DW080LRS, DW080LGS

Rotary Laser

Laser rotatif

Láser rotativo

Laser Rotativo

Instruction Manual

Guide d’utilisation

Manual de instrucciones

Manual de Instruções

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

Dúvidas? Visite-nos na Internet em www.D

eWALT.com.br

1-800-4-DeWALT

English 8

Français 18

Español 29

Português 41

A

15

10

11

12

2

3 618

9

14

13

25

24

745

1

B

5

X

Y

3

RPM

˚/45˚/90˚

15

4

2

6

7

3

C

20

20

5/8-11"

5/8-11"

PLUMB MODE/MODE APLOMB /MODALIDAD DE PLOMADA/

MODO NIVELAMENTO VERTICAL

LEVEL MODE/MODE NIVEAU/MODALIDAD DE NIVEL/

D

PLUMB MODE

MODE APLOMB

MODALIDAD DE

PLOMADAL

MODO NIVELAMENTO

VERTICAL

E F

15

MODO DE NIVELAMENTO

LEVEL MODE

MODE NIVEAU

MODALIDAD DE

NIVEL

MODO DE

NIVELAMENTO

4

G

H

21

I

28

54

53

27

26

22

22

30

30

23

J

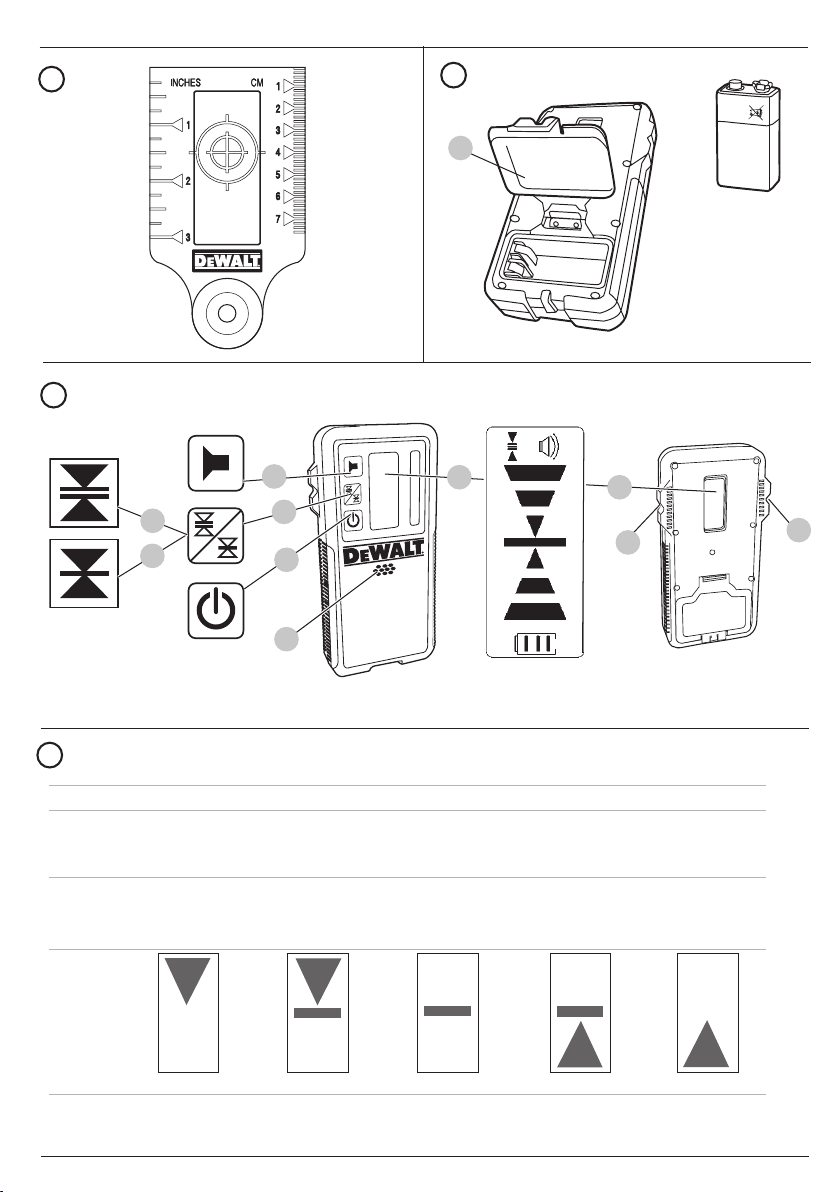

INDICATORS/INDICATEURS /INDICADORES/INDICADORES

Above Grade/

Au-dessus du niveau /

Por encima del nivel

Acima do grau

fast beep /

bip rapide /

bip rápido/

sinais audíveis

signal sonore /

audible signals/

señales auditivas/

ícones da tela

display icons/

icône affichée /

íconos en pantalla/

Bipe rápido

Slightly Above Grade/

Légèrement au-dessus du niveau /

Ligeramente por encima del nivel/

Ligeiramente acima do grau

fast beep /

bip rapide /

bip rápido/

Bipe rápido

On Grade/

Au niveau /

En nivel/

Um grau

steady tone/

tonalité constante /

tono constante/

Tom estável

Slightly below Grade/

Légèrement au-dessous du niveau /

Ligeramente por debajo del nive/

Ligeiramente abaixo do graul

slow beep/

bip lent /

bip lento/

Bipe lento

Below Grade/

Au-dessous du niveau /

Por debajo del nivel/

Abaixo do grau

slow beep/

bip lent /

bip lento/

Bipe lento

5

K

33

47

32

L

M

42

41

45

39

37

46

42

40

44

45

40

44

46

43

N

6

O

BEAM

FAISCEAU

RAYO

RAIO

A

B

L

P

LASER UNIT ROTATED 180˚

ROTATION DE L’APPAREIL LASER A 180˚

UNIDAD LÁSER ROTADA EN 180º

UNIDADE DE LASER EM ROTAÇÃO DE 180º

BEAM

FAISCEAU

RAYO

RAIO

AA

L

Q R

Marks on walls

Reperes sur les murs

Marcas en la pared

Marcas na parede

BB

7

ENGLISH

Definitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations and your risk of

personal injury or property damage.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

(Used without word) Indicates a safety related message.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in property damage.

If you have any questions or comments about this or any DeWALT tool, call us toll free at: 1-800-4-DeWALT

(1-800-433-9258).

Warning: To reduce the risk of injury, user must read instruction manual.

Safety Instructions for Lasers

WARNING! Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

WARNING! Laser Radiation Exposure. Do not disassemble or modify the laser level. There are no user serviceable

parts inside. Serious eye injury could result.

WARNING: Hazardous Radiation. Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

• Do not operate the laser in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

• Use the laser only with the specifically designated batteries. Use of any other batteries may create a risk of fire.

• Store idle laser out of reach of children and other untrained persons. Lasers are dangerous in the hands of untrained

users.

• Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for

one laser, may create a risk of injury when used on another laser.

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified

personnel may result in injury. To locate your nearest

to http://www.DeWALT.com on the Internet.

• Do not use optical tools such as a telescope or transit to view the laser beam. Serious eye injury could result.

• Do not place the laser in a position which may cause anyone to intentionally or unintentionally stare into the laser

beam. Serious eye injury could result.

• Turn the laser off when it is not in use. Leaving the laser on increases the risk of staring into the laser beam.

• Do not position the laser near a reflective surface which may reflect the laser beam toward anyone’s eyes. Serious eye

injury could result.

