Page 1

Petrol grass trimmer

Petrol grass trimmer

STR-750

GB

Original instructions

Page 2

2

Manufactured under license by:

MATRIX GmbH • Postauer Straße 26 • D-84109 Wörth/Isar • www.matrix-direct.net

Stanley is a registered trademark of The Stanley Works or its affiliates and is used under license.

GB

Page 3

3

A1

12

4

9

7

5

6

16

15 17 1819 14

5

6

1

16

13

10

11

3

2

8

4

Page 4

4

Fig. 1

Fig. 4

Fig. 8

Fig.10

Fig. 2

Fig. 5

Fig. 7

Fig.11

Fig. 3

Fig. 6

Fig. 9

Fig.12

Page 5

5

1. Symbols

Warning!

Read the operating manual prior to

commissioning!

Wear goggles, a helmet and ear protection!

Do not use a metal blade.

Wear sturdy shoes!

Wear protective gloves!

Protect the device from rain or humidity

Mind parts being ejected.

Turn off the device and remove the spark

plug prior to maintenance work!

The distance between the device and

people in the vicinity must be at least

15 m!

Tool lags behind!

Attention. Hot parts.

Stay away.

Guaranteed sound power level

Table of Contents

1. Symbols ........................................................................5

2. Intended use.................................................................6

3. Safety instructions....................................................... 6

4. Parts List.......................................................................8

5. Assembly.......................................................................9

6. FueL............................................................................10

7. Operation instructions................................................10

8. Maintenance and repairs ..........................................12

9. Technical data ............................................................14

10. Troubleshooting........................................................15

11. Recycling and disposal.............................................15

114

G

B

Page 6

6

2. Intended use

The intended purpose of the device is the trimming of

lawns or grass for private use.

If the device is not used for its intended purpose, or in

case of any modification to the device, the manufacturer

does not accept any liability.

Please also observe the safety notes, the assembly and

operating instructions, as well as the general applicable

accident prevention regulations.

3. Safety instructions

Warnings! Read this instruction carefully before

operating this machine. Make sure that you are familiar

with the controls and properly operate the machine.

Following this instructions, you can reduce the risk of

fire, electric shock and personal injury.

Save all warnings and instructions for future reference.

TRAINING

1. Read the instructions carefully. Become familiar with

the owner's manual before attempting to operate the

machine.

2. Never allow children or people unfamiliar with these

instructions to use the machine. Local regulations can

restrict the age of the operator.

3. Never operate while people, especially children, or

pets are nearby.

4. Keep in mind that the operator or user is responsible

for accidents or hazards occurring to other people or

their property.

5. Do not operate the machine when you are tired, ill or

under the influence of alcohol, drugs or medication.

PREPARATION

1. This machine can cause serious injuries. Read

the instructions carefully for the correct handling,

preparation, maintenance, starting and stopping

of the machine. Become familiar with all controls and

the proper use of the machine.

2. Beware of overhead power lines.

3. Avoid operating while people, especially children, are

nearby.

4. Dress properly! Do not wear loose clothing or

jewellery, which can be caught in moving parts. Use of

sturdy gloves, non-skid footwear and safety glasses is

recommended.

5. Use extra care when handling fuels. They are

flammable and the vapours are explosive. The following

points should be observed.

- Use only an approved container.

- Never remove the fuel cap or add fuel with the power

source running.

Allow engine and exhaust components to cool down

before refuelling.

- Do not smoke. Never refuel indoors.

- Never store the machine or fuel container inside where

there is an open flame, such as near a water heater

- If fuel is spilled, do not attempt to start the power

source, but move the machine away from the spillage

before starting.

- Always replace and securely tighten the fuel cap after

refuelling.

- If the fuel tank is drained, this should be done outdoors.

6. If the cutting mechanism strikes any foreign object

or the machine starts making any unusual noise or

vibration, shut off the power source and allow the

machine to stop. Disconnect the spark plug wire from

the spark plug and take the following steps:

- Inspect for damage;

- Check for, and tighten, any loose parts;

- Have any damaged parts replaced or repaired with

parts having equivalent specifications.

