Page 1

4 in 1 Garden tool

Original instructions

GB

Übersetzung der Originalbetriebsanleitung

D

Traduction des instructions originales

F

Traduzione delle istruzioni originali

I

Traducere după manualul original de exploatare

RO

STR-4 IN 1

4 in 1 Garden tool

Page 2

Manufactured under license by:

MATRIX GmbH • Postauer Straße 26 • D-84109 Wörth/Isar • www.matrix-direct.net

GB

Stanley is a registered trademark of The Stanley Works or its affiliates and is used under license.

Hergestellt unter Lizenz durch:

MATRIX GmbH • Postauer Straße 26 • D-84109 Wörth/Isar • www.matrix-direct.net

D

Stanley ist eine eingetragene Marke der The Stanley Works oder ihren Partnern und wird unter Lizenz verwendet.

Fabriqué sous licence par :

MATRIX GmbH • Postauer Straße 26 • D-84109 Wörth/Isar • www.matrix-direct.net

F

Stanley est une marque déposée de The Stanley Works ou de ses sociétés affiliées, qui est utilisée sous licence.

Prodotto sotto licenza di:

MATRIX GmbH • Postauer Straße 26 • D-84109 Wörth/Isar • www.matrix-direct.net

I

Stanley is a registered trademark of The Stanley Works or its affiliates and is used under license.

Fabricat sub licenţă de către:

RO

MATRIX GmbH • Postauer Straße 26 • D-84109 Wörth/Isar • www.matrix-direct.net

Stanley este marcă înregistrată a Stanley Works sau a partenerilor săi şi este utilizată sub licenţă.

2

Page 3

Table of Contents

1. Symbols........................................................................4

2. Device...........................................................................5

3. Safety Precautions and Warnings................................8

4. Technical data.............................................................13

5. Assembly and commissioning....................................15

6. Operation....................................................................24

7. Working with the brush cutter / grass trimmer......... 26

8. Working with the pruner.............................................27

9. Cleaning, maintenance , transport and storage.........30

10. Working with petrol hedge cutter.............................36

11. Fault and troubleshooting........................................ 46

12. Disposal....................................................................47

G

B

3

Page 4

G

114

B

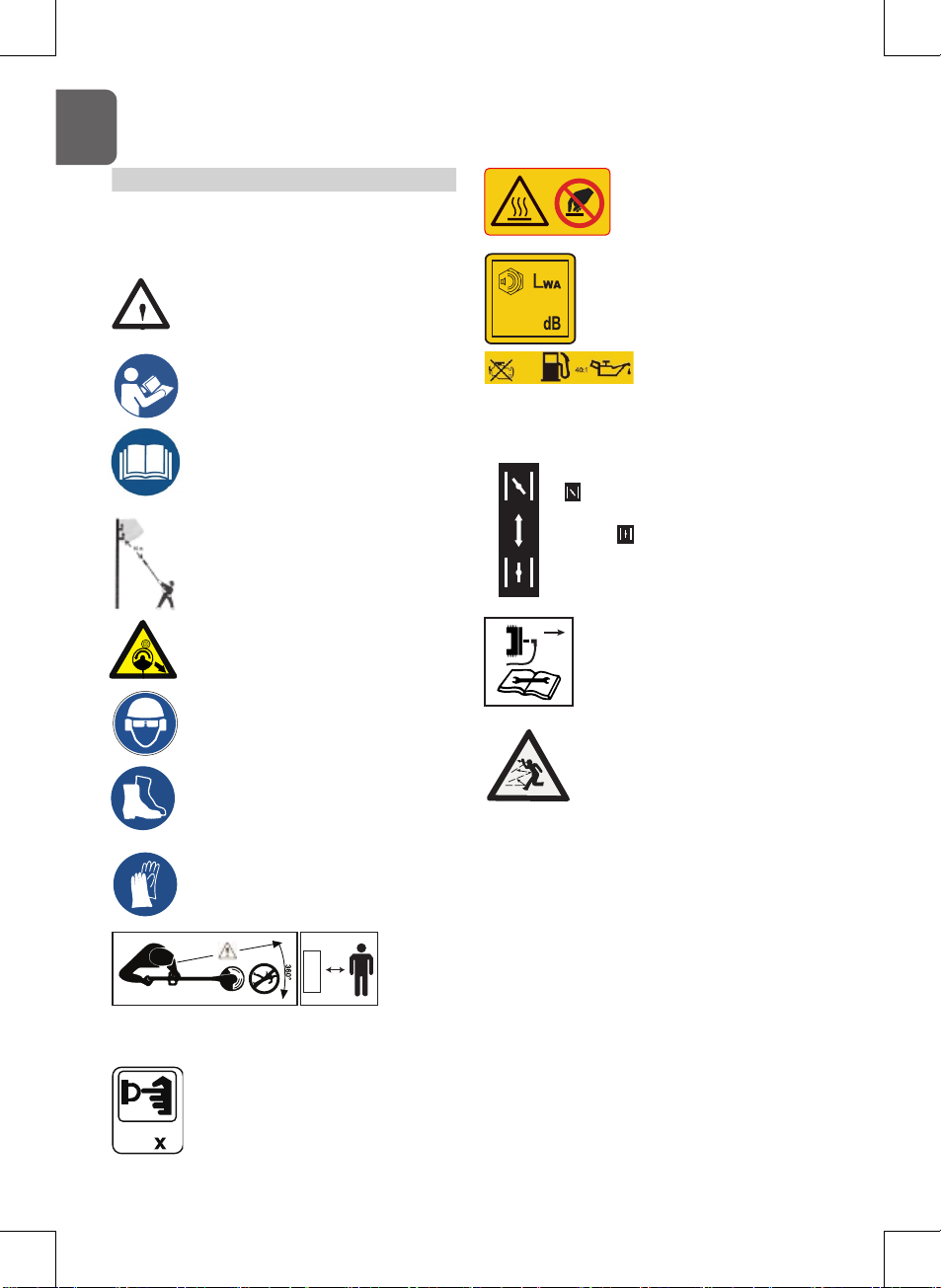

1. Symbols

Markings on the device

Explanation of symbols

In this manual and/or on the device the following

symbols are used:

Warning/Caution

Warning against hot surfaces

Guaranteed sound power level

Read the operating instructions before

use

Pay attention to electric cables. Keep

at least 15 m distance

Caution against backlash

Use safety goggles, protective helmet

and hearing protection.

Wear safety shoes.

Wear safety gloves.

Before refuelling the tank,

stop the engine

Mixture ratio of fuel/engine

oil.

During a cold start, raise the choke lever to

to close the choke.

In case of a warm start, raise the choke

lever to to open the choke.

Remove the spark plug connector in case

of repairs

Caution against parts that can be hurled

away.

The distance between the machine and the third parties

must be at least 15 m.

Primer

6

4

Page 5

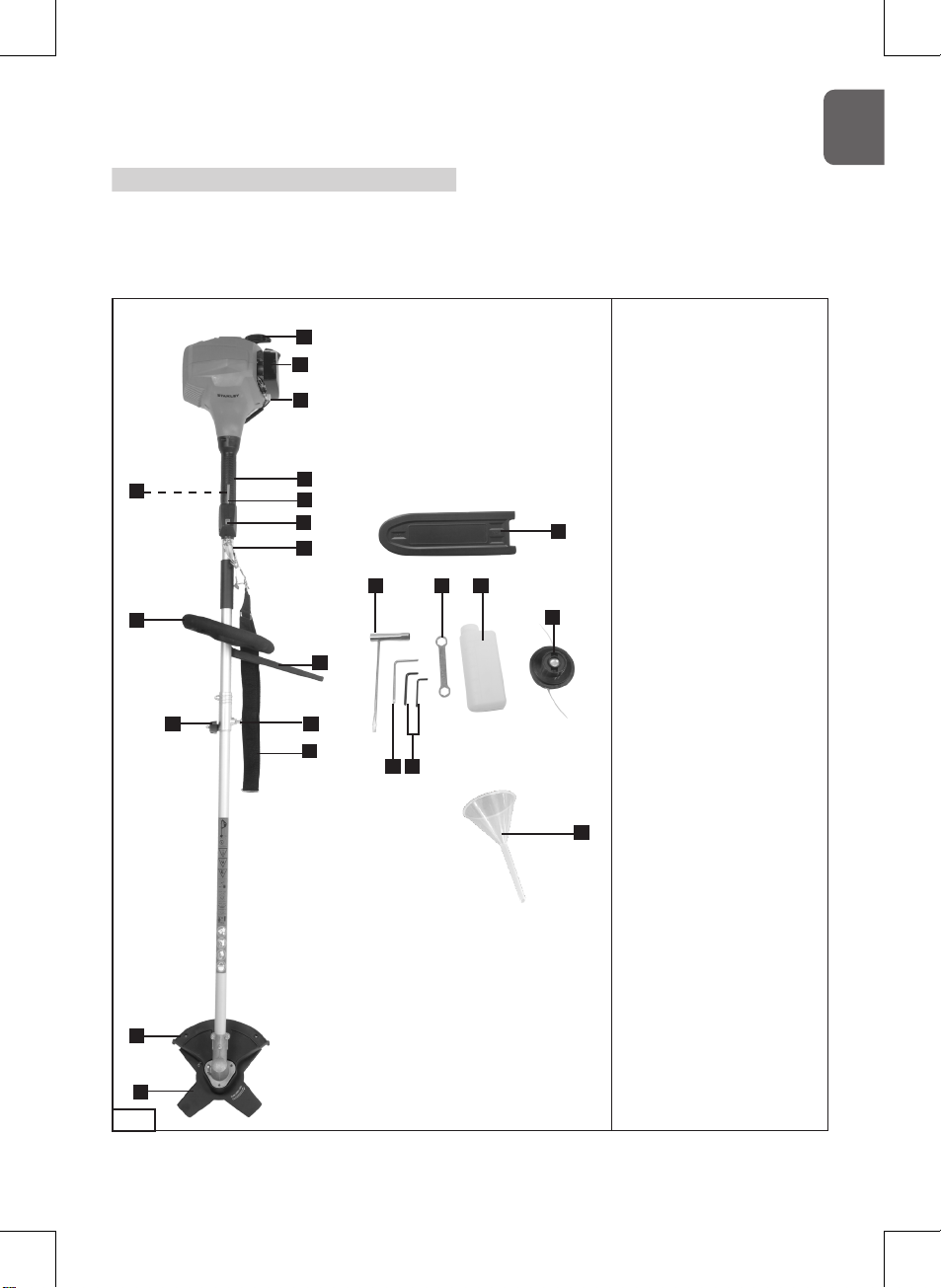

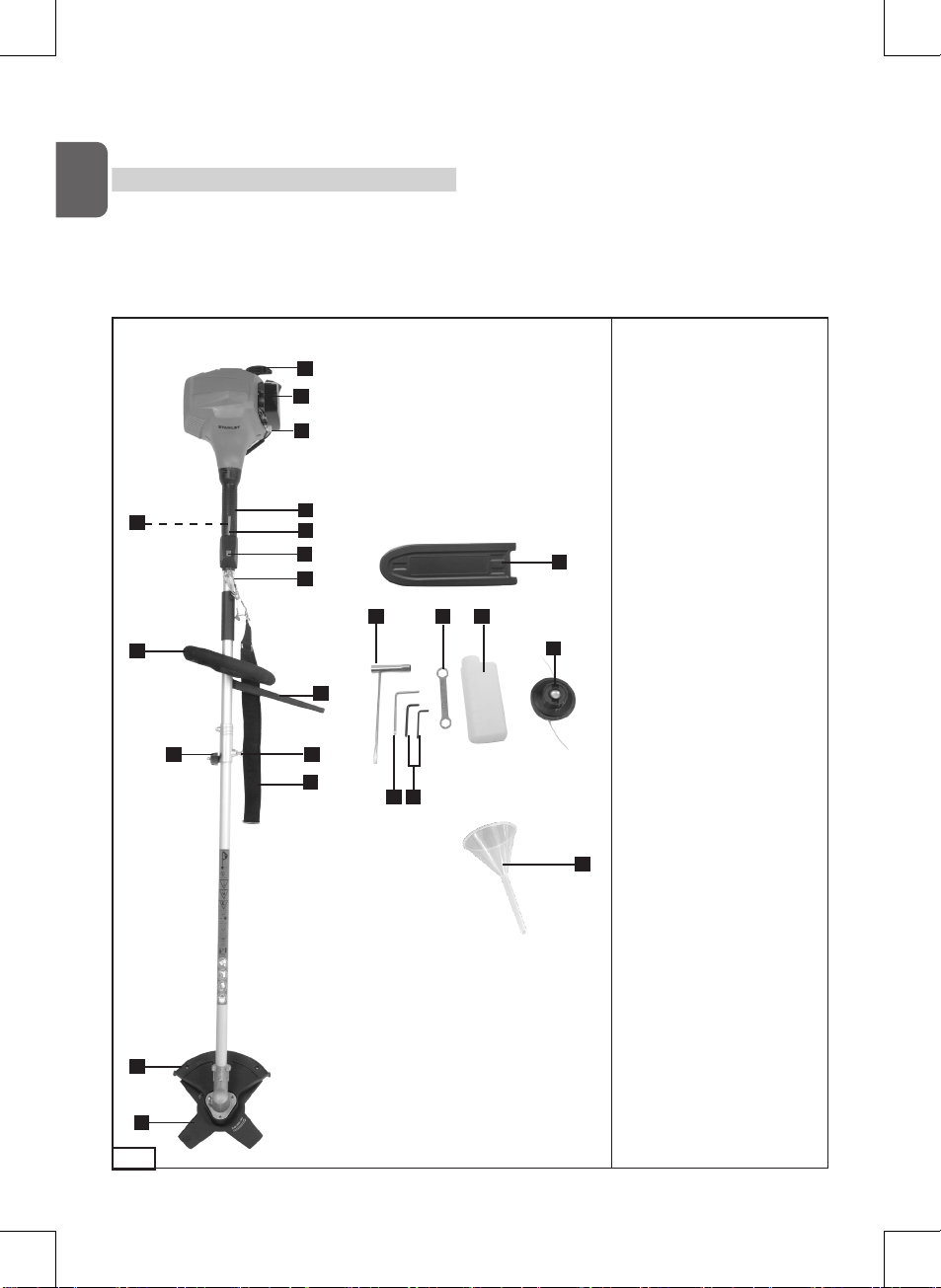

2. Device

Universal brush cutter-grass trimmer -pruner-hedge trimmer combination device for perfect care of garden and garden

maintenance. With just one device, you will carry out your lawn care, tree care and your garden work.

2.1 Scope of delivery

2.1.1 Propulsion unit and accessories

1. Front handle

1b. Rear handle

2. Eyelet for shoulder strap

3. Operating switch

4. Unlocking

5. Air filter

6. Wire rope hoist

7. Tank

8. Throttle

9. Shoulder strap

10. Locking screw

11. Blade

12. Chain guard

13. Clamping flange

14. Lock nut for the

Cutter blade

15. Cutting protection

16. Retaining plate

17. Support flange

18. Protection device

19. Thread spool

20. Extension

21. Oil Tank

22. Chain

23. Blade

24. Choke lever

25. Primer

27

26. Locking pin

26a. Cover

Accessories:

27. Funnel

28. Allen Key

29. Wrench

30. Mixing container

31.Screwdriver

32. Wrench

33. Blade

34. Handle

35. Unlocking

36. Unlocking

37. Oil flow rate in the adjustment

screw

A1

6

5

7

8

1

10

12

15

11

1b

4

3

2

29

18

26

9

31 28

32

30

12

19

G

B

5

Page 6

G

B

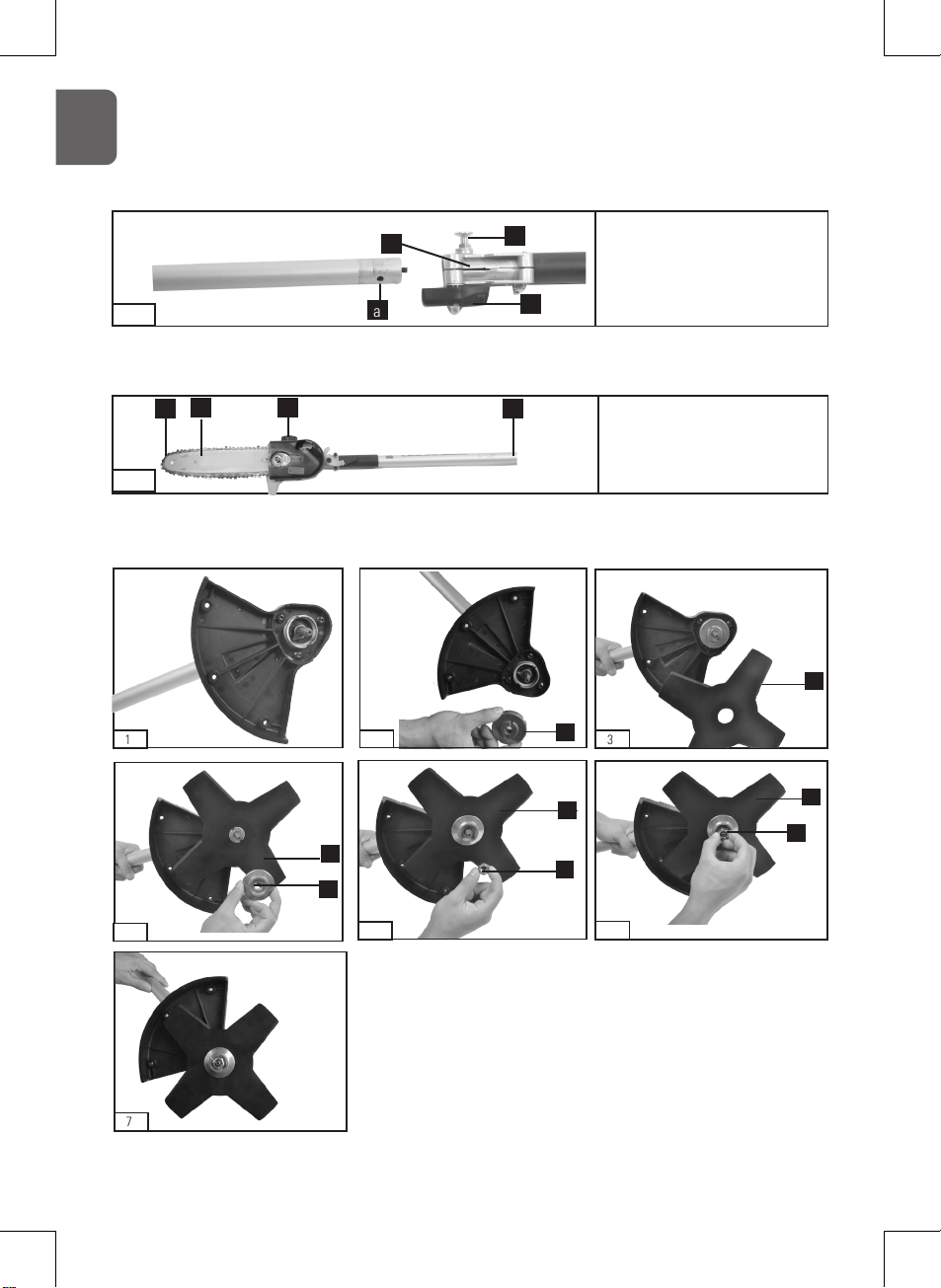

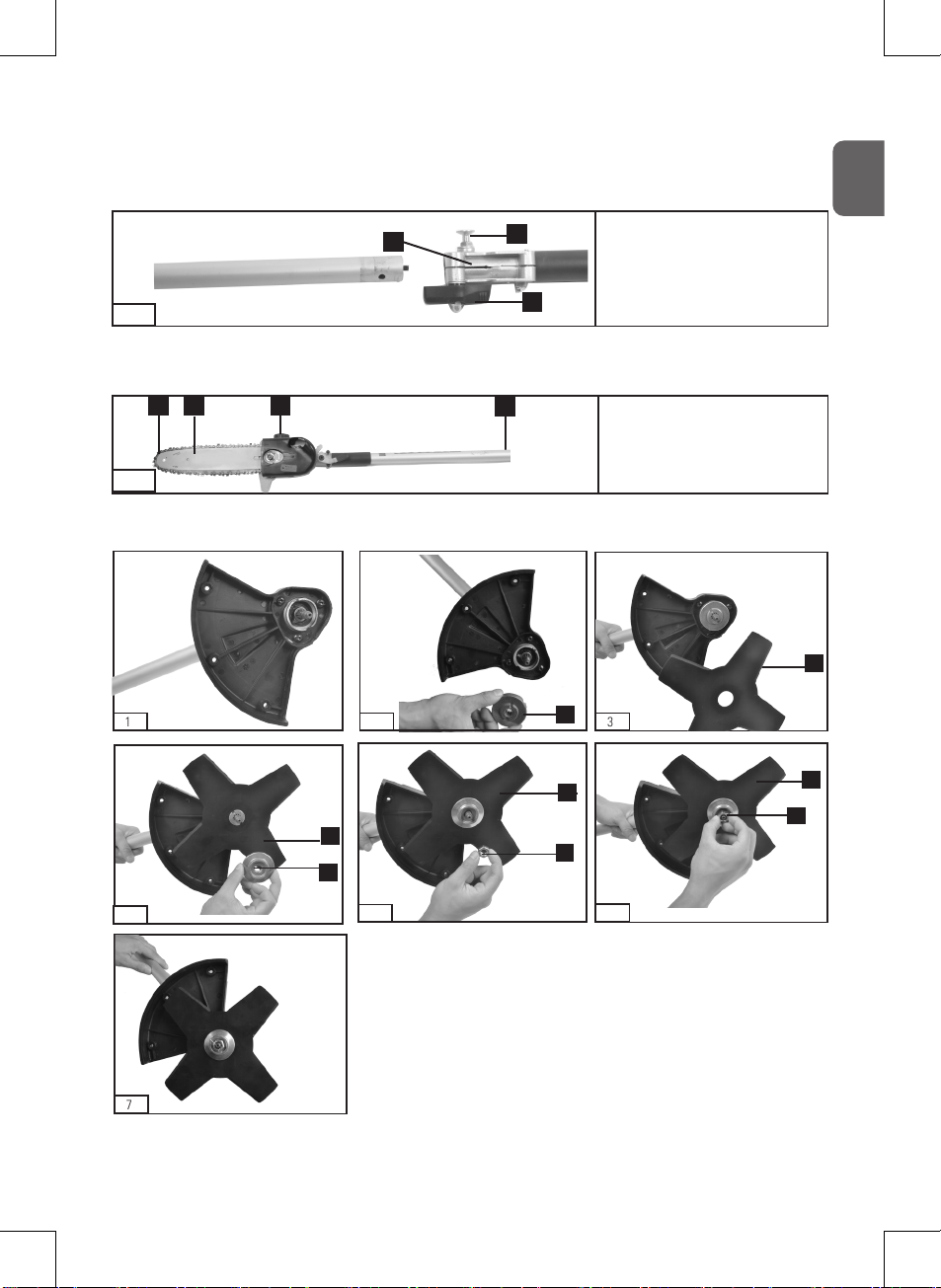

2.1.2 Extension

26a

A2

a

2.1.3 Pruners

23

22 a

21

A3

2.1.4 Bursh cutter

1

2 3

26

20. Extension

a. Lock holes

10. Locking screw

26. Locking pin

10

26a. Cover

a. Lock holes

21. Oil Tank

22. Chain

23. Blade

11

17

11

11

13

4

7

5

14

6

11

14

6

Page 7

G

B

15.

