Page 1

STSC1618

English Page 4

Turkish Page 14

Russian Page 24

Ukrainian Page 35

Page 2

ENGLISH

(Original instructions)

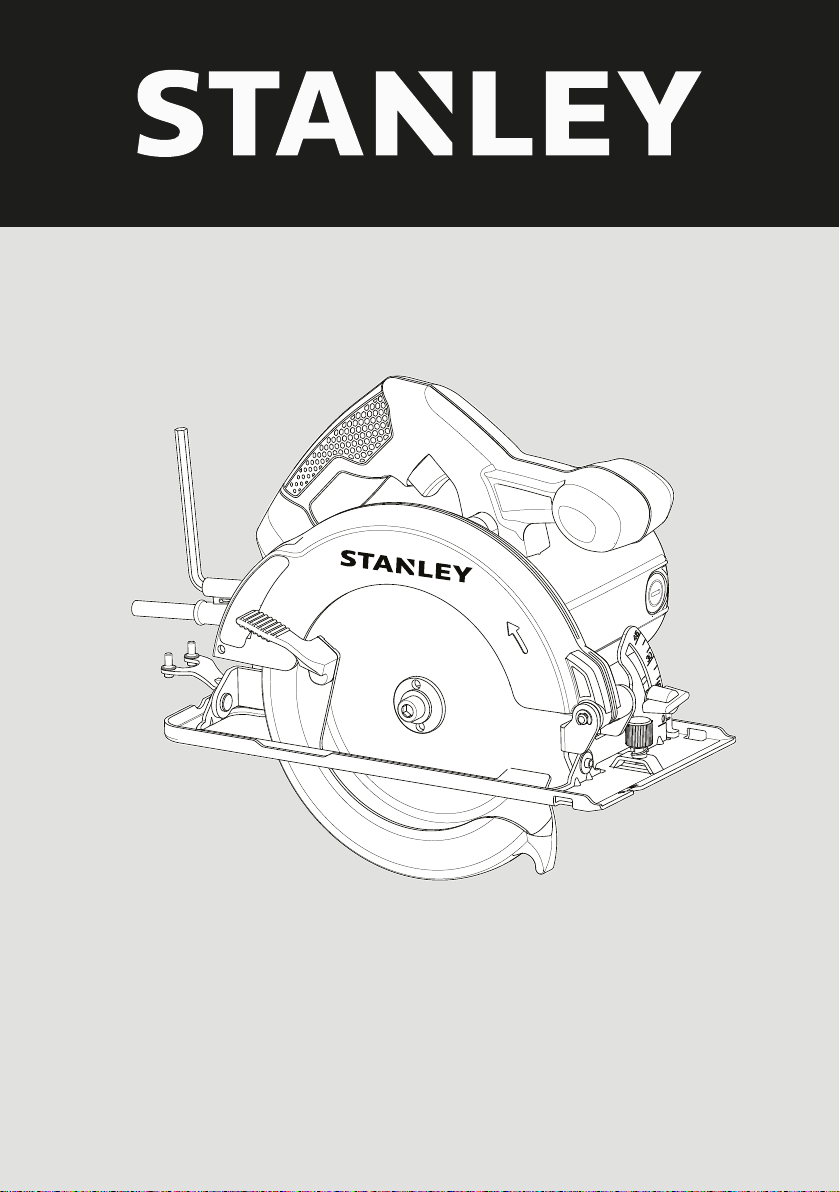

FIG. A FIG. B

FIG. C FIG. D

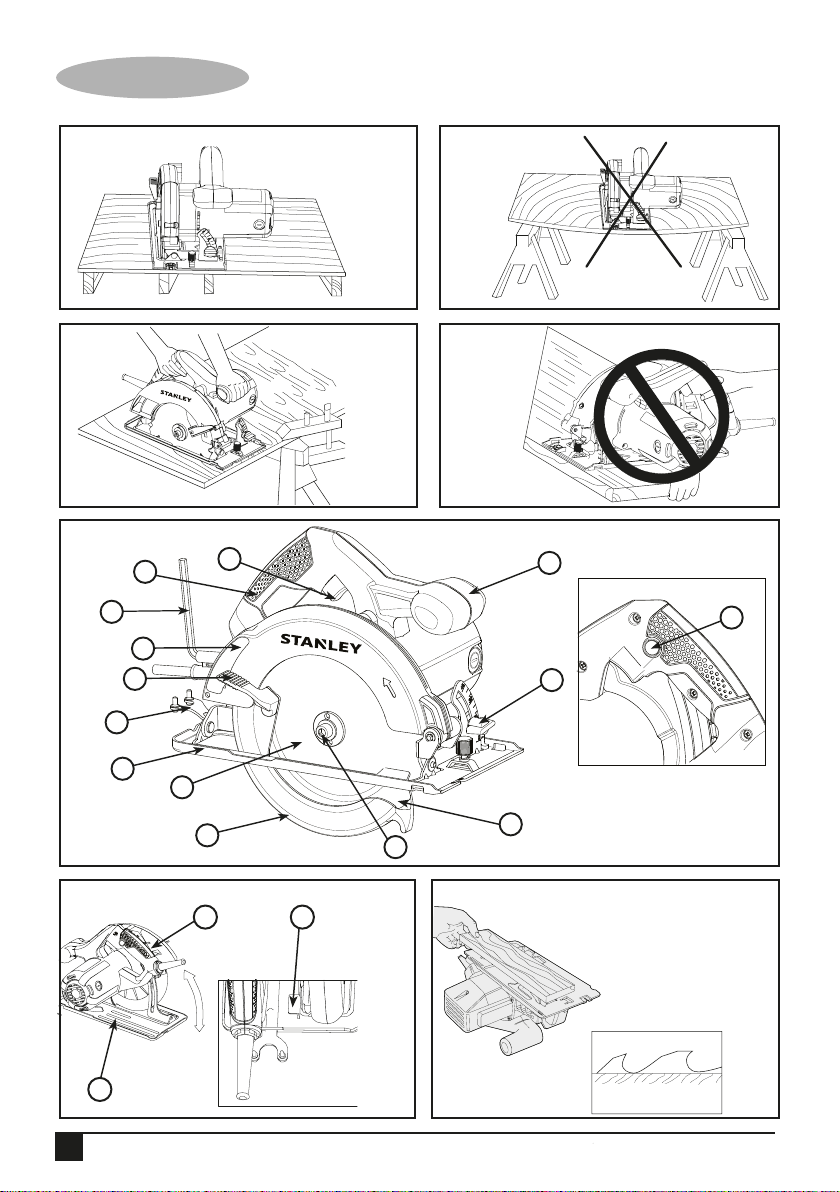

FIG. E

2

1

3

FIG. F

2

15

23

7

9

21

8

4

10

6

11

5

FIG. G

13 12

4

Page 3

(Original instructions)

