Page 1

PETROL LINE TRIMMER

CURVED SHAFT

4 STROKE 26CC

MODEL NO.

SXPG42601

For service, spare parts or product information,

please contact Smart Marketing Group Pty. Ltd.

AUST. 1300 660 457 N.Z. 0800 474 876

www.stanleyproducts.com.au

03615 03/19

Page 2

2

CONTENTS

Section Page

Contents 2

Suggested Applications 2

2 Years Warranty / Serial Number 2

Specifications 3

Introduction 4

Express Warranty Statement 4

Complete Warranty Statement 5

Important Safety Instructions 6 - 8

SUGGESTED APPLICATIONS

These are some suggested articles which could be used by this Line Trimmer:

• Edges

• Paths and walkways

• Classic Garden design

• Lawn

Section Page

Description & Components 9

Unpacking 10

Assembly 10 – 12

Operation 12 - 15

Maintenance 15 – 17

Trouble Shooting 18

Service Log 19

Contact Information 20

YEARS

WARRANTY

PLEASE CONTACT CUSTOMER SERVICE

SMART MARKETING GROUP PTY. LTD.

Australia: 1300 660 457

New Zealand: 0800 474 876

Operating times: Monday – Friday

8.00am - 5.00pm Australian Eastern Standard Time (AEST)

2 YEARS WARRANTY

Please take note of serial number and write here for ease of

reference:

Serial Number:

Date of Purchase:

Place of Purchase:

Receipt Number:

2 3

Page 3

OWNER’S OPERATING MANUAL

PETROL LINE TRIMMER

CURVED SHAFT 4 STROKE 26CC

MODEL NO. SXPG42601

SPECIFICATIONS

Engine type...............................................................................................................................................4-Stroke, air cooled

Engine displacement ........................................................................................................................................................ 26cc

No Load Speed ......................................................................................................................................................... 7000min

Engine idle speed ........................................................................................................................................... 3000+/-300min

Clutch speed .............................................................................................................................................................. 4500min

Fuel tank capacity ............................................................................................................................................................280ml

Fuel type .................................................................................................................................................... 91 Unleaded petrol

Oil capacity .........................................................................................................................................................................60ml

Engine lubricant oil type ..................................................................... 4 Stroke oil SAE 30, SAE 10W-30 or SAE 10W-40

Starting system...................................................................................................................................................Recoil starter

Spark plug type...................................................................................................................TORCH CMR5H or NGK CMR5H

Cutting diameter ............................................................................................................................................................ 430mm

Cutting line size ..................................................................................................................................................... 2.0mm x 5m

-1

-1

-1

THANK YOU FOR BUYING A STANLEY

4 STROKE PETROL LINE TRIMMER

Your new Petrol Line Trimmer has been engineered and manufactured to

STANLEY’s high standard of dependability, ease of operation and operator safety.

Properly cared for, it will give you years of rugged, trouble free performance. If

you use your Petrol Line Trimmer properly and only for what it is intended, you will

enjoy years of safe, reliable service.

CAUTION: Carefully read through this entire owner’s manual, paying close

attention to the general safety rules and rules for safe operation, before using.

KEEP THIS MANUAL FOR FUTURE REFERENCE

Page 4

INTRODUCTION

Dear Customer,

Thank you for purchasing this Line Trimmer which has passed

through our extensive quality assurance processes. Every

care has been taken to ensure that it reaches you in perfect

condition. However, in the unlikely event that you should

experience a problem, or if you require any assistance please

do not hesitate to contact us.

If you have a problem, call customer service, do not

return this Line Trimmer to the place of purchase.

EXPRESS WARRANTY STATEMENT - LINE TRIMMER

You are not required to do anything to register your Line Trimmer

purchase. Please attach the purchase receipt to this manual and

ensure both are kept safe. We hope you enjoy your new Line

Trimmer, and if you have any problems call customer service on

the above phone numbers. Do not return to place of purchase.

Smart Marketing Group Pty Ltd (SMG) warrants that this Line

Trimmer will be free from manufacturing faults or defects for 2

years from the date of purchase, providing original purchase

receipt is kept and shown when needed and is subject to the

terms and conditions below.

If a warranty fault appears within the warranty period, SMG

reserves the right to replace or repair the product. In the event

that SMG chooses to replace the product, this original warranty

will expire at the original date. If the product includes various

accessories or components, only the defective accessory or

component will be replaced or repaired.

SMG reserves the right to replace defective parts of the

product with parts and components of similar quality, grade

and composition where an identical part or component is not

available.

Products presented for repair may be replaced by refurbished

products of the same type rather than being repaired.

Refurbished parts may be used to repair the products.

What is covered.

• Manufacturing fault or defect.

How to claim under this warranty.

• Call customer service, phone number at the top.

• Ensure you have the following: Original purchase receipt,

Model of Line Trimmer, Serial number of Line Trimmer.

• Discuss the issue.

• Customer service will advise which authorised service

agent to take the Line Trimmer too, provided the issue is a

warranty one.

• Take Line Trimmer to authorised service agent for repair.

CUSTOMER SERVICE

Australia: 1300 660 457

New Zealand: 0800 474 876

Operating times: Monday – Friday

8.00am - 5.00pm

Australian Eastern Standard Time (AEST)

What is not covered.

• Commercial use of Line Trimmer.

• Use of Line Trimmer in a commercial premises.

• Damage or deterioration due to transport.

• Damage caused by negligence, misuse or abuse.

• Any corrosion or rusting.

• Damage caused by incorrect set up and start up.

• Replacement parts due to general wear and tear.

• Line Trimmer with serial number defacement, modification

or removal.