a

a. Lock hole

11. Blade

15. Cutting protection

A4

2.1.5 Grass trimmer

a

A5

2.1.6 Hedge shears

33

11

15

19

36

34

a. Lock hole

15. Cutting protection

19. Thread spool

33. Blade

34. Handle

35. Unlocking

36. Unlocking

A57

35

7

Page 8

G

B

3. Safety Precautions and Warnings

This device complies with the required safety provisions

for combustion engines.

Read the manual carefully before operating the machine.

An improper use can lead to damage to persons and

property.

Persons who are not familiar with the instructions may

not operate the device.

Keep the safety instructions in a safe place.

Children and young people under the age of 16 are not

permitted to use the device.

Young people over 16, who work under the guidance of

a trained person, are permitted to use this.

Make sure that no persons or animals are found in the

vicinity of the working area (minimum distance of 15 m).

Foreign objects such as stones can be found in the cut

and stirred-up grass. You will carry the responsibility for

the safety in your work area and are subject to liability

for damage to persons or objects.

The petrol-brush cutter may not be started or used in the

vicinity of people or animals.

Do not use the appliance if you feel tired, sick or cannot

concentrate or are under the influence of alcohol or

drugs. Inattention can result in serious injury.

Wear personal protective equipment, in order to protect

yourself against a threat to your safety and health.

This includes wearing approved safety glasses, hearing

protection, protective gloves and non-slip foot protection

and protective clothing.

Never work with the device wearing sandals or even

barefoot.

Wear a permitted helmet in any case, in case of

afforestation work.

Do not wear loose clothing or jewellery. Wear long pants

to protect your legs. If you have long hair, wear a head

cover. Loose clothing, jewellery or long hair could get

caught by moving parts.

Wear suitable tough clothes that are tight.

Keep parts of your body and clothing away from the

cutting tool when you start the engine and let it run.

When you work, make sure that you have a fixed and

a secure position. Avoid walking backwards with the

device, due to risk of tripping.

Avoid abnormal postures of your body. In case of a

prolonged use of the gasoline- brush cutter, it can lead

to a vibration-related disorder of the blood circulation

(white finger disease). The white finger syndrome is a

vascular disease in which the small blood vessels of

the fingers and toes cramp in a paroxysmal manner. The

affected areas are no longer supplied sufficient with

blood and appear extremely pale due to this. Information

on the duration of use cannot be given in this case

because this can be different from person to person. The

following factors can influence this phenomenon:

Blood circulation disorders of the hands of the operator,

low external temperatures, long periods of usage. It is

therefore recommended to wear warm working gloves

and have regular work breaks.

Dispose the equipment, accessories and packaging as

well as used oil and petrol at the points provided for this

and bring it away to an environmental-friendly recycling.

This little effort will be beneficial to our environment.

The exhaust gases from internal combustion engines are

toxic and can cause suffocation among other things.

The device must be in operation only outdoors.

Fill the fuel tank only outdoors or in well-ventilated

areas.

Petrol and petrol vapours can be easily ignited. Keep the

appliance away from flammable materials and sources

of ignition such as ovens or stoves.

The resulting gases are toxic and are suffocating!

CAUTION Danger of fire!

Petrol and petrol vapours are easily ignitable!

Used oil must be disposed of in accordance with

applicable regulations.

8

Page 9

Do not smoke while refuelling or operating

the device.

Wipe off dry the petrol that possibly spill.

Start the device only at a location remote location from

the area of refuelling.

Make sure that the lid of the tank-container is always

well closed. Look for any leaks.

While the engine is running or in case the machine

is hot, the fuel tank cap should not be opened or fuel

should not be refilled.

Slowly open the filler cap so that petrol vapors can

escape.

Make sure that the handles are dry, clean and free of

gasoline mixture.

Do not use the device without and correctly installed

exhaust guard.

Do not touch the exhaust. Risk of burns.

Use only the fuel recommended in the manual.

Keep gasoline only in containers designated for it in a

safe place.

Caution: Petrol and oil can leak in the case of incorrect

use, improper storage or defect. Take precautions, as to

how you can prevent environmental damage in such a

case. Oil and petrol can for example be vacuumed with

special binders.

In the event of a fire, use the CO2 extinguisher to

smother the flames. Also foam, powder or sand are

suitable for extinguishing small fires. Never extinguish

fires due to petrol and oil with water. Danger of

explosion!

In case of emergency, please contact your fire

department!

While cutting on a slope, please stand always below the

cutting tool.

Always make sure that there are no objects etc. collect

in the cord head, in the protective cover or in the engine.

G

B

Do not use a wire or similar things in the running-spool.

Work only in daylight or good artificial light.

Check before each use of the device and its components

and protective devices for damage or wear and make

the necessary repairs if required. Never disable safety

devices

Do not use the appliance if damage or wear and tear

should come to light.

Keep the tools clean and operative, in order to be able to

work better and safer.

Always hold the device at a sufficient distance from the

body when working.

During work breaks and change of location, always turn

off device, wait for the standstill of the cutting tool and

shut off engine.

Never leave the appliance unattended at the workplace.

Store the device during work breaks in a safe place.

While working with this device, do not get distracted. As

a result of that, you could lose control of the device.

Never use the device in the rain, in a damp or wet

environment and do not store it outdoors.

If the device gets wet, wait until it is completely dry

before you use it again.

Search for foreign objects in the working area before

working with this device and remove them. If you

encounter a foreign object despite this while cutting,

switch off the device and remove it.

In the event of a blockage by foreign objects (stone,

collection of grass), switch off the appliance and remove

it with a blunt object. Never remove debris stuck with

your fingers as this could cause serious injury.

The running device must be implicitly kept away from

your body.

Do not overload the machine and do not do any work for

which the appliance is not intended.

Make sure that the ventilation openings are always free

of dirt.

Keep the device out of the reach of children.

9

Page 10

G

B

Store the appliance in a safe and dry place.

After an impact or other damages, check the machine for

damage.

Pay particular attention while trimming lawn edges,

gravel borders and similar places that stones and soil

could hurl away by the cutting line.

Never cross streets or roads with the device switched

on.

Never cut against hard objects such as stones, etc.

Thus you will prevent personal injury and damage to the

device.

Never use the device without protection device.

Never stop the cutter with your hands. Always wait until

it stops by itself.

Hold the cord head as close as possible to the ground.

Cut only grass that grows on the ground. Grass in wall

cracks or on stones may not be cut.

Always make sure that no objects etc. collect in the cord

head, in the protective cover or in the engine .

Operate the device only with protective device.

Always switch off the device before you turn it off.

Pay attention to risk of injury in the area of the cutting

device, which is used for cutting the thread.

Danger of kick-back! There is always kick-back hazard

if the cutting blade comes into contact with branches or

other objects. The brush cutter becomes uncontrollable

due to this and can pushed with great force in the

direction of the operator.

Do not use the device without and correctly installed

exhaust guard.

Do not touch the exhaust. Risk of burns.

Do not use a wire or similar things in the running-spool.

Never cut against hard objects such as stones, etc.

Thus you will prevent personal injury and damage to the

device.

Never use the device without protection device.

Always use only the original thread. Never use a metal

wire instead of the nylon thread.

The petrol-brush cutter is dependent on the mounted

cutting tool meant for trimming lawn or grass, for cutting

scrub, shrubs, bushes and young trees in the private

area.

The device must not be used for other purposes.

The manufacturer does not assume any liability in case

of Improper use as well as changes to the machine.

Please also note the safety instructions, the instructions

for installation and operation, as well as the other

generally applicable accident prevention regulations.

The appliance and the cutting tools must be regularly

and properly checked and maintained. Damages must be

repaired by a specialist workshop.

Use only accessories specified by the manufacturer.

Let your device repaired only by qualified personnel and

only with original spare parts. This is to ensure that the

safety of the device is maintained.

Make sure that the cutting tool is stopped when the

engine is idling.

Check this regularly and do not use the machine if

you detect a movement in the idle position. Bring the

machine to a specialist workshop for checking and and

repair. The setting of the idle speed should also be done

only in a professional workshop.

ATTENTION: The cutting tool rotates after the engine

has been shut off for a few seconds after that.

Put down the device only after the cutting tool has come

to a standstill and the engine has been shut off.

Replace a damaged cutting tool immediately with a new

one.

Always use only the original thread. Never use a metal

wire instead of the nylon thread.

The appliance and the cutting tools must be regularly

and properly checked and maintained. Damages must be

repaired by a specialist workshop.

10

Page 11

Use only accessories specified by the manufacturer. The

use of accessories, including cutting equipments and

protection equipment, which is not recommended by the

manufacturer can cause very severe injuries and damage

to property.

You can leave your unit are only carried out by qualified

personnel and repair with original spare parts only. This

is to ensure that the safety of the device is maintained.

Kick back - Backlash

When working with metal cutting blades, it can lead to a

backlash of the whole device or to a sudden movement

forward, if solid objects (trees, branches, stones, or the

like) are touched.

This backlash takes place without prior warning and can

lead to loss of control over the device and the device

and endanger the user and bystanders around. There are

special threats in areas which are not very visible and in

dense vegetation.

So you will keep the control in case of a backlash

• Always hold the device with both hands securely

when working .

• Make sure you have a secure position. Keep your

feet comfortably apart and always expect a possible

backlash.

• Do not overestimate your abilities and maintain

Balance at all times while working.

• Before you begin to cut, the cutting blade should have

reached the full working speed.

While cutting brush, stones and debris can be flung up

and cause serious injury. Make sure that the protective

hood is mounted securely.

If rotating parts (cutting blades) are incorrectly attached,

this can lead to serious accidents. Before starting work,

check the cutting blade that it is securely fixed.

Other risks

Even if you operate this power tool as per specifications,

there will still be other risks. The following risks may

occur in connection with the style and design of this

power tool:

G

B

1. Health risks, which result from hand-arm vibrations, in

case the device is used over a longer period of time, is

not properly held or maintained.

2. Personal injury and property damage caused by tool

adapters, which are flung around unexpectedly due

to sudden damage, wear or incorrect fitting from the

device.

3. For an adequate protective equipment during the use,

care has to be taken as per the operating instructions.

All other usages are ruled out. The user / operator is

responsible for injuries resulting damage or injury due

to incorrect use, and not the manufacturer. Only 3-teeth

blades suitable for the machine as mentioned in the

operating manual may be used.

The frequent use of vibrating devices can cause

nerve damage for persons whose blood circulation is

compromised (for example, smokers, diabetic patients).

If you notice unusual impairments, discontinue work

immediately and seek medical attention. Observe the

following precautions to reduce the risks:

1. Keep your body, in particular your hands warm

especially in cool weather.

2. Take regular breaks and move your hands while doing

so, to promote blood circulation

3. Take up different working positions regularly, to avoid

a one-sided stress to the body and to prevent damage to

health.

Ensure that there is lowest possible vibration of the

device by regular maintenance and solid parts at the

tool.

Do not smoke while refuelling or operating the device.

Wipe off any fuel spilled immediately

Check the device for possible leaks. Do not use the

device if you find any such thing.

While the engine is running or in case of a hot engine,

the fuel tank cap may not be opened and the fuel may

not be refilled.

Do not touch the exhaust. Risk of burns.

Use only the fuel recommended in the manual.

Keep gasoline only in containers designated for it in a

11

Page 12

G

B

safe place.

Turn off the device always before you put it down.

Work only in daylight or good artificial light.

Before each use,carry out a visual inspection of the

device.

Check if all screws and connecting parts are tightened.

Always hold the device with both hands tightly.

Check before each use of the device and its components

and protective devices for damage or wear and make the

necessary repairs if required. Never deactivate safety

equipment. Do not use the appliance if damage or wear

and tear come to light.

Keep the tools clean and operative, in order to be able to

work better and safer.

Always hold the device at a sufficient distance from the

body when working.

Switch off the device during work breaks and change of

location always completely, wait for the standstill of the

chain saw and put on the chain guard.

Never leave the appliance unattended at the workplace.

Store the device during work breaks in a safe place.

Do not get distracted while operating the device.

Otherwise, you could lose control of the device.

Never use the device in the rain, in a damp or wet

environment and do not store it outdoors.

Do not use the chain saw in the vicinity of flammable

liquids or gases and wet or humid environment. If this is

not observed, there is danger of fire or explosion.

Work only under appropriate light conditions.

You are responsible for the safety in your work area.

Caution! Some tools/cutting equipments show sharp

edges and tips. Please be especially careful while

dealing with them and wear protective gloves to protect

yourself against injury!

Make sure you have a secure position and wear slipresistant, high closed shoes.

Protect the device against rain and moisture. In case the

engine is running, hold the saw always with both your

hands firmly.

Use the claw as starting point for each cut, always start

to cut with the operating chain saw.

Carry out the cut so that the saw does not get stuck in

the wood.

Pay particular attention to the branches found under

tension.

Pull out the device only with the operating saw chain

from the wood.

Never work with the device above shoulder height or

with one-hand.

Stand always outside the direction of falling. Stand on

slopes above the falling tree. Carry out sawing work on

a tree, which is standing on a slope always sidewise,

never from above or from below.

Always be aware of the direction of the fall of the part

to be cut off.

Never position yourself with the rail tip for cutting and

never cut with the bar tip.

- Danger of backlash! There is always danger of

backlash if the bar tip comes in contact with wood or

other objects. The chain saw becomes uncontrollable

through this and can be pushed with great force in the

direction of the operator.

Always saw through just one branch all at once. Please

pay attention while cutting to length on the adjacent

trunk.

Do not use the device as lever to move objects.

During transport and while storing, always use the chain

guard.

Secure the device during transport to avoid lost of fuel,

damage or injury.

Warning!

Keep passers-by away from the running device, never

work alone however.

Keep yourself within earshot of other person, in case

you need assistance.

Stop the engine immediately, if someone approaches

you.

12

Page 13

Ensure that the saw chain does not come in contact with

foreign objects such as stones, fences, nails, etc... These

objects could be flung away and injure the the user or

passers-by or damage the saw chain.

National regulations can restrict the use of the device.

Do not use the machine in any position from which it can

come within a radius of 10 m to high-voltage power.

For an adequate protective equipment during the use,

care has to be taken as per the operating instructions.

All other usages are ruled out. The user / operator is

responsible for injuries resulting damage or injury due

to incorrect use and not the manufacturer. Only 3-teeth

blades suitable for the machine as mentioned in the

operating manual may be used.

Pull out the spark plug connector before any work

is carried out on the device itself (e.g. transport,

construction, conversion, cleaning and maintenance

work) !!!!

3.1 Usage according to the intended purpose

Brush Cutter, Grass trimmer

The Petrol-brush cutter is dependent on the mounted

cutting tool intended for trimming lawn or grass, for

cutting scrub, shrubs, bushes and young trees in the

private area.

The device must not be used for other purposes.

The manufacturer does not assume any liability in case

of improper use as well as changes to the machine.

Please also take note of the safety instructions, the

installation and operating instructions as well as

the other generally applicable accident prevention

regulations.

High Button

The Petrol-pruner is built as per the state of the art and

the recognized technical safety regulations. However,

in the event of improper use or usage not according the

intended purpose there may be a hazard to life and limb

of the user or third parties or damage to the device itself

and/or other material assets.

The Petrol-pruner is a portable, hand-held device, which

is fitted with a cutting equipment, which is fixed to a

shaft. This pruner is designed only for cutting trees and/

or other wood from the ground. The cutting equipment

used is a saw chain with guide rail.

This appliance is only designed for private use or for

use in the home and must not be used in continuous

operation for commercial purposes. Any other use is the

responsibility of the the user.

The observance of the operating and installation manual

as well as the adherence of the maintenance conditions

are part of the usage as per intended use.

4. Technical data

Motor:

Motor type: 2-stroke engine, air-cooled;

chrome cylinder engine

Power (max): 0.75 kW

Displacement: 26 cm

Max. engine speed: 12500 min

Volume (fuel tank): 400 cm3 (0.4 l)

Start system: Rewind starter

Speed range in idle speed: 3000 min

Speed at coupling: 4430 min-1

Carburettor: Ruixing H142A-30H-00-00

Huayi MC1359BE

Spark plug: TORCH L8RTC

CHAMPION RCJ6Y

Mixing ratio: 40:1

Pruner

Length of cut: 10"

Chain spacing: 3/8"

Chain thickness: 0.050"

Chain type: 91PJ040X, pitch:3/8''

Sound pressure level LpA: 80.4 dB(A)

Sound power level LWA: 100.4 dB(A)

Uncertainty K: 3 dB(A)

G

B

3

-1

-1

13

Page 14

G

B

Uncertainty K: 3 dB(A)

Guaranteed sound power level LWA: 114 dB(A)

Vibration 10.220m/s

Uncertainty K: 1.5 m/s

Brush cutter and grass trimmer

Cutting diameter: 230 mm (brush

Cutter blade:

Cutting threads/thread spool: 6m x ø2 mm

The rotation speed of the cutting

accessories at maximum motor

speed:

Sound pressurel(Brush cutter) L

Sound pressurel(Brush cutter) L

Uncertainty K: 3 dB(A)

Sound pressurel(Grass trimmer) L

Sound pressurel(Grass trimmer) L

Uncertainty K: 3 dB(A)

Vibration level (Brush cutter) a

Uncertainty K: 1.5 m/s

Vibration level (Grass trimmer)

Uncertainty K: 1.5 m/s

Pole hedge trimmer:

Sound pressurel(Hedge trimmer)L

Sound pressurel(Hedge trimmer)

L

:

wAav

Uncertainty K: 3 dB(A)

Vibration level (Hedge trimmer) a

Uncertainty K: 1.5 m/s

Blade for hedge shears: Blade spacing:

Angle range

The angle of the hedge shears can be at 80° set up to

-90° with regard to the shaft tube.