ENGLISH

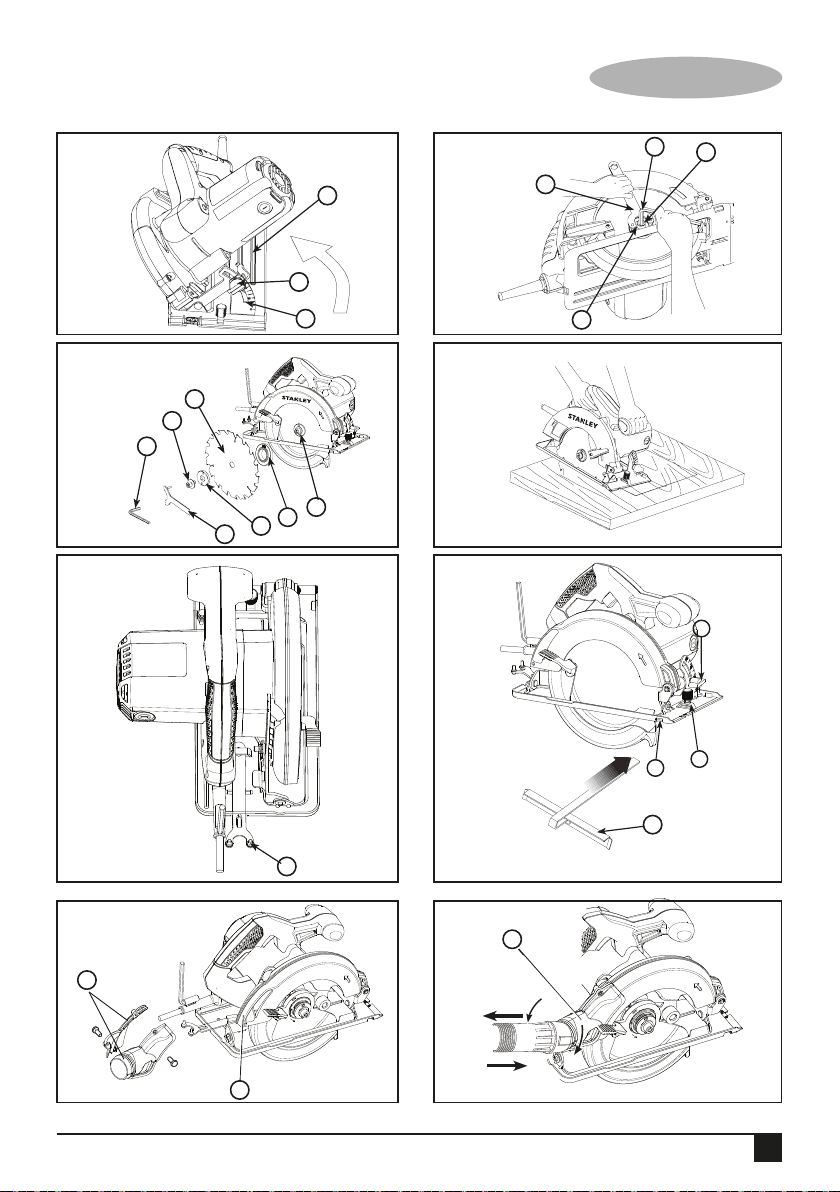

FIG. H FIG. I

4

9

14

FIG. J

FIG. L

5

11

15

16

20

10

8

FIG. K

FIG. M

15

11

8

10

19

8

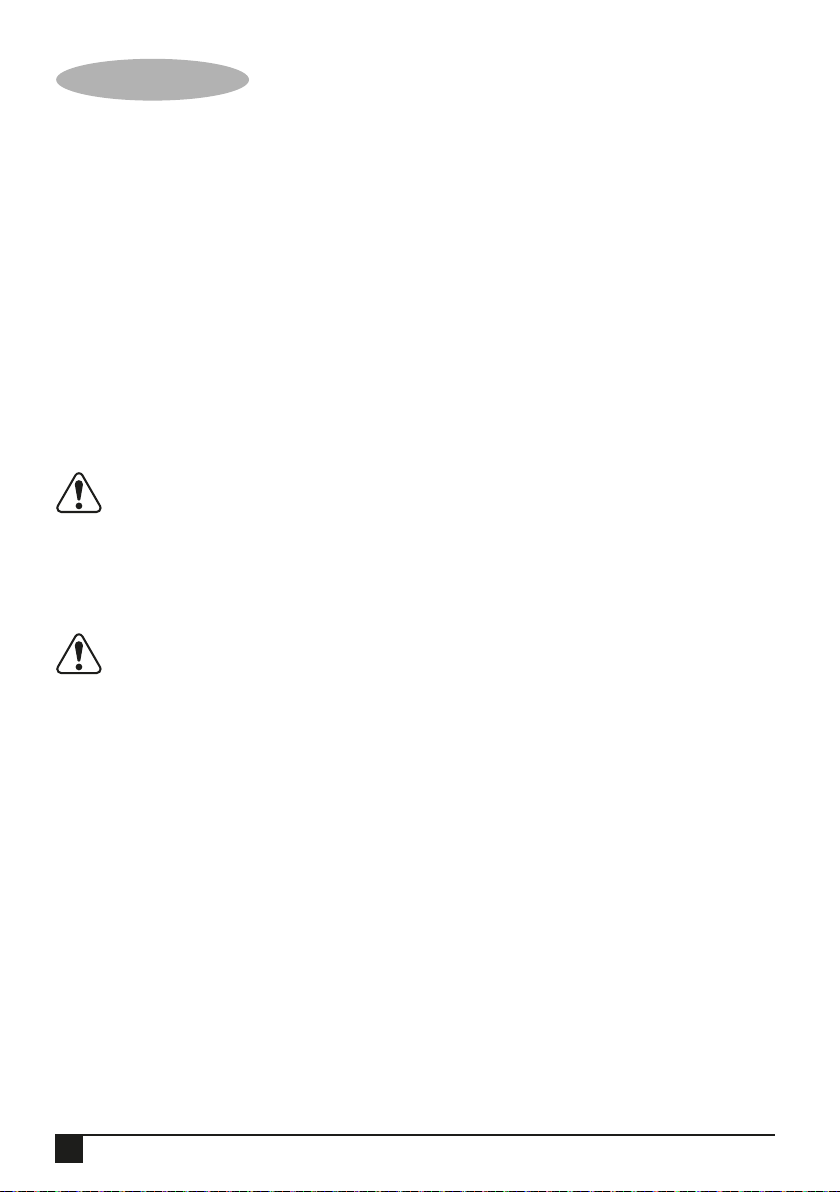

FIG. N FIG. O

22

23

17

19

18

22

3

Page 4

ENGLISH

(Original instructions)

Intended Use

Your STANLEY STSC1618 Circular Saw has been designed

for sawing wood and wood products. This tool is intended for

semi-professional and professional use.

• For tools intended to cut wood, instruction on correct

use of the dust collection system.

• For tools intended to cut wood, instruction to wear a

dust mask.

• Instrcution to only use saw blades recommended.

• Instruction to always wear hearing protection.

DO NOT RETURN THIS PRODUCT TO THE STORE,

first contact your local STANLEY Office

or nearest authorized service center.

General Safety Rules

Warning! Read and understand all instructions.

result in electric shock, fire and/or serious personal injury.

Failure to follow all instructions listed below, may

SAVE THESE INSTRUCTIONS

Safety instructions

General power tool safety warnings

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

b. Do not operate power tools in explosive

c. Keep children and bystanders away while operating

2. Electrical safety

a. Power tool plugs must match the outlet. Never

instructions listed below may result in electric

areas invite accidents.

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

a power tool. Distractions can cause you to lose

control.

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

4

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock. Note: The term “Residual Curent Device

(RCD)” can be replaced by “Ground Fault Circuit

Interrupter (GFCI)” or by “Earth Leakage Circuit Breaker

(ELCB)”.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

Page 5

(Original instructions)

ENGLISH

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean.

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in

g.

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Properly

Additional power tool safety warnings

Warning! Safety instructions for all saws

Cutting procedures

a.

hands are holding the saw, they cannot be cut by the blade.

b. Do not reach underneath the workpiece.

c. Adjust the cutting depth to the thickness of the

d. Never hold piece being cut in your hands or across

e. Hold the power tool by insulated gripping surfaces

f. When ripping, always use a rip fence or straight

g. Always use blades with correct size and shape

h. Never use damaged or incorrect blade washers or

Danger! Keep hands away from cutting area

and the blade. Keep your second hand on

auxiliary handle, or motor housing. If both

The guard

cannot protect you from the blade below the workpiece.

workpiece. Less than a full tooth of the blade teeth

should be visible below the workpiece.

your leg. Secure the workpiece to a stable platform. It

is important to support the work properly to minimize

body exposure, blade binding, or loss of control.

only, when performing an operation where the

cutting tool may contact hidden wiring. Contact with a

"live" wire will also make exposed metal parts of the

power tool "live" and could give the operator an electric

shock.

edge guide. This improves the accuracy of cut and

reduces the chance of blade binding.

(diamond versus round) of arbour holes. Blades that

do not match the mounting hardware of the saw will run

eccentrically, causing loss of control.

bolt. The blade washers and bolt were specially

designed for your saw, for optimum performance and

safety of operation.

Kickback Causes And Related Warnings

• Kickback is a sudden reaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw tolift

upandoutoftheworkpiecetowardtheoperator.

5

Page 6

ENGLISH

(Original instructions)

• When the blade is pinched or bound tightly by the kerf

closing down, the blade stalls and the motor reaction

drives the unit rapidly back toward the operator.

• If the blade becomes twisted or misaligned in the cut,

the teeth at the back edge of the blade can dig into the

top surface of the wood causing the blade to climb out of

the kerf and jump back toward operator.

• Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be avoided

by taking proper precautions as given below.

a. Maintain a firm grip with both hands on the saw and

position your body and arm to allow you to resist

kickback forces. Kickback forces can be controlled by

the operator, if proper precautions are taken.

b. When blade is binding, or when interrupting a cut

for any reason, release the trigger and hold the saw

motionless in the material until the blade comes to a

complete stop. Never attempt to remove the saw

from the work or pull the saw backward while the

blade is in motion or kickback may occur. Investigate

and take corrective actions to eliminate the cause of

blade binding.

c. When restarting a saw in the workpiece, center the

saw blade in the kerf and check that the saw teeth

are not engaged into the material. If saw blade is

binding, it may walk up or kickback from the workpiece

as the saw is restarted.

d. Support large panels to minimize the risk of blade

pinching and kickback. Large panels tend to sag under

their own weight. Support must be placed under the

panel on both sides, near the line of cut and near the

edge of the panel.

g. Use extra caution when making a “Pocket Cut” into

existing walls or other blind areas. The protruding

blade may cut objects that can cause kickback.

Lower guard function

a. Check lower guard for proper closing before each

use. Do not operate the saw if lower guard does not

move freely and close instantly. Never clamp or tie

the lower guard into the open position. If saw is

accidentally dropped, lower guard may be bent. Raise

the lower guard with the retracting handle and make sure

it moves freely and does not touch the blade or any other

part, in all angles and depths of cut.

b. Check the operation of the lower guard spring. If the

guard and the spring are not operating properly, they

must be serviced before use. Lower guard may

operate sluggishly due to damaged parts, gummy

deposits, or a build-up of debris.

c. Lower guard may be retracted manually only for

special cuts such as "plunge cuts" and "compound

cuts". Raise lower guard by retracting handle and as

soon as blade enters the material, the lower guard must

be released. For all other sawing, the lower guard should

operate automatically.

d. Always observe that the lower guard is covering the

blade before placing saw down on bench or floor. An

unprotected, coasting blade will cause the saw to walk

backwards, cutting whatever is in its path. Be aware of

the time it takes for the blade to stop after switch is

released.

Residual risks

e. Do not use dull or damaged blade. Unsharpened or

improperly set blades produce narrow kerf causing

excessive friction, blade binding, and kickback.

f. Blade depth and bevel adjusting locking levers must

be tight and secure before making cut. If blade

adjustment shifts while cutting, it may cause binding and

kickback.

6

Additional residual risks may arise when using the tool which

may not be included in the enclosed safety warnings. These

risks can arise from misuse, prolonged use etc.

Even with the application of the relevant safety regulations

and the implementation of safety devices, certain residual

risks can not be avoided. These include:

Page 7

(Original instructions)

ENGLISH

• Injuries caused by touching any rotating/moving parts.

• Injuries caused when changing any parts, blades or

accessories.

• Injuries caused by prolonged use of a tool. When using

any tool for prolonged periods ensure you take regular

breaks.

• Impairment of hearing.

• Health hazards caused by breathing dust developed

when using your tool (example:- working with wood,

especially oak, beech and MDF.)

Safety Guidelines/definitions

It is important for you to read and understand this manual.

The information it contains relates to protecting Your Safety

and Preventing Problems. The symbols below are used to

help you recognize this information.

Danger! Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

Warning! Indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

Caution! Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

Caution! Used without the safety alert symbol

indicates potentially hazardous situation which, if

not avoided, may result in property damage.

Additional Safety Rules For Circular Saws

Warning! Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products,

• Arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals:

• Work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

Caution! Wear appropriate hearing protection

during use. Under some conditions and duration of

use, noise from this product may contribute to hearing loss.

• Snagging the lower guard on a surface below the

material being cut can momentarily reduce operator

control. The saw can lift partially out of the cut

increasing the chance of blade twist. Ensure there is

sufficient clearance under the workpiece.

• When necessary to raise lower guard manually, use

the retracting lever.