OPERATION

1. This machine should not be used for any other

purpose than described.

2. While operating, always wear substantial footwear

and long trousers. Do not operate the machine when

barefoot or wearing open sandals. Wearprotective

glasses or goggles.

3. Thoroughly inspect the area where the machine is to

be used and remove all objects which can be thrown by

the machine.

4. Before using the machine and after any impact, check

for signs of wear or damage and repair as necessary.

5. Never operate the machine with damaged guards or

without the guards in place.

6. Keep hands and feet away from the cutting means at

all times and especially when switching on the motor.(

G

B

Page 7

7

G

B

Keep hands and feet away from the cutting means at all

times, especially when he motor are switched on)

7. Never allow children or people unfamiliar with the

instructions to use the machine.

8. Stop using the machine while people, especially

children, or pets are nearby.

9. Only use the machine in daylight or good artificial

light.

10. Stop the engine before

- cleaning or when clearing a blockage,

- checking, carrying out maintenance or working on the

machine,

- adjusting the working position of the cutting device,

- leaving the machine unattended.

11. Ensure that the machine is correctly located in a

designated working

position before starting the engine.

12. While operating the machine, always ensure that the

operating position is safe and secure.

13. Do not operate the machine with a damaged or

excessively worn cutting device.

14. To reduce fire hazards, keep the engine and silencer

free of debris,

leaves and excessive lubricant.

15. Always ensure that all handles and guards are

fitted when using the machine. Never attempt to use an

incomplete machine or one fitted with an unauthorised

modification.

16. Always use two hands to operate the machine fitted

with two handles.

17. Always be aware of your surroundings and stay alert

for possible hazards of which you may not be aware due

to the noise of the machine.

18. Take care against injury from any device fitted for

trimming the filament line length. After extending new

cutter line always return the machine to its normal

operating position before switching on.

19. Always ensure that ventilation openings are kept

clear of debris.

MAINTENANCE AND STORAGE

1. When the machine is stopped for servicing, inspection

or storage, shut off the power source, disconnect the

spark plug wire from the spark plug and make sure all

moving parts have come to a stop. Allow the machine to

cool before making any inspections, adjustments, etc.

2. Store the machine where the fuel vapour will not

reach an open flame or spark. Always allow the machine

to cool down before storing.

3. When not in use, store the machine out of the reach

of children.

4. Use only manufacturers recommended replacement

parts and accessories.

5. When transporting or storing the machine, always fit

the cutting device transport guard.

6. Store the machine and its accessories in a dry, clean

place protected from direct sunlight only after the fuel

tank has been emptied and the machine is cleaned. The

machine must be stored inside only under these

conditions.

FUEL HANDLING

1. Follow the maintenance and repair instructions for

this machine. Never carry out any modifications of the

machine. Never change the preset rotary speed or the

engine and machine settings. Information about

maintenance and repair is provided in this user manual.

2. Never touch the machine heedlessly. You can burn

yourself. While the machine is in operation or shortly

thereafter, its parts such as the exhaust pipe, engine,

and other surfaces are extremely hot! Pay attention to

the markings on the machine.

3. Make sure that the air intake of the combustion

engine is clear. Keep the air intake free of dust, dirt

particles, gases and fumes.

4. Make sure that air circulation is adequate and good.

The machine must be easily accessible from all sides.

5. Always switch the machine off and let it cool down

before refuelling it.

Petrol is easily flammable. Never smoke when you are

refuelling tool. Do not refuel the machine if there is an

open fire in the vicinity!

6. Always use suitable aids such as funnels and filler

necks. Do not spill any fuel on the machine or its exhaust

system. There is a risk of ignition.

However, if fuel should be spilled, then you must remove

it carefully from all parts of the machine. Any residue

which may be present must have completely removed

before the machine is put into operation!