: 94.8 dB(A)

pAav

: 110.8 dB(A)

wAav

: 93.5 dB(A)

pAav

: 107.8 dB(A)

wAav

: 10.220 m/s

hv,eq

: 8.712 m/s

ahv,eq

: 80.4 dB(A)

pAav

hv,eq:

Max. cutting length

cutter );

430 mm (grass

trimmer)

230x1.6-4T

8500 min-1(brush

cutter);

8500 min-1 (grass

trimmer)

100.4 dB(A)

10.220 m/s

24mm;

365 mm.

Take measures to protect against the stress of vibration.

Take into account of the whole workflow, also points

2

in time at which the tool functions without load or is

2

switched off.

Among other things, appropriate measures include a

regular maintenance and care of the device and the

insertion tools, keeping the hands warm, regular breaks

and a good planning of the work processes.

2

2

2

2

2

2

Note: The vibration value stated is ascertained as per

the standardized test procedures and can be used to

compare different devices with one another.

Wear hearing protection to prevent hearing impairment.

In addition, this value is suitable to be able to estimate

loads for the user, which happen through vibrations, in

advance.

Warning! Depending on how you use the device, the

actual vibration values can deviate from the specified

values.

14

Page 15

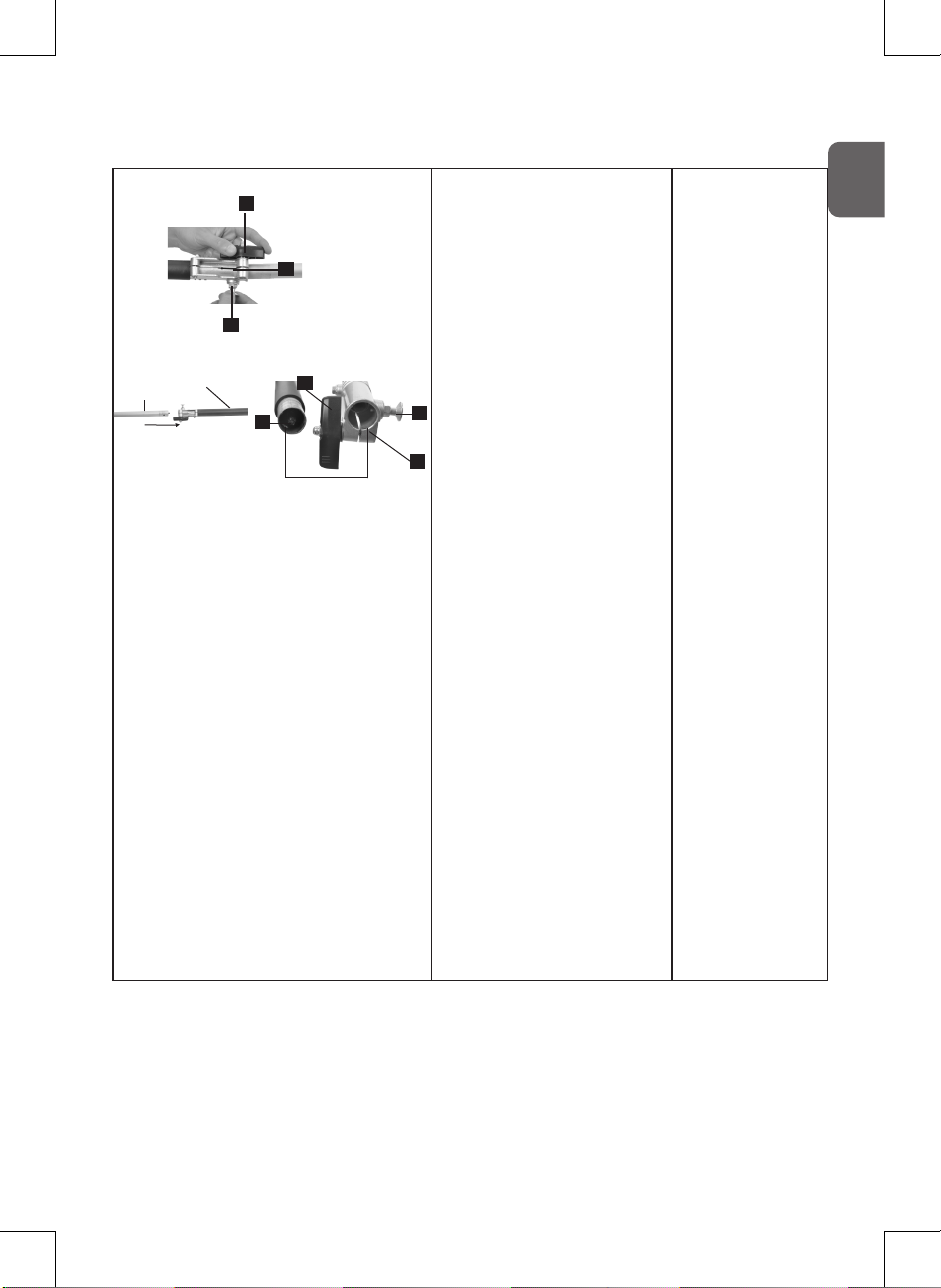

5. Assembly and commissioning

Note:

Before affixing cutting equipment, first remove the transport protection. When replacing thread spool or

the blade, the cutting guard (15) should not be removed.

To reduce the risk of unintentional start-up, pull out the spark plug connector.

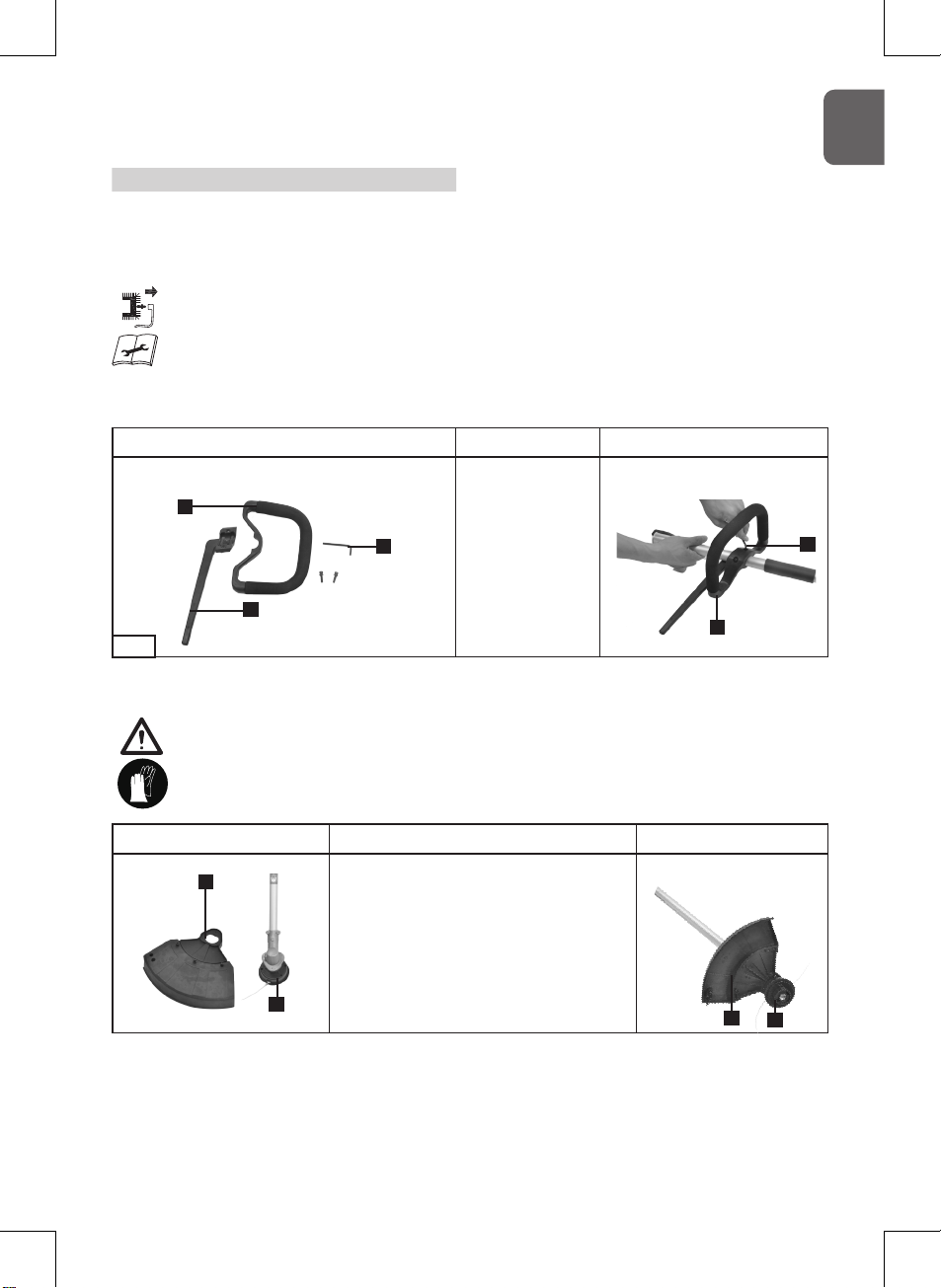

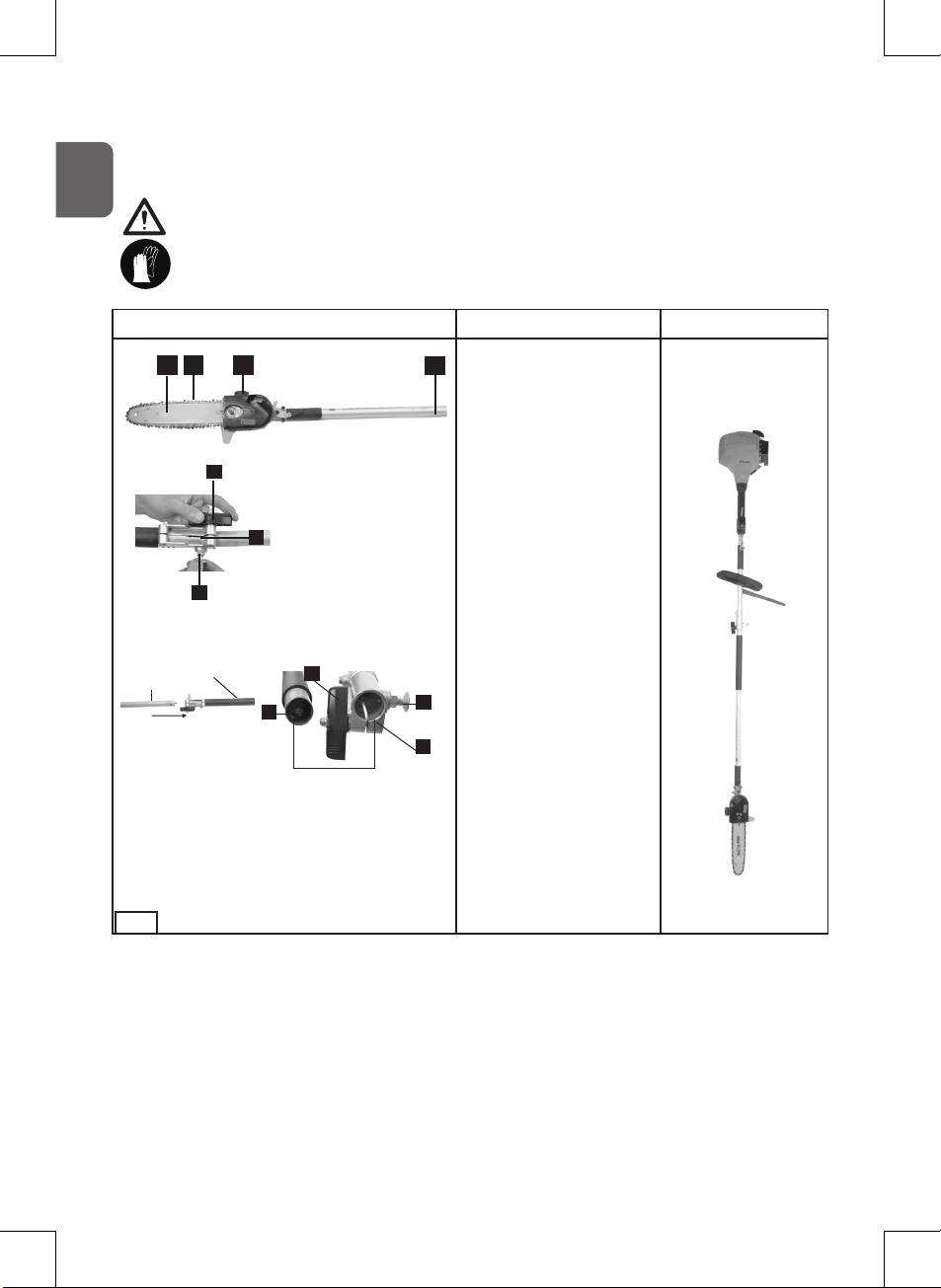

5.1 Brush cutter-grass trimmer-pruner--hedge shear- combination device: Handle

Module 1 Mounting

Secure the handle (1)

1

28

with the 4 mounting

bolts and the nuts of

the protective device

(18) to the drive unit.

G

B

28

18

A6

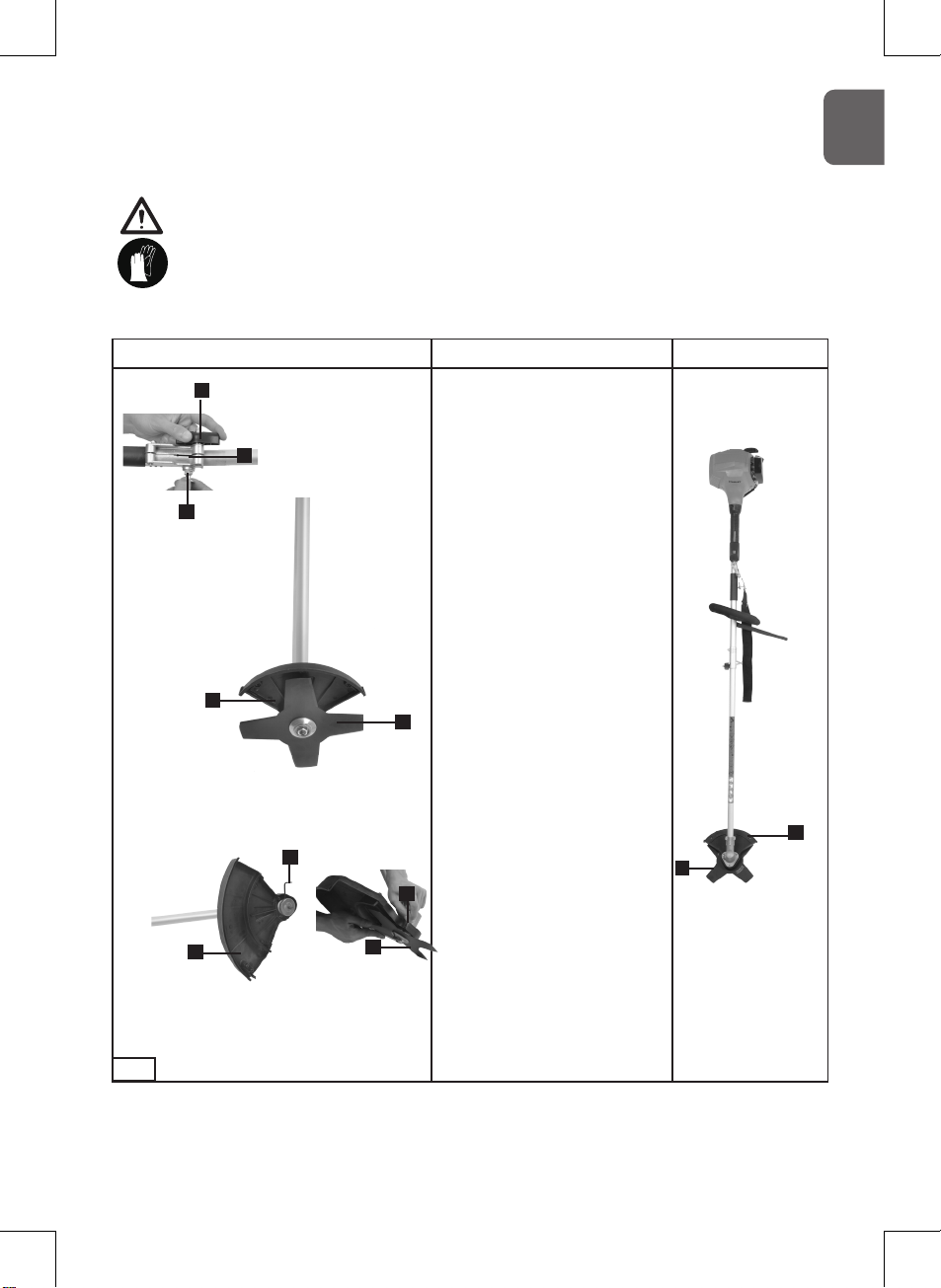

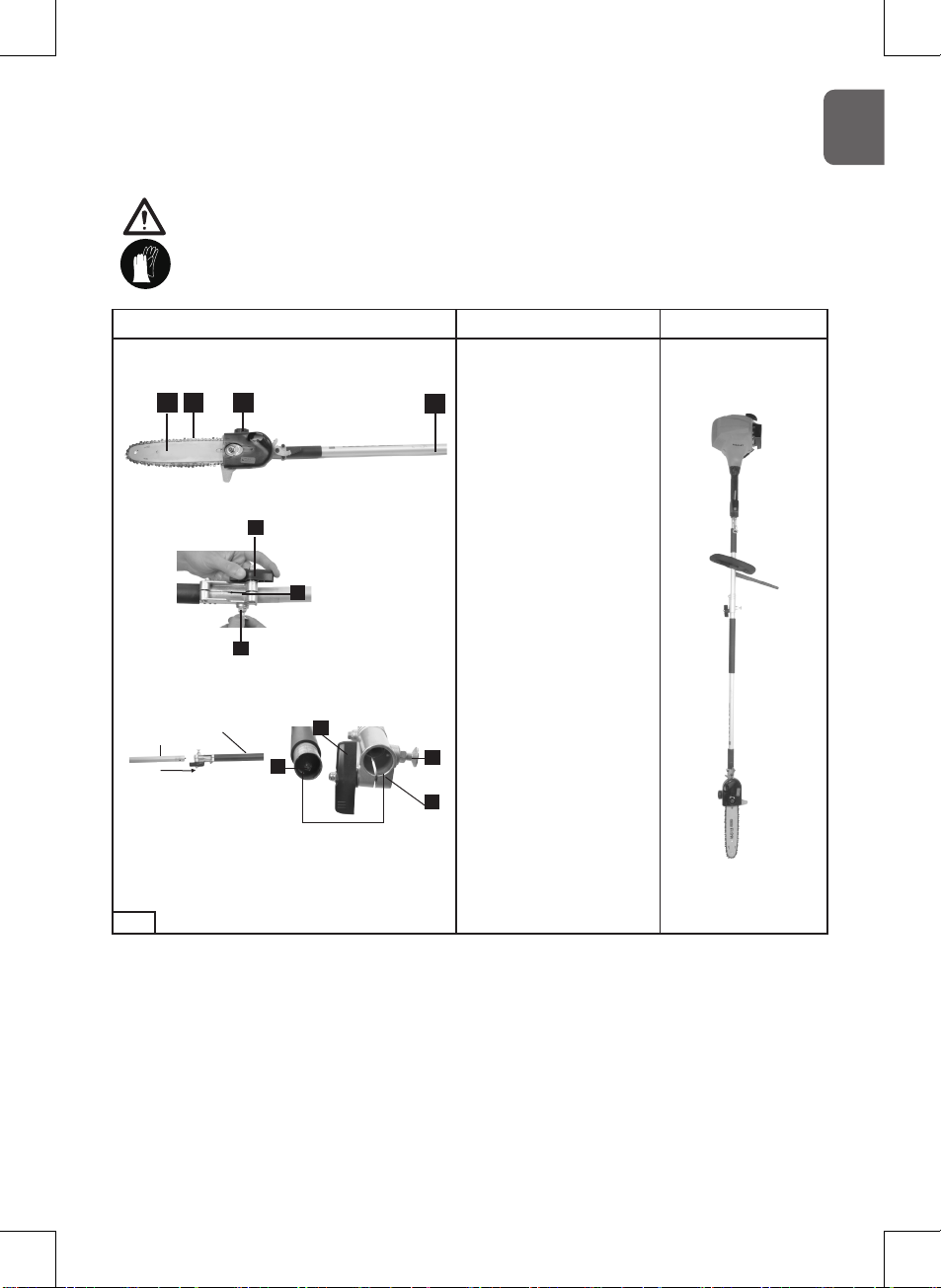

5.2 Brush cutter-grass trimmer-pruner--hedge shear- combination device: Grass trimmer

Risk of injury

ATTENTION: For all work performed on and for cutting tools, always wear protective gloves.