• Keep the Blades Clean and Sharp. Sharp blades

minimize stalling and kickback. The use of dull and/ or

dirty blades can increase the saw loading causing the

operator to push harder which promotes twisting.

Caution! Laceration Hazard. Keep hands away from

cutting areas. Keep hands away from blades. Never place

hands in front of or behind the path of the blade while

cutting. Do not reach underneath work while blade is

rotating. Do not attempt to remove cut material when blade

is moving.

7

Page 8

ENGLISH

(Original instructions)

• Support large panels. Large panels must be supported

as shown (Fig. A) in this manual to minimize the risk of

blade pinching and kickback. Material supported only at

the ends (Fig. B) will lead to blade pinching. When

cutting operation requires the resting of the saw on the

workpiece, the saw shall be rested on the larger portion

and the smaller piece cut off.

• Use only correct blades and blade assembly

components when mounting blades. Do not use

blades with incorrect size holes. Never use defective or

incorrect blade washers or bolts. Follow blade assembly

procedures.

Saw blades

• Do not use blades of larger or smaller diameter than

recommended. For the proper blade rating refer to the

technical data. Use only the blades specified in this

manual, complying with EN 847-1.

Warning! Never use abrasive wheels.

Safety of others

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person

responsible for their safety.

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Electrical safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main voltage

corresponds to the voltage on the rating plate.

Warning! If the power cord is damaged, it must

be replaced by the manufacturer, authorized

STANLEY Service Center or an equally qualified person in

order to avoid damage or injury. If the power cord is replaced

by an equally qualified person, but not authorized by

STANLEY, the warranty will not be valid.

• Adjustments. Before cutting be sure depth and bevel

adjustments are tight.

• Support and secure the work properly. Insure that the

material to be cut is clamped (Fig. C), and solidly

• Children should be supervised to ensure that they do

not play with the appliance.

Labels on tool

The label on your tool may include the following symbols

along with the date code:

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

....... No-Load

0

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

8

Page 9

(Original instructions)

ENGLISH

supported and balanced on a strong, stable and level

work surface. Support the work so that the wide portion

of the saw shoe is on the portion of the material that

doesn’t fall after the cut is made. Never hold cut off

piece by hand (Fig. D). Kickback from blade pinch can

result. Keep both hands on saw at all times.

• Stay alert and exercise control. Keep body positioned

to one side of blade. Always maintain a firm grip and

control of saw with both hands. Do not change hand grip

or body position while saw is running. Take precaution to

avoid injury from cut off pieces and other falling material

during operation.

Danger! Release switch immediately if blade

binds or saw stalls.

Features (Fig. E)

This tool includes some or all of the following features.

1. Trigger switch

2. Main Handle

3. Secondary Handle

4. Shoe

5. Saw Blade

6. Lower blade guard

7. Blade Guard Retracting Lever

8. Saw Blade Spanner Wrench

9. Bevel Adjustment Knob

10. Outer Washer

11.

Blade Retaining Screw

15.

Saw Blade Hex Wrench (Shown on Fig.I)

18.

Rip Fence (Shown on Fig. M)

20.

Inner Flange (Shown on Fig. J)

21. Lock-off button

23. Upper blade guard

Assembly/adjustment Set-up

Warning! Always unplug saw from power supply

before any of the following operations.

Adjusting the depth of cut (Fig. F and G)

The depth of cut should be set according to the thickness of

the workpiece.

• Loosen the lever (12) to unlock the saw shoe.

• Move the saw shoe (4) into the desired position. The

corresponding depth of cut can be read from the scale (13).

• Tighten the lever to lock the saw shoe in place.

• Set depth adjustment of saw such that one tooth of the

blade projects below the workpiece as shown in Fig. G.

Adjusting the bevel angle (Fig. H)

This tool can be set to bevel angles between 0° and 45°

• Loosen the locking knob (9) to unlock the saw shoe.

• Move the saw shoe (4) into the desired position. The

corresponding bevel angle can be read from the scale

(14).

• Tighten the locking knob to lock the saw shoe in place.

Attaching the blade (Fig. I and J)

• To prevent spindle rotation engage the protrusions of the

spanner wrench (8) into the holes in the outer washer

(10) as shown in Fig. I.

• Loosen and remove the blade retaining screw (11) by

turning the hex wrench (15) counter- clockwise.

• Remove the outer washer.

• Check and re-assembly inner flange (20) on spindle (16).

Insure the correct side of inner flange (20) faces outward

and match saw blade with diameter arbor well.

• Place the saw blade (5) onto the inner flange (20),

making sure that the arrow on the blade points in the

same direction as the arrow on the tool.

• Fit the outer washer (10) on the spindle.

• Insert the blade retaining screw (11) into the hole in the

spindle.

• Prevent spindle rotation by engaging the spanne wrench

into the holes of the outer washer.

• Securely tighten the blade retaining screw by holding the

spanner wrench and turning hex wrench clockwise to

tighten the blade retaining screw.

Warning! Inner flange (20) respectively marked

with “19” and “20”, match the saw blade (5) with

19mm and 20mm diameter arbor.

Removing the blade

To prevent spindle rotation, engage the protrusions of the

spanner wrench (8) into the holes in the outer washer (10).

9

Page 10

ENGLISH

(Original instructions)

• Loosen and remove the blade retaining screw (11) by

turning it counterclockwise using the hex wrench (15).

• Remove the outer washer (10).

• Remove the saw blade (5). Warning! To reduce the risk

of serious personal injury, read, understand and follow

all important safety warnings and instructions prior to

using tool.

General Cuts

Guard against kickback

With unit unplugged, follow all assembly, adjustment and set

up instructions. Make sure lower guard operates. Select the

proper blade for the material to be cut.

• Measure and mark work for cutting.

• Support and secure work properly (See Safety Rules

and Instructions).

• Use appropriate and required safety equipment (See

Safety Rules).

• Secure and maintain work area (See Safety Rules).

• With plug inserted and guard closed, make sure switch

turns saw on and off.

Warning! It is important to support the work

properly and to hold the saw firmly to prevent loss

of control which could cause personal injury. Fig.

C illustrates recommended hand position.

Operation

Switching On and Off (fig. E)

For safety reasons the trigger switch (1) of your tool is equipped with a lock-off button (21). Press the lock-off button to

unlock the tool.

To run the tool, press the trigger switch (1). As soon as the

trigger switch is released, the lock-off switch is automatically

activated to prevent unintended starting of the machine.

NOTICE: Do not switch the tool ON or OFF when the saw

blade touches the workpiece or other materials.

Sawing

Warning! To reduce the risk of serious personal

injury,always hold the tool with both hands.

• Let the blade run freely for a few seconds before starting

the cut.

• Apply only a gentle pressure to the tool while performing

the cut.

• Work with the shoe pressed against the workpiece.

Hints For Optimum Use

• As some splintering along the line of cut on the top side

of the workpiece cannot be avoided, cut on the side

where splintering is acceptable.

• Where splintering is to be minimized, e.g. when cutting

laminates, clamp a piece of plywood onto the top of the

workpiece.

Pocket cutting (Fig. K)

Pocket cutting is used to cut a hole in a piece of material

without cutting from the side.

• Measure and mark work.

• Tilt saw forward and rest front of the shoe on material to

be cut. Align so that cut will begin at the back of the

drawn rectangle shown in Fig. K.

• Using the retracting lever, retract blade guard to an

upward position, with the blade just clearing the material,

start motor and gradually lower the saw into the material.

Warning! As blade starts cutting the material,

release the retracting lever immediately.

• Never tie the blade guard in a raised position.

• When the shoe rests flat on the material being cut,

complete the cut in forward direction.

• Allow the blade to come to a complete stop before lifting

saw from material.

• When starting each new cut, repeat the above steps

Wrench storage (Fig. L)

The spanner wrench (8) can be stored on the saw shoe as

shown in Fig. L.

Attaching and removing the rip fence (Fig. M)

The rip fence is used to saw in a straight line parallel to the

edge of the working piece.

Attaching

• Loosen the locking knob (17).

• Insert the rip fence (18) through the openings (19).

• Slide the rip fence into the desired position.

10

Page 11

(Original instructions)

ENGLISH

• Tighten the locking knob.

Removing

• Loosen the locking knob.

• Pull the rip fence out of the tool. Note: If you do not have

a proper fitting fence, use a straight edge guide in

contact with the edge of the shoe to improve accuracy of

cut and reduce the possibility of binding and kickback.

Mounting the Dust Extraction Spout

(fig. E, F, N)

Your circular saw is supplied with a dust extraction spout.

TO INSTALL DUST EXTRACTION SPOUT (FIG. N)

1. Fully loosen depth adjustment lever (Fig. F, 12).

2. Place base plate (Fig. a, 4) in the lowest position.

3. Align the two halves of the dust extraction spout (22) over

upper blade guard (23) as shown.

4. Insert screws and tighten securely.

Dust Extraction (fig. O)

A dust extraction spout (22) is supplied with your tool.

Vacuum hoses of most common vacuum extractors

will fit directly into the dust extraction spout.

WARNING: Risk of dust inhalation.

To reduce the risk of personal injury,

ALWAYS wear an approved dust mask.

WARNING: ALWAYS use a vacuum

extractor designed in compliance with

the applicable directives regarding dust

emission when sawing wood. Vacuum

hoses of most common vacuum

cleaners will fit directly into the dust

extraction outlet.

Accessories

The performance of your tool depends on the accessory

used. Stanley and Piranha accessories are engineered to

high quality standards and designed to enhance the

performance of your tool. By using these accessories you

will get the very best from your tool.

Warning! The use of any accessory not

recommended for use with this tool could be

hazardous. Use only 185mm blades with 19mm

or 20mm diameter arbor.

Maintenance

Your tool has been designed to operate over a long period

of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and

regular cleaning.

Warning! Before performing any maintenance,

switch off and unplug the tool.

• Regularly clean the ventilation slots in your tool using a

soft brush or dry cloth.

• Regularly clean the motor housing using a damp cloth.

Do not use any abrasive or solvent-based cleaner.

Important! To assure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(other than those listed in this manual) should be

performed by authorized service centers or other

qualified service personnel, always using identical

replacement parts.

Lubrication

Stanley tools are properly lubricated at the factory and are

ready for use.