• Do not operate the laser around children or allow children to operate the laser. Serious eye injury may result.

• Do not remove or deface warning labels. Removing labels increases the risk of exposure to radiation.

• Position the laser securely on a level surface. Damage to the laser or serious injury could result if the laser falls.

WARNING: Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

WARNING! DO NOT DISASSEMBLE THE ROTARY LASER. There are no user serviceable parts inside.

Disassembling the rotary laser will void all warranties on the product. Do not modify the product in any way.

Modifying the tool may result in hazardous laser radiation exposure.

DeWALT service center call 1–800–4-DeWALT (1–800–433–9258) or go

8

• The label on your tool may include the following symbols.

V ........................volts

mW ....................milliwatts

........laser warning symbol

Warning Labels

For your convenience and safety, the following label is on your laser.

WARNING: To reduce the risk of injury, user must read instruction manual.

WARNING: LASER RADIATION. DO NOT STARE INTO BEAM. Class 3R Laser Product

AVOID EXPOSURE -LASER RADIATION IS EMITTED FROM THIS APERTURE

ENGLISH

nm..........wavelength in nanometers

3R .......... Class 3R Laser

DW080LGS

DW080LRS

Laser Information

The DW08

except for deviations pursuant to laser notice No. 50, dated June 24, 2007.

These devices comply with Part 15 of the FCC Rules. Operation is subject to the following two conditions: 1) this device may

not cause harmful interference, and 2) this device must accept any interference received, including interference that may cause

undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio and television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

0LRS/LGS Cordless Rotary Laser is a CLASS 3R laser product and complies with 21 CFR 1040.10 and 1040.11

Conforms to UL STDS 61010-1 & 2595

Certified to CSA STD C22.2 No. 61010-1

Complies with IEC 60825-1:2014

9

ENGLISH

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit

differentfrom that which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

Canada, Industry Canada (IC) Notices

Class B digital circuitry of this device complies with Canadian

ICES-003. This device complies with Industry Canada licenseexempt RSS standard(s). Operation is subject to the following

two conditions: 1) this device may not cause interference,

and 2) this device must accept any interference, including

interference that may cause undesired operation of the device.

READ ALL INSTRUCTIONS

Batteries and Power

This DeWALT rotary laser will accept all DeWALT 20 volt

lithium ion batteries, but is built to best resist damage during a

fall when used with the following batteries: All 1.5Ah and 2Ah

DeWALT 20 volt lithium ion batteries.

Charging the Battery

The battery pack is not fully charged out of the carton. You

need to use a DeWALT 20 volt charger to charge the battery

pack before you can use the rotary laser.

• Refer to the chart at the end of this manual for compatibility

of chargers and battery packs.

• Be sure to read all safety instructions before using your

charger.

WARNING:

• DO NOT attempt to charge the battery pack

1. Slide the battery pack into the charger as described in the

2. Wait until the battery pack is fully charged.

3. Slide the battery pack out of the track.

NOTE: When ordering replacement battery packs, be sure to

include the catalog number and voltage.

with any chargers other than the ones listed

in this manual. The charger and battery pack are

specifically designed to work together.

• Carefully follow all instructions and warnings on

the battery label and package and accompanying

Battery Safety Manual.

Battery Safety Manual.

3. Slide the battery pack all the way into the track on the side

of the laser.

4. Release the button on the battery pack.

Removing the Battery Pack

1. Press and hold the release button on the battery pack.

2. Slide the battery pack out of the track on the laser.

3. Release the button on the battery pack.

4. To recharge the battery pack, insert it into the charger, as

described in the Battery Safety Manual.

WARNING: Batteries can explode or leak, and can

cause injury or fire. To reduce this risk, follow the

instructions in the Battery Safety Manual.

Storing Battery Packs

• The best storage place is one that is cool and dry, and

away from direct sunlight and excess heat or cold.

• Long storage will not harm the battery pack or charger.

Under proper conditions, they can be stored for 5 years

or more.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

User Safety

Personal Safety

• Stay alert, watch what you are doing, and use common

sense when operating a laser product. Do not use

the tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while

operating laser products may result in serious personal

injury.

• Use appropriate personal protective equipment,

including eye protection when working in a construction

environment.

Tool Use and Care

• Do not use the tool if the switch does not turn it on or

off. Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

• Store idle laser products out of the reach of children

and do not allow persons unfamiliar with the laser

product or these instructions to operate the laser

product. Laser products are dangerous in the hands of

untrained users.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be

suitable for one tool, may become hazardous when used

with another tool.

Installing the 20V DeWALT Battery Pack

1. Position the fully-charged 20V DeWALT battery pack so the

release button (Figure

to the right.

2. Press and hold down the release button on the battery

pack.

E

15

) is facing away from you and

10

Caution:

This device complies with Part 15 of the FCC Rules / Industry

Canada licence-exempt RSS standard(s). Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference

received, including interference that may cause undesired

operation.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence. L'exploitation

est autorisée aux deux conditions suivantes : (1) l'appareil ne doit

pas produire de brouillage, et (2) l'utilisateur de l'appareil doit

accepter tout brouillage radioélectrique subi, même si le brouillage

est susceptible d'en compromettre le fonctionnement.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to

operate the equipment.

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This

equipment generates uses and can radiate radio frequency

energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of

the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for

help.

MPE Reminding

To satisfy FCC / IC RF exposure requirements, a separation

distance of 20 cm or more should be maintained between the

antenna of this device and persons during device operation.

To ensure compliance, operations at closer than this distance is

not recommended.

L'antenne installée doit être située

de facon à ce que la population ne puissey être exposée à une dis

tance de moin

de 20 cm. Installer l'antenne de facon à ce que le personnel ne

puisse approcher à 20 cm ou moins de la position centrale de l’

antenne.

La FCC des éltats-unis stipule que cet appareil doit être en tout

temps éloigné d’au

moins 20 cm des personnes pendant son functionnement.

11

The RBRC® Seal

15˚/45˚/90˚

The RBRC® (Rechargeable Battery

Recycling Corporation) Seal on the nickel

cadmium, nickel metal hydride or lithium-ion

batteries (or battery packs) indicates that the

costs to recycle these batteries (or battery

packs) at the end of their useful life have already been paid

DeWALT. In some areas, it is illegal to place spent nickel

by

cadmium, nickel metal hydride or lithium-ion batteries in the

trash or municipal solid waste stream and the Call 2 Recycle®

program provides an environmentally conscious alternative.

Call 2 Recycle, Inc., in cooperation with

battery users, has established the program in the United

States and Canada to facilitate the collection of spent nickel

cadmium, nickel metal hydride or lithium-ion batteries. Help

protect our environment and conserve natural resources by

returning the spent nickel cadmium, nickel metal hydride or

lithium-ion batteries to an authorized

or to your local retailer for recycling. You may also contact

your local recycling center for information on where to drop off

the spent battery. RBRC® is a registered trademark of Call 2

Recycle, Inc.

DeWALT and other

DeWALT service center

Operation

Operating Tips

• To extend battery life per charge, turn the laser off when it

is not in use.

• To ensure the accuracy of your work, check the laser

calibration often. Refer to Calibrating the Laser.

• Before attempting to use the laser, make sure the tool is

positioned on a relatively smooth, secure surface.

• Always mark the center of the laser line or dot. If you

mark different parts of the beam at different times you will

introduce error into your measurements.