• Line Trimmer which have been serviced by other than an

authorised SMG service agent.

• Line Trimmer with no original purchase receipt.

• Line Trimmer which have been on sold,

not original purchaser.

• Damage due to non-servicing of Line Trimmer as is required

by this manual.

• Blockages / damage caused by dust, dirt, spiders webs

or insects.

• Damage caused by the incorrect fitting of accessories.

• Damage caused by overloading, overworking

the Line Trimmer.

• Damage to attached equipment or third party accessories.

• Damage caused by attached equipment or

third party accessories.

4 5

Page 5

COMPLETE WARRANTY STATEMENT - LINE TRIMMER

As soon as you have purchased the Line Trimmer, we

recommend that you check to make sure it is intact and that

you read the operating instructions carefully before using it.

The purchase receipt for this product is to be retained and must

be presented if making a claim under the terms of the Smart

Marketing Group (SMG) warranty. Bank account statements are

not acceptable for proof of purchase.

This warranty does not cover Line Trimmer intended for

hire or use in commercial applications or in commercial

premises. The warranty will under no circumstances extend to

reimbursement or payment of damages, whether direct, indirect

or consequential. The warranty is void if there is evidence the

Line Trimmer has been modified or tampered with in any way or

used with unauthorised accessories without our consent.

SMG declines any responsibility or liability whatsoever arising

from misuse or abuse, negligent handling of the Line Trimmer or

if the product has not been installed or failure to comply with the

relevant safety, operating, setting and maintenance instructions

(see further in this manual).

The warranty does not extend to installation or disconnection

costs.

Any item sent freight forward/collect for repair will be refused.

Warranty repairs are free of charge, provided the appliance is

delivered to our service department or authorised service agent.

The Line Trimmer will need to be returned, adequately protected

in a box. SMG will not be responsible for any in-transit loss

or damage. Assistance under the warranty will only be made

available if the request is made to our customer service team

on the contact numbers listed below and proof of purchase is

provided.

This is a repair only warranty you will need to take the Line

Trimmer to the authorised service agent after contacting our

customer service centre.

If the product includes various accessories or components,

only the defective accessory or component will be replaced or

repaired.

SMG reserves the right to replace defective parts of the

product with parts and components of similar quality, grade

and composition where an identical part or component is not

available.

Products presented for repair may be replaced by refurbished

products of the same type rather than being repaired.

Refurbished parts may be used to repair the products.

Damage caused by third party accessories is not covered under

this warranty.

Damage caused to attached equipment or third party

accessories will not be covered under this warranty.

Rust and corrosion are not covered under this warranty.

If a warranty fault is found the freight cost will be credited to the

owner. If no fault is found the product will be returned and any

costs associated with the service will be charged to the owner.

Blockages caused by spider webs, insects, dirt, accumulated

dust or incorrect fuel are not covered by warranty. SMG

reserves the right to replace or repair the appliance within

the warranty period. Parts found to be defective due to a

manufacturing fault will be replaced free of charge.

In the event of SMG choosing to replace the product, the

warranty will expire at the original date of purchase. If no

warranty fault is found the owner will be advised and the

product will be returned and any costs associated with the

service will be charged to the owner.

Our goods come with guarantees that cannot be excluded under

the Australian Consumer Law. You are entitled to a replacement

or refund for a major failure and for compensation for any other

reasonably foreseeable loss or damage. You are also entitled

to have the goods repaired or replaced if the goods fail to be of

acceptable quality and the failure does not amount to a major

failure. The benefits of this warranty are in addition to any

rights and remedies imposed by Australian State and Federal

legislation that cannot be excluded.

In New Zealand, this SMG warranty is in addition to the

conditions and guarantees which are mandatory as implied by

the New Zealand Consumer Guarantee Act 1993. For service,

spare parts or product information please contact customer

service:

Australia: 1300 660 457

New Zealand: 0800 474 876

Page 6

IMPORTANT SAFETY INSTRUCTIONS

The purpose of safety rules is to attract your attention to

possible dangers. The safety symbols and the explanations

with them, require your careful attention and understanding.

The safety warnings do not by themselves eliminate any

danger. The instruction or warnings they give are not

substitutes for proper accident prevention measures.

SAFETY ALERT SYMBOL

Indicates danger, caution or warning. May be used in

conjunction with other symbols or pictures.

Failure to obey a safety warning can result in serious injury to

yourself or to others. Always follow the safety precautions to

reduce the risk of fire, electric shock and personal injury.

Do not attempt to operate this product until you have read

thoroughly and completely understood the safety rules, etc.

contained in this manual. Failure to comply can result in

accidents involving fire, electric shock or serious personal

injury. Save this Owner’s Operating Manual and review it

frequently for continual safe operation and for instructing others

who may use this product.

INTENDED USE

This product should only be used outdoors. The product is

intended for cutting long grass, weed and similar vegetation

at or about ground level. The cutting plane should be

approximately parallel to the ground surface. The product

should not be used to cut or trim hedges, bushes or other

vegetation where the cutting plane is not parallel to the ground

surface.

WARNING

To reduce the risk of injury, the user must read and

understand the operator’s manual.

WARNING

Do not attempt to operate this trimmer until you have

read thoroughly and understood completely all

instructions, safety rules etc contained in this manual.

Failure to comply may result in accidents involving

fire, electric shock or serious personal injury. Save

operator’s manual and review frequently for continuing

safe operation and instructing others who may use this

product.

SPECIFIC SAFETY INSTRUCTIONS

Read the instructions with due care. Familiarise yourself with

the settings and proper operation of the machine. Like all power

equipment, this unit must be handled carefully.

