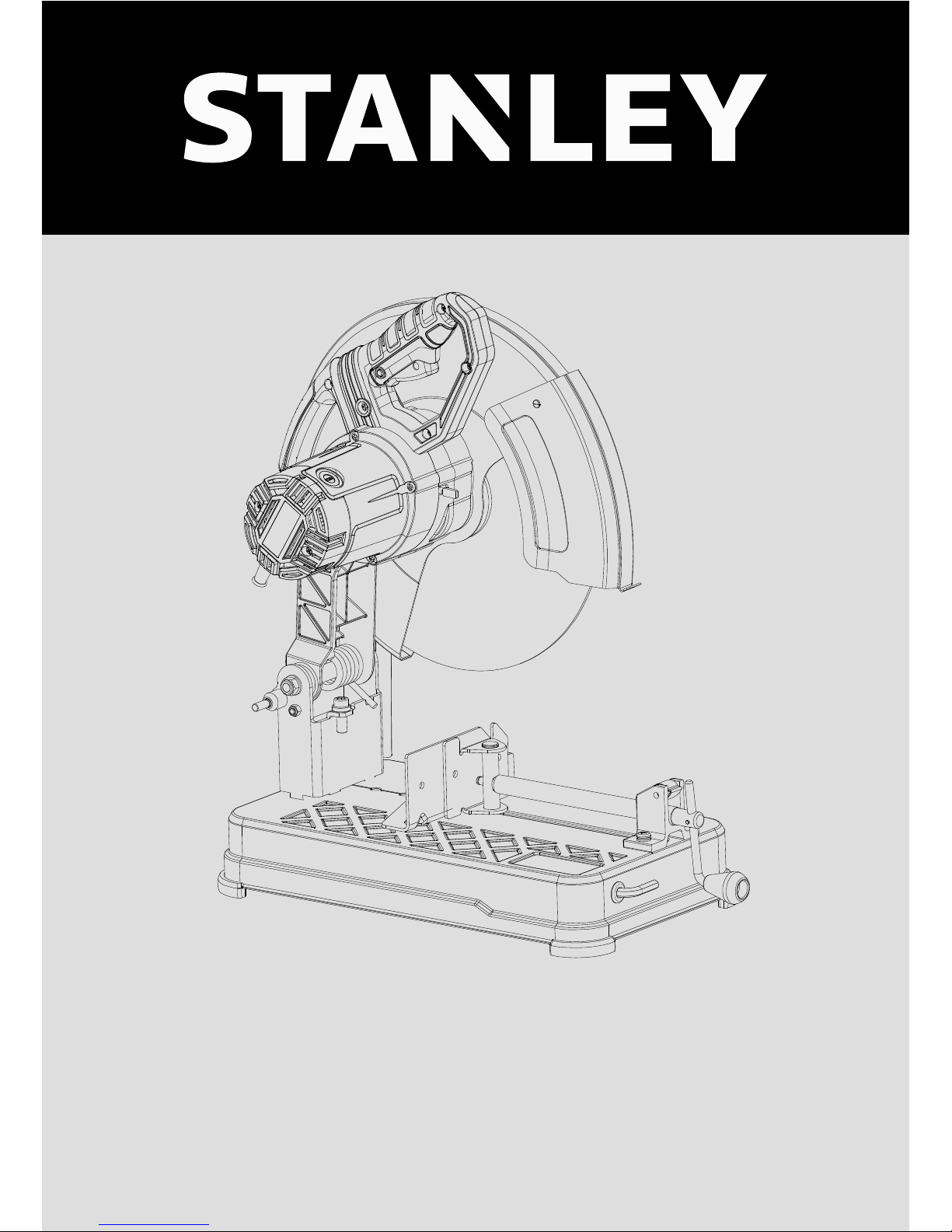

Page 1

STSC2135

English Page 3

Turkish Page 12

Page 2

2

DIAMETER OF WORK PIECE

WIDTH OF SPACE BLOCK

SPACE BLOCK

E

F

X

.3"

(8mm)

FIG. A

FIG. B

FIG. E

FIG. I

FIG. D

E

H

I

F

P

FORWARD

FIG. G

L

FIG. H

R

J

U

T

S

Y

W

V

K

J

F

H

I

L

N

o

A

M

G

X

E

D

FIG. C

CUT-OFF END

BLOCK

C

B

F

P

A

E

FIG. F

P

E

AD

ENGLISH (Original instructions)

Page 3

3

Intended use

Your STANLEY Chop Saw has been designed for the cutting

of variously shaped steel materials.

General safety rules

Warning! Read all instructions. Failure to follow all

instructions listed below may result in electric shock, fire

and/or serious injury. The term “power tool” in all of the

warnings listed below refers to your mains operated

(corded) power tool or battery operated (cordless) power

tool. SAVE THESE INSTRUCTIONS.

Safety instructions

General power tool safety warnings

1. Work area safety

a. Keep work area clean and well lit. Cluttered and dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

aunavoidable, use a residual current device

(RCD)protected supply.Use of an RCD reduces the

risk of electric shock.

Note: The term "Residual Curent Device (RCD)" can be

replaced by "Ground Fault Circuit Interrupter (GFCI)" or by

"Earth Leakage Circuit Breaker (ELCB)".

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c. Avoid accidental starting. Ensure the switch is in the

off position before plugging in. Carrying power tools

with your finger on the switch or plugging in power tools

that have the switch on invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

toolin unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices

can reduce dust related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools.Such preventive safety measures reduce

the risk of starting the power tool accidentally

(Original instructions) ENGLISH

Page 4

4

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Use the power tool, accessories and tool bits etc., in

accordance with these instructions, takinginto

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Additional safety instruction for chopsaws

• Always wear proper eye and respiratory protection.

• Before using, inspect the cutting wheel for cracks or

flaws. If such a crack or flaw is evident, discard the

wheel. The wheel should also be inspected

whenever you think the tool may have been

dropped. Flaws may cause wheel breakage.

• When starting the tool with a new or replacement

wheel or if you are unsure of the condition of the

wheel, hold the tool in a well protected area and let it

run for one minute. If the wheel has an undetected

crack or flaw, it should burst in less than one minute.

Never start the tool with a person in line with the wheel.

This includes the operator.

• In operation, avoid bouncing the wheel or giving it

rough treatment. If this occurs, stop the tool andinspect

the wheel for cracks or flaws.

During use

• If the saw blade becomes blocked, switch off the tool

immediately and disconnect the plug; only then remove

the wedged workpiece.

• In case of jamming or electrical or mechanical

malfunction, immediately switch off the tool and

disconnect the plug.

• Clean your chop saw periodically following the procedure

in this manual.

• Do not remove wheel guards or base.

• ALWAYS USE THE VISE OR SPECIAL FIXTURE TO

CLAMP WORK SECURELY. Other aids such as spring,

bar, or C-clamps may be appropriate for certain sizes

and shapes of workpiece. Use care in selecting and

placing these clamps and make a dry run before making

a cut.

• Use only 14" type 1 wheels rated at 4100 rpm or higher.

• Allow cut off parts to cool before handling.

• Do not attempt to cut wood or plastic with this tool.

• NEVER CUT MAGNESIUM WITH THIS TOOL.

• Use chop saw in a well-ventilated area.

• Turn chop saw off before removing any pieces from the

base.

• DO NOT CUT ELECTRICALLY LIVE MATERIAL.

• Do not use circular saw blades or any other toothed

blades with this tool.Serious injury may result.

• DO NOT OPERATE THIS TOOL NEAR FLAMMABLE

LIQUIDS, GASES OR DUST.Sparks or hot chips from

cutting or arcing motor brushes may ignite combustible

materials.

• Do not use the side of the abrasive wheel as a deburring

grinder. This will substantially weaken the wheel creating

an unsafe condition. The wheel may come apart.

Caution: Wear appropriate hearing protection

during use. Under some conditions and duration

ofuse, noise from this product may contribute to

hearing loss.

Caution:Spark deflector will get hot. Avoid

touching or adjusting while hot. Keep cordset

and materials away from spark deflector.

• Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

ENGLISH (Original instructions)

Page 5

5

Warning: Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust

exposure. Direct particles away from face and

body.For your convenience and safety, the following

warnings are on your Heavy-Duty 14" (355mm) Chop Saw:

For safe operation read the instruction

manual.

• Do not use toothed blades.

