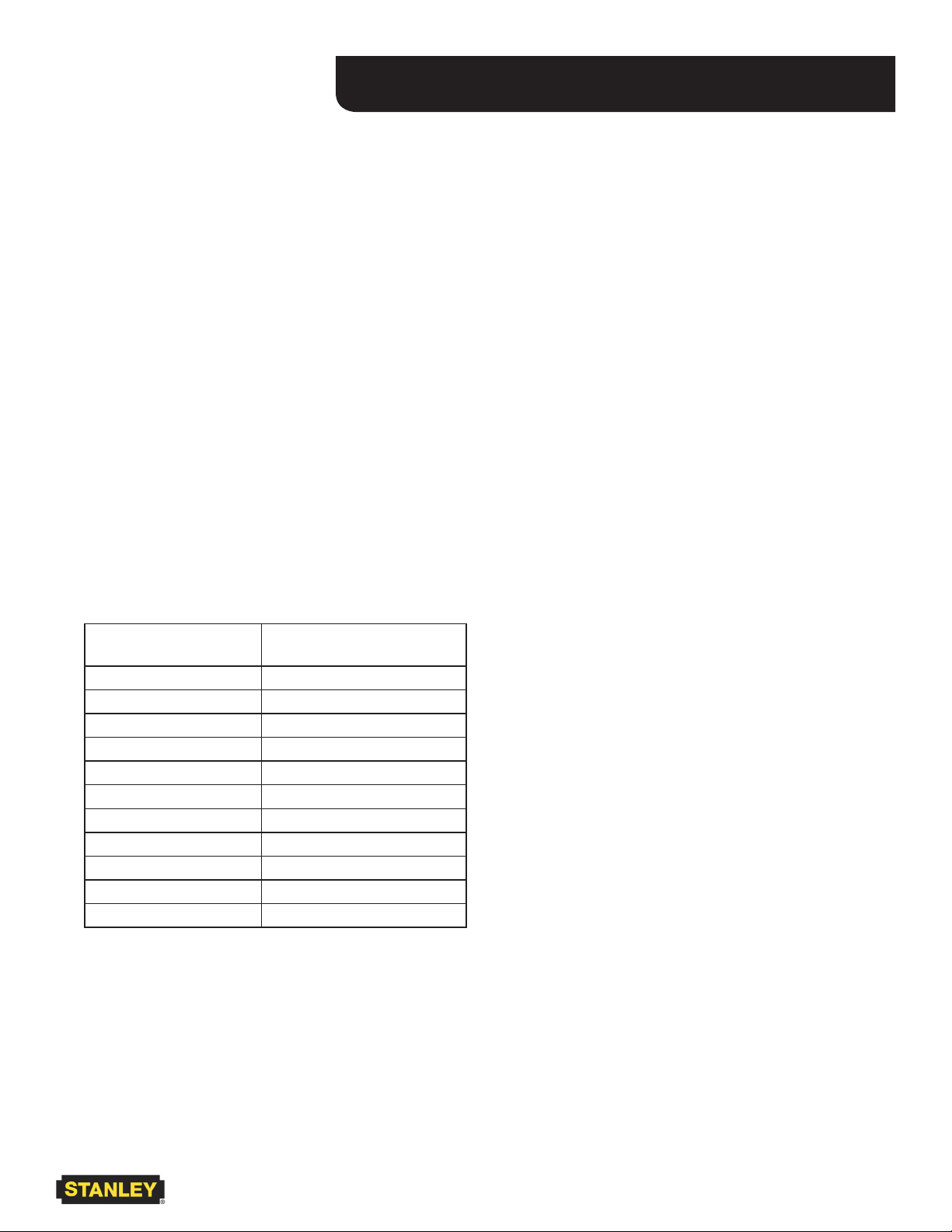

Tool operators must maintain the following clearances

from energized conductors:

Voltage Range

(phase-to-phase) (kV)

2.1–15.0 2 ft 0 in./0.6 m

15.1–35.0 2 ft 4 in./0.7 m

35.1–46.0 2 ft 6 in./0.75 m

46.1–72.5 3 ft 0 in./0.9 m

72.6–121.0 3 ft 4 in./1.0 m

138.0–145.0 3 ft 6 in./1.05 m

161.0–169.0 3 ft 8 in./1.1 m

230.0–242.0 5 ft 0 in./1.5 m

345.0–362.0 7 ft 0 in./2.1 m

500.0–552.0 11 ft 0 in./3.35 m

700.0–765.0 15 ft 0 in./4.55 m

All other tree workers must maintain a minimum clearance of 10 feet (3 meters) from energized conductors

rated 50 kV phase-to-phase or less. Conductors rated

over 50 kV phase-to-phase require a minimum clearance of 10 feet plus 4/10 of an inch (3 meters plus 10

mm) for each kilovolt over 50 kV.

Minimum Working

Distance

When a lifting device contacts an electrical conductor,

the truck supporting the device is considered to be energized and contact with the truck must be avoided except

when emergency rescue procedures are being carried

out. Emergency rescue should only be attempted by

properly trained personnel familiar with electrical hazards.

Storm work and emergency conditions create special

hazards. During these conditions, only authorized tool

operators shall perform any tree operation.The follow-

ing guidelines must be followed to prevent accidental

contact with overhead electrical conductors and/or communication wires and cables. (Ref. ANSI Z133.1-2000)

Working in Proximity to Electrical Hazards:

An inspection shall be made by a qualied arborist to

determine whether an electrical hazard exists before

climbing, or otherwise entering, or performing work in

or on a tree.

Only qualied line-clearance arborists or qualied line-

clearance arborist trainees shall be assigned to work

where an electrical hazard exists. Qualied line-clearance arborist trainees shall be under the direct supervi-

sion of qualied line-clearance arborist.

A second qualied line-clearance arborists or line-clear-

ance arborist trainees shall be within vision or voice

communication during line-clearing operations aloft

when line-clearance arborists or line-clearance arborist

trainees must approach closer than 10 feet (3.05 meters) to any energized electrical conductor in excess of

750 volts (primary conductor) or when:

1. Branches or limbs being removed cannot rst be

cut (with a pole pruner/pole saw) to sufciently clear

electrical conductors, so as to avoid contact.

