Page 1

WARNINGS

• Always read tool manual before operating.

• Always wear safety glasses while operating or

while in the vicinity of a tool in operation.

• For testing, always cycle tool away from work

to insure proper ring closure. For safety

reasons, an improperly functioning tool must

not be used. When operating tool, never point

or actuate tool other than into work.

• Operate tool in an unobstructed work area.

• Disconnect air supply prior to maintenance

and/or repair of tool.

• Use clean dry air to maximize efficiency. Do

Not Exceed 100 P.S.I. (7.0 kg/cm sq.)

• Do not use bottled gases such as oxygen,

hydrogen, carbon dioxide, acetylene, etc.

• Tools shall be operated with a fitting or hose

coupling on or near the tool in such a manner

that all compressed air in the tool is discharged

at the time the fitting or hose coupling is

disconnected.

SPRING RETURN

PNEUMATIC D-RING TOOL

TR201 TR203

SAFETY INSTRUCTIONS

WARNING:

The employer and/or user must ensure

that proper eye protection is worn. Eye

protection equipment must conform to

the requirements of the American

National Standard Institute, ANSI Z87.1-1989 and

provide frontal and side protection. Eye protection

should be worn by the operator and others in the work

area when loading, operating, or servicing this tool.

Eye protection is required to guard against possible

flying particles and/or debris, which could cause

severe eye injury.

NOTE: Non-side shielded prescription glasses and

faceshields alone do not provide adequate protection.

OPERATION

Always handle tool with care:

• Never engage in horseplay.

• Never pull the trigger unless nose of tool is

directed toward the work.

• Keep others at a safe distance from the tool while

the tool is in operation as actuation occurs,

possibly causing injury. Keep hands and body

away from the jaw mechanism of the tool.

LOADING TOOL

When loading tool:

• Never place a hand or any part of body in jaw

mechanism area of tool.

• Never point tool at anyone.

• Never actuate tool when loading, accidental injury

may occur.

AIR CONSUMPTION

SC7 Series Tools require 1.6 cubic feet per minute

(.045 cubic meters per minute) of free air to operate at

a rate of 100 fasteners per minute, at 100 P.S.I. (7.0

kg/cm sq.).

1 of 6 01/03

Page 2

2 of 6 01/03

Page 3

3 of 6 01/03

Page 4

TO DISASSEMBLE

Carriage and magazine assembly

1. Remove (2) socket head cap screws (#2).

2. Remove carriage and magazine assembly from housing

(#1) by turning counter clockwise.

3. Detach magazine assembly (#22) by removing (4) socket

head cap screws (#24) from carriage assembly.

Piston, jaws and teeth

1. Remove o-ring (#5).

2. Remove piston rod nut (#3) from piston rod (#6). Apply

heat as needed to break down thread lock adhesive on

threaded end of piston rod.

3. Remove piston, bumper and spring (#4, #7 and #8).

4. Remove socket head cap screw (#25).

5. Remove slide (#16) by sliding it away from teeth area

and pulling it up through the carriage.

6. Remove jaw assembly from carriage.

7. Drive out pin (#14) from jaws (#15 and #18) and arm

links (#13 and #19).

8. Drive out pin (#12) from arm links (#13 and #19) and

clevis #10).

9. Remove clevis lock screw (#11) from clevis (#10).

10. Remove clevis (#10) from piston rod (#6). Apply heat

as needed to break down thread lock adhesive on

threaded end of piston rod.

11. Detach teeth (#21) by driving (2) roll pins (#20) from

carriage and teeth (#32 and #21).

12. Apply heat as needed to break down thread lock

adhesive on threaded end of piston rod.

13. Detach stop spacer (#9) by removing set screw (#33)

and then use a spanner wrench to remove stop spacer

(#9) from carriage (#32).

Throttle

1. Remove air valve assembly (#27) from housing (#1).

2. Remove o-ring, ball, valve ball retainer and o-ring (#28,

#29, #30 and #31).

TO RE-ASSEMBLE

1. Assemble o-ring, valve ball retainer, ball and o-ring

(#31, #30, #29 and #28) and insert into throttle bore of

housing (#1).