DO NOT EXPOSE YOURSELF OR OTHERS TO

DANGER.

Follow these safety rules. Do not permit others to use this unit

unless they are thoroughly responsible and have read and

understood the Line Trimmer manual and are trained in its

operation.

Always wear safety goggles for eye protection. Dress properly.

Do not wear loose clothing or jewellery that could become

caught in moving parts of the unit. Safe, sturdy, nonskid

footwear should always be worn. Long hair should be tied back.

It is recommended that legs and feet should be covered to

protect from flying debris during operation.

Inspect the entire unit for loose parts (nuts, bolts, screws, etc.)

and any damage before start and operation. Repair or replace

as necessary before using the machine.

DO NOT USE any attachment with this power head other than

the ones recommended by our manufacturer. Serious injury to

the operator or bystanders could result as well as damage to

the machine.

Keep the handles free from oil and fuel.

Do not operate the unit in insufficient lighting conditions.

Do not operate the unit when you are tired, when your

concentration is impaired and/or under the influence of drugs,

medication or alcohol.

Always use proper handles when trimming.

Do not smoke while filling tank.

Do not fill fuel in an enclosed room or near open flames. Ensure

adequate ventilation.

Always store fuel in a properly marked container that is

approved by local codes and ordinances for such usage.

Never remove the fuel tank cap while the engine is running.

6 7

Page 7

IMPORTANT SAFETY INSTRUCTIONS

Never start or run the product inside a closed room or

building. Fumes from the exhaust contain dangerous carbon

monoxide.

Never attempt to make engine adjustments while the unit

is running. Always make engine adjustments with the unit

resting on a flat, clear surface and with engine off.

Do not use the unit if it is damaged or poorly adjusted. Never

remove the unit’s guard. Serious injury to the operator or

bystanders could result as well as damage to the machine.

Inspect the area to be cut and remove all debris that could

become entangled in the nylon cutting head. Also remove

any objects that the unit may throw during cutting.

Keep children away. Onlookers should be kept at a safe

distance from the work area, at least 15 metres away.

Never leave the unit unattended while engine is running.

Do not use this unit for any job other than those for which it

is intended as described in this manual.

Do not overreach. Keep proper footing and balance at all

times. Do not use the unit while standing on a ladder or on

any other unstable footing location.

Keep hands and feet in safe distance from the nylon cutting

line while unit is in use.

Do not use this type of unit for sweeping away debris.

Use nylon cutting head which is free of damage. If a stone or

any other obstacle is hit, stop the engine and check the nylon

cutting head. A broken or unbalanced nylon cutting head

must never be used.

Follow instructions for assembling and operation.

Do not store the unit in a closed area where fuel vapours can

reach an open flame from hot water heaters, furnaces, etc.

Store in a locked, well ventilated area only.

Ensure safe and proper performance of your unit. Please only

use original accessories. The use of any other accessories

or attachments may cause a potential hazard or injury to the

user, damage to the unit, and void this warranty.

If the unit will not be used for a long time, clean the unit

completely, especially the fuel/oil tank, its surroundings, and

the air cleaner.

When refuelling, be sure to stop the engine and confirm that

it is cooled down. Never refuel when the engine is running

or hot. When gasoline spills, be sure to wipe it up completely

and dispose of those materials before starting the engine.

Stay clear of other workers or bystanders by at least 15

metres.

Whenever approaching an operator of the unit, carefully

call their attention and confirm that the operator stops the

engine. Be careful not to startle or distract the operator

which can cause an unsafe situation.

Never touch the nylon cutting head whenever the engine is

running. If it is necessary to adjust the protector or nylon

cutting head, be sure to stop the engine and confirm that the

nylon cutting head has stopped running.

The engine should be turned off when the unit is moved

between work areas.

Be careful not to hit the nylon cutting head against stones, or

the ground. Unreasonable rough operation will shorten the

life of the unit as well as create an unsafe environment for

yourself and those around you.

Pay attention to loosening and overheating parts. If there is

any abnormality of the unit, stop operation immediately and

check the unit carefully. If necessary, have the unit serviced

by an authorised service agent. Never continue to operate a

unit which may be malfunctioning.

In start-up or during operation of the engine, never touch hot

parts such as the muffler, the high voltage wire or the spark

plug.

After the engine has stopped, the muffler is still hot. Never

place the unit in any place where there are flammable

materials (dry grass, etc.), combustible gasses or

combustible liquids.

Pay special attention to operation in the rain or just after the

rain as the ground may be slippery.

If you slip or fall to the ground, release the throttle lever

immediately.

Page 8

IMPORTANT SAFETY INSTRUCTIONS

Be careful not to drop the unit or hit it against obstacles.

Before proceeding to adjust or repair the unit, be sure to stop

the engine and detach the spark plug.

When the machine is placed in storage for a long time, drain

fuel/oil from the fuel/oil tank and carburettor, clean the

parts, move the machine to a safe place and confirm that the

engine has cooled down.

Make periodic inspections to ensure safe and efficient

operation. For a thorough inspection of your unit, contact

customer service or your nearest authorised service agent.

Keep the unit away from fire or sparks.

Keep your body warm, especially the head, neck, feet,

ankles, hands and wrists.

Maintain good blood circulation by performing vigorous

arm exercises during frequent work breaks and also avoid

cigarette smoking.

Limit the hours of operation.

If you experience discomfort, redness and swelling of the

fingers followed by whitening and loss of feeling, consult

your physician before further exposing yourself to cold and

vibration.

Always wear ear protection. Loud noises for long periods can

cause hearing loss, even permanent deafness.

Wear non-slip, heavy duty work gloves to improve your

grip on the handle. Gloves also reduce the transmission of

machine vibration to your hands.

