Page 1

STSM1510

English Page 5

Page 2

2

5

4

2

1

9

8

7

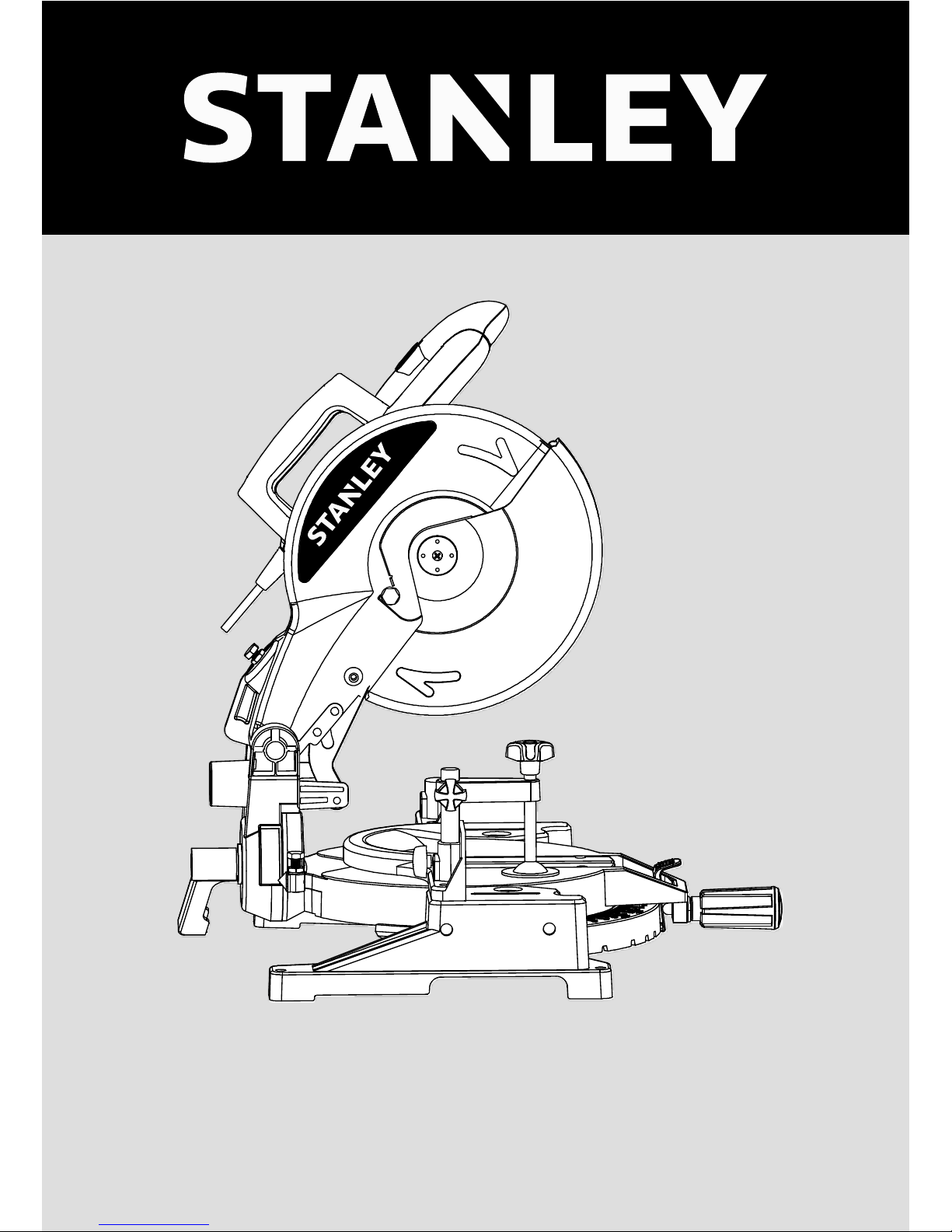

FIG. 1

FIG. 2

13

16

15

14

11

Parts Description (Fig. 1 )

FIG. 1 1. Operating Handle

2. Guard

3. Saw Blade

4. Miter Clamp Handle

5. Miter Latch

6. Miter Scale

7. Left Side Fence

8. Bench Mounting Hole

9. Dust Spout

Parts Description (Fig. 2 )

FIG. 2 10.Lock Down Pin

11.Hand Indentation

12.Right Side Fence

13.Kerf Plate

14.Motor Housing

15.Spindle Lock Button

16.Trigger Switch

17.Bevel Clamp Knob

3

6

12

17

10

ENGLISH (Original instructions)

Page 3

3

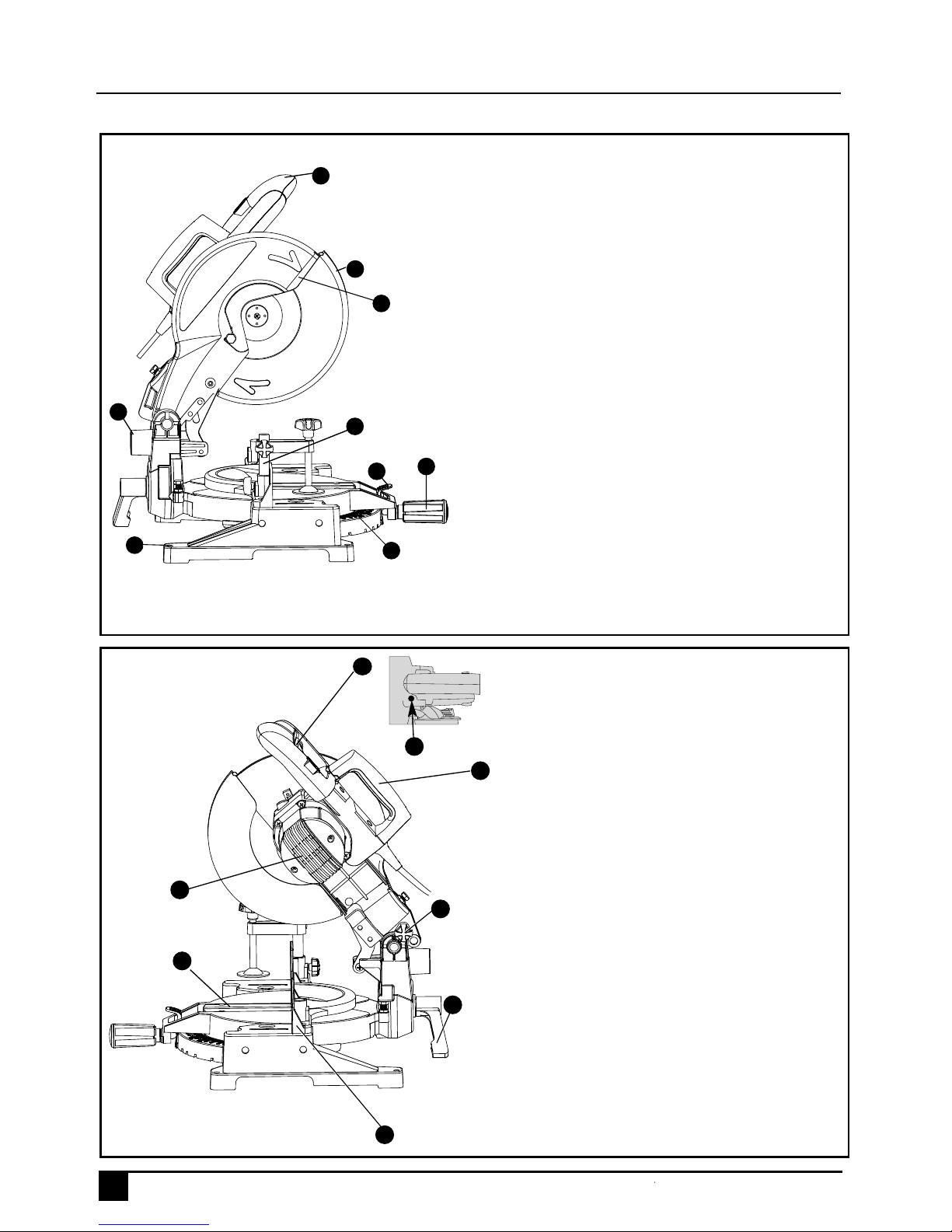

FIG. 3 FIG. 4

31.