• Use only reinforced wheels rated 4100 rpm or higher.

• When servicing use only identical replacement

parts.

• Always: wear eye protection, use guards, clamp

work in vise, use proper respiratory protection.

• Do not expose to rain or use in damp locations.

• Only use chop saw wheel of a max. Thickness of

2.8mm and a max. Diameter of 355mm.

Vibration

The declared vibration emission values stated in the

technical data and the declaration of conformity have been

measured in accordance with a standard test method

provided by EN 61029 and may be used for comparing one

tool with another. The declared vibration emission value may

also be used in a preliminary assessment of exposure.

Warning! The vibration emission value during actual use of

the power tool can differ from the declared value depending

on the ways in which the tool is used. The vibration level

may increase above the level stated.

When assessing vibration exposure to determine safety

measures required by 2002/44/EC to protect persons

regularly using power tools in employment, an estimation of

vibration exposure should consider, the actual conditions of

use and the way the tool is used, including taking account of

all parts of the operating cycle such as the times when the

tool is switched off and when it is running idle in addition to

the trigger time.

Electrical safety

Warning! If the power cord is damaged, it must bereplaced

by the manufacturer, authorized Stanley Service Center or

an equally qualified person in order to avoid damage or

injury.If the power cord is replaced by an equally qualified

person, but not authorized by Stanley, the warranty will not

be valid.

Features (fig. 1, 4)

A. Spark Deflector Screw

B. Spark Deflector

C. Base

D. Fence

E. Vise

F. Flat Wrench

G. Crank

H. Vise Level

I. Wheel

J. Guard

K. Spindle Lock

L. Depth Stop Bolt and Jam Nut

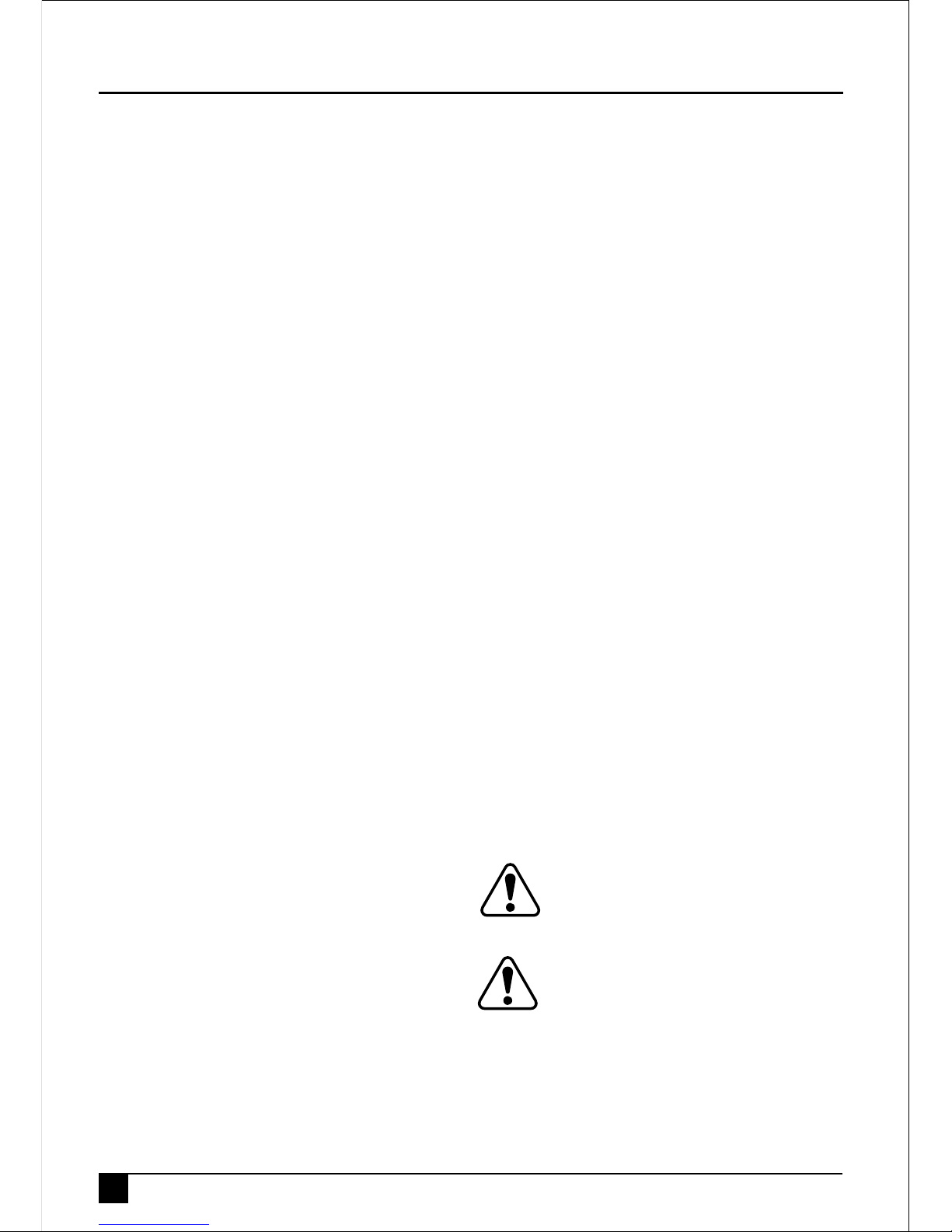

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

0

....... No-Load

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

7. Labels on tool

The label on your tool may include the following symbols:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

(Original instructions) ENGLISH

Page 6

6

M. Trigger Switch

N. Padlock Hole

O. Fence Bolts

P. Lock Pin

Power supply

Be sure your power supply agrees with the nameplate

marking. A voltage decrease of more than 10% will cause a

loss of power and overheating.