2. Install air valve assembly (#27) into throttle bore of

housing (#1). (Do Not Over-Tighten).

3. Install stop spacer (#9) onto the carriage (#32). Use

Loctite #242 or equivalent.

4. Install set screw (#33) into carriage, locking stop spacer

onto carriage.

5. Install teeth (#21) by driving in (2) roll pins (#20) until

flush with carriage.

6. Connect outer jaw to left arm link (#15 and #13) by

driving roll pin (#14) in aligned holes.

7. Connect inner jaw to right arm link (#18 and #19) by

driving roll pin (#14) in aligned holes. (Make sure you

match the correct jaw with the correct arm link for the

tool to operate correctly.)

8. Connect jaws and arm link assemblies to clevis (#10) by

driving roll pin (#12) into aligned holes.

9. Place piston rod (#6) into a vise with long threaded end

sticking out.

10. Install piston (#4) onto long threaded end of the piston

rod with piston rod nut (#3) and remove from vise. (Use

Loctite #242 or equivalent on both piston and flexlock

nut.)

11. Install bumper and return spring (#7 and #8) onto piston

rod.

12. Place jaws, arm linkage and clevis assembly onto

carriage.

13. Insert piston rod, return spring, bumper and piston

assembly through the carriage and connect to the clevis.

(Use Loctite #242 or equivalent.)

14. Install set screw (#11) into clevis locking piston rod to

clevis.

15. Pivot jaws and arm linkage apart so that the slide (#16)

can be installed onto carriage.

16. Install magazine assembly (#22) with (4) socket head

cap screws (#24).

17. Install o-ring (#5) onto the piston.

18. Apply lubrication to piston, o-ring, threaded stop spacer,

housing bore and thread in housing.

19. Install front end assembly into housing. (Be careful not

to damage the o-ring during installation.) Do not overtighten front end assembly onto the housing.

20. Install (2) socket head cap screws (#2), locking front end

assembly into place. Do not over tighten as damage

could occur to front end assembly.

21. Cycle tool to ensure everything operates freely.

22. Cycle tool with rings in magazine. If tool is picking up

next ring or breaking next ring away from the strip,

disconnect air from tool.

23. Push slide back toward the housing and remove slide.

24. Install wavy washer onto the post of the slide.

25. Re-install slide in tool.

26. Test tool again for picking up next ring. If picking up

next ring, repeat steps 24 through 27.

27. Make sure tool is disconnected from air supply. Push

slide toward teeth area. Install socket head cap screw

(#25) into carriage. This keeps the slide from coming

out during use. If the slide is not pushed forward during

socket head cap screw installation, you will break the

carriage.

FILTER AND REGULATOR

1. The air line should always contain a filter and regulator

unit to provide the tool with a constant flow of clean, dry

air. If moisture and contaminates are allowed to enter

the tool, the tool’s serviceable life will be decreased.

2. The regulator should be set between 70 and 90 psi. (4.8

to 6.2 bar). Never operate this tool beyond 100 psi. (6.9

bar).

4 of 6 01/03

Page 5

LUBRICATION

1. The “TR” series D-Ring tools are designed for long,

trouble-free service with minimal air line lubrication. (If

an in-line lubricator is used, it should be set at the

minimum rate of flow.)

2. Excess oil in the tool will attract dirt, lint, and the

adhesive material used in collating the fasteners,

preventing smooth operation. When lubrication is used,

always use a good grade of 5W non-detergent oil with

no additives.

3. When servicing or repairing tool use lithium grease on

all moving parts.

TIPS ON EXTENDING TOOL LIFE

The serviceable life of the “TR” series tools can be extended

greatly by using the following guidelines:

1. Always use Stanley Fastening brand fasteners. Never

replace worn or broken parts with anything other than

genuine Stanley Fastening parts. Generic fasteners

may shorten the life of your D-Ring tool and will void

the manufacturer’s warranty.

2. Keep your tool(s) clean and dry. Always use clean, dry

air and never exceed the recommended air pressure

noted above.

3. Use of this tool at minimum air pressure required for the

work at hand will greatly extend the life of the tool.