2. Roping is required to remove branches or limbs

from such electrical conductors. This does not apply to individuals working on behalf of, or employed

by, electrical system owners/operators engaged in

line-clearing operations incidental to their normal

occupation.

Qualied line-clearance arborists and line-clearance

arborist trainees shall maintain minimum approach distances from energized electrical conductors in accordance with Table 1.

All other arborists shall maintain a minimum approach

distance from energized electrical conductors in accordance with Table 2.

Branches hanging on an energized electrical conductor

shall be removed using non-conductive equipment.

CR27 User Manual ◄ 7

Page 8

ELECTRICAL HAZARDS

Table 1. Minimum approach distances from energized conductors for qualied line-clearance arborists and

qualied line-clearance arborist trainees.

Nominal

Voltage

kV phase-to-phase

Includes 1910.269

elevation factor, sea

level to 5000 ft1)

ft-in m ft-in m ft-in m

Includes 1910.269

elevation factor,

5001–10,000 ft1)

Includes 1910.269

elevation factor,

10,000–14,000 ft1)

0.05–1.0 Avoid contact Avoid contact Avoid contact

1.1–15.0 2-04 0.71 2-08 0.81 2-10 0.86

15.1–36.0 2-09 0.84 3-02 0.97 3-05 1.04

36.1–46.0 3-00 0.92 3-05 1.04 3-09 1.14

46.1–72.5 3-09 1.14 4-03 1.30 4-07 1.40

72.6–121.0 4-06 1.37 5-02 1.58 5-07 1.70

138.0–145.0 5-02 1.58 5-11 1.80 6-05 1.96

161.0–169.0 6-00 1.83 6-10 2.08 7-05 2.26

230.0–242.0 7-11 2.41 9-00 2.75 9-09 2.97

345.0–362.0 13-02 4.02 15-00 4.58 16-03 4.96

500.0–550.0 19-00 5.80 21-09 6.63 23-06 7.17

765.0–800.0 27-04 8.34 31-03 9.53 33-10 10.32

1)

Exceeds phase-to-ground; elevation factor per 29 CFR 1910.269.

Table 2. Minimum approach distances to energized conductors for persons other than qualied line-clearance arborists and qualied line-clearance arborist trainees.

Nominal Voltage

kV phase-to-phase

1)

Distance

ft-in m

0.0–1.0 10-00 3.05

1.1–15.0 10-00 3.05

15.1–36.0 10-00 3.05

36.1–50.0 10-00 3.05

50.1–72.5 10-09 3.28

72.6–121.0 12-04 3.76

138.0–145.0 13-02 4.00

161.0–169.0 14-00 4.24

230.0–242.0 16-05 4.97

345.0–362.0 20-05 6.17

500.0–550.0 26-08 8.05

785.0–800.0 35-00 10.55

1)

Exceeds phase-to-ground.

8 ► CR27 User Manual

Page 9

ELECTRICAL HAZARDS

The tie-in position should be above the work area and

located in such a way that a slip would swing the arborist

away from any energized electrical conductors or other

identied hazard.

While climbing, the arborist should climb on the side of

the tree that is away from energized electrical conductors as required in Tables 1 and 2.

Footwear, including lineman’s overshoes, having electrical-resistant soles, shall not be considered as providing

any measure of safety from electrical hazards.

Rubber gloves, with or without leather or other protective covering, shall not be considered as providing any

measure of safety from electrical hazards.

Ladders, platforms and aerial devices, including insulated aerial devices, shall be subject to minimum approach

distances in Table 1 and 2.

Aerial devices and attached equipment (such as chippers) contacting energized electrical conductors shall be

considered energized. Contact shall be avoided, except

where emergency rescue procedures are being carried

out. Emergency rescue should be performed in accordance with 4.3.

STORM WORK AND EMERGENCY

CONDITIONS-LINE CLEARANCE

Line clearance shall not be performed during adverse

weather conditions such as thunderstorms, high winds

and snow and ice storms.

Qualied line-clearance arborists and qualied line-

clearance arborists trainees performing line clearance

in the aftermath of a storm or under similar conditions

shall be trained in the special hazards associated with

this type of work.

Line-clearance operations shall be suspended when

storm work or emergency conditions develop involving

energized electrical conductors. Electrical system own-

ers/operators shall be notied immediately.

CR27 User Manual ◄ 9

Page 10

TOOL STICKERS & TAGS

DANG ER

THIS SAW BLADE OF THE CR27 WIL L CONTINUE TO ROTATE

FOR UP TO 15 SECONDS OR MORE AFTER RELEASING THE

ON/OFF TRIGGER. DURING THIS “COAST DOWN” TIME,

CONTACT WITH THE BLADE OF THE CR27 MAY RESULT IN

SEVERE PERSONAL INJURY.

AFTER RELEASING THE ON /OFF TRIGGE R, SAW OPERATORS

MUST BE CERTAIN THAT THE BLADE HAS COME TO A COMPLET E

STOP BEFORE PLACING THE SAW ON THE GROU ND, LOWERIN G

THE SAW INTO THE TRUCKS BUCKET, STORING THE SAW OR

CONTACTING THE BLADE IN ANY WAY. FAILURE TO OBSERVE

THESE PRECAUTIO NS MAY RESULT IN SEVERE PERSONAL

INJURY.

OTHER WORKERS AND BYSTANDERS MUST STAY CLEAR OF

THE WORK AREA TO AVOID SEVE RE PERSO NAL INJURY RESULTING

FROM CONTACT WITH THE SAW BLADE AS WELL AS FALLING

LIMBS, BRANCHES AND OTHER D EBRIS.

St anley Hydraulic Tools

3810 SE Naef Road

Milwaukie, OR 97062

Model

ELECTROCUTION

DANGER

Failure touse hydraulic hose labeledand certified

as non-conductivewhen using hydraulic toolson

or nearelectric lines mayresultin deathor

serious injury.

