Page 1

STRR1200

English Page 3

Russian Page 15

Ukrainian Page 26

Page 2

ENGLISH

(Original instructions)

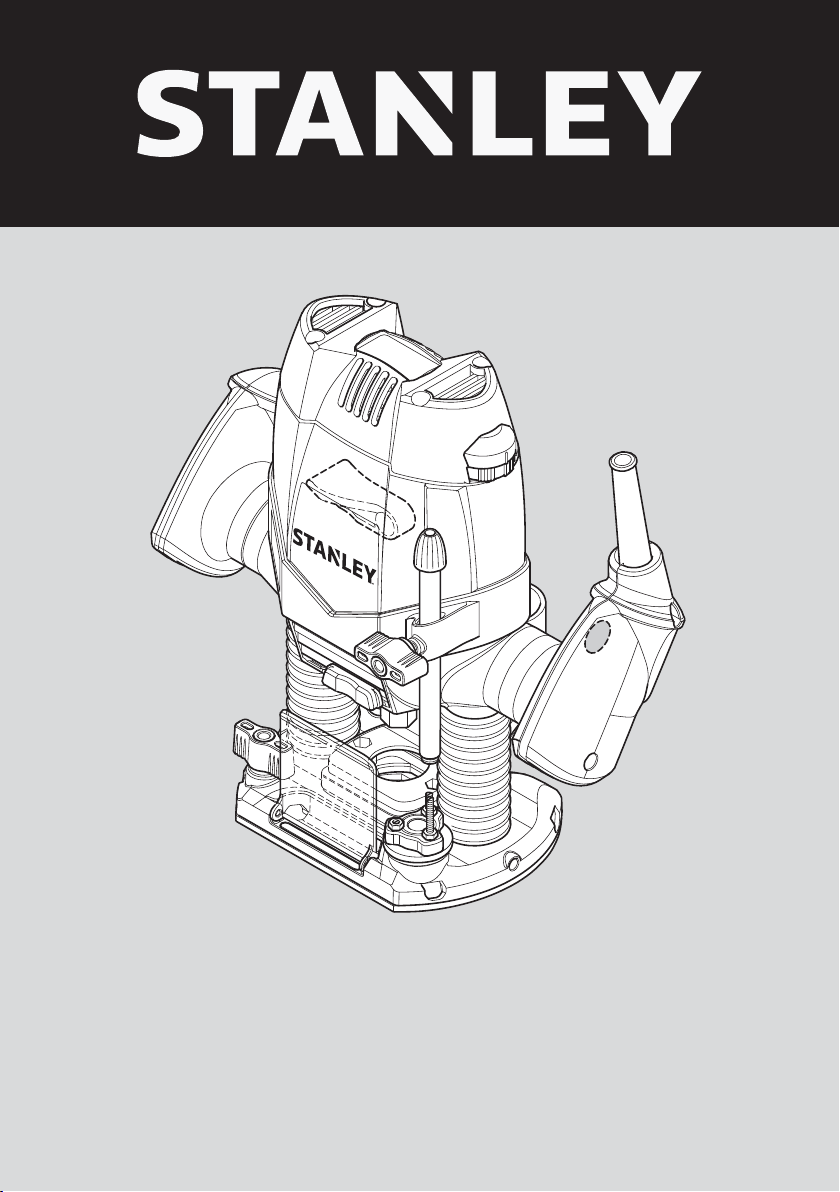

FIG. A FIG. B

3

4

10

11

5

6

1

8

7

FIG. C

2

9

FIG. D

14

5

6

12

13

13

18

FIG. E

2

20

17

15

19

16

11

FIG. F

21

Page 3

(Original instructions)

ENGLISH

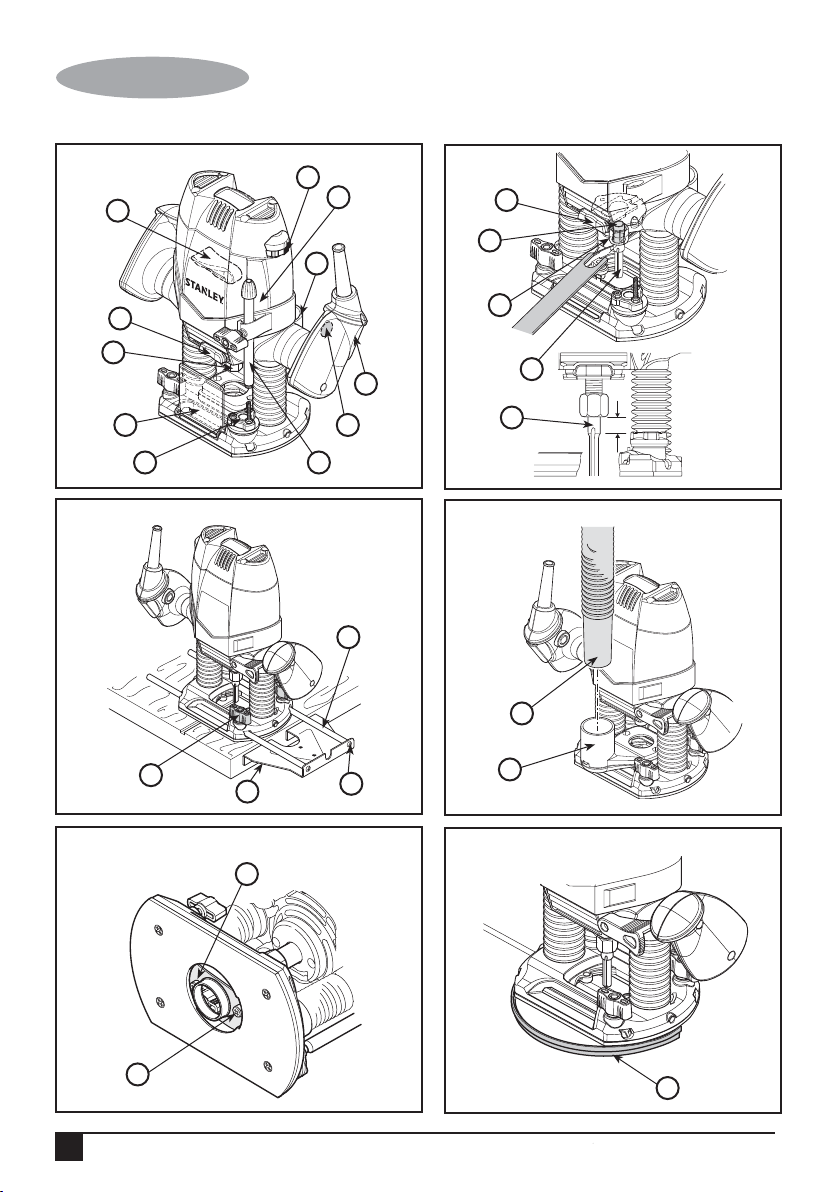

FIG. G

FIG. I

22

23

27

FIG. H

24

25

26

FIG. J

30

9

10

29

28

FIG. K

9

FIG. L

30

9

1

28

31

27

3

Page 4

ENGLISH

(Original instructions)

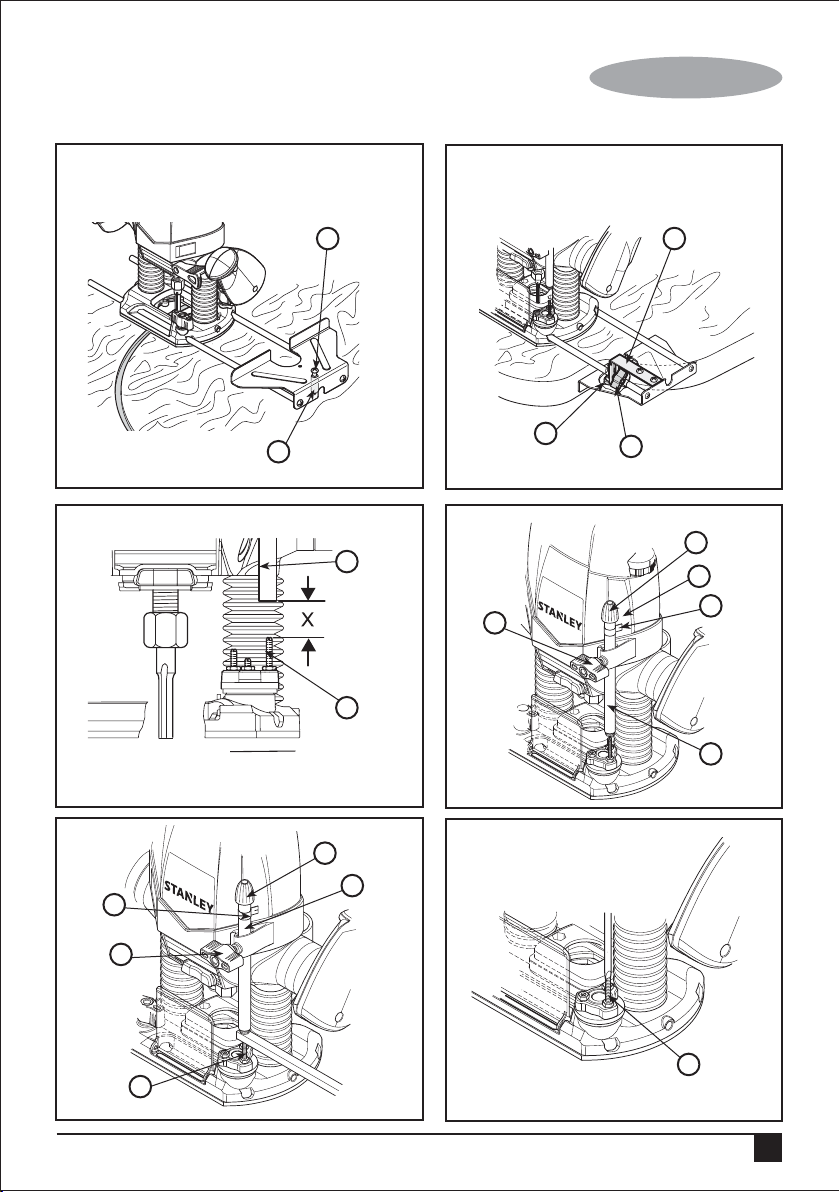

FIG. M FIG. N

FIG. O

FIG. P

*Router bit types, for reference only

4

Page 5

(Original instructions)

