WS10

HYDRAULIC

WELD SHEAR

USER MANUAL

Safety, Operation and Maintenance

© 2014 STANLEY Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

28860 11/2018 Ver. 18

DECLARATION OF CONFORMITY

Nuerenberg, David

Directive/Standards

No.

Approved body

EN ISO

3744

Self

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

______________________________________________________________________

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

hereby declare that the equipment specified hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especifica a continuación:

Dichiaro che le apparecchiature specificate di seguito:

Surname and First names/Familiennname und Vornamen/Nom et pr énom/Nombre y apellido/Cognome e nome

1. Category:

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca

3. Type/Typ/Type/Tipo/Tipo: WS1032101A, WS1022001A

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Richtlinie/Standards

Directives/Normes

Directriz/Los Normas

Direttiva/Norme

Machinery Directive

5. Special Provisions: None

Spezielle Bestimmungen:

Dispositions particulières:

Provisiones especiales:

Disposizioni speciali:

Nr

Numéro

No

n.

2006/42/EC

Weld Shear, Hydraulic

STANLEY

All

Prüfung durch

Organisme agréé

Aprobado

Collaudato

Self

6. Representative in the Union: Patrick Vervier, Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

Done at/Ort/Fait à/Dado en/Fatto a STANLEY Infrastructure, Milwaukie, Oregon USA Date/Datum/le/Fecha/Data 4-27-2018

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione North America Quality Manager

2 ► WS10 User Manual

TABLE OF CONTENTS

SAFETY SYMBOLS .................................................................................................................................................4

SAFETY PRECAUTIONS .......................................................................................................................................5

TOOL STICKERS & TAGS ......................................................................................................................................6

HOSE TYPES ..........................................................................................................................................................7

HOSE RECOMMENDATIONS ................................................................................................................................8

HTMA / EHTMA REQUIREMENTS ........................................................................................................................9

OPERATION ..........................................................................................................................................................10

EQUIPMENT PROTECTION & CARE .................................................................................................................12

TROUBLESHOOTING ..........................................................................................................................................13

SPECIFICATIONS .................................................................................................................................................14

PARTS ILLUSTRATION ........................................................................................................................................15

PARTS LIST ...........................................................................................................................................................16

To ll out a product warranty validation form, and for information on your warranty,

visit www.stanleyinfrastructure.com and select the Company tab > Warranty.

Note: The warranty validation record must be submitted to validate the warranty.

SERVICING: This manual contains safety, operation and routine maintenance instructions. STANLEY Infrastructure

recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an authorized

and certied dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest certied dealer, call STANLEY Infrastructure at (503) 659-5660 and ask for a Customer Service Representative.