Module 2 Mounting

To use the device as grass trimmer, the cutting

15

19

guard (15) and thread spool (19) are fitted.

1

15

19

15

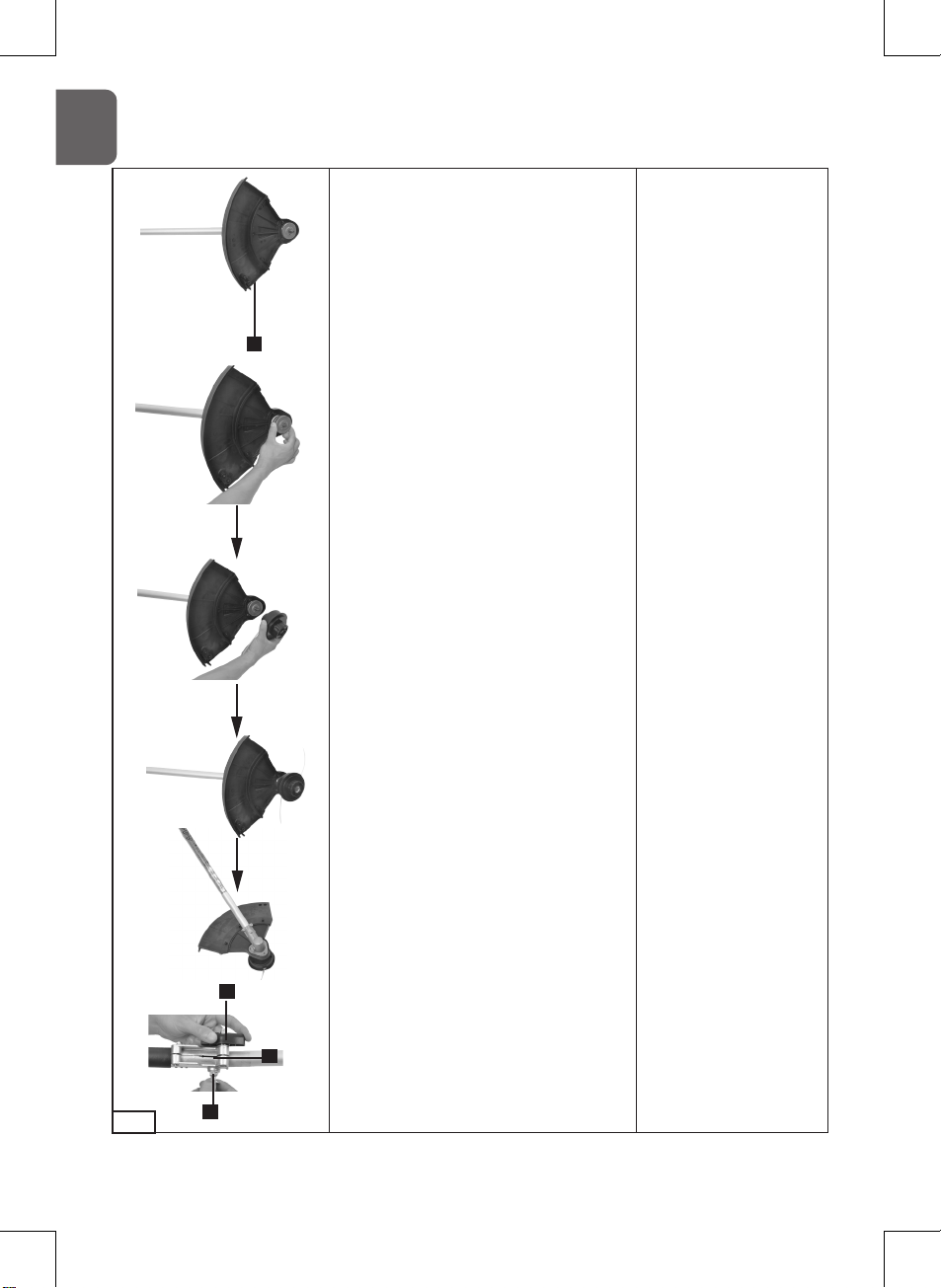

Page 16

G

B

- Attach the cutting guard (15) with the 4 screws

on the retaining device on the shank (if not

already fitted). In addition, the protective cover

must be fitted with the blade at the cutting guard.

- Lock the shaft of the brush cutter at the required

position with a screwdriver or with the Allen key

(28).

- Loose with the spark plug wrench (29) the

15

locknut for the blade (14), by turning in a

clockwise direction (if already installed).

- Remove the hexagon nut (14), the clamping

flange (13) and the retaining plate (16) for the

thicket of knives. Keep these parts sage.

- Leave the support flange (17) on the shaft.

- Lock the shaft of the brush cutter at the required

position with a screwdriver or with the supplied

Hex Key (28).

- Rotate the thread spool (19) against the

clockwise on the shaft.

ATTENTION: Left hand thread

Connect the drive unit and assembly:

Put the ends of the modules to be connected

into one another. While doing so, make sure that

the lock pin (26) is snapped in place. Check by a

pulling apart by way of trial. Fold down the (26a)

cover and secure the modules by tightening the

locking screw (10).

Release of the drive unit and assembly:

Release the locking screw (10). The cover (26a)

jumps back. Hold the locking pin (26)found below

the cover pressed down and and at the same

time release the modules from one another by

carefully pull apart.

10

26a

A7

26

16

Page 17

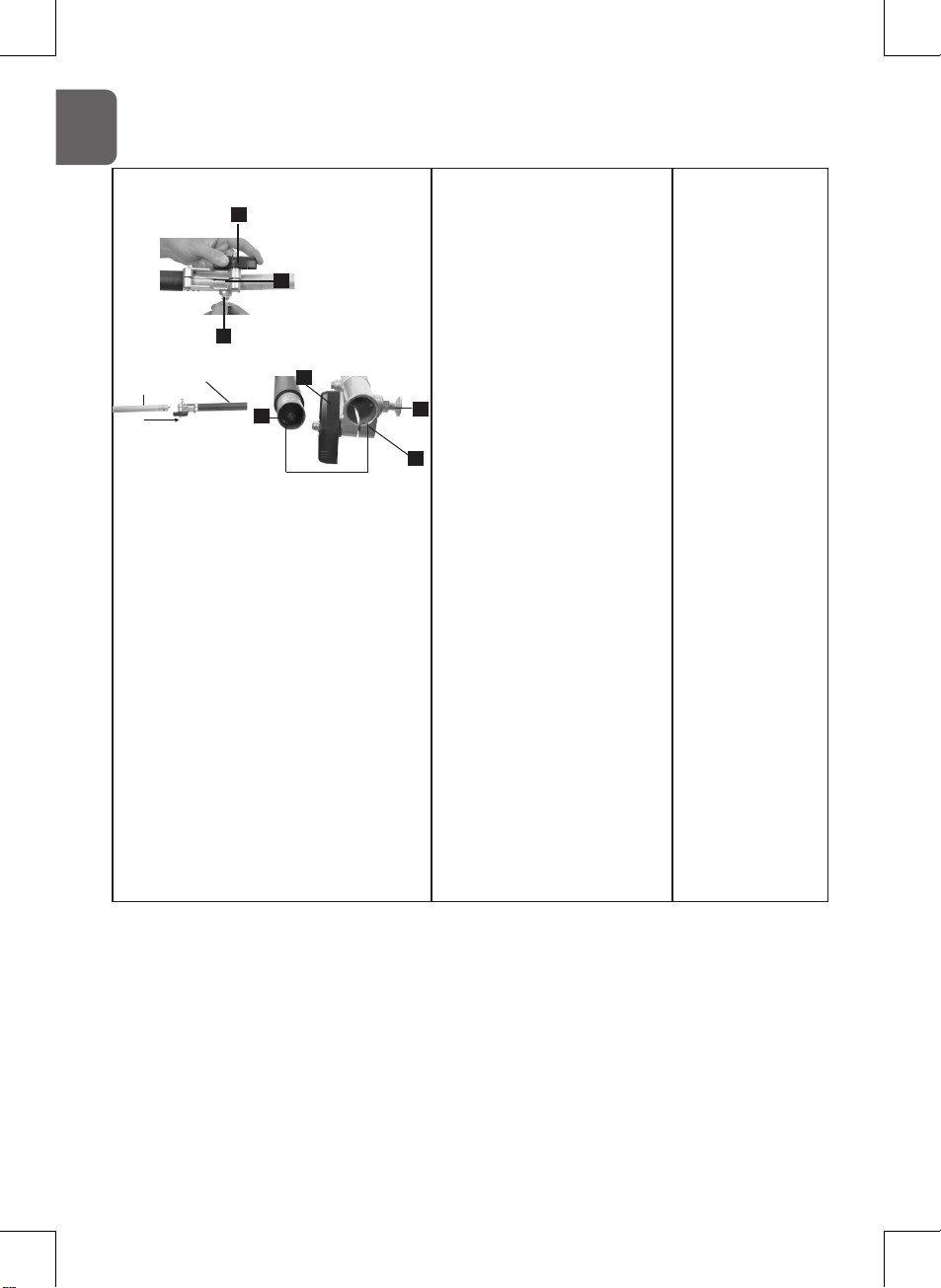

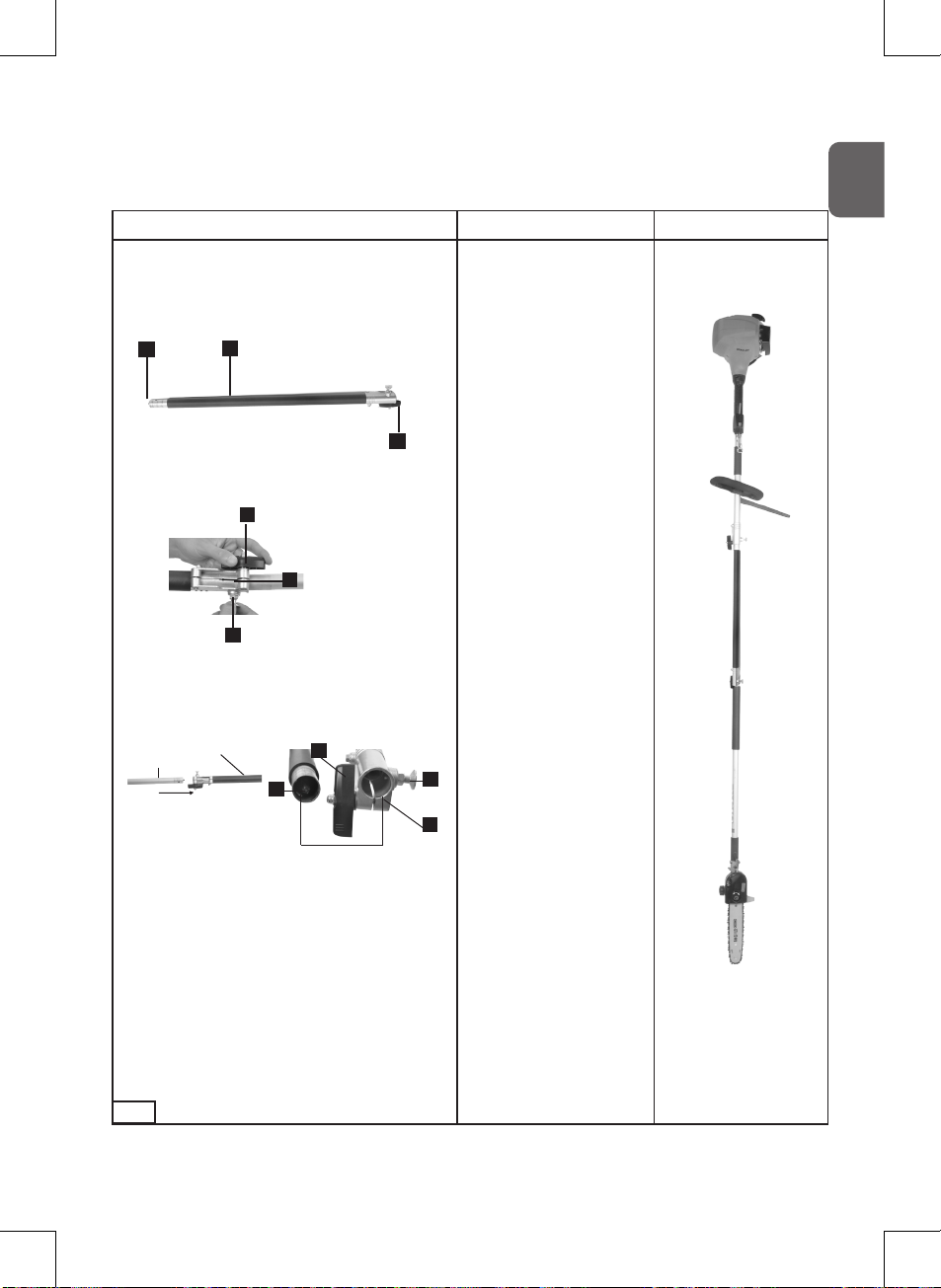

5.3 Brush cutter-grass trimmer-pruner-hedge cutter combination device: Brush cutter

RISK OF INJURY

ATTENTION: For all work performed on and for cutting tools, always wear gloves.

- Danger of backlash! There is always danger of backlash, if the blade tips come into contact

with branches or other objects. The brush cutter becomes uncontrollable due to this and can

pushed with great force in the direction of the operator.

Module 3 Mounting

10

To use the device as brush cutter, the

cutting guard and the cutter blade

have to be mounted. Do not remove

26a

the cutting guard (15), if you replace

thread spool (19), or blade (11)

- Attach the cutting guard (15) with the

26

4 screws to the holding bracket at the

shank (if not already fitted). - Install

blade (11) as shown in Figures 1 to 6.

- Lock the shaft of the brush cutter

in the required position using a

screwdriver or with the hex key (28)

supplied.

- Turn the thread spool (19) in the

clockwise direction from the shaft (if

already installed).

15

- Leave the support flange (17) on the

shaft.

11

- Set the cutter blade (11) on the

support flange (inscription facing the

user).

- Place the clamping flange

(13) and the retaining plate (16) (note

orientation) on the cutter blade (11).

28

29

G

B

15

11

A8

15

11

17

Page 18

G

B

- Lock the shaft of the brush cutter

10

26a

26

Teil C

Teil B

10

a

at the intended location with a

screwdriver or with the hex key (28)

supplied.

- Turn the hex nut counter-clockwise to

the shaft and tighten with spark plug

wrench (29).

ATTENTION: Left hand thread

Connecting the drive unit and

Assembly:

Plug in the ends of the connected

26a

modules together. Make sure that the

locking pin (26) snaps into place. Check

by pulling apart on a trial basis. Fold

26

down cover (26a) and secure assembly

by tightening the locking screw (10).

Release of the drive unit and

Assembly:

Release the locking screw (10).

The cover (26a) jumps back. Hold

the locking pin (26) under the cover

pressed down and at the same time

loosen the modules from one another

simultaneously by carefully pulling

apart.

The blade must be polished only by

suitably qualified and experienced

specialists.

Improperly polished blades increase

the risk of breakage and cracks.

18

Page 19

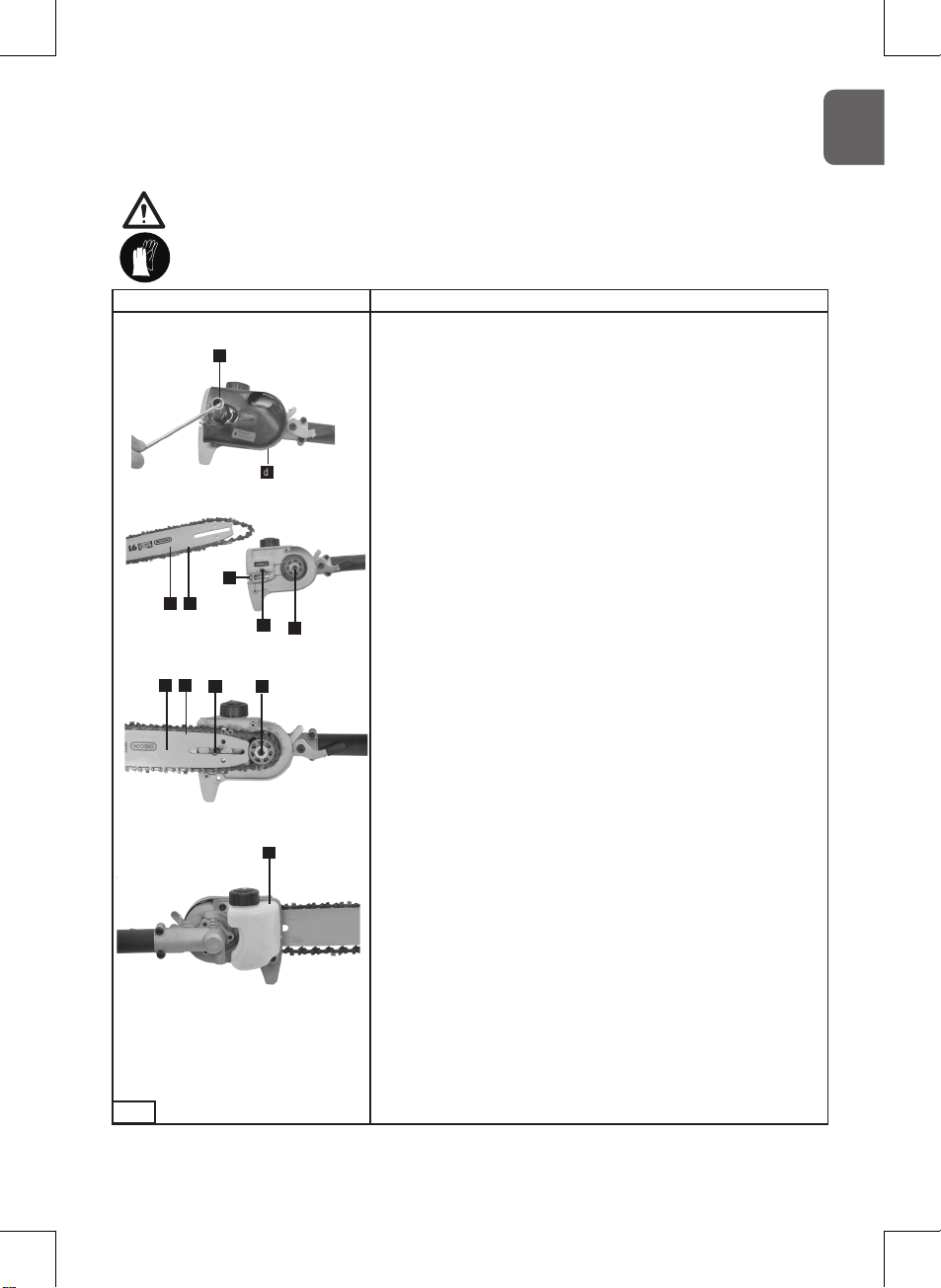

5.4 Brush cutter-grass trimmer-pruner-hedge cutter combination device: Pruner

RISK OF INJURY

ATTENTION: For all work performed on and for cutting tools, always wear gloves

Module 4 Mounting

Before you begin with the tree care, it is necessary to mount the saw

29

chain and the blade to the device. The chain (22) has very sharp edges.

When raising the chain (22) use safety gloves without fail.

1. First remove the chain guard from the blade unit.

2. Then rotate the locking screw on the cutting head (d) with the wrench (29)

counter-clockwise and remove the upper housing cover.

3. Set the saw chain into the groove guide of the blade unit (23). Start as

d

far as possible at the blade's top edge.

Pay close attention to the correct direction of the cut. On the blade unit

as well as in the inner housing below the chain wheel there is a direction

arrow, which must align with the direction of rotation on the blade.

Place the saw chain around the chain sprocket (e) and set the blade unit

on the bolt of the tension slide (f). Make sure that the bolt intervenes in

g

22

23

f

e

the corresponding opening on the blade.

If necessary, turn the screw on the tensioner (g). So that a uniform wear

of the chain blade is ensured, the the chain blade (23) should be rotated

after 8 - 10 working hours.

