Stanley U-Install Owner's Manual

HON'IE AUTOTNAflON

IJ.INSTALL@

GARAGE

DOOR

OPENERS

OWNER'S

MANUAL

...

FOR

USE ON MOST TVPES

OF GARAGE DOORS

DO NOT THROW

THIS MANUAL

AWAY.

Keep in a

safe

location

for future

reference.

Do not

connect to

power

until instructed to

do so.

Do not run

door opener

until completely installed.

Door

opener will not

operate until

beam sensor

is

installed

and

properly

aligned.

.

For

your protection,

wear

safety

glasses.

Read

and

follow

ALL

instructions

carefully.

o

a

o21

.O259E

Dear Homeowner,

Please take

a moment to read the

following

IMPORTANT

INSTALLATION

INSTRUCTIONS

prior

to beginning assembly

and

installation of

your

new

garage

door opener.

THIS CAUTION

SYMBOL

APPEARS

PERIODICALLY

THROUGHOUT THIS

MANUAL.

IT WILL

IDENTIFY IMPORTANT SAFETY

INSTRUCTIONS.

A. Br suRE

To

READ

AND FoLLow

ALL

rNsrALLATtoN

TNSTRUCnONS.

B.

lnsmll

rHE GARAGE

DooR

opENER oNLY

oN A

PRoPERLY

BALANCED

AND

LUBRICATED

GARAGE DOOR.

AN

ilPROP.

ERLY

BALANCED

DOOR

COULD

CAUSE

SEVERE

INJURY.

LuentcRre

youR

DooR

BY APPLYTNG

A LIcHT olL oR

SILICONE

LUBRICANT

TO

THE DOOR HINGES,

MOUNTING

HARDWARE

AND

THE ROLLER

BEARINGS,

YOUN

OOON

SHOULD

MOVE FREELY

BY

HAND WITHOUT

STICKING OR

BINDING.

DO ruOT

APPLY OIL

OR GREASE

TO THE ROLLER

TRACKS. COI'IOUCT

DOOR

BALANCE TEST

BEFORE

BEGINNING

INSTALLATION,

DOOR

BALANCE

TEST

Raise

your

door to its

mid-point and

release

it, The door

should

remain in this

position

without moving

up or down.

If the

door is

moved to the 314

open

position

and released,

it

should

remain in

place

or move

slowly to

the full open

position.

If the

door

is moved to the

3/4 close

position

and

released,

it

should

remain

in

place

or

move

slowly to

the full close

position.

If the door

fails any of

these three

door

tests, the springs

may

be

out of adjustment.

Ilave

a

qualified

service

person

make

repairs

to cables,

spring

assemblies

and ot[er

hardware

before

installing

the opener.

Some

parts

are

under

EXTREME

tension

at times

and

can cause serious

injury

if

improperly

handled.

C, Reuove

ALL

RopEs

AND

REMovE oR

MAKE INoPERATIVE

ALL LOCKS

CONNECTED

TO

THE GARAGE

DOOR

BEFORE

INSTALLING

OPENER,

ACCIOENTRT

ENGAGEMENT

OF

DOOB

LOCKS

MAY RESULT

IN

DAMAGE

TO DOOR OR

OPENER

AND

POSSIBLE

PERSONAL

INJURY.

D, lr

posslElE,

tNsrALL

DooR

oPENER

7 FEET oR

itoRE

ABOVE

THE

FLOOR. THIS

IUNY

NOT BE

POSSIBLE WITH

MOST

ONE.PIECE

DOORS, Iru

TNIS CASE

INDIVIDUALS

OVER 6

TOOT

SHOULD

BE ALERT

TO THIS

POTENTIAL

OBSTACLE

WHILE

IN

THE GARAGE.

Mouw rHE

RED EUERGENcv

RELEASE KNoB 6

FEET

ABOVE THE FLOOR.

IT

SNOUIO

BE REACHABLE

BY ADULTS

IN THE HOUSEHOLD TO ALLOW

MANUAL USE OF THE GARAGE

DOOR IN AN EMERGENCY.

Do tor coNNEcr opENER

To

powEn

souncE

UNTIL

INSTRUCTED TO DO SO.

EXTTruSION CORDS

SHOULD

NOT BE

USED. THE OPENER

MUST BE PLUGGED

INTO A PROPERLY-

GROUNDED

120 VOIT

THREE-PRONG

OUTLET,

Locnre rHE

pusHBurroN

courRol

BurroN

wtrHtN slcHT

OF THE

DOOR AND AT A MINIIIUM

HEIGTIT OF 5

FEET ABOVE

THE FLOOR SO

SMALL CHILDREN

CANNOT REACH

tI. MOUNT

rT AWAY FROM

ALL MOVING PARTS OF

THE DOOR.

Be suRe ro

rNsrALL rHE ENTRAPMENT

WARNING

LABEL

NExr ro rHE coNTRoL

BUTToN.

Reno rte

CONTROL

ADJUSTMENT

WARNING LABEL

ott

THE REAR OF THE OPENER AND

ALSO THE

EMERGENCY

RELEASE

TAG,

wHrcH

ts TNSTALLED oN

THE

EMERGENCY

RELEASE CORD OF

THE TRAVELER.

Arrsn

TNSTALLING DooR opENER,

THE

DooR MUsr

REVERSE

WHEN IT COMES IN COiITACT

WITII A

1.1/2 II'ICTI

HrcH oBJECT

(On

l2X4 BOARD

LA|D FLAT ON THE

FLOOR).