6

2

2.5

2

2

.

5

31.6

1

5

15

3

0

30

0

45

45

FIG. 5 FIG. 6

FIG. 7

FIG. 8

A

B

C

(Original instructions) ENGLISH

Page 4

4

31.6

22.5

2

2.5

3

1.6

15

15

30

30

0

45

45

31.

6

22.5

22.5

31.

6

15

15

30

30

0

45

45

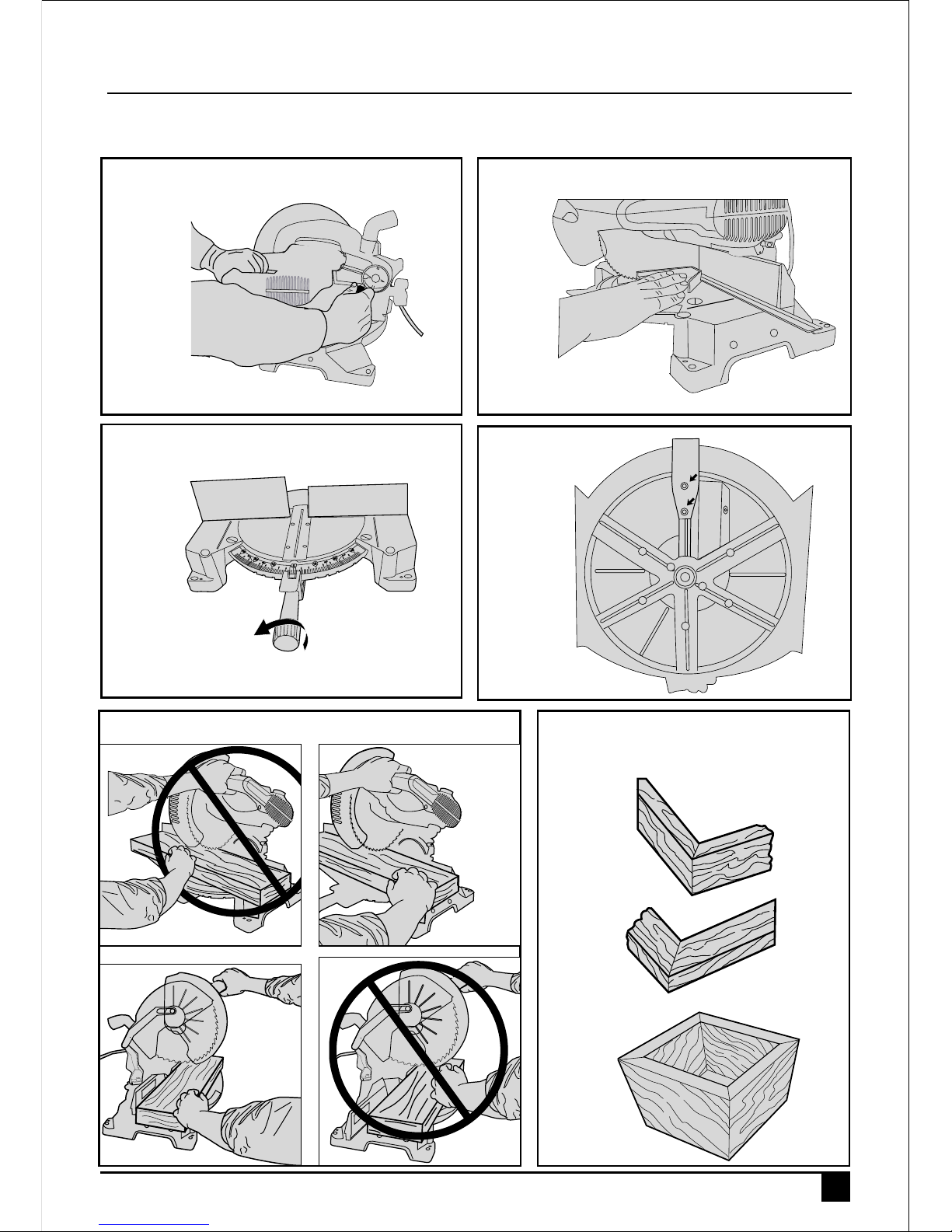

FIG. 9

FIG. 10

FIG. 11

FIG. 12

ENGLISH (Original instructions)

Page 5

5

Key Information You Should Know:

• Cut only with sharp blades. Dull blades cut poorly and

overload the motor.

• If the saw does not cut accurately, refer to the

TROUBLE SHOOTING chart in this manual.

Intended use

Your Stanley Mitre Saw has been designed for fast cutting in

wood, fine finishing or aluminum cutting .

General Safety Instructions

WARNING: When using electric tools, basic

safety precautions should always be followed to

reduce risk of fire, electric shock, and personal

injury, including the following:

Read All Instructions

Safety Warnings: Double Insulation Double

insulated tools are constructed throughout with two

separate layers of electrical insulation or one

double thickness of insulation between you and the tool’s

electrical system. Tools built with this insulation system are

not intended to be grounded. As a result, your tool is

equipped with a two prong plug which permits you to use

extension cords without concern for maintaining a ground

connection.

NOTE: Double insulation does not take the place of normal

safety precautions when operating this tool. The insulation

system is for added protection against injury resulting from a

possible electrical insulation failure within the tool.

Replacement parts: When servicing all tools, USE

IDENTICAL REPLACEMENT PARTS. Repair or replace

damaged cords.

Safety Instructions: Polarized Plugs

To reduce the risk of electric shock, this

equipment has a polarized plug (one blade is

wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit fully

into the outlet, reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper utlet. Do not

change the plug in any way.

Safety Instructions For All Tools

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting

wrenches are removed from spindle before turning tool

on.

• KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept at a

safe distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

• DON’T FORCE TOOL. It will do the job better and be

safer at the rate for which it was designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do

a job for which it was not designed.

• WEAR PROPER APPAREL. No loose clothing, gloves,

neckties, rings, bracelets, or other jewelry which may get

caught in moving parts. Nonslip footwear is

recommended. Wear protective hair covering to contain

long hair.

• ALWAYS WEAR SAFETY GLASSES. Also use face or

dust mask if cutting operation is dusty. Everyday

eyeglasses have only impact resistant lenses, they are

NOT safety glasses.

• SECURE WORK. Use clamps or vise when you cannot

secure the workpiece on the table and against the fence

by hand or when your hand will be dangerously close to

the blade (within 6”).

• DON’T OVERREACH. Keep proper footing and balance

at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

• DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure switch is in OFF position before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the

instruction manual for recommended accessories. The

use of improper accessories may cause risk of injury to

persons.

• NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the cutting tool is unintentionally

contacted.

• CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate

(Original instructions) ENGLISH

Page 6

6

properly and perform its intended function—check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting and any other conditions

that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced. Do

not use tool if switch does not turn it on and off.

• NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave tool until it comes to a

complete stop.

• DO NOT OPERATE ELECTRIC TOOLS NEAR

FLAMMABLE LIQUIDS OR IN GASEOUS OR

EXPLOSIVE ATMOSPHERES. Motors in these tools

may spark and ignite fumes.