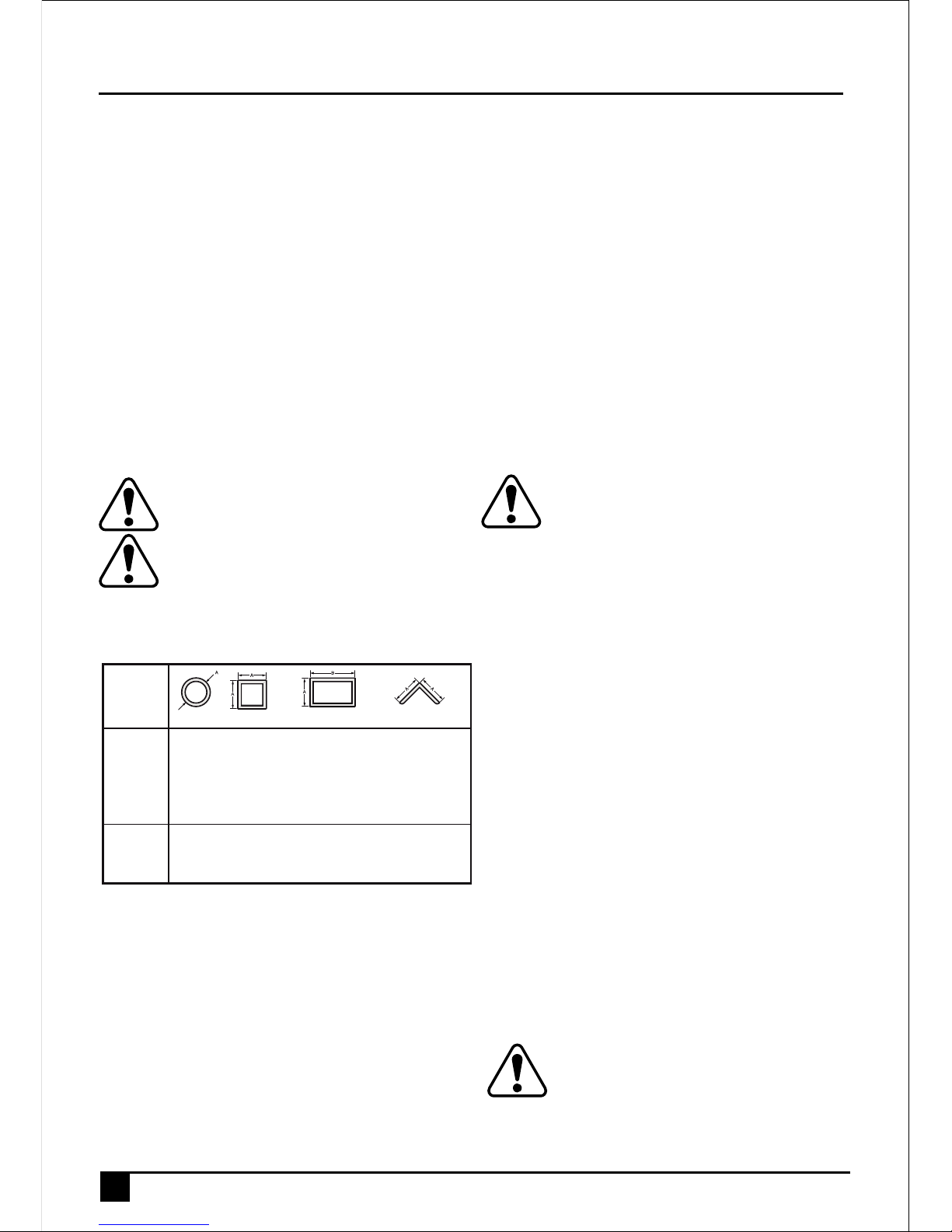

Cutting capacity

The wide vise opening and high pivot point provide cutting

capacity for many large pieces. Use the cutting capacity

chart to determine total maximum size of cuts that can be

made with a new wheel.

Caution: Certain large, circular or irregularly

shaped objects may require additional

holding means if they cannot be held

securely in vise.

Caution: do not cut magnesium with this tool.

Maximum cutting capacity

Note: Capacity shown on chart assumes no wheel wear and

optimum fence position.

Use

Standard equipment

• 355mm Metal Cutting Abrasive Wheel

• 1 Wheel Wrench

• 1 Instruction manual

To carry (fig. 1)

Fold down unit to position where you can carry the saw.

Push in lock pin (X) to lock arm down.

Unlocking (fig. 1)

To unlock tool and raise head, depress motor arm slightly

and pull lock pin (X) out. Motor arm will then pivot upward.

Spark deflector adjustment (fig. 1)

To best deflect sparks away from surrounding persons and

materials, loosen the screw (A), adjust the spark deflector

(B) and then retighten screw. Do not allow cordset to come

into contact with deflector or sparks as damage to cordset

may occur.

Depth stop (fig. 1)

Depth stop is set at the factory for a new 14" wheel to

prevent wheel from cutting into the supporting surface.To

allow more depth of cut, use the flat wrench provided (F) to

loosen the depth stop bolt (L) and raise bolt todesired height

and then turn jam nut (L) clockwise until seated firmly on the

casting. Securely tighten the depth stop bolt before use.

Caution: When changing to a new wheel,

readjust epth stop to original position to prevent

cutting intosupporting surface.

Trigger switch (fig. 1)

To start the tool, depress the trigger switch (M). To turn the

tool off, release the trigger switch. Keep hands and material

from wheel until it has coasted to a stop.To prevent

unauthorized use of tool, install a standard padlock (not

included) into the padlock hole (N) located inthe trigger.

Material clamping and supporting

• Angles are best clamped and cut with both legs resting

against base.

• A spacer block slightly narrower than the work piece can

be used to increase wheel utilization (Fig. 2).

• Long work pieces must be supported by a block so it will

be level with top of base (Fig. 3). The cut off end should

be free to fall downward to avoid wheel binding.

Vise operation (fig. 4)

The vise (E) has a quick-travel feature. To release the vise

when it is clamped tightly, turn the crank (G)

counterclockwise one or two times to remove clamping

pressure. Lift vise lever (H) up. Pull crank assembly out as

far asdesired. Vise may be pushed forward into work without

cranking. Lower vise lever (H) then tighten vise (E) onwork

by using crank (G).

Fence operation (fig. 5, 6)

Caution: Turn off and unplug the tool before

making any adjustments or removing or

installing attachments or accessories. Be

sure the trigger switch is in the OFF position.The fence

(D) can be adjusted two ways: to change desired cutting

angle and to change spacing between the fence and vise.

A x B

Workpiece

Shape:

90°

Cutting

Angle

45°

Cutting

Angle

A = 4-7/8"

(125mm)

A= 4-1/2"

(115mm)

A = 4-1/2"

(115mm)

A = 3-13/16"

(98mm)

4-1/2" x 5-1/8"

(115mm x 130mm)

4" x 7-5/8"

(102mm x 188mm)

3" x 7-3/8"

(76mm x 229mm)

4-1/2" x 3-13/16"

4-1/8" x 3-3/4"

(105mm x 95mm)

A = 4-1/2" x 5-3/8"

(115mm x 137mm)

A = 3-13/16"

3-3/4"

(95mm)

ENGLISH (Original instructions)

Page 7

7

To change the desired cutting angle

Use the wrench provided to loosen (do not remove) the two

fence bolts (O). Align the desired angle indicator line with

theslot line in the base (C). Securely tighten both fence bolts

before use. For more accurate square cuts, disconnect the

power supply, loosen the two fence bolts, push arm down

until wheel extends into base. Place a square against

thewheel and adjust fence against the square. Securely

tighten both fence bolts before use. When making a miter

cut, the vise (E) may not clamp securely, depending on the

thickness of the workpiece and the miter angle. Other aids

(such as spring, bar or C-clamps) will be necessary to

secure the work piece to the fence when making these cuts.

To change spacing between the fence and vise

Using the wrench provided, loosen and remove the two

fence bolts (O). Adjust the fence (D) to desired

locations.Insert both fence bolts in provided locations.

Securely tighten both fence bolts before use.

Removal and installation of wheels (fig. 7, 8)

Caution: Turn off and unplug the tool before

making any adjustments or removing or

installin gattachments or accessories. Be

sure the trigger switch is in the OFF position. Do not

make any adjustment while the wheel is in motion. Do not

make any adjustment while chop saw is plugged into power

supply.

1. Push in spindle lock (K) and rotate wheel (I) by hand

until wheel lock lever engages slot in inside flange(Q) to

lock wheel. Loosen the bolt (R) counterclockwise in the

center of the abrasive wheel with the 8mm hex wrench

(F). Bolt has right-hand thread.

2. Remove the bolt (S), washer (R), outside flange (T) and

old wheel (I).

3. Make sure flange surfaces are clean and flat. Install the

new abrasive wheel by reversing the above steps.

4. Do not overtighten bolt.

Warning: Check the work surface that the chop

saw rests on when replacing with a new

abrasive wheel. Itis possible that the wheel may

contact ANY ITEMS OR STRUCTURE THAT EXTENDS

ABOVE work surface (under the base) when the arm is fully

lowered.

Operation tips for more accurate cuts

• Allow the wheel to do the cutting. Excessive force will

cause the wheel to glaze reducing cutting efficiency

and/or to deflect causing inaccurate cuts.

• Properly adjust fence angle.

• Make sure material is laying flat across base.

• Properly clamp material to avoid movement and

vibration.

Motor brush inspection and replacement (fig.9)

Warning:Turn off and unplug the tool. Be sure

the trigger switch is in the OFF position.

Brushes should be regularly inspected for wear.

To inspect brushes, unscrew the two end cap screws (V) and

remove end cap (W). Remove brush cap (Y). Brushes (X)

should slide freely in brush box.

If brushes are worndown to .3" (8mm) as shown in Figure 9

they should be replaced. To reinstall, push new brush back

into brushbox. If replacing existing brush, maintain same

orientation as when removed. Replace the brush cap (do not

overtighten). Replace end cap and two screws. Tighten

securely.

Accessories

The performance of any power tool is dependent upon the

accessory used. STANLEY accessories areengineered to

high quality standards and are designed to enhance the

performance of power tool.

Note: Accessory must be rated for use at speed

equal to or higher than nameplate RPM of tool

with which it is being used.

Caution: The use of any other accessory not recommended

for use with this tool could be hazardous.Use only

high-strength Type 1 organic bonded wheels rated 4100 rpm

or higher. Recommended accessories for use with your tool

are available at extra cost from your local dealer or

authorized service center.

(Original instructions) ENGLISH

Page 8

8

Maintenance

Your STANLEY power tool has been designed to operate

over a long period of time with a minimum of

maintenance.Continuous satisfactory operation depends

upon proper tool care and regular cleaning.Your tool is not

user-serviceable. Take the tool to an authorized STANLEY

repair agent. This tool should be serviced at regular

intervals or when showing a noticeable change in

performance.