Make sure that there is always a correct tension of the chain and check

23 22

f e

them before each use of the device. A loose chain could get loosened

from the guide groove of the blade unit and cause serious injury. Further a

loose chain also increases the danger of a backlash. In addition, the blade

, chain and chain sprocket get worn out faster

G

B

A9

21

19

Page 20

G

B

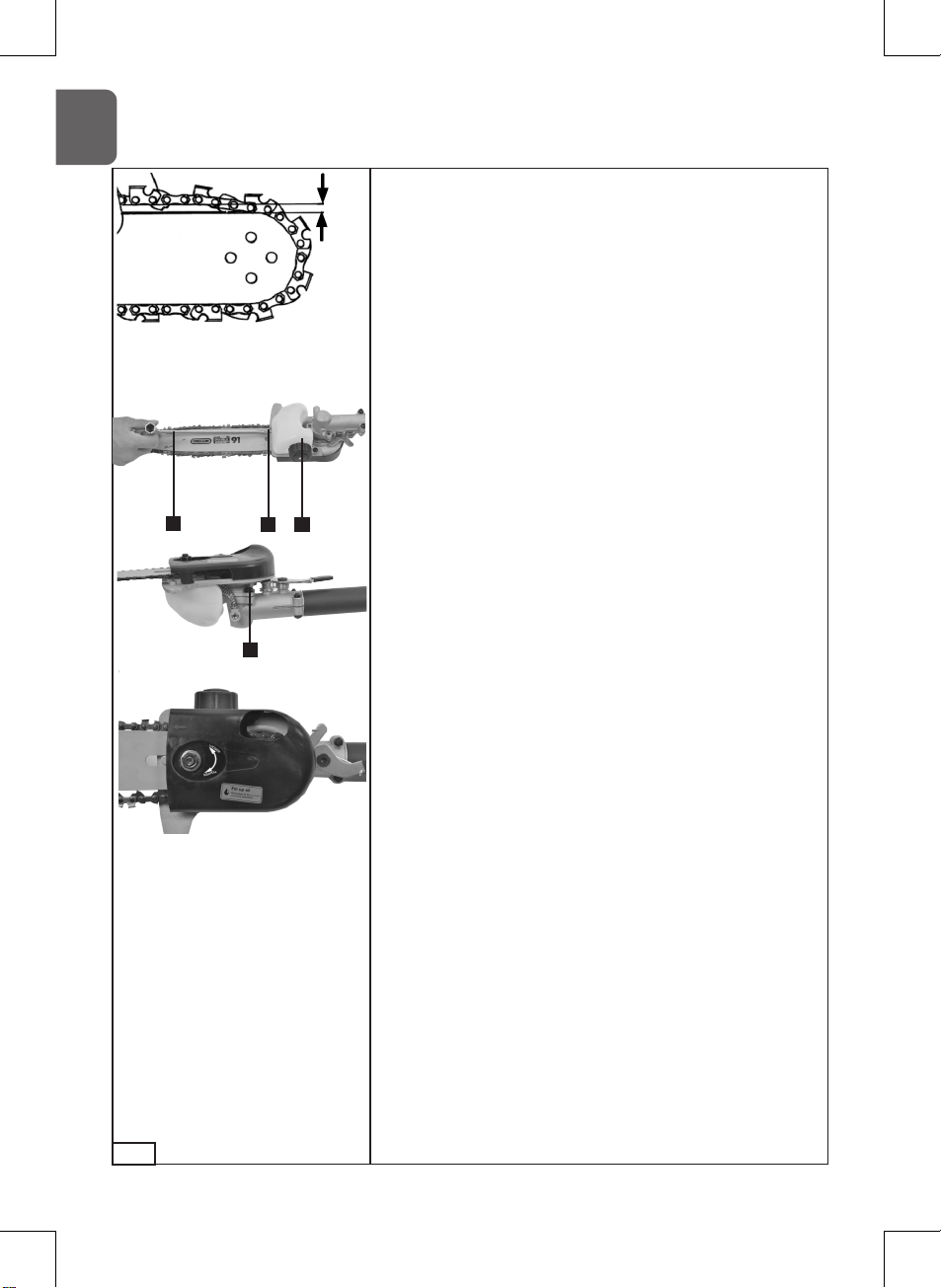

Adjustment of the chain stretching

1. First turn the locking screw at the sprocket cover slightly.

2. Below the chain blade, the screw of the tensioner (g) is located on the front side of the

2-3 mm

head of the device. Turn this with the help of the spark plug wrench (29) supplied along

with, in the corresponding direction, to increase and/ or loosen the tension of the chain.

Turn in clockwise direction: Chain tension is increased.

Rotate counter-clockwise: Tension of the chain is loosened.

A correct chain tension can be recognized through the saw chain resting at every point of

the blade unit uniformly and does not sag or is not too strongly tensed.

3. If the chain tension is correctly set, tighten the locking knob of the chain

sprocket cover again. New chains stretch out. Check the new chain after a few minutes

of the operation. Let the chain to cool down and then, if necessary, set the chain tension

again.

Fill the oil:

The prerequisite for a proper function and a long product life cycle is a regular lubrication.

You should therefore check the oil tank in this device before each start-up and fill oil as

required. Proceed as follows:

1. Open the cap of the oil reservoir

(21). Remove oil residues and other impurities by wiping the tank cap and the oil filler neck

with a cloth.

2. Fill in environmentally-friendly and biodegradable chain lubricant oil in the oil reservoir

(21) and plug it back subsequently. To rule out the risk of a fire as much as possible, when

filling, ensure that there are no oil residues are found outside the tank. Always use a

29

g

21

37

funnel to fill the oil.

Never use waste oil for the chain lubrication.

Waste oil does not have the necessary lubrication properties, is harmful to the

environment and causes skin cancer due to prolonged and repeated contact with the skin.

Use only lube oil, which is a sufficient resistance to aging, so that it does not resinify and

forms solid deposits, which could damage the device.

Always adhere to the specified oil intervals. This device must be provided with new oil

after a working time of max. 15 min.

Adjustment of the flow of the oil Warning:

An increase in the oil flow accelerates the oil consumption, leading to more frequent

inspections/refill.

In order to ensure a sufficient lubrication, it may be necessary to check the oil level more

frequently than in the case of filling the fuel tank.

The guide rail and chain are automatically lubricated by a pump that works when the chain

is turning.

The pump is set at the factory, to deliver a mean flow velocity. However, it can be adjusted

in the field. Temporary increase of the oil flow is often desirable when cutting of hard

wood and resinous wood.

Set the pump as described below:

1. Stop the engine and make sure that the stop switch is in the "STOP" position.

2. Set the product on its side with the oil tank on top. You will see the Image A10.

3. Use a screwdriver to turn the adjusting screw of the oil flow in the desired direction

. in a clockwise direction : Reduce lubrication

. Counter clockwise: Increase lubrication:

Warning! The adjusting screw of the oil flow must be pressed slightly when

rotating, otherwise the pump and screw will be damaged.

20

A10

Page 21

5.5 Brush cutter-grass trimmer-pruner-hedge cutter combination device: Pruner

RISK OF INJURY

ATTENTION: For all work performed on and for cutting tools, always wear gloves.

Module 5 Mounting

Remove the transport cover.

G

B

A11

23

21

22

Connection of the drive unit

a

and module:

Insert the ends of the modules

to be connected together into

one another.

Make sure that the locking pin

10

(26) is snapped in place. Check

what has been pulled apart

on a trial basis. Fold down the

26a

cover (26a) and and secure the

modules by tightening the set

screw (10).

26

Release of the drive unit and

module:

Teil C

Teil B

10

a

Release the locking screw (10).

The cover (26a) jumps back.

26

Hold the locking pin (26) found

under the cover pressed and

26a

simultaneously release the

modules from one another by

carefully pulling them apart.

21

Page 22

G

B

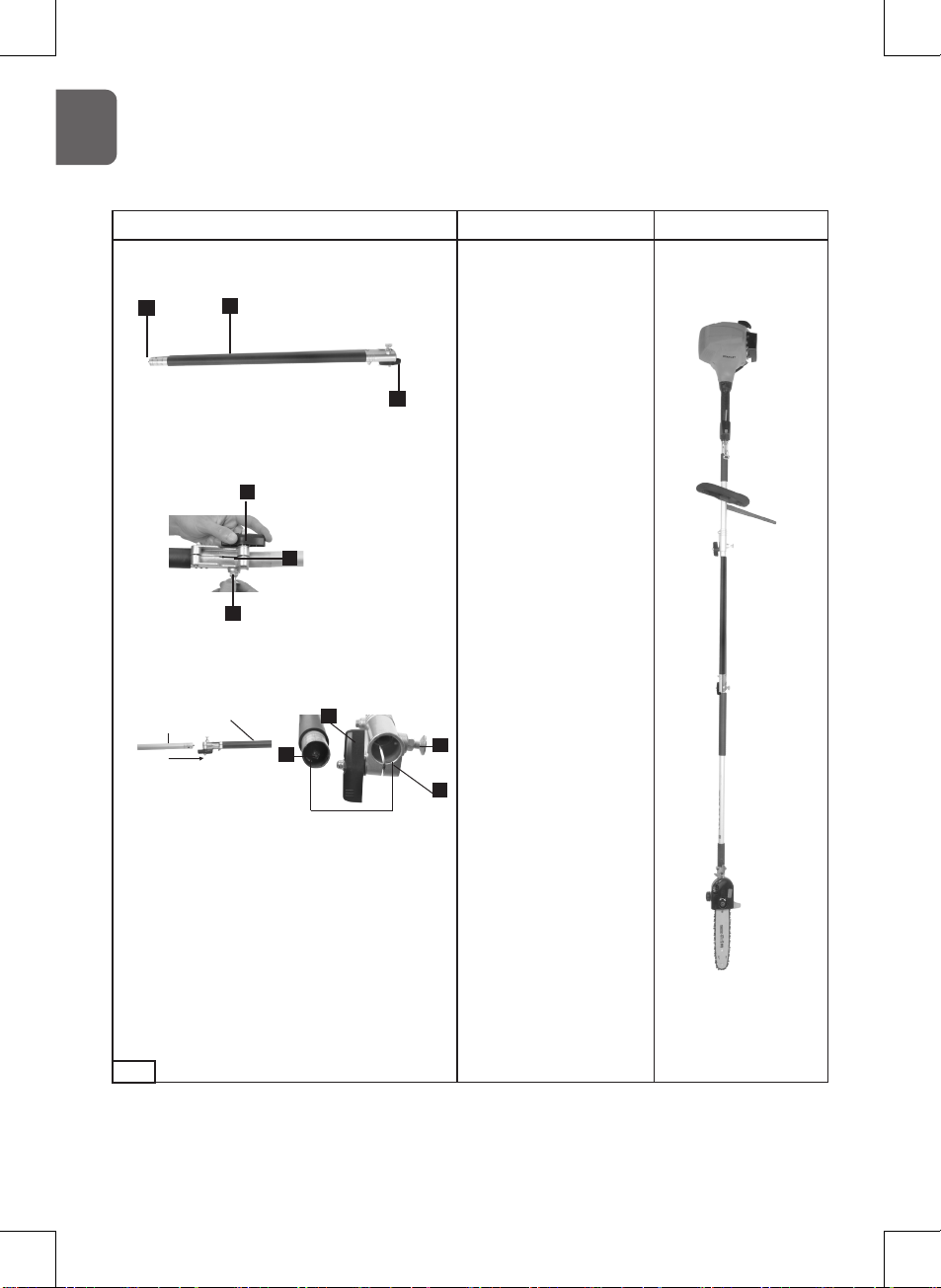

5.6 Brush cutter-grass trimmer-pruner-hedge cutter-combination device: Extension (only for high-button)

Module 6 Mounting

Remove the transport cover.

a

20

Connect the drive unit, the

extension and assembly:

Insert the ends of the modules

to be connected together into

10

one another.

Make sure that the locking pin

(26) is snapped in place. Check

what has been pulled apart

on a trial basis. Fold down

10

the cover (26a) and secure

the modules by tightening

the locking screw (10). Carry

26a

out the process for each of

the drive unit and extension

separately.

26

Release the drive unit, the

extension and assembly:

Release the locking screw (10).

Teil C

Teil B

10

a

The cover (26a) jumps back.

Hold the locking pin (26) found

26

under the cover pressed and

simultaneously release the

modules from one another by

26a

carefully pulling them apart.

Carry out each process for

the drive unit and extension

separately.

A12

22

Page 23

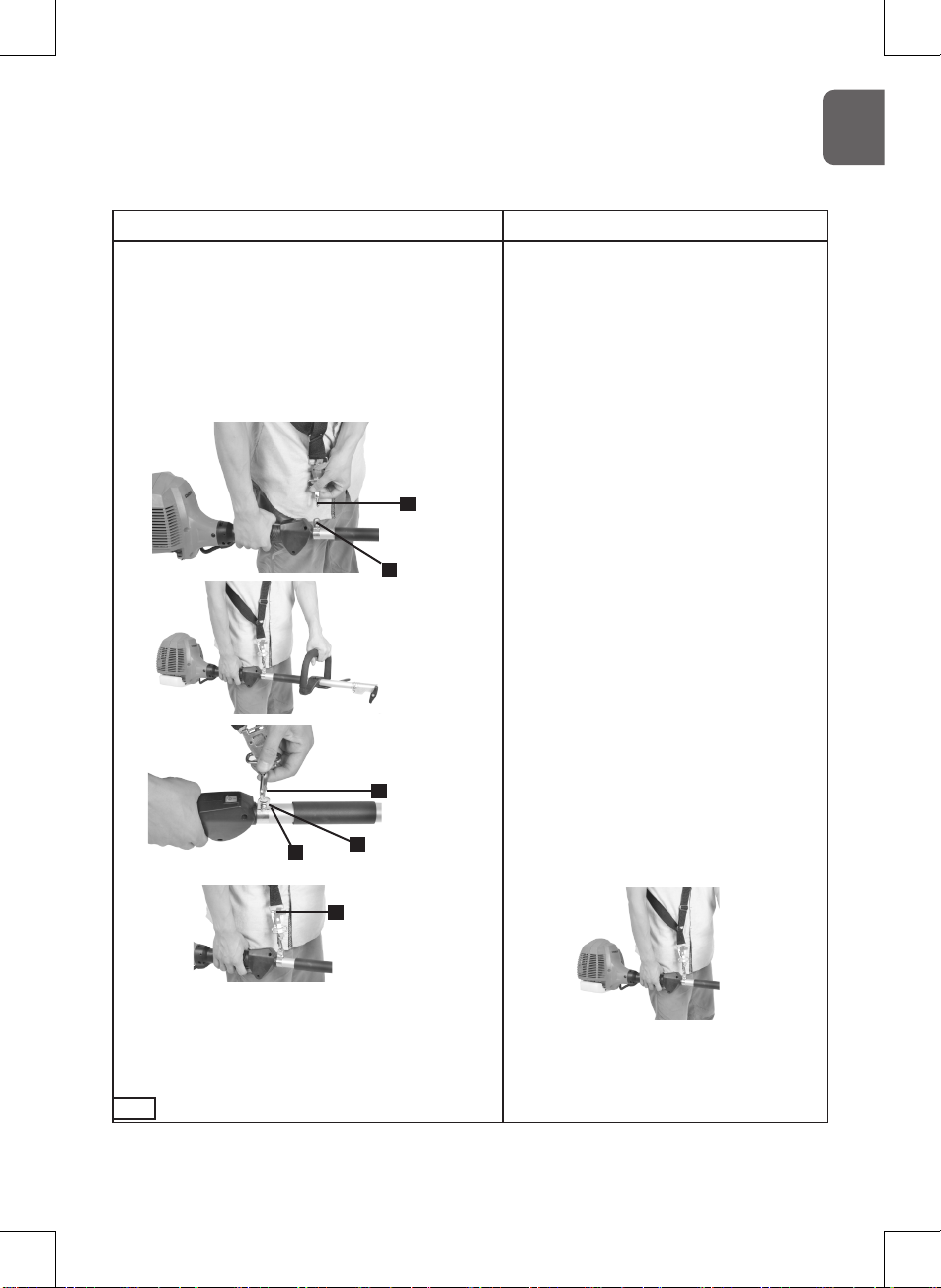

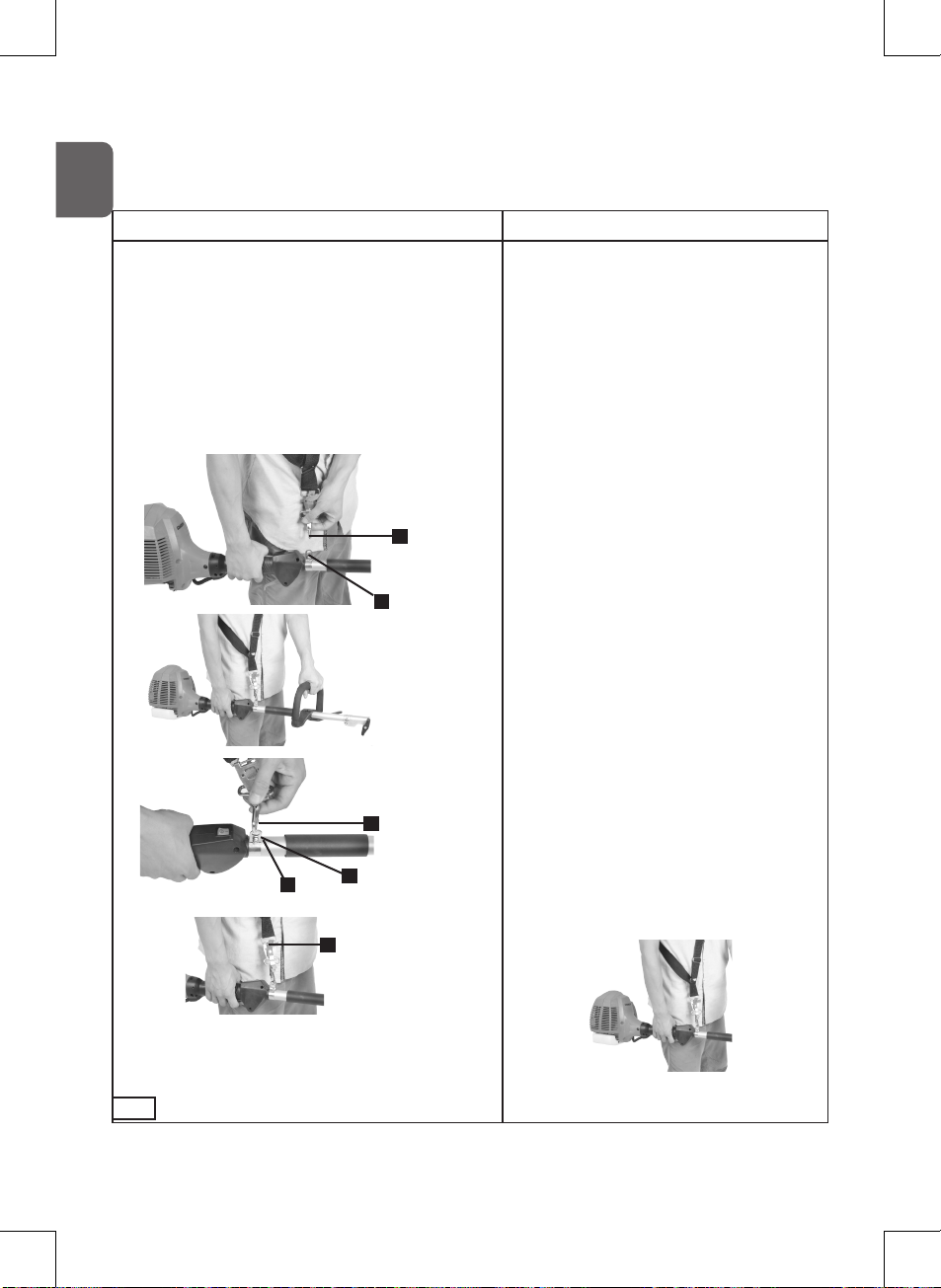

5.7 Mounting Trolley System

Module 7 Mounting

Checks before use:

Distance from the shoulder strap suspension up to

the cutting tool min. 750mm

Distance of the cutter from the floor, while using as

trimmer 0-300mm and while using with cutter blade

100- 300mm. The fuel tank should be filled up to the

half with the two-stroke petrol in the mixture ratio

of 40:1.

Keep a safe distance between yourself and the

cutting tool while working.

The Petrol-brush cutter/trimmer/ pruner unit must be

used with the shoulder strap

9

(9). Balance out the machine first at the switched-off

state.

- Put on the shoulder strap (9).

- Adjust the strap length in such a way that the snap

2

hook (b) is located in about a hand's width below the

right hip.

- Hang up the petrol-brush cutter at the snap hook.

- Let the machine swing.

The cutting tool may just about touch the ground

during normal work posture.

Hang the device with the running engine to the snap

hook (b) of the shoulder strap.

G

B

A13

Secure-fit tab on the shoulder strap

ATTENTION! In the event of an emergency, the

9

secure-fit tab (C) can be pulled out at the shoulder

strap (9). The machine will then be immediately

released from the shoulder strap (9) and falls to the

2

b

c

floor.

23

Page 24

G

B

5.8 Fuel

ATTENTION: Turn the device off, let it

cool down and pull out the spark plug

connector before you fill up with fuel.

Use only a mixture of lead-free normal petrol and special

2-cycle engine oil in the mixture ratio of 40:1.

petrol. Seal the container and mix petrol

and oil by vigorous shaking.