Forproper and safeoperationreadownersmanual

and mwkesure that you havebeen properly

trained incorrect procedures requiredfor work

on oraround electric lines.

HAZARD

27694

Danger Decal

03784

5-7 GPM Sticker

12412

Electrical Warning Decal

05153

Stanley Decal

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CER-

TIFIED AS NON-CONDUCTIVE WHEN USING HYDRAULIC

TOOLS ON OR NEAR ELECTRICAL LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTIFIED AS NON-

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE THE

HOSE IS MAINTAINED AS NON-CONDUCTIVE. THE HOSE

SHOULD BE REGULARLY TESTED FOR ELECTRIC CUR-

RENT LEAKAGE IN ACCORDANCE WITH YOUR SAFETY

DEPARTMENT INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJECTION INTO THE BODY OR CAUSE OTHER SEVERE

PERSONAL INJURY.

A. DO NOT EXCEED SPECIFIED FLOW AND PRESSURE

FOR THIS TOOL. EXCESS FLOW OR PRESSURE MAY

CAUSE A LEAK OR BURST.

B. DO NOT EXCEED RATED WORKING PRESSURE OF

HYDRAULIC HOSE USED WITH THIS TOOL. EXCESS

PRESSURE MAY CAUSE A LEAK OR BURST.

C. CHECK TOOL HOSE COUPLERS AND CONNECTORS

DAILY FOR LEAKS. DO NOT FEEL FOR LEAKS WITH

YOUR HANDS. CONTACT WITH A LEAK MAY RESULT

IN SEVERE PERSONAL INJURY.

15863

Danger Decal

24827

Name Tag

DANGERDANGER

D. DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO

NOT ABUSE HOSE. DO NOT USE KINKED, TORN OR

DAMAGED HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CON-

NECTED TO THE TOOL BEFORE PRESSURING SYSTEM.

SYSTEM PRESSURE HOSE MUST ALWAYS BE CONNECTED TO TOOL “IN” PORT. SYSTEM RETURN HOSE

MUST ALWAYS BE CONNECTED TO TOOL “OUT” PORT.

REVERSING CONNECTIONS MAY CAUSE REVERSE

TOOL OPERATION WHICH CAN RESULT IN SEVERE

PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSED-

CENTER HYDRAULIC SYSTEMS. THIS MAY RESULT IN

LOSS OF OTHER HYDRAULIC FUNCTIONS POWERED BY

THE SAME SYSTEM AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA.

KEEP BYSTANDERS CLEAR OF YOUR WORK AREA.

6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PROTECTION.

7. TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE,

ALL TOOL REPAIR MAINTENANCE AND SERVICE MUST

ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY

TRAINED PERSONNEL.

10 ► CR27 User Manual

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

TAG TO BE REMOVED ONLY BY

SEE OTHER SIDE

SAFETY TAG P/N 15875 (Shown smaller then actual size)

TOOL BEFORE USING IT.

OPERATION MANUAL.

TOOL OPERATOR.

SEE OTHER SIDE

Page 11

HOSE TYPES

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use with

Stanley Hydraulic Tools. They are:

Certied non-conductive — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid

reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certied non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) — constructed of synthetic rubber inner tube, single or double wire braid reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used near

electrical conductors.

Fabric-braided (not certied or labeled non-conductive) — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover. This

hose is not certied non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from Stanley Hydraulic

Tools. DO NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your Stanley Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

ON OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND

TEST HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH

SAFETY DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE

OR HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.