ENGLISH

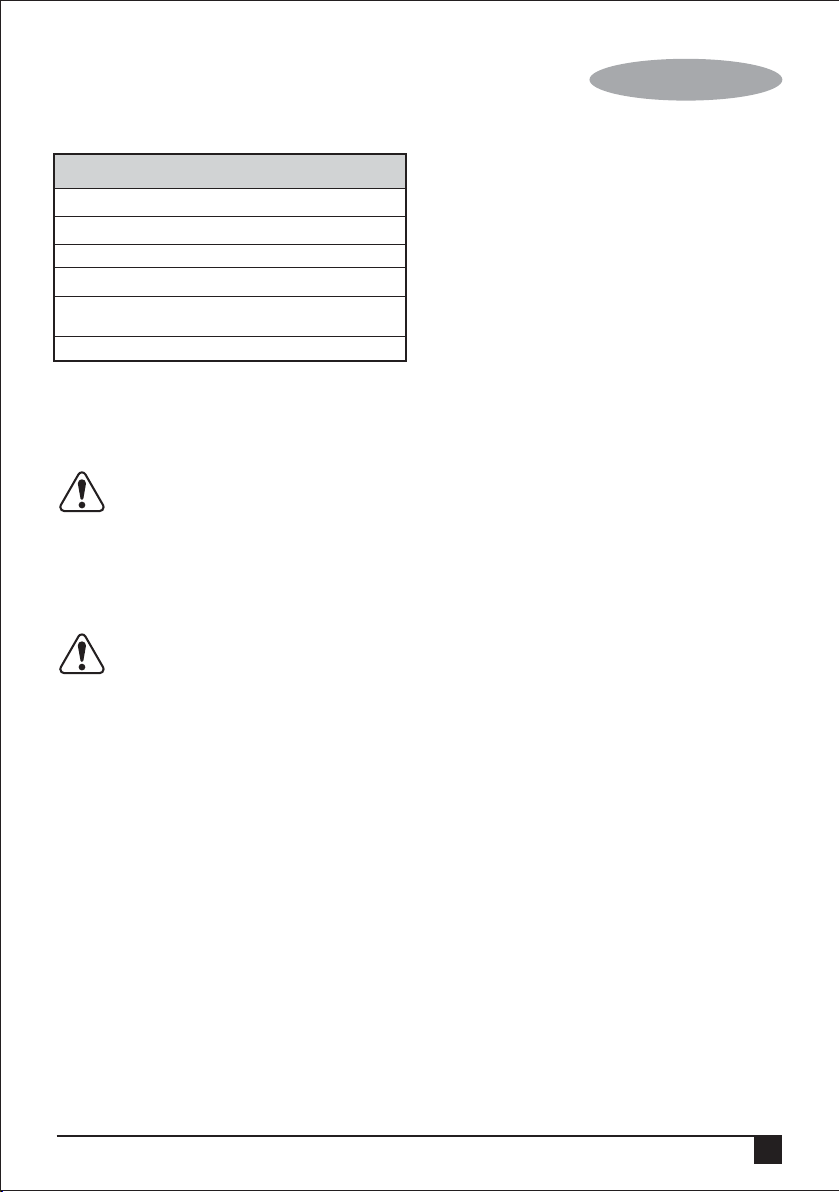

Technical data

STRR1200

Input voltage VAC 220-240

Frequency Hz 50/60

Power input W 1,200

No-load speed

Collet size 6 mm /

6.35 mm / 6 mm

Cord m 2.5

DO NOT RETURN THIS PRODUCT TO THE STORE,

first contact your local STANLEY Office

or nearest authorized service center.

/min

8,000 - 27,000

General Safety Rules

Warning! Read and understand all instructions.

Failure to follow all instructions listed below, may

personal injury.

result in electric shock, fire and/or serious

Save These Instructions

Safety instructions

General power tool safety warnings

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

b. Do not operate power tools in explosive

c. Keep children and bystanders away while operating

2. Electrical safety

a. Power tool plugs must match the outlet. Never

instructions listed below may result in electric

areas invite accidents.

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

a power tool. Distractions can cause you to lose

control.

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock. Note: The term “Residual Curent Device

(RCD)” can be replaced by “Ground Fault Circuit

Interrupter (GFCI)” or by “Earth Leakage Circuit Breaker

(ELCB)”.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

5

Page 6

ENGLISH

(Original instructions)

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Additional Safety Instructions For Routers

• Hold power tool by insulated gripping surfaces,

because the cutter may contact its own cord. Cutting

a "live" wire may make exposed metal parts of the power

tool "live" and shock the operator.

• Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding

6

the work by your hand or against the body leaves it

unstable and may lead to loss of control.

• Only use router bits with a shank diameter equal to the

size of the collet installed in the tool.

• Only use router bits suitable for the no-load speed of the

tool.

• Never use router bits with a diameter exceeding the

maximum diameter specified in the technical data

section.

• Do not use the tool in an inverted position.

• Do not attempt to use the tool in a stationary mode.

• Take special care when routing MDF or surfaces coated

with lead-based paint.

• Wear a dust mask specifically designed for protection

against lead paint dust and fumes and ensure that

persons within or entering the work area are also

protected.

• Do not let children or pregnant women enter the work

area.

• Do not eat, drink or smoke in the work area.

• Dispose of dust particles and any other debris safely.

• Always wear a dust mask.

• This appliance is not intended for use by young or infirm

persons without supervision. Children must be

supervised to ensure they do not play with the appliance.

Features (Fig. A)

1. On/off switch

2. Lock-off button

3. Variable speed control knob

4. Plunge lock lever

5. Spindle lock button

6. Collet

7. Revolver depth stop

8. Chip deflector

9. Depth stop bar

10. Depth of cut scale

11. Dust extraction adaptor

Page 7

(Original instructions)

ENGLISH

6. Labels on tool

The label on your tool may include the following symbols:

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

....... No-Load

0

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety A lert

Symb ol

.../min.. Revolut ions

or Recipr ocation p er

minute

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

7. Electrical safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main

voltage corresponds to the voltage on the rating

plate.

Warning! If the power cord is damaged, it must

be replaced by the manufacturer, authorized

STANLEY Service Center or an equally qualified

person in order to avoid damage or injury. If the power cord

is replaced by an equally qualified person, but not authorized

by STANLEY, the warranty will not be valid.

Assembly

Warning! Before assembly, make sure that the

tool is switched off and unplugged.

Fitting A Router Bit (Fig. B)

• Remove the chip deflector (8).

• Keep the spindle lock button (5) depressed and rotate

the spindle until the spindle lock fully engages.

• Loosen the collet nut (12) using the spanner provided.

• Insert the shank of the router bit (13) into the collet (6).

Make sure that the shank protrudes at least 3mm from

the collet as shown.

• Keep the spindle lock button (5) depressed and tighten

the collet nut (12) using the spanner provided.

Fitting The Edge Guide (Fig. C)

The edge guide helps to guide the tool parallel to an edge.

• Fit the bars (14) to the edge guide (15) using the two

screws (16) provided.

• Insert the bars (14) into the router base as shown.

• Set the edge guide to the required distance.

• Tighten the fixing screws (17).

Fitting The Dust Extraction Adaptor (Fig. D)

The dust extraction adaptor allows you to connect a vacuum

cleaner to the tool.

• Connect the hose (18) of the vacuum cleaner to the

adaptor (11).

Fitting The Template Guide (Fig. E)

(Template Guide Not Included)

• Fit the template guide (19) to the base of the router, with

the flange to the bottom (workpiece) side.

• Insert the two long screws (20) from the bottom side

through the template guide and the holes in the base.

• Place a nut onto each of the screws and securely tighten

the nuts.

Fitting The Distance Piece (Fig. F)

(Distance Piece Not Included)

• Fit the distance piece (21) to the base of the router using

the screws provided.

Fitting The Centring Pin (Fig. G)

(Centring Pin Not Included)

• Fit the edge guide to the router as shown in FIG. C, but

upside down.

• Fit the centring pin (22) to the workpiece side of the

edge guide with the screw (23) provided.

Fitting The Copy Follower (Fig. H)

(Copy Follower Not Included)

• Fit the edge guide to the router as shown in FIG. C.

• Fit the ‘L’ bar (24) to the upper side of the edge guide

using the two screws and nuts provided.

• Adjust the rotating attachment (25) on the ‘L’ bar with the

wing knob (26).

7

Page 8

ENGLISH

(Original instructions)

Use

Warning! Let the tool work at its own pace. Do not

overload.

• Carefully guide the cable in order to avoid accidentally

cutting it.

Adjusting The Depth Of Cut (Fig. I, J & K)

• The depth of cut is the distance X between the depth

stop bar (9) and the depth stop (27).

• The depth of cut can be set in two different ways as

described below.

Adjusting The Depth Of Cut Using The Scale (Fig. J)

• Fit the router bit as described above.

• Loosen the locking screw (28).

• Pull the plunge lock lever (4) up.

• Plunge the router down until the router bit touches the

workpiece.

• Push the plunge lock lever (4) down.

• Move the pointer (29) in the zero position on the scale

(10).

• Add the desired depth of cut to the starting position.

• Move the depth stop bar (9) to the calculated position on

the scale.

• Tighten the locking screw (28).

• Fine adjust using the adjusting knob (30).

• Pull the plunge lock lever (4) up and let the router return

to its original position.

• After switching the router on, plunge it down and make

the desired cut.

Adjusting The Depth Of Cut Using A Piece Of Wood

(Fig. K)

• Fit the router bit and plunge the router down as

described above.