Cnecr

rHE

sAFEw

REVERSTNG

MEcHANtsM orreru

(oruce

A MoNTH

rs REcoMMENoeo) ro ENSURE

tr REVERSES

wtrH

A MINIMUM AMoUNT oF

FoRcE. Txs uusr BE

RETESTED

ANY Tlf,E AN ADJUSTMENT

lS MADE TO

THE DOOR ARttl'

FORCE ANUSTIiENTS,

OR CLOSED

POSmON AIITUSTilENT.

lp oRtuRee ro ANy MEcHANtcAL

DRtvE

oR srRUcruRAL

COMPONENT

OF UNIT IS OBSERVED

DISCONTINUE

USE

AND coNTAcr

AN AUTHoRtzED

GARAGE

oooR/oooR

opENER

DEALER oR THE Coltsutrlen

SeRvtce

DrpRRrlerur

rMMEDrArELy.

NEVER OPERATE

THE

OPENER

IF

THE

SYSTEM

IS NOT FUNCTIONING

PROPERLY

OR IF

IT WILL

NOT REVERSE

OFF

OF A 1.1/2 INCH

HIGH

OBJECT.

E,

F.

G,

H.

L

J,

Page

2

02c.2

CONTROLS

Your new

garage

door opener offers momentary

control. To

operate

the door

simply

press

either the hand held transmitter

button or the wall mounted

pushbutton

for one to two seconds

and

the

door will

automatically open or close. The opener can

be

stopped

during

any

portion

of the opening or closing cycle

by

pressing

either of the buttons. The next time the button is

pressed,

the opener will re-start the door in motion in

the

opposite direction.

OBSTRUGTION SENSING

When

properly

adjusted, the

door will automatically reverse if

it

senses an obstruction during

the closing cycle. This

system

will also stop

the door if it hits an obstacle when opening.

SAFE.T.CYCLETM

This electronic system will

reverse

the door in 30 seconds or

less if the door is unable to travel to the full closed

position.

This feature

provides

automatic

reversing

should other sys-

tems fail to operate and the

door

does not fully

close.

SAFE.T.SIGNALTM

Lights will flash whenever Safety Reverse or Safe-T-Cycle

has

been activated.

FORCE ADJUSTMENTS

Independent OPEN and CLOSE dials allow

you

to select the

minimum required opening and closing force.

EMERGENCY

RELEASE

Your door

opener is

equipped with

an emergency release

device.

In the

event of a

power

failure, pull

the knob on the

pull

cord down

and slightly

to the back

(away

from door)

allowing the disconnect

to latch. This

will allow

you

to

man-

ually open or close

the door. When

power

has been restored,

gently

pull

the

disconnect cord, releasing

the traveler detent,

then

press

either

the transmitter

or

pushbutton.

The opener

will

automatically reconnect.

SAFE.T.MONITORTM

A dynamic

obstruction

detection device

that continuously

monitors

the amount

of force required to move

the

garage

door, and

automatically

adjusts the obstruction detection level

in addition

to the homeowner

adjustable force levels. This

SAFETY

SYSTEM adds

the additional level

of

protection

indicating

our commitment

to safe

garage

door operation.

CONTROL

CONNECTIONS

All opener

models are

provided

with screw

terminals

for the

attachment

of a wall

mounted

pushbutton

or four-function

wall console.

The console

includes

a

pushbutton,

worklight

switch,

vacation switch,

and

pedestrian

light. Some models

are

provided

with a

pushbutton

only, but ALL MODELS

can

be connected

to the four-function

wall console

which

is

sold

separately.

Voltage

Required: 120

Volts a.c.

60 cycle

Single Phase

A

grounded,

three

(3)

hole

electrical outlet is required.

Motor

Specs:

Permanent

Split Capacitor

-Internal

Automatic Over load Reset

Current

Required:

7

AMPS

Overload

Protection:

The motor is equipped

with an auto-

matic

thermal over load

device. Should the motor

become

over heated,

the

over

load

device will render

the opener inop-

erative.

Simply wait

approximately 5 to 10 minutes

for the

motor to cool.

Opener Length:

Minimum

Head

Room

Required:

Average Door

Speed:

Maximum

Door

Size:

10Feet-8Inches

From

end of tube assembly to

rear

of opener

power

unit.

2

Inches

(Tracked

Doors)

6 Inches

(Trackless

Doors)

6 Inches

per

second

L/4H}.:

16 Ft. Wide / 7 Ft. High

1/3 H.P. or I/2HP.:

18 Ft. Wide l7 ll2Ft.High

03c.1

Page

3

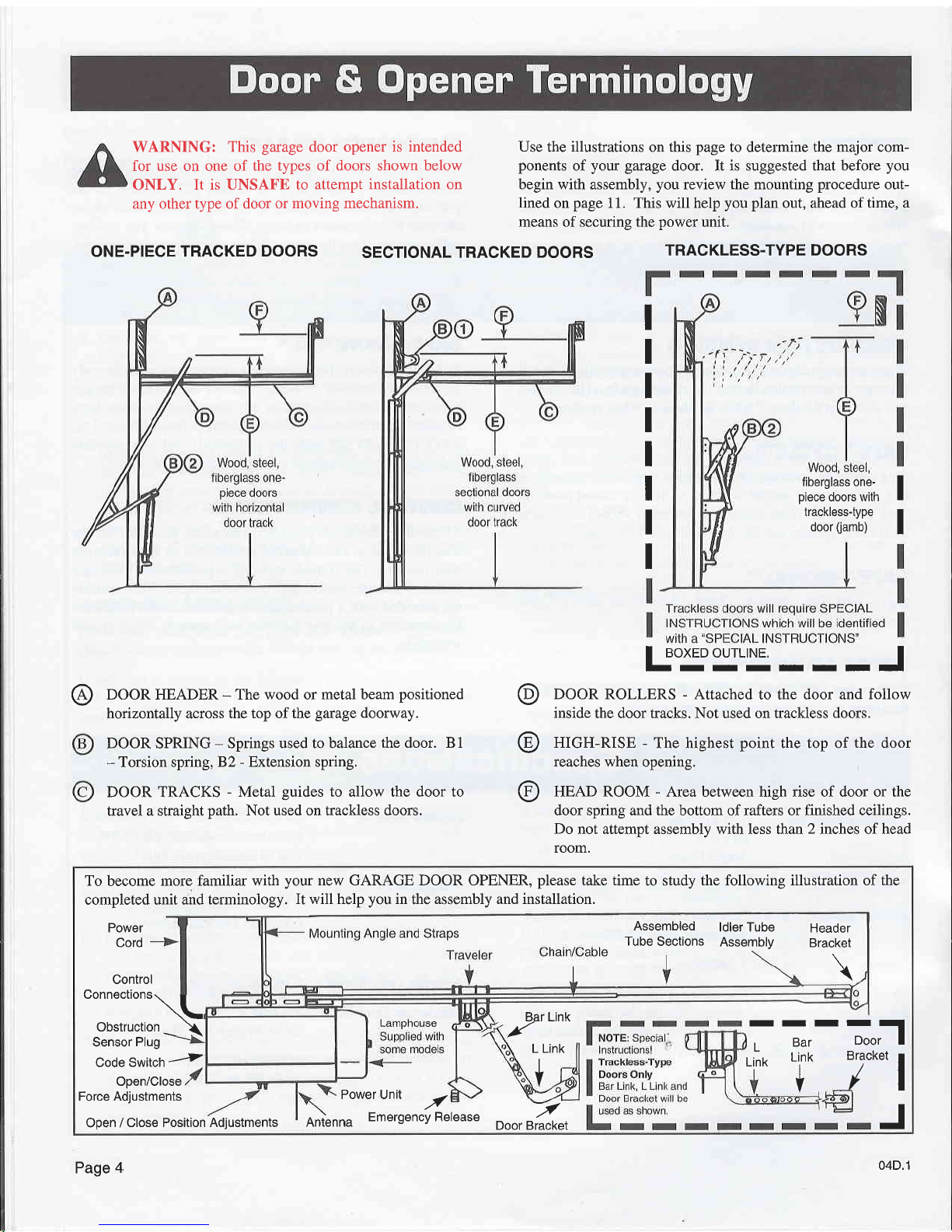

WARNING:

This

garage

door opener

is intended

for use on one of the

types of doors shown below

ONLY.

It is UNSAFE to

attempt installation on

any other type of door or

moving mechanism.

ONE.PIECE TRACKED

DOORS

SECTIONAL TRACKED

DOORS

Use

the

illustrations

on this

page

to determine the major com-

ponents

of

your garuge

door. It is suggested that before

you

begin with

assembly,

you

review the mounting

procedure

out-

lined

on

page

11. This will help

you plan

out, ahead of time, a

means of securing the

power

unit.

TRACKLESS.TYPE

DOORS

I

I

I

I

I

I

I

I

,i:::',x:iJlh

I

'T:5ff:;l',!'

I

@

DOOR HEADER - The wood or metal beam

positioned

horizontally across

the top ofthe

garage

doorway.

DOOR SPRING - Springs

used to balance

the door. 81

-

Torsion spring,

82 - Extension spring.

DOOR TRACKS

-

Metal

guides

to allow the door to

travel a straight

path.

Not used on trackless doors.

@

@

@

I

aoxeo ourLrNE.

I

-IIIIIII

DOOR ROLLERS

-

Attached to the door and

follow

inside

the door tracks. Not used on trackless doors.

HIGH-RISE

-

The highest

point

the top of

the

door

reaches

when opening.

HEAD ROOM - Area between high rise of door or the

door spring and the bottom ofrafters or finished ceilings.

Do not attempt assembly with less than 2 inches of head

room.

To

become

more familiar with

your

new GARAGE DOOR OPENER,

please

take time

to study

the following illustration of the

completed unit and

terminology.

It will help

you

in

the

assembly and installation.

Control

Connections

Power

Cord

Sensor

Plug

Code

Switch

..-i

Open/Close

Force Adjustments

power

Unit

./

Open /

Close Position Adjustments

RnLnna

EmergencyRelease

/tiltguuvtto\

Obstruction

_ \

Bar Link

.f'