Lubrication

STANLEY power tools are properly lubricated at the factory

and are ready for use. Tools should be re-lubricated

regularly , depending on usage. This lubrication should only

be attempted by trained power tool repair persons, such as

those at STANLEY service centers or by other qualified

service personnel. Closed-type, grease-sealed ball bearings

are used throughout. These bearings have sufficient

lubricationpacked in them at the factory to last the life of the

chop saw.

Cleaning

Warning: unplug the tool before you use a cloth

to clean the housing.With the motor running,

blow dirt and dust out of all air vents with dry air

at least once a week. Wear safety glasses when performing

this. Exterior plastic parts may be cleaned with a damp cloth

and mild detergent. Although these parts are highly solvent

resistant, NEVER use solvents.

Blowing dust and grit out of the main housing by means of

an air hose is recommended and may be done as often as

dirt is seen collecting in and around the air vents. Always

wear proper eye and respiratory protection.

Tool care

Avoid overloading the machine.Overloading will result in a

considerable reduction in speed and efficiency and the unit

will become hot. In this event,run the machine at no load for

a minute or two until cooled to normal working temperature

by the built in fan. Switching your machine on and off whilst

under load will considerably reduce the life of the switch.

Important

To ensure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment (other than those listed in this

manual) should be performed by authorized service centers

or other qualified organizations, always-using identical

replacement parts. Unit contains no user serviceable parts

inside.Blowing dust and grit out of the main housing by

means of an air hose is recommended and may be done as

often as dirt is seen collecting in and around the air vents.

Always wear proper eye and respiratory protection.

Note: Unit may be converted to a 3-wire twist lock cord set

at an authorized service center.

Notes

• STANLEY's policy is one of continuous improvement to

our products and, as such, we reserve the right

tochange product specifications without prior notice.

• Standard equipment and accessories may vary by

country.

• Product specifications may differ by country.

• Complete product range may not be available in all

countries.

• Contact your local STANLEY dealers for range

availability.

ENGLISH (Original instructions)

Page 9

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your STANLEY product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

STANLEY provides a facility for the collection and recycling

of STANLEY products once they have reached the end of

their working life. To take advantage of this service please

return your product to any authorised repair agent who will

collect them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local STANLEY office at the

address indicated in this manual. Alternatively, a list of

authorised STANLEY repair agents and full details of our

after-sales service and contacts are available on the Internet

at: www.2helpU.com

9

Technical data

Specifications STSC2135

POWER W 2100

NO-LOAD SPEED /min 3800

MAX. DIAMETER mm 355

Weight kg 15.5

STANLEY declares that these products described under

"technical data" are in compliance with:

2006/42/EC, EN 61029-1, EN 61029-2-10

These products also comply with Directive

“2004/108/EC (until 19.04.2016),

2014/30/EU (from 20.04.2016)” and 2011/65/EU.

For more information, please contact STANLEY at the

following address or refer to the back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

STANLEY.

R.Laverick

Engineering Manager

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2015

EC declaration of conformity

MACHINERY DIRECTIVE

STSC2135

LpA (sound pressure) dB(A) 95,5

K

pA

(sound pressure uncertainty) dB(A) 3

LWA (sound power) dB(A) 105,5

KWA (sound power uncertainty) dB(A) 3

Vibration emission value a

h

a

h

= m/s² 4.3

Uncertainty K = m/s² 1.5

(Original instructions) ENGLISH

Page 10

10

Service Information

STANLEY offers a full network of company-owned and

authorized service locations. All STANLEY Service Centers

are staffed with trained personnel to provide customers with

efficient and reliable power tool service. For more information

about our authorized service centers and if you need

technical advice, repair, or genuine factory replacement

parts, contact the STANLEY location nearest you.

Two years full warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY guarantees to replace all defective

parts free of charge or – at our discretion – replace the unit

free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

ENGLISH (Original instructions)

Page 11

11

İŞ PARÇASININ ÇAPI

DESTEK PARÇASININ GENİŞLİĞİ

DESTEK PARÇASI

E

F

X

.3 "

(8m m)

ŞEKİL A

ŞEKİL I

E

H

I

F

P

İLERİ

ŞEKİL G

L

ŞEKİL H

R

J

U

T

S

Y

W

V

K

J

F

H

I

L

N

o

A

M

G

X

E

D

KESİLMİŞ UÇ

TAHTA PARÇA

C

B

F

P

A

E

ŞEKİL F

P

E

AD

ŞEKİL B

ŞEKİL C

ŞEKİL D ŞEKİL E

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Page 12

12

Kullanım amacı

Stanley profil kesme makineniz kesim uygulamaları için

tasarlanmıştır.

Genel güvenlik kuralları

Uyarı! Tüm talimatları okuyun. Aşağıda belirtilen tüm

talimatların herhangi birisine uyulmaması elektrik çarpması,

yangın ve/veya ciddi yaralanma riskine neden olabilir.

Aşağıda yer alan uyarılardaki «elektrikli alet» terimi şebeke

elektriğiyle (kablolu) veya akü/pille (şarjlı) çalışan elektrikli

aletinizi ifade etmektedir.

BU TALİMATLARI SAKLAYIN.

1. Çalışma alanı

a. Çalışma alanını temiz ve aydınlık tutun. Karışık ve

karanlık alanlar kazaya davetiye çıkartır.

b. Elektrikli aletleri, yanıcı sıvılar, gazlar ve tozların

bulunduğu yerler gibi yanıcı ortamlarda

çalıştırmayın. Elektrikli aletler, toz veya dumanları

ateşleyebilecek kıvılcımlar çıkartır.

c. Bir elektrikli aleti çalıştırırken çocuklardan ve

etraftaki kişilerden uzak tutun. Dikkatinizi dağıtıcı

şeyler kontrolü kaybetmenize neden olabilir.

2. Elektrik güvenliği

a. Elektrikli aletlerin fişleri prizlere uygun olmalıdır. Fiş

üzerinde kesinlikle hiçbir değişiklik yapmayın.

Topraklı elektrikli aletlerde hiçbir adaptör fişi

kullanmayın. Değiştirilmemiş fişler ve uygun prizler

elektrik çarpması riskini azaltacaktır.

b. Borular, radyatörler, ocaklar ve buzdolapları gibi

topraklanmamış yüzeylerle vücut temasından

kaçının. Vücudunuzun topraklanması halinde yüksek bir

elektrik çarpması riski vardır.

c. Elektrikli aletleri yağmura maruz bırakmayın veya

ıslatmayın. Elektrikli alete su girmesi elektrik çarpması

riskini arttıracaktır.

d. Elektrik kablosunu uygun olmayan amaçlarla

kullanmayın. Elektrikli aleti kesinlikle kablosundan

tutarak taşımayın, çekmeyin veya prizden

çıkartmayın. Kabloyu sıcaktan, yağdan, keskin

kenarlardan veya hareketli parçalardan uzak tutun.

Hasarlı veya dolaşmış kablolar elektrik çarpması riskini

arttırır.

e. Elektrikli bir aleti açık havada çalıştırıyorsanız, açık

havada kullanıma uygun bir uzatma kablosu

kullanın. Açık havada kullanıma uygun bir kablonun

kullanılması elektrik çarpması riskini azaltır.

f. Eğer bir elektrikli aletin nemli bir bölgede

çalıştırılması zorunluysa, bir artık akım aygıtı (RCD)

korumalı bir kaynak kullanın. Bir RCD kullanılması

elektrik şoku riskini azaltır.

Not: «Artık Akım Aygıtı (RCD)» tanımı, «Kaçak Akım

Koruma Cihazı (GFCI)» veya «Toprak Kaçağı Devre Kesici

(ELCB)» tanımları ile değiştirilebilir.

3. Kişisel güvenlik

a. Elektrikli bir aleti kullanırken her zaman dikkatli olun,

yaptığınız işe yoğunlaşın ve sağduyulu davranın.