WS10 User Manual ◄ 3

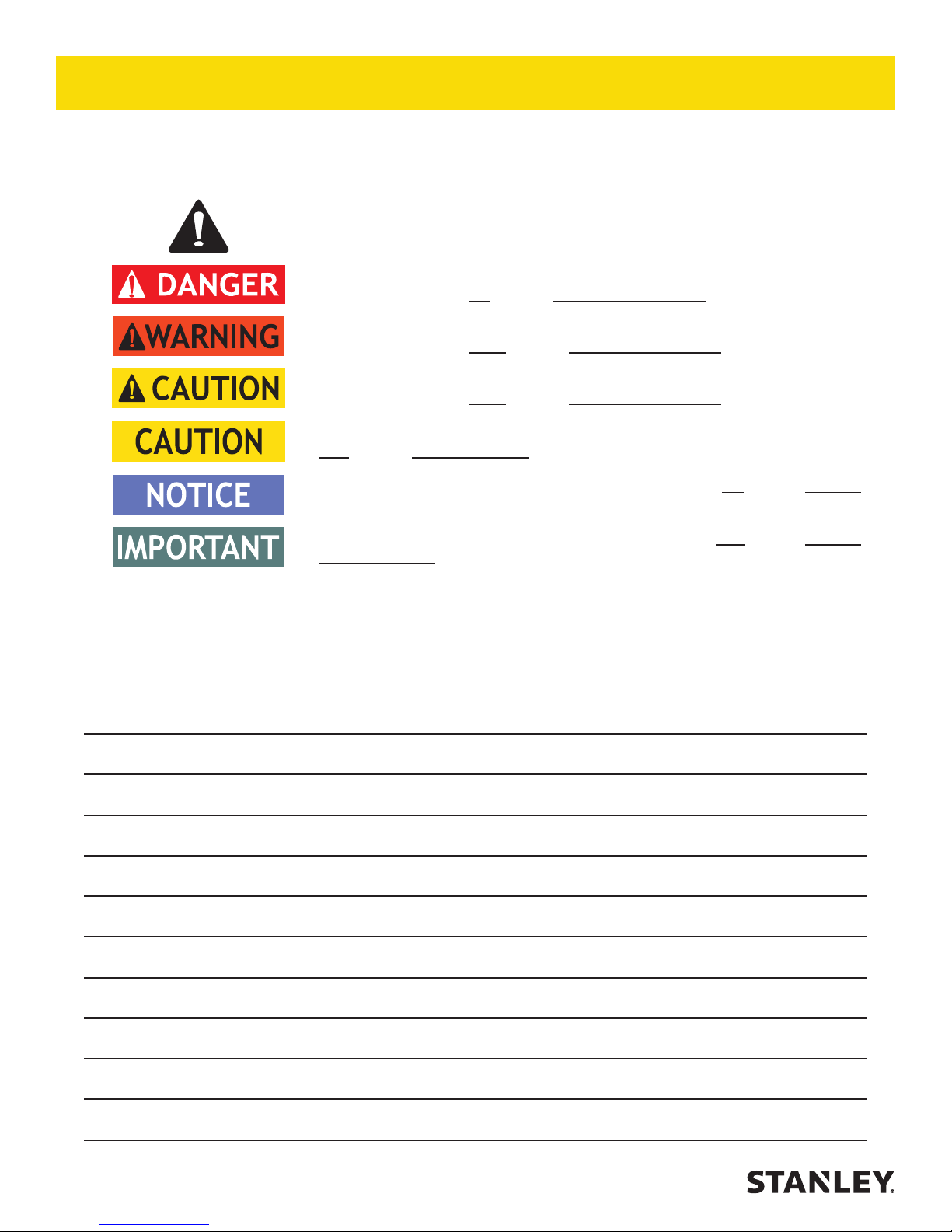

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage

to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and

maintenance personnel.

4 ► WS10 User Manual

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must comply

with the safety precautions given in this manual and on

the stickers and tags attached to the tool and hose.

These precautions are given for your safety. Review

them carefully before operating the tool and before

performing general maintenance or repairs.

Supervising personnel should develop additional

precautions relating to the specic work area and local

safety regulations. Place the added precautions in the

space provided in this manual.

The model WS10 Hydraulic Weld Shear will provide

safe and dependable service if operated in accordance

with the instructions given in this manual. Read and

understand this manual and any stickers and tags

attached to the pressure washer and hose before

operation. Failure to do so could result in personal injury

or equipment damage.

• The operator must start in a work area without

bystanders. Flying debris can cause serious injury.

• Do not operate the tool unless thoroughly trained

or under the supervision of an instructor. Establish

a training program for all operators to ensure safe

operation.

• Always wear safety equipment such as goggles,

ear, head protection, breathing protection, gloves

rated for extreme hot material and safety shoes at

all times when operating the tool.

• The operator must be familiar with all prohibited work

areas such as excessive slopes and dangerous

terrain conditions.

• Do not inspect, clean or replace the shear blades

while the hydraulic power source is connected. Do

not inspect or clean the tool while the hydraulic

power source is connected. Accidental engagement

of the tool can cause serious injury.

• Always connect hoses to the tool hose couplers

before energizing the hydraulic power source. Be

sure all hose connections are tight and are in good

condition.

• Do not operate the tool at oil temperatures above

140°F/60°C. Operation at higher temperatures can

cause higher than normal temperatures at the tool

which can result in operator discomfort.

• Never wear loose clothing that can become

entangled in the working parts of the tool.

• To avoid personal injury or equipment damage,

all tool repair, maintenance and service must only

be performed by authorized and properly trained

personnel.

• The hydraulic circuit control valve must be in the

OFF position when coupling or uncoupling the tool.

Wipe all couplers clean before connecting. Failure

to do so may result in damage to the quick couplers

and cause overheating. Use only lint-free cloths.

• Never transport or carry the tool with the unit

energized.

• Keep all parts of your body away from the cylinders

and shear blades. Long hair or loose clothing can

become drawn into moving components.

• Do not use a shear blade that is cracked, chipped

or otherwise damaged. Always inspect shear blades

for possible damage before installation or use.

• Do not operate a damaged, improperly adjusted or

incompletely assembled tool.

• Do not exceed the rated limits of the tool or use the

tool for applications beyond its design capacity.