-

-o*ll

_y*

l

J

L Link

I

Bar

Link

I

Y

I

l1

Link

V

-./

BracketDoor

Assembled

ldler Tube

Tube

Sections

Assembly

Header

Bracket

\

Page

4

04D.1

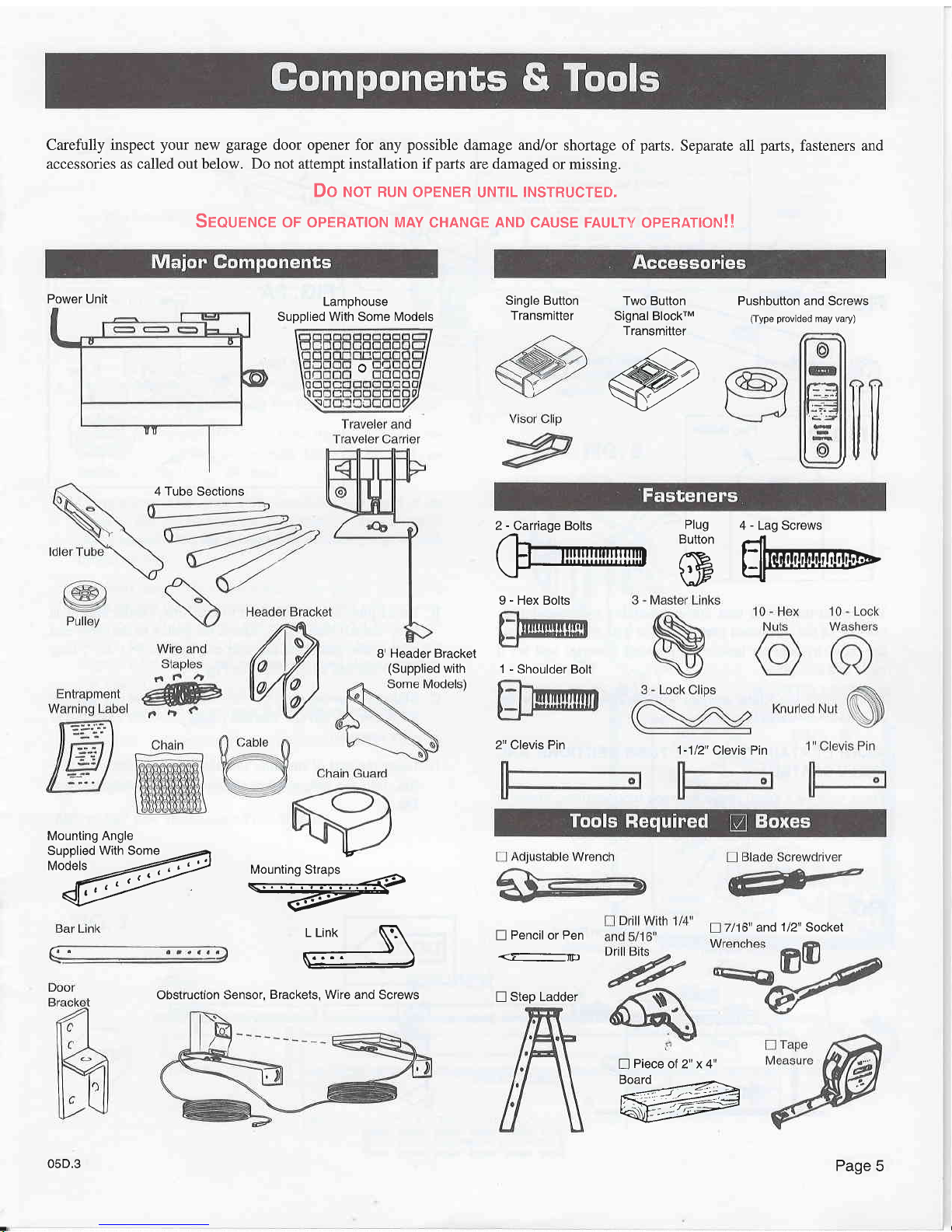

Carefully inspect

your

new

garage

door opener for any

possible

damage and,ior

shortage of

parts.

Separate all

parts,

fasteners and

accessories as called out below. Do not attempt installation if

parts

are damaged or missing.

Oo r'ror nur,r

operrreR uNTrL

TNSTRUcTED,

Srourruce oF opERATroN

MAy

cHANGE

AND

cAUsE FAULTv

opERATroN!!

Pushbutton

and

Screws

(Type provided

may vary)

5" and

1/2"

Socket

n

Piece

of 2" x 4"

,W

Single Button

Transmitter

2" Clevis Pin

n

Pencil

or

Pen

<.F-m)

n

Step Ladder

Power Unit

Lamphouse

Supplied With Some Models

Two Button

Signal BlockrM

Transmitter

.,#

(-\

-YZZ)7

/'

NZ

4 Tube

Sections

05D.3

B'

Header Bracket

(Supplied

with

2 - Carriage Bolts

Plug

4 - Lag Screws

@rofl@'

\'lP

-u

Mounting Angle

rffiry

%

L Link

N\

--) \

\=-

9 - Hex Bolts

1

-

Shoulder Bolt

1-112"