• To increase working distance and accuracy, set up the

laser in the middle of your working area.

• When attaching to a tripod or wall, mount the laser

securely.

• When working indoors, a slow rotary head speed will

produce a visibly brighter line, a faster rotary head speed

will produce a visibly solid line.

• To increase beam visibility, wear Laser Enhancement

Glass es and/or use a Laser Target Card to help find the

beam.

• Extreme temperature changes can cause movement or

shifting of building structures, metal tripods, equipment,

etc., which can effect accuracy. Check your accuracy often

while working.

• When working with the

the laser’s rotation speed to the fastest setting.

• If the laser is dropped or has suffers a sharp blow, have

the calibration system checked by a qualified service

center before using the laser.

DeWALT Digital Laser Detector, set

ENGLISH

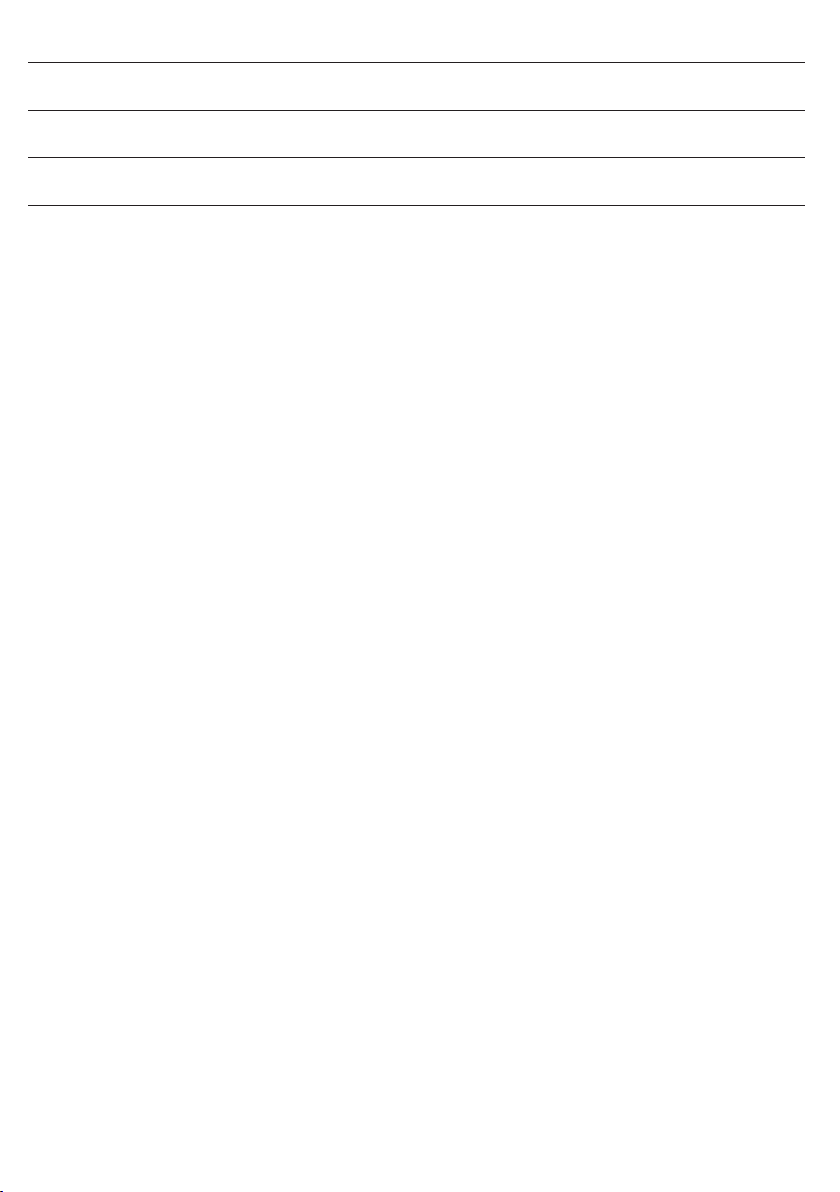

Control Panel (Fig. A)

2

6

and

again.

1

, the

7

.

2

.

The laser is primarily controlled by the power button

mode button

4

. These features are then modified when used with either the

Axis selection button

or the two direction/elevation adjustment buttons

The direction/elevation adjustment buttons control the rotational

direction of the laser head as well as adjust the elevation of the

beam when the unit is in slope mode. These buttons can also

be used to incrementally rotate the beam when the unit is in

Scan mode.

The buttons on the DW080LRS/DW080LGS control panel and

the DW080LRS/DW080LGS Remote keypad work the same,

unless otherwise indicated.

2

, the speed button

5

(DW080LRS/LGS in Slope mode only),

3

and the scan mode button

Power Button

The Power button is used to turn the laser unit on and off.

• To power ON the DW080LRS/LGS laser unit, press the

Power button once.

• To completely power OFF the DW080

unit, press the power button for 3 sec.

LRS/LGS laser

Speed/Rotation Button

The speed button

laser beam through its 4 preset speeds (150, 300, 600, and

1200 RPM).

3

is used to adjust the rotation speed of the

Scan Mode Button

The scan mode button

sweep back and forth, creating a short, bright laser line. This

short line is much brighter and more visible than when the unit

is in full rotation mode.

Using Scan Mode

• To enter Scan Mode, push and release the scan mode

• The direction of the scan zone can be controlled with the

4

button

press the button until you reach the desired angle.

arrow buttons

4

is used to make the laser head

. To cycle through the scan angles, continue to

6

7

and

.

Slope Mode Button

• To activate Slope Mode press the slope mode button

• To return to self-leveling mode and re-engage full self-

leveling, press and hold the mode button

Setting the Slope Direction

When Slope Mode is activated, the unit automatically engages

the X- Axis. This allows you to slope the laser in the direction of

the X-Axis, as indicated by the “gunsights” on the rollcage.

11

The LED light

In certain situations, it may be desirable to slope the laser in

the Y-axis. The direction of Slope Mode can be changed back

and forth between the Y-axis and the X-axis by pressing the

X-Y axis button

24

25

or

.

12

or

indicates the current slope direction.

5

. The selected axis is identified by LED light

12

ENGLISH

Setting the Amount of Slope

1. Turn on Slope Mode.

2. Select the desired axis.

6

3. Use the Arrow buttons (Fig.

B

7

,

and

) to tilt the laser

rotor head up and down.

A

Arrow Buttons (Fig.

The arrow buttons (Figure

R

,

)

A

6

7

and

) are used for different

functions depending on the operating mode of the laser unit.

• In Self-Leveling Horizontal Mode, the arrow buttons

rotate the direction of the laser beam clockwise or counterclockwise during rotation, or adjust the position of the laser

beam clockwise or counter-clockwise during Scan Mode.

• In Self-Leveling Vertical Mode, the arrow buttons rotate

the direction of the laser beam clockwise or counterclockwise during rotation, or adjust the position of the laser

beam clockwise or counter-clockwise during Scan Mode.

• In Slope Mode, the arrow buttons are used to tilt the

laser head.

Connection Buttons

A

10

The connection buttons (Figure

13

and

) provide

different ways to wirelessly connect to the laser.

A

• Press the radio waves button

(Figure

10

) to

connect your cell phone to the Detector which is connected

to the laser.

• Press the Bluetooth button

(Figure A

13

) to enable

Bluetooth on the laser. If the laser is within 100 ft (30 m),

you can use the Tool Connect application on your

cell phone to control the laser, instead of using the remote.