• Pull the depth stop bar (9) up.

• Place a piece of wood with a thickness equal to the

desired depth of cut between the depth stop (27) and the

depth stop bar (9).

• Tighten the locking screw (28).

• Fine adjust using the adjusting knob (30).

• Remove the piece of wood.

• Pull the plunge lock lever (4) up and let the router return

to its original position.

• After switching the router on, plunge it down and make

the desired cut.

Adjusting The Revolver Depth Stop (Fig. L)

After turning the revolver depth stop to the desired setting,

you can fine-adjust the depth stop to be used. If you want to

make several cuts with a different depth of cut, adjust each

of the depth stops.

• Turn the depth stop screw (31) up or down as required

using a screwdriver.

Setting The Speed

• Set the speed control knob (3) to the required speed.

Use a high speed for small diameter router bits. Use a

low speed for large diameter router bits.

Fitting The Dust Extraction Adaptor (Fig. M)

When it is not possible to use the edge guide, for example

when routing grooves in the back panel of a bookcase to

support shelves, proceed as follows:

• Select a piece of wood with a straight edge to use as a

batten.

• Place the batten onto the workpiece.

• Move the batten until it is in the correct position to guide

the tool.

• Securely clamp the batten to the workpiece.

Using The Template Guide (Fig. E)

(Template Guide Not Included)

The template guide can be used to make a cutout shape

from a template, for instance a letter.

• Secure the template over the workpiece with

doublesided tape or ‘G’ clamps.

8

Page 9

(Original instructions)

ENGLISH

• The router bit must extend below the flange of the

template guide, to cut the workpiece in the shape of the

template.

Using The Distance Piece (Fig. F)

(Distance Piece Not Incldued)

The distance piece can be used for trimming wooden or

laminate vertical projections.

Using The Centring Pin (Fig. G) (Centring Pin Not

Included)

The centring pin can be used to cut out circular patterns.

• Drill a hole for the point of the centring pin in the centre

of the circle to be cut.

• Place the router on the workpiece with the point of the

centring pin in the drilled hole.

• Adjust the radius of the circle with the bars of the edge

guide.

• The router can now be moved over the workpiece to cut

out the circle.

Using The Copy Follower (Fig. H) (Copy Follower Not

Included)

The copy follower helps to maintain an equal cutting

distance along the edge of irregularly shaped workpieces.

• Place the router on the workpiece at the desired

distance from the edge to be copied.

• Adjust the bars of the edge guide until the wheel is in

contact with the workpiece.

Switching On And Off

The centring pin can be used to cut out circular patterns.

Switching on

Hints For Optimum Use

• When working on outside edges, move the tool

counterclockwise (FIG. M). When working on inside

edges, move the tool clockwise.

• Use HSS router bits for softwood.

• Use TCT router bits for hardwood.

• You can use the tool without a guide (FIG. O). This is

useful for signwriting and creative work. Only make

shallow cuts.

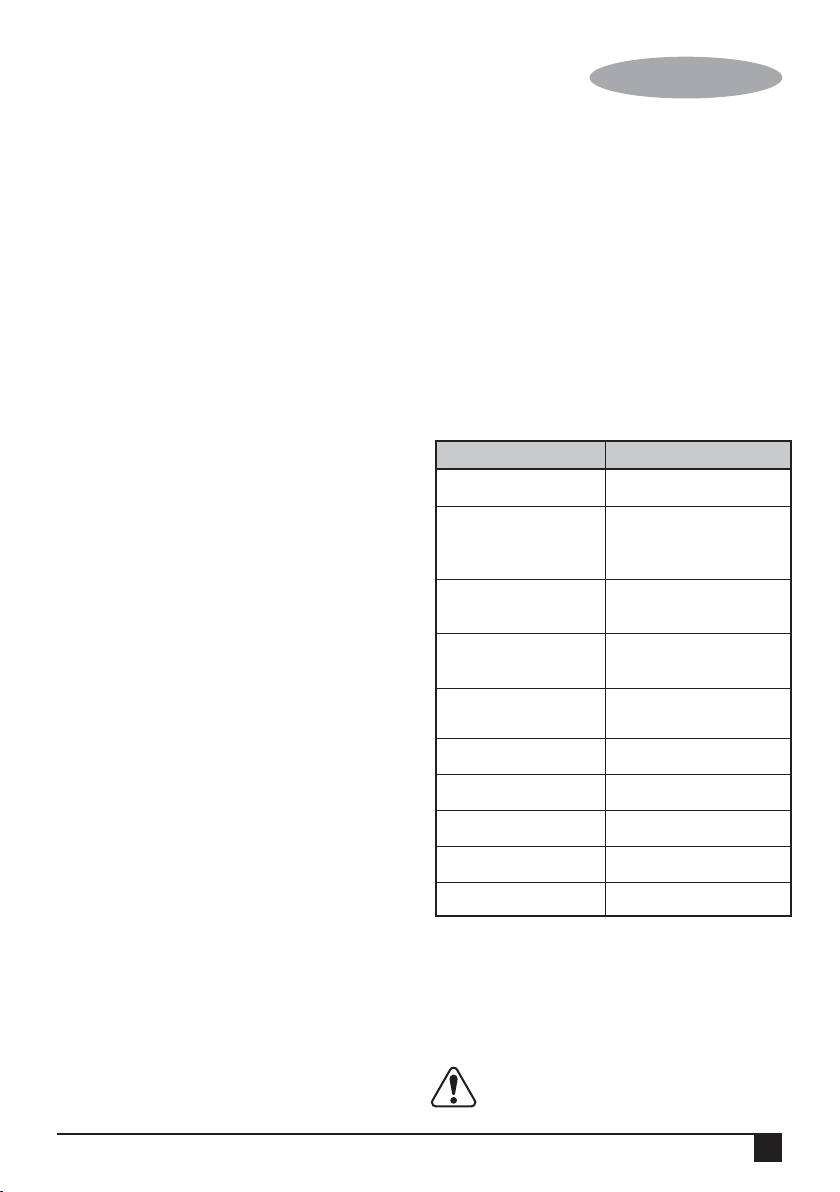

• Refer to the table below for common types of router bits.

Router Bits (Fig. P)

DESCRIPTION APPLICATION

Straight bit (1) Grooves and rebates

Trimming bit (2) Trimming laminates or

hardwood; accurate

profiling using a template

Rebating bit (3) Rebates on straight or

curved workpieces

V-grooving bit (4) Grooves, engraving and

edge bevelling

Core box bit (5) Fluting, engraving and

decorative edge moulding

Cove bit (6) Decorative edge moulding

Ogee moulding bit (7) Decorative edge moulding

Rounding over bit (8) Rounding over edges

Dovetail bit (9) Dovetail joints

Chamfer bit (10) Chamfer edges

• Keep the lock-off button (2) depressed and press the

on/off switch (1).

• Release the lock-off button.

Switching off

• Release the on/off switch.

Warning! Always operate the tool with both hands.

Maintenance

Your tool has been designed to operate over a long period of

time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and

regular cleaning.

Warning! Before performing any maintenance,

switch off and unplug the tool.

9

Page 10

ENGLISH

(Original instructions)

• Regularly clean the ventilation slots in your tool using a

soft brush or dry cloth.

• Regularly clean the motor housing using a damp cloth.

Do not use any abrasive or solvent-based cleaner.

Accessories

The performance of your tool depends on the accessory

used. STANLEY accessories are engineered to high quality

standards and designed to enhance the performance of

your tool. By using these accessories you will get the very

best from your tool.

Service Information

STANLEY offers a full network of company-owned and

authorized service locations. All STANLEY Service Centers

are staffed with trained personnel to provide customers with

efficient and reliable power tool service. For more

information about our authorized service centers and if you

need technical advice, repair, or genuine factory

replacement parts, contact the STANLEY location nearest

you.

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your STANLEY product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

STANLEY provides a facility for the collection and recycling

of STANLEY products once they have reached the end of

their working life. To take advantage of this service please

return your product to any authorised repair agent who will

collect them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local STANLEY office at the

address indicated in this manual. Alternatively, a list of

authorised STANLEY repair agents and full details of our

after-sales service and contacts are available on the Internet

at: www.2helpU.com

10

Page 11

Two years full warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY Europe guarantees to replace all

defective parts free of charge or – at our discretion – replace

the unit free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

(Original instructions)

ENGLISH

11

Page 12

РУССКИЙ

(Оригинальные инструкции)

FIG. A FIG. B

3

4

10

6

11

5

6

1

8

7

FIG. C

2

9

FIG. D

14

5

12

13

13

18

FIG. E

12

20

17

15

19

16

11

FIG. F

21

Page 13

(Оригинальные инструкции)

РУССКИЙ

FIG. G

FIG. I

22

23

27

FIG. H

24

25

26

FIG. J

30

9

10

29

28

FIG. K

9

FIG. L

30

9

1

28

31

27

13

Page 14

РУССКИЙ

(Оригинальные инструкции)

FIG. M FIG. N

FIG. O

FIG. P

* Тип фрезы для контурной обработки, только для справки

14

Page 15

(Оригинальные инструкции)

РУССКИЙ

Технические данные

STRR1200

Входное напряжение VAC 220-240

Частота Hz 50/60

Входная мощность W 1200

Cкорость холостого хода /мин 8000-27000

Размер цанги (патрона) 6 мм/6,35 мм/6 мм

Шнур м 2,5

НЕ ВОЗВРАЩАЙТЕ ЭТО ИЗДЕЛИЕ В МАГАЗИН,

сначала обратитесь в ваш местный офис STANLEY или

в ближайший авторизованный сервисный центр.

Общие правила техники безопасности

Внимание! Прочитайте и поймите все

инструкции. Несоблюдение любых

инструкций, указанных ниже, может привести к

поражению электрическим током, пожару и/или

серьезной травме.