Clevis Pin

obstructron Sensor,

Brackets, Wire

and Screws

I

Page

5

ldler Tube

Assemble Tube

Sections

Align Holes

on the Side

to Make

Assembly

Stronger

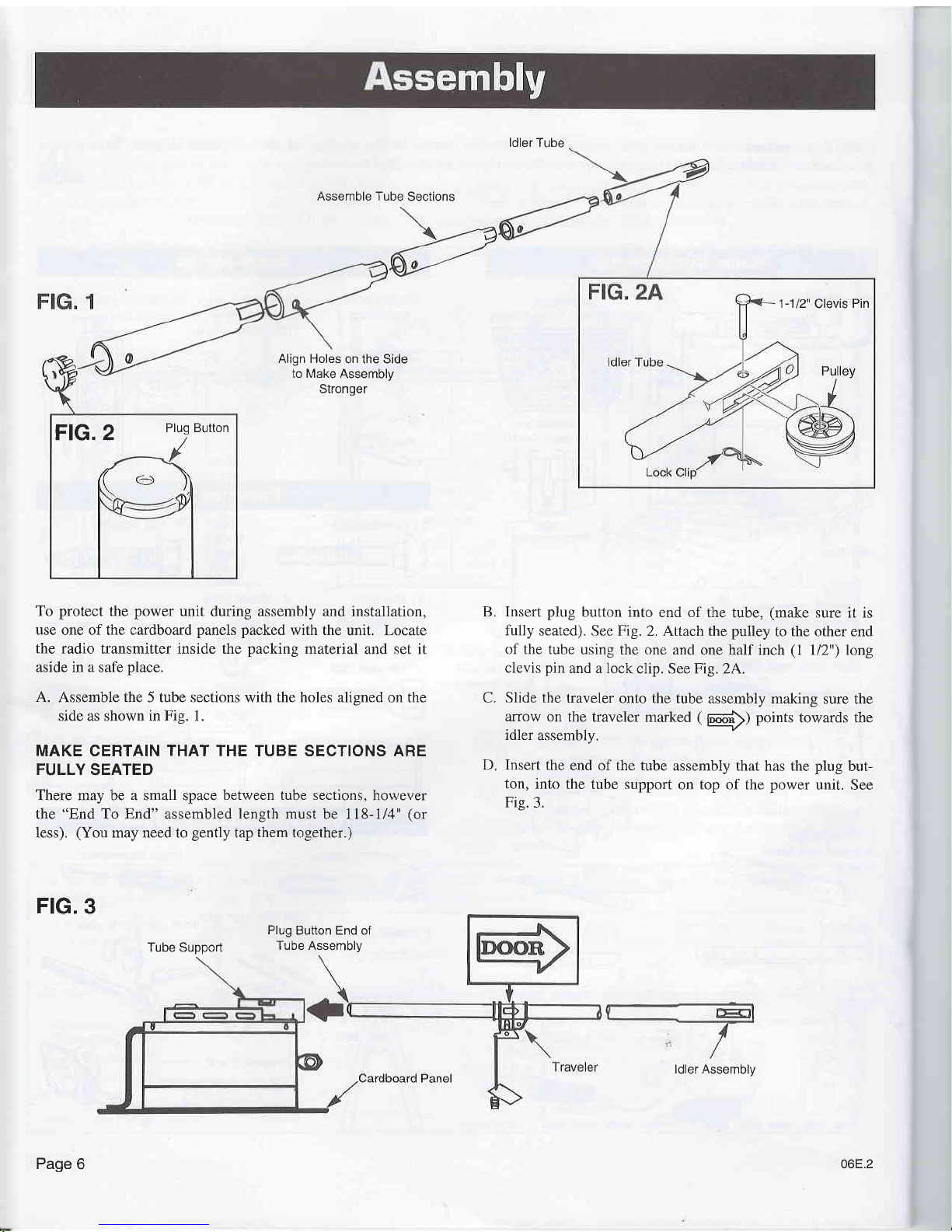

To protect

the

power

unit during assembly and

installation,

use

one of the cardboard

panels packed

with the

unit. Locate

the

radio transmitter inside the packing

material and set it

aside in a safe

place.

A. Assemble the 5 tube sections

with

the holes alisned

on the

side as shown in Fig. 1.

MAKE CERTAIN THAT THE TUBE SECTIONS ARE

FULLY SEATED

There may be a small space

between tube sections,

hou,ever

the "End To End" assembled

length must

be 118-1i4"

(or

less).

(You

may need to

gently

tap

them

together.)

FIG. 3

Tube Support

Insert plug

button into

end of the

tube,

(make

sure it is

fully

seated). See Fig.

2. Attach the

pulley

to the other end

of the

tube using

the one and

one half inch

(l

l/2") long

clevis

pin

and a lock

clip. See Fig.

24.

Slide the

traveler

onto the

tube assembly making

sure the

arrow

on the

traveler marked

(

|D|o6;>)

points

towards the

idler

assembly.

Insert

the

end of the tube

assembly that has the

plug

but-

ton,

into

the tube support

on top of the power

unit. See

Fis.

3.

B.

C.

D

1-112"