7. Exhaust gases and fuel fumes are noxious. Fuel fumes

can ignite. Never use the machine in environments

where there is a risk of explosion.

8. Never breathe in any fuel fumes when you are

refuelling the machine.

Page 8

8

Never fill the tank in enclosed spaces, such as

basements or sheds.

There is a risk of poisoning and explosion!

9. Avoid skin contact with petrol.

10. Do not eat or drink, while you are refuelling the

machine. If you have swallowed petrol or oil, or if petrol

or oil has got into your eyes, then seek the advice of a

doctor immediately.

11. Close the tank lid immediately after filling the tank.

Make sure that it is properly closed.

12. Never use the machine without an air filter.

RESIDUAL RISKS

Even if you are operating this machine in accordance

with the provisions, residual risks will always still

remain. The following dangers can arise in connection

with the structure and design of this machine:

1. Health defects resulting from vibration emission if the

machine is being used over longer period of time or not

adequately managed and properly maintained.

2. Injuries and damage to property to due to broken

accessories or hidden objects that are suddenly dashed.

3. Injuries and damage to property to due to thrown

objects.

4. Burns, if touching hot surfaces.

EMERGENCY

Familiarise yourself with the use of this machine by

means of this instruction manual. Memorise the safety

directions and follow them to the letter. This

will help to prevent risks and hazards.

1. Be alert when using this machine, so that you can

recognise and handle risks early. Fast intervention can

prevent serious injury and damage to property.

2. Stop the engine and unplug the spark plug connector

if there's malfunctions. Have the machine checked by a

qualified professional and repaired, if necessary, before

you put it into operation again.

3. In case of fire stop the engine and unplug the spark

plug connector.

Immediately use fire-extinguishing measures, if the

switch of the machine is no longer accessible.

Warnings! Never use water to extinguish a

machine on fire.

Burning fuel must be extinguished with

special extinguishing agents. We recommend that

you keep a suitable fire extinguisher within reach

in your work area!

VIBRATION AND NOISE REDUCTION

To reduce the impact of noise and vibration emission,

limit the time of operation, use low-vibration and

low-noise operating modes as well as wear personal

protective equipment.

Take the following points into account to minimize the

vibration and noise exposure risks:

1. Only use the machine as intended by its design and

these instructions.

2. Ensure that the machine is in good condition and well

maintained.

3. Use correct application tools for the machine and

ensure they in good condition.

4. Keep tight grip on the handles/grip surface.

5. Maintain this machine in accordance with these

instructions and keep it well lubricated (where

appropriate).

6. Plan your work schedule to spread any high vibration

tool use across a number of days.