Also, if the laser is dropped, disturbed, etc., it will send

messages to the Tool Connect application to inform you.

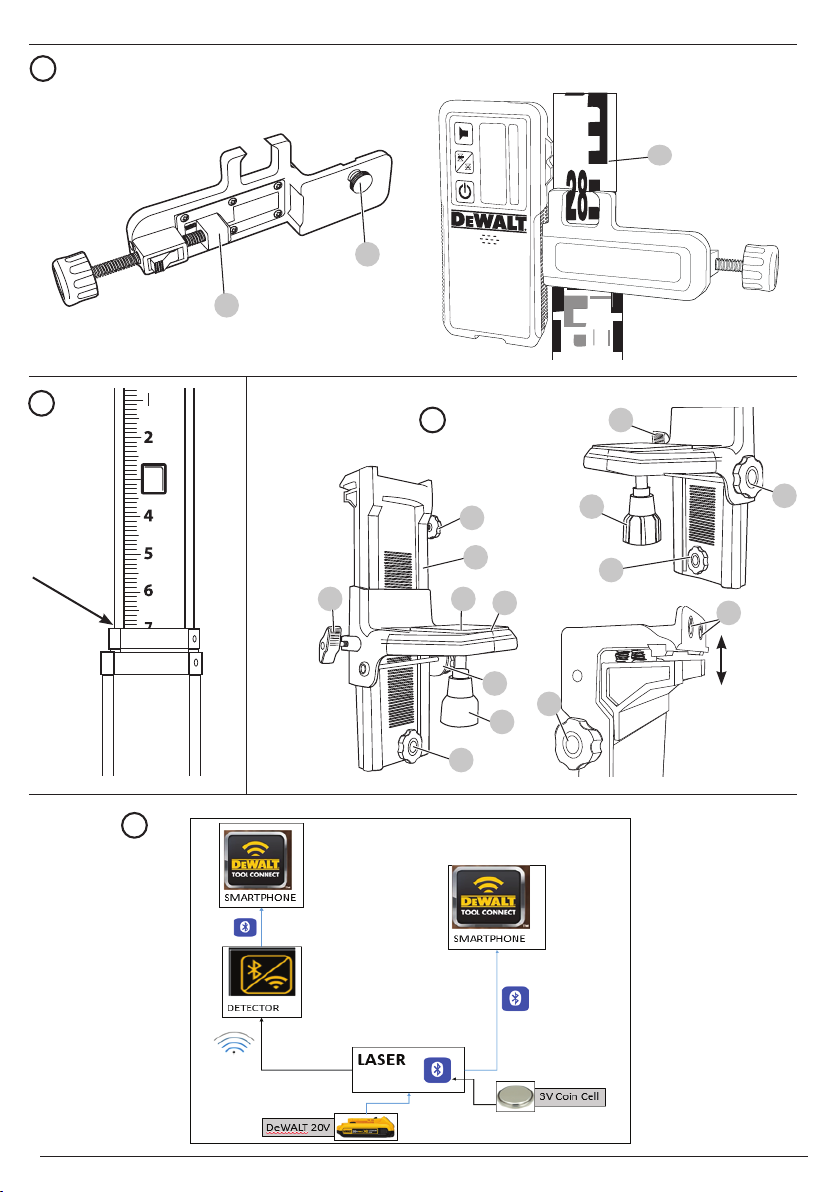

Using the Tool Connect Application

You can use Bluetooth® capability to pair the laser with the

DEWALT® Tool Connect application on your cell phone, and then

use your cell phone to control the laser (Figure N).

1. From either

®

Tool Connect application to your cell phone.

DEWALT

2. On the laser keypad, press

3. On the laser keypad, press to turn on Bluetooth

Bluetooth does not turn on, replace the coin cell battery (3V

CR2430) on the bottom of the laser.)

4. Using the DEWALT® Tool Connect application, select the

product type (Rotary Laser) and pair your cell phone to the

DW080LRS/DW080LGS.

or , download the

to turn the laser on.

®. (

If

When the laser is on, the DEWALT® Tool Connect application will

display information about the laser:

• A laser safety icon to let you know the laser is on.

• The laser's current settings for RPM, Slope, etc.

• If the current settings are one of the "favorite settings" you

have saved for the laser, it will display the name of that

setting (e.g., Main St - Site 1).

• If the Tracking feature is on, the application will know

where the laser is and will let you know if the laser has

been taken and is now out-of-range.

THE BLUETOOTH® WORD MARK AND LOGOS ARE REGISTERED TRADEMARKS OWNED

BY BLUETOOTH SIG, INC. AND ANY USE OF SUCH MARKS BY STANLEY TOOLS IS UNDER

LICENSE. APPLE AND THE APPLE LOGO ARE TRADEMARKS OF APPLE INC., REGISTERED

IN THE U.S. AND OTHER COUNTRIES. APP STORE IS A SERVICE MARK OF APPLE INC.,

REGISTERED IN THE U.S. AND OTHER COUNTRIES. GOOGLE PLAY AND THE GOOGLE PLAY

LOGO ARE TRADEMARKS OF GOOGLE INC.

Turning the Laser On (Fig. E, B)

1. Insert the fully charged 20V battery pack as shown in

Figure E.-

2. Gently press the power button

- The power LED indicator light (Figure

to power ON the laser.

A

9

) will

illuminate.

- Self-leveling mode is activated automatically and the

laser unit will self-level. Once the laser unit is level, the

beam will rotate clockwise once at 600 RPM.

- After 10 sec., Hi Mode (Anti- Drift) is activated

A

automatically and the Hi LED (Figure

8

) will

illuminate.

A

3. Press the speed/rotation button (Figure

3

) to adjust the

rotation speed. The direction can be changed using buttons

6

7

and

.

A

4. Press the Scan button (Figure

4

) to set the laser to

scan in 0°, 15°, 45°, or 90° degree mode.

A

12

If you turn ON Slope Mode, the Slope LED (Figure

)

will light. If using X-axis leveling, the X-axis LED (Figure A

24

) will light, or if using Y-axis leveling, the Y-axis LED (Figure

A

25

) will light instead.

Calibrating the Laser (Fig. O, P)

Field calibration checks should be done frequently. This section

provides instructions for performing simple field calibration

checks of your DeWALT Rotary Laser. Field calibration checks

do not calibrate the laser. That is, these checks do not correct

errors in the leveling or plumbing capability of the laser. Instead,

the checks indicate whether or not the laser is providing a

correct level and plumb line. These checks cannot take the

place of professional calibration performed by a

service center.

DeWALT

13

Level Calibration Check (X-axis)

1. Set up a tripod between two walls that are at least 50 feet

apart. The exact location of the tripod is not critical.

2. Mount the laser unit on the tripod so that the X-axis points

directly toward one of the walls.

3. Turn the laser unit on and allow it to self-level.

4. Mark and measure points A and B on the walls as shown

in Figure O.

5. Turn the entire laser unit 180º so the X-axis points directly

toward the opposite wall.

6. Allow the laser unit to self-level, and mark and measure

points AA and BB on the walls as shown in Figure P.

7. Calculate the total error using the equation:

Total Error = (AA – A) – (BB– B)

8. Compare total error to the allowable limits shown in the

following table.