KEEP HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT

CONTACT DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION

AND SEVERE PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT

USE HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAM-

AGE TO COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE

IMMEDIATELY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

DANGER

SEE OTHER SIDE

SIDE 2

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

DANGER

DANGER

1. DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

SEE OTHER SIDE

SIDE 2

DO NOT REMOVE THIS TAG

DO NOT REMOVE THIS TAG

CR27 User Manual ◄ 11

Page 12

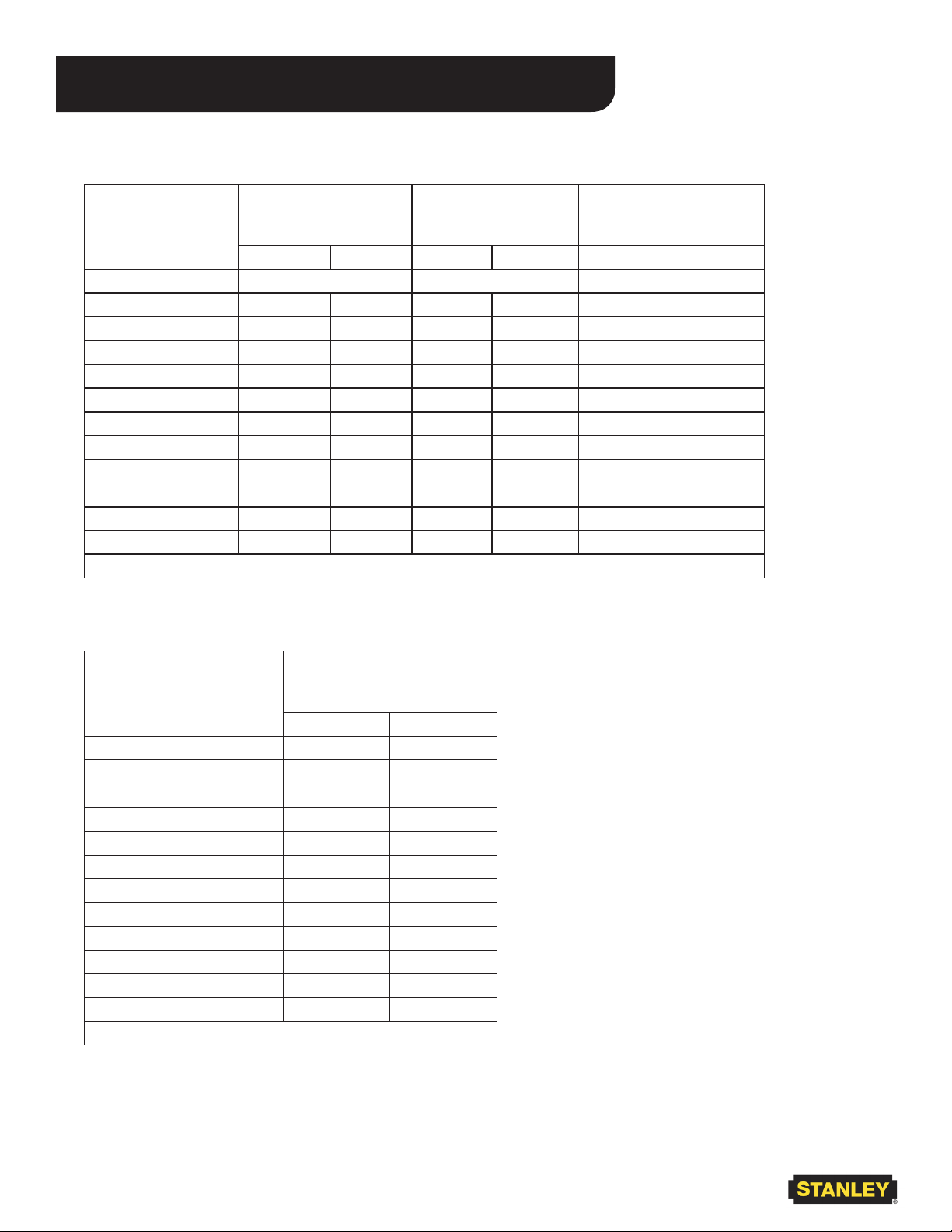

HOSE RECOMMENDATIONS

Min. Working Pressure

USE

(Press/Return)

Certied Non-Conductive Hose - Fiber Braid - for Utility Bucket Trucks

Oil Flow Hose Lengths Inside Diameter

GPM LPM FEET METERS INCH MM PSI BAR

4-9 15-34 up to 10 up to 3 3/8 10 Both 2250 155

Conductive Hose - Wire Braid or Fiber Braid -DO NOT USE NEAR ELECTRICAL CONDUCTORS

4-6 15-23 up to 25 up to 7.5 3/8 10 Both 2500 175

4-6 15-23 26-100 7.5-30 1/2 13 Both 2500 175

5-10.5 19-40 up to 50 up to 15 1/2 13 Both 2500 175

5-10.5 19-40 51-100 15-30 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

5-10.5 19-40 100-300 30-90

10-13 38-49 up to 50 up to 15 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

10-13 38-49 51-100 15-30

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

10-13 38-49 100-200 30-60

5/8 16 Pressure 2500 175

13-16 49-60 up to 25 up to 8

3/4 19 Return 2500 175

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

13-16 49-60 26-100 8-30

PRESSURE

<<< FLOW

RETURN

FLOW >>>

Figure 1. Typical Hose Connections

Tool to Hydraulic Circuit Hose

Recommendations

The chart to the right shows recommended

minimum hose diameters for various hose

lengths based on gallons per minute (gpm)/

liters per minute (lpm). These recommenda-

tions are intended to keep return line pressure

(back pressure) to a minimum acceptable lev-

el to ensure maximum tool performance.

12 ► CR27 User Manual

This chart is intended to be used for hydraulic

tool applications only based on Stanley Hy-

draulic Tools tool operating requirements and

should not be used for any other applications.

All hydraulic hose must have at least a rated

minimum working pressure equal to the maxi-

mum hydraulic system relief valve setting.

All hydraulic hose must meet or exceed

specications as set forth by SAE J517.

Page 13

HTMA / EHTMA REQUIREMENTS

HTMA REQUIREMENTS

HTMA

HYDRAULIC SYSTEM REQUIREMENTS

Flow Range

Nominal Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

Maximum back pressure

(at tool end of the return hose)

Measured at a max. uid viscosity of:

(at min. operating temperature)

Temperature: Sufcient heat rejection

capacity to limit max. uid temperature to:

(at max. expected ambient temperature)

Min. cooling capacity at a temperature

difference of between ambient and uid

temps

NOTE:

Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator

discomfort at the tool.

Filter

Min. full-ow ltration

Sized for ow of at least:

(For cold temp. startup and max.

dirt-holding capacity)

4-6 gpm 7-9 gpm 9-10.5 gpm 11-13 gpm

(15-23 lpm) (26-34 lpm) (34-40 lpm) (42-49 lpm)

1500 psi 1500 psi 1500 psi 1500 psi

(103 bar) (103 bar) (103 bar) (103 bar)

2100-2250 psi 2100-2250 psi 2200-2300 psi 2100-2250 psi

(145-155 bar) (145-155 bar) (152-159 bar) (145-155 bar)

250 psi 250 psi 250 psi 250 psi

(17 bar) (17 bar) (17 bar) (17 bar)

400 ssu* 400 ssu* 400 ssu* 400 ssu*

(82 centistokes) (82 centistokes) (82 centistokes) (82 centistokes)

140° F 140° F 140° F 140° F

(60° C) (60° C) (60° C) (60° C)

3 hp 5 hp 6 hp 7 hp

(2.24 kW) (3.73 kW) (5.22 kW) (4.47 kW)

40° F 40° F 40° F 40° F

(22° C) (22° C) (22° C) (22° C)

25 microns 25 microns 25 microns 25 microns

30 gpm 30 gpm 30 gpm 30 gpm

(114 lpm) (114 lpm) (114 lpm) (114 lpm)

TYPE I TYPE II

TOOL TYPE

TYPE RR

TYPE III

Hydraulic uid Petroleum based

(premium grade, anti-wear, non-conductive)

Viscosity (at min. and max. operating temps)

NOTE:

When choosing hydraulic uid, the expected oil temperature extremes that will be experienced in service determine the

most suitable temperature viscosity characteristics. Hydraulic uids with a viscosity index over 140 will meet the requirements

over a wide range of operating temperatures.