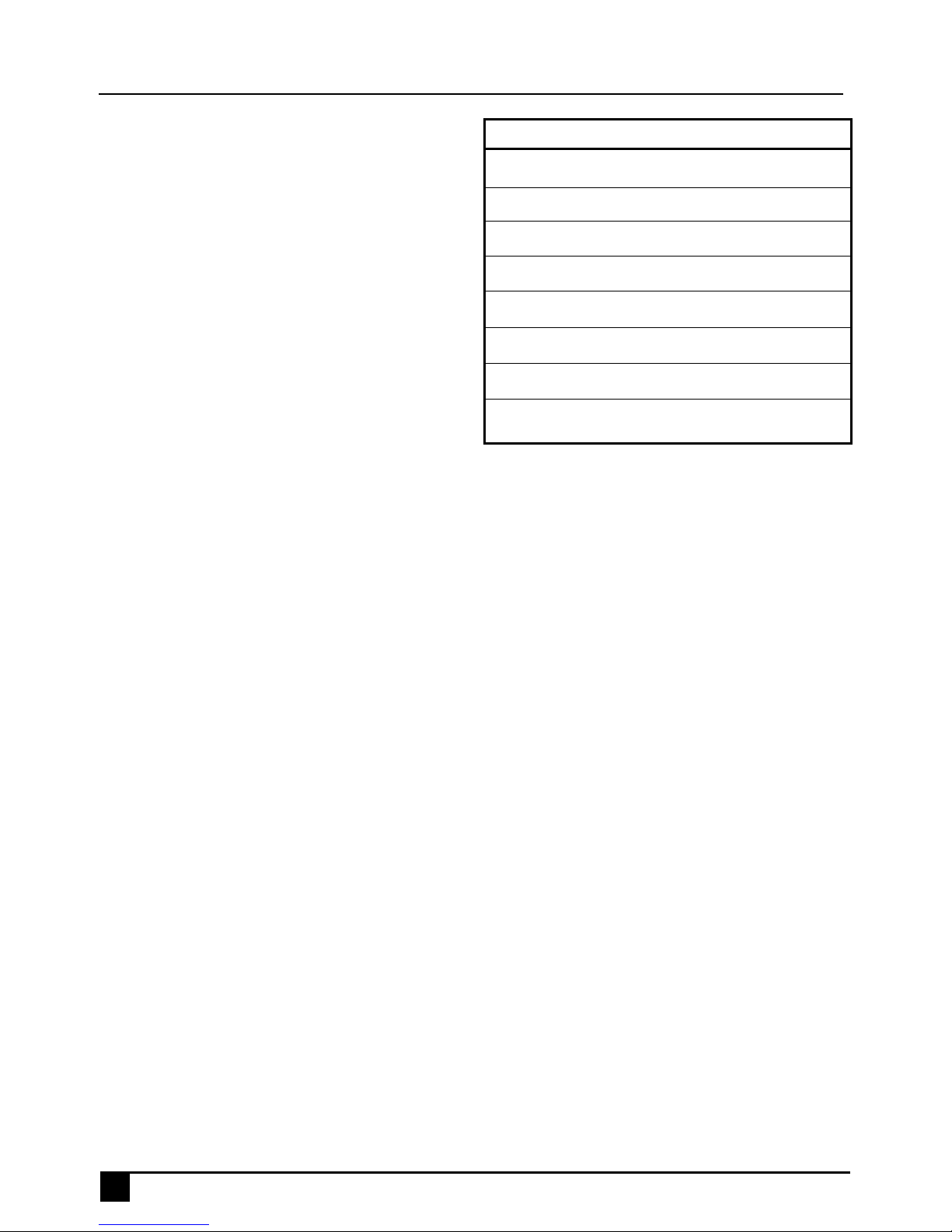

• USE PROPER EXTENSION CORDS. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the

correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier

the cord.

Additional Safety Rules For Mitre Saws

CAUTION: FAILURE TO HEED THESE

WARNINGS MAY RESULT IN PERSONAL

INJURY AND SERIOUS DAMAGE TO THE SAW.

• DO-Protect electric supply line with at least a 15 ampere

time-delay fuse or a circuit breaker.

• Replace table insert when worn

• Use only saw blades recommended by the manufacturer

• Connect mitre saw to a dust connecting device when

sawing

• Take care when slotting

• DO-Make certain the blade rotates in the correct

direction and that the teeth at the bottom of the blade are

pointing to the rear of the mitre saw.

• DO-Be sure all clamp handles are tight before starting

any operation.

• DO-Be sure all blade and clamp washers are clean and

recessed sides of collars are against blade. Tighten

arbor screw securely.

• DO-Keep saw blade sharp.

• DO-Keep motor air slots free of chips and dirt.

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - 230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

ENGLISH (Original instructions)

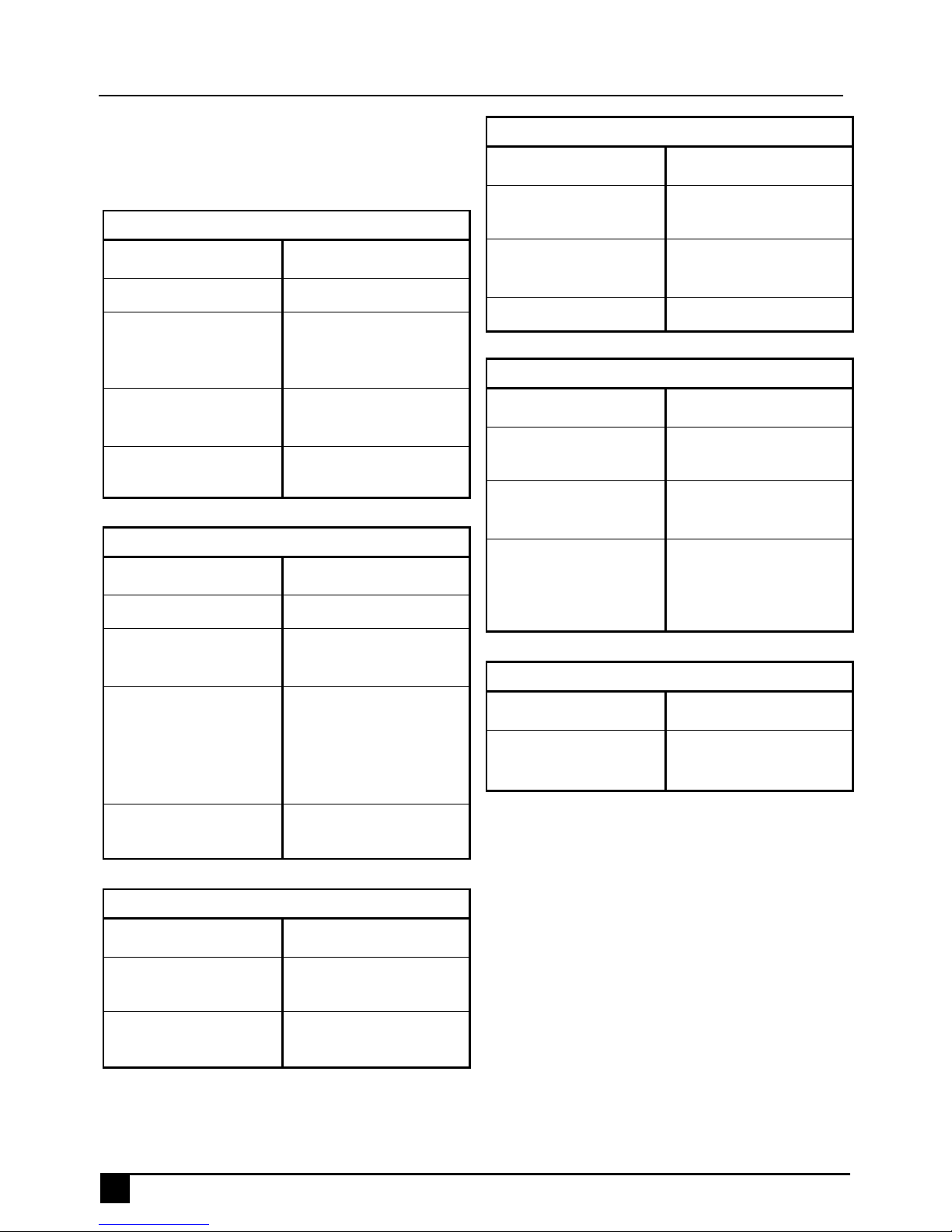

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

0

....... No-Load

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

Labels on tool

The label on your tool may include the following symbols:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Page 7

7

• DO-Use blade guards at all times.