WARNING: The string head is still dangerous while the

machine is coming to a stop.

Do not lay the machine on its side; otherwise the fuel could

spill out.

Fuel evaporation during refuelling and exhaust gases are

harmful to the operator and people around the unit.

Ensure the fuel evaporation and exhaust gases will not drift

to the face of operator and keep other people away from

your working area.

Do not allow children or untrained individuals to use this unit.

RESIDUAL RISKS

Even when the unit is used as prescribed it is not possible to

eliminate all residual risk factors. The following hazards may

arise in connection with the unit’s construction and design:

1. Damage to lungs if an appropriate dust mask is not worn.

2. Damage to hearing if appropriate hearing protection is

not worn.

3. Health defects may arise from vibration emission if the

unit is being used over long periods of time or not

adequately managed and properly maintained.

WARNING

This unit produces an electromagnetic field during operation.

This field may under some circumstances interfere with

active or passive medical implants. To reduce the risk of

serious or fatal injury, we recommend persons with medical

implants to consult their physician and the medical implant

manufacturer before operating this unit.

8 9

Page 9

DESCRIPTION

DESCRI TION

3

2

1

7

8

4 5

10

9

11

6

12

13

15

14

For information regarding spare parts, please refer to contact details on the front of this manual

1. Fuel tank cap

2. Primer button

3. Air filter with choke button

4. Spark plug

5. Muffler

6. Oil tank cap

7. Starter handle

8. Cutting line spool

9. Cutting head shield

10. Knob for drive shaft connection

11. Front handle

12. Rear handle

13. Harness hook

14. Choke button

15. Harness

Page 10

UNPACKING

CAUTION.

This packaging contains sharp objects. Take care when

unpacking. Remove the machine, together with the accessories

supplied, from the packaging. Check carefully to ensure

that the machine is in good condition and account for all the

accessories listed in this manual. Also make sure that all the

accessories are complete.

ASSEMBLY

PACKING CONTENTS (FIG. 1)

• Trimmer Assembly (Engine with rear shaft).

• Front handle Assembly.

• Front shaft with cap.

• Cutting line spool.

• Cutting head shield with 1 screw pre-assembly.

• Harness.

• 1pc screw driver.

• 1pc wrench for spark plug.

• Bottle of engine oil.

• Operator’s manual.

WARNING. To prevent an accidental start that

could cause serious personal injury, always

disconnect the engine spark plug wire from the spark

plug when assembling parts.

If any parts are found to be missing, please contact customer

service (details on page 2 & 4). Do not throw the packaging

away, keep it safe throughout the warranty period, then recycle

if possible, otherwise dispose of it by the proper means. Do

not let children play with empty plastic bags due to the risk of

suffocation.

Fig. 1

shaft

hub

WARNING. Never install, remove, or adjust any

attachments while power head is running. Failure to

stop the engine can cause serious personal injury.

INSTALLING THE CUTTING LINE SPOOL

Rotate the hub slowly to align the hole in the hub with the hole

in the shaft, Fig.2.

Lock the hub firmly using the screw driver provided by aligning

and insert through the two holes as shown in Fig.3. Hold the hub

with fingers at all times.

Screw the spool in place and turn the spool clockwise until it

cannot rotate any more with the locked hub.

WARNING. The cutting line spool must be fixed

firmly with the hub. Failure to fix the cutting line spool

with the hub can result in serious personal injury.

Fig. 2

Fig. 3

10 11

Page 11

ASSEMBLY

INSTALLING THE CUTTING HEAD SHIELD

WARNING.

head shield is sharp. Avoid connection with the blade.

Failure to avoid contact can result in serious personal

injury.

1. Locate the bolt, nut and washer used to fix the cutting head

shield.

2. Align the screw hole in the mounting bracket with the

screw hole in the cutting head shield, Fig. 4.

3. Push the bolt through the mounting bracket and into the

cutting head shield and fix in place with the washer and

nut. Ensure it is tightly fitted before use.

The line cut-off blade on the cutting

CONNECTING THE UPPER AND LOWER

SHAFTS

The attachment connects to the power head by means of a

coupler device.

1. Ensure the engine is not on. Disconnect the spark plug wire

2. Turn the knob counterclockwise to loosen the coupler

of the power head shaft and remove the end cap from the

attachment.

3. Insert while rotating the lower shaft into the coupler until

the button locks into the positioning hole (the fixing hole is

opposite the knob), Fig.5

NOTE: If the button does not release completely in the

positioning hole, the shafts are not locked into place.

Slightly rotate from side to side until the button is locked

into place.

4. Turn the knob clockwise to tighten the coupler.

Fig. 4

1.

2.

Fig. 5

WARNING! Be certain the knob is fully tightened

before operating equipment, check it periodically for

tightness during use to avoid serious personal injury.

REMOVING THE UPPER AND LOWER

SHAFTS

1. Turn the knob counter clockwise to loosen the coupler.

2. Press and hold the release button.

3. Pull the attachment straight out of the coupler.

Fig. 6

INSTALLING AND ADJUSTING THE FRONT

HANDLE

To avoid injury, adjust the auxiliary handle for optimum control

and balance. Do not overreach when operating Line Trimmer.

Keep proper balance at all times for better control of the

product in unexpected situations.

The auxiliary handle can be moved either up and down the shaft

or rotated 360º around the shaft. To find your optimum desired

position unscrew the front handle locking knob, Fig.6. Once you

have the desired position tighten the front handle locking knob.

Page 12

ASSEMBLY

INSTALLING THE HARNESS

Connect the latch on the shoulder harness to the strap hanger,

Fig 7.