Elektrikli bir aleti yorgunken veya ilaç ya da alkolün

etkisi altındayken kullanmayın. Elektrikli aletleri

kullanırken bir anlık dikkatsizlik ciddi kişisel

yaralanmayla sonuçlanabilir.

b. Kişisel koruyucu ekipmanları kullanın. Daima

koruyucu gözlük takın. Koşullara uygun toz maskesi,

kaymayan güvenlik ayakkabıları, baret veya kulaklık gibi

koruyucu donanımların kullanılması kişisel yaralanmaları

azaltacaktır.

c. Aletin istem dışı çalıştırılmasını engelleyin. Elektrik

şebekesine bağlamadan önce aletin kapalı

olduğundan emin olun. Aleti, parmağınız düğme

üzerinde bulunacak şekilde taşımak veya açık

konumdaki elektrikli aletleri elektrik şebekesine bağlamak

kazaya davetiye çıkartır.

d. Elektrikli aleti açmadan önce tüm ayarlama

anahtarlarını çıkartın. Elektrikli aletin hareketli bir

parçasına takılı kalmış bir anahtar kişisel yaralanmaya

neden olabilir.

e. Ulaşmakta zorlandığınız yerlerde kullanmayın. Daima

sağlam ve dengeli basın. Bu, beklenmedik durumlarda

elektrikli aletin daha iyi kontrol edilmesine olanak tanır.

f. Uygun şekilde giyinin. Bol elbiseler giymeyin ve takı

takmayın. Saçınızı, elbiselerinizi ve eldivenlerinizi

hareketli parçalardan uzak tutun. Bol elbiseler ve

takılar veya uzun saç hareketli parçalara takılabilir.

g. Eğer kullandığınız üründe toz emme ve toplama

özellikleri olan ataşmanlar varsa bunların bağlı

olduğundan ve doğru şekilde kullanıldığından emin

olun. Bu ataşmanların kullanılması tozla ilgili tehlikeleri

azaltabilir.

4. Elektrikli aletlerin kullanımı ve bakımı

a. Elektrikli aleti zorlamayın. Uygulamanız için doğru

elektrikli aleti kullanın. Doğru elektrikli alet, belirlendiği

kapasite ayarında kullanıldığında daha iyi ve güvenli

çalışacaktır.

b. Düğme açmıyor ve kapatmıyorsa elektrikli aleti

kullanmayın. Tetikle kontrol edilemeyen tüm elektrikli

aletler tehlikelidir ve tamir edilmesi gerekmektedir.

c. Herhangi bir ayarlama, aksesuar değişimi veya

elektrikli aletlerin saklanması öncesinde fişi güç

kaynağından çekin ve/veya aküyü elektrikli aletten

ayırın. Bu tür önleyici güvenlik tedbirleri aletin istem

dışı olarak çalıştırılması riskini azaltacaktır

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

DUMMY TEXT

Page 13

13

d. Elektrikli aleti, çocukların ulaşamayacağı yerlerde

saklayın ve elektrikli aleti tanımayan veya bu

talimatları bilmeyen kişilerin elektrikli aleti

kullanmasına izin vermeyin. Elektrikli aletler, eğitimsiz

kullanıcıların elinde tehlikelidir.

e. Elektrikli aletleri iyi durumda muhafaza edin.

Hareketli parçalardaki hizalama hatalarını ve

tutuklukları, parçalardaki kırılmalar ve elektrikli

aletin çalışmasını etkileyebilecek tüm diğer koşulları

kontrol edin. Hasarlı ise, elektrikli aleti kullanmadan

önce tamir ettirin. Kazaların çoğu, elektrikli aletlerin

bakımının yeterli şekilde yapılmamasından kaynaklanır.

f. Elektrikli aleti, aksesuarlarını ve aletin diğer

parçalarını kullanırken bu talimatlara mutlaka uyun

ve çalışma ortamının koşullarını ve yapılacak işin ne

olduğunu göz önünde bulundurun. Elektrikli aletin

öngörülen işlemler dışındaki işlemler için kullanılması

tehlikeli durumlara neden olabilir.

5. Servis

a. Elektrikli aletinizi, sadece orijinal yedek parçaların

kullanıldığı yetkili servise tamir ettirin. Bu, elektrikli

aletin güvenliğinin muhafaza edilmesini sağlayacaktır.

Profil kesmeler için ek güvenlik talimatları

• Her zaman koruyucu gözlük ve solunum korumasını

kullanın.

• Kullanmadan önce, kesme diskinde herhangi bir

çatlak ya da yarık olup olmadığını kontrol edin.

Üzerinde çatlak ya da yarık olan kesme diskini atın.

Aletin düşmüş olabileceğini düşünüyorsanız her

zaman kesme diski kontrol edin. Çatlaklar veya

yarıklar disk kırılmasına neden olabilir.

• Yeni veya değiştirilmiş diski taktıktan sonra veya

diskin durumundan emin değilseniz aleti iyi

korunmuş bir alana yerleştirin ve bir dakika boyunca

çalışmasına izin verin. Diskte fark edilmemiş bir çatlak

ya da yarık varsa, bir dakikadan daha kısa bir süre

içinde disk kırılacaktır. Disk ile aynı hizada insanlar

varsa, aleti asla çalıştırmayın. Bu koşul kullanıcı için de

geçerlidir.

• Çalışma esnasında, diskin yerinden oynamasını

engelleyin veya diski zorlamayın. Aksi olursa, aleti

durdurun ve diskinde herhangi bir çatlak ya da yarık olup

olmadığını kontrol edin.

• Bu kılavuzdaki prosedürü izleyerek periyodik olarak

profil kesmenizi temizleyin.

Kullanim sirasinda

• Testere bıçağı bloke olur • Eğer, derhal aleti kapatın ve

fişini çekin; ancak o zaman kamalı parçasını kaldırmak

• sıkışma veya elektrik veya mekanik arıza durumunda,

derhal aleti kapatın ve fişini çekin

• Disk muhafazası veya tabanı çıkartmayın.

• MALZEMEYİ SABİTLEMEK İÇİN HER ZAMAN

MENGENE VEYA BAŞKA BAĞLANTI

EKİPMANLARINI KULLANIN. Yay, pala veya C-kelepçe

gibi diğer yardımcı ekipmanlar iş parçasının boyutlara ve

şekillere uygun olmalıdır. Bu kelepçelerin seçim ve

yerleştirme sırasında dikkatli olun ve bir asıl kesim

yapmadan önce deneme çalışmasını yapın.

• Sadece 355 mm (14") 4100 dev/dak veya daha yüksek

nominal hıza sahip olan tip 1 diskleri kullanın.

• Ellemeden önce kesilen parçaların soğumasına izin

verin.

• Ahşap veya plastik malzemeleri kesmeye kalkışmayın.

• ASLA MAGNEZYUM MALZEMELER KESMEYİN.

• Profil kesmeyi iyi havalandırılan bir alanda kullanın.

• Tabandan herhangi parça çıkartmadan önce kesme

profilinizi kapatın.

• ELEKTRİĞE BAĞLI MALZEMELERİ KESMEYİN.

• Bu aletle dairesel kesim bıçaklarını veya diğer dişli

bıçakları kullanmayın. Ciddi yaralanmaya neden

olabilir.

• ALETİ YANICI SIVILAR VEYA GAZLARIN YANINDA YA

DA TOZLU ALANLARDA KULLANMAYIN. Kesmeden

kaynaklanan kıvılcım veya sıcak yonga ya da yaylı motor

fırçaları, yanıcı maddelerin tutuşmasına neden olabilir.

• Aşındırıcı diskin kenarını taşlama işlemleri için

kullanmayın. Bu büyük ölçüde diski zayıflatır ve tehlikeli

bir duruma yol açabilir. Disk aletten çıkabilir.

Uyarı: Aleti kullanırken koruyucu kulaklık

takın. Bazı koşullarda ve kullanım süresine göre

bu aletin gürültüsü işitme kaybına neden olabilir.

Uyarı: Kıvılcım yön saptırıcısı ısınacaktır.

Sıcakken dokunmaktan ve ayarlamaktan

kaçının. Kablo ve malzemeleri kıvılcım yön

saptırıcısından uzak tutun.

• Zımpara, kesme, taşlama, delme ve diğer inşaat

faaliyetleri sırasında toz ile uzun süreli temastan

kaçının. Koruyucu giysiler giyin ve açıkta kalan

yerlerinizi sabun ve su ile yıkayın. Tozun ağıza, göze

girmesi veya cilt üzerinde bulunması zararlı kimyasallar

emilimini teşvik edebilir.