4. Exercise caution not to drop equipment. Tools dropping

onto the floor or ground is a primary reason for parts

replacement.

5. Should the tool leak air in both the triggered and rest

positions, a damaged piston o-ring may be the cause.

Once the piston o-ring has been replaced, lubricate with

lithium grease.

CARRIAGE ASSEMBLY ROTATION

INSTRUCTIONS

The carriage is normally shipped in position #1, magazine

pointing downward, parallel to the handle.

To rotate the carriage to new position, loosen (2) socket head

cap screws (#2). Grasp the handle firmly in one hand, and

the carriage (#32) in the other hand.

With steady force, rotate the two sections. This will enable

you to put the front carriage assembly into any position you

need. Tighten the (2) socket head cap screws (#2).

DO NOT use excessive force when tightening any of the

screws. Screws should be snug but not over-torqued.

HELPFUL HINTS FOR FIELD SERVICE TOOL JAMS

The most common reason for jamming problems in the TR

tool is worn parts. The two most common replaced parts are

the jaws and the pusher assembly.

If tool begins to close ring poorly or spit rings, check for

worn parts.

RING DOES NOT CLOSE COMPLETELY

1. Check air pressure. Line pressure at the tool should be

between 70 and 90 psi (4.8 - 6.2 bar) for most

applications. The tool should never be operated at

pressures exceeding 100 psi (6.90 bar).

2. A 3/8” (9.5 mm) or larger air line should be used with

the “TR” Series Tools. Air lines in excess of 100’ (30.5

meters) in length can cause air volume deficiencies at

the tool which will prevent normal operation.

3. Check for foreign debris in the jaw area. This is

especially true in the area between the jaws and the

carriage.

4. The jaws may be worn from extended use. Check the

ring groove of the jaws. If the grooves are worn

excessively or have a chip out of them, replacing the

jaw(s) is recommended.

5. The arm links or pivot pins may be worn excessively,

replacing the part(s) is recommended.

6. When the tool is used in corrosive applications, light oil

should be applied on a regular basis to the carriage,

jaws, linkages and pins. Unlubricated and/or corroded

jaw linkages may cause the tool to function poorly.

FEEDING PROBLEMS

1. If rings do not feed smoothly through the magazine,

check pusher spring for proper tension. If the magazine

is covered with dirt from field use, clean the magazine

and apply a light coating of oil.

2. When rings feed properly through the magazine but do

not feed into the jaws without spitting out of the tool, or

if the rings sit in the jaw grooves on an angle, check

jaws to insure freedom of movement.

3. NEVER USE LOOSE RINGS IN THE TR201 /

TR203 TOOL.

NOTE:

Tool model number TR201 uses a short magazine/pusher

combination, part numbers TR417051F and TR105A027F,

measuring 6 inches long and capable of holding up to 50

rings.

Tool model number TR203 uses a long magazine/pusher

combination, part numbers TR419051F and TR107A027F,

measuring 11.25 inches long and capable of holding up to

100 rings.