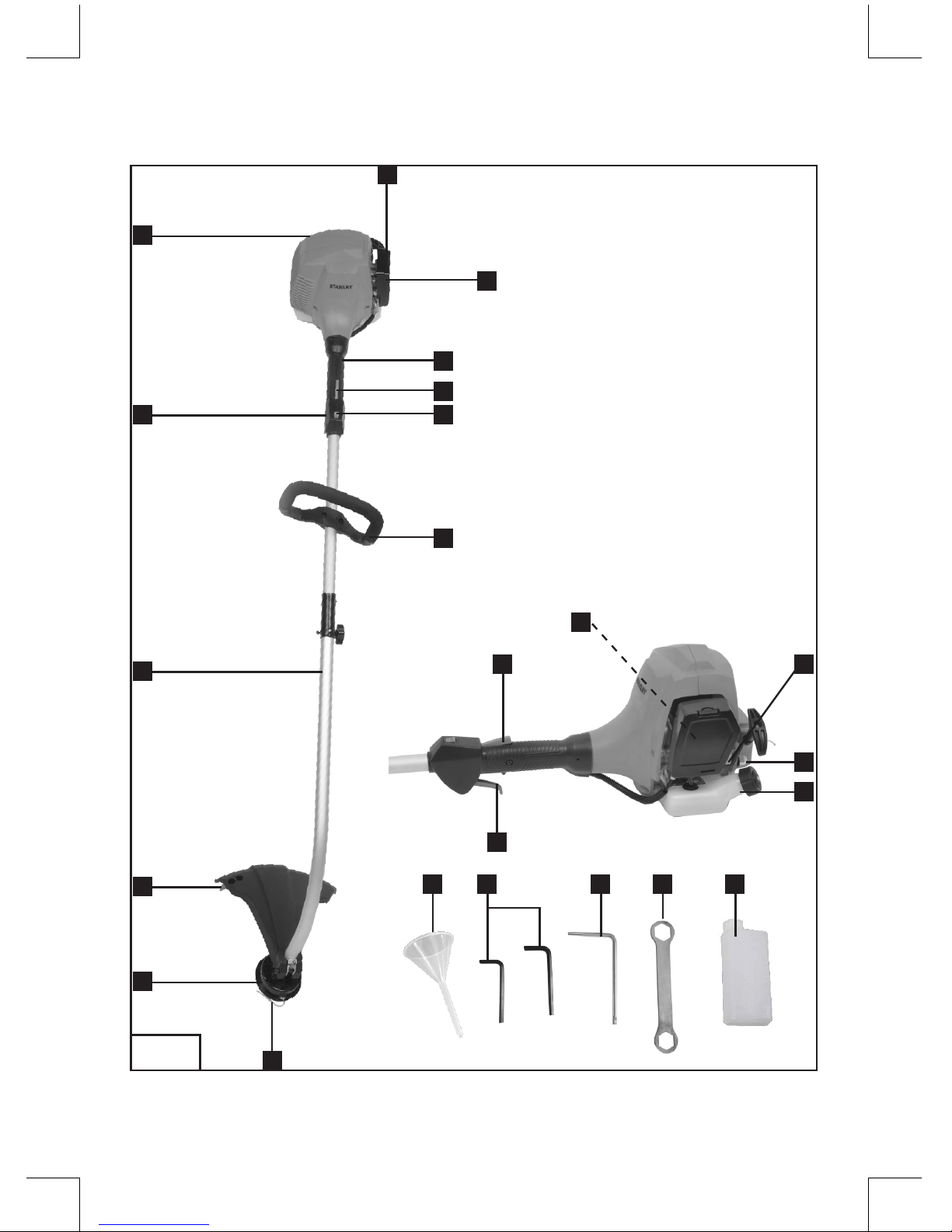

4. Parts List

1. Handle

2. Guide handle

3. Ignition switch

4. Hand throttle

5. Choke lever

6. Air filter

7. Petrol tank

8. Exhaust pipe protection

9. Injector

10. String protection hood

11. String head

12. Cutting string

13. Guiding bar

14. Spark plug wrench

15. Allen keys

16. Safety push button

17. Screw driver

18. Oil/petrol mixing bottle

19.

Funnel

G

B

Page 9

9

5. Assembly

WARNING! The machine must be fully

assembled before operation! Do not use a

machine that is only partly assembled or

assembled with damaged parts.

Always use gloves during assembly.

Disconnect the spark plug connector from the

spark plug.

INTENDED USE

1. This machine is designated with a maximum power

output of max. 0.75 kW.

2. With attached trimming guard and fitted trimmer

head, the grass trimmer is intended to be used to cut

small weeds, grass or similar soft vegetation.

3. With attached trimming guard and fitted cutting

blade, the brush cutter is intended to be used to cut

weed, brush, small trees and similar vegetation with a

thickness of up to 20mm.

4. It may not be used to work on unusual thick, dry or

wet grass, e. g. pasture grass, or to shredder leaf.

5. For safety reasons it is essential to read the entire

instruction manual before first operation and observe all

instructions.

6. This machine is for private use only, not for any

commercial applications.

It may not be used for any purposes other than

described.

ASSEMBLY HANDLE

Assembly auxiliary handle

1. Loosen the outer pre-assembled screws on the

handle.

2. Place the handle onto the shaft from the top, secure it

with the retainer and the screws.