СОХРАНИТЕ ЭТИ ИНСТРУКЦИИ

Правила техники безопасности

Общие предупреждения по технике безопасности

электроинструментов

Внимание! Ознакомьтесь со всеми

правилами безопасности и инструкциями.

Несоблюдение предупреждений и инструкций,

указанных ниже, может привести к поражению

электрическим током, пожару и/или серьезной травме.

Сохраните все предупреждения и инструкции для

будущего использования.

Термин "электроинструмент" во всех предупреждениях,

указанных ниже, относится к вашему сетевому (с

кабелем) электроинструменту или аккумуляторному

электроинструменту (без кабеля питания).

1. Безопасность рабочего места

а. Содержите рабочее место в чистоте и хорошо

освещенным. Беспорядок на рабочем месте или

отсутствие освещения рабочего места может

привести к аварии.

b. Не работайте с электроинструментом в месте

хранения взрывоопасных материалов,

например, в присутствии огнеопасных

жидкостей, газов или пыли. Электрические

инструменты создают искры, которые могут

воспламенить пыль или пары.

с. Дети и посторонние лица должны находиться как

можно дальше во время работы с

электроинструментом. Вы можете отвлечься и

потерять контроль.

2. Электробезопасность

а. Вилка электроинструмента должна

соответствовать розетке. Никогда не

модифицируйте вилку каким-либо образом. Не

используйте никакие вилки-переходники с

заземленными (замкнутыми на землю)

электроинструментами. Вилки и розетки, которые

не подвергались никаким изменениям снижают риск

поражения электрическим током.

b. Избегайте контакта тела с заземленными

поверхностями, такими как трубы, радиаторы,

плиты и холодильники. Существует повышенный

риск поражения электрическим током, если ваше

тело заземлено.

с. Избегайте любого воздействия дождя или влаги

на электроинструменты. Вода, попавшая в

электроинструмент, увеличивает риск поражения

электрическим током.

d. Аккуратно обращайтесь со шнуром питания.

Никогда не используйте шнур питания для

переноски, перемещения или извлечения вилки

из розетки. Держите шнур вдали от источников

тепла, масла, острых краев или движущихся частей.

Поврежденные или запутанные шнуры увеличивают

риск поражения электрическим током.

е. При работе с электроинструментом на улице,

используйте удлинитель, подходящий для

наружного использования. Использование кабеля,

пригодного для использования на открытом воздухе,

снижает риск поражения электрическим током.

f. При необходимости работы с

электроинструментом во влажной среде,

используйте устройство защитного отключения

(УЗО). Использование УЗО снижает риск поражения

электрическим током. Примечание: Термин

“устройство защитного отключения (УЗО)” может

быть заменен на "аварийный прерыватель

заземления" или "автоматический выключатель тока

утечки".

3. Личная безопасность

a. Будьте внимательны, смотрите, что вы делаете,

используйте здравый смысл при работе с

электроинструментом. Не используйте

электроинструмент, если вы устали или находитесь

под влиянием наркотиков, алкоголя или лекарств.

Малейшая неосторожность при работе с

электроинструментом может привести к серьезным

травмам..

b. Используйте средства индивидуальной защиты.

Всегда надевайте защитные очки. Другое

защитное оборудование, включая респиратор,

ботинки на нескользящей подошве, защитный

шлем или средства защиты органов слуха,

используемые в надлежащих условиях, уменьшат

риск получения травмы.

15

Page 16

РУССКИЙ

(Оригинальные инструкции)

с. Для предотвращения случайного запуска,

убедитесь, что переключатель находится в

выключенном положении перед подключением к

источнику питания и/или аккумуляторной

батарее, поднятия или переноски инструмента.

Не переносите электроинструмент с пальцем на

выключателе и не включайте питание на инструмент

с включенным выключателем, что может привести к

несчастному случаю.

d. Перед включением электроинструмента

снимайте регулировочный или гаечный ключ.

Гаечный или регулировочный ключ, оставленный на

вращающейся части электроинструмента, может

привести к травме.

е. Не тянитесь. Сохраняйте правильную стойку и

баланс все время. Это позволяет лучше

контролировать инструмент в неожиданных

ситуациях.

f. Одевайтесь правильно. Не надевайте свободную

одежду или украшения. Держите волосы, одежду

и перчатки вдали от движущихся частей.

Свободная одежда, украшения или длинные

волосы могут попасть в движущиеся части.

g. Если имеются устройства для подключения

пылесборника или вытяжки, убедитесь в том,

что они подсоединены и используются

правильно. Использование пылесборника снижает

вероятность возникновения рисков, связанных с

пылью.

4. Использование и уход за электроинструментом

a. Не перегружайте электроинструмент.

Используйте подходящий электрический

инструмент для соответствующего применения.

Правильно подобранный электроинструмент

позволит выполнить работу лучше и безопаснее при

скорости, для которой он был разработан.

b. Не используйте электроинструмент, если

переключатель не может его включить и

выключить. Любой электроинструмент, который

нельзя контролировать с помощью переключателя,

опасен и должен быть отремонтирован.

c. Отключите кабель питания от источника питания

и/или аккумуляторный блок от электрического

инструмента перед выполнением любых

регулировок, замены принадлежностей или при

хранении электроинструмента. Такие

профилактические меры безопасности уменьшают

риск непреднамеренного запуска электрического

инструмента.

d. Храните неиспользуемые электроинструменты в

недоступном для детей месте и не позволяйте

лицам, не знакомым с электроинструментом или

данными инструкциями, работать с

электроинструментом. Электроинструменты опасны

в руках неопытных пользователей.

е. Поддержание электроинструмента. Проверяйте

разрегулированность или cоединение

подвижных частей, поломки частей и любые

другие условия, которые могут повлиять на

работу электроинструмента. При наличии

повреждения, отремонтируйте

электроинструмент перед использованием.

Многие несчастные случаи являются следствием

плохого ухода за электроинструментом.

f. Держите режущий инструмент острым и чистым.

Хорошо ухоженный режущий инструмент с острыми

режущими кромками легче контролировать.

g. Используйте электроинструмент, аксессуары и

насадки в соответствии с данными

инструкциями, принимая во внимание рабочие

условия и характер выполняемой работы.

Использование электрического инструмента для

операций, отличающихся от тех, для которых он

предназначен может привести к опасной ситуации.

5. Обслуживание

а. Обеспечьте, чтобы обслуживание и ремонт

вашего электроинструмента проводился в

авторизованном сервисном центре по ремонту с

использованием только оригинальных запасных

частей. Это станет гарантией безопасности

электроинструмента.

Дополнительные инструкции по

безопасности для фасонно-фрезерных

станков

• Держите инструмент за изолированные

поверхности, потому что режущий инструмент

может повредить свой собственный шнур.

Повреждение работающего провода во время резки,

делает металлические части электроинструмента

«проводниками», что может привести к удару

электрическим током.

• Используйте тиски или другой подходящий

способ для обеспечения и поддержания

обрабатываемого изделия на устойчивой

платформе. Проведение работы по руке или против

тела может привести к потере контроля.

• Используйте только фрезы с диаметром хвостовика,

равного размеру цанги, установленной в

инструменте.

• Используйте только фрезы, пригодные для скорости

холостого хода инструмента.

• Никогда не используйте фрезы с диаметром,

превышающим максимальный диаметр, указанный в

разделе технических данных.

• Не используйте инструмент в перевернутом

положении.

• Не пытайтесь использовать инструмент в

стационарном режиме.

16

Page 17

(Оригинальные инструкции)

РУССКИЙ

• Соблюдайте особую осторожность при работе с

древесноволокнистой плитой средней плотности или

с поверхностями, покрытыми краской на основе

свинца.

• Надевайте респиратор, специально разработанный

для защиты от пыли и паров от свинцовых красок и

следите, чтобы лица, находящиеся в рабочей зоне,

также были защищены.

• Не позволяйте детям или беременным женщинам

находиться в рабочей зоне.

• Не принимайте пищу, не пейте и не курите в рабочей

зоне.

• Удаляйте частицы пыли и прочие отходы

безопасным способом.

• Всегда надевайте защитную маску.

• Данный инструмент не предназначен для

использования детьми или немощными людьми.

Дети должны быть под присмотром, чтобы они не

играли с инструментом.

Характеристики (рис. А)

1. Переключатель плавного хода

2. Кнопка блокировки

3. Ручка управления с переменной скоростью

4. Блокировка рычага

5. Кнопка блокировки шпинделя

6. Цанга

7. Револьверный ограничитель глубины

8. Пылесос

9. Ограничитель глубины

10. Шкала глубины резки

11. Адаптер для пылесоса

6. Этикетки на инструменте

Этикетка на вашем инструменте может включать

следующие символы:

Читайте

инструкции по

эксплуатации

Используйте

средства

защиты глаз

Используйте

средства

защиты

органов слуха

В ........ Вольт

A ........ Ампер

Гц ....... Герц

Вт ........ Ватт

мин...... минуты

Пере мен-

.....

ный ток

Посто ян-

.....

ный т ок

Скоро сть

n

.......

0

без н агруз ки

Конструкция

......

класса II

Терминал

....

заземления

Символ

предуп реж-

....

дения об

опасно сти

обороты или

...мин..

возвратнопоступательное движение

в минуту

Положение даты штрих-кода

Дата кода, который также включает год изготовления,

печатается на корпусе.

Пример:

2014 XX JN

Год изготовления

7. Электрическая безопасность

Ваш инструмент имеет двойную изоляцию;

поэтому заземление не требуется. Всегда

проверяйте, чтобы основное напряжение

соответствовало напряжению, указанному на заводской

табличке.

Предупреждение! Если шнур питания

поврежден, он должен быть заменен

производителем в авторизованном сервисном

центре STANLEY или квалифицированным

специалистом во избежание повреждений или травм.

Если шнур питания заменен квалифицированным

специалистом, не уполномоченным STANLEY, гарантия

не будет считаться действительной.

Сборка

Предостережение! Перед сборкой убедитесь,

что инструмент выключен и отключен от сети.