Distance between walls Allowable Error

L = 50 ft. (15.3 m) 1/8" ( 3 mm)

L = 75 ft. (22.9 m) 3/16" (4.5 mm)

L = 100 ft. (30.5 m) 1/4" (6 mm)

Level Calibration Check (Y-axis)

Repeat the procedure above, but with the laser unit positioned

so the Y-axis is pointed directly toward the walls.

Plumb Error Check (Fig. Q)

1. Using a standard plumb bob as a reference, mark the top

and bottom of a wall. (Be sure to mark the wall and not the

floor and ceiling.)

2. Position the rotary laser securely on the floor approximately

3' (1 m) from the wall.

3. Turn the laser on, and point the dot at the mark on the

bottom of the wall. Then, using the up/down arrows on the

remote control, rotate the dot upwards. If the center of the

dot scans over the mark on the top of the wall, the laser is

properly calibrated.

NOTE: This check should be done with a wall no shorter than

the tallest wall for which this laser will be used.

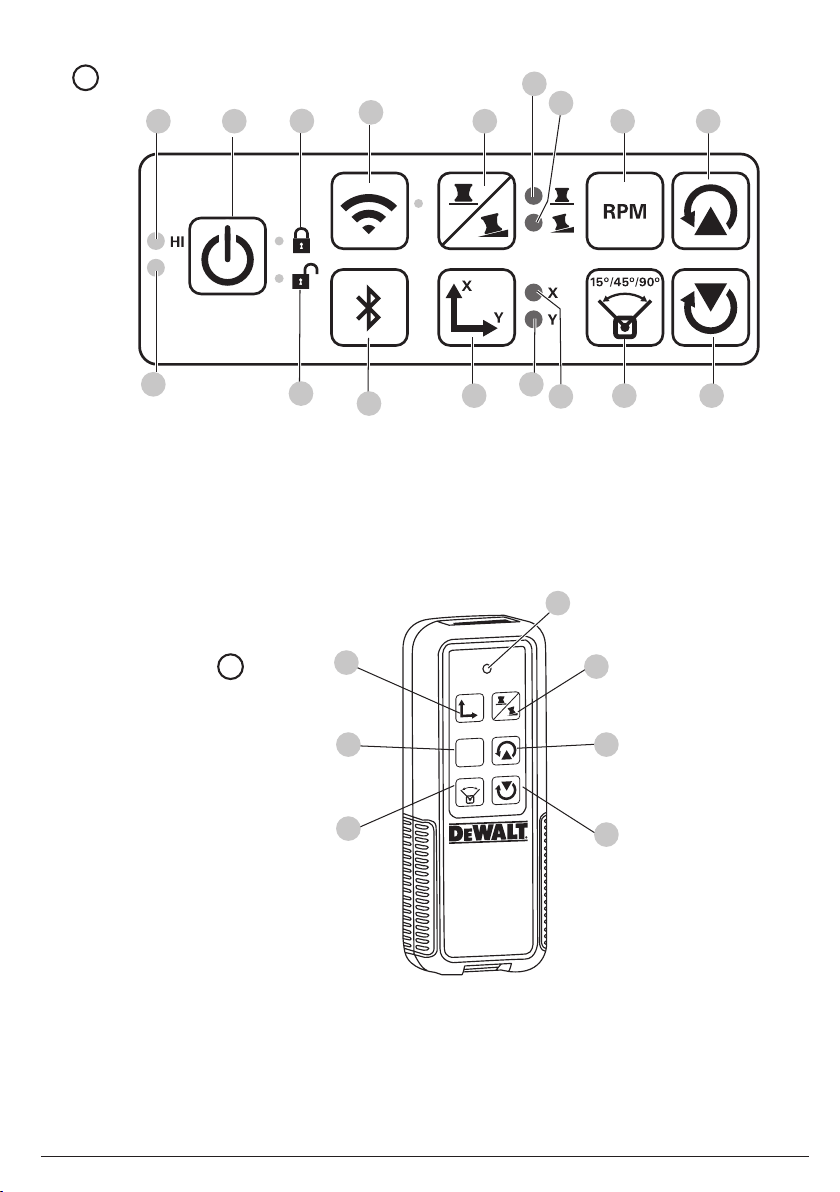

Using the Laser on a Tripod (Fig. C)

1. Position the tripod securely and set it to the desired height.

2. Make sure that the top of the tripod is roughly level. The

laser will self-level only if the top of the tripod is within ± 5˚

of level. If the laser is set up too far out of level, it will beep

when it reaches the limit of its leveling range. No damage

will be done to the laser, but it will not operate in an “out of

level” condition.

3. Secure the laser to the tripod by attaching the tripod

20

adapter

adapter may be assembled to the bottom for level mode

or to the side for plumb mode. Place the assembly on the

tripod and screw the threaded knob on the tripod into the

female thread on the tripod adapter.

as shown in Figure C to the laser body. The

NOTE: Be sure that the tripod you are working with has a

5/8"–11 threaded screw to ensure secure mounting.

4. Turn the laser on and adjust the rotation speed and controls

as desired.

Using the Laser on a Floor (Fig. D)

The laser level can be positioned directly on the floor for

leveling and plumbing applications such as framing walls.

1. Place the laser on a relatively smooth and level surface

where it will not be disturbed.

2. Position the laser for a level or plumb setting as shown.

3. Turn the laser on and adjust the rotation speed and controls

as desired.

NOTE: The laser will be easier to set up for wall applications if

the rotation speed is set to 0 rpm's and if the remote control is

used to line up the laser with control marks. The remote allows

one person to set up the laser.

Using the DW080LRS/LGS Remote

The remote control allows one person to operate and set up

the laser from a distance. The remote is powered by a Li-Ion

battery. Use the USB port to charge the battery.

You must press the radio waves button

order to use the remote.The LED light on the remote control

(Figure B

DW080LRS/LGS laser unit.

NOTE: Whenever Bluetooth® is enabled on the laser, you will

NOT be able to use the remote.

Any remote could control the laser unless the laser is paired to

one remote.

• If the laser is not paired to the remote, the unlocked

• If the laser is paired to the remote, the locked

You can use all the buttons on the keypad to control the

laser unit. To completely power OFF a DW080

laser unit using the Remote keypad, press the X-Y

button

14

1

) indicates a signal is being transmitted from the

LED will be lit on the laser keypad to indicate that any

remote can control the laser.

be lit to indicate that currently only one remote can control

the laser.

14

(

)

and the MODE button

on the laser in

13

(

)

simultaneously.

LED will

LRS/LGS

axis

ENGLISH

ENGLISH

Specifications

SKU

Laser Wavelength 630-680nm 515-530nm

Laser Power/Class ≤ 5mw /CLASS 3R ≤ 5mw /CLASS 3R

Rotation Speed 150, 300, 600, 1200 RPM 150, 300, 600, 1200 RPM

Self-Leveling Range ± 5° ± 5°

Indoor Visibile Range 200' (60 m) diameter 250' (80 m) diameter

Range with Detector 2000' (600 m) diameter 2000' (600 m) diameter

Leveling Accuracy +/- 1/16” per 100’

Power Source 20V D

Operating Temperature 23°F to 122°F

Storage Temperature -4°F to 158°F

Environmental Water resistant Water resistant

DW080LRS DW080LGS

630-680nm

(+/- 1.5 mm per 30m)

eWALT batteries 20V DeWALT batteries

(-5°C to 50°C)

(-20°C to 70°C)

+/- 1/16” per 100’

(+/- 1.5 mm per 30m)

23°F to 122°F

(-5°C to 50°C)

-4°F to 158°F

(-20°C to 70°C)

Accessories

Recommended accessories for use with your tool are available

for purchase at your factory-owned local service center.