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

DUMMY TEXT

Page 14

14

Uyarı: Her zaman NIOSH / OSHA tarafından

onaylı toz maruziyeti için uygun bir solunum

korumasını kullanın. Yüzünüzü ve vücudunuzu

uçan parçacıklardan uzakta tutun. Sizin rahatlığınız ve

güvenliğiniz için, ağır hizmet tipi 14"(355mm) profil kesmeniz

üzerinde aşağıdaki uyarılar vardır:

Güvenli bir çalışma için kullanım kılavuzunu

okuyun.

• Dişli diskleri kullanmayın.

• Sadece 4100 dev/dak veya daha yüksek devirli

güçlendirilmiş diskler kullanın.

• Servis işlemleri sırasında sadece orijinal yedek

parçaları kullanının.

• Her zaman göz koruması takın, muhafazalar kullanın,

çalışma parçasını mengene ile sabitleyin, uygun

soluma koruması kullanın.

• Aleti ıslak yerlerde kullanmayın veya yağmura maruz

bırakmayın.

• Sadece maksimum kalınlığı 2,8 mm olan ve

maksimum çapı 355 mm olan profil kesme diski

kullanın.

Titreşim

Teknik veriler ve uygunluk beyanatı içerisinde belirtilen

titreşim emisyon değerleri EN61029 tarafından belirlenen

standart bir test yöntemine uygun olarak ölçülmektedir ve

diğer bir aletle karşılaştırma yaparken kullanılabilir. Beyan

edilen titreşim emisyon değeri aynı zamanda maruz

kalmanın önceden değerlendirilmesinde de kullanılabilir.

Uyarı! Elektrikli aletin mevcut kullanımı sırasındaki titreşim

emisyon değeri, aletin kullanım yöntemine bağlı olarak,

beyan edilen değere göre farklılık sergileyebilir. Titreşim

düzeyi belirlenen seviyenin üzerinde artış gösterebilir.

İşyerinde düzenli olarak elektrikli alet kullanan çalışanları

korumak amacıyla 2002/44/EC tarafından getirilen elektrik

güvenliği önlemlerini belirlemek üzere titreşime maruz

kalmayı değerlendirirken, çalışma döngüsü içerisinde

örneğin aletin kapalı olduğu ve aktif durumda olmasının yanı

sıra boşta çalıştığı zamanlar gibi, bütün zaman dilimleri dahil

olmak üzere mevcut kullanım durumu ve aletin kullanım şekli

göz önünde bulundurularak değerlendirilmelidir.

Elektrik güvenliği

Uyarı! Elektrik kablosu hasarlı ise, bir tehlike oluşmasını

önlemek için üretici ya da yetkili Stanley Servis Merkezi

tarafından değiştirilmelidir. Elektrik kablosu Stanley yetkili

servisi haricinde değiştirilirse, garanti geçerli olmayacaktır.

Açıklama (Şekil 1, 4)

A. Kıvılcım yön saptırıcısı vidası

B. Kıvılcım yön saptırıcısı

C. Taban

D. Kesme kılavuzu

E. Mengene

F. Düz anahtar

G. Döndürme kolu

H. Mengene kolu

I. Disk

J. Muhafaza

K. Mil kilidi

L. Derinlik ayarı cıvata ve emniyet somunu

M. Açma/kapama tetik düğmesi

V ........ Volt

A ........ Amper

Hz ....... Hertz

W ........ Vat

dak ..... dakika

.....

.....

boş .......

......

....

....

.../min..

7. Alet üzerindeki etiketler

Alet üzerinde aşağıdaki semboller bulunabilir:

Kullanım

Kılavuzunu

Okuyun

Koruyucu

Gözlük kullanın

Kulaklık

Kullanın

Alternatif

Akım

Direkt

Akım

Yüksüz

Hız

Sınıf II

İnşaat

Topraklama

Terminal

Güvenlik

uyarısı

Sembolü

Dakikada

devir veya

gel git sayısı

Tarih kodu konumu

İmalat yılını da içeren Tarih Kodu gövdeye basılıdır.

Örnek:

2014 XX JN

İmalat Yılı

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

Page 15

15

N. Asma kilit deliği

O. Kesme kılavuzu cıvataları

X. Kilit pimi

Şebeke gerilimi

Her zaman şebeke geriliminin aletin üretim etiketinde

belirlenmiş değerlere uyup uymadığını kontrol edin. %

10'dan daha fazla bir gerilim azalması güç kaybına ve aşırı

ısınmaya neden olacaktır.

Kesme kapasitesi

Geniş açılan mengene ve yüksek dönme noktası birçok

geniş malzemenin kesilmesi için gerekli kapasiteyi sağlar.

Yeni bir diskle kesilebilecek maksimum kesme ölçüsünü

belirlemek için kesme kapasitesi tablosunu kullanın.

Uyarı: Bazı geniş, dairesel veya düz olmayan

şekilli nesneler, mengene ile güvenli bir

şekilde sabitlenemeyebilir ve ek tutma

desteğine ihtiyaç duyabilir.

Uyarı: Bu aletle magnezyum kesmeyin.

Maksimum kesme kapasitesi

Not: Tabloda gösterilen kapasite aşınmamış disk ve en

uygun mengene konumuna göre kabul edilmiştir.

Kullanımı

tandart ekipman

• 355mm Metal Kesme Aşındırıcı Diski

• Disk anahtarı

• Kullanım kılavuzu

Taşıma (Şekil 1)

Aleti taşımak için ilk önce alet katlanmalıdır. Kilit pimi (X)

yardımı ile profil kesme kafasını sabitleyin.

Kilidi Açma (Şekil 1)

Aletin kilidini açmak ve kafasını kaldırmak için motor

gövdesine hafif olarak basın ve kilit pimini (X) çıkartın. Motor

gövdesi yukarı doğru dönecektir.

Kıvılcım Yön Saptırıcısının Ayarlanması (Şekil 1)

Çevredeki kişiler ve malzemelerden kıvılcımları daha iyi

saptırmak için vidayı (A) gevşetin, kıvılcım yön saptırıcısını

(B) ayarlayın ve ardından vidayı sıkın. Kablonun saptırıcı

veya kıvılcım ile temas etmesine izin vermeyin, hasar

oluşabilir.

Derinlik Ayarı (Şekil 1)

Derinlik ayarı, destek yüzeyinin kesmesini önlemek için yeni

bir 355 mm (14 ") disk için fabrikada ayarlanmıştır. Kesme

derinliği ayarlamak için aletle verilen düz anahtarı (F)

kullanarak derinlik ayarı cıvatasını (L) gevşetin, cıvatayı

istenilen yüksekliğe kaldırın ve emniyet somununu (L) saat

yönünde sonuna kadar sıkın. Aleti kullanmadan önce derinlik

ayarı cıvatasını iyice sıkın.

Diski değiştirirken derinlik ayarını, destek

yüzeyinin kesmesini önlemek için daima orijinal

konumuna ayarlayın.

Açma/Kapama Tetik Düğmesi (Şekil 1)

Aleti açmak için, açma/kapama tetik düğmesine (M) basın.

Aleti kapatmak için, açma/kapama tetik düğmesini bırakın.

Alet tamamen durana kadar elleri ve malzemeleri diskten

uzak tutun. Aletin izinsiz kullanılmasını önlemek için standart

bir asma kilidi (alet ile birlikte verilmemektedir), tetik

mekanizmasında bulunan asma kilit deliğine (N) takın.

Malzeme Sıkıştırma ve Destekleme

• Açılı kesimler her iki köşe de taban üzerinde

desteklendiğinde en iyi şekilde sıkıştırılır ve kesilir.

• Kesim kapasitesini arttırmak için, çalışma parçasının

altına bir destek parçası yerleştirin. Destek parçası,

çalışma parçasından biraz daha dar olmalıdır (Şekil 2).

• Uzun çalışma parçalarını taban yüzeyi ile hizalayarak bir

parça tahta kullanarak destekleyin (Şekil 3). Diskin

sıkışmasını önlemek için kesilmiş uç serbest olarak aşağı

düşmelidir.

Mengene Kullanımı (Şekil 4)

Mengene (E), hızlı hareket özelliğine sahiptir. Fazla sıkılmış

mengeneyi serbest bırakmak için döndürme kolunu (G) bir

veya iki tur saat yönünün tersine çevirin ve mengeneyi

gevşetin. Mengene kolunu (H) yukarı kaldırın. Döndürme

kolunu istediğiniz kadar dışarı çekin. Mengene, döndürme

kolunu kullanmadan çalışılan parçaya doğru itilebilir.