Clevis

Pin

FlG. 2

Plug Button

Plug

Button End of

Tube Assembly

ldler Assembly

Page

6

06E.2

ldler

Assembly

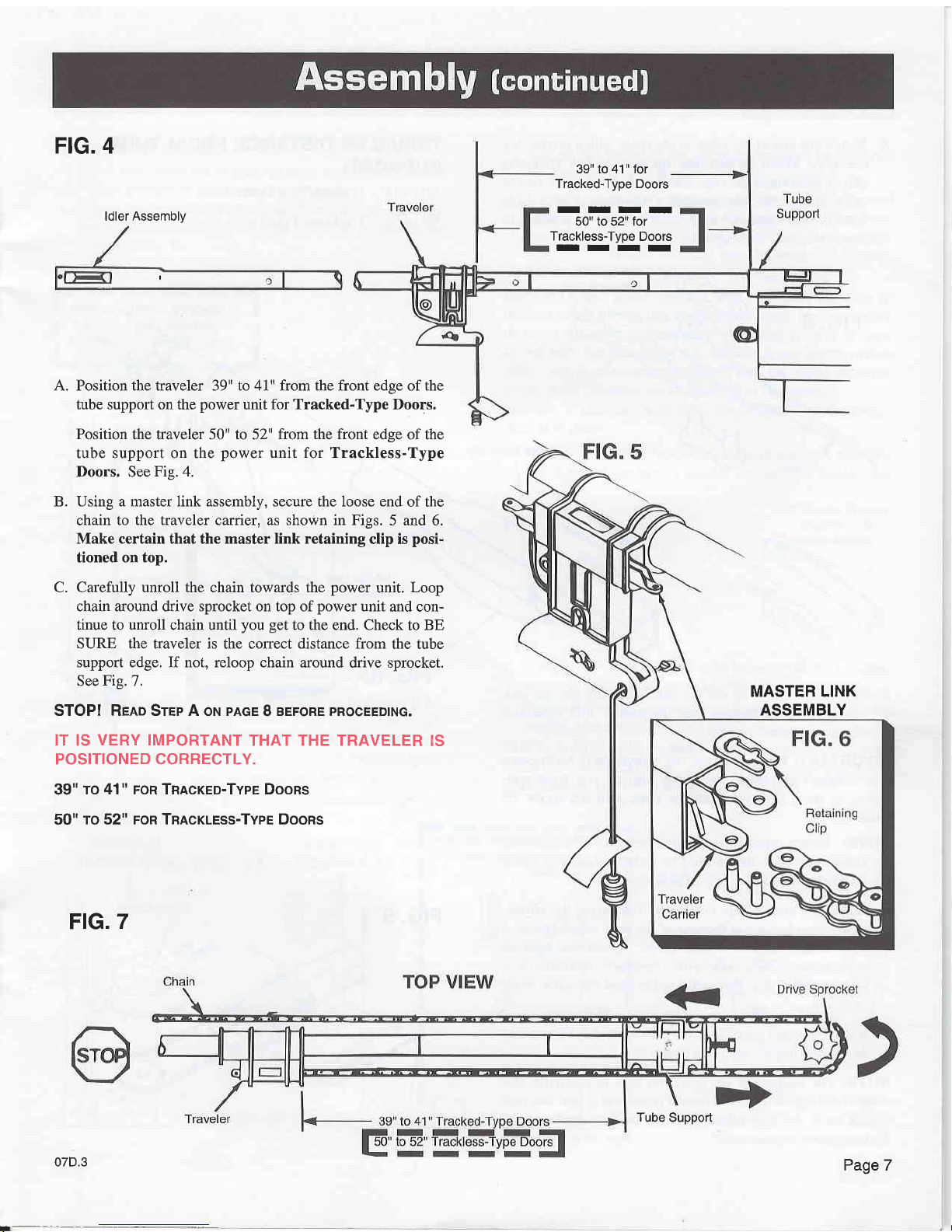

FIG. 4

39" to 41" for

Tracked-Type Doors

III-

50" to 52" for

Trackless-Type

Doors

IIII

A. Position the traveler 39" to 41" from the front edge of the

tube support on the

power

unit for Tracked-Type Doors.

Position

the traveler 50" to 52"

from the front

edge of the

tube support on the

power

unit for Trackless-Type

Doors. See

Fig. 4.

B. Using a master link assembly, secure the loose end

of the

chain

to the traveler carrier, as shown in Figs.

5 and 6.

Make certain that the master link retaining

clip is

posi.

tioned on top.

C. Carefully unroll the chain towards the

power

unit.

Loop

chain around drive sprocket on top of

power

unit

and con-

tinue to unroll chain until

you get

to the end. Check

to BE

SURE the traveler is the correct distance from

the tube

support edge. If not, reloop chain

around drive sprocket.

See

Fig.

7.

STOP! Rrno Srep A oru

pnce

I

aerone

pRocEEDtNG.

IT IS

VERY IMPORTANT

THAT THE TRAVELER

!S

POSITIONED CORRECTLY.

39"

To 41" FoR Tnncreo-TvpE DooRS

50"

ro

52"

FoR Tnncruess-Tvpe Doons

FIG.