Крепление фрезы (рис. B)

• Снимите пылеулавливатель (8).

• Нажмите и удерживайте кнопку блокировки

шпинделя (5) и поворачивайте шпиндель до полной

блокировки.

• Ослабьте цанговую гайку (12), используя гаечный

ключ.

• Вставьте хвостовик фрезы (13) в цангу (6).

Убедитесь, что хвостовик выступает по крайней мере

3 мм от цанги, как показано на рисунке.

• Нажмите и удерживайте кнопку блокировки

шпинделя (5) и затяните цанговую гайку (12),

используя гаечный ключ.

Установка направляющей кромки (рис. C)

Направляющая кромка помогает направлять инструмент

параллельно краю.

• Установите стержни (14) направляющей кромки (15),

используя два винта (16), входящих в комплект.

• Вставьте стержни (14) в основание фрезы, как

показано на рисунке.

• Установите направляющую на требуемом

расстоянии.

• Затяните крепежные винты (17).

17

Page 18

РУССКИЙ

(Оригинальные инструкции)

Установка адаптера для пылесоса (рис. D)

Адаптер для подключения пылесоса позволяет

подключать пылесос к инструменту.

• Подключите шланг (18) пылесоса к адаптеру (11).

Установка шаблонной направляющей (рис. E)

(шаблонная направляющая не входит в комплект)

• Установите шаблонную направляющую (19) к

основанию фрезы, с фланцем на нижней стороне

заготовки.

• Вставьте два длинных винта (20) из нижней части

через шаблонную направляющую и отверстия в

основании.

• Поместите гайку на каждый винт и затяните гайки.

Установка распорки (рис. F) (распорка не входит в

комплект)

• Установите распорную деталь (21) на основание

фрезы, используя винты, входящие в комплект.

Установка центрирующего штифта (рис. G)

(центрирующий штифт не входит в комплект)

• Установите направляющую кромки к фрезе, как

показано на рис. C, но вверх ногами.

• Установите центрирующий штифт (22) в сторону

заготовки направляющей кромки с винтом (23),

входящим в комплект.

Установка резчика копий (рис. H) (резчик копий не

входит в комплект)

• Установите направляющую кромки к фрезе, как

показано на рис. C.

• Установите планку 'L' (24) в верхней части

направляющей кромки с помощью двух винтов и

гаек.

• Отрегулируйте вращающийся аксессуар (25) на 'L'

планку с регулятором крыла (26).

Использование

Внимание! Дайте инструменту работать в

своем собственном темпе. Не перегружайте

его.

• Осторожно переносите кабель, чтобы избежать его

случайного повреждения.

Регулировка глубины реза (рис. I, J и K)

• Глубиной реза является расстояние X между

пластиной ограничителя глубины (9) и

ограничителем глубины (27).

• Глубина реза может быть установлена двумя

различными способами, как описано ниже.

18

Регулировка глубины реза с помощью шкалы (рис. J)

• Установите фрезу, как описано выше.

• Ослабьте фиксирующий винт (28).

• Потяните рычаг блокировки (4) вверх.

• Опустите фрезу вниз, до тех пор, пока фреза не

коснется заготовки.

• Нажмите на рычаг блокировки (4) вниз.

• Переместите указатель (29) в нулевое положение на

шкале (10).

• Добавьте нужную глубину реза в исходное

положение.

• Переместите пластину ограничителя глубины (9) к

расчетной позиции на шкале.

• Затяните фиксирующий винт (28).

• Точная регулировка производится с помощью кнопки

регулировки (30).

• Потяните рычаг блокировки (4) вверх и дайте фрезе

вернуться в ее исходное положение.

• После включения фрезы, опустите ее вниз и

сделайте нужный срез.

Регулировка глубины реза с помощью куска дерева

(рис. K)

• Установите фрезу и опустите ее вниз, как описано

выше.

• Потяните панель ограничителя глубины (9) вверх.

• Поместите кусок дерева с толщиной равной

желаемой глубине реза между ограничителем

глубины (27) и пластиной ограничителя глубины (9).

• Затяните винт (28).

• Точная регулировка производится с помощью кнопки

регулировки (30).

• Снимите кусок дерева.

• Потяните рычаг блокировки (4) вверх и дайте фрезе

вернуться в ее исходное положение.

• После включения фрезы, опустите ее вниз и

сделайте нужный срез.

Регулировка револьверного ограничителя глубины

(рис. L)

После включения револьверного ограничителя глубины

в нужное положение, вы можете точно настроить

ограничитель глубины сверления, который будет

использоваться. Если вы хотите сделать несколько

надрезов с различной глубиной резания, регулируйте

каждую глубину отдельно.

Page 19

(Оригинальные инструкции)

РУССКИЙ

• Поверните винт ограничителя глубины (31) вверх

или вниз как необходимо с помощью отвертки.

Установка скорости

• Установите ручку переключателя скорости (3) на

требуемую скорость. Используйте высокую скорость

для фрез малых диаметров. Используйте низкую

скорость для фрез больших диаметров.

Установка адаптера для пылесоса (рис. M)

Когда не представляется возможным использовать

направляющую кромку, например, когда просверливают

канавки в задней панели книжного шкафа, чтобы

поддержать полки, действуйте следующим образом:

• Выберите кусок дерева с прямой кромкой для

использования в качестве рейки.

• Поместите рейку на обрабатываемую деталь.

• Переместите рейку, до тех пор, пока она не займет

правильное положение, чтобы направлять

инструмент.

• Надежно закрепите планки к заготовке.

Использование шаблонной направляющей (рис. E)

(шаблонная направляющая не входит в комплект

поставки)

Шаблонная направляющая может быть использована

для того, чтобы сделать форму выреза из шаблона,

например букву.

• Закрепите шаблон на заготовке при помощи

двусторонней ленты или зажимов "G".

• Фреза должна выступать за нижний край фланца

направляющей шаблона, чтобы вырезать

обрабатываемую деталь в форме шаблона.

Использование распорки (рис. F) (распорка не

входит в комплект)

Распорка может быть использована для отделки

деревянных или ламинированных вертикальных

проекций.

Использование центрирующего штифта (рис. G)

(центрирующий штифт не входит к комплект)

Центрирующий штифт может быть использован для

вырезки круглых деталей.

• Сделайте отверстие для точки центрирующего

штифта в центре круга, который необходимо

вырезать.

• Поместите фрезу на заготовку с точкой

центрирующего штифта в просверленное отверстие.

• Отрегулируйте радиус окружности при помощи

направляющей кромки.

• Фреза может быть перемещена над деталью, чтобы

вырезать круг.

Использование резчика копий (рис. H) (резчик копий

не входит в комплект)

Резчик копий помогает поддерживать одинаковое

расстояние во время резки вдоль края заготовок

неправильной формы.

• Поместите фрезу на заготовку на нужном расстоянии

от края для копирования.

• Отрегулируйте боковую направляющую линейку,

пока колесо находится в контакте с заготовкой.

Включение и выключение

Центрирующий штифт может быть использован, чтобы

вырезать круглые образцы.

Включение

• Нажмите на кнопку блокировки (2) и удерживайте ее,

потом нажмите переключатель

включения/выключения (1).

• Отпустите кнопку блокировки.

Выключение

• Отпустите переключатель включения/выключения

Предостережение! Всегда работайте с инструментом

обеими руками.

Советы для оптимального использования

• При работе на внешних краях, переместите

инструмент против часовой стрелки (рис. M). При

работе на внутренних краях, переместите инструмент

по часовой стрелке.

• Используйте фрезу HSS для древесины хвойных

пород.

• Используйте фрезу TCT для древесины твердых

пород.

• Вы можете использовать инструмент без

направляющей (рис. O). Это удобно для SignWriting и

творческой работы. Только делайте неглубокие

порезы.

• Обратитесь к таблице ниже для распространенных

типов фрез.

19

Page 20

РУССКИЙ

(Оригинальные инструкции)

Фрезы (рис. Р)

ОПИСАНИЕ ПРИМЕНЕНИЕ

Пазовая фреза (1) Для высечения

канавок и желобов

Профильная фреза (2) Для обрезки ламината

или древесины твердых

пород; точного

профилирования с

помощью шаблона

Четвертная фреза (3) Для смягчения прямых

и закругленных заготовок

V-образная пазовая фреза (4) Для прорези канавок,

гравирования и

фацетирования краев

Галтелная фреза (5) Для рифления,

гравирования и обработки

края декоративного литья

Конусная фреза (6) Для обработки края

декоративного литья

Калевочная фреза (7) Обработка края

декоративного литья

Четвертная фреза (8) Закругление краев

Обслуживание

Ваш инструмент рассчитан на работу в течение

длительного периода времени при минимальном

техническом обслуживании. Срок службы и надежность

зависят от правильного ухода и регулярной чистки.

Предостережение! Перед проведением

технического обслуживания, выключите и

отсоедините прибор.

• Регулярно очищайте вентиляционные прорези

вашего инструмента мягкой щеткой или сухой

тканью.

• Регулярно очищайте корпус двигателя влажной

тканью. Не используйте абразивные чистящие

средства или чистящие средства на основе

растворителя.

Аксессуары

Производительность вашего электроинструмента

зависит от используемых принадлежностей. Аксессуары

STANLEY разработаны согласно высоким стандартам

качества, они способны увеличить производительность

вашего электроинструмента. Используя эти

принадлежности, вы получите самое лучшее, на что

способен ваш инструмент.

Информационная служба

STANLEY предлагает полную сеть принадлежащих

компании авторизованных сервисных точек. Все

сервисные центры STANLEY укомплектованы

персоналом, прошедшим обучение, чтобы предоставить

клиентам эффективное и надежное обслуживание

электроинструмента. Для получения более подробной

информации о наших авторизованных сервисных

центрах или если вам необходим технический совет,

ремонт или оригинальные запасные части, обратитесь в

ближайший сервисный центр STANLEY.