Adjust the strap to a comfortable position, Fig. 8.

WARNING. Do not allow familiarity with this

product to make you careless. Remember that a

careless fraction of a second is sufficient to inflict

serious injury.

WARNING. Always wear eye protection with side

shields marked to comply with ANSI Z87.1, along with

hearing protection. Failure to do so could result in

objects being thrown into your eyes and other possible

serious injuries.

OPERATION

WARNING. Do not use any attachments or

accessories not recommended by the manufacturer

of this product. The use of attachments or accessories

not recommended can result in serious personal injury.

WARNING. Operation of this equipment could

create sparks that can start fires around dry vegetation.

A spark arrestor may be required. The operator should

contact local fire agencies for laws or regulations

relating to fire prevention requirements.

ADDING/CHECKING ENGINE OIL

NOTE:

1. Attempting to start the engine before it has been properly

filled with oil will result in equipment failure.

2. Engine oil has a major influence on engine performance

and service life. This unit is shipped without engine oil.

Fig. 7

Fig. 8

3. Always use a good quality 4-stroke engine oil. SAE 30,

SAE 10W-30 or SAE 10W-40 are all acceptable oils to use in

this product. Non-detergent or 2-stroke engine oil will

damage the engine and should not be used.

4. Check oil levels before each use.

TO ADD ENGINE OIL: INITIAL USE

1. Remove the cap from the empty lubricant bottle provided.

2. Pour 60ml 4-Stroke engine oil into lubricant bottle with

funnel.

3. Unscrew the oil cap from the engine and remove.

4. Pour 60ml lubricant oil into oil fill hole. Replace and tighten

the oil cap.

12 13

Page 13

OPERATION

TO CHECK ENGINE LEVEL BEFORE EACH

USE

1. Separate the attachment from the power head.

2. Set power head on a flat level surface with shaft parallel to

surface.

3. Unscrew the oil cap and remove.

4. Lubricant level should fall within the top of oil fill hole (the

top of screw thread).

5. If level is low, add engine lubricant until the fluid level rises

to the top of oil fill hole (the top of screw thread) and does

not overfill, Fig.9.

6. Replace and tighten the oil cap.

NOTE: Do not overfill. Overfilling the crankcase may cause

excessive smoke, oil loss and engine damage.

FUELLING AND REFUELLING THE TRIMMER

WARNING.

flammable and explosive. To prevent serious personal

injury and property damage, handle it with care.

Keep away from ignition sources and open flames, handle

outdoors only, do not smoke and wipe up spills immediately.

Always shut off engine before fuelling.

Never add fuel to a machine with a running or hot engine. Move

at least 9 metres from refuelling site before starting engine.

Do not smoke cigarettes and stay away from open flames and

sparks. Never operate the unit without the fuel cap securely

fitted. Failure to safely handle fuel could result in serious

personal injury.

Note: Visually inspect to see if fuel level is low. If fuel is low,

refill with unleaded fuel carefully without overfilling and tighten

the fuel tank cap immediately.

This unit has a 4-Stroke engine. Do not mix oil with petrol.

The use of old fuel is the most common cause of performance

problems. Use only fresh, clean unleaded petrol (less than 30

days old).

Dispose of old fuel according to federal, state and local

regulations.

Drain the tank and run the engine dry before storing the unit.

Do not use E15 or E85 fuel (or fuel containing greater than 10%

ethanol) in this product. It will damage the unit and void your

warranty.

Petrol and its vapours are highly

MAX

Fig. 9

STARTING AND STOPPING

The Line Trimmer should be laid out on a flat, bare surface for

starting.

TO START A COLD ENGINE

Turn switch to “I” ON position.

Slowly press the primer bulb 5-10 times.

NOTE: After the 7th press, fuel should be visible in

the primer bulb. If it is not, continue to press the

primer until you see fuel in the bulb.

Push the choke button in to set the choke to

FULL CHOKE position. NOTE: Do not squeeze the

throttle trigger because the choke will pop out

automatically.

Pull the starter grip /cord until resistance is

detected. Rapidly pull 3 to 5 times or until you

hear engine turn over or begin to start.

If engine does not start, release choke by

squeezing throttle trigger and red choke button

pops out.

Engine is now in the run position.

Rapidly pull starter grip/cord until engine starts.

Allow the engine to run for 10 seconds, then squeeze throttle to

provide fuel to engine and use for intended task.

Note: The choke button is only used when starting a cold

engine. Never push the choke button in once the engine

has been turned over or run. Otherwise the engine could be

damaged or not run due to FULL CHOKE.

Page 14

OPERATION

TO RESTART A WARM ENGINE

Do NOT push choke button in.

a. Turn switch to “I” ON position.

b. Ensure primer bulb has fuel inside.

c. Rapidly pull starter/grip until engine starts.

d. Squeeze throttle to provide fuel to engine and use for

intended task.

TO STOP THE ENGINE

To stop the engine, depress the STOP switch to the

“STOP”position.

OPERATING THE LINE TRIMMER

WARNING.

operation. Do not rest or place your arm, hand, or any

body part against the engine housing during operation.

Only hold the Line Trimmer with all body parts clear of

engine housing. Extended contact with the engine

housing can result in burns or other injuries.

Always position the unit on the operator’s right side. The use of

the unit on the operator’s left side will expose the user to hot

surfaces and can result in possible burn injury.

To avoid burns from hot surfaces, never operate unit with the

bottom of the engine above waist level.

Engine housing can become hot during

STARTING/STOPPING THE CUTTING HEAD

SPOOL (FIG. 10)

The cutting head spool will be engaged if the operator squeezes

the throttle lever and then squeezes the throttle lever release to

increase the engine speed.