5 of 6 01/03

Page 6

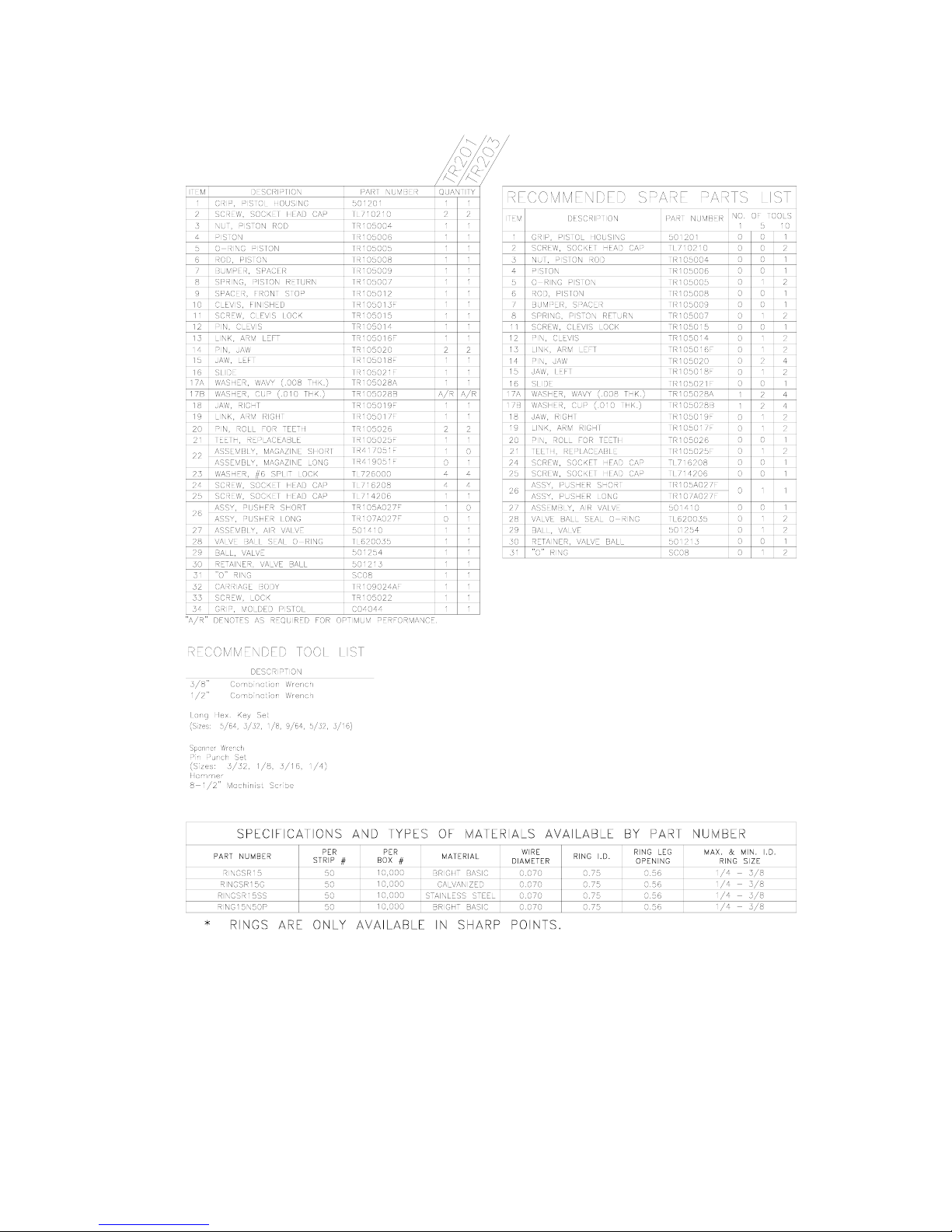

SPECIFICATIONS AND TYPES OF MATERIALS AVAILABLE BY PART NUMBER

Part Number Per

Strip #

RINGSR15 50 10,000 Bright Basic 0.070 0.75 0.56 1/ 4 – 3/8

RINGSR15SS 50 10,000 Stainless Steel 0.070 0.75 0.56 1/ 4 – 3/8

0.56

Per

Box #

Material Wire

Diameter

Ring I.D. Ring Leg

Opening

Operating Range of Tool

TR201 TR203

RINGS ARE ONLY AVAIBLE IN SHARP POINTS

LIMITED WARRANTY

Stanley Fastening Systems warrants to the original retail purchaser that this product is free from defects in

material and workmanship, and agrees to repair or replace, at Stanley Fastening Systems’ option, any defective

product within 60 days from the date of purchase. This warranty is not transferable. It only covers damage

resulting from defects in material or workmanship, and it does not cover conditions or malfunctions resulting

from normal wear, neglect, abuse, or accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED TO THE DURATION

OF THIS WARRANTY. STANLEY FASTENING SYSTEMS SHALL NOT BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of

incidental or consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To obtain warranty service, you must return the product at your expense together with proof of purchase to a

Stanley-Bostitch Regional warranty repair center or you may call us at 1-800-556-6696 or 1-800-832-3080 for

the location of additional authorized warranty service locations in your area.

6 of 6 1/03

Loading...

Loading...