NOTE: Pay attention to the screws and nuts. Avoid loss.

ASSEMBLY SHAFT

1. Align the lower shaft(19) with the clamp(16) so that

the lock pin(18) is orientated to the centre hole in the

clamp.

19

18

16

2. Press the lock pin down and insert the lower shaft

into the upper shaft.

The lock pin must engage in the centre hole of upper

shaft.

3. Secure the connection by tightening the locking

knob(17).

17

ASSEMBLY SAFETY GUARD

1. Remove the bolt and washer on the guard.

2. Place the guard over the end of the spindle and align

the holes in the front of the guard with the slots in the

brackets on the shaft.

3. Insert and secure the guard by the bolt with washer.

NOTE: Local regulations might restrict the size of

the cutting guard so that it might be necessary to

G

B

Page 10

10

use the bigger trimming guard for cutting.

Ask your local authorities.

INSTALL CUTTING ATTACHMENT

Install spool assembly

1. Make sure that the guard has been attached properly.

2. Attach the trimmer head onto the spindle.

3. Secure the trimmer head with bumper clockwise.

6. Fuel

WARNING! This machine is not supplied

with fuel in the engine!

Before operating this machine it is essential to fill

in fuel!

WARNING! Fuel and oil are highly

inflammable! Fumes will explode if lit!

Ensure that there are no open flames around the

machine!

Do not smoke while filling in fuel and oil!

1. This machine is equipped with a 2-stroke engine.

2. Mix a regular-grade unleaded petrol and a quality

motor oil for air cooled 2 stroke engines.

3. Use an anti-oxidant added quality oil expressly

labelled for air-cooled 2 stroke engine use (JASO FC

GRADE OIL or ISO EGC GRADE).

4. Do not use BIA or TWC (2 stroke water-cooling type)

mixed oil.

5. The recommended mixing ratio for petrol: oil is 40:1.

6. Place the machine on a stable and level surface. We

recommend laying an inflammable sheet under the unit.

7. Mix and store fuel only in an approved petrol

container.

8. Unscrew and remove the fuel tank cap.

9. Add proper fuel. Do not overfill. Leave approximately

5mm of space to the lower edge for fuel expansion.

10. Use proper a funnel with filter to avoid that debris

can enter the tank and avoid splitting and overfilling the

tank.

11. Wipe up spilled fuel with a soft cloth and refit the

fuel tank cap.

12. Always dispose fuel, used oil and objects soiled with

those according to local regulations.

7. Operation instructions

WARNING! For your safety, please read the

safety warnings carefully before operate the

machine!

START ENGINE

Start cold engine

1. Place the machine on a flat stable ground that is not

flammable. Ensure that the cutting means to not touch

any objects or the ground.

2. Set ignition switch to “I” position (“ON” position).

3. Move choke lever to “COLD START” position and

pump primer bulb(5) until fuel is visible and flows freely

in the clear fuel tank return line. Pump bulb an additional

5~ 6 times.

G

B

Page 11

11

4. Press throttle interlock and throttle trigger.

1

2

5. Pull the recoil starter to start engine and the move

choke lever to “WARM START” position. Now, your

machine is under idle speed condition.

6. Let the machine run in idle speed for 10-15s to warm

up.

7. Depress throttle trigger to get full engine speed for

operation.

Start warm engine

1. Set ignition switch to “I” position.

2. Move choke lever to “WARM START” position, do not

depress primer bulb.

3. Press throttle interlock and throttle trigger.

4. Pull the recoil starter to start engine. Now, your

machine is under idlespeed condition.

5. Depress throttle trigger to get full engine speed for

operation.

STOP ENGINE

WARNING! The cutting device will continue to

rotate for some time even after the engine has

been switched off! Wait until it comes to a complete

stop before you place down the machine!

1. Release throttle interlock and throttle trigger to return

to idle before shutting off engine

2. Set ignition switch to “STOP” position to shut off

engine.