Fill petrol

- Unscrew the lid of the tank (7) slowly so that pressure

and petrol vapours escape safely.

Caution: Do not use a different mixing ratio and not a

pure gasoline. Do not use fuel that is older than 2 to 3

months.

For longer work breaks, drain the tank and refill before

starting work.

Mix petrol

Provide fuel and suitable 2-stroke engine oil in the ratio

of 40:1 in the mixing tank (30), e.g. 10 ml of oil to 400 ml

- Fill the fuel mixture at best with a funnel and screw the

cap back on again tightly.

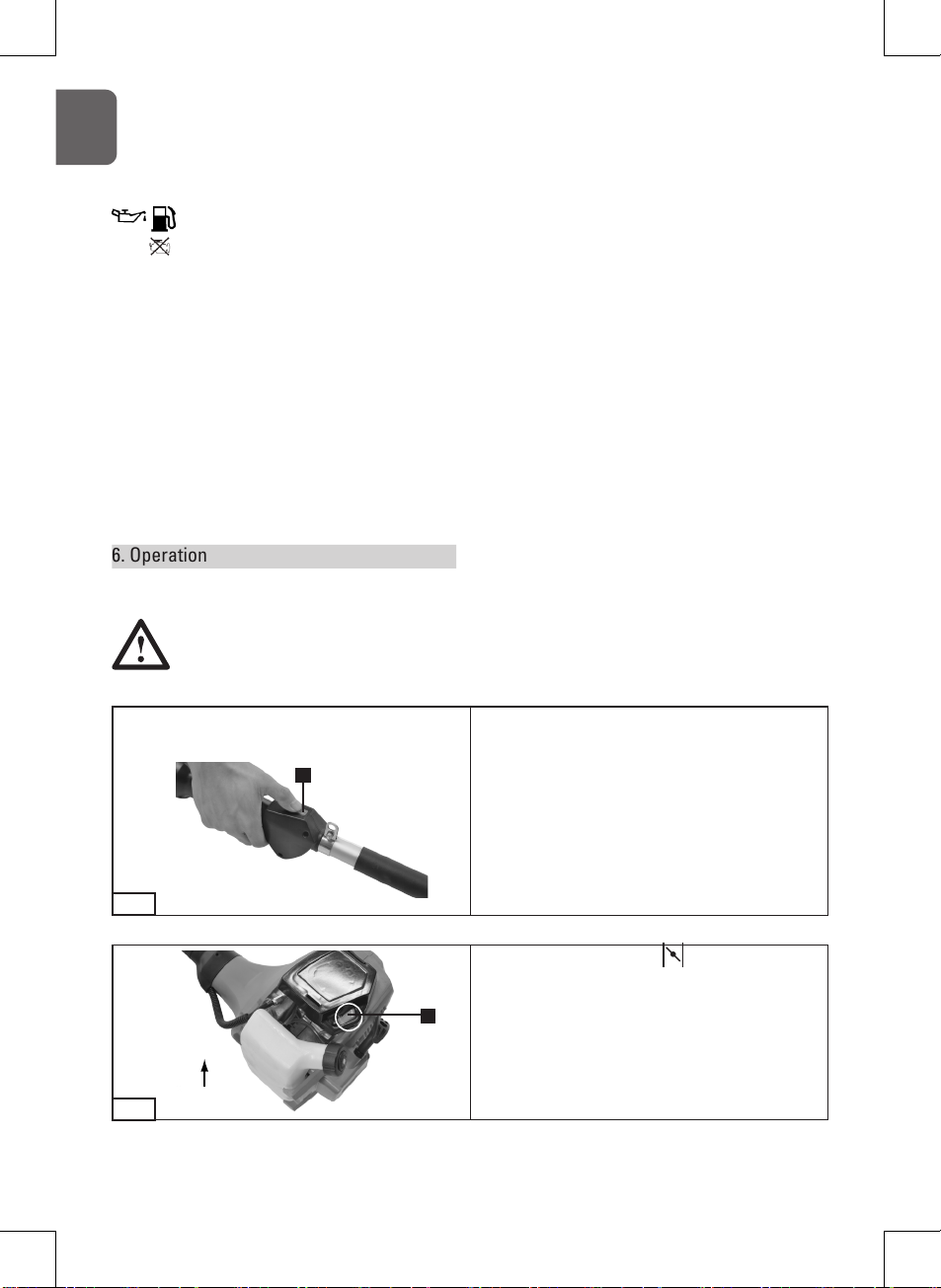

6. Operation

Start the brush cutter-grass trimmer-pruner-hedge cutter combination device only if an

accessory equipment is connected! Test the corresponding transport protection

and inspect the device for a good operating condition. Never use a damaged, poorly adjusted or

badly maintained or not completely and safely mounted device.

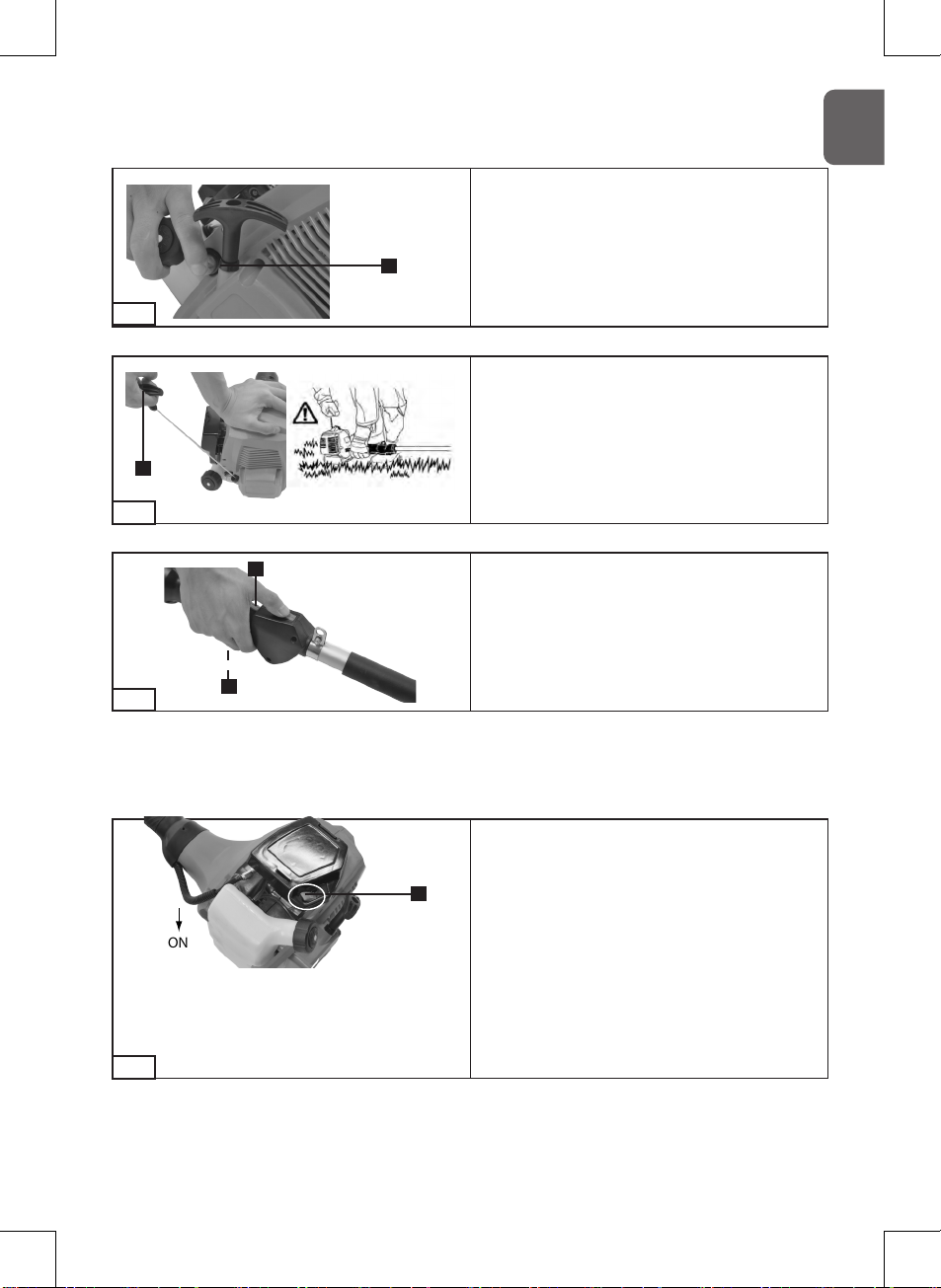

Set the operating switch (3) in On-position "I".

3

A14

Set the choke lever (24) in the " " position.

24

OFF

A15

24

Page 25

A16

A17

G

B

Press the primer (25) 6 times.

25

• Start the machine by controlled pulling on the cable (6).

• While doing so, press the device with the 2nd hand on

the floor.

ATTENTION: Never set foot on the shaft or kneel on it.

6

4

Now press the release mechanism (4) and then the

throttle lever (8) until the device is running smoothly and

has reached the full speed.

A18

8

Start with a warm engine

- Corresponds to the procedure as with cold engine. Choke lever is always in the "ON" position.

As soon as the device is running, the choke lever (24) can

be reset to the "ON" position again.

Switching off:

24

- Start the engine to return without gas to idle speed.

Set the operating switch (3) at the operating handle in the

ON

Off-position "O".

ATTENTION: The cutting device continues to rotate

after switching off the engine for a few seconds.

Hold both handles tight up to complete standstill of

the cutting device.

A19

25

Page 26

G

B

6.2 Stop and switch off

Let go off the throttle lever (8).

- Let the engine to return without gas to the idle speed

and let the device to continue to run for 10 to 15

seconds.

- Set the operating switch (3) on the operating handle to

"STOP".

7. Working with the brush cutter / grass

trimmer

- Familiarize yourself - if the device is switched off - first

with the operation and holding, if you are working with

the Petrol- brush cutter work for the first time.

- The Petrol-brush cutter has to be designed in such a

way that they are held by the operator only on the right

side of the body’s side.

- Hold the petrol-brush cutter tight always with both

hands on the handles.

- Hold the operating handle with your right hand and

with the left hand the handle of the hand bar.

- Always make sure that the cutting tool still continues

to rotate for a short time after the throttle is released.

- Always ensure you have a good engine idle speed, so

that the cutting tool does not rotate any more when the

throttle is pressed.

- Work with high speed, and thus you will have the best

cutting results.

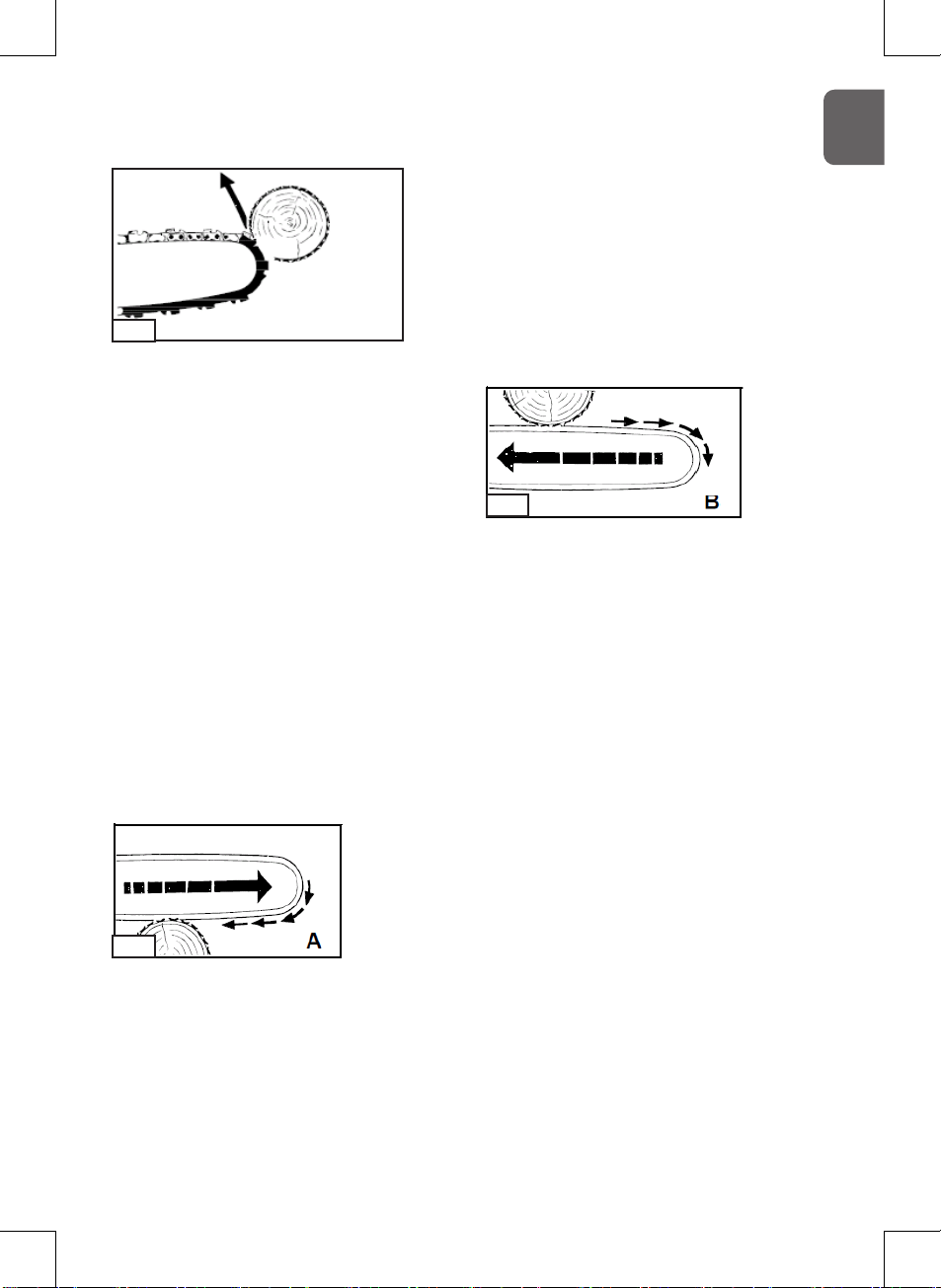

- Hold the device with evenly curved movement from left

to right and back again.

Then cut the next length.

Caution: Direct the device always back only again to the

initial position before you cut the next length.

- If you bump into a stone or a tree while working, switch

off the engine and disconnect the spark plug connectors

and inspect the Petrol-brush cutter for damage.

Caution: When working in difficult terrain and slopes,

please be especially careful. In case of high grass, cut

gradually in order not to overload the device. First cut

the tips, work then gradually.

Always wear safety glasses and a hearing protection

and during deforestation work, a protective helmet.

7.1 Mowing with a thread head

- Use the thread cartridge to maintain a clean cut also of

uneven edges, fence posts and trees.

- Guide the trim line carefully past an obstacle and cut

with the thread tip around the obstacle. In case the trim

line comes in contact with rocks, trees and walls, the

thread becomes frayed prematurely or breaks.

- Never replace the plastic thread never by a metal wire

- Risk of injury!

7.2 Mowing with a cutter blade

- Use the cutter blade to thin out scrub, uncontrolled

growth, young stocks of trees (maximum 2 cm trunk

diameter) and tall grass.

- While using the metal cutting tools, there is always the

danger of a backlash, if the tool comes into contact with

a solid obstacle (rocks, trees, branches etc.).

While doing so, the device is thrown back against the

direction of rotation.

- In case of uncontrolled growth and scrub, let the cutter

blad to "dive" from above. Through this, the material to

be cut is chopped.

ATTENTION: Follow the procedures for this work

technology with caution, because the greater the

distance of the cutting tool to the ground, the greater

the risk that the material to be cut and foreign objects

are thrown to the side.

For an adequate protective equipment during the use,

care has to be taken as per the operating instructions.

All other usages are ruled out. The user / operator is

responsible for injuries resulting damage or injury due to

incorrect use.

and not the manufacturer. Only 4-teeth blades suitable

for the machine as mentioned in the operating manual

may be used.

26

Page 27

- To comb through young stocks of trees and for cutting

grass, hold the device such as a string trimmer close to

the ground.

ATTENTION: Incorrect use and abuse can damage the

cutter blade and cause serious injury through the parts

that are hurled down.

- To reduce the risk of accident due to the cutter blade,

note the following points:

- Never cut shrubs or wood with more than 2 cm in

diameter

- Avoid contact with the metal bodies, stones, etc.

- Check the cutter blade regularly for damage. Never use

damaged cutter blade again.

- If the cutter blade is noticeably dulled, it must

be sharpened by a qualified specialist, as per the

specifications. In case of noticeable imbalance, the

cutter blade must be replaced.

7.3 Trim-line Automatic

The Petrol-brush cutter is delivered with a full spool

holder.

The thread becomes worn out during the work. So that

new thread is supplied, press the shutter release at the

spool holder vigorously on the ground, with the engine

running.

The thread is automatically released by the centrifugal

force. Through the blade at the cutting guard, the trim

thread is shortened on the correct length.

G

B

8. Working with the pruner

A20

A21

A22

8.1 Precaution measures for the sawing procedure

So that the injury or accident risk is reduced as far as

possible, it is important to be sufficiently informed

about the sawing procedures as well as about the

precautionary measures for accident prevention.

Therefore please read the following information carefully

and note the safety instructions in Chapter 2 also during

your entire operation without fail:

A23

max 60

o

27

Page 28

G

B

- Never position yourself directly under the branch,

which you want to saw. There is a very big risk that the

branch falls down unexpectedly on you. In general it is

recommended that the pruning saw is set at an angle of

60° to the branch.

- Hold the device well with both hands tightly during the

cutting process and make sure you always pay attention

to a balanced as well as a good firm position.

- Never try to operate your tool with one hand. Loss of

control over your machine can cause serious or fatal

injuries. Never work on a ladder, a branch of a tree or

other unsafe substrates.

- Do not saw strong branches in one cut, but always in

several steps.

- Put the saw chain for cutting on the branch.

- Put a little pressure for guiding the device but do not

overload the engine.

- Adhere to the cutting technique specified in Chapter

8.2 to avoid injuries and so that you do not damage your

tree in the long term.

Clean the working area before cutting the disruptive

branches and undergrowth. Then you create a retreat

area, far from the area, on which the cut branches could

fall and remove all obstacles. Keep the work area free,

remove the branches that have been cut off immediately.

Pay attention to your position, the wind direction and

the possible falling direction of the branches. Please be

prepared that the fallen branches could hit back. Place

all other tools and equipment in a safe distance from the

branches to be cut, but not in the area of a backlash.

Always observe the condition of the tree.

Look for decay and rot in the roots and branches. If these

are decayed inside, they can break off unexpectedly and

fall down while cutting. Please look out also for broken

and dead branches, which get loosened through shaking

and could fall on you. In case of very thick or heavy

branches, first make a small cut under the branch before

you work from top to bottom, to prevent a breakage.

8.2 Basic cutting technology

the trunk, which damages the tree long term. With

the following technology you can reduce this risk

significantly:

1. Saw the branch first about 10 cm from the trunk, at

the branch’s lower side (see Image A20).

2. Estimate another cut from above at a distance of

about 15 cm to the trunk. Saw it for so long till the

branch breaks. The risk of a breach in a bark at the trunk

is no longer there any more (See Image A21).

3. Finally, remove the remaining snag with a clean cut

along the top of the trunk (See Image A22).

So that the damages to the tree are kept as low as

possible, we recommend seal up the cut surface in

addition with tree wax seal.

8.3 Dangers caused by reactive forces

Reactive forces come during the operation of the saw

chain. In this, the force, which should be used on the

wood is effected on the operator. This happens when

the operating chain comes in contact with a solid object

such as a branch or is jammed. These forces can lead

to a loss of control and injury from it. Understanding

the origin of these forces can help you determine the

moment of shock and to avoid the loss of control.

This saw is designed in such a way that the rebound

effects are not felt as in the case of conventional chain

saws. Nevertheless always keep a firm grip and a good

position, to have control over the tool in case of doubt.

The most common effects are:

• backlash,

• rebound,

• retraction.

Backlash

The backlash can take place if the operating saw chain

at the upper area of the guide rail comes in contact with

a fixed object or if it is jammed.

Heavy branches will slightly break when cutting and

while doing so long branch straps can tear away from

28

Page 29

A23

The cutting force of the chain exerts a rotational force

on the saw in the opposite direction to the movement of

the chain.

This leads to an upward movement of the guide rail.

Avoid backlash

G

B

Avoid backlash

1. Be aware of the forces and situations, which could

lead to the jamming of the chain at the rail's bottom

part.

2. Always start with the chain running at full speed

cutting for cutting.