WARNING: Since accessories, other than those

offered by DeWALT, have not been tested with this

product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only

recommended accessories should be used with this

product.

If you need assistance in locating any accessory, please

contact

DeWALT Industrial Tool Co., 701 East Joppa Road,

Towson, MD 21286, call 1–800–4-DeWALT (1–800–433–9258)

or visit our website www.DeWALT.com

Digital Laser Detector (Fig. H–K)

Some laser kits include a DeWALT Digital Laser Detector. The

DeWALT Digital Laser Detector allows you to locate a laser

beam emitted by a rotary laser in bright light conditions or over

long distances. The detector can be used in both indoor and

outdoor situations where it is difficult to see the laser beam.

The detector is not for use with non-rotating lasers but is

compatible with most rotary red-beam (DW0743R) and green

beam (DW0743G) lasers. It can be set to indicate the location

of the beam to either the nearest 1/8" (3 mm) or the nearest

1/25" (1 mm). The detector gives both visual signals through

the display window

23

to indicate the location of the laser beam.

The

DeWALT Digital Laser Detector can be used with or without

the detector clamp. When used with the clamp, the detector can

be positioned on a grade rod, leveling pole, stud or post.

Installing a Battery in the Detector (Fig. H)

The Digital Laser Detector is powered by a 9 volt battery. To

install the battery provided, lift up on the battery compartment

21

cover

the battery as shown.

22

and audio signals through the speaker

. Place the 9 volt battery in the compartment, aligning

DeWALT,

Detector Controls (Fig. I)

The detector is controlled by the power button

accuracy mode button

27

.

When the power button is pushed once, the detector is turned

on. The top of the display window shows the accuracy icon

27

, and the volume icon

28

. To decrease the volume of the

audible signal that the detector emits when it senses a laser

beam, push the button again; one of the half circles next to the

horn icon will dissappear. To turn off the audible signal push the

button a third time; the volume icon will dissapear. The

Digital Laser Detector also has an auto shut-off feature. If a

rotary laser beam does not strike the beam detection window,

or if no buttons are pressed, the detector will shut itself off in

about 30 minutes.

When the detector is on, the top of the window shows an

accuracy mode icon. Either the ±1/25" (1 mm) accuracy mode

53

icon

will appear, or the ±1/8" (3 mm) accuracy mode icon

54

will appear. When the ±1/25" (1 mm) accuracy mode icon

appears, it indicates that the detector will give an “on grade”

reading only when the laser beam is on grade or no more

than 1/25" (1 mm) above or below it. When the 1/8" (3 mm)

accuracy mode icon appears, it indicates that the detector will

give an “on grade” reading when the laser beam is on grade

or approximately 1/8" (3 mm) above or below it. Push the

27

accuracy mode button

once to change the accuracy mode.

26

and the

DeWALT

Detector Operation (Fig. I, J)

1. Set up and position the rotary laser that you will be using

according to the manufacturer’s directions. Turn the laser

on and make sure that the laser is rotating and emitting a

laser beam. NOTE: This detector has been designed to be

used only with a rotating laser. The detector will not work

with a stationary beam laser level.

2. Turn the detector on by pressing the power/volume

26

button

.

3. Adjust the volume as desired as described in the

Detector Controls.

4. Position the detector so that the detector window

facing the laser beam produced by the rotary laser. Move

the detector up or down within the approximate area of the

beam, until you have centered the detector. For information

about the display window indicators and the audible signal

indicators, refer to the table titled Indicators (Fig.

5. Use the marking notches

30

to accurately mark the

position of the laser beam.

Detector Cleaning and Storage

• Dirt and grease may be removed from the exterior of the

detector using a cloth or soft, non-metallic brush.

• The D

eWALT Digital Laser Detector is waterproof. If you

should drop the detector in mud, wet concrete, or a similar

substance, simply hose the detector off. Do not use high

pressure water, e.g., from a pressure washer.

• The best storage place is one that is cool and dry–away

from direct sunlight and excess heat or cold.

22

J

is

).

15

Detector Service

Except for batteries, there are no user serviceable parts in the

Digital Laser Detector. Do not disassemble the unit. Unauthorized tampering with the laser detector will void all warranties.

Detector Troubleshooting

The detector will not turn on.

• Press and release the power/volume button.

• Check to see that the battery is in place and in the

proper position.

• If the detector is very cold, allow it to warm up in a

heated area.

• Replace the 9 volt battery. Turn the unit on.

• If the detector still does not turn on, take the detector to a

DeWALT service center.

The detector’s speaker makes no sound.

• Ensure that the detector is on.

• Press the power/volume button. It will toggle from high, to

low, to mute.

• Ensure that the rotary laser is spinning and that it is emitting

a laser beam.

• If the detector is still not making any sound, take it to a

DeWALT service center.

The detector does not respond to a stationary laser beam.

The

DeWALT Digital Laser Detector has been designed to work

only with rotary lasers.

The detector gives off a tone but the LCD display window

does not function.

• If the detector is very cold, allow it to warm up in a

heated area.

• If the LCD display window is still not functioning, take the

detector to a

DeWALT service center.

Mounting Bracket (Fig. C, M)

Some laser kits include a Wall Mount. It can be used for

attaching the tool to track or ceiling angle and to aid in

acoustical ceiling installation. Follow the directions below for

using the wall mount.

CAUTION: Before attaching the laser level to wall

track or ceiling angle, be sure that the track or angle is

properly secured.

1. Place the laser on the mounting base

11 screw hole on the tripod adapter (

to the bottom of the laser with the hole

base. Turn the mounting knob

2. With the wall mount measuring scale

the wall mount clamp locking knob

jaws.

3. Position the clamp jaws around the wall track or ceiling

angle and tighten the wall mount clamp locking knob

42

to close the clamp jaws onto the track. Be sure that

the wall mount clamp locking knob is securely tightened

before proceeding.

37

aligning the 5/8–

20

, Fig. C) attached

39

40

in the mounting

to secure the laser.

41

facing you, loosen

42

to open the clamp

CAUTION: Always use a ceiling wire hanger or

equivalent material, in addition to the wall mount

clamp locking knob, to help secure the laser level

while mounting it to a wall. Thread the wire through

the handle of the laser level. DO NOT thread the wire

through the protective metal cage. Additionally, screws

may be used to fasten the wall mount directly to the

wall as a back up. Screw holes

top of the wall mount.

4. Using the base leveling knob

position from the wall.

5. The tool can be adjusted up and down to the desired offset

height for working. To change the height, loosen the locking

45

knob

located on the left of the wall mount. Support the

mounting base when adjusting the height.

6. Turn the adjustment knob

wall mount, to move the laser level up and down to set your

height. Use the wall mount measuring scale

your mark.

NOTE: It may be helpful to turn the power on and turn the

rotary head so that it puts a dot on one of the laser scales.

DeWALT target card is marked at 1–1/2" (38 mm),

The

therefore, it may be easiest to set the offset of the laser to

1–1/2" (38 mm) below the track.

7. Once you have positioned the laser at the desired height,

tighten the locking knob

45

43

are located at the

44

approximate a level

46

, located to the right of the

41

to maintain this position.

to pinpoint

Mounting on a Grade Rod (Fig.K)

To secure your detector to a grade rod, first attach the detector

to the clamp using the 1/4"-20 threaded knob

of the clamp. Slide the tracks

33

on the grade rod.