Mengene kolunu (H) aşağı indirin ve mengeneyi (E)

döndürme kolunu (G) kullanarak çalışılan parça üzerinde

sıkın.

A x B

Çalışma

parçası

şekli:

90°

Kesme

Açısı

45°

Kesme

Açısı

A = 4-7/8"

(125mm)

A= 4-1/2"

(115mm)

A = 4-1/2"

(115mm)

A = 3-13/16"

(98mm)

4-1/2" x 5-1/8"

(115mm x 130mm)

4" x 7-5/8"

(102mm x 188mm)

3" x 7-3/8"

(76mm x 229mm)

4-1/2" x 3-13/16"

4-1/8" x 3-3/4"

(105mm x 95mm)

A = 4-1/2" x 5-3/8"

(115mm x 137mm)

A = 3-13/16"

3-3/4"

(95mm)

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Page 16

16

Kesme Kılavuzu Kullanımı (Şekil 5, 6)

Uyarı: Herhangi bir ayarlama veya

aksesuarları takıp çıkarmadan önce aleti

kapatın ve fişini çekin. Tetik düğmesinin

kapalı konumda olduğunu kontrol edin.

Kesme kılavuzu (D) iki şekilde ayarlanabilir: istenilen kesim

açısının değiştirerek ve kesme kılavuzu ve mengene

arasındaki aralığı değiştirerek.

İstenilen Kesme Açısının Değiştirilmesi

Aletle birlikte verilen anahtarı kullanarak iki adet kesme

kılavuzu cıvatasını (O) gevşetin (ama çıkartmayın). İstenilen

açı gösterge çizgisini taban (C) üzerindeki bölme ile

hizalayın. Aleti kullanmadan önce her iki kesme kılavuzu

cıvatasını sağlam bir şekilde sıkın. Daha hassas köşeli

kesimler için, aleti güç kaynağından ayırın, iki kesme

kılavuzu cıvatasını gevşetin ve disk tabanına ulaşına kadar

kesme kafasını aşağı itin. Diskin karşısına bir köşebent

yerleştirin ve kesme kılavuzunu köşebente göre ayarlayın.

Aleti kullanmadan önce her iki kesme kılavuzu cıvatasını

sağlam bir şekilde sıkın. Gönye kesimleri yaparken

mengene (E), çalışılan parça kalınlığına ve gönye açısına

göre sabitlenmelidir. Böyle kesimler yaparken çalışılan

parçayı kesme kılavuzuna sabitlemek için başka yardımcı

ekipmanlar da gerekebilir (yay, pala, C-kelepçe gibi).

Kesme Kılavuzu Ve Mengene Arasındaki Aralığı

Değiştirilmesi

Aletle birlikte verilen anahtarı kullanarak iki adet kesme

kılavuzu cıvatasını (O) gevşetin ve çıkartın. Kesme

kılavuzunu (D) istenilen pozisyonuna ayarlayın. Sunulan

yerlere her iki kesme kılavuzu cıvatalasını yerleştirin. Aleti

kullanmadan önce her iki kesme kılavuzu cıvatasını sağlam

bir şekilde sıkın.

Kesme Diskinin Takılması ve Çıkartılması (Şekil 7, 8)

Uyarı: Herhangi bir ayarlama veya

aksesuarları takıp çıkarmadan önce aleti

kapatın ve fişini çekin. Tetik düğmesinin

kapalı konumda olduğunu kontrol edin. Disk hareket

ederken herhangi bir ayar yapmayın. Profil kesme elektrik

prizine takılıyken, herhangi bir ayarlamayı yapmayın.

1. Kesme diskini sabitleyin. Bunun için mil kilidine (K)

basın ve diskin (I) sabitleme kolu iç flanşın (Q)

üzerindeki yuvaya oturana kadar elle çevirin. Aşındırıcı

diskin merkezinde bulunan cıvatayı (R) 8 mm altıgen

anahtarı (F) kullanarak saatin ters yönünde çevirerek

gevşetin. Cıvata sağ oluğa sahiptir.

2. Cıvatayı (R), pulu (S), dış flanşı (T) ve eski kesme

diskini (I) çıkartın.

3. Flanş yüzeylerinin temiz ve düz olduğundan emin olun.

Yukarıdaki adımları tersten izleyerek teni kesme diskini

takın.

4. Cıvatayı aşırı sıkmayın.

Uyarı: Yeni aşındırıcı diski takarken profil

kesmenin yerleştirildiği çalışma yüzeyini kontrol

edin. Kesme kafası tamamen indirilmiş

olduğunda disk çalışma yüzeyinin üstünde

UZANAN (tabanın altında) HERHANGİ BİR ÖĞE YA DA

YAPI ile temas edebilir.

Daha Hassas Kesimler İçin Çalışma Tavsiyeleri

• Kesme diskine kesim yapmasına izin verin. Aşırı kuvvet

uygulanması diskin kesme verimliliğini azaltacak ve /

veya diskin saptırılmasına ve hatalı kesimlere neden

olacaktır.

• Kesme kılavuzu açısını doğru bir şekilde ayarlayın.

• Malzemenin taban üzerinde düz bir şekilde

yerleştiğinden emin olun.

• Hareket etmesini ve titreşimi önlemek için malzemeyi

sağlam bir şekilde sabitleyin.

Motor Kömürünün Kontrol Edilmesi ve Değiştirilmesi

(Şekil 9)

Uyarı: Aleti kapatın ve fişten çekin. Tetik

düğmesinin kapalı konumda olduğunu

kontrol edin. Kömürler düzenli olarak aşınma

durumu için kontrol edilmelidir. Kömürleri kontrol

etmek için arka kapaktaki iki vidayı (V) sökün ve arka kapağı

(W) çıkartın. Kömür kapağını (Y) sökün. Kömürler (X) kömür

yuvası içinde serbestçe kaymalıdır.

Eğer kömürler Şekil 9'da gösterildiği gibi 8mm'nin (3") altına

inecek şekilde aşınmışlarsa değiştirilmelidir. Yeniden takmak

için, yeni kömürü, kömür yuvasının içine itin. Eğer mevcut

kömürü yeniden takıyorsanız, çıkardığınız şekilde, aynı

yönde takın. Kömür kapağını yerine takın (gereğinden fazla

sıkmayın). Arka kapağı ve iki vidasını yerine takın. İyice

sıkın.

Aksesuarlar

Herhangi bir elektrikli aletin performansı kullanılan

aksesuarlara bağlıdır. STANLEY aksesuarları, yüksek kalite

standartlarına göre üretilmiş ve elektrikli aletinizin

performansını arttıracak şekilde tasarlanmıştır.

Not:

Aksesuarın nominal hızı, kullanıldığı

elektrikli alet üzerinde yazan maksimum hıza

eşit olmalı veya bundan yüksek olmalıdır.

Uyarı: Bu alet ile kullanılması önerilmeyen aksesuarların

kullanılması ciddi yaralanmaya yol açabilir. Sadece 4100

dev/dak veya daha yüksek bir değere sahip organik

bağlamalı yüksek dayanıklılığa sahip Tip 1 diskleri kullanın.

Aletinizle kullanılabilecek, tavsiye edilen aksesuarlar bedeli

karşılığı satış noktalarından temin edilebilir.

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

Page 17

17

Bakım

STANLEY elektrikli aletiniz minimum bakımla uzun bir süre

çalışacak şekilde tasarlanmıştır. Kesintisiz olarak

memnuniyet verici bir şekilde çalışması gerekli özenin

gösterilmesine ve düzenli temizliğe bağlıdır. Bu aletin servisi

kullanıcı tarafından yapılamaz. Aleti yetkili STANLEY

servisine götürün. Bu alet, belirli aralıklarla veya

performansında gözle görülür bir değişiklik gösterince

bakıma götürülmelidir.

Yağlama

STANLEY elektrikli el aletleri, fabrikada uygun bir şekilde

yağlanmıştır ve çalışmaya hazırdır. Aletler, kullanımına bağlı

olarak, düzenli bir şekilde yağlanmalıdır. Bu yağlama

sadece STANLEY servislerindeki gibi eğitimli elektrikli el

aleti tamir personeli tarafından yapılmalıdır. Aletin

tamamında kapalı tipte, yağ sızdırmaz bilyalı yataklar

kullanılmıştır. Bu yataklar, fabrikada profil kesmenin kullanım

ömrü boyunca yetecek miktarda yağla doldurulmuştur.