ADJUST CUTTING ANGLE

1. The angle of gear head can be adjusted in 3 positions

according to the performed work.

2. To adjust, depress the lock pin and rotate the lower

shaft either to the right or left side until the pin locks in

position.

WARNING! Never operate the machine if the

pin is not locked properly!

TRIMMING

Trimmer

1. Use the trimmer head and trimming guard to cut small

weeds, grass or similar soft vegetation.

2. Hold the machine with sufficient distance to your

body.

3. Pay attention to your posture. Stand upright, do not

lean forward.

4. Hold the trimmer head just above the ground at an

angle of about 30°.

G

B

Page 12

12

5. Move the machine with slow and regular horizontal

movements from the right to the left and then lead it

back to starting point before trimming the next row.

1

6. Clean the cutting means regularly. Stop the engine,

switch the machine off and unplug the spark plug

connector before checking.

7. Trim in steps when the grass is very high. Do not cut

the total height at once.

8. Wait until the machine has come to a standstill before

placing it down.

9. The trimmer head is equipped with a bumper helping

to cut the trimmer line while operating. Tap the bumper

on a stable surface and the spool will release a fresh

trimmer line.

10. A knife which is integrated in the guard will cut the

line to the required length. Always remove the knife

protection before operation and refit afterwards.

TIPS

1. For best results, do not cut wet grass because it tends

to stick to the cutting means and guard, prevents proper

discharge of grass clippings, and could cause you to slip

and fall.

2. Pay special attention when performing the work close

to trees and bushes. The cutting means can damage

sensitive bark, and damage fence posts.

3. Regularly remove clippings and dirt around the

trimmer head with a switched off product.

4. After use, switch the machine off, unplug the spark

plug connector and let it cool down.

8. Maintenance and repairs

STORAGE

1. Store the machine and its accessories in a dark, dry,

frost-free, wellventilated place.

2. Always store the machine in a place that is

inaccessible to children. The ideal storage temperature

is between 10 and 30 degree. For best results,

cover the machine with a proper cloth or foil to protect it

against dust.

3. If you are not going to use the machine for an

extended period of time (more than 1 month), empty the

fuel tank before storing it.

GENERAL CLEANING

1. Regular and proper cleaning will not only ensure safe

use but also prolongs the life time of this machine.

2. Switch the machine off, let it cool down and unplug

the spark plug connector.

3. Clean the machine with a damp cloth and neutral

soap. Use a brush for areas that are hard to reach.

4. In particular clean ventilation openings and the cutting

means after every use with a cloth and brush.

5. Remove stubborn dust with high pressure air (max. 3

bar).

6. Check for any damage and worn. Repair damages

according to this instruction manual or bring it to an

authorised service centre before using this machine

again.

CUTTING MEANS AND GUARDS

WARNING! Wear safety gloves when

working on the cutting means and around it!

Use proper tools to remove debris, e. g. a

wooden stick! Never use your bare hands!

1. Keep the cutting means and guards clean and free of

debris. Remove grass clippings.

2. Replace a worn or damaged cutting means with new

ones of the same type.

G

B

Page 13

13

AIR FILTER

1. Inspect the air filter regularly. Clean it at least every

25 hours or replace with a new one if necessary.

2. Press the air filter seat,open the air filter case. Tap

the filter on a stable surface to remove dust. Use high

pressure air (max. 3 bar) to remove stubborn dust.

A

3. Apply a small amount of air filter oil on the filter to

increase the filter performance. Wring out surplus oil

and put the filter into the case.

4. Close the air filter case.

FUEL

1. Empty the fuel tank when storing the machine over 30

days to avoid deterioration of the fuel.

2. Open the tank by unscrewing the tank cap and use a

proper fuel pump to empty the tank.

NOTE: Petrol deteriorates over time. Engine starting

may be difficult if you use petrol kept for more than

30 days. Always empty the fuel tank when storing

over 30 days.

FUEL FILTER

The fuel tank of this machine is fitted with a filter

located at the free end of fuel pipe. Periodically ask an

authorised service centre or similar qualified

person to check and replace it.