*SSU = Saybolt Seconds Universal

EHTMA

100-400 ssu* 100-400 ssu* 100-400 ssu* 100-400 ssu*

(20-82 centistokes)

CLASSIFICATION

HYDRAULIC SYSTEM

REQUIREMENTS

Flow Range

Nominal Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

NOTE: These are general hydraulic system requirements. See tool specication page for tool specic requirements

B

3.5-4.3 gpm 4.7-5.8 gpm 7.1-8.7 gpm 9.5-11.6 gpm 11.8-14.5 gpm

(13.5-16.5 lpm) (18-22 lpm) (27-33 lpm) (36-44 lpm) (45-55 lpm)

1870 psi 1500 psi 1500 psi 1500 psi 1500 psi

(129 bar) (103 bar) (103 bar) (103 bar) (103 bar)

2495 psi 2000 psi 2000 psi 2000 psi 2000 psi

(172 bar) (138 bar) (138 bar) (138 bar) (138 bar)

C

D

CR27 User Manual ◄ 13

Page 14

OPERATION

IMPORTANT

PREOPERATION PROCEDURES

PREPARATION FOR INITIAL USE

Each unit as shipped has no special unpacking or assembly requirements prior to usage. Inspection to assure the unit was not damaged in shipping and does not

contain packing debris is all that is required. After installation of a saw blade a unit may be put to use.

CHECK HYDRAULIC POWER SOURCE

1. Using a calibrated owmeter and pressure gauge,

check that the hydraulic power source develops a

ow of 5–7 gpm/19–26 lpm at 1000–2000 psi/70–

140 bar.

2. Make certain the hydraulic power source is equipped

with a relief valve set to open at 2100–2250 psi/145–

155 bar minimum.

3. Check that the dual spool valve is set to the hydraulic system type (open-center (OC) or closed-center

(CC) operation).

CHECK TOOL

1. Make sure all tool accessories are correctly installed. Failure to install tool accessories properly

can result in damage to the tool or personal injury.

2. There should be no signs of leaks.

3. The tool should be clean, with all ttings and fasten-

ers tight.

CHECK TRIGGER MECHANISM

Check that the trigger operates smoothly and is free to

travel between the ON and OFF positions.

SETTING THE DUAL SPOOL FOR OC

(OPEN-CENTER) OR CC (CLOSEDCENTER) OPERATION

This tool is furnished with a ON/OFF spool

commonly referred to as a “dual spool” which permits

adjustment so the tool may be operated on either an

open-center (OC) or closed-center (CC) hydraulic

system. The dual spool is normally set to the OC

position at time of manufacture. The dual spool can

also be disabled so that the tool may be set to OC

only operation. For more details, please refer to the

following instructions.

SETTING FOR OPEN-CENTER (OC) OR

CLOSED-CENTER (CC) OPERATION

1. To set the tool for open-center (OC) system operation turn the selector screw located in the top of the

valve spool fully out (counter-clockwise) until it hits

the stop.

2. To set the tool for closed-center (CC) system operation turn the selector screw located in the top of the

valve spool fully in (clockwise) until it bottoms.

TO DISABLE DUAL SPOOL OPERATION

AND CONVERT TO OPEN-CENTER ONLY

OPERATION

1. Turn the selector screw located in the top of the

valve spool fully out (counter-clockwise) until it hits

the stop.

2. Insert the small plug from the kit (furnished with the

tool) into the hole located in the top of the selector

screw. Tap the plug down using a small punch and

hammer. DO NOT USE ANY ADHESIVES.

TO DISABLE DUAL SPOOL OPERATION

AND CONVERT TO CLOSED-CENTER

ONLY OPERATION

1. Turn the selector screw located in the top of the

valve spool fully in (clockwise) until it bottoms.

2. Insert the small plug from the kit (furnished with the

tool) into the hole located in the top of the selector

screw. Tap the plug down using a small punch and

hammer. DO NOT USE ANY ADHESIVES.

BLADE INSTALLATION

1. Handle the saw blade with care. The cutting edges

are sharp and careless handling could result in injury.

2. Install the blade over the motor shaft and onto the

xed collar so that the points of the teeth on the

blade are facing clockwise as viewed from the front

of the motor (see Figure 2).

3. Install the moveable collar followed by the collet nut

(see Figure 3). Tighten the collet nut hard (not wrist

tight).

4. Install the locking nut with internal taper facing toward the collet nut and tighten it hard against the

collet nut.

5. As a nal tightening procedure, with a wrench on

each of the nuts, tighten the locking nut one half

wrench at further.

14 ► CR27 User Manual

Page 15

OPERATION

BLADE INSTALLATION

CLOCKWISE ROTATION

nect the return hose fi rst and disconnect it last to minimize

or avoid trapped pressure within the saw motor.

3. Observe fl ow indicators stamped on hose couplers to

be sure that oil will fl ow in the proper direction. The female

coupler is the inlet coupler.

NOTE:

The pressure increase in uncoupled hoses left in the

sun may result in making them diffi cult to connect.

When possible, connect the free ends of operating

hoses together.

OPERATING PROCEDURES

Observe all safety precautions.

DO NOT OPERATE A CIRCLE SAW UNLESS YOU HAVE

BEEN SPECIFICALLY TRAINED TO DO SO.

Keep all parts of the body away from the saw blade during

operation of the tool.

Carry the saw with the unit de-energized and the blade

away from the body.

Always connect the hoses to the tool hose couplers before

energizing the power source.

Do not operate a circle saw that is damaged, improperly

adjusted or is not completely and securely assembled.

Keep the saw and handles clean and free of oil and con-

taminates.

OPERATION

BLADE INSTALLATION

Figure 1. Correct Rotation Direction

CLOCKWISE ROTATION

nect the return hose fi rst and disconnect it last to minimize

or avoid trapped pressure within the saw motor.

3. Observe fl ow indicators stamped on hose couplers to

be sure that oil will fl ow in the proper direction. The female

coupler is the inlet coupler.