• Always keep critical tool markings, such as labels

and warning stickers, legible.

• Eye injury and cutting or severing of body parts is

possible if proper procedures are not followed.

• WARNING! The thermite weld process creates

extremely hot parts (mold, crucible, rail etc.).

Keep all body parts away until all parts have

cooled. Use your Personal Protective Equipment

(PPE).

WS10 User Manual ◄ 5

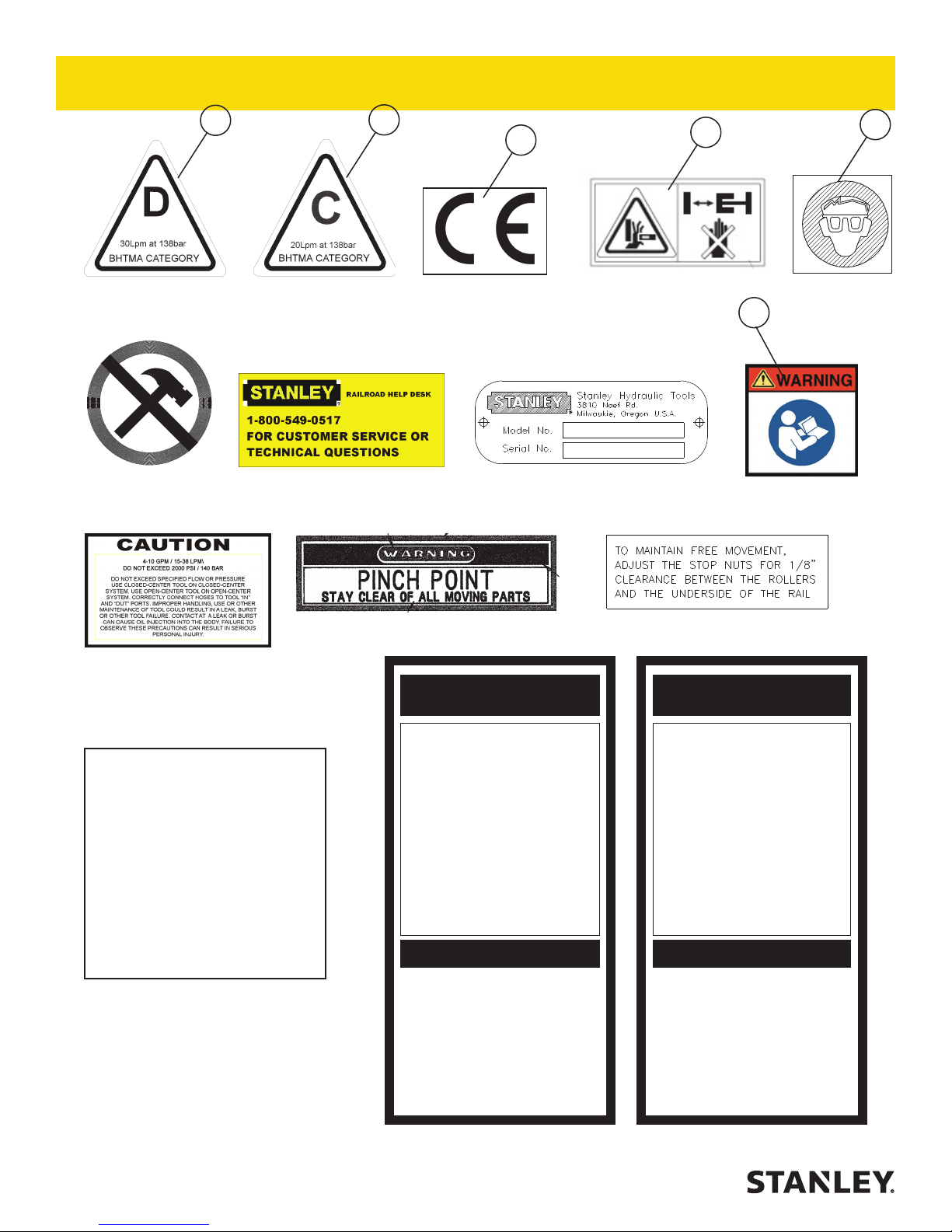

TOOL STICKERS & TAGS

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the

hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use with

STANLEY hydraulic tools. They are:

Certi ed non-conductive — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid

reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certifi ed non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) — constructed of synthetic rubber inner tube, single or double wire braid

reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used

near electrical conductors.

Fabric-braided (not certi ed or labeled non-conductive) — constructed of thermoplastic or synthetic rubber

inner tube, synthetic ber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover.