Защита окружающей среды

Раздельный сбор и утилизация. Этот продукт

не следует утилизировать вместе с бытовым

мусором.

Если вы поймете, что ваш продукт Stanley нуждается в

замене, или если он не имеет никакого дальнейшего

применения для вас, не выбрасывайте его вместе с

бытовыми отходами. Предоставьте этот продукт для

раздельного сбора/утилизации.

Раздельный сбор продуктов и упаковок

позволяет осуществить их переработку и

использовать их повторно. Повторное

использование переработанных материалов помогает

защищать окружающую среду от загрязнения и снижает

расход сырьевых материалов.

Местное законодательство может обеспечить сбор

старых электроинструментов отдельно от бытового

мусора на муниципальных свалках отходов или в

торговом предприятии при покупке нового изделия.

Stanley обеспечивает возможность для сбора и

утилизации продуктов Stanley, как только они достигли

конца своего срока службы. Для того чтобы

воспользоваться этой услугой, вы можете сдать ваше

изделие в любой авторизованный сервисный центр,

который собирает их по нашему поручению.

Вы можете узнать место нахождения вашего

ближайшего авторизованного сервисного центра,

обратившись в местное отделение Stanley по адресу,

указанному в данном руководстве. Кроме того, список

авторизованных ремонтных агентов Stanley и полную

информацию о нашем послепродажном обслуживании и

контактах вы можете найти в Интернете:

www.2helpU.com10

20

Page 21

(Оригинальные инструкции)

Два год полной гарантии

Если ваш продукт STANLEY выходит из строя из-за

дефектных материалов или изготовления в течение 24

месяцев с даты покупки, STANLEY Europe гарантирует

замену всех неисправных деталей бесплатно или - по

своему усмотрению - замену продукта бесплатно при

условии, что:

• Продукт использовался правильно, его эксплуатация

проводилась строго в соответствии с инструкцией

по эксплуатации.

• Продукт подвергался естественному износу;

• Ремонт не проводился посторонними лицами;

• Представлены документы, подтверждающие

покупку.

• Продукт STANLEY возвращается в полном

комплекте со всеми оригинальными компонентами

Если вы хотите сделать заявку, свяжитесь с продавцом

или узнайте место нахождения вашего ближайшего

авторизованного сервисного агента Stanley в каталоге

Stanley или обратитесь в местное представительство

Stanley по адресу, указанному в данном руководстве.

Список авторизованных сервисных агентов Stanley и

полную информацию о нашем послепродажном

обслуживании можно найти в Интернете по адресу:

www.stanleytools.com

РУССКИЙ

21

Page 22

РУССКИЙ

(Оригинальные инструкции)

Гарантийные условия

Уважаемый покупатель!

1. Поздравляем Вас с покупкой высококачественного

изделия STANLEY и выражаем признательность за Ваш

выбор.

2. При покупке изделия требуйте проверки его комплектности

и исправности в Вашем присутствии, инструкцию по

эксплуатации и заполненный гарантийный талон на

русском языке.

В гарантийном талоне должны быть внесены: модель,

дата продажи, серийный номер, дата производства

инструмента; название, печать и подпись торговой

организации. При отсутствии у Вас правильно заполненного гарантийного талона, а также несоответствия

указанных в нем данных мы будем вынуждены откло- нить

Ваши претензии по качеству данного изделия.

3. Во избежание недоразумений убедительно просим Вас

перед началом работы с изделием внимательно

ознакомиться с инструкцией по его эксплуатации.

Правовой основой настоящих гарантийных условий

является действующее Законодательство. Гарантийный

срок на данное изделие составляет 24 месяца и

исчисляется со дня продажи. В случае устранения

недостатков изделия, гарантийный срок продлевается на

период его нахождения в ремонте. Срок службы изделия

составляет 5 лет со дня продажи.

4. В случае возникновения каких-либо проблем в про- цессе

эксплуатации изделия рекомендуем Вам обра- щаться

только в уполномоченные сервисные центры STANLEY,

адреса и телефоны которых Вы сможете найти в

гарантийном талоне, на сайте www.2helpU.com или узнать

в магазине. Наши сервисные станции - это не только

квалифицированный ремонт, но и широкий ассортимент

запчастей и принадлежностей.

5. Производитель рекомендует проводить периодическую

проверку и техническое обслуживание изделия в

уполномоченных сервисных центрах.

Изготовитель

Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

6. Наши гарантийные обязательства распространяются

только на неисправности, выявленные в течение гарантийного срока и вызванные дефектами производства и \

или материалов.

7. Гарантийные условия не распространяются на

неисправности изделия, возникшие в результате:

7.1. Несоблюдения пользователем предписаний инструкции по

эксплуатации изделия, применения изделия не по

назначению, неправильном хранении, использования

принадлежностей, расходных материалов и запчастей, не

предусмотренных производителем.

7.2. Механического повреждения (сколы, трещины и разрушения) внутренних и внешних деталей изделия,

основных и вспомогательных рукояток, сетевого электрического кабеля, вызванного внешним ударным или

любым иным воздействием

7.3 Попадания в вентиляционные отверстия и проникновение внутрь изделия посторонних предметов,

материалов или веществ, не являющихся отходами,

сопровождающими применение изделия по назначению,

такими как: стружка, опилки, песок, и пр.

7.4. Воздействий на изделие неблагоприятных атмосферных и

иных внешних факторов, таких как дождь, снег,

повышенная влажность, нагрев, агрессивные среды,

несоответствие параметров питающей электросети,

указанных на инструменте.

7.5. Стихийного бедствия. Повреждение или утрата изделия,

связанное с непредвиденными бедствиями, стихийными

явлениями, в том числе вследствие действия

непреодолимой силы (пожар, молния, потоп и другие

природные явления), а так же вследствие перепадов напряжения в электросети и другими причинами, которые

находятся вне контроля производителя.

8. Гарантийные условия не распространяются:

8.1. На инструменты, подвергавшиеся вскрытию, ремонту или

модификации вне уполномоченного сервисного центра.

8.2. На детали и узлы, имеющие следы естественного износа,

такие как:

приводные ремни и колеса, угольные щетки, смазка,

подшипники, зубчатое зацепление редукторов, резиновые уплотнения, сальники, направляющие ролики,

муфты, выключатели, бойки, толкатели, стволы, и т.п.

8.3. На сменные части: патроны, цанги, зажимные гайки и

фланцы, фильтры, аккумуляторные батареи, ножи,

шлифовальные подошвы, цепи, звездочки, пильные шины,

защитные кожухи, пилки, абразивы, пильные и

абразивные диски, фрезы, сверла, буры и т.п.

8.4. На неисправности, возникшие в результате перегрузки

инструмента (как механической, так и электрической),

повлекшей выход из строя одновременно двух и более

деталей и узлов, таких как: ротора и статора, обеих

обмоток статора, ведомой и ведущей шестерни редуктора или других узлов и деталей. К безусловным

признакам перегрузки изделия относятся, помимо прочих:

появление цветов побежалости, деформация или

оплавление деталей и узлов изделия, потемнение или

обугливание изоляции проводов электродвигателя под

воздействием высокой температуры.

22

Page 23

(Оригінальні інструкції)

УКРАЇНСЬКА

FIG. A FIG. B

3

4

10

6

11

5

6

1

8

7

FIG. C

2

9

FIG. D

14

5

12

13

13

18

FIG. E

20

17

15

19

16

11

FIG. F

21

23

Page 24

УКРАЇНСЬКА

(Оригінальні інструкції)

FIG. G

FIG. I

22

23

27

FIG. H

24

25

26

FIG. J

30

9

10

29

28

FIG. K

24

9

FIG. L

30

9

1

28

31

27

Page 25

(Оригінальні інструкції)

FIG. M FIG. N

FIG. O

УКРАЇНСЬКА

FIG. P

* Тип фрези для контурної обробки, тільки для довідки

25

Page 26

УКРАЇНСЬКА

(Оригинальные инструкции)

Технічні дані

STRR1200

Вхідна напруга VAC 220-240

Частота Hz 50/60

Вхідна потужність W 1200

Швидкість холостого ходу /хвил. 8000-27000

Розмір цанги (патрона) 6 мм/6,35 мм/6 мм

Шнур м 2,5

НЕ ПОВЕРТАЙТЕ ЦЕЙ ВИРІБ В МАГАЗИН,

спочатку зверніться у місцевий офіс STANLEY або в

найближчий авторизований сервісний центр.

Загальні правила техніки безпеки

Увага! Прочитайте і зрозумійте всі інструкції.

Недотримання будь-яких інструкцій,

ураження електричним струмом, пожежі та/або

серйозної травми.

зазначених нижче, може призвести до

ЗБЕРЕЖІТЬ ЦІ ІНСТРУКЦІЇ

Правила техніки безпеки

Загальні попередження з техніки безпеки

електроінструментів

Увага! Ознайомтеся з усіма правилами

безпеки та інструкціями. Недотримання

може призвести до ураження електричним струмом,

пожежі та/або серйозної травми.

Збережіть всі попередження та інструкції для

майбутнього використання.

Термін "електроінструмент" у всіх попередженнях,

зазначених нижче, відноситься до мережевого (з

кабелем) електроінструменту або акумуляторної батареї

(без кабелю живлення).

1. Безпека робочого місця

а. Утримуєте робоче місце в чистоті і добре

b. Не працюйте з електроінструментом в місці

с. Діти і сторонні особи повинні знаходитися

попереджень та інструкцій, зазначених нижче,

освітленим. Безлад на робочому місці або

відсутність освітлення робочого місця може

призвести до аварії.

зберігання вибухонебезпечних матеріалів,

наприклад, у присутності легкозаймистих рідин,

газів або пилу. Електричні інструменти створюють

іскри, що можуть запалити пил або пари.

якнайдалі під час роботи з електроприладами. Ви

можете відволіктися і втратити контроль.