1. Position the detector at the height needed and turn the

clamp knob clockwise to tighten the jaws of the clamp

around the grade securing the clamp on the rod.

2. To make adjustments in height, slightly loosen the clamp,

reposition and retighten.

32

on the clamp around the rail

47

on the back

Construction Grade Rod (Fig. L)

DANGER: NEVER attempt to use a grade rod in a

storm or near overhanging electric wires. Death or

serious personal injury will occur.

Some laser kits include a grade rod. The

Rod is marked with measurement scales on both sides and

is constructed in telescoping sections. A spring-loaded button

actuates a lock to hold the grade rod at various lengths.

The front of the grade rod has the measurement scale starting

at the bottom. Use this for measuring from the ground up when

grading or leveling jobs.

The back of the grade rod is designed to measure the height

of ceilings, joists, etc. Fully extend the top section of the grade

rod until the button locks into the previous section. Extend that

section either until it locks into the adjacent section or until the

grade rod touches the ceiling or joist. The height is read where

the last extended section exits the previous lower section, as

shown in Figure

16

L

.

DeWALT Grade

ENGLISH

ENGLISH

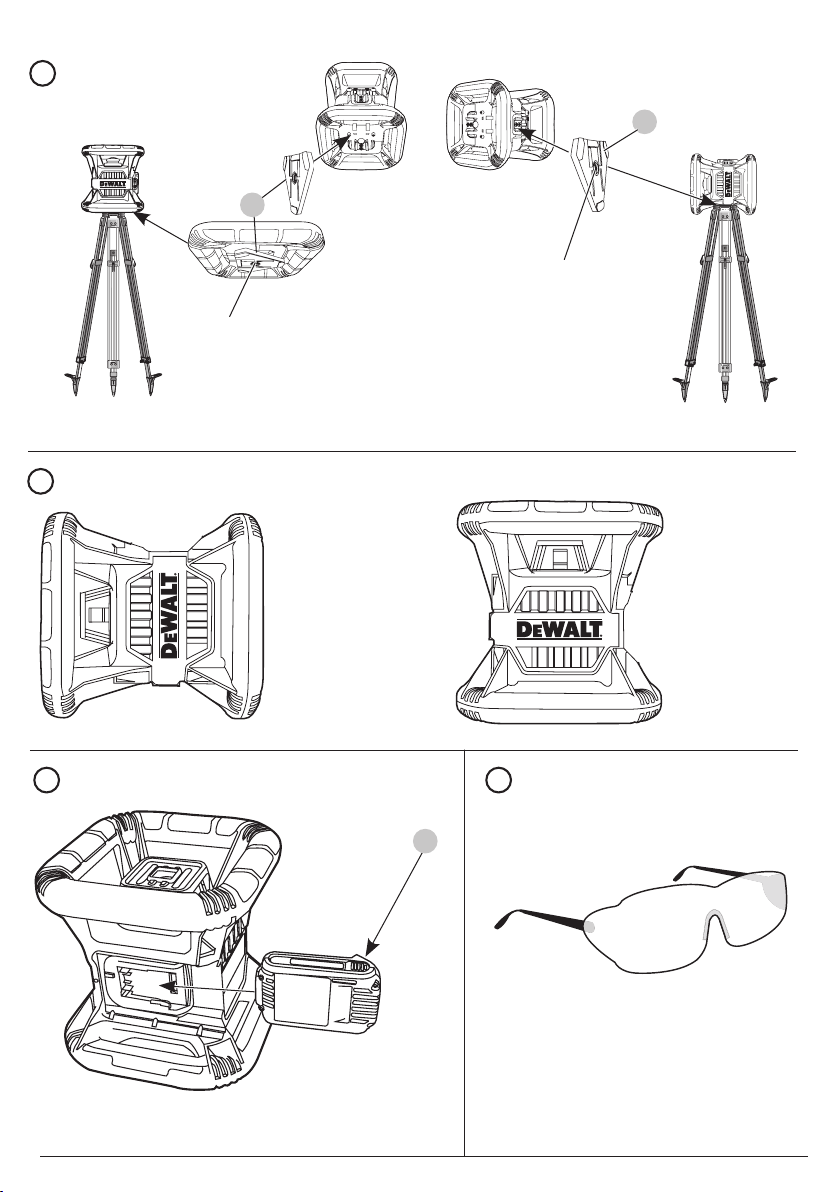

Target Card (Fig. G)

Some laser kits include a Laser Target Card to aid in locating

and marking the laser beam. The target card enhances the

visibility of the laser beam as the beam crosses over the card.

The card is marked with standard and metric scales. The laser

beam passes through the red plastic and reflects off of the

reflective tape on the reverse side. The magnet at the top of

the card is designed to hold the target card to ceiling track or

steel studs to determine plumb and level positions. For best

performance when using the Target Card, the

should be facing you.

DeWALT logo

Laser Enhancement Glasses (Fig. F)

Some laser kits include a pair of Laser En hancement Glasses.

These glasses improve the visibility of the laser beam under

bright light conditions or over long distances when the laser is

used for interior applications. These glasses are not required to

operate the laser.

CAUTION: These glasses are not ANSI approved

safety glasses and should not be worn while operating

other tools. These glasses do not keep the laser beam

from entering your eyes.

DANGER: To reduce the risk of serious personal injury,

never stare directly into the laser beam, with or without

these glasses.

Maintenance

• Under some conditions, the glass lens may collect some

dirt or debris. This will affect beam quality and operating

range. The lens should be cleaned with a cotton swab

moistened with water.

• The flexible rubber shield can be cleaned with a wet lintfree cloth such as a cotton cloth. USE WATER ONLY — DO

NOT use cleansers or solvents. Allow the unit to air dry

before storing.

• To maintain the accuracy of your work, check the calibration

of the laser often. Refer to Calibrating the Laser.

• Calibration checks and other maintenance repairs can be

performed by

checks are included under the DeWALT One Year Free

Service Con tract.

• When the laser is not in use, store it in the kit box provided.

• Do not store your laser in the kit box if the laser is wet. Dry

exterior parts with a soft, dry cloth and allow the laser to

air dry.

• Do not store your laser at temperatures below 0˚F (-18˚C)

or above 105˚F (41˚C).

DeWALT service centers. Two free calibration

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of the

tool. These chemicals may weaken the materials used

in these parts. Use a cloth dampened only with water

and mild soap. Never let any liquid get inside the unit;

never immerse any part of the unit into a liquid. Never

use compressed air to clean the laser.

Troubleshooting

Height of Instrument Alert

The DW080LRS/DW08LGS has a built-in alarm feature that

alerts the operator if the unit is disturbed after the unit has selfleveled. The laser unit will stop rotating, the control panel LED

indicator light will flash, and the beeper will sound.

Turning the Laser Off

Press the the power button for 3 sec to turn the laser off. The

power LED indicator light will no longer be illuminated.

To Reset The Laser Unit for Continued Use

Turn the unit off and back on again using the power button on

the laser unit control panel.

NOTE: Always recheck the laser setup after the Height of

Instrument Alert (Hi mode) has triggered.

Service and Repairs

NOTE: Disassembling the laser level will void all warranties on

the product.

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment should be performed by

authorized service centers. Service or maintenance performed

by unqualified personnel may result in a risk of injury. To locate

your nearest D

(1–800–433–9258) or visit our website: www.DeWALT.com.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help

you obtain more efficient warranty service in case there is a

problem with your product.