11

Page 12

ENGLISH

(Original instructions)

Technical Data

Specifications STSC1618

Voltage 220-240V

zH06/05 ycneuqerF

Power 1600W

No-Load Speed 5500/min (rpm)

Maximum cutting depth 62mm AT 90°

46mm AT 45°

LpA (sound pressure) dB(A) 92,5

K

(sound pressure uncertainty) dB(A) 3

pA

LWA (sound power) dB(A) 103,5

KWA (sound power uncertainty) dB(A) 3

Vibration emission value a

ah= m/s² 6,6

Uncertainty K = m/s² 1.5

(cutting wood)

h

Vibration

The declared vibration emission values stated in the

technical data and the declaration of conformity have been

measured in accordance with a standard test method

provided by EN 60745 and may be used for comparing one

tool with another. The declared vibration emission value may

also be used in a preliminary assessment of exposure.

Warning! The vibration emission value during actual use of

the power tool can differ from the declared value depending

on the ways in which the tool is used. The vibration level

may increase above the level stated.

When assessing vibration exposure to determine safety

measures required by 2002/44/EC to protect persons

regularly using power tools in employment, an estimation of

vibration exposure should consider, the actual conditions of

use and the way the tool is used, including taking account of

all parts of the operating cycle such as the times when the

tool is switched off and when it is running idle in addition to

the trigger time.

EC declaration of conformity

MACHINERY DIRECTIVE

Circular Saw STSC1618

STANLEY declares that these products described under

"technical data" are in compliance with:

2006/42/EC, EN 60745-1:2009 + A11:2010,

EN 60745-2-5:2010

These products also comply with Directive

2004/108/EC (until 19/04/2016) 2014/30/EU (from

20/04/2016) and 2011/65/EU. For more information, please

contact STANLEY at the following address or refer to the

back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

STANLEY.

R.Laverick

Engineering Manager

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

08.2015

Service Information

STANLEY offers a full network of company-owned and

authorized service locations. All STANLEY Service Centers

are staffed with trained personnel to provide customers with

efficient and reliable power tool service. For more

information about our authorized service centers and if you

need technical advice, repair, or genuine factory

replacement parts, contact the STANLEY location nearest

you.

12

Page 13

(Original instructions)

ENGLISH

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Stanley product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Stanley provides a facility for the collection and recycling of

Stanley products once they have reached the end of their

working life. To take advantage of this service please return

your product to any authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Stanley office at the address

indicated in this manual. Alternatively, a list of authorised

Stanley repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com

Two years warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY guarantees to replace all defective

parts free of charge or – at our discretion – replace the unit

free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

13

Page 14

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Kullanım Amacı

STANLEY testereniz STSC1618, ahşap ve ahşap ürünleri

kesmek için tasarlanmıştır. Bu alet profesyonel ve yarı

profesyonel kullanım için tasarlanmıştır.

• Ahşap kesmek için tasalanmış aletlerde, toz toplama

sisteminin doğru kullanımı ile ilgili talimat.

• Ahşap kesme için tasalanmış aletlerde, toz maskesi

kullanımı ile ilgili talimat.

• Sadece önerilen testere bıçaklarının kullanımı ile ilgili

talimat.

• Daima kulaklık kullanma ile ilgili talimat.

BU ÜRÜNÜ MAĞAZAYA İADE ETMEYİN,

önce yerel STANLEY Ofisi ile veya en yakın yetkili servis

merkezi irtibata geçin.

Genel Güvenlik Talimatları

Uyarı! Bütün talimatları okuyun ve anlayın.

Aşağıda yer alan uyarılar ve talimatlara

uyulmaması elektrik çarpması, yangın ve/veya

ciddi yaralanmalara neden olabilir.

BU TALİMATLARI SAKLAYIN

Güvenlik talimatları

Genel elektrikli alet güvenlik uyarıları

Uyarı! Bütün güvenlik uyarılarını ve tüm

talimatları okuyun. Aşağıda yer alan uyarılar ve

talimatlara uyulmaması elektrik çarpması, yangın

ve/veya ciddi yaralanmalara neden olabilir.

Bütün uyarı ve talimatları ileride bakmak üzere saklayın.

Aşağıda listelenen tüm uyarılarda kullanılan "elektrikli alet"

terimi şebeke elektriği ile (kablolu) veya aküyle (kablosuz)

çalışan elektrikli aleti ifade etmektedir.

1. Çalışma alanının güvenliği

a. Çalışma alanını temiz ve aydınlık tutun. Dağınık ve

karanlık alanlar kazaya davetiye çıkarır.

b. Elektrikli aletleri, yanıcı sıvılar, gazlar ve tozların

bulunduğu yerler gibi yanıcı ortamlarda

çalıştırmayın. Elektrikli aletler, toz veya dumanları

ateşleyebilecek kıvılcımlar çıkarır.

c. Bir elektrikli aleti çalıştırırken çocuklardan ve

etraftaki kişilerden uzak tutun. Dikkatinizi dağıtıcı

şeyler kontrolü kaybetmenize neden olabilir.

2. Elektrik güvenliği

a. Elektrikli aletlerin fişleri prizlere uygun olmalıdır. Fiş

üzerinde kesinliklehiçbir değişiklik yapmayın.

Topraklı (topraklanmış) elektrikli aletlerde hiçbir

adaptor fişi kullanmayın. Değiştirilmemiş fişler ve

uygun prizler elektrik çarpması riskini azaltacaktır.

b. Borular, radyatörler, ocaklar ve buzdolapları gibi

topraklanmış yüzeylerle vücut temasından kaçının.

Vücudunuzun topraklanması halinde yüksek elektrik

çarpma riski vardır.

c. Elektrikli aletleri yağmura maruz bırakmayın veya

ıslatmayın. Elektrikli alete su girmesi, elektrik çarpması

riskini artıracaktır.

d. Kablosuna zarar vermeyin. Elektrikli aleti kesinlikle

kablosundan tutarak taşımayın, çekmeyin veya

prizden çıkarmayın. Kabloyu sıcaktan, yağdan,

keskin kenarlardan veya hareketli parçalardan uzak

tutun. Hasarlı veya dolaşmış kablolar elektrik çarpma

riskini arttırır.

e. Elektrikli aleti açık havada kullanırken, açık hava

kullanımına uygun bir uzatma kablosu kullanın. Açık

havada kullanıma uygun bir kablonun kullanılması

elektrik çarpma riskini azaltır.

f. Eğer bir elektrikli aleti nemli bir bölgede çalıştırması

zorunluysa, bir artık akım aygıtı (RCD) korumalı bir

kaynak kullanın. Bir RCD kullanılması elektrik çarpma

riskini azaltır. Not: “Artık Akım Aygıtı (RCD)” terimi,

“Topraklama Hatası Devre Kesici (GFCI)” veya “Kaçak

Akım Devre Kesici (ELCB)” olarak değiştirilebilir.

3. Kişisel güvenlik

a. Elektrikli bir alet kullanırken her zaman dikkatli olun,

yaptığınız işe yoğunlaşın ve sağduyulu davranın.

Elektrikli bir aleti yorgunken veya ilaç ya da alkolün

etkisi altındayken kullanmayın. Elektrikli aletleri

kullanırken bir anlık dikkatsizlik ciddi yaralanmalara yol

açabilir.

b. Kişisel koruyucu ekipmanları mutlaka kullanın.

Daima koruyucu gözlük takın. Koşullara uygun toz

maskesi, kaymayan güvenlik ayakkabıları, baret veya

kulaklık gibi koruyucu donanımların kullanılması kişisel

yaralanmaları azaltacaktır.

c. İstem dışı çalıştırılmasını önleyin. Cihazı güç

kaynağına ve/veya aküye bağlamadan, kaldırmadan

veya taşımadan önce düğmenin kapalı konumda

olduğundan emin olun. Aleti, parmağınız düğme

üzerinde bulunacak şekilde taşımak veya açık

konumdaki elektrikli aletleri elektrik şebekesine bağlamak

kazaya davetiye çıkarır.

14

Page 15

(Çevirisi orijinal talimatlardan yapılmıştır)

TÜRKÇE

d. Elektrikli aleti çalıştırmadan önce herhangi bir

ayarlama anahtarını veya vida anahtarını çıkarın.

Elektrikli aletin hareketli parçasına takılı bırakılan bir vida

anahtarı veya anahtar, kişisel yaralanmaya neden

olabilir.

e. Ulaşmakta zorlandığınız yerlerde kullanmayın. Her

zaman sağlam ve dengeli basın. Bu, beklenmedik

durumlarda elektrikli aletin daha iyi kontrol edilmesine

olanak tanır.

f. Uygun şekilde giyinin. Bol giysiler giymeyin ve takı

takmayın. Saçınızı, giysinizi ve eldivenlerinizi

hareketli parçalardan uzak tutun. Bol giysiler, takılar

veya uzun saçlar hareketli parçalara takılabilir.

g. Eğer kullandığınız üründe toz emme ve toplama

özellikleri olan ataşmalar varsa bunların bağlı

olduğundan ve doğru şekilde kullanıldığından emin

olun. Bu toz toplama ataşmanların kullanılması tozla

ilgili tehlikeleri azaltabilir.

4. Elektrikli aletlerin kullanımı ve bakımı

a. Elektrikli aleti zorlamayın. Uygulamanız için doğru

elektrikli aleti kullanın. Doğru elektrikli alet, belirlendiği

kapasite ayarında kullanıldığında daha iyi ve güvenli

çalışacaktır.

b. Düğme açmıyor ve kapatmıyorsa elektrikli aleti

kullanmayın. Düğmeyle kontrol edilemeyen tüm

elektrikli aletler tehlikelidir ve tamir edilmesi

gerekmektedir.

c. Herhangi bir ayarlama yapmadan, aksesuar

değiştirmeden veya aleti yerine koymadan önce, fişi güç

kaynağından çekin ve/veya aküyü aletten çıkartın. Bu tür

önleyici güvenlik tedbirleri elektrikli aletin çalıştırılma

riskini azaltır.

f. Kesim aletlerini keskin ve temiz tutun.