The engine will stop when depressing the switch in “STOP”

position.

Note: This ignition switch will come back to ON position

automatically.

WORKING WITH THE LINE TRIMMER

1. Hold the Line Trimmer with your right hand on the rear

handle and your left hand on the front handle. Keep a firm

grip with both hands while in operation. Line Trimmer

should be held at a comfortable position with the rear

handle about hip height, Fig.11.

2. Keep your body and feet in safety distance to cutting head.

3. Squeezing the throttle lever to full speed before cutting.

4. The cutting line should run parallel to the ground surface.

Ignition switch Throttle lever

Throttle lever release

Fig. 10

Fig. 11

TO ADJUST THE TRIMMING LINE LENGTH

The line spool has bump feed function. The line will be extended

by tapping the spool head shortly and lightly onto the ground

while the unit is running at high speed.

1. Run engine at high speed.

2. Tap the spool head on bare ground to release line.

3. A blade in the cutting head shield will cut the line to the

proper length if any excess line is released.

NOTE: Do not hold the spool head on the ground while the unit

is running.

The line releases each time the spool head is tapped.

Always keep the trimming line fully extended. Line release

becomes more difficult when the cutting line gets shorter.

14 15

Page 15

OPERATION

TIPS FOR TRIMMING

Avoid hot surfaces by always keeping the product away from

your body.

Cut all grass from top to down. This will prevent grass from

wrapping around the shaft housing and string head which could

cause damage from overheating. If grass becomes wrapped

around the string head, STOP THE ENGINE, disconnect the

spark plug wire, and remove the grass.

MAINTENANCE

Use the tip of line to trim grass; do not force string head into

uncut grass.

Avoid trees, flowers, stones, walls and other objects which can

cause the line breakage.

Check and feed the line regularly to maintain full cutting width

and performance.

CLEANING AND CARE

Correct and regular cleaning is not only important for the safe

use of this product, but also extends its life span.

WARNING. Always stop the engine and wait for the

engine to cool down.

Please remove dust, grass etc. from machine after every

application. Clean the machine with a wet cloth. For cleaning

difficult to reach areas, use a brush.

You may use pressurised air to remove persistent dust.

NOTE: Do not use chemical, acid, alkaline, grinding or other

aggressive cleaning agents. They could destroy the surface of

the product.

MAINTENANCE

WARNING.

engine to cool down.

Disconnect spark plug wire and move it away from

spark plug.

When servicing, use only identical replacement parts. Use of

any other parts could create a hazard or cause product damage.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into your

eyes and other possible serious injuries.

Always stop the engine and wait for the

INSPECTION AND MAINTENANCE

SCHEDULE

The maintenance interval is only a recommendation for

machines in ordinary operating condition. If there are any

abnormal signs from the machine, please do the proper

inspection and maintenance immediately.

The tightening torque should follow the general screw

specification of different size, class and material.

If anything is unclear to you, please contact our service team for

help. See Page 2 or 4 for contact details.

All other repairs or maintenances which are not mentioned here

shall only be done by our service team or authorised service

agent.

ITEM HOURS OF OPERATION

Engine lubricant oil level Every time before use

Loosened or lost screws Every time before use

Damage of any part Every time before use

Function of control elements Every time before use

Fuel level Every time before use

Leakage of oil or fuel Every time before use

Cutting line Every time before use

Engine oil replacement Every 20 hours

Air filter cleaning

Spark plug check Every 20 hours

Every 20 hours but every

10 hours if work condition

is dusty

Page 16

ENGINE OIL REPLACEMENT

MAINTENANCE

WARNING.

waste and has to be disposed of according to your local

environment protection regulation. Do not pour the oil

into a garbage can, sewer, soil etc.

1. The engine oil replacement is easier if engine is warm

(NOT HOT!).

2. Open the oil tank cap and drain the old oil into an approved

container.

3. Return the engine to an upright position and refill with

lubricant following the instructions in the Adding/Checking

Engine Oil section in this manual (Pages 12 & 13).

4. Clean the oil dropped on the unit if necessary.

Old engine oil is considered special

CLEANING THE AIR FILTER

1. The air filter elements should be cleaned to provide the

engine abundant clean air which benefits the starting,

power and life time of the engine.

2. Remove the air filter cover. To remove, press the Red

button on the top of the cover with thumb and gently push

up the cover with index finger, Fig.12.

3. Remove the air filter

4. If only cleaning of the air filter is necessary, take the air

filter pad out and clean it with a jet of dry compressed air

until all dust is removed. Wear protective goggle and

mask to protect your health during this work.

5. Reinstall the air filter cover by closing the air filter cover

over the button on the housing, then push the cover until it

locks securely in place.

NOTE: Make sure the filter is seated properly inside the cover.

Installing the filter incorrectly will allow dirt to enter the engine,

causing rapid engine wear. If the filter element is lost, contact

customer service for a spare part.

Fig. 12

0.6-0.8mm

Fig. 13

1. Pull out the spark plug cap and clean the dust in the spark

plug area.

2. Screw out the spark plug with the provided socket wrench.

3. Check the ceramic isolation. Replace the spark plug if

damaged.

4. Clean the electrodes (metal tip) to refresh the surfaces.

5. Restore the spark plug and its cap.

SPARK PLUG

Do not attempt to remove the spark plug from a hot engine.

Clean or replace the spark plug if it is soiled with heavy oil

deposits.

Replace the spark plug if the centre electrode is worn at the

end.