• CONFIRMATION OF OWNERSHIP: In case of an

insurance loss, such as fire, flood or theft, your registration

of ownership will serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow

us to contact you in the unlikely event a safety notification is

required under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

eWALT service center call 1–800–4-DeWALT

17

Three Year Limited Warranty

DeWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of

purchase. This warranty does not cover part failure due to

normal wear or tool abuse. For further detail of warranty

coverage and warranty repair information, visit www.

com or call 1–800–4-DeWALT (1–800–433–9258). This

warranty does not apply to accessories or damage caused

where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other

rights which vary in certain states or provinces.

In addition to the warranty,

DeWALT will maintain the tool and replace worn parts caused

by normal use, for free, any time during the first year after

purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DeWALT Power Tool, Laser, or Nailer for any reason, you can

return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

RECONDITIONED PRODUCT: Reconditioned product is

covered under the 1 Year Free Service Warranty. The 90 Day

Money Back Guarantee and the Three Year Limited Warranty

do not apply to reconditioned product.

FREE WARNING LABEL REPLACEMENT: If your warning

labels become illegible or are missing, call 1–800–4visit your local service center for a free replacement.

DeWALT tools are covered by our:

1 YEAR FREE SERVICE

DeWALT.

DeWALT or

ENGLISH

18

DeWALT BATTERY AND CHARGER SYSTEMS/ SYSTÈMES DE BATTERIES ET DE

CHARGEURS DeWALT /BATERÍA Y SISTEMAS DE CARGADORES DeWALT/BATERIA E

SISTEMAS DE CARREGADOR DeWALT

Chargers/Charge Time (Minutes)

Chargeurs/Temps de chargement (minutes)

Cargadores/tiempo de carga (minutos)

Carregadores/tempo de carga (minutos)

Battery Cat /

Nº de cat.

batterie /N.°

de catálogo

batería/Nº

de Categoria

da Bateria

DCB203BT* 20 X X X X 35 35 35 90 60 45 X 30 30 30 60 X

DCB204BT* 20 X X X X 70 70 70 185 120 90 X 60 60 60 120 X

*BT - Bluetooth

SIG, Inc. and any use of such marks by

respective owners.

**Battery Datecode 201536 or later.

*BT - Bluetooth

utilisées sous licence par DeWALT. Les autres marques de commerce et les appellations commerciales appartiennent à leurs

propriétaires respectifs.

**Code-date de batterie 201536 ou ultérieur.

*BT - Bluetooth

Bluetooth®, SIG, Inc. y todo uso de dichas marcas por DeWALT se hace bajo licencia. Otras marca y nombres comerciales son

de sus respectivos propietarios.

** Código de fecha de la batería 201536 o posterior.

*BT - Bluetooth

Bluetooth® SIG Inc. e quaisquer usos dessas marcas pela DeWALT são feitos sob licença. Outras marcas registradas ou

comerciais pertencem aos respectivos proprietários.

**Bateria com código de data 201536 ou posterior.

“X” Indicates that the battery pack is not compatible with that specific charger. All charge times are approximate. Actual charge time

may vary. Read the instruction manual for more specific information.

Le «X» indique que le bloc batterie n’est pas compatible avec ce chargeur spécifique. Tous les temps de chargement sont

approximatifs. Le temps de chargement réel peut varier. Lisez le mode d’emploi pour plus d’informations spécifiques.

La “X” indica que el paquete de baterías no es compatible con ese cargador específico. Todos los tiempos de carga son aproximados.

El tiempo de carga real puede variar. Lea el manual de instrucciones para obtener información más específica.

“X” Indica que o pack de baterias não está compatível ao carregador específico. Todos os tempos de carregamento são estimativas. O

tempo de carregamento real pode variar. Leia o Manual de Instruções para mais informações específicas.

*** Maximum initial battery voltage (measured without a workload) is 20 volts. Nominal voltage is 18.

*** La tension initiale maximale de la batterie (mesurée sans charge) est de 20 volts. La tension nominale est de 18volts.

*** La tensión inicial máxima de la batería (medida sin una carga de trabajo) es de 20 voltios. La tensión nominal es de 18.

*** A tensão inicial máxima da bateria (medida sem carga) é de 20 volts. A tensão nominal é 18.

Output

120 Volts 12 Volts

Voltage/

Tension

de sortie

de la

/Tensión

de salida/

DC9000

DC9310

DC9320

DCB095

DCB101

DCB102

DCB103

DCB107

DCB112

DCB113

DCB114

DCB115

DCB118

DCB132

DCB119

Tensão de

saída

DCB606 60/20 X X X X 100 100 100 272 170 140 X 90 60 90 X X

DCB200 20 X X X X 60 60 60 140 90 67 X 45 45/30** 45 90 X

DCB201 20 X X X X 30 30 30 70 45 35 X 22 22 22 45 X

DCB203 20 X X X X 35 35 35 90 60 45 X 30 30 30 60 X

DCB204 20 X X X X 70 70 70 185 120 90 X 60 60/40** 60 120 X

DCB205 20 X X X X 95 95 95 240 150 112 X 75 75/47** 75 150 X

DCB207 20 X X X X 30 30 30 60 40 30 X 22 22 22 X X

®

NOTE: The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth®,

DeWALT is under license. Other trademarks and trade names are those of their

MD

REMARQUE: Bluetooth

®

NOTA: La marca denominativa y los logotipos de Bluetooth® son marcas registradas propiedad de

®

OBSERVAÇÃO: A marca nominativa e os logotipos Bluetooth® são marcas registradas da

MD

et ses logos sont des marques déposées de BluetoothMD SIG, Inc. et sont

DW0249

Solamente para propósito de Argentina:

Importado por: Black & Decker Argentina S.A.

Pacheco Trade Center

Colectora Este de Ruta Panamericana

Km. 32.0 El Talar de Pacheco

Partido de Tigre

Buenos Aires (B1618FBQ)

República de Argentina

No. de Importador: 1146/66

Tel. (011) 4726-4400

Solamente para propósito de México:

Importado por: Black & Decker S.A. de C.V.

Avenida Antonio Dovali Jaime, # 70 Torre B Piso 9

Colonia Santa Fé

Delegación Alvaro Obregón

México D. F.: 01210

Tel. (52) 555-326-7100

R.F.C.: BDE810626-1W7

Solamente para propósito de Colombia:

Importado por: Black & Decker de Colombia S.A.S

Cra 85D #46A-65 Bodega 23

Complejo Logístico San Cayetano

Tel. (57) 1-744 – 71 - 00

Bogotá

Colombia

Imported by/Importado por:

Black & Decker do Brasil Ltda.

Rod. BR 050, s/n° - Km 167

Dist. Industrial II

Uberaba – MG – Cep: 38064-750

CNPJ: 53.296.273/0001-91

Insc. Est.: 701.948.711.00-98

S.A.C.: 0800-703-4644

Made in China

Hecho en China

Fabricado no China

DeWALT Industrial Tool Co., 701 East Joppa Road, Towson, MD 21286

(MARCH 2018) Part No. Nxxxxxx

The following are trademarks for one or more DeWALT power tools: the yellow and black color scheme, the “D” shaped air intake grill,

the array of pyramids on the handgrip, the kit box configuration, and the array of lozenge-shaped humps on the surface of the tool.

DW080LRS, DW080LGS Copyright © 2018 DeWALT

Loading...

Loading...