• DO-Keep hands out of path of saw blade.

• DO-Shut off power, disconnect cord from power source

and wait for saw blade to stop before servicing or

adjusting tool.

• DO-Support long work with an outboard tool rest.

• DO-Use only 10 inch diameter blades.

• Do not use saw blades which are damaged or deformed

• DON’T-Attempt to operate on anything but designated

voltage.

• DON’T-Operate unless all clamp handles are tight.

• DON’T-Use blades larger or smaller than those which

are recommended.

• DON’T-Wedge anything against fan to hold motor shaft.

• DON’T-Force cutting action. (Stalling or partial stalling of

motor can cause major damage. Allow motor to reach

full speed before cutting.)

• DON’T-Cut ferrous metals (Those with any iron or steel

content) or any masonry.

• DON’T-Use abrasive wheels. The excessive heat and

abrasive particles generated by them will damage saw.

• DON’T-Allow anyone to stand behind saw.

• DON’T-Apply lubricants to the blade when it’s running.

• DON’T-Place either hand in the blade area when the

saw is connected to the power source.

• DON’T-Use blades rated less than 5500 R.P.M.

• DON’T-Attempt to cut small pieces (hand within 6" of

blade) without clamping.

• DON’T-Operate saw without guards in place.

• DON’T-Perform any operation freehand.

• DON’T-Reach around or behind saw blade.

• DON’T-Place hands closer than 6 inches from the saw

blade.

• DON’T-Reach underneath the saw unless it is turned off

and unplugged. The saw blade is exposed on the

underside of the saw.

• DON’T-Move either hand from saw or workpiece or raise

arm until blade has stopped.

• DON’T-Use without Kerf Plate or when kerf slot is wider

than 3/8"

• DON’T- Carry saw by work extension or other accessory.

CAUTION: Some wood contains preservatives

such as copper chromium arsenate (CCA) which

can be toxic. When cutting these materials extra

care should be taken to avoid inhalation and minimize skin

contact.

CAUTION: Use of this tool can generate dust

containing chemicals known to cause cancer,

birth defects or other reproductive harm. Use

appropriate respiratory protection.

CAUTION: Do not connect unit to electrical

power source until complete instructions are

read and understood.

For your convenience and safety, the following warning

labels are on your mitre saw.

ON MOTOR HOUSING:

WARNING: FOR YOUR OWN SAFETY, READ

INSTRUCTION MANUAL BEFORE OPERATING SAW.

WHEN SERVICING, USE ONLY IDENTICAL

REPLACEMENT PARTS. ALWAYS WEAR EYE

PROTECTION.

ON FENCE:

CLAMP SMALL PIECES BEFORE CUTTING. SEE

MANUAL.

ON GUARD:

DANGER – KEEP AWAY FROM BLADE.

ON GUARD RETAINER PLATE: “PROPERLY SECURE

BRACKET WITH BOTH SCREWS BEFORE USE.”

ON TABLE: (2 PLACES)

ALWAYS TIGHTEN ADJUSTMENT KNOBS BEFORE USE.

KEEP HANDS 6" FROM PATH OF SAW BLADE. NEVER

PERFORM ANY OPERATION FREEHAND. NEVER CROSS

ARMS IN FRONT OF BLADE. THINK! YOU CAN PREVENT

ACCIDENTS. DO NOT OPERATE SAW WITHOUT

GUARDS IN PLACE. NEVER REACH IN BACK OF SAW

BLADE. ALWAYS WEAR EYE PROTECTION. SHUT OFF

POWER AND WAIT FOR BLADE TO STOP BEFORE

SERVICING, ADJUSTING TOOL, OR MOVING HANDS.

(Original instructions) ENGLISH

Page 8

8

Electrical Connection

Be sure your power supply agrees with the nameplate

marking. A voltage decrease of 10 percent or more will

cause a loss of power and overheating. All B&D tools are

factory tested. If this tool does not operate, check the power

supply.

Familiarization

Place the saw on a smooth, flat surface such as a

workbench or strong table. Examine Figures 1 & 2 and refer

to the parts description to become familiar with the saw and

its various parts. The following section on adjustments will

refer to these terms and you must know what and where the

parts are. The part name is followed by the corresponding

part number Example - lock down pin (10). Press down

lightly on the operating handle and pull out the lock down

pin (10), as shown in Figure 3. Gently release the downward

pressure and allow the arm to rise to its full height. Use the

lock down pin when carrying the saw from one place to

another. Use the operating handle (1) to transport the saw

or the hand indentations (11) shown in Figure 2 after

unplugging.

Specifications

Capacity of cut

47° mitre left and right

47° bevel left

0° mitre -Max. Height 3-1/2” -Max. Width 5-1/2”

45° mitre -Max. Height 3-1/2” -Max. Width 4-1/8”

45° bevel -Max. Height 2-1/2” -Max. Width 5-1/2”

Bench Mounting

Bench mounting holes (8) are provided in all four feet to

facilitate bench mounting, as shown in Figure 1. (Two

different sized holes are provided to accommodate different

sizes of screws. Use either hole, it is not necessary to use

both.) Always mount your saw firmly to prevent movement.

To enhance the tool’s portability, it can be mounted to a

piece of 1/2" or thicker plywood which can then be clamped

to your work support or moved to other job sites and

reclamped.

NOTE: If you elect to mount your saw to a piece of plywood,

make sure that the mounting screws don’t protrude from the

bottom of the wood. The plywood must sit flush on the work

support. When clamping the saw to any work surface, clamp

only on the clamping bosses where the mounting screw

holes are located. Clamping at any other point will interfere

with the proper operation of the saw.

CAUTION: To prevent binding and inaccuracy, be

sure the mounting surface is not warped or

otherwise uneven. If the saw rocks on the surface,

place a thin piece of material under one saw foot until the

saw sits firmly on the mounting surface.

Installing a New Saw Blade

(UNPLUG THE MITRE SAW)

DO NOT USE FERROUS METAL or masonry cutting blades

in this saw

• Loosen hex bolt on center cover counter clockwise with

box wrench.

• Lift up the safe cover and center cover.

• Press down the lock to lock spindle.

• Loosen hex bolt clockwise with box wrench, then

dismount the bolt and flange.

• Mount the blade of saw on spindle. Make sure that the

arrow direction on surface of saw blade is same as one

of the cover.

Note: There are two different internal diameters of cutter in

inner plate which have steel stamp marked 25.4mm 16mm.

When mounting, the outer diameter of inner plate must be

correspondent with the internal diameter of saw blade.

• Mount flange and hex bolt.

• Press axle lock and tighten hex bolt counter clock wise

with box wrench firmly, then tighten hex bolt clockwise to

fix centre cover.

Note: Only use attached wrench when mounting or

dismounting saw blade. When dismounting saw blade, lift up

safe cover and centre cover. Loosen hex bolt with box

wrench and disassemble hex bolt, flange and saw blade.

NEVER DEPRESS THE SPINDLE LOCK PIN WHILE THE

BLADE IS ROTATING.

• Be sure to hold the guard bracket down and firmly

tighten the guard bracket screw when you finish installing

the saw blade. Failure to do so will cause serious

damage to the saw.

Assembling and Adjusting Your Saw

PERFORM ALL ASSEMBLY WITH SAW UNPLUGGED.

Attach Mitre Clamp Handle

Remove the mitre clamp handle (4) from the plastic parts

bag and carefully thread it into the bracket in the front of the

saw.

Attaching Dust Bag

A zippered cloth dust bag is included with your saw. To

attach the bag, fit the plastic opening firmly over the dust

spout (9).

NOTE: The saw can also be used with a vacuum cleaner

hose attached to the dust spout or without any attachment.