Temizleme

Uyarı: Aletin gövdesini bezle temizlemeden

önce fişini şebekeden çekin. Tüm hava

deliklerini, motor çalışırken haftada en az bir

kere kuru hava ile kir ve tozdan temizleyin. Bu uygulamayı

yaparken koruyucu gözlük takın. Dış plastik parçalar nemli

bir bezle ve yumuşak deterjanla silinebilir. Bu parçaların,

çözücüye karşı yüksek direnci olmasına rağmen, çözücü

maddeleri ASLA kullanmayın.

Havalandırma çıkışlarının içinde ve civarında toz birikmeye

başladığında, hortumla hava üfleyerek ana gövdenin toz ve

kirden temizlenmesi önerilir. Her zaman koruyucu gözlük ve

solunum korumasını kullanın.

Alet bakımı

Aşırı yüklemeden kaçının. Aşırı yüklenme hız ve verimliliğin

azalmasına neden olacak ve alet ısınacaktır. Bu durumda

dahili fan sayesinde normal çalışma sıcaklığına soğuyana

kadar bir ya da iki dakika boyunca makineyi yüksüz

çalıştırın. Aletinizi yük altında iken kapatmanız açma/kapama

düğmesinin ömrünü azaltacaktır.

Önemli

Alet EMNİYET GÜVENLİĞİ ve GÜVENİLİRLİK için bu

kılavuzda belirtilenler dışında tamir, bakım ve ayarlamaların

her zaman orijinal yedek parça kullanılarak, yetkili servisler

tarafından yapılması gerekmektedir. Aletin içinde bakımı

kullanıcı tarafından yapılabilecek herhangi bir parça yoktur.

Havalandırma çıkışlarının içinde ve civarında toz birikmeye

başladığında, hortumla hava üfleyerek ana gövdenin toz ve

kirden temizlenmesi önerilir. Her zaman koruyucu gözlük ve

solunum korumasını kullanın.

Not: Alet kablosu yetkili serviste üç telli kablo seti ile

değiştirilebilir.

Notlar

• STANLEY olarak, ürünlerimizi sürekli iyileştirme

politikası uyguladığımızdan, önceden haber vermeden

ürün özelliklerini değiştirme hakkını saklı tutarız.

• Standart ekipman ve aksesuarlar ülkeye göre değişebilir.

• Ürün özellikleri ülkelere göre farklı olabilir.

• Komple ürün çeşidi tüm ülkelerde geçerli olmayabilir.

• Ürün çeşidi durumu hakkında lütfen en yakın STANLEY

yetkili servisiyle temas kurun.

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Page 18

18

Çevrenin korunması

Ayrı olarak atın. Bu ürün, normal evsel atıklarla

birlikte atılmamalıdır.

STANLEY ürününüzün değiştirilmesi gerektiğini düşünmeniz

veya artık kullanılamaz durumda olması halinde onu, evsel

atıklarla birlikte atmayın. Bu ürünü, ayrı olarak toplanacak

şekilde atın.

Kullanılmış ürünlerin ve ambalajların ayrı olarak

toplanması bu maddelerin geri dönüşüme sokularak

yeniden kullanılmasına olanak tanır. Geri dönüşümlü

maddelerin tekrar kullanılması çevre kirliliğinin önlenmesine

yardımcı olur ve ham madde ihtiyacını azaltır.

Yerel yönetmelikler, elektrikli ürünlerin evlerden toplanıp

belediye atık tesislerine aktarılması veya yeni bir ürün satın

alırken perakende satıcı tarafından toplanması yönünde

hükümler içerebilir. STANLEY, hizmet ömrünün sonuna

ulaşan STANLEY ürünlerinin toplanması ve geri dönüşüme

sokulması için bir imkân sunmaktadır. Bu hizmetin

avantajlarından faydalanmak için, lütfen, ürününüzü bizim

adımıza teslim alacak herhangi bir yetkili servise iade edin.

Bu kılavuzda belirtilen listeden size en yakın STANLEY

yetkili tamir servisinin yerini öğrenebilirsiniz. Ya da, alternatif

olarak internet’ten STANLEY yetkili tamir servislerinin

listesini ve satış sonrası hizmetlerimizle ilgili tüm bilgiler ve

temas bilgilerine aşağıdaki siteden ulaşabilirsiniz.

www.2helpU.com

Teknik özellikleri

Teknik özellikler STSC2135

GÜÇ W 2100

YÜKSÜZ HIZI dev/dak 3800

MAKS. DİSK ÇAPI mm 355

Ağırlık kg 15,5

STANLEY, «teknik özellikleri» bölümünde açıklanan bu

ürünlerin aşağıda belirtilen yönergelere uygun olduğunu

beyan eder: 2006/42/EC, EN 61029-1, EN 61029-2-10

Bu ürünler ayrıca 2004/108/EC (until 19.04.2016),

2014/30/EU (from 20.04.2016) ve 2011/65/EU Direktiflerine

de uygundur. Daha fazla bilgi için, lütfen aşağıdaki adresten

STANLEY ile irtibata geçin veya kılavuzun arkasına bakın.

Bu belge altında imzası bulunan yetkili, teknik dosyanın

derlenmesinden sorumludur ve bu beyanı STANLEY adına

vermiştir.

R.Laverick

Mühendislik Bölümü Müdürü

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2015

AT Uygunluk Beyanatı

MAKİNE DİREKTİFİ

STSC2135

LpA (ses basıncı) dB(A) 95,5

KpA (ses basıncı belirsizlii) dB(A) 3

LWA (ses gücü) dB(A) 105,5

KWA (ses gücü belirsizlii) dB(A) 3

Titreim emisyon deeri a

h

ah = m/s² 4.3

Belirsizlik K = m/s² 1,5

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

Page 19

19

Sanayi ve Ticaret Bakanlığı tebliğince kullanım ömrü 7 yıldır.

Türkiye Distribütörü

STANLEY BLACK&DECKER TURKEY ALET URETIM SAN. TIC. LTD.STI.

Kozyatağı Mh Değirmen Sk. Nida Kule No:18 Kat:6

34742 Kadıköy İstanbul

Tel : (0216) 665 29 00

Faks : (0216) 665 29 01

E-posta: info-tr@sbdinc.com

Servis Bilgisi

STANLEY şirket sahibi ve yetkili servis konumlarının tam

ağını sunmaktadır. Tüm STANLEY Servis Merkezleri’nde,

müşterilere etkili ve güvenilir elektrikli aletler sunmak üzere

eğitimli kişiler çalışmaktadır. Yetkili servis merkezleri ile ilgili

daha fazla bilgi için ve teknik öneriye, onarıma veya orijinal

fabrika parçalarına ihtiyacınız varsa, en yakın STANLEY

servisi ile temasa geçin.

İki yıl tam garanti

Sahip olduğunuz STANLEY ürünü satın alma tarihinden

itibaren 24 ay içinde hatalı malzeme veya işçilik nedeniyle

bozulursa, STANLEY Europe aşağıdaki şartlara uyulması

koşuluyla ücretsiz olarak tüm kusurlu parçaların

yenilenmesini veya -kendi inisiyatifine bağlı olarak- satın

alınan ürünün değiştirilmesini garanti eder:

Ürün, hatalı kullanılmamış kullanım kılavuzuna uygun

kullanılmıştır.

Ürün yıpranmamış, hırpalanmamış ve aşınmamıştır;

Yetkili olmayan kişilerce tamire çalışılmamıştır.

Satın alma belgesi (fatura) ibraz edilmiştir.

STANLEY ürünü, tüm orijinal parçaları ile birlikte iade

edilmiştir

Garanti talebinde bulunmak için, lütfen satıcıyla irtibata geçin

veya STANLEY katalogunda belirtilen size en yakın

STANLEY yetkili satıcı adresini kontrol edin veya ürünün

kılavuzunda belirtilen adresteki yerel STANLEY yetkili tamir

servisi ile temas kurun. İnternet’ten Stanley yetkili tamir

servislerinin listesine ve satış sonrası hizmetlerimizle ilgili

tüm bilgilerine aşağıdaki siteden ulaşabilirsiniz:

www.stanleytools.com

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Page 20

01/2015

Loading...

Loading...