şekilde yapılmış keskin kesim uçlu kesim aletlerinin

sıkışma ihtimali daha düşüktür ve kontrol edilmesi

kolaydır.

g. Elektrikli aleti, aksesuarlarını ve aletin diğer parçalarını

vs. kullanırken bu talimatlara mutlaka uyun ve elektrikli

alet türü için öngörüldüğü şekilde, çalışma ortamının

koşullarını ve yapılacak işin ne olduğunu göz önünde

bulundurun. Elektrikli aletin öngörülen işlemler dışındaki

işlemler için kullanılması tehlikeli durumlara neden olabilir.

5. Servis

a. Elektrikli aletinizi, sadece orijinal yedek parçaların

kullanıldığı yetkili servise tamir ettirin. Bu, elektrikli

aletin güvenliğinin muhafaza edilmesini sağlayacaktır.

Bakımı uygun

d. Elektrikli aleti, çocukların ulaşamayacağı yerlerde

saklayın ve elektrikli aleti tanımayan veya bu

talimatları bilmeyen kişilerin elektrikli aleti

kullanmasına izin vermeyin. Elektrikli aletler, eğitimsiz

kullanıcıların elinde tehlikelidir.

e. Elektrikli aletlerin bakımını yapın. Hareketli

parçalardaki hizalama hatalarını ve tutuklukları,

parçalardaki kırılmalar ve elektrikli aletin çalışmasını

etkileyebilecek tüm koşulları kontrol edin. Hasarlı

ise, elektrikli aleti kullanmadan önce tamir ettirin.

Kazaların çoğu, elektrikli aletlerin bakımının yeterli

şekilde yapılmamasından kaynaklanır.

15

Page 16

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Kesme Prosedürleri

Tehlike! Ellerinizi kesim alanından ve bıçaktan

uzak tutun. Elinizin birini yardımcı kol ya da motor

gövdesinin üzerinde tutun. İki elinizde testere

üzerinde olursa bıçak tarafından kesilme riski olmaz.

b. Elinizi iş parçasının altından tutmayın. Koruma, iş

parçasının altından sizi koruyamaz.

c. Kesim derinliğini iş parçasının kalınlığına göre

ayarlayın. Bıçak dişlerinden bir dişten az bir kısım iş

parçasının altından görülebilmelidir.

d. Kesilmekte olan bir parçayı asla elinizle veya

bacaklarınız arasında tutmayın. İş parçasını sabit

platforma oturtun. Vücut temasını, bıçak takılma veya

kontrol kaybını önlemek için, yapılan işi uygun şekilde

desteklemek önemlidir.

e. Kesme aletinin gizli kablolara temas edebileceği

yerlerde çalışma yaparken elektrikli aleti yalıtımlı

kavrama yüzeylerinden tutun. "Akım taşıyan" bir

kabloya temas etmesi durumunda elektrikli aletin metal

kısımları da "akım taşır" hale gelebilir ve kullanıcının

çarpılmasına neden olabilir.

f. Yarma sırasında daima bir destek perdesi ya da düz

kenar kılavuzu kullanın. Bu daha doğru bir kesim

yapılmasını sağlar ve bıçağın takılma riskini azaltır.

g. Her zaman doğru delik şekline (elmasa karşın

yuvarlak) ve boyutuna sahip bıçaklar kullanın.

Testerenin donanımına uymayan bıçaklar eksen dışı

çalışır ve kontrolün kaybedilmesine neden olur.

h. Asla hasarlı ya da yanlış bıçak pulları veya cıvata

kullanmayın. Bıçak pulları ve cıvata, en iyi performans

ve kullanım güvenliğinin sağlanması amacıyla testereniz

için özel tasarlanmıştır.

Geri Tepme Nedenleri Ve İlgili Uyarılar

• Geri tepme, sıkışan, takılan ya da yanlış hizalanan

testere bıçağına karşı gösterilen ani bir tepkidir ve

kontrol edilemeyen testerenin iş parçasından çıkıp

kullanıcıya doğru yukarı kalkmasına neden olur.

• Kesim aralığı kapanarak bıçağın sıkışmasına ya da

takılmasına neden olduğunda bıçak durur ve motorun

tepkisi sonucu ünite hızlı bir şekilde kullanıcıya doğru

geri teper.

• Kesim sırasında bıçak bükülür ya da yanlış hizalanırsa,

bıçağın arka kenarındaki dişler tahtanın üst yüzeyine

geçebilir ve bıçağın kesikten dışarı çıkarak kullanıcıya

doğru geri tepmesine neden olabilir.

• Geri tepmenin nedeni, testerenin yanlış kullanılması

ve/veya hatalı kullanım prosedürleri veya koşullarının

izlenmesidir ve aşağıda belirtilen önlemler alınarak

bundan kaçınılabilir.

a. Testereyi iki elinizle sıkıca tutun ve kollarınızı geri

tepme gücüne karşı koyabilecek şekilde yerleştirin.

Uygun önlemler alınırsa geri tepme kuvvetleri,

kullanıcı tarafından kontrol edilebilir.

b. Bıçak takılırsa veya herhangi bir nedenle kesime ara

vermeniz gerektiğinde, tetiği serbest bırakın ve bıçak

tamamen durana kadar testereyi malzeme üzerinde

hareketsiz bir şekilde tutun. Bıçak hareket

halindeyken testereyi asla iş parçasından çıkarmaya

veya geri çekmeye çalışmayın, aksi takdirde geri

tepme yaşanabilir. Bıçağın takılmasının nedenini

araştırıp, önlemek için gerekli düzeltici eylemleri yerine

getirin.

c. Testereyi iş parçasının içinde yeniden başlatırken,

testere bıçağını kesiğe ortalayın ve testere dişlerinin

malzemenin içine girmemiş olduğundan emin olun.

Testere bıçağı takılırsa, testere yeniden başlatıldığında iş

parçasından yukarı kalkabilir ya da geri tepebilir.

d. Bıçağın sıkışmasını ve geri tepme riskini en aza

indirmek için, geniş panelleri destekleyin. Geniş

paneller kendi ağırlıkları yüzünden eğilebilir. Panelin

altına her iki tarafa, kesim çizgisinin yanına ve panel

kenarlarının yanına destek yerleştirilmelidir.

e. Kör ya da hasarlı bıçaklar kullanmayın.

Keskinleştirilmemiş ya da yanlış ayarlanmış bıçaklar dar

bir kesik yapılmasına ve sonuç olarak aşırı sürtünmeye,

bıçağın sıkışmasına ve geri tepmeye neden olabilir.

f. Kesim yapmadan önce, bıçak derinliği ve eğimi

ayarlamaya yarayan kilitleme kolları sıkı ve sağlam

olmalıdır. Bıçağın ayarı kesim sırasında

değişirse,sıkışmaya ve geri tepmeye neden olabilir.

g. Mevcut duvar veya kör alanlarda “ Dalarak Kesim”

yaparken daha dikkatli olun. Dalan bıçak geri tepmeye

neden olabilecek nesneleri kesebilir.

Düşük koruma fonksiyonu

a. Her kullanım öncesinde alt siperin doğru şekilde

kapandığını kontrol edin. Alt siper serbest olarak

hareket etmiyorsa ve hemen kapanmıyorsa testereyi

çalıştırmayın. Alt siperi asla açık konumda

sıkıştırmayın veya bağlamayın. Testere yanlışlıkla

düşerse, alt siperi bükülebilir. Alt siperi geri çekme kolu

ile indirin ve kesimin tüm açı ve derinliklerinde serbestçe

hareket ettiğinde, bıçak veya diğer parçalara

dokunmadığından emin olun.

16

Page 17

(Çevirisi orijinal talimatlardan yapılmıştır)

TÜRKÇE

b. Alt siper yayının çalışmasını kontrol edin. Koruma

ve yay düzgün çalışmıyorsa, kullanmadan önce

servise alınmalıdır. Alt Siper, arızalı parçalar, yapışkan

tortular ya da biriken pislikler nedeniyle yavaş çalışabilir.

c. Alt siper yalnızca “dalarak kesim” ve “birleşik

kesim” gibi özel kesim işlemlerinde el ile hareket

ettirilmelidir. Bıçak malzemeye girince, hareketli kolu

kaldırarak alt siperi kaldırın, alt siper serbest

bırakılmalıdır. Diğer tüm kesme işlemleri için, alt siper

otomatik olarak çalışmalıdır.

d. Testereyi tezgaha ya da zemine yerleştirmeden

önce, her zaman alt siperin bıçağı örttüğünü

gözlemleyin. Korumasız, hızlı dönen bir bıçak, kestiği

şey ne olursa olsun geriye doğru yürüyecektir. Düğme

bırakıldıktan sonra bıçağın durması için gereken süreye

dikkat edin.

Arta Kalan riskler

Aleti kullanırken, ekte sunulan güvenlik uyarılarına dahil

olmayan ek riskler çıkabilir. Bu riskler hatalı ve uzun süreli

vs. kullanımlarda ortaya çıkabilir.

sağlık sorunları (örneğin:- ahşapta çalışma, özellikle

meşe, kayın ve MDF.)

Güvenlik Kuralları/tanımları

Bu kılavuzu okumanız ve anlamanız çok önemlidir. İçerdiği

bilgiler, Güvenliğinizin Koruması ve Problemleri Engelleme

ile ilgilidir. Aşağıdaki semboller, bu bilgileri tanımanıza

yardımcı olmak için kullanılır.

Tehlike! Dikkate alınmadığı takdirde ölüm veya

ciddi yaralanma ile sonuçlanacak tehlikeli bir

durumu belirtir.

Uyarı! Dikkate alınmadığı takdirde ölüm veya

ciddi yaralanmaya yol açabilecek potansiyel

tehlikeli bir durumu belirtir.

Dikkat! Dikkate alınmadığı takdirde, hafif veya

orta derecede yaralanmaya neden olabilecek

olası potansiyel tehlikeli bir durumu belirtir.

Dikkat! Güvenlik uyarı sembolü olmadan

kullanıldığında, önlenmezse maddi hasara yol

açabilir potansiyel tehlikeli bir durumu işaret eder.

Hatta ilgili güvenlik düzenlemeleri ve güvenlik cihazlarının

uygulanmasıyla bile belirli risklerden kaçınmak mümkün

değildir. Bunların dahilinde:

• Herhangi bir dönen/hareketli parçanın temas etmesi ile

yaralanmalar.

• Herhangi bir parçayı, bıçak veya aksesuarı değiştirirken

meydana gelen yaralanmalar.