NOTE:

The pressure increase in uncoupled hoses left in the

sun may result in making them diffi cult to connect.

When possible, connect the free ends of operating

hoses together.

OPERATING PROCEDURES

Observe all safety precautions.

DO NOT OPERATE A CIRCLE SAW UNLESS YOU HAVE

BEEN SPECIFICALLY TRAINED TO DO SO.

Keep all parts of the body away from the saw blade during

operation of the tool.

Carry the saw with the unit de-energized and the blade

away from the body.

Always connect the hoses to the tool hose couplers before

energizing the power source.

Do not operate a circle saw that is damaged, improperly

adjusted or is not completely and securely assembled.

Keep the saw and handles clean and free of oil and con-

taminates.

Do not hang the saw on utility wires or cables.

Do not leave the saw hanging in a tree.

Do not leave cut branches in a tree.

Branches bent under tension are considered hazardous.

Do not allow binding of the saw blade.

Figure 2. Correct Rotation Direction

COLLET NUT

LOCKING NUT

Figure 3. Collet Nut & Locking Nut

CONNECT HOSES

1. Wipe all hose couplers with a clean lint-free cloth

before making connections.

2. Connect the hoses from the hydraulic power source

to the hose couplers on the saw. It is a good prac-

tice to connect the return hose rst and disconnect

it last to minimize or avoid trapped pressure within

the saw motor.

3. Observe ow indicators stamped on hose couplers

to be sure that oil will ow in the proper direction.

The female coupler is the inlet coupler.

NOTE:

The pressure increase in uncoupled hoses left in the

sun may result in making them difcult to connect.

When possible, connect the free ends of operating

hoses together.

OPERATING PROCEDURES

Observe all safety precautions.

• DO NOT OPERATE A CIRCLE SAW UNLESS YOU

HAVE BEEN SPECIFICALLY TRAINED TO DO

SO.

• Keep all parts of the body away from the saw blade

during operation of the tool.

• Carry the saw with the unit de-energized and the

blade away from the body.

OPERATION

• Always connect the hoses to the tool hose couplers

before energizing the power source.

• Do not operate a circle saw that is damaged, improperly adjusted or is not completely and securely

assembled.

• Keep the saw and handles clean and free of oil and

contaminates.

• Do not hang the saw on utility wires or cables.

• Do not leave the saw hanging in a tree.

• Do not leave cut branches in a tree.

• Branches bent under tension are considered haz-

ardous.

• Do not allow binding of the saw blade.

• The saw blade will continue to spin for up to 5 sec-

onds or more after releasing the ON/OFF trigger.

During this “coast down” time, contact with the saw

blade may result in severe personal injury. Refer to

page 2. On early model saws the “coast down” time

will be up to 15 seconds.

• Use extreme caution when sawing small size brush

and saplings. Slender material may catch in the saw

blade and be thrown toward the operator.

• Keep the saw blade away from all surfaces when

starting rotation of the blade.

• Do not reverse blade rotation direction by changing

oil ow direction. The saw is designed to operate in

only one direction.

• Do not use the saw around energized transmission

lines.

• Do not inspect, clean or repair the saw with the power source operating or with operating pressure at the

saw. Accidental engagement of the tool can cause

serious injury.

• Do not operate the saw at oil temperatures above

140 °F/60 °C. Operation at higher temperatures can

cause higher than normal temperatures at the tool

which can cause operator discomfort.

• After releasing the ON/OFF trigger, be certain that

the saw blade has come to a complete stop before

placing the saw on the ground, lowering the saw into

the truck’s bucket, storing the saw or contacting the

blade in any way. Failure to observe these precautions may result in severe personal injury.

• The saw operator must keep other workers and bystanders clear of the work area, including the area

into which cut limbs or debris fall. Failure to heed

this precaution can result in severe personal injury.

CR27 User Manual ◄ 15

Page 16

OPERATION

IMPORTANT

MAKING CUTS

WARNING

The following are general wood cutting procedures

and techniques. Differences in the terrain,

vegetation, and type of wood will make this

information more or less valid for particular areas.

For advice on specic wood cutting problems or

techniques for your area, consult your local Stanley

representative or your county agent. They can often

provide information that will make your work safer

and more productive.

1.

Move the hydraulic circuit control valve to the ON

position to pressurize the circuit.

2. Maintain a rm grip on the saw handle. While main-

taining rm footing and balance, position the saw

blade near the material to be cut.

3. Squeeze the ON/OFF valve handle trigger and allow

the saw blade to reach FULL speed.

4. In sawing limbs which have a tendency to split or

tear when making a single saw ush cut, Figure 4, it

is advisable to make more than one cut. The rst cut

is made a few inches from the point of the ush cut

removing the weight of the limb being trimmed out

and leaving a short stub. The stub is then ushed off

as shown in Figure 5. Whenever practical, the cut

shall be treated with tree paint if it is larger than 1

inch in diameter. This technique will avoid breaking

the lateral which you are trying to save or splitting

the remaining limb down the center as the ush cut

is made.

FINAL CUT

THE FIRST CUT IS TO TAKE WEIGHT

OFF BEFORE THE FINAL CUT TO

PREVENT THE LIMB FROM SPLITTING

DOWN THE CENTER.

The saw blade must reach FULL speed before

attempting a cut.

LATERAL BRANCH

BRANCH TO BE CUT

PLACING BLADE

TOWARDS LATERAL

BRANCH WILL LEAVE

EDGE FLUSH WITH

LATERAL BRANCH

NO STUB LEFT

Figure 4. Flush Cutting a Limb That Might Split or Tear.

Figure 5. Flush Cut

WARNING

Do not cut material that is directly overhead. When it

falls it may cause operator injury.

5.

Watch the saw reaction to making a cut. Control the

movement of the saw.