7

Tube

Support

PageT

07D.3

MASTER LINK

ASSEMBLY

I

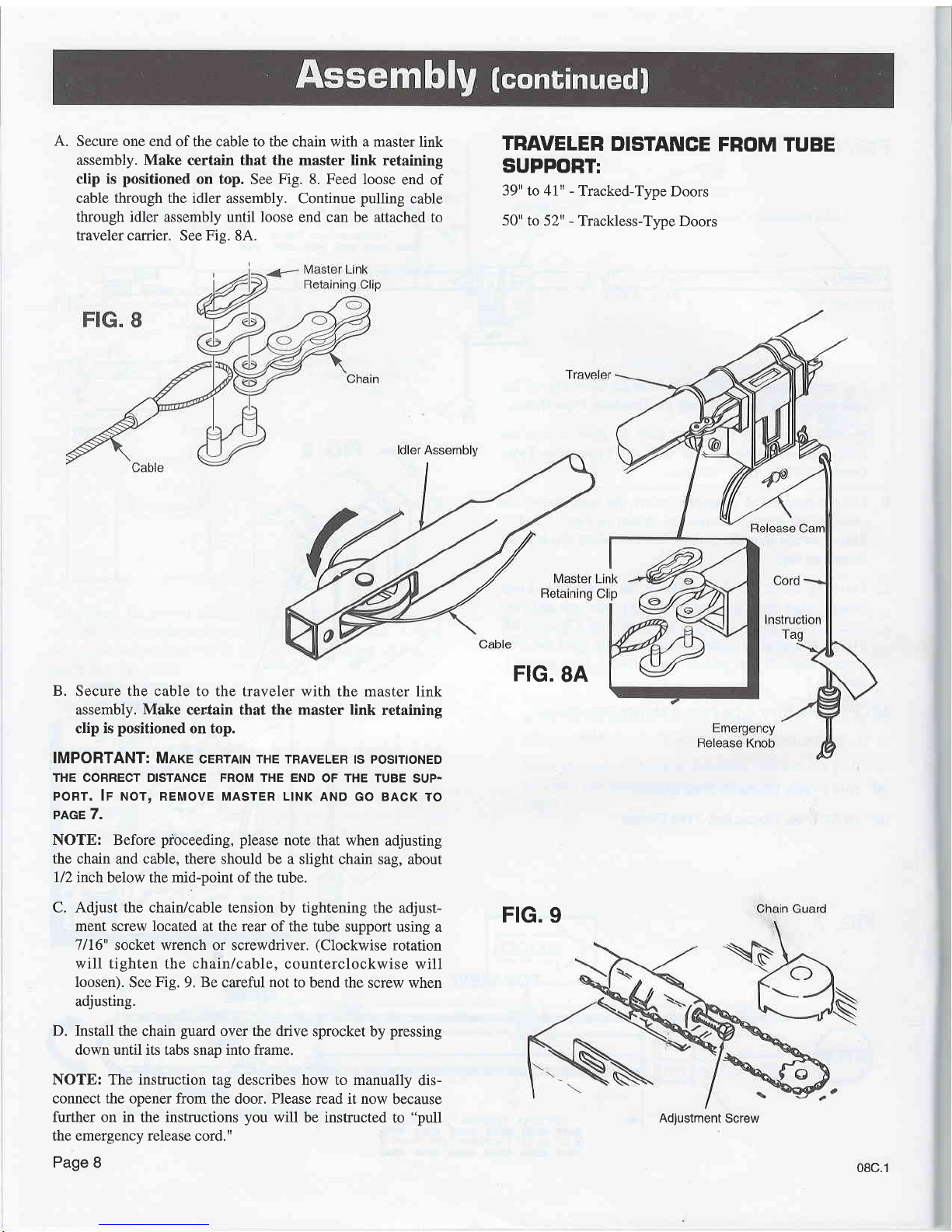

A. Secure one end

of the cable to the chain with a master

link

assembly. Make

certain that the master link retaining

clip is

positioned

on top. See

Fig.

8. Feed loose

end of

cable through the idler

assembly. Continue

pulling

cable

through idler

assembly until

loose

end can be attached

to

traveler carrier.

See

Fis.

8A.

TRAVELER

DISTANCE

FROM

TUBE

SUPPORT:

39" to 41u

-

Tracked-Type

Doors

50"

to 52" - Trackless-Type

Doors

B.

Secure the cable to the

traveler with the master

link

assembly. Make certain that the

master

link

retaining

clip is

positioned

on top.

IMPORTANT: MnrE

cERrAtN THE TRAVELER ts

postnoNED

THE CORRECT DISTANCE FROM THE END

OF THE TUBE

SUP.

PORT, lF NOT, REMOVE MASTER L|NK

AND GO BACK

TO

PAGE 7.

NOTE:

Before

pioceeding, please

note that when

adjusting

the chain

and cable, there should be a slight

chain sag, about

l/2

inch below the mid-point of the tube.

C. Adjust the chain/cable tension by

tightening the

adjust-

ment screw located

at

the rear

of the tube support

using a

7/16"

socket wrench or screwdriver.

(Clockwise

rotation

will tighten the chain/cable,

counterclockwise

will

loosen).

See

Fig.

9.

Be

careful

not

to bend the

screw when

adjusting.

D.

Install the chain

guard

over the drive

sprocket by

pressing

down until its tabs

snap

into frame.

NOTE: The instruction

tag describes how to manually

dis-

connect the opener from

the door. Please read it now

because

further on in the instructions you

will be instructed

to

"pull

the emergency release

cord."

Page

8

FIG.

8A

FIG.