SPARK PLUG

1. Inspect the spark plug at least every 25 hours, clean

and replace with a new one if necessary.

2. Unplug the spark plug connector by pulling.

3. Loosen the spark plug with the spark plug wrench and

remove it.

4. The colour of the electrode shall be light brown.

5. Remove debris like oil with a brass brush. Do not force

the brush to avoid any damage.

6. Dry the spark plug with a soft cloth if it is wet.

7. Check the spark plug gap. It should be 0.6-0.7mm.

8. Replace with a new spark plug if you find damages

like cracks or a splintered insulation.

9. Screw in the spark plug by hand, and then tighten it

with a spark plug wrench.

WARNING! Do not over tighten the spark plug to

avoid any damage!

CARBURETTOR

The carburettor is readjusted by the manufacturer.

Should it be necessary to make any changes please

contact an authorised service centre or similar

qualified person. Do not attempt to make adjustments by

yourself.

SILENCER

Should it be necessary to make any changes or

replacement, please contact

an authorised service centre or similar qualified person.

REPLACING SPOOL

1. If the cutting line is used up the spool must either

be replaced by one of the same type or the cutting line

must be refilled.

2. To refill the cutting line lay the machine on a flat

stable surface with its spool assembly facing upwards.

3. Open the spool assembly by unscrewing the bumper

clockwise.

4. To replace the spool simply remove from the spool

assembly and replace with a new one of the same type

that recommended.

G

B

Page 14

14

5. To replace the line take out the spool and remove the

remaining cutting line.

6. Cut a new 6m long cutting line with a diameter of

2mm. Form a loop at the middle of the line and insert

this loop into the hook on the spool.

7. Wind the two parts of the cutting line in clockwise

direction firmly around the spool each part in the guide

on the spool.

8. Insert each end of the threads in the respective holes.

The threads should stick out 150 mm on each side.

9. Screw the bumper anti-clockwise until it is completely

and safely locked.

9. Technical data

Air-cooled 2-stroke engine

Displacement: 26 cm

3

Power: 0.75 kW

Idle speed of engine: 3000 rpm

Max. speed of double string: 12500 rpm

Tank capacity: 400 ml

Cutting width: 430 mm

String thickness: 2.0 mm

Spark plug: TORCH L8RTC

CHAMPION RCJ6Y

Weight (empty tank): 5.0 kg

Sound pressure level LpA: 97,4 dB(A), k=3 dB(A)

Sound power level LwA: 110 dB(A), k=3 dB(A)

Vibration ahv: 8,712 m/s2; k=1.5 m/s

2

Guaranteed sound power level LWA: 114 dB(A)

The operating noise may exceed 114 dB. Please always

wear ear protection.

G

B

Page 15

15

11. Recycling and disposal

1. Petrol, oil, used oil, a mixture of oil and petrol and

objects soiled with oil e. g. cleaning cloths do not belong

in the household rubbish. Dispose of oil-contaminated

items in accordance with the local guidelines and hand

them in at recycling centres.

2. The machine comes in a package that protects it

against damages during shipping. Keep the package

10. Troubleshooting

Problem Possible cause Fault correction

Engine does not start There is not enough fuel in

the fuel tank

Add fuel

The primer has been not

pressed at cold start

Press the primer and restart

The primer has been not

pressed at warm start

Press the primer and restart

The spark plug is wet Dry the spark plug

The spark plug is damaged Replace the spark plug

Engine stops There is not enough fuel in the

fuel tank

Add fuel

The cutting means are blocked Remove the blockage

The engine speed don’t fit the

terrain requirements

Increase the engine speed

Bad cutting performance The cutting means are not sharp

enough

Replace the cutting means

The cutting means are not fitted

correctly

Fit the cutting means correctly

Cutting height is wrong Adjust the cutting height

The cutting/trimming guard is

clogged

Clean the cutting/trimming guard

Excessive vibration/noise

or big smoke came out

The cutting means are broken Replace the cutting means

The flanges on the cutting mans

are loosen

Tighten the flanges

The flanges on the cutting means

are broken

Replace the flanges

The mixture scale and oil type is

wrong

Re-fill fuel and oil mixture into the tank

until you are sure that all parts have been delivered and

the machine is function properly. Recycle the package

afterwards.