This engine uses either a TORCH CMR5H or

spark plug with a 0.6-0.8mm electrode gap, Fig.13. Use an exact

replacement and replace annually.

a NGK CMR5H

16 17

Page 17

MAINTENANCE

REPLACING THE CUTTING LINE SPOOL

1. Open the cutting line spool by pressing two release buttons

on the side and take out the winding core (Fig.14 & 15).

2. Divide a spare cutting line in 2 equal halves, fix it in the

winding core and start to wind the cutting line in two

separated rails (Fig.15). Please follow the indicated

winding.

3. Fix the 2 line ends (approx. 15cm) at the opening to keep

the line wound tightly. (Fig.16)

4. Guide the 2 line ends into the holes on the spool housing

and restore the spool cover. (Fig.17)

Fig. 14

Fig. 16

Fig. 15

Fig. 17

Page 18

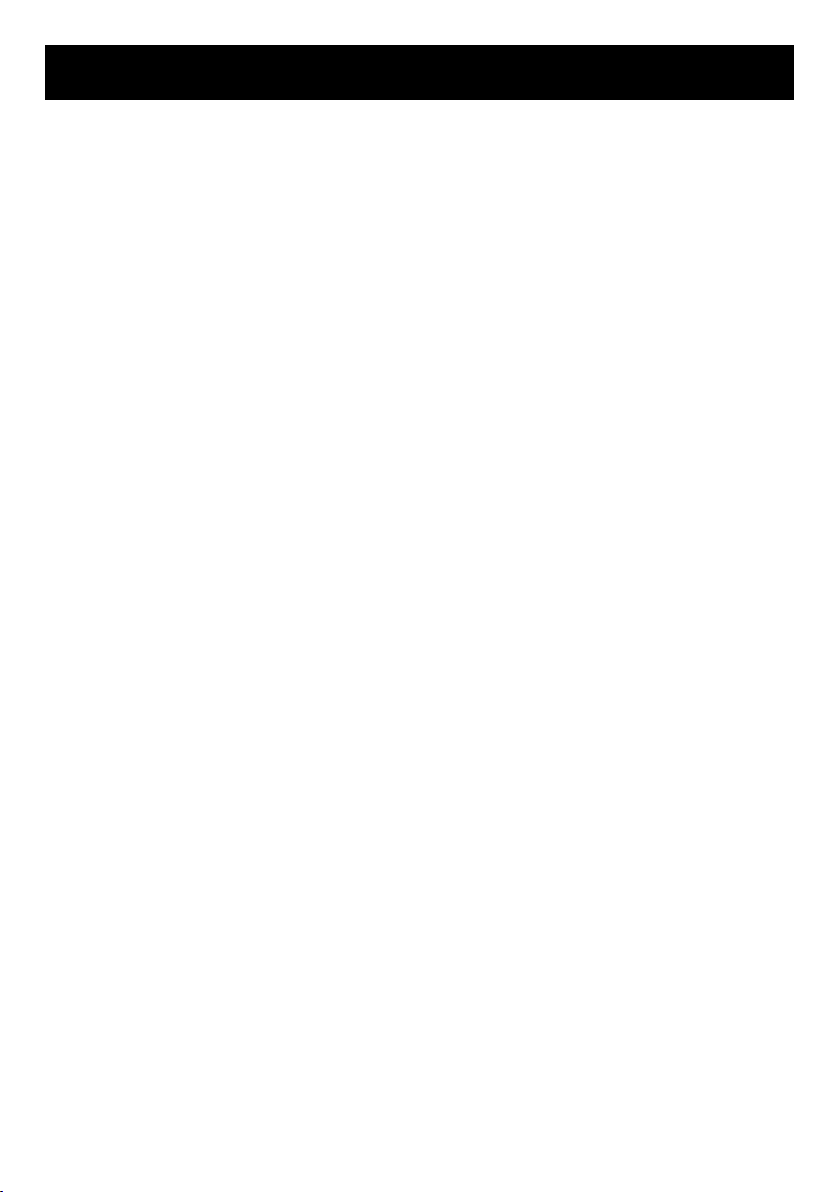

Problem Possible Cause Solution

Check spark. Remove spark plug. Reattach the spark plug

cap and lay spark plug on metal cylinder. Pull the starter rope

and watch for spark at spark plug tip. If there is no spark,

repeat test with a new spark plug.

Push primer bulb until bulb is full of fuel. If bulb does not fill,

primary fuel delivery system is blocked. Contact customer

service. If primer bulb fills, engine may be flooded, proceed

to next item.

Set the choke lever to the FULL CHOKE position. Squeeze the

trigger and pull the rope repeatedly until the engine starts

and runs.

NOTE: Depending on the severity of the flooding, this may

require numerous pulls of the rope.

Clean air filter. Refer to “Cleaning the Air Filter”

earlier in this manual.

Clean or replace spark plug. Reset spark plug gap. Refer to

“Spark Plug” section earlier in this manual.

Engine will not start

Engine does not reach full

speed and emits excessive

smoke

No spark

No fuel

Engine is flooded

Air filter is dirty

Spark arrestor screen is dirty Contact customer service.

Spark plug fouled

Engine starts, runs, and

accelerates but will not idle.

Engine emits too much

smoke.

Line will not advance.

Spool retainer hard to turn.

Grass wraps around

driveshaft housing and string

head.

Idle speed screw on carburettor

needs adjustment.

Too much oil in crankcase.

Line welded to itself. Lubricate with silicone spray.

Not enough line on spool Install a new spool

Line is worn too short.

Line is tangled on spool. Remove line from spool and rewind.

Engine speed is too slow Advance line at full throttle.

Screw threads are dirty or

damaged

Cutting tall grass at ground level. Cut tall grass from the top down to prevent wrapping.