2. Електробезпека

а. Вилка електроінструмента повинна відповідати

розетці. Ніколи не змінюйте вилку будь-яким

чином. Не використовуйте ніякі

вилки-перехідники з заземленими (замкнутими на

землю) електроінструментами. Вилки і розетки, які

не піддавалися ніяким змінам знижують ризик

ураження електричним струмом.

b. Уникайте контакту тіла з заземленими

поверхнями, такими як труби, радіатори, плити та

холодильники. Існує підвищений ризик ураження

електричним струмом, якщо ваше тіло заземлене.

с. Уникайте будь-якого впливу дощу або вологи на

електроінструменти. Вода, що потрапила в

електроінструмент, збільшує ризик ураження

електричним струмом.

d. Обережно поводьтеся зі шнуром живлення.

Ніколи не використовуйте шнур живлення для

перенесення, переміщення або вилучення вилки з

розетки. Тримайте шнур подалі від джерел тепла,

масла, гострих країв або рухомих частин.

Пошкоджені або заплутані шнури збільшують ризик

ураження електричним струмом.

е. При роботі з електроінструментом на вулиці,

використовуйте подовжувач, відповідний для

зовнішнього використання. Використання кабелю,

придатного для використання на відкритому повітрі,

знижує ризик ураження електричним струмом.

f. При необхідності роботи з електроінструментом у

вологому середовищі, використовуйте пристрій

захисного відключення (ПЗВ). Використання ПЗВ

знижує ризик ураження електричним струмом.

Примітка: Термін "пристрій захисного відключення

(ПЗВ)" може бути замінений на "аварійний переривач

заземлення" або "автоматичний вимикач струму

витоку".

3. Особиста безпека

a. Будьте уважні, дивіться, що ви робите,

використовуйте здоровий глузд при роботі з

електроприладами. Не використовуйте

електроінструмент, якщо ви втомилися або

перебуваєте під впливом наркотиків, алкоголю або

ліків. Найменша необережність при роботі з

електроінструментом може призвести до серйозних

травм.

b. Використовуйте засоби індивідуального захисту.

Завжди надягайте захисні окуляри. Інше захисне

обладнання, включаючи респіратор, черевики на

нековзній підошві, захисний шолом або засоби

захисту органів слуху, використовувані в належних

умовах, зменшать ризик отримання травми.

с. Для запобігання випадкового запуску,

переконайтеся, що перемикач знаходиться у

вимкненому положенні перед підключенням до

джерела живлення та/або акумуляторної батареї,

підняття або перенесення інструменту.

26

Page 27

(Оригинальные инструкции)

УКРАЇНСЬКА

Не переносьте електроінструмент з пальцем на

вимикачі і не включайте електроживлення на

інструмент з увімкненим вимикачем, що може

призвести до нещасного випадку.

d. Перед включенням електроінструменту знімайте

регулювальний або гайковий ключ. Гайковий або

регулювальний ключ, залишений на обертовій

частині електроінструменту, може призвести до

травми.

е. Не тягніться. Зберігайте правильну стійку і

баланс весь час. Це дозволяє краще контролювати

інструмент в несподіваних ситуаціях.

f. Одягайтеся правильно. Не надягайте вільний

одяг або прикраси. Тримайте волосся, одяг і

рукавички далеко від рухомих частин. Вільний

одяг, прикраси або довге волосся можуть потрапити

в рухомі частини.

g. Якщо є пристрої для підключення пилозбірника

або витяжки, переконайтеся в тому, що вони

під'єднані і використовуються правильно.

Використання пилозбірника знижує ймовірність

виникнення ризиків, пов'язаних з пилом.

4. Використання та догляд за електроінструментом

a. Не перевантажуйте електроінструмент.

Використовуйте відповідний електричний

інструмент для відповідного застосування.

Правильно підібраний електроінструмент дозволить

виконати роботу краще і безпечніше при швидкості,

для якої він був розроблений.

b. Не використовуйте електроінструмент, якщо

перемикач не може його включити і вимкнути.

Будь-який електроінструмент, який не можна

контролювати за допомогою перемикача, є

небезпечний і повинен бути відремонтований.

c. Від'єднайте кабель живлення від джерела

живлення та/або акумулятора від електричного

інструменту перед виконанням будь-яких

регулювань, заміни приладдя або при зберіганні

електроінструменту. Такі профілактичні заходи

безпеки зменшують ризик ненавмисного запуску

електричного інструменту.

d. Зберігайте електроприлади в недоступному для

дітей місці і не дозволяйте особам, які не знайомі

з електричним інструментом або даними

інструкціями, працювати з електроприладами.

Електроінструменти небезпечні в руках

недосвідчених користувачів.

е. Підтримання електроінструменту. Перевіряйте

разрегульованість або з'єднання рухомих частин,

поломки частин і будь-які інші умови, які можуть

вплинути на роботу електроінструменту. При

наявності пошкодження, відремонтуйте

електроінструмент перед використанням. Багато

нещасних випадків є наслідком поганого догляду за

електроінструментом.

f. Тримайте ріжучий інструмент гострим і чистим.

Добре доглянутий ріжучий інструмент з гострими

ріжучими крайками легше контролювати.

g. Використовуйте електроінструмент, аксесуари та

насадки відповідно до цих вказівок, беручи до

уваги робочі умови та характер виконуваної

роботи. Використання електричного інструменту для

операцій, які відрізняються від тих, для яких він

призначений може призвести до небезпечної ситуації.

5. Обслуговування

а. Забезпечте, щоб обслуговування і ремонт вашого

електроінструменту проводився в

авторизованому сервісному центрі по ремонту з

використанням тільки оригінальних запасних

частин. Це стане гарантією безпеки

електроінструменту.

Додаткові інструкції з безпеки для

фасонно-фрезерних верстатів

• Тримайте інструмент за ізольовані поверхні, тому

що різальний інструмент може пошкодити свій

власний шнур. Пошкодження працюючого проводу

під час різання, робить металеві частини

електроінструменту «провідниками», що може

призвести до удару електричним струмом.

• Використовуйте лещата або інший відповідний

спосіб для забезпечення і підтримки

оброблюваного виробу на стійкій платформі.

Проведення роботи по руці або проти тіла може

призвести до втрати контролю.

• Використовуйте тільки фрези з діаметром

хвостовика, рівного розміру цанги, встановленої в

інструменті.

• Використовуйте тільки фрези, придатні для швидкості

холостого ходу інструменту.

• Ніколи не використовуйте фрези з діаметром, що

перевищує максимальний діаметр, зазначений в

розділі технічних даних.

• Не використовуйте інструмент в перевернутому

положенні.

• Не намагайтеся використовувати інструмент в

стаціонарному режимі.

• Дотримуйтесь особливої обережності при роботі з

деревоволокнистими плитами середньої щільності

або з поверхнями, покритими фарбою на основі

свинцю.

• Одягайте респіратор, спеціально розроблений для

захисту від пилу і парів від свинцевих фарб, і стежте,

щоб особи, які перебувають в робочій зоні, також

були захищені.

• Не дозволяйте дітям або вагітним жінкам перебувати

в робочій зоні.

27

Page 28

УКРАЇНСЬКА

(Оригинальные инструкции)

• Не приймайте їжу, не пийте і не паліть у робочій зоні.

• Видаляйте частинки пилу та інші відходи безпечним

способом.

• Завжди надягайте захисну маску.

• Даний інструмент не призначений для використання

дітьми або немічними людьми. Діти повинні бути під

наглядом дорослих, щоб вони не мали змоги гратися

з інструментом.

Характеристики (мал. А)

1. Перемикач плавного ходу

2. Кнопка блокування

3. Ручка управління зі змінною швидкістю

4. Блокування важеля

5. Кнопка блокування шпинделя

6. Цанга

7. Револьверний обмежувач глибини

8. Пилосос

9. Обмежувач глибини

10. Шкала глибини різання

11. Адаптер для пилососа

6. Етикетки на інструменті

Етикетки на вашому інструменті можуть включати

такі символи:

Гц ....... Герц

Читайте

інструкції з

Вт ........

експлуатації

Використовуйте

засоби захисту

очей

Використовуйте

засоби захисту

органів слуху

В ........ Вольт

A ........ Ампер

Ватт

мин .....

хвилини

Змін ний

.....

стру м

Пості йний

.....

струм

n

.......

Швидк ість

0

без н авант аженн я

Положення дати штрих-коду

Дата коду, який також включає рік виготовлення,

друкується на корпусі.

Приклад:

2014 XX JN

Рік виготовлення

......

....

....

хв..

Конструкція

класу II

Термінал

заземлення

Символ

попере дження п ро

небезп еку

обороти або

зворотно

поступальний рух в

хвилину

7. Електрична безпека

Ваш інструмент має подвійну ізоляцію, тому

заземлення не потрібне. Завжди перевіряйте,

щоб основна напруга відповідала напрузі,

вказаній на табличці.

Попередження! Якщо шнур живлення

пошкоджений, він повинен бути замінений

виробником, в авторизованому сервісному

центрі STANLEY або кваліфікованим фахівцем, щоб

уникнути пошкоджень чи травм. Якщо шнур живлення

замінений кваліфікованим фахівцем, не уповноваженім

STANLEY, гарантія не буде вважатися дійсною.

Збірка

Застереження! Перед складанням

переконайтеся, що інструмент вимкнений і

відключений від мережі.

Кріплення фрези (мал. B)

• Зніміть пиловловлювач (8).

• Натисніть і утримуйте кнопку блокування шпинделя

(5) і повертайте шпиндель до повного блокування.

• Послабте цангову гайку (12), використовуючи

гайковий ключ.

• Вставте хвостовик фрези (13) в цангу (6).

Переконайтеся, що хвостовик виступає принаймні на

3 мм від цанги, як показано на малюнку.

• Натисніть і утримуйте кнопку блокування шпинделя

(5) і затягніть цангову гайку (12), використовуючи

гайковий ключ.