3. Used products are potentially recyclable but do not

belong with household waste. We would like to request

that you assist us and make a contribution to preserving

resources and protecting the environment and

hand this production at an equipped collection centre (if

there is one available).

G

B

Page 16

Petrol grass trimmer / STR-750

EN ISO 11806-1; EN ISO 14982

Geräuschemission 2000/14/EC, Anhang III & 2005/88/EC, Garantierter Schallleistungspegel: LwA= 114 dB(A), Benannte

Stelle , Name und Anschrift der beteiligten Stelle: TÜV SÜD certification and Testing (China) Co., Ltd. Shanghai Branch

Wörth/Isar, den 13.10.2017

Art.-Nr.: 604.200.030

2006/42/EC

R&TTED 1999/5/EC

2000/14/EC_2005/88/EC

97/68/EC_2012/46/EC

95/54/EC

2006/95/EC

2002/95/EC_2005/618/EC

2014/30/EU

GB

hereby declares the following conformity

under the EU Directive and standards for the

following article

Matrix GmbH

Postauer Str. 26

D-84109 Wörth/Isar

Germany

Fax: +49 (0) 8702/45338 98

E-Mail: info@matrix-direct.net

The technical documentation is kept by our authorized representative:

Matrix GmbH

Postauer Str. 26

D-84109 Wörth/Isar

Germany

Joachim Lichtl (Geschäftsführer)

Original Konformitätserklärung

16

Page 17

17

GARANTIE

Guarantee

GB

This appliance is a quality product. It was designed in compliance with

current technical standards and made carefully using normal, good quality

materials.

The warranty period is 24 months and commences on the date of purchase,

which can be verified by the receipt, invoice or delivery note. During this

warranty period all functional errors, which, despite the careful treatment

described in our operating manual, are verifiably due to material aws, will

be rectified by our after-sales service staff.

The warranty takes the form that defective parts will be repaired or replaced

with perfect parts free of charge at our discretion. Replaced parts will

become our property. Repair work or the replacement of individual parts

will not extend the warranty period not will it result in a new warranty period

being commenced for the appliance. No separate warranty period will

commence for spare parts that may be fitted. We cannot offer a warranty for

damage and defects on appliances or their parts caused by the use of excessive

force, improper treatment and servicing.

This also applies for failures to comply with the operating manual and the

installation or spare and accessory parts that are not included in our range of

products. In the event of interference with of modifications to the appliance by unauthorised

persons, the warranty will be rendered void.

Damages that are attributable to improper handling, over loading, or natural wear and tear

are excluded from the guarantee.

Damages caused by the manufacturer or by a material defect will be corrected at no

charge by repair or by providing spare parts.

The prerequisite is that the equipment is handed over assembled, and complete with

the proof of sale and guarantee.

For a guarantee claim, only use the original packaging.

That way, we can guarantee quick and smooth guarantee processing.

Please send us the appliances post-paid or request a Freeway sticker.

Unfortunately we will be unable to accept appliances that are not postpaid.

The warranty does not cover parts that are subject to natural wear and tear.

If you wish to make a warranty claim, report faults or order spare parts or

accessories, please contact the after-sales centre below:

Subject to change without prior notice.

210 Bath Road; Slough, Berks SL1 3YD

www.stanleytools.co.uk

Tel: +44 (0)1753 511234

Fax: +44 (0)1753 512365

Page 18

18

Petrol grass trimmer / STR-750

GB

WARRANTY

Purchased at:

in (city, street):

Name of customer:

Street address:

Postal code, city:

Telephone:

Date, signature:

Fault description:

Loading...

Loading...