9

Adiustment

Screw

08c.1

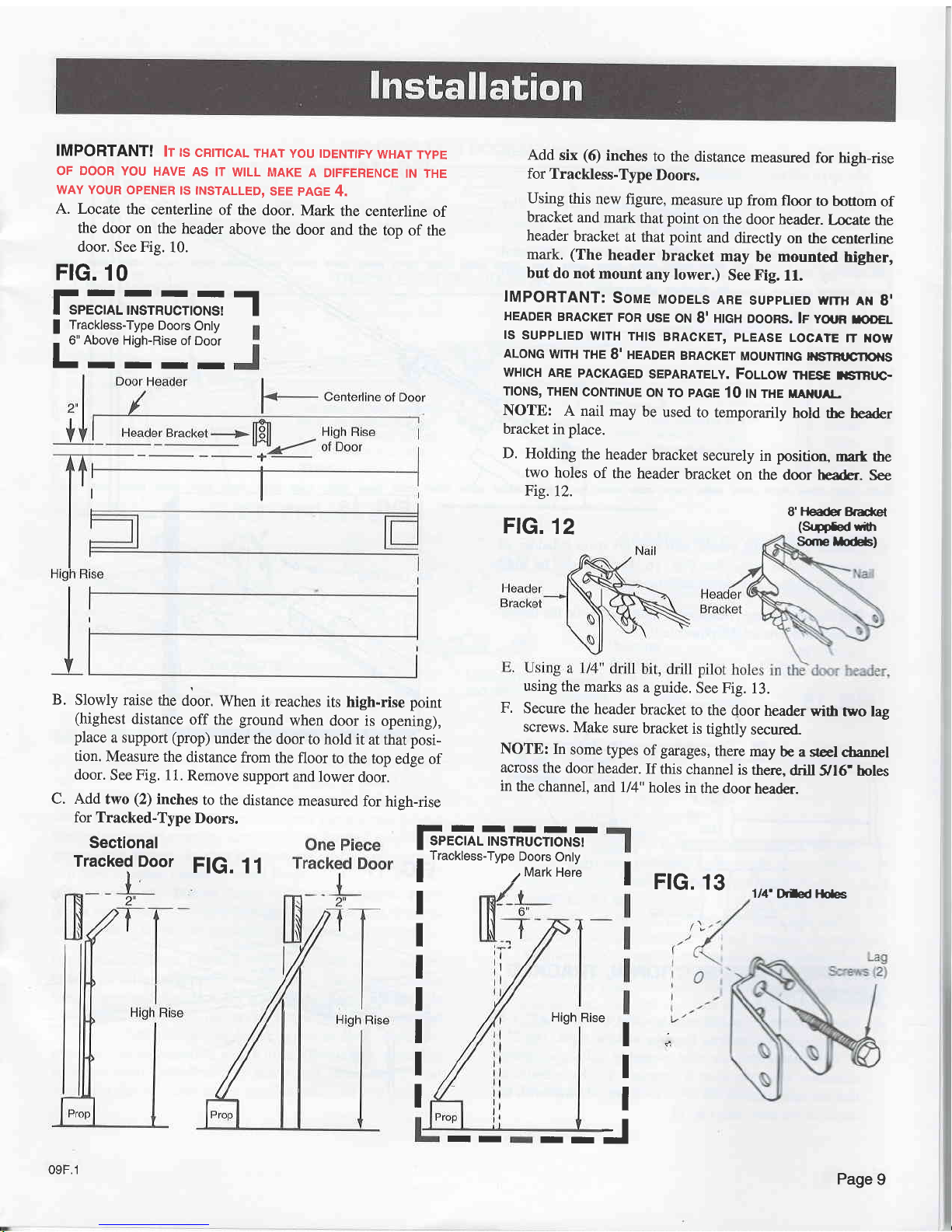

IMPORTANT!

lr rs

cRtlcAL

rHAr

you

tDENlFy

wHAr

rypE

OF DOOR YOU

HAVE

AS IT

WILL

MAKE

A DIFFERENCE

IN THE

wAy

youR

opENER

ls INSTALLED,

seE

pnce

4.

A. Locate

the

centerline

of the

door.

Mark

the centerline

of

the door on

the header

above the

door

and the

top

of the

door, See Fig.

10.

FrG.

10

Add

six

(6)

inches

to

the distance

measured

for high-rise

for

Trackless-Type

Doors.

Using

this

new figure,

measure

up

from floor

to bouom

of

bracket

and mark

that

point

on the

door header.

Laate

the

header

bracket

atthal point

and

directly

on rhe

centerline

mark.

(The

header

bracket

may

be

mounted

higher,

but

do not

mount

any lower.)

See Fig.

11.

IMPORTANT:

Soue

MoDELs

ARE

suppLtEo wmr

rr

g'

HEADER

BRAcKET

FoR

usE

oN

I' HtcH DooRs.

lr voun

rco€L

ls

SUPPL|ED

W|TH

TH|S

BRACKET,

PLEASE

LOCATE

1T xOW

ALoNG

wtrH

THE

8' nEADeR

BRACKET

MouNnNG

FrsrBt

cnot{s

WHICH

ARE

PACKAGED

SEPARATELY.

FOLLOW

THESE T|STRIJC.

TloNs,

THEN

CONTTNUE

ON

TO PAGE

10 rru

rxe rAfllrAt_-

NOTE:

A nail

may

be

used

to temporarily

hold

the header

bracket

in

place.

D.

Holding

the header

bracket

securely

in

position,

mart the

two

holes

of

the header

bracket

on

the door header.

See

Fig.12.

F-rrrT

SPECIAL

INSTRUCTIONS!

T

I

Trackless-Type

Doors

Only

-

6"

Above

Hiqh-Rise

of Door

T-

T

IIITI

B.

C.

Slowly

raise the

door.

When

it reaches

its high.rise point

(highest

distance

off the

ground

when

door is

opening),

place

a support

(prop)

under

the

door

to hold it

at that

pos!

tion. Measure

the

distance

from

the

floor to

the top

edge

of

door.

See Fig.

1 1.

Remove

support

and

lower

door.

Add

two

(2)

inches

to the

distance

measured

for

hieh-rise

for Tracked-Type

Doors.

Sectional

Tracked

Door

FlG.

11

SorellorB)

using

the

marks

as

a

guide.

See Fig.

13.

F.

Secure

the

header

bracket

to

the door

header wift

two lag

screws.

Make

sure

bracket

is

tightly

secured

NOTE:

In

some

types

of

garages,

there

may

be a

geel

chann€l

across

the

door

header.

If

this channel

is

there,

drill

g16.

boles

in

the

channeT,

and I/4"

holes

in

the door

header.

FtG.

12

8'l-leaderBrdet

(Sugftd

*fr

1/4'Drled

lG

I

rrc.

rs

I

I

I

I

I

I

I

High

Rise

t:

I

I

IIIIII

I

SPECTAL

TNSTRUCTTONS!

a

Trackless-Type

Doors

Only

I I

Mark

Here

09F.1

II

II

-J

Page

9

A.

B.

Place

the

power unit on

the

floor

and

raise

the

idler

assem-

bly

up to

the

header

bracket.

See

Fig.

14.

Using

the

2"

clevis

pin and

a

lock clip,

secure

the idler

assembly

to the

header

bracket.

See

Fig.

15.

NOTE:

The

header

bracket

is designed

with

an additional

positioning

hole

if

height

adjustment

is necessary.

It can also

be mounted

upside

down

for

further

adjustment.

Carefully

raise

the

power unit

and set

it

on a

ladder

or

other

suitable

prop. See

Fig.

16. Unit

should

be

high

enough

to clear

door

when

fully

opened'

Pull

the

emergency

release

cord

down

and slide

the

travel-

er assembly

toward

the

Power

unit.

Traveler

Assembly

ONE

PIECE

AND

SECTIONAL

TRACKED

DOORS

ONLY

E. Raise

the

door

to the

full

open

position and

place a2"

x 4"

board

(on

edge)

between

the

tube and

the

door.

The

2" x

4" will

ensure

that the

tube

assembly

will

have

enough

clearance

when

the

door

is opening.

Set

the operator

so

that the

tube

rests

on

the

2" x

4" directly

in line

with the

center

ofthe

door.

See

Fig.

17.

Page

10

FrG.

14

FtG. 17

ldler Assembly

C.

D.

FlG.

15

Header

Brackel

Lock Clip

Fo<

108

Loading...

Loading...