Установка направляючої кромки (мал. C)

Направляюча кромка допомагає направляти інструмент

паралельно краю.

• Встановіть стрижні (14) направляючої кромки (15),

використовуючи два гвинти (16), що входять в

комплект.

• Вставте стрижні (14) в підставу фрези, як показано на

малюнку.

• Встановіть направляючу на необхідній відстані.

• Затягніть кріпильні гвинти (17).

Установка адаптера для пилососа (рис. D)

Адаптер для підключення пилососа дозволяє підключати

пилосос до інструмента.

28

Page 29

(Оригінальні інструкції)

УКРАЇНСЬКА

• Підключіть шланг (18) пилососа до адаптера (11).

Установка шаблонної направляючої (рис. E)

(шаблонна направляюча не входить в комплект)

• Встановіть шаблонну направляючу (19) до основи

фрези з фланцем на нижньому боці (заготовки).

• Вставте два довгих гвинти (20) з нижньої частини

через шаблонну направляючу і отвори в основі.

• Помістіть гайку на кожен гвинт і затягніть гайки.

Установка розпірки (рис. F) (распірка не входить в

комплект)

• Встановіть распірку (21) на основі фрези,

використовуючи гвинти, що входять у комплект.

Установка центруючого штифта (рис. G)

(центруючий штифт не входить в комплект)

• Встановіть направляючу кромки до фрезі, як

показано на мал. C, але догори ногами.

• Встановіть центруючий штифт (22) в сторону

заготівлі направляючої кромки з гвинтом (23), що

входить в комплект.

Установка різця копій (рис. H) (різець копій не

входить в комплект)

• Встановіть напрямну кромки до фрези, як показано

на мал. C.

• Встановіть планку 'L' (24) у верхній частині

направляючої кромки за допомогою двох гвинтів і

гайок.

• Відрегулюйте обертовий аксесуар (25) на 'L' планку з

регулятором крила (26).

Використання

Увага! Дайте інструменту працювати у своєму

власному темпі. Не перевантажуйте його.

• Обережно переносіть кабель, щоб уникнути його

випадкового пошкодження.

Регулювання глибини різу (мал. I, J і K)

• Глибиною різу є відстань X між пластиною

обмежувача глибини (9) і обмежувачем глибини (27).

• Глибина різу може бути встановлена двома різними

способами, як описано нижче.

Регулювання глибини різу за допомогою шкали

(мал. J)

• Встановіть фрезу, як описано вище.

• Послабте фіксуючий гвинт (28).

• Потягніть важіль блокування (4) вгору.

• Опустіть фрезу вниз, до тих пір, поки фреза не

торкнеться заготівлі.

• Натисніть на важіль блокування (4) вниз.

• Перемістіть покажчик (29) в нульове положення на

шкалі (10).

• Додайте потрібну глибину різу у вихідне положення.

• Перемістіть пластину обмежувача глибини (9) до

розрахункової позиції на шкалі.

• Затягніть фіксуючий гвинт (28).

• Точне регулювання проводиться за допомогою

кнопки регулювання (30).

• Потягніть важіль блокування (4) вгору і дайте фрезі

повернутися в її вихідне положення.

• Після включення фрези, опустіть її вниз і зробіть

потрібний зріз.

Регулювання глибини різу за допомогою шматка

дерева (мал. K)

• Встановіть фрезу і опустіть її вниз, як описано вище.

• Потягніть панель обмежувача глибини (9) вгору.

• Помістіть шматок дерева з товщиною рівною бажаній

глибині різу між обмежувачем глибини (27) і

пластиною обмежувача глибини (9).

• Затягніть гвинт (28).

• Точне регулювання проводиться за допомогою

кнопки регулювання (30).

• Зніміть шматок дерева.

• Потягніть важіль блокування (4) вгору і дайте фрезі

повернутися в її вихідне положення.

• Після включення фрези, опустіть її вниз і зробіть

потрібний зріз.

Регулювання револьверного обмежувача глибини

(мал. L)

Після включення револьверного обмежувача глибини в

потрібне положення, ви можете точно налаштувати

обмежувач глибини свердління, який буде

використовуватися. Якщо ви хочете зробити кілька

надрізів з різною глибиною різання, регулюйте кожну

глибину окремо.

29

Page 30

УКРАЇНСЬКА

(Оригінальні інструкції)

• Поверніть гвинт обмежувача глибини (31) вгору або

вниз як необхідно за допомогою викрутки.

Установка швидкості

• Встановіть ручку перемикача швидкості (3) на

необхідну швидкість. Використовуйте високу

швидкість для фрез малих діаметрів. Використовуйте

низьку швидкість для фрез великих діаметрів.

Установка адаптера для пилососа (мал. M)

Коли не представляється можливим використовувати

направляючу кромку, наприклад, коли просвердлюють

канавки в задній панелі книжкової шафи, щоб

підтримати полки, дійте наступним чином:

• Виберіть шматок дерева з прямою кромкою для

використання в якості рейки.

• Помістіть рейку на оброблювану деталь.

• Перемістіть рейку, до тих пір, поки вона не займе

правильне положення, щоб направляти інструмент.

• Надійно закріпіть планки до заготівлі.

Використання шаблонної направляючої (рис. E)

(шаблонна направляюча не входить в комплект

поставки)

Шаблонна направляюча може бути використана для

того, щоб зробити форму вирізу з шаблону, наприклад

букву.

• Закріпіть шаблон на заготівлі за допомогою

двосторонньої стрічки або затискачів "G".

• Фреза повинна виступати за нижній край фланця

направляючої шаблону, щоб вирізати оброблювану

деталь у формі шаблону.

Використання розпірки (рис. F) (розпірка не входить

в комплект)

Розпірка може бути використана для обробки дерев'яних

або ламінованих вертикальних проекцій.

Використання центрувального штифта (рис. G)

(центрувальний штифт не входить до комплекту)

Центрувальний штифт може бути використаний для

вирізки круглих деталей.

•aЗробіть отвір для точки штифта в центрі кола, який

необхідно вирізати.

• Помістіть фрезу на заготівлю з точкою штифта в

просвердлений отвір.

30

• Відрегулюйте радіус кола за допомогою

направляючої кромки.

• Фреза може бути переміщена над деталлю, щоб

вирізати коло.

Використання різця копій (рис. H) (різець копій не

входить до комплекту)

Різець копій допомагає підтримувати однакову відстань

під час різання уздовж краю заготовок неправильної

форми.

• Помістіть фрезу на заготівлю на потрібній відстані від

краю для копіювання.

• Відрегулюйте бічну напрямну лінійку, поки колесо

знаходиться в контакті із заготівлею.

Выключение

Вмикання і вимикання

Центрувальний штифт може бути використаний, щоб

вирізати круглі зразки.

Вмикання

• Натисніть на кнопку блокування (2) і утримуйте її,

потім натисніть перемикач включення/виключення (1).

• Відпустіть кнопку блокування.

Вимикання

• Відпустіть перемикач включення/вимикання

Застереження! Завжди працюйте з інструментом обома

руками.

Поради для оптимального використання

• При роботі на зовнішніх краях, перемістіть інструмент

проти годинникової стрілки (мал. M). При роботі на

внутрішніх краях, перемістіть інструмент за

годинниковою стрілкою.

• Використовуйте фрезу HSS для деревини хвойних

порід.

• Використовуйте фрезу TCT для деревини твердих

порід.

• Ви можете використовувати інструмент без

направляючої (мал. O). Це зручно для SignWriting та

творчої роботи. Тільки робіть неглибокі порізи.

• Зверніться до таблиці нижче для поширених типів

фрез.

Page 31

(Оригінальні інструкції)

УКРАЇНСЬКА

Фрезы (рис. Р)

ОПИС ВИКОРИСТАННЯ

Пазова фреза (1) Для висічення канавок і жолобів

Профильна фреза (2) Для обрізки ламінату або

деревини твердих порід; точне

профілювання за допомогою

шаблону

Четвертна фреза (3) Для пом'якшення прямих

і заокруглених заготівель

V-подібна пазовая фреза (4) Для прорізи канавок,

гравіювання і фацетування країв

Галтелна фреза (5) Для рифлення, гравірування

і обробки краю декоративного

лиття

Конусна фреза (6) Для обробки краю

декоративного лиття

Калевочна фреза (7) Для обробки краю

декоративного лиття

Четвертна фреза (8) Закруглення країв

Шипова фреза

(ластівчин хвіст) (9) Kінцеві з'єднання

Зенковка (10) Cкошування крайок

здатні збільшити продуктивність вашого

електроінструменту. Використовуючи ці приналежності,

ви отримаєте найкраще, на що здатний ваш інструмент.

Інформаційна служба

STANLEY пропонує повну мережу авторизованих

сервісних точок, що належать компанії. Всі сервісні

центри STANLEY укомплектовані персоналом, який

пройшов навчання, щоб надати клієнтам ефективне і

надійне обслуговування електроінструменту. Для

отримання більш докладної інформації про наші

авторизовані сервісні центри, або якщо вам необхідна

технічна рада, ремонт або оригінальні запасні частини,

зверніться в найближчий сервісний центр STANLEY.

Oбслуговування

Ваш інструмент розрахований на роботу протягом

тривалого періоду часу при мінімальному технічному

обслуговуванні. Термін служби і надійність залежать від

правильного догляду та регулярного чищення.

Застереження! Перед проведенням технічного

обслуговування, вимкніть і відключіть прилад.

Регулярно очищайте вентиляційні прорізи вашого

інструменту м'якою щіткою або сухою тканиною.

Регулярно очищайте корпус двигуна вологою тканиною.

Не використовуйте абразивні чистячі засоби або чистячі

засоби на основі розчинника.

Аксесуари

Продуктивність вашого електроінструменту залежить від

використовуваних аксесуарів. Аксесуари STANLEY

розроблено відповідно високим стандартам якості, вони

31

Page 32

УКРАЇНСЬКА

(Оригинальные инструкции)

Захист навколишнього середовища