Adjustments

PERFORM ALL ADJUSTMENTS WITH THE MITRE SAW

UNPLUGGED

ENGLISH (Original instructions)

Page 9

9

NOTE: Your mitre saw is fully and accurately adjusted at the

factory at the time of manufacture. If readjustment due to

shipping and handling or any other reason is required, follow

the steps below to adjust your saw.

Mitre Scale Adjustment

Place a square against the saw’s fence and blade, as

shown in Figure 4. (Do not touch the tips of the blade teeth

with the square. To do so will cause an inaccurate

measurement.) Loosen the mitre clamp handle (4) as shown

in Figure 5 and swing the mitre arm until the mitre latch (5)

locks it at the 0 mitre position. Do not tighten the clamp

handle. If the saw blade is not exactly perpendicular to the

fence, loosen the two screws that hold the handle to the

base (shown in Figure 6) and move the arm of the saw left

or right until the blade is perpendicular to the fence, as

measured with the square. Retighten the two screws. Pay

no attention to the reading of the mitre pointer at this point.

Guard Actuation and Visibility

The blade guard on your saw has been designed to

automatically raise when the arm is brought down and to

lower over the blade when the arm is raised. The guard can

be raised by hand when installing or removing saw blades

or for inspection of the saw. NEVER RAISE THE BLADE

GUARD MANUALLY UNLESS THE SAW IS TURNED OFF.

NOTE: Certain special cuts will require that you manually

raise the guard. To do this, simply place your right thumb on

the upper side of the guard and roll the guard up just

enough to clear the workpiece. Never tie up or otherwise

prevent the guard from operating normally.

Operation

Plug the saw into any power source. Refer to the nameplate

for voltage. Be sure the cord will not interfere with your

work.

Switch

To turn the saw on, depress the trigger switch (16). To turn

the tool off, release the switch. There is no provision for

locking the switch on.

Body and Hand Position (See figure 7)

Proper positioning of your body and hands when operating

the mitre saw will make cutting easier, more accurate and

safer. Never place hands near cutting area. Place hands no

closer than 6" from the blade. Hold the workpiece tightly to

the table and the fence when cutting. Keep hands in position

until the trigger has been released and the blade has

completely stopped. ALWAYS MAKE DRY RUNS

(UNPOWERED) BEFORE FINISH CUTS SO THAT YOU

CAN CHECK THE PATH OF THE BLADE. DO NOT CROSS

HANDS, AS SHOWN IN FIGURE 7.

Cutting With Your Saw

NOTE: Although this saw will cut wood and many nonferrous

materials, we will limit our discussion to the cutting of wood

only. The same guidelines apply to the other materials. DO

NOT CUT FERROUS (IRON AND STEEL) MATERIALS OR

MASONRY WITH THIS SAW. Do not use any abrasive

blades.

Crosscuts

NOTE: Cutting of multiple pieces is not recommended, but

can be done safely by ensuring that each piece is held firmly

against the table and fence.

A crosscut is made by cutting wood across the grain at any

angle. A straight crosscut is made with the mitre arm at the

zero degree position. Set the mitre arm at zero, hold the

wood on the table and firmly against the fence. Turn on the

saw by squeezing the trigger switch. When the saw comes

up to speed (about 1 second) lower the arm smoothly and

slowly to cut through the wood. Let the blade come to a full

stop before raising arm.

Mitre crosscuts are made with the mitre arm at some angle

other than zero. This angle is often 45 degrees for making

corners, but can be set anywhere from zero to 47 degrees

left or right. After selecting the desired mitre angle, be sure

to tighten the mitre clamp handle (4). Make the cut as

described above.

Bevel Cuts

A bevel cut is a crosscut made with the saw blade at a bevel

to the wood. In order to set the bevel, loosen the bevel

clamp knob (17) and move the saw to the left as desired.

Once the desired bevel angle has been set, tighten the bevel

clamp knob firmly. Bevel angles can be set up to 45 degrees

left and can be cut with the mitre arm set between zero and

47 degrees right or left.

Quality of Cut

The smoothness of any cut depends on a number of

variables. Things like material being cut, blade type, blade

sharpness and rate of cut all contribute to the quality of the

cut.

When smoothest cuts are desired for molding and other

precision work, a sharp (60 tooth carbide) blade and a

slower, even cutting rate will produce the desired results.

Ensure that material does not creep while cutting, clamp it

securely in place. Always let the blade come to a full stop

before raising arm.

(Original instructions) ENGLISH

Page 10

10

If small fibers of wood still split out at the rear of the

workpiece, stick a piece of masking tape on the wood where

the cut will be made. Saw through the tape and carefully

remove tape when finished.

Keep both feet firmly on the floor and maintain proper

balance. As you move the mitre arm left and right, follow it

and stand slightly to the side of the saw blade. Sight through

the guard louvers when following a pencil line

Clamping the Workpiece

Turn Off and Unplug Saw

If you cannot secure the workpiece on the table and against

the fence by hand (irregular shape, etc.) or your hand will be

within 6” of the blade, a clamp or fixture must be used.

Other convenient clamps such as spring, bar or Cclamps

may be appropriate for certain sizes and shapes of

workpieces. Use care in selecting and placing these clamps

and make a dry run before making the cut.

Support for Long Pieces

Turn Off and Unplug Saw

ALWAYS SUPPORT LONG PIECES For best results, use

an extension work support to extend the table width of your

saw. Support long workpieces using any convenient means

such as sawhorses or similar devices to keep the ends from

dropping.

Cutting Picture Frames, and Other Four Sided Projects

To best understand how to make the items listed here, we

suggest that you try a few simple projects using scrap wood

until you develop a “FEEL” for your saw. Your saw is the

perfect tool for mitring corners like the ones shown in Figure

8, which shows a joint made by setting the mitre arm at 45

degrees to to mitre the two boards to form a 90 degree

corner. To make this type of joint, set the mitre arm to 45

degrees. The wood was positioned with the broad flat side

against the table and the narrow edge against the fence.

As the number of sides changes, so do the mitre angles.

The chart below gives the proper angles for a variety of

shapes.

(The chart assumes that all sides are of equal length.) For a

shape that is not shown in the chart, use the following

formula. 180 degrees divided by the number of sides equals

the mitre.

Cutting Compound Mitres

A compound mitre is a cut made using a mitre angle and a

bevel angle at the same time. This is the type of cut used to

make frames or boxes with slanting sides like the one shown

in Figure 8.

NOTE: If the cutting angle varies from cut to cut, check that

the bevel clamp knob (10) and the mitre clamp handle (4)

are securely tightened. These knobs must be tightened after

making any changes in bevel or mitre.

Cutting Crown Molding

In order to fit properly, crown molding must be mitred with

extreme accuracy. The two flat surfaces on a given piece of

crown molding are at angles that, when added together,

equal exactly 90 degrees. Most, but not all, crown molding

has a top rear angle (the section that fits flat against the

ceiling) of 52 degrees and a bottom rear angle (the part that

fits flat against the wall) of 38 degrees.

Pretesting with scrap material is extremely important! Place

the bottom side (the side that will be against the wall) against

the Mitre SAW FENCE. Place the top (that part that will be

against the ceiling) against the saw table and the crown

molding fence. Instructions for cutting crown MOLDING

angled between the fence and the TABLE of the saw for all

cuts:

1. Angle the molding so the bottom of the molding (part

which goes against the wall when installed) is against the

fence and the top of the molding is resting on the table of

the saw.

- Examples -

No. Sides Angle Mitre

4 45°

5 36°

6 30°

7 25.7°

8 22.5°

9 20°

10 18°

ENGLISH (Original instructions)

Page 11

2. The angled “flats” on the back of the molding must rest

squarely on the fence and table of the saw.