Operating trimmer at part throttle Operate trimmer at full throttle.

Turn idle speed screw clockwise to increase idle speed.

Drain oil and refill with correct amount of 10W-30 engine

lubricant. See “Adding/Checking Engine Oil” in the Operation

section of this manual.

Pull lines while alternately pressing down on and releasing

spool retainer.

Clean threads and lubricate with grease - if no improvement,

replace the spool retainer.

18 19

Page 19

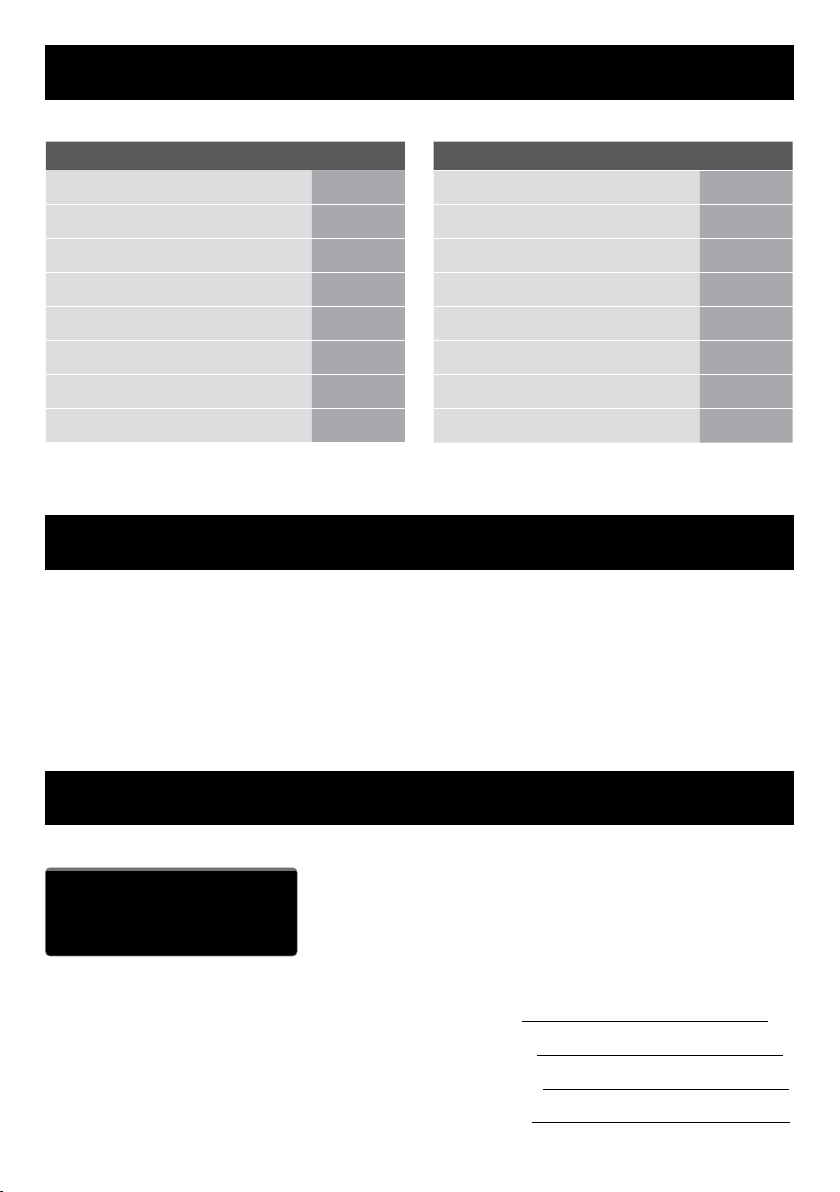

This Service is to be complete within 20 hours or

3 months of purchase, which ever comes first.

Replace Replace

Air filter Spark plug

Oil

Authorised Service Agent

(Name or Company Stamp)

Technician

This Service is to be complete within 40 hours or

6 months of purchase, which ever comes first.

Replace Replace

Air filter Spark plug

Oil

Authorised Service Agent

(Name or Company Stamp)

Technician

Date

This Service is to be complete within 60 hours or

9 months of purchase, which ever comes first.

Replace Replace

Air filter Spark plug

Oil

Authorised Service Agent

(Name or Company Stamp)

Technician

Date

This Service is to be complete within 100 hours or

15 months of purchase, which ever comes first.

Replace Replace

Air filter Spark plug

Oil

Authorised Service Agent

(Name or Company Stamp)

Technician

Date

Date

This Service is to be complete within 80 hours or

12 months of purchase, which ever comes first.

Replace Replace

Air filter Spark plug

Oil

Authorised Service Agent

(Name or Company Stamp)

Technician

Date

This Service is to be complete within 120 hours or

18 months of purchase, which ever comes first.

Replace Replace

Air filter Spark plug

Oil

Authorised Service Agent

(Name or Company Stamp)

Technician

Date

This Service is to be complete within 140 hours or

21 months of purchase, which ever comes first.

Replace Replace

Air filter Spark plug

Oil

Authorised Service Agent

(Name or Company Stamp)

Technician

Date

This Service is to be complete within 160 hours or

24 months of purchase, which ever comes first.

Replace Replace

Air filter Spark plug

Oil

Authorised Service Agent

(Name or Company Stamp)

Technician

Date

Page 20

For any queries or assistance call

Customer Service

AUST. 1300 660 457

NZ 0800 474 876

www.stanleyproducts.com.au

Hours of operation:

Monday to Friday 8.00am - 5.00pm AEST

Do not return to place of purchase.

Keep your purchase receipt, this will be required to

make any claims under the 2 year warranty.

Loading...

Loading...