• Aletin uzun süreli kullanılması sonucu ortaya çıkan

yaralanmalar. Herhangi bir aletin uzun süreli

kullanımında düzenli olarak çalışmanıza ara verin.

• Duyma bozukluğu.

• Aleti kullanırken toz soluması sonucu ortaya çıkan

Dairesel Testere İçin Ek Güvenlik Kuralları

Uyarı! Elektrikli zımparalama, kesme, taşlama,

delme ve diğer inşaat faaliyetleri tarafından

ortaya çıkan tozlar, kansere, doğum kusurlarına veya

diğer üreme bozukluklarına yol açan kimyasallar içerir.

Bu kimyasallara örnek olarak:

• Kurşun bazlı boyalardan kurşun,

• Tuğla ve çimento ve diğer duvarcılık ürünlerinden

kristalize silika,

• Kimyasal işlem görmüş keresteden krom ve arsenik

(CCA).

17

Page 18

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Bu maruziyet ile risk, bu tür çalışmayı ne sıklıkta yaptığınıza

göre değişiklik gösterir. Bu kimyasallara maruz kalmayı

azaltmak için:

• İyi havalandırılmış bir alanda çalışın ve onaylanmış,

mikroskobik partikülleri filtrelemek için tasarlanmış özel

tasarım toz maskeleri gibi güvenlik ekipmanları kullanın.

• Elektrikli zımparalama, kesme, taşlama, delme ve

diğer inşaat faaliyetlerinin tozundan uzun süreli

temastan kaçının. Koruyucu giysiler giyin ve maruz

kalan bölgeleri su ve sabunla yıkayın. Tozun ağzınıza,

gözlerinize girmesi veya cilde temas etmesi, zararlı

kimyasalların emilimini teşvik edebilir.

Dikkat! Kullanım sırasında uygun kulaklık

kullanın. Bazı koşullar ve kullanım süresine göre,

bu üründen çıkan gürültü işitme kaybına katkıda

bulunabilir.

• Kesilen malzemenin altında bir yüzey üzerinde alt

siperin takılması kullanıcının kontrolünü bir anlık

düşürebilir. Testere, bıçağın bükülme olasılığını artıran,

kesiğin içinden kısmen çıkabilir. İş parçasının altında

yeterli boşluk olduğundan emin olun.

• Gerektiğinde alt siperi elle kaldırmak için, geri

çekme kolunu kullanın.

• Bıçakları Temiz ve Keskin Tutun. Keskin bıçaklar

takılmayı ve geri tepmeyi en aza indirir. Kör ve/veya kirli

bıçaklar kullanıldığında, kullanıcı daha sert iter bu da

testere yükünü artırır ve bükülmeyi tetikler.

Dikkat! Laserasyon Tehlikesi. Ellerinizi kesim

alanlarından uzakta tutun. Ellerinizi bıçaklardan uzakta

tutun. Kesme esnasında, ellerinizi bıçak yolu üzerinin

önünde veya arkasında tutmayın. Bıçak dönerken iş

parçasının altına elinizi sokmayın. Bıçak hareket

halindeyken kesilen parçayı çıkarmaya çalışmayın.

• Geniş panallere destek. Büyük panellerin, sıkışma ve

geri tepme riskini azaltmak için bu kılavuzda gösterildiği

gibi desteklenmesi gerekir (Şekil A). Sadece ucundan

desteklenen malzeme, bıçağın sıkışmasına yol açacaktır

(Şekil B). Kesme işlemi esnasında testerenin çalışma

parçası üzerinde dayanması gerektiğinde, testere geniş

bölüme dayanır ve daha küçük parça kesilir.

bıçakları kullanmayın. Asla arızalı ya da hatalı bıçak

pulları veya cıvataları kullanmayın. Bıçak takımı

prosedürlerini izleyin.

Testere bıçakları

• Önerilenden daha büyük veya daha küçük çaplı bıçaklar

kullanmayın. Doğru bıçak değerlendirmesi için teknik

verilere bakın. Sadece bu kılavuzda belirtilen uygun

bıçakları kullanın EN 847-1.

Uyarı! Asla aşındırıcı jantlar kullanmayın.

Diğer kişilerin güvenliği

• Bu alet fiziksel, zihinsel veya algılama gücü azalmış

veya yeterince deneyim ve bilgisi bulunmayan kişiler

(çocuklar dahil) tarafından kullanılmak üzere

üretilmemiştir, bu tür kişiler aleti ancak güvenliklerinden

sorumlu bir kişi tarafından cihazın kullanımıyla ilgili

talimatları verilmesi veya sürekli kontrol altında tutulması

ile kullanabilir.

• Çocuklar, aletle oynamalarını önlemek amacıyla kontrol

altında tutulmalıdır.

Alet üzerindeki etiketler

Alet üzerinde aşağıdaki semboller bulunabilir:

Hz ....... Hertz

Kullanım

Kılavuzunu

Okuyun

Koruyucu

Gözlük kullanın

Kulaklık

Kullanın

V ........ Volt

A ........ Amper

W ........ Vat

dak ..... dakika

boş .......

Alternatif

.....

Akım

Direkt

.....

Akım

Yüksüz

Hız

Tarih kodu konumu

İmalat yılını da içeren Tarih Kodu gövdeye basılıdır.

Örnek:

2015 XX JN

İmalat Yılı

Elektrik güvenliği

Bu alet çift yalıtımlıdır; bu yüzden hiç bir güvenlik

kablosuna gerek yoktur. Her zaman şebeke

geriliminin aletin üretim etiketinde belirlenmiş

değerlere uyup uymadığını kontrol edin.

......

....

....

.../min..

Sınıf II

İnşaat

Topraklama

Terminal

Güvenlik

uyarısı

Sembolü

Dakikada

devir veya

gel git sayısı

• Bıçakları monte ederken yalnızca doğru bıçakları ve

bıçak bileşenlerini kullanın. Yanlış ebatta delikleri olan

18

Page 19

(Çevirisi orijinal talimatlardan yapılmıştır)

TÜRKÇE

Uyarı! Güç kablosu hasarlı ise, zarar veya

yaralanmayı önlemek için, üretici tarafından,

STANLEY Hizmet Merkezinde veya eşit nitelikte

yetkili kişi tarafından değiştirilmelidir. Kablo, eşit nitelikte

yetkili kişi tarafından değiştirildi ise, ancak STANLEY

tarafından yetkili değilse, garanti geçerli olmayacaktır.

Ek elektrikli alet güvenlik uyarıları

Uyarı! Tüm testereler için güvenlik talimatları

• Ayarlamalar. Kesime başlamadan önce derinlik ve eğim

ayarlarının sıkı olduğundan emin olun.

• Çalışmayı düzgünce destekleyin ve güvenceye alın.

Kesilecek malzemenin, çalışma yüzeyine dengeli, sabit

ve güçlü şekilde kenetlendiğinden (Şekil C) ve sağlam

desteklendiğinden ve dengeli olduğundan emin olun.

Kesme yaparken, testere tabanının geniş bölümünü iş

parçasının düşecek kısmının değil altı sağlam şekilde

desteklenen kısmının üzerine yerleştirin. Kesilen parçayı

asla elinizle tutmayın (Şekil D). Bıçak sıkışması geri

tepmeye neden olabilir. Testereyi her zaman iki elinizle

tutun.

• Uyanık kalın ve kontrole sahip olun. Vücudunuzu

bıçağın bir tarafında tutun. Testereyi daima iki elinizle

sağlam bir şekilde tutun ve kontrolünü sağlayın. Testere

çalışırken el tutuş veya vücut pozisyonunu

değiştirmeyin. Çalışma sırasında kesilen parçalar ve

diğer düşen malzemelerden yaralanmamak için önlem

alın.

Tehlike! Bıçak takılır veya testere saplanırsa

derhal düğmeyi bırakın.

Özellikler (Şekil E)

Bu alet aşağıdakilerin bir kısmını veya tümünü içermektedir.

1. Açma/Kapama Düğmesi

2. Ana Kol

3. Yan Kol

4. Taban

5. Testere Bıçağı

6. Alt muhafaza

7. Muhafaza geri çekme kolu

8. Bıçak anahtarı

9. Açı ayarlama kolu

10. Dış conta

11. Bıçak tutma vidası

15. Bıçak altıgen anahtarı (Şekil I’da gösterilmektedir)

18. Paralel kesme kılavuzu (Şekil M’de gösterilmektedir)

20. İç flanş (Şekil J’de gösterilmektedir)

21. Kesintisiz çalıştırma düğmesi

23. Üst muhafaza

Montaj/ayarlama düzeni

Uyarı! Aşağıdaki işlemlerden herhangi birini

uygulamadan önce daima testerenin fişini güç

aracından çıkarın.

Kesim derinliğinin ayarlanması (Şekil F ve G)

Kesim derinliği, üzerinde çalışılan parçanın kalınlığına göre

ayarlanmalıdır.

• Testere tabanı kilidini açmak için kolu gevşetin (12).

• Testere tabanını (4) istediğiniz konuma getirin. İlgili

konuma karşılık gelen kesim derinliği ölçekten (13)

okunabilir.

• Testere tabanını ilgili konumda kilitlemek için kolu sıkın.

• Testerenin derinlik ayarını bıçak dişlerinden yalnızca bir

tanesi iş parçası altından çıkacak şekilde ayarlayın, Şekil

G’de gösterildiği gibi.

Eğim açısının ayarlanması (Şekil H)

Bu alet, 0° ila 45° derece arasındaki kesme açılarına

ayarlanabilir

• Testere tabanının kilidini açmak için kilitleme düğmesini

gevşetin (9).

• Testere tabanını (4) istediğiniz konuma getirin. İlgili

konuma karşılık gelen gönye açısı ölçekten (14)

okunabilir

• Testere tabanını ilgili konumda kilitlemek için kilitleme

düğmesini sıkın.

Bıçağın takılması (Şekil I ve J)

• Mil dönmesini önlemek için, dış rondeladaki (10)

deliklerin içine somun anahtarının (8) çıkıntılarını geçirin,

şekil I’da görüldüğü gibi.

• Altıgen anahtarı (15) saat yönünün tersine çevirerek

bıçak tutucu vidayı (11) gevşetin ve çıkartın.