INSIDE CORNER:

Left side

1. Mitre right at 45°

2. Save the right side of cut

Right side

1. Mitre left at 45°

2. Save left side of cut

OUTSIDE CORNER:

Left side

1. Mitre left at 45°

2. Save the right side of cut

Right side

1. Mitre right at 45°

2. Save left side of cut

ALWAYS MAKE DRY RUNS TO CHECK FOR CLEARANCE

AND CORRECTNESS OF CUTS.

Special Cuts

NEVER MAKE ANY CUTS UNLESS THE MATERIAL IS

SECURED ON THE TABLE AND AGAINST THE FENCE.

Aluminum Cutting (Carbide tipped blade only)

Aluminum extrusions such as those used when making

aluminum screens and storm windows can easily be cut with

your saw using the proper blade designed for non-ferrous

metal cutting. Position the material so that you will be cutting

the thinnest cross section, as shown in Figure 9.

Figure 10 illustrates the wrong way to cut these extrusions.

Use a wax lubricant when cutting aluminum such as

Johnson’s Stick Wax No.140. Apply the stick wax directly to

the saw blade before cutting. Never apply stick wax to a

moving blade.

The wax, available at most hardware stores and industrial

mill supply houses, provides proper lubrication and keeps

chips from adhering to the blade.

Be sure to properly secure work. Certain workpieces, due to

their size, shape or surface finish, may require the use of a

clamp, jig or fixture to prevent movement during the cut.

Bowed Material

When cutting bowed material always position it as shown in

Figure 11 and never like that shown in Figure 12. Positioning

the material incorrectly will cause it to pinch the blade near

the completion of the cut.

Cutting Plastic Pipe and other round cross-sectional

material

Plastic pipe can be easily cut with your saw. It should be cut

just like wood and clamped or held firmly to the fence to

keep it from rolling particularly when making angle cuts.

Carrying the tool

1. Lower the cutting head and push in the lock pin (10)

2. Carry the mitre saw with the carrying handles (11).

Warning! Do not carry the machine by the guard.

DURING USE

• If the saw blade becomes blocked, switch off the tool

immediately and disconnect the plug; only then remove

the wedged workpiece

• In case of jamming or electrical or mechanical

malfunction, immediately switch off the tool and

disconnect the plug

Maintenance

(PERFORM ALL MAINTENANCE WITH MITRE SAW

UNPLUGGED.)

1. All bearings are sealed. They are lubricated for life and

need no further maintenance.

2. Periodically clean all dust and wood chips from around

AND UNDER the base and the rotary table. Even though

slots are provided to allow debris to pass through, some

dust will accumulate.

3. The brushes are designed to give you several years of

use. If they ever need replacement follow the instructions

in this manual or return the tool to the nearest service

center for repair.

Important

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment (including brush inspection and

replacement) should be performed by authorized service

centers or other qualified service organizations, always using

identical replacement parts.

11

(Original instructions) ENGLISH

Page 12

TROUBLE! SAW WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1. Saw not plugged in 1. Plug in saw

2. Fuse blown or circuit 2. Replace fuse or reset

breaker tripped circuit

breaker

3. Cord damaged 3. Have cord replaced by

authorized service center

4. Brushes worn out 4. See “Brushes” in this

manual

TROUBLE! SAW MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1. Dull blade 1. Replace blade

2. Blade mounted 2. Turn blade around

backwards

3. Gum or pitch on blade 3. Remove blade and

clean with turpentine

and coarse steel wool

or household oven

cleaner

4. Incorrect blade for work 4. Change the blade

being done

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1. Extension cord too light 1. Replace with adequate

or too long size cord

2. Low house current 2. Contact your electric

company

TROUBLE! MATERIAL PINCHES BLADE

WHAT’S WRONG? WHAT TO DO…

1. Cutting bowed material 1. Position bowed material

as shown in Figure 11

TROUBLE! MACHINE VIBRATES EXCESSIVELY

WHAT’S WRONG? WHAT TO DO…

1. Saw not mounted 1. Tighten all mounting

securely hardware

2. Stand or bench on 2. Reposition on flat level

uneven floor surface

3. Damaged saw blade 3. Replace blade

TROUBLE! DOES NOT MAKE ACCURATE MITRE CUTS

WHAT’S WRONG? WHAT TO DO…

1. Mitre scale not adjusted 1. Check and adjust

correctly

2. Blade is not square to 2. Check and adjust

fence

3. Workpiece moving 3. Clamp workpiece to

fence or glue 120 grit

sandpaper to fence

with rubber cement

12

NOTE

• Stanley's policy is one of continuous improvement to our

products and, as such, we reserve the right to change

product specifications without prior notice.

• Standard equipment and accessories may vary by

country.

• Product specifications may differ by country.

• Complete product range may not be available in all

countries. Contact your local Stanley dealers for range

availability.

Trouble Shooting Guide

BE SURE TO FOLLOW SAFETY RULES AND

INSTRUCTIONS

ENGLISH (Original instructions)

Page 13

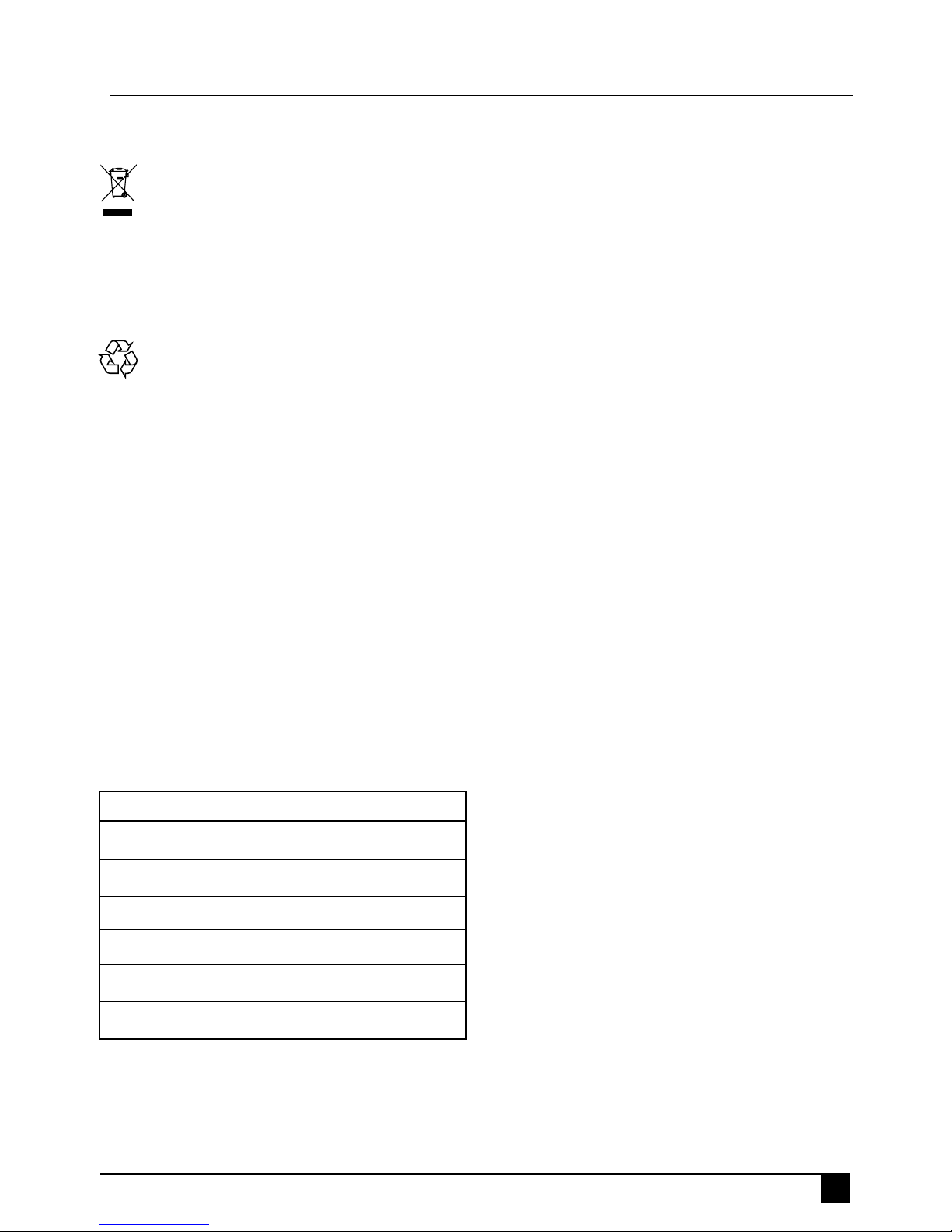

STSM1510

POWER W 1500

NO-LOAD SPEED /min 5500

MAX. DIAMETER mm 140x70

BLADE DIAMETER mm 254

BLADE BORE mm 30

Weight kg 12.5

Specifications

13

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Stanley product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Stanley provides a facility for the collection and recycling of