This hose is not certifi ed non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from STANLEY. DO

NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your STANLEY Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

(Shown smaller than actual size)

SIDE 1

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

ON OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING

WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND TEST

HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH SAFETY

DEPARTMENT INSTRUCTIONS.

SEE OTHER SIDE

SIDE 2

DO NOT REMOVE THIS TAG

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE

OR HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.

KEEP HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT

CONTACT DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION

AND SEVERE PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT

USE HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAM-

AGE TO COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE

IMMEDIATELY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

SEE OTHER SIDE

DANGER

DO NOT REMOVE THIS TAG

DANGER

(Shown smaller than actual size)

SIDE 2

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

DANGER

DO NOT REMOVE THIS TAG

DANGER

SIDE 1

1. DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELEC-

TRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

DANGER

SEE OTHER SIDE

SEE OTHER SIDE

62

61

63

66

11207

Circuit Type D Sticker

11206

Circuit Type C Sticker

28322

CE Sticker

31064

Crushing Hazard

Warning Sticker

64

31049

Eye Protection

Sticker

35294

No Hammer Decal

25610

Railroad Help Desk Sticker

372037

Serial Number Plate

28788

Manual Sticker

65

17572

Pinch Point Warning Sticker

29188

GPM/Pressure Caution Sticker

NOTE:

THE INFORMATION LISTED

ON THE STICKERS SHOWN,

MUST BE LEGIBLE AT ALL

TIMES.

REPLACE DECALS IF

THEY BECOME WORN OR

DAMAGED. REPLACEMENTS

ARE AVAILABLE FROM

YOUR LOCAL STANLEY

DISTRIBUTOR.

The safety tag (P/N 15875) at right is

attached to the tool when shipped from

the factory. Read and understand the

safety instructions listed on this tag before

removal. We suggest you retain this tag and

attach it to the tool when not in use.

35295

Roller Adjustment Sticker

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE WHEN USING HYDRAULIC

TOOLS ON OR NEAR ELECTRICAL LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTIFIED AS NON-

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE THE

HOSE IS MAINTAINED AS NON-CONDUCTIVE. THE HOSE

SHOULD BE REGULARLY TESTED FOR ELECTRIC CURRENT LEAKAGE IN ACCORDANCE WITH YOUR SAFETY

DEPARTMENT INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJECTION INTO THE BODY OR CAUSE OTHER SEVERE

PERSONAL INJURY.

A. DO NOT EXCEED SPECIFIED FLOW AND PRESSURE

FOR THIS TOOL. EXCESS FLOW OR PRESSURE MAY

CAUSE A LEAK OR BURST.

B. DO NOT EXCEED RATED WORKING PRESSURE OF

HYDRAULIC HOSE USED WITH THIS TOOL. EXCESS

PRESSURE MAY CAUSE A LEAK OR BURST.

C. CHECK TOOL HOSE COUPLERS AND CONNECTORS

DAILY FOR LEAKS. DO NOT FEEL FOR LEAKS WITH

YOUR HANDS. CONTACT WITH A LEAK MAY RESULT

IN SEVERE PERSONAL INJURY.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

SAFETY TAG P/N 15875 (Shown smaller then actual size)

D. DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO

NOT ABUSE HOSE. DO NOT USE KINKED, TORN OR

DAMAGED HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CONNECTED TO THE TOOL BEFORE PRESSURING SYSTEM.

SYSTEM PRESSURE HOSE MUST ALWAYS BE CONNECTED TO TOOL “IN” PORT. SYSTEM RETURN HOSE

MUST ALWAYS BE CONNECTED TO TOOL “OUT” PORT.

REVERSING CONNECTIONS MAY CAUSE REVERSE

TOOL OPERATION WHICH CAN RESULT IN SEVERE

PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSEDCENTER HYDRAULIC SYSTEMS. THIS MAY RESULT IN

LOSS OF OTHER HYDRAULIC FUNCTIONS POWERED BY

THE SAME SYSTEM AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA.

KEEP BYSTANDERS CLEAR OF YOUR WORK AREA.

6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PROTECTION.

7. TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE,

ALL TOOL REPAIR MAINTENANCE AND SERVICE MUST

ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY

TRAINED PERSONNEL.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

TAG TO BE REMOVED ONLY BY

DANGERDANGER

TOOL BEFORE USING IT.

OPERATION MANUAL.

TOOL OPERATOR.

SEE OTHER SIDE

6 ► WS10 User Manual

Loading...

Loading...