6. Release the ON/OFF trigger to stop saw blade rotation.

7. Reposition the saw to make the next cut and continue operating the saw as stated above.

WARNING

After releasing the ON/OFF trigger, saw operators

must be certain that the saw has come to a complete

stop after a few seconds or more. The saw blade

must come to a complete stop before placing the saw

into the truck’s bucket, storing the saw or contacting

the blade in any way. Failure to observe this warning

may result in severe personal injury.

16 ► CR27 User Manual

Page 17

OPERATION

AFTER OPERATION

1. Wipe the saw thoroughly with a clean dry or slightly

oiled cloth.

2. Clean tree pitch and residue from the blade. Handle

the blade with care to avoid getting cut by the sharp

teeth.

3. Check all fasteners for tightness.

4. When the saw is not in use, store horizontally in a

clean, dry space and protected from damage.

5. Protect the blade teeth and keep the teeth sharp. A

sharp blade will cut cleaner and faster.

BLADE CARE

Every day visually check the blade for cracks and warp-

age. Cracks will lead to a break and “out of at” will

cause excessive vibration. Make sure the spindle locknut is tight.

When sharpening, never use a at le which may leave

a square corner in the gullet. Because of high speed

vibration, this becomes a point from which a crack will

start.

Do not let gum, sap or dirt build up underneath the cutting edges. This adds undue friction and reduces cutting

efciency due to loss of clearance.

Inspection of the cutting teeth should be made often during each day’s use. It is faster to touch up the teeth with

a few strokes of the le than to allow the teeth to get dull.

Dull teeth cause loss of cutting capacity and too much

friction. A sharp spare blade is a good back-up in case

of trouble.

BLADE SHARPENING

BLADE TEETH

Using a le holder with a 7/16 inch round le (Stanley

Part Number 11299), place the le holder at on top of

the cutter with the le against the cutter tooth.

CUTTER

CUTTER TOOTH

FILE HOLDER

FILE

Maintain a 20° angle and always le outwards on each

right or left cutter tooth. File only with a slight pressure

against the cutter tooth (not on top of the cutter) during

the forward stroke. Release pressure as you pull the le

back. The le will only cut during the forward stroke.

While ling, always try to keep the le holder perpendicular to the side of the blade. Try not to move the le

holder up or down or move the le holder to the setting

of the tooth.

Figure 7. Filing Angle

TOP OF CUTTERS

The top of each cutter is factory ground to ensure the

best cutting performance. Normally, the tops of the cut-

ters will not require ling unless the edge is badly worn

or damaged.

If the top of a cutter requires ling, use a smooth at le

to give the cutter its original shape. After ling, ensure

that all cutters have the same length and prole.

SETTING TOOTH ANGLE

A sharp outside corner and an exact angle setting will

give maximum cutting performance. Special setting tool

(Stanley part number 34653) is required to verify or properly set the angle of each cutter tooth at .040 inch/1 mm.

Match one of the grooves in the setting tool to the blade

thickness. Place the setting tool over the cutter near the

cutter tooth and bend the tooth until the angle on the setting tool touches the side of the blade. DO NOT OVER

SET. Over-setting will cause rough cutting and vibration

which may result in stress cracks and eventual blade

failure.

PLACE FILE HOLDER FLAT ON TOP OF CUTTER

Figure 6. Blade Sharpening

CR27 User Manual ◄ 17

Page 18

OPERATION

Figure 8. Setting Cutter Tooth Angle

COLD WEATHER OPERATION

If the saw is to be used during cold weather, preheat

the hydraulic uid at low engine speed. When using the

normally recommended uids, uid temperature should

be at or above 50 °F/10 °C (400 ssu/82 centistokes) before use.

18 ► CR27 User Manual

Page 19

TOOL PROTECTION & CARE

NOTICE

In addition to the Safety Precautions found in

this manual, observe the following for equipment

protection and care.

• Make sure all couplers are wiped clean before connection.

• The hydraulic circuit control valve must be in the

OFF position when coupling or uncoupling hydraulic tools. Failure to do so may result in damage to

the quick couplers and cause overheating of the hydraulic system.

• Always store the tool in a clean dry space, safe from

damage or pilferage.

• Make sure the circuit PRESSURE hose (with male

quick disconnect) is connected to the IN port. The

circuit RETURN hose (with female quick disconnect)

is connected to the opposite port. Do not reverse cir-

cuit ow. This can cause damage to internal seals.

• Always replace hoses, couplings and other parts

with replacement parts recommended by Stanley

Hydraulic Tools. Supply hoses must have a minimum working pressure rating of 2500 psi/172 bar.

• Do not exceed the rated ow and pressure. Refer

to the Specications page in this manual for correct

ow and pressure rates. If ow and pressure are ex-

ceeded, rapid failure of the internal seals may result.

• Always keep critical tool markings, such as warning

stickers and tags legible.

• Tool repair should be performed by experienced

personnel only.

• Make certain that the recommended relief valves

are installed in the pressure side of the system.

• Do not use the tool for applications for which it was

not intended.

CR27 User Manual ◄ 19

Page 20

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem. When

diagnosing faults in operation of the saw, always make sure the hydraulic power source is supplying the correct

hydraulic ow and pressure to the saw as listed in the table. Use a owmeter know to be accurate. Check the ow

with the hydraulic uid temperature at least 80 °F/27 °C.

PROBLEM CAUSE REMEDY

Tool will not operate. Hydraulic system not engaged or

running.

Hydraulic system control valve is

OFF.

Tool not connected to the hydraulic

system.

Trigger and valve spool stick. Damaged trigger guard. Have repaired by an authorized

High back pressure. Determine cause of high back

Tool reverse plumbed to the

system.

Valve spool or spool bore scored by

contaminated hydraulic uid.

Saw cuts poorly. Blade is dull. Replace with sharp blade.

Saw is running backwards. Check direction of rotation. Correct

Blade installed backwards. Install the blade correctly. Blade

Saw slows excessively under load. System relief valve set too low. Check system relief and adjust

Tool motor worn. Have inspected and repaired by an

Hydraulic oil leaks from motor shaft. Motor shaft seal worn or failed. Have inspected and repaired by an

Hydraulic oil leaks between valve

handle and outer tube handle.