B = Rebound

The best protection is to avoid situations that lead to

backlashes.

1. Keep your eyes on the position of the upper guide rail

always.

2. Let this area never come in contact with an object.

Do not cut anything with it. Be especially careful in

the vicinity of wire fences and when cutting small,

hard branches, in which the chain can become slightly

jammed.

3. Cut only one branch at a time.

A = Retraction

A24

The retraction takes place if the chain suddenly gets

stuck at the lower side of the rail, since it is jammed

or comes in contact with a foreign body in the wood.

The chain then pulls the saw forward. The retraction

happens often when the chain during contact with the

wood is not running at full speed.

A25

The rebound takes place if the chain gets stuck on the

top side of the rail suddenly, since it is jammed or if it

comes in contact with a foreign body in the wood. The

chain can press the saw jerkily against the operator.

Rebounds happen often when the rail's upper side is

used for cutting.

Avoid rebounds

- Danger of backlash! There is always danger of

backlash, if the blade tips come into contact with

branches or other objects. The brush cutter becomes

uncontrollable due to this and can pushed with great

force in the direction of the operator.

1. Be aware of the forces and situations, which can lead

to jamming of the chain at the rail's top side.

2. Do not cut more than a branch at a time.

3. Do not tilt the rail to the side when you drag it from a

cutting gap, since the chain could be otherwise jammed.

29

Page 30

G

B

9. Cleaning, maintenance , transport and

storage

if you adhere to the specifications of this instructions

manual.

RISK OF INJURY

ATTENTION: For all work performed

on and for cutting tools, always wear

protective gloves.

To reduce the risk of unintentional startup, pull out the spark plug connector.

9.1 Cleaning

Use a damp cloth for cleaning the plastic parts. Do not

use detergents, solvents or sharp objects.

Depending on technical factors, during the course of the

work, wet grass and weeds grow around the drive axle

under the cutting guard.

Remove them, since otherwise the engine will be

overheated due to high friction.

9.2 Maintenance

9.2.1 Regular checks

Please note that the following information refer to a

normal usage. Under certain circumstances (longer daily

work, strong dust pollution, etc.) shorten the specified

intervals accordingly.

Prior to commencing work and after each tank filling:

Check for loose attachments especially at the cutting

equipment and shoulder strap, fuel leakage and

damaged parts such as cracks in the cutting assembly

(visual inspection).

Perform visual inspection also after every time the

device falls down and also for other impacts, to detect

significant defects.

For all damages caused by failure to observe the

instructions given in this operating manual, the user is

responsible.

This also applies for non-authorized changes on the

device, use of non-authorized replacement parts,

attachment parts, work tools, unrelated use and usages

not as per intended purpose, consequential damages

due to use of defective components.

Hold the device as well as all cutting equipment and

protection system always in good operating condition.

Weekly inspection: Gearbox lubrication (also as per

requirement).

If required: Tighten accessible mounting bolts and nuts.

You will avoid excessive wear and damage to the device,

30

Page 31

9.2.2 Spark plug replacement

i

32 i

h

G

B

Check at least once a year or in case of regular bad starts,

the gap between the electrodes in the spark plug (H). The

correct distance between the ignition flag and ignition

contact is 0.63 mm/0.25".

- Wait until the engine is completely cooled.

- Pull out the spark plug cap (I) from the spark plug (H) and

rotate the spark plug with the supplied spark plug wrench

0,63 mm

(32).

- In case of excessive wear of the electrode or if there is

very heavy incrustation, the spark plug must be replaced

with one of the same type.

Heavy incrustation on the spark plug can be caused by:

Too high percentage of oil in the fuel mixture, bad oil

h

quality, very old gasoline mixture or clogged air filter .

- Turn the ignition plug (h) by hand completely into the

thread. Avoid any tilting of the spark plug while doing so.

- Tighten the spark plug (H) using the supplied spark plug

wrench (32).

- When using a torque wrench, the tightening torque is

12-15 Nm.

- Insert the spark plug connectors (I) correctly on the spark

plug.

To avoid the risk of accidental start-up,remove the spark

plug cap.

A26

9.2.3 Wear Parts

Even with proper use, some components are subject to

normal wear.

These must be replaced regularly depending on the type

and duration of use. These parts include the cutting tool

and the retaining plate.

31

Page 32

G

B

9.2.4 Bobbin change

A27

9.2.5 Air Filter Cleaning

- Pull the bobbin cover by vigorously pressing the retaining

tabs of the bobbin (19)

- Move the coil cover in the "Off" position. Remove the

OFF

19

15

ON

19

j

coil with the pieces of thread and the pressure spring.

- Remove the used coil.

- Take the new bobbin and pull out 10 cm of both threads

respectively.

- Now insert the bobbin (19) on the tapered spring and

lead both threads respectively through the eyelets on the

housing of the spool of thread.

- Now place the spool cover on the new bobbin. Turn it so

that the recesses of the spool cover match with the loops

in the thread spool housing.

- Now press the coil cover together with the thread spool

until it snaps into place in the thread housing. Then bring

the coil cover in the "On" position. Through the blade in

the cutting guard (15), the trim thread is shortened to the

correct length, if the machine starts up again.

After prolonged operation you should clean the air filter (5).

Dust and pollen clog the pores of the foam filter.

- Remove the cover (J) and wash the filter (K), in slightly

soapy water. Caution: Do not use gasoline or solvents.

- Dry the filter before you put it back. In order not to

shorten the life of the engine, a damaged air filter must

be replaced immediately.

k

A28

32

Page 33

9.2.6 Maintenance of the guide rail

G

B

The saw chain cannot be fixed on the guide rail. It is

therefore best to take the chain from the rail and then to

sharpen it.

• Select a suitable sharpening tool for the chain pitch.

See "Technical Specifications" for the approved chain

pitches.

A29

• Rotate the rail every time around, if you have

sharpened or replaced the chain. This avoids a onesided wear of the rail, particularly at the top and bottom.

Clean regularly.

1 = the opening for the oil supply 2 = the oil passage

3 = the groove of the rail regularly

9.2.7 Maintenance and sharpening of the saw chain

The right sharpened chain

A properly sharpened chain goes effortlessly through the

wood and requires very little pressure. Do not work with

a dull or damaged saw chain. It increases physical effort,

increases the the vibration and leads to unsatisfactory

results and higher wear.

• Clean the chain.

• Check for breaks in the parts and for damaged rivets.

• Replace damaged or worn chain parts with matching

spare parts, which you may file in the form and size of

the original parts, if necessary.

• The sharpening of a chain should be carried out only

by experienced users!

Note the specified angles and measurements below. If

the saw chain is not correctly sharpened or the depth

dimension is too small, there is a higher risk of backlash

effects and injuries resulting out of this!

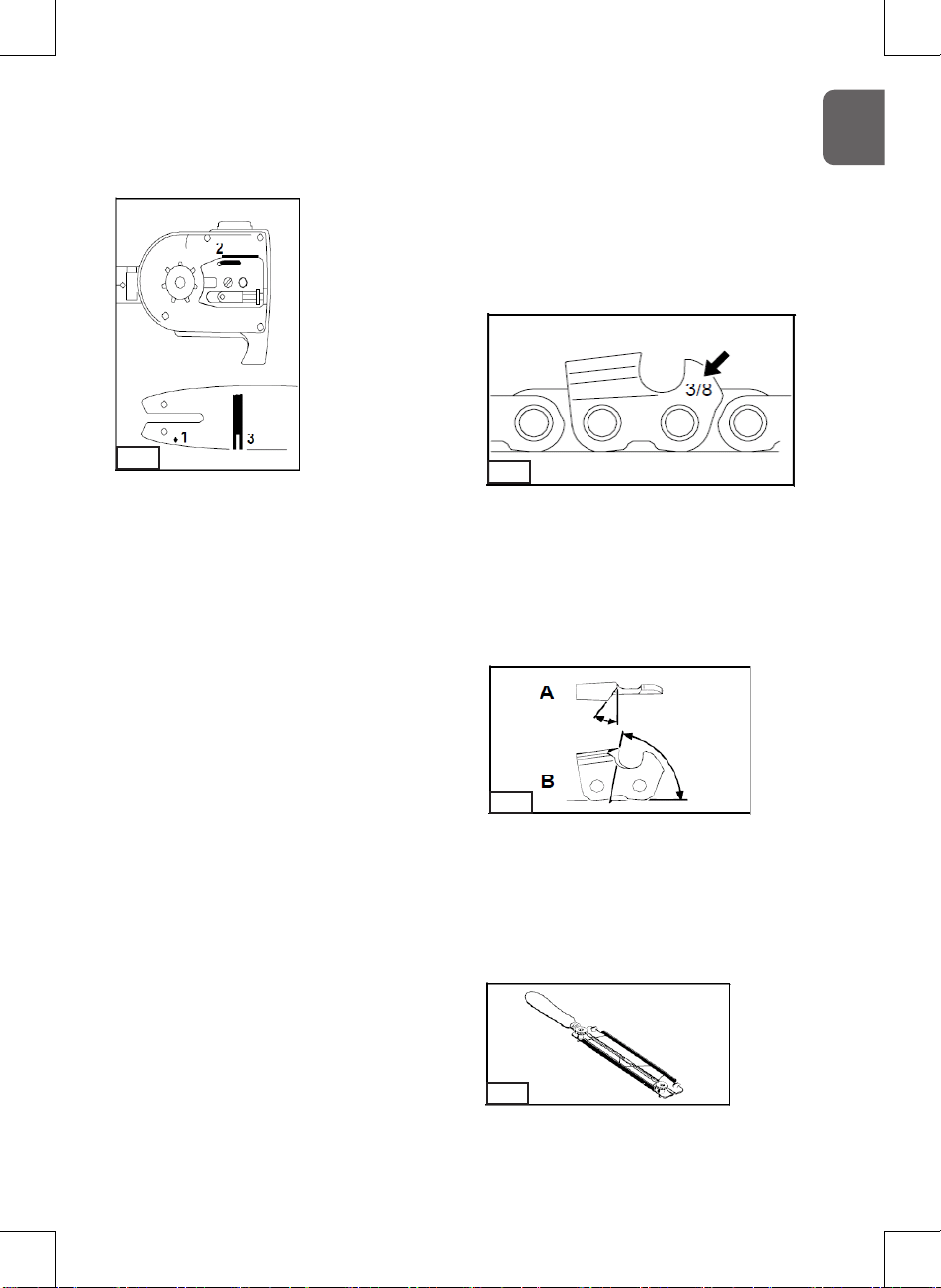

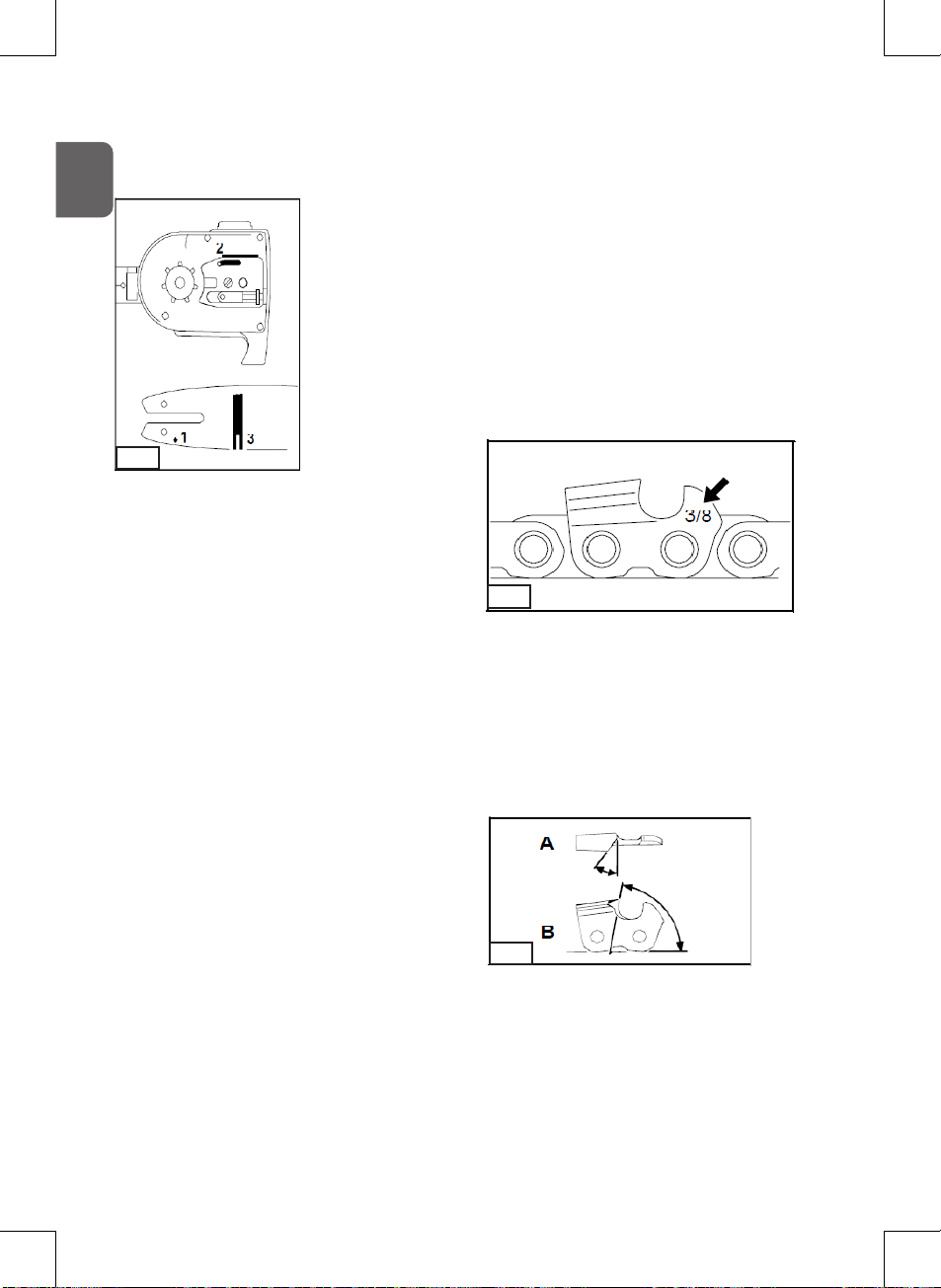

A30

The chain pitch (for example, 3/8 ") is highlighted in the

depth gauge of each blade.

Use only special files for saw chains! Other files have

the wrong form and the wrong sharpening.

Select the diameter of the file according to your chain

pitch. Please also pay attention to the following angle

when sharpening the chain blade.

A31

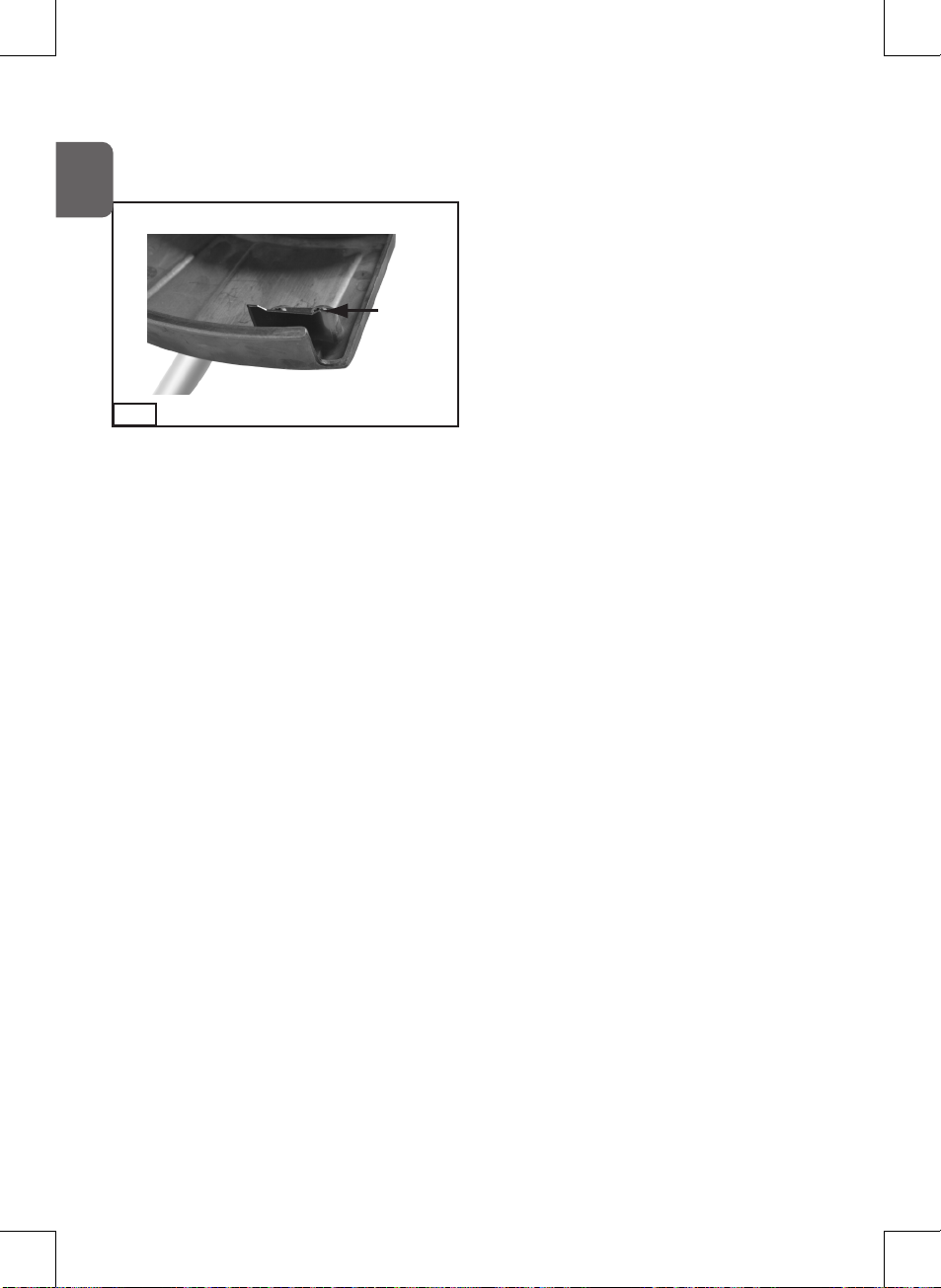

A = filing angle

B = angle of the side plate

The angle must also be maintained for all blades.

In uneven angles, the chain will run irregularly, wear out

quickly and break prematurely.

A32

33

Page 34

G

B

Since these requirements can be fulfilled only with

sufficient and regular training:

• Use a file holder

A file holder must be used while sharpening the saw

chain by hand. The correct filing angle marked thereon.

9.2.8 Gear Lubrication

A33

A34

• Hold the file horizontally (at right angles to the guide

rail) and file according to the angle mark on the file

holder. Support the file holder on the top plate and the

depth gauge.

• File the blade always from the inside to the outside.

• The file sharpens only in forward motion. Lift it up

during the reverse motion.

• Touch the retaining straps and the dynamic parts not

with the file.

• Turn the file regularly to avoid a one-sided wear.

• Take a piece of hard wood to remove ridges from the

cutting edges.

All blades must have the same length, otherwise they

will be of uneven height. Thus, the chain does not run

smoothly and it increases the risk of getting broken.

A35

Check the grease level about every 25 operating hours.

- Rotate the locking screw with a suitable screwdriver.

- If no grease can be seen any more on the screw,

fill approx. 5 g of grease (DIY market) in the gearbox

housing and seal the opening again.

Make sure that the gearbox housing is never completely

filled with grease.

9.2.9 Carburetor Setting

Ex factory the carburetor has been set for optimum

performance. If an improved setting is necessary, please

contact a specialist workshop.