• Dış rondelayı çıkartın.

• Milin üzerindeki (16) iç flanşı (20) kontrol edin ve tekrar

monte edin. Doğru ebattaki iç flanşın (20) dışa dönük

olduğundan ve testere bıçağı ile mil çapının

eşleştiğinden emin olun.

• İç flanş (20) üzerine testere bıçağını (5) yerleştirin, alet

üzerindeki ok ile bıçak üzerindeki okun aynı yönü

gösterdiğinden emin olun.

• Dış rondelayı (10) milin üzerine takın.

• Bıçak tutucu vidayı (11) mildeki deliğe takın.

19

Page 20

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

• Dış rondela deliklerine somun anahtarını geçirerek mil

dönüşünü engelleyin.

• Somun anahtarını tutarak bıçak tutucu vidayı sıkılayın ve

altıgen anahtarı saat yönünde çevirerek bıçak tutucu

vidayı sıkın.

Uyarı! Sırasıyla “19” ve “20” olarak işaretli iç flanşı

(20), 19mm ve 20mm çaplı mil ile testere bıçağını

(5) eşleştirin.

Bıçağı çıkartma

Mil dönmesini engellemek için, dış rondeladaki (10)

deliklerin içine somun anahtarının (8) çıkıntılarını geçirin.

• Altıgen anahtar (15) kullanarak, bıçak tutucu vidayı (11)

saat yönünün tersine çevirerek gevşetin ve çıkarın.

• Dış rondelayı çıkartın (10).

• Testere bıçağını (5) çıkartın. Uyarı! Ciddi kişisel

yaralanma riskini azaltmak için, bu aleti kullanmadan

önce tüm güvenlik uyarılarını ve talimatları izleyin.

Genel Kesimler

Geri tepme koruması

Alet fişten çekili olarak, tüm montaj, ayarlamalar ve kurulum

talimatlarını takip edin. Alt siperin çalışır olduğundan emin

olun. Malzeme kesmek için uygun bıçağı seçin.

• Kesmek için ölçün ve işaretleyin.

• Çalışmayı destekli ve güvenli yapın (Güvenlik Kuralları

ve Talimatlara bakın).

• Uygun ve gerekli güvenlik elemanlarını kullanın

(Güvenlik Kurallarına Bakın).

• Çalışma alanını sağlama alın ve bunu sürdürün

(Güvenlik Kurallarına Bakın).

• Fiş takılı ve koruma kapalı iken, anahtarın testereyi açık

ve kapalı konuma getirdiğinden emin olun.

Uyarı! Çalışmayı düzgün desteklemek ve kişisel

yaralanmayı önlemek için testereyi güvenli

şekilde tutmak önemlidir. Şekil C önerilen el

pozisyonunu göstermektedir.

İşlem

Açılması ve kapatılması (Şekil E)

Güvenlik nedeniyle açma/kapama tetiği (1) tetik kilidi düğmesi

(21) ile donatılmıştır. Tetik kilidini açmak için tetik kilidi

düğmesine basın.

Aleti çalıştırmak için, açma/kapama tetiğine (1) basın.

Tetiği bırakınca tetik kilidi düğmesi aletin istem dışı

çalıştırılmasını engelleyerek otomatik olarak devreye girer.

İKAZ: Bıçak, üzerinde çalışılan parçaya veya diğer

malzemelere temas halindeyken aleti açmayın veya

kapatmayın.

Testere ile kesme

Uyarı! Ciddi kişisel yaralanmayı azaltmak için,

aleti daima iki elinizle tutun.

• Kesim başlamadan birkaç saniye bıçağı serbest

çalışmaya bırakın.

• Kesme işlemi sırasında alete yalnızca hafif bir baskı

uygulayın.

• İş parçasına karşı sıkıştırılmış taban ile çalışın.

Optimum Kullanım İçin İpuçları

• İş parçasının üst kısmında kesme çizgisi boyunca bir

çatlama önlenemez, çatlamanın kabul edilebilir olduğu

yüzeyden kesin.

• Çatlamanın en aza indirilmesi için, örn. laminat

keserken, iş parçasının üzerine kontrplak sıkılayın.

Dalarak kesim (Şekil K)

Dalarak kesim, bir malzeme parçasında kenar

kesilmeden bir boşluk kesmek için kullanılır.

• İş parçasını ölçün ve işaretleyin.

• Testereyi kesilecek malzeme üzerinde tabanın ön

kısmında ileriye ve geri çevirin. Hizalayın, böylece kesim

çizilmiş dörtgenin arkasından başlayacak, Şekil K’da

gösterildiği gibi.

• Geri çekme kolunu kullanarak, bıçak muhafazasını

yukarı konuma çekin, bıçak malzemenin üzerinde olacak

şekilde, motoru çalıştırın ve testereyi yavaş yavaş

malzemenin içine yöneltin.

Uyarı! Bıçak malzemeyi kesmeye başladığında,

geri çekme kolunu derhal bırakın.

• Bıçak muhafazayı asla yukarı pozisyonda bağlamayın.

• Kesilen malzemenin üzerinde taban düz duruyorsa,

kesimi ileri yönde tamamlayın.

• Testereyi malzemeden çıkarmadan önce, testerenin

tamamen durmasını bekleyin.

• Her yeni kesimde, yukarıdaki adımları tekrarlayın.

Anahtar saklama (Şekil L)

Somun anahtarı (8), şekil L’de gösterildiği gibi testere

tabanında saklanabilir.

Destek perdesi takma ve çıkarma (Şekil M)

Destek perdesi, bir iş parçasının kenarına paralel düz bir

çizgi kesimi için kullanılır.

20

Page 21

(Çevirisi orijinal talimatlardan yapılmıştır)

TÜRKÇE

Takılması

• Kilitleme düğmesini (17) gevşetin.

• Destek perdesini (18) açıklığa takın (19).

• Destek perdesini istenen konuma getirin.

• Kilitleme düğmesini sıkın.

Çıkarma

• Kilitleme düğmesini gevşetin.

• Destek perdesini aletten çıkarın. Not: Uygun bir perdeniz

yoksa, doğru kesimi geliştirmek için taban kenarı ile

temas halinde olan bir düz kenar kılavuzunu kullanın ve

takılma ve geri tepme olasılığını azaltın.

Toz atma çıkışının takılması (Şekil E, F, N)

Daire testereniz toz atma çıkışı ile birlikte sunulur.

TOZ ATMA ÇIKIŞINI TAKMAK İÇİN (ŞEKİL N)

1. Kesim derinliği tırnağını tamamen gevşetin (Şekil F, 12).

2. Taban plakasını (Şekil a, 4) en düşük konuma yerleştirin.

3. Toz atma çıkışının (22) iki yarısını resimde gösterildiği

şekilde üst muhafaza (23) üzerinde hizalayın.

4. Vidaları takın ve sağlam bir şekilde sıkın.

Toz atma (Şekil O)

UYARI! Toz solunması riski. Yaralanma riskini

azaltmak için, DAİMA onaylı toz maskesi takın.

Toz atma çıkışı (22) aletiniz ile birlikte sunulur. Yaygın olarak

kullanılan çoğu elektrik süpürgelerin hortumları toz atma

çıkışına doğrudan takılmaya uygundur.

UYARI! HER ZAMAN ağaç kesme işleri sırasında

oluşturan toz emisyonlarıyla ilgili yönetmeliklere göre

tasarlanmış olan bir elektrik süpürgeyi kullanın. Yaygın olarak

kullanılan çoğu elektrik süpürgelerin hortumları toz atma

çıkışına doğrudan takılmaya uygundur.

Aksesuarlar

Aletinizin performansı kullanılan aksesuarlara bağlıdır.

Stanley ve Piranha aksesuarları, yüksek kalite standartlara

göre üretilmiş ve aletinizin performansını artıracak şekilde

tasarlanmıştır. Bu aksesuarları kullanarak, aletinizden en iyi

verimi alacaksınız.

Uyarı! Bu alet ile kullanılması önerilmeyen

aksesuarların kullanılması tehlikeli olabilir. Sadece,

19mm veya 20mm çaplı mil ile 185mm bıçak

kullanın.

Bakım

Stanley aletiniz minimum bakımla uzun bir süre çalışacak

şekilde tasarlanmıştır. Kesintisiz olarak memnuniyet verici bir

şekilde çalışması gerekli özenin gösterilmesine ve düzenli

temizliğe bağlıdır.

Uyarı! Herhangi bir bakım yapmadan önce, aleti

kapatın ve fişten çekin.

• Aletinizdeki havalandırma deliklerini yumuşak bir fırça

veya kuru bir bezle düzenli olarak silin.

• Motor muhafazasını düzenli olarak nemli bir bezle silin.

Aşındırıcı veya çözücü bazlı temizleyiciler kullanmayın.

Önemli! Ürün EMNİYET ve GÜVENİLİRLİĞİNİ sağlamak

için, onarımlar, bakımlar ve ayarlar (bu kılavuzda

belirtilenler dışında), yetkili servis merkezleri veya diğer

yetkili merkez personeli tarafından yapılmalıdır, her

zaman birbirinin aynı yedek parçalar kullanılmalıdır.

Yağlama

Stanley aletleri, fabrikada düzgün şekilde yağlanmış ve

kullanıma hazırdır.

Teknik Veriler

Özellikler STSC1618

Voltaj 220-240V

Frekans 50/60Hz

Güç 1600W

Yüksüz Hız 5500/dak (dds)

Maksimum kesme derinliği 62mm DE 90°

46mm DE 45°

LpA (ses basıncı) dB(A) 92.5

K

pA

L

(akustik güç) dB(A) 103,5

WA

K

WA

Göre toplam titreşim değerleri (üç yönün vektör

toplamı) EN 60745:

) = 6,6 m/s²

h.w

Belirsizlik (K) = 1.5 m/s²

dB(A) 3

Titreşim

Teknik veriler ve uygunluk beyanatı içerisinde belirtilen

titreşim emisyon değerleri EN 60745 tarafından belirlenen

standart bir test yöntemine uygun olarak ölçülmektedir ve

diğer bir aletle karşılaştırma yaparken kullanılabilir. Beyan

edilen titreşim emisyon değeri aynı zamanda maruz

kalmanın önceden değerlendirilmesinde de kullanılabilir.