Stanley products once they have reached the end of their

working life. To take advantage of this service please return

your product to any authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Stanley office at the address

indicated in this manual. Alternatively, a list of authorised

Stanley repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com

Service Information

STANLEY offers a full network of authorized service

locations. All STANLEY Service Centers are staffed with

trained personnel to provide customers with efficient and

reliable power tool service. For more information about our

authorized service centers and if you need technical advice,

repair, or genuine factory replacement parts, contact the

STANLEY location nearest you.

One year warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 12 months from the date of

purchase, STANLEY guarantees to replace all defective

parts free of charge or – at our discretion – replace the unit

free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

(Original instructions) ENGLISH

Page 14

ALGERIA: Sarl Outillage Corporation, 08 Rue Med Boudiaf - Cheraga - Algiers, Algeria. Tel: (213-21) 375130, Fax: (213-21) 369667. ANGOLA: Angoferraria,

Lda., Rua Robert Shields, No. 61, Luanda, Angola, Tel: 00244-222-395837 / 222-395034, Fax: 00244-222-394790. AZERBAIJAN: Royalton Holdings Ltd. 41

Khagani St. Apt. 47 AZ 1001, Baku. Tel: (994-12) 4935544, Fax: (994-12) 5980378. BAHRAIN: Kavalani & Sons W.L.L., P.O. Box 71, Sitra, Manama, Tel: (973)

17732888, Fax: (973) 17737379. Alfouz Services Co. WLL., P.O. Box 26562, Tubli, Manama. Tel: (973) 17783562, Fax: (973) 17783479. EGYPT: El Farab

S.A.E., 15-Nabil El Wakkad Street, Dokki, Giza, Egypt, Tel: 00202-37603946 / 002-010-2582544, Fax: 00202-33352796. ETHIOPIA: Seif Tewfik Sherif, Arada

Sub-City, Kebele 01/02, Global Insurance Building, 2nd Floor, Room 43, P.O. Box 2525, Addis Ababa, Ethiopia. Tel: (251-11) 1563968/ 1563969, Fax: (251-11)

1558009. IRAQ: Financial Links, Kazzaz Building Arasat Al-Hindia Block No: 629 Street: 31Building No: 1 Baghdad – Iraq. Tel: 00964 (0)780 195 2223/ 00964

(0)781 3763044. Al Sard Co. for General Trading Ltd. Jbara Bldg. 3Flr, Al Rasheed St. Bagdad. Tel: (964) 18184102. Sakhar Group, Arrassat al-hindya Al

Masbah, Bagdad. (964) 7400144446. JORDAN: Palestine Bldg. Matl. (Bashiti Hardware), 93 King Abdullah 2nd Street, Opp. ELBA House, P.O. Box 3005,

Amman 11953, Tel: (962-6) 5349098, Fax: (962-6) 5330731. KENYA: Dextron Tools Ltd., P.O. Box 20121-00200, Shariff House, Kimathi Street, Nairobi. Tel:

(254-20) 6905000/ 2358021, Fax: (254-20) 6905111/ 6905112. KUWAIT: Al Omar Technical Co., P.O. Box 4062, 13041 Safat, Kuwait. Tel: (965) 24848595/

24840039, Fax: (965) 24845652. Fawaz Al Zayani Establishment, P.O. Box 42426, Shop No. 18, Al Humaizi Commercial Complex, Khalifa Al Jassim,

Shuwaikh, Kuwait. Tel: (965) 24828710, Fax: (965) 24828716. Fawaz Al Zayani Establishment, P.O. Box 42426, Shop No.18, Al Humaizi Commercial

Complex, Khalifa Al Jassim, Shuwaikh, Kuwait, Tel: (965) 24828710, Fax: (965) 24828716. Fawaz Al Zayani Establishment, Fahaheel Industrial Area, Main St.,

Sanaya, Kuwait, Tel: (965) 23925830, Fax: (965) 24828716. LEBANON: Est. Shaya & Azar S.A.R.L., Boulvard Jdeideh - Mar Takla - Bouchrieh .P.O. Box

90545 Jdeideh.Beirut - Lebanon, Tel: 00961 1 872305 / 306 , Fax: 00961 1 872303. LIBYA: North Africa Trading ( El Ghoul Brothers), AlHilal Service Center

Tawergha St. Misurata, Tel: 00218-091-3221408. (Benghazi) Sniydel st., Amr Ibn EL-Aas Rd. Tel: (+218) 92 5771120. (Tripoli) Al Barniq Service Center,

Mokhazin elsukar st., ElFallah. Tel: (+218) 21 4808019. (Misrata) Al Hilal Service Center, Tawergha st. Tel: (+218) 51 2626743. MAURITIUS: Robert Le Marie

Limited, Old Moka Road, Bell Village, P.O. Box 161, Port Louis, Tel: 00230-212 1865/ 212 2847, Fax: 00230-2080843. MOROCCO: Ets Louis Guillaud & Cie,

149, Quartier Industriel, Moulay Rachid, Casablanca, Postal Code 20450, Morocco, Tel: 00212-522729233, Fax: 00212-522729096. NIGERIA: Meridian

Power Tools Ltd., Gr.Floor, #1 Alhaji Masha Rd, Next toTeslim Balogun Stadium, Near National Stadium Surulere, Lagos, Nigeria, Tel: 00234-1-7740431 /

7740410, Fax: 00234-1-7913798. OMAN: Al Jizzi Company LLC, P.O. Box 1704,PC 112 Ruwi, Oman, Tel: (968) 24832618/ 24835153, Fax: (968)

24831334/24836460. Al Hassan Technical & Construction Supplies Co. LLC, P.O. Box 1948, P.C. 112, Ruwi, Tel: (968) 24810575 / 24837054, Fax: (968)

24810287/ 24833080. Oman Hardware Co. LLC, P.O. Box 635, Ruwi Postal Code 112, Te: (968) 24815131, Fax: (968) 24816491. Khimji Ramdas, P.O. Box

19, Post Code 100, Ghala, Muscat, Oman. Tel: (968) 24595906/ 907, Fax: (968) 24852752. Oman Marketing & Service Co. (Omasco), P.O. Box 2734, Behind

Honda Showroom, Wattayah, Oman. Tel: (968) 24560232/ 24560255, Fax: (968) 24560993. Oman Marketing & Service Co. (Omasco), Al Ohi, Sohar, Oman.

Tel: (968) 26846379, Fax: (968) 26846379. Oman Marketing & Service Co. (Omasco), Sanaya, Salalah, Oman. Tel: (968) 23212290, Fax: (968) 23210936.