34

Page 35

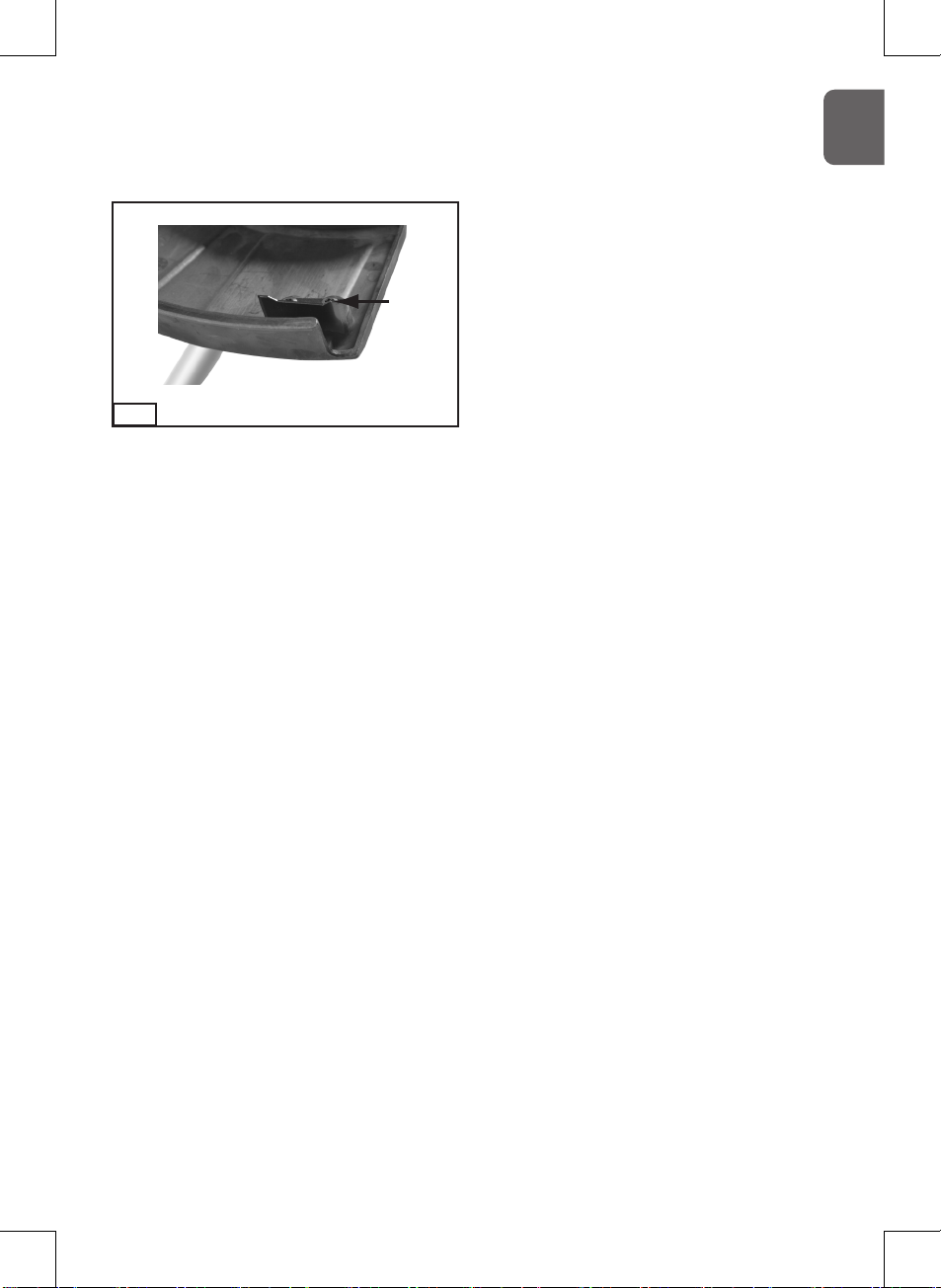

9.2.10 Trimline blade

A36

G

B

This will blow out the soot deposits and the piston and

cylinder will be lubricated.

- Keep the brush cutter-grass trimmer-prunercombination device in a dry place, out of the reach of

children and which does not have a fire-hazard.

9.4.1. Restart after longer work breaks

1. Check the spark plug, replace it if necessary and

screw it into the opening.

2. Pull the wire rope hoist several times quickly to clean

the engine room of oil and debris.

- If the trim thread is not cut clean any more while

lengthening, file the cutting edge with a file. File in one

direction and in the specified angle.

9.3 Transport

Remove the spark plug before transporting and empty

the oil tank as well as the petrol tank, to prevent leaking.

In order to prevent damage and/or injuries, also

remove the cutting equipment that was attached last

before every transport and store it in a transport guard

designated for it.

Clean and maintain the equipment before transport (see

above) and secure it against slipping.

For a longer transport it is recommended to dismantle

the extension (20) from the drive unit.

9.4 Storage / Winter

Clean and maintain the device before storing.

So that the brush cutter-grass trimmer- prunercombination device works after longer periods of storage

you should note the following:

- Drain the fuel tank (7) before storing.

- Start the engine and let it run until it comes to a

standstill.

- If the engine is cooled, remove the spark plug.

- Fill a small spoonful of 2-stroke mixture into the spark

plug hole and pull the wire rope hoist several times

slowly.

3. Fill the fuel tank with 2-stroke mixture 40:1. Start as

described in 5.1.

35

Page 36

G

B

10. Working with petrol hedge cutter

The hedge cutter is designed with articulated arm for

a high level of performance and reliability without

compromising on quantity, user-friendliness, safety or

service life.

Wear non-slip work gloves to be hold the

hedge cutter better. Wear sturdy shoes with

anti-slip sole for a secure position. Safety

shoes with steel caps are recommended.

Wear tight-fitting clothing that nevertheless

allows you freedom of movement.

Safety Instructions

Danger!

The hedge cutter with articulated arm is not insulated

against electric shock!

The approach to or contact with electrical power cables

with the hedge cutter can result in death or serious

injury. Hold the hedge cutter at least 10 meters away

from power cables or branches, which touch the power

cables.

In the case of a hedge shears with articulated arm,

there is a risk of serious injury if it is incorrectly used

or handled. In order to minimize the risk of injury, the

device must be under control at all times and during the

use, pay attention to all safety instructions. Do not allow

a person to work with the device, who has not been

trained or who has not been given instructions.

Instructions for Use

Read the operating instructions carefully

before you switch on the device.

Incorrect use can lead to personal injury or

damage to property. People who are not familiar with

the operating instructions may not use the device.

Keep the manual in a safe place.

Children and young people may not use the device.

Always wear a helmet to avoid head injuries

while using the device. In addition, wear eye

protection and hearing protection. We also

recommend wearing a face protection as

additional protection for face and eyes.

Do not use this device or other powered

devices if you are tired or sick or under

the influence of alcohol, drugs or other

substances, which could affect your skills

or your competence of judgement.

There must be a distance of at least 10 meters between

people standing nearby and the switched on hedge

cutter, so that they do not come in contact with objects

falling down or small parts flying around.

Never cut branches above your head. The

cut branches could hit you and cause

serious injury.

Warning!

Do not allow a person to work with the device, who has

not been trained or who has not been given instructions.

Make sure that the cutting attachment is properly

mounted and fixed before use.

Do not use the hedge cutter or cutting device if they are

damaged or warped. Replace or repair the components

before use.

Make sure that there are no objects in the vicinity of the

hedge cutter before you start the engine.

Turn the engine off immediately and check the device for

damage, if you come into contact with a hard object or

if the device gets caught. Do not use the appliance if it

is damaged or broken. Pay attention to the springback,

if you cut a branch found under tension, so that you are

not injured by the branch springing back.

Switch off the device immediately when it suddenly

begins to vibrate or shake. Check the device for

broken, missing or incorrectly mounted components or

attachments.

It is not permitted to smoke or light a fire in the vicinity

of the hedge shears. Keep the hedge shears away from

excessive heat. The engine fuel can be easily ignited and

a fire can cause severe injury to persons and property.

36

Page 37

Never use the hedge cutter with articulated arm without

sound-absorber.

Ensure adequate ventilation when you use the hedge

cutter with articulated arm. The exhaust gases can

cause serious injury or death. Never start the engine in

closed rooms.

Check that there are no fasteners are missing or are

loose and that the stop switch and throttle are working

properly.

If the hedge cutter is stuck, switch off the engine

immediately. Push the twigs or branch to the side and

free the hedge cutter.

Make sure that the blade is aligned properly before

using the hedge cutter with articulated arm. Never

adjust the blade when the engine is running. Make sure

that no fuel flows out from the tank, the lid, the fuel line

and the carburettor or other parts, from which fuel can

leak out.

Repair the device if fuel leaks and make sure that there

is no leakage any more.

Safety instructions in case of backlash and

jamming

Warning!

Through setbacks or jamming, you could lose control

over the hedge cutter and injure yourself seriously. Do

not rely on yourself alone with regard to the integrated

safety device of the hedge cutter. You will need to take

various measures so that no accidents or injuries can

occur.

1. Be prepared for backlashes or jamming. Avoid or

eliminate the element of surprise.

Surprise moments contribute to accidents.

2. Hold the hedge cutter firmly with both hands when

the engine is running. By holding well, you will reduce

the impact of backlashes or jamming and keep control

over the device.

3. Ensure that the area in which you work is free from

obstruction.

4. Cut with a high speed.

5. Use only the spare blade or an equivalent blade,

specified by the manufacturer.

G

B

Warning!

The hedge cutter with articulated arm must neither be

transported or put down, with the engine running. The

running engine could accidentally accelerate and thus

make the blade to vibrate.

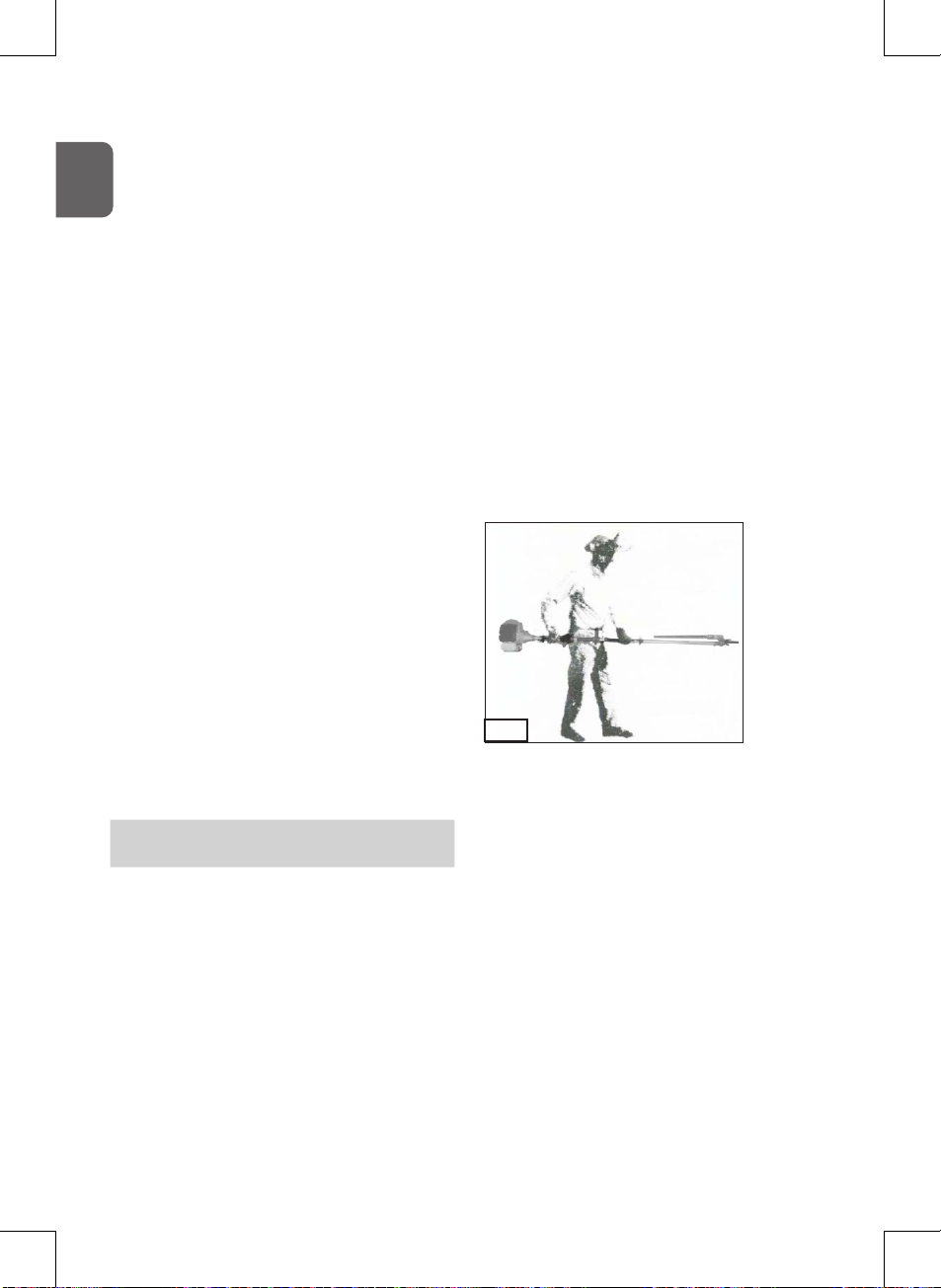

If the hedge cutter is carried with articulated arm, the

cutting attaching must be found in the transport position.

See A 37.

A37

Caution!

The safety devices of the hedge cutter may not be

manipulated or deactivated.

For the repair and maintenance of this device, use only

original parts and accessories.

Do not make any unauthorized modifications to the

hedge cutter with articulated arm.

In case of transport in a vehicle, the hedge shears must

be secured, so that there is no fuel leak or the device

can be damaged.

Remove rubbish and small parts from your work area in

order to ensure a secure position.

Hold the blade sharp and correctly aligned.

Keep the hedge cutter with articulated arm as clean as

possible. Remove loose branches, mud, dirt, etc.

37

Page 38

G

B

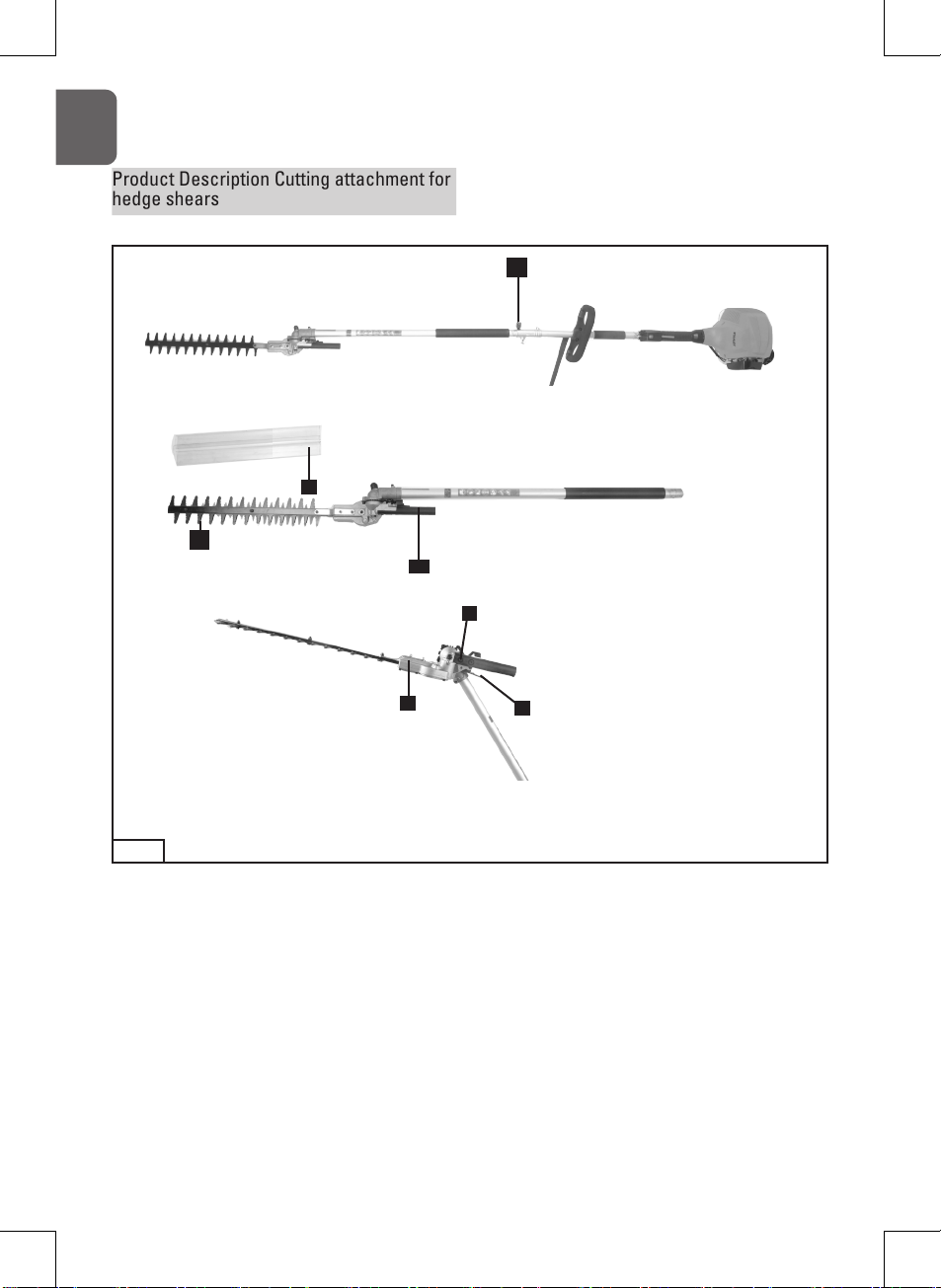

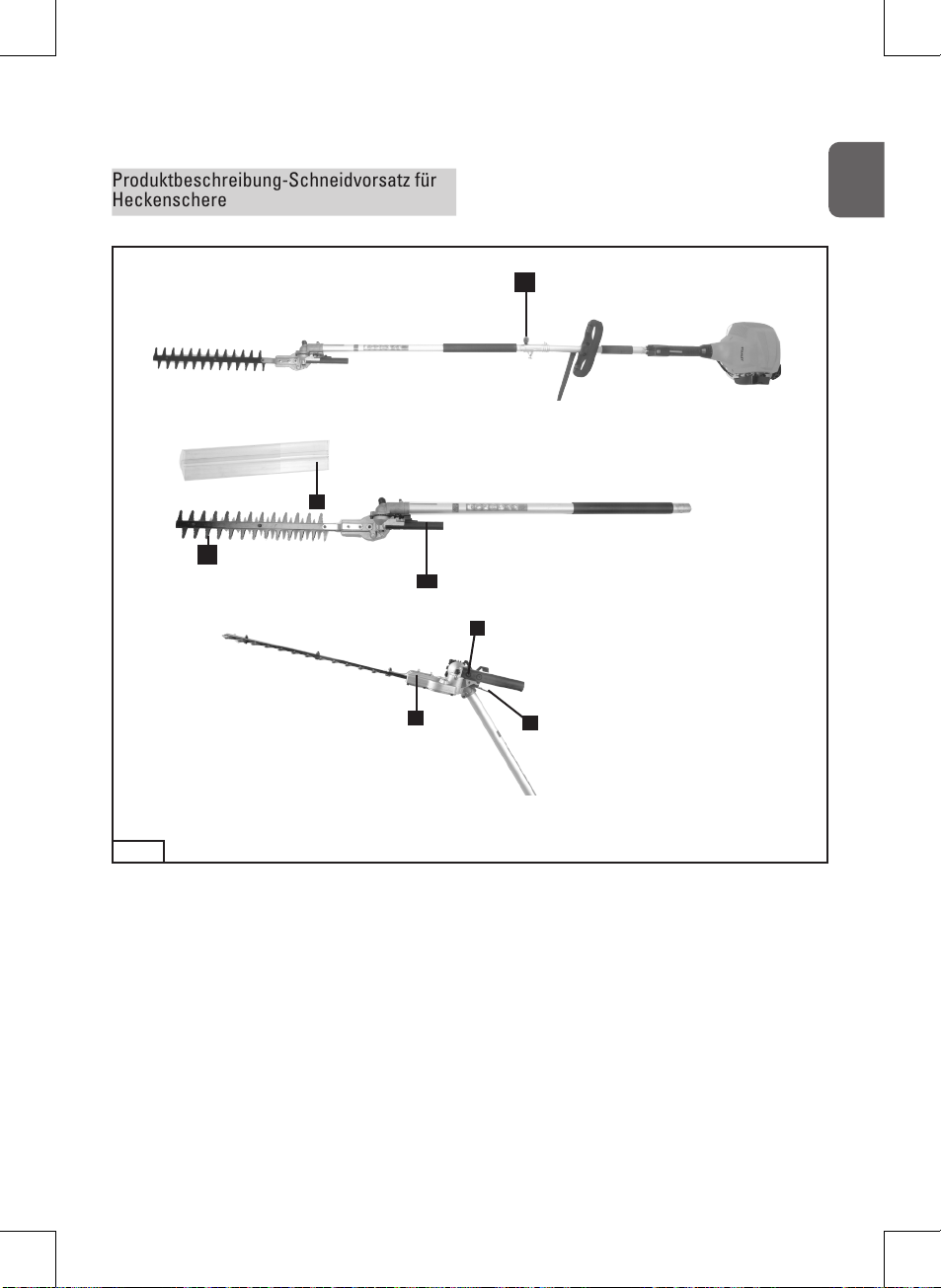

Product Description Cutting attachment for

hedge shears

2

4

5