Oil tube seals worn or oil tubes

worn.

Engage or start hydraulic system.

Turn the system control valve ON.

Connect tool to the system.

Stanley Hydraulic Tools dealer.

pressure and return line and

remove restriction.

Correctly connect the pressure and

return lines.

Have repaired by an authorized

Stanley Hydraulic Tools dealer.

rotation is counterclockwise as

viewed from the motor side of the

saw blades.

teeth point in direction of rotation,

counterclockwise as viewed from

the motor side of the saw blades.

relief valve to crack open at 2100

psi.

authorized Stanley Hydraulic Tools

dealer.

authorized Stanley Hydraulic Tools

dealer.

Have inspected and repaired by an

authorized Stanley Hydraulic Tools

dealer.

20 ► CR27 User Manual

Page 21

SPECIFICATIONS

Capacity............................................................................................................................9 in. Diameter/23 cm Blade

Pressure Range................................................................................................................ 1000–2000 psi/70–140 bar

Maximum Back Pressure...................................................................................................................... 250 psi/17 bar

Flow Range ................................................................................................................................. 5–7 gpm/19–26 lpm

Porting ...................................................................................................................................................-8 SAE O-ring

Connect Size and Type ............................................................................... 3/8 in. NPT × -8 SAE Male Pipe Adapter

Hose Whips ............................................................................................................................................................ No

Weight ..................................................................................................................................................9.75 lbs/4.4 kg

Overall Length ....................................................................................................................................... 79 in./200 cm

Maximum Fluid Temperature .................................................................................................................. 140 °F/60 °C

ACCESSORIES

Description Part No.

9 in./23 cm Saw Blade, 44 tooth ........................................................................................................................ 00425

9 in./23 cm Brushcutter Saw Blade ...................................................................................................................34356

File Holder with 7/32 Round File (for sharpening brushcutter blades) .............................................................. 11299

Setting Tool (for setting cutter angles on brushcutter) ....................................................................................... 34653

Certied Non-Conductive Dual Oil Resistant Hose, 3/8 in. Diameter × 10 ft with Guards.................................05005

CR27 User Manual ◄ 21

Page 22

CR27 PARTS ILLUSTRATION

22 ► CR27 User Manual

Page 23

CR27 PARTS LIST

PART

ITEM

NO. QTY DESCRIPTION

1 00042 2 OIL TUBE ASSY

2 24829 1 OUTER TUBE ASSY

3 18089 6 CAPSCREW, BUTTONHEAD, 1/4-20 ×

4 00227 1 FIXED COLLAR

5 00103 1 RETAINING RING

6 07407 2 CAPSCREW, HEX SOCKET HEAD, 10-

7 00118 1 RETAINING RING

8 00008 1 RETAINING RING

9 00007 1 BALL BEARING

10 24842 1 MOTOR SHAFT

11 04856 1 RETAINING RING

12 19215 1 SEAL LINER

13 00173 1 QUAD RING

14 60804 1 O-RING

15 03227 1 NEEDLE ROLLER

16 04106 2 DRIVE GEAR

17 00289 2 DOWEL PIN

18 07305 2 HAND GUARD

19 11458 2 LINER

20 04041 4 DU BUSHING

21 04044 1 NEEDLE ROLLER

22 07612 1 IDLER SHAFT

23 00020 1 O-RING

24 07652 1 GEAR HOUSING ASSY (INCL ITEMS 17,

25 24827 1 NAME TAG

26 00753 8 CAPSCREW, HEX SOCKET HEAD, 10-

27 31689 1 FRONT BEARING HOUSING

28 16668 4 O-RING, 7/16 × 9/16 × 1/16 -017

31700 1 MOTOR ASSY (INCL ITEMS 7 THRU 17,

29 00026 1 O-RING, 3/16 × 5/16 × 1/16 -008

30 19875 1 SELECTOR SCREW

31 16070 1 RETAINING RING

32 22807 1 PLUG (FURNISHED IN 26414 LOCK-

33 31633 1 VALVE SPOOL

67128 1 VALVE SPOOL (MODEL CR27191P

34 07626 1 O-RING, 1/2 × 5/8 × 1/16

35 31630 1 VALVE HANDLE

36 01605 2 O-RING (INCL W/ ITEM 37)

37 00936 2 ADAPTER

3/8

32 × 3/4

20 & 24)

24 × 1-1/4

& 20 THRU 28)

OUT KIT)

ONLY)

PART

ITEM

NO. QTY DESCRIPTION

38 07627 1 O-RING, 5/8 × 3/4 × 1/16

39 65151 1 SPRING

40 22147 2 CAPSCREW, HEX SOC FLAT HD, 1/4-20

41 51183 1 TRIGGER

42 01534 1 ROLL PIN

43 51182 1 TRIGGER GUARD

44 12412 1 ELECTRICAL WARNING STICKER

45 27694 1 DANGER STICKER

46 03784 1 5–7 GPM STICKER

47 05153 1 STANLEY STICKER

48 15863 1 WARNING STICKER

49 N/A 1 DIELECTRIC TEST STICKER

50 34356 1 SAW BLADE

51 00125 1 MOVEABLE COLLAR

52 24853 1 COLLET NUT

53 24850 1 LOCKING NUT

54 31186 1 POPPET

55 34303 1 SPRING

56 34257 1 POPPET STOP

57 03364 1 O-RING

58 03709 1 PLUG

59 24837 4 HELICOIL

03972 1 FEMALE COUPLER

03973 1 MALE COUPLER

03971 1 COUPLER SET

29829 1 SEAL KIT

× 3/4

CR27 User Manual ◄ 23

Page 24

IMPORTANT

Stanley Hydraulic Tools

3810 SE Naef Road

Milwaukie, Oregon 97267-5698 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyhydraulic.com

To ll out a Product Warranty Recording form, and for information on your warranty,

visit Stanleyhydraulic.com and select the Warranty tab.

(NOTE: The warranty recording form must be submitted to validate the warranty).

Loading...

Loading...