21

Page 22

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Uyarı! Elektrikli aletin mevcut kullanımı sırasındaki titreşim

emisyon değeri, aletin kullanım yöntemine bağlı olarak,

beyan edilen değere göre farklılık sergileyebilir Titreşim

düzeyi belirlenen seviyenin üzerinde artış gösterebilir.

İşyerinde düzenli olarak elektrikli alet kullanan çalışanları

korumak amacıyla 2002/44/EC tarafından getirilen elektrik

güvenliği önlemlerini belirlemek üzere titreşime maruz

kalmayı değerlendirirken, çalışma döngüsü içerisinde

örneğin aletin kapalı olduğu ve aktif durumda olmasının yanı

sıra boşta çalıştığı zamanlar gibi, bütün zaman dilimleri dahil

olmak üzere mevcut kullanım durumu ve aletin kullanım şekli

göz önünde bulundurularak değerlendirilmelidir.

AT uygunluk beyanı

MAKİNE DİREKTİFİ

Daire Testere STSC1618

STANLEY, "teknik özellikler" bölümünde açıklanan bu

ürünlerin bu yönergelere uygun olduğunu beyan eder:

2006/42/EC, EN 60745-1:2009 +

A11:2010, EN 60745-2-5:2010

Bu ürünler aynı zamanda Direktif ile uyumludur. 2004/108/EC

(19/04/2016'ya kadar) 2014/30/EU (20/04/2016'dan itibaren)

ve 2011/65/EU. Daha fazla bilgi için, lütfen aşağıdaki

adresten STANLEY ile temasa geçin veya kılavuzun

arkasına bakın.

Bu belge altında imzası bulunan yetkili, teknik dosyanın

derlenmesinden sorumludur ve bu beyanı STANLEY adına

vermiştir.

Servis Bilgisi

STANLEY, yetkili servisler ile tam bir servis ağı sunmaktadır.

Tüm STANLEY Servis Merkezleri müşterilere etkili ve güvenilir

elektrikli el aleti hizmeti sunmak için eğitimli personel ile

donatılmıştır. Yetkili servis merkezlerimiz hakkında daha fazla

bilgi almak istiyorsanız veya teknik danışmanlık, onarım ya da

orijinal fabrika yedek parçası ihtiyacınız varsa, size en yakın

STANLEY satış noktasına başvurun.

Çevrenin korunması

Ayrı toplanmalı. Bu ürün normal ev atıklarıyla birlikte

atılmamalıdır.

Stanley ürünlerinizin değiştirilmesi gerektiğinde ya da artık

kullanmanızı gerektirmeyen bir gün geldiğinde, evsel atıklarla

birlikte atmayın. Bu ürünün ayrı toplanmasını sağlayın.

Kullanılmış ürünlerin ve ambalajların ayrı toplanması

bu maddelerin geri dönüşüme tabii tutularak yeniden

kullanılmasına olanak tanır.

Yeniden kullanım, geri dönüşümlü malzemelerin çevre

kirliliğinin önlenmesine yardımcı olur ve ham madde

ihtiyacını azaltır.

Yerel düzenlemeler, elektrikli ürünlerin evlerden toplanıp

belediye atık tesislerine aktarılmasını veya yeni bir ürün satın

alırken perakende satıcı tarafından toplanmasını sağlayabilir.

Stanley hizmet ömrünün sonuna ulaşan Stanley ürünlerinin

toplanması ve geri dönüşüme sokulması için bir imkan

sunmaktadır. Bu hizmetin avantajlarından faydalanmak için,

lütfen, ürününüzü bizim adımıza teslim alacak herhangi bir

yetkili servise iade edin.

Bu kılavuzda belirtilen adresteki yerel Stanley ofisine

başvurarak size en yakın yetkili tamir servisinin yerini

öğrenebilirsiniz. Alternatif olarak, internet’ten Stanley yetkili

tamir servislerinin listesini ve satış sonrası hizmetlerimizle

ilgili tüm bilgiler ve temas bilgilerine bu adresten

ulaşabilirsiniz: www.2helpU.com

R.Laverick

Mühendislik Yöneticisi

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

08.2015

22

Page 23

(Çevirisi orijinal talimatlardan yapılmıştır)

İki yıl garanti

Stanley ürününüz, satın alma tarihinden itibaren 24 ay içinde

hatalı malzeme veya işçilik nedeniyle bozulursa, Stanley

tüm arızalı parçaları ücretsiz değiştirmeyi garanti

ediyor veya – takdirimize bağlı olarak – birimlerin ücretsiz

olarak değiştirilme koşulları şunlardır:

• Ürün, yanlış kullanılmamıştır ve kullanım kılavuzuna

uygun olarak kullanılmıştır.

• Ürün, normal aşınma ve yıpranmaya maruz kalmıştır;

• Onarımlar, yetkisiz kişiler tarafından yapılmamıştır;

• Satın alma belgesi, ibraz ediliyor.

• Stanley ürünü tüm orijinal bileşenleri ile tam olarak geri

getiriliyor

Bir talepte bulunmak isterseniz, satıcınızla temasa geçin

veya Stanley kataloğunda size en yakın yetkili Stanley

onarım servisinin yerini kontrol edin veya bu kılavuzda

belirtilen adresteki yerel Stanley ofisine başvurun. Yetkili

Stanley tamir ajanları ve satış sonrası hizmetlerimizle ilgili

tüm detayların bir listesini bu internet adresinde bulabilirsiniz:

www.stanleytools.com

TÜRKÇE

Sanayi ve Ticaret Bakanlığı tebliğince kullanım ömrü 7 yıldır.

Türkiye Distribütörü

STANLEY BLACK&DECKER TURKEY ALET URETIM SAN. TIC. LTD.STI.

Kozyatağı Mh Değirmen Sk. Nida Kule No:18 Kat:6

34742 Kadıköy İstanbul

Tel : (0216) 665 29 00

Faks : (0216) 665 29 01

E-posta: info-tr@sbdinc.com

23

Page 24

РУССКИЙ

(Перевод с оригинала инструкции)

Использование по назначению

Ваша пила STANLEY предназначена для распиловки

древесины и изделий из нее.

• Для инструментов, предназначенных для

распиловки леса, инструкция по правильному

использованию системы сбора пыли.

• Для инструментов, предназначенных для

распиловки леса, инструкции по ношению защитной

маски.

• Инструкция для использования только

рекомендованных циркулярных пил.

• Инструкция для обязательного использования

средств защиты органов слуха.

НЕ ВОЗВРАЩАЙТЕ ЭТО ИЗДЕЛИЕ В МАГАЗИН,

сначала обратитесь в ваш местный офис STANLEY или

в ближайший авторизованный сервисный центр.

Общие правила техники безопасности

Внимание! Прочитайте и поймите все

инструкции. Несоблюдение любых

инструкций, указанных ниже, может привести

к поражению электрическим током, пожару и/или

серьезной травме.

СОХРАНИТЕ ЭТИ ИНСТРУКЦИИ

Правила техники безопасности

Общие предупреждения по технике безопасности

электроинструментов

Внимание! Ознакомьтесь со всеми правилами

безопасности и инструкциями. Несоблюдение

предупреждений и инструкций, указанных ниже, может

привести к поражению электрическим током, пожару

и/или серьезной травме.

Сохраните все предупреждения и инструкции для

будущего использования.

Термин "электроинструмент" во всех предупреждениях,

указанных ниже, относится к вашему сетевому (с

кабелем) электроинструменту или аккумуляторному

электроинструменту (без кабеля питания).

1. Безопасность рабочего места

а. Содержите рабочее место в чистоте и хорошо

освещенным. Беспорядок на рабочем месте или

отсутствие освещения рабочего места может

привести к аварии.

b. Не работайте с электроинструментом в месте

хранения взрывоопасных материалов, например,

в присутствии огнеопасных жидкостей, газов или

пыли. Электрические инструменты создают искры,

которые могут воспламенить пыль или пары.

с. Дети и посторонние лица должны находиться как

можно дальше во время работы с

электроинструментом. Вы можете отвлечься и

потерять контроль.

2. Электробезопасность

а. Вилка электроинструмента должна

соответствовать розетке. Никогда не

модифицируйте вилку каким-либо образом. Не

используйте никакие вилки-переходники с

заземленными (замкнутыми на землю)

электроинструментами. Вилки и розетки, которые

не подвергались никаким изменениям снижают риск

поражения электрическим током.

b. Избегайте контакта тела с заземленными

поверхностями, такими как трубы, радиаторы,

плиты и холодильники. Существует повышенный

риск поражения электрическим током, если ваше

тело заземлено.

с. Избегайте любого воздействия дождя или влаги

на электроинструменты. Вода, попавшая в

электроинструмент, увеличивает риск поражения

электрическим током.

d. Аккуратно обращайтесь со шнуром питания.

Никогда не используйте шнур питания для

переноски, перемещения или извлечения вилки

из розетки. Держите шнур вдали от источников

тепла, масла, острых краев или движущихся частей.

Поврежденные или запутанные шнуры увеличивают

риск поражения электрическим током.

е. При работе с электроинструментом на улице,

используйте удлинитель, подходящий для

наружного использования. Использование кабеля,

пригодного для использования на открытом воздухе,

снижает риск поражения электрическим током.

f. При необходимости работы с

электроинструментом во влажной среде,

используйте устройство защитного отключения

(УЗО). Использование УЗО снижает риск поражения

электрическим током. Примечание: Термин

“устройство защитного отключения (УЗО)” может

быть заменен на "аварийный прерыватель

заземления" или "автоматический выключатель тока

утечки".

24

Page 25

(Перевод с оригинала инструкции)

РУССКИЙ

3. Личная безопасность

a. Будьте внимательны, смотрите, что вы делаете,

используйте здравый смысл при работе с

электроинструментом. Не используйте

электроинструмент, если вы устали или находитесь

под влиянием наркотиков, алкоголя или лекарств.

Малейшая неосторожность при работе с

электроинструментом может привести к серьезным

травмам.

b. Используйте средства индивидуальной защиты.

Всегда надевайте защитные очки. Другое

защитное оборудование, включая респиратор,

ботинки на нескользящей подошве, защитный

шлем или средства защиты органов слуха,