PAKISTAN: ZIT Co - Nasir & Bros., 2nd Floor, Qadri Center, Chowk Dalgran Railway Road, Lahore, Pakistan, Tel: 0092 42 37670839, Fax: 0092 42

37652989. Ammar Service & Spares, 60-Bank Arcade, Serai Road, Karachi, Pakistan. Tel: (92-21) 32426905, Fax: (92-21) 32427214. QATAR: Teyseer

Industrial Supplies & Services Co. WLL, 55, Al Wakalat St. (Between St. 18 & 19) Salwa Industrial Area, P.O. Box 40523 Doha,Qatar, Te: (974) 44581536, Fax:

(974) 44682024. Shaheen Electrical Works & Trading Co. WLL, Gate 34, St. 44 Industrial Area P.O. Box 9756, Doha, Tel: (974) 44600230 /44600525, Fax:

(974) 44601338. Al Muftah Service Centre, Al Wakrah Road, P.O. Box 875, Doha,Qatar, Tel: (974) 44650880/ 44650110/ 44446868, Fax: (974) 44441415 /

44662599. SAUDI ARABIA: (Al Bahr) Mohamed Ahmed Bin Afif Est., P.O. Box 530, Yanbu, Al Bahr. Tel: (966-4) 3222626/ 3228867, Fax: (966-4) 3222210.

(Al Khobar) Fawaz Ebrahim Al Zayani Trading Est., P.O. Box 76026, Al Khobar # 31952, Tel: (966-3) 8140914, Fax: (966-3) 8140824. MSS (Al-Mojil Supply &

Services) P.O. Box 450, Jubail 31951, Opp. Gulf Bridge Library & Riyadh House. Tel: (966-3) 3612850/ 3624487/ 3621729, Fax: (966-3) 3623589/ 3620783.

(Dammam) MSS (Al-Mojil Supply & Services), P.O. Box 450, Jubail 31951.Opp-Gulf Bridge Library & Riyadh House, Tel: (966-3) 3612850 / 3624487 /

3621729, Fax: (966-3) 3623589 / 3620783. Al Bawardi Tools & Hardware, P.O. Box 112, Dammam, Tel: (966-3) 8330780 Ext.24 / 8348585 Ext. 24 /

+966-3-8335555, Fax: (966-3) 8336303. (Al Hassa) Mutawa Trading & Gen. Services, Maliki road Hafuf city, Al Hassa, KSA. Tel: (966) 502846275 (Jeddah) Al

Bawardi Tools & Hardware, P.O. Box 16905, Jeddah 21474, Tel: (966-2) 6444547 / 6439035 / 6456095, Fax: (966-2) 6439024. EAC (Al Yousef Contg. & Trdg.

Est.), P.O. Box 30377, Jeddah -21477, Tel: (966-2) 6519912, Fax: (966-2) 6511153. (Madina) Garziz Trading for Bldg Mat & Decoration, P.O. Box 3364,

Madina, Tel: (966-4) 826 14 90 / 8227636, Fax: (966-4) 8265741. (Riyadh) Industrial Material Organization (IMO), P.O. Box 623, Rail Street ,Riyadh, Tel:

(966-1) 4028010 Ext 26 / 8001245757, Fax: (966-1) 4037970. Sultan Garment Factory (RSC), P.O. Box 29912, Riyadh 11467, KSA, Tel: (966-1) 4055148 /

4042889, Fax: (966-1) 4055148. Al Bawardi Tools & Hardware, P.O. Box 68, Riyadh 11411, Tel: (966-1) 4484999, Fax: (966-1) 4487877. (Yanbu) Fawaz

Ebrahim Al Zayani, Opposite to Al Fouzan, Jeddah highway or King Abdul Aziz road, Yanbu. Tel: (966-4) 3960980, Fax: (966-4) 3961980. Mohamed Ahmed

Bin Afif Est., P.O. Box 530, Yanbu, Al Bahr, Tel: (966-4) 3222626/ 3228867, Fax: (966-4) 3222210. SOUTH AFRICA: Stanley Black & Decker - RSA, 199

Winze Drive Stormill Ext 9 Roodepoort, Tel: (2711) 472 0454, Fax: (2711) 472 0482. Trevco Power Tool Service 14 Steenbok Street, Koedoespoort, 0186,

Pretoria, South Africa. Tel: (27-86) 1873826, Fax: (27-86) 5001771. TANZANIA: General Motors investment Ltd., P.O. Box 16541, 14 Nyerere Road,

Vingunguti, Dar-es-Salaam. Tel: (255 22) 2862661/ 2865022, Fax: (255 22) 2862667. TUNISIA: Societe Tunisienne De Maintenance (STM), Rue de la

Physique. Nouvelle Zone Industrielle Ben Arous., 2013 Ben Arous, Tunisia. Tel: (+216) 79 389687, Fax: (+216) 71 385154. UAE: (Abu Dhabi) Light House

Electrical, P.O. Box 120, Abu Dhabi, Tel: (971-2) 6726131, Fax: (971-2) 6720667. Galaxy Equipment Trading, Madinath Zayed (Baada Zaid), Abu Dhabi P.C.

58910, Tel: (971-2) 8844279, Fax: (971-2) 8844297 (Ajman) Al Sukoon Gen. Trdg. Co. LLC, P.O. Box 2975, Ajman. Tel: (971-6) 7435725/ 7438317, Fax:

(971-6) 7437350. Al Sukoon Gen. Trdg. Co. LLC, P.O. Box 2975, Ajman, Tel: (971-6) 7435725 / 7438317, Fax: (971-6) 7437350 (Al Ain) Zillion Equipment and

Spare Parts Trading LLC, P.O. Box 19740, Opp. Bin Sadal/ Trimix Redymix Sanaiya, Al Ain. Tel: (971-3) 7216690, Fax: (971-3) 7216103. (Dubai) Black &

Decker (Overseas) GmbH, P.O. Box 5420, Dubai, Tel: (971-4) 8127400/ 8127406, Fax: (971-4)2822765. Ideal Star Workshop Eqpt.Trading LLC, P.O. Box

37116, Al Quoz, Dubai, Tel: (971-4) 3474160, Fax: (971-4) 3474157, Fine Tools, P.O.Box 30139 , Al Quoz, Dubai, Tel: (971-4) 3385240, Fax: (971-4) 3385239,

Alebrah Engineering Service, P.O. Box 78954, Al Qusais , Dubai, Tel: (971-4) 2850044, Fax: (971-4) 2844802. (Musaffah) Light House Electrical, P.O. Box

120, Abu Dhabi, Tel: (971-2) 5548315, Fax: (971-2) 5540461. (Sharjah) Mc Coy Middle East LLC, P.O. Box 25793, Sharjah, Tel: (971-6) 5395931, Fax:

(971-6) 5395932. Burj Al Madeena, Industrial Area No.1, Opp. Pakistani Masjid, P.O. Box 37635, Sharjah. Tel: (971-6) 5337747, Fax: (971-6) 5337719. Burj Al

Madeena, , Industrial Area No 1,opp Pakistani Masjid P.O. Box 37635, Sharjah, Tel: (971-6) 5337747, Fax: (971-6) 5337719 (Ras Al Khaimah) Mc Coy Middle

East LLC, P.O. Box 10584, Ras Al Khaimah, Tel: (971-7) 2277095, Fax: (971-7) 2277096. UGANDA: The Building Center (U) Ltd., 52 Station Road, Kitgum

House, P.O. Box 7436, Kampala, Uganda. Tel: (256-41) 4234567/ 4259754, Fax: (256-41) 4236413. YEMEN: (Aden) Middle East Trad. Co. Ltd. (METCO),

Mualla Dakka, Aden, Yemen. Tel: (967-2) 222670, Fax: (967-2) 222670. (Sana'a) Middle East Trad. Co. Ltd. (METCO), Hayel St., Sana'a, Yemen. Tel: (967-1)

204201, Fax: (967-1) 204204. (Taiz) Middle East Trading Co. (METCO), P.O. Box 12363, 5th Flr, Hayel Saeed Anam Bldg, Al-Mugamma St. Taiz, Yemen. Tel:

(967-4) 213455, Fax: (967-4) 219869.

Names & Addresses for STANLEY Service Concessionaries - MIDDLE EAST & AFRICA

Loading...

Loading...