Page 1

STHR263

English Page 3

Turkish Page 10

Page 2

ENGLISH

2

(Original instructions)

Page 3

3

ENGLISH

(Original instructions)

C

BA

* the picture above may differ slightly to actual unit.

Page 4

Intended use

Your STANLEY SDS plus rotary hammer drill has been

designed for drilling in wood, metal, plastics, and masonry

as well as for light chiselling applications.

Safety instructions

General power tool safety warnings

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions listed below may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

ENGLISH

4

(Original instructions)

Page 5

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Additional power tool safety warnings

Warning! Additional safety warnings for rotary and

chiselling hammers

• Wear ear protectors. Exposure to noise can cause

hearing loss.

• Use auxiliary handles supplied with the tool. Loss of

control can cause personal injury.

• Hold power tool by insulated gripping surfaces when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting

accessory contacting a "live" wire may make exposed

metal parts of the power tool "live" and could give the

operator an electric shock

• Never use a chisel accessory in rotary mode. The

accessory will bind in the material and rotate the drill.

• Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding the

work by hand or against your body leaves it unstable and

may lead to loss of control.

• Before drilling into walls, floors or ceilings, check for the

location of wiring and pipes.

• Avoid touching the tip of a drill bit just after drilling, as it

may be hot.

• The intended use is described in this instruction manual.

The use of any accessory or attachment or performance

of any operation with this tool other than those

recommended in this instruction manual may present a

risk of personal injury and/or damage to property.

Safety of others

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

• Children should be supervised to ensure that they do not

play with the appliance.

Residual risks.

Additional residual risks may arise when using the tool which

may not be included in the enclosed safety warnings. These

risks can arise from misuse, prolonged use etc. Even with

the application of the relevant safety regulations and the

implementation of safety devices, certain residual risks can

not be avoided. These include:

• Injuries caused by touching any rotating/moving

parts.

• Injuries caused when changing any parts, blades or

accessories.

5

ENGLISH

(Original instructions)

Page 6

6

ENGLISH

• Injuries caused by prolonged use of a tool. When using

any tool for prolonged periods ensure you take regular

breaks.

• Impairment of hearing.

• Health hazards caused by breathing dust developed

when using your tool (example:- working with wood,

especially oak, beech and MDF.)

Electrical safety

This tool is double insulated; therefore no earth

wire is required. Always check that the power

supply corresponds to the voltage on the rating

plate.

• If the supply cord is damaged, it must be replaced by the

manufacturer or an authorised STANLEY Service Centre

in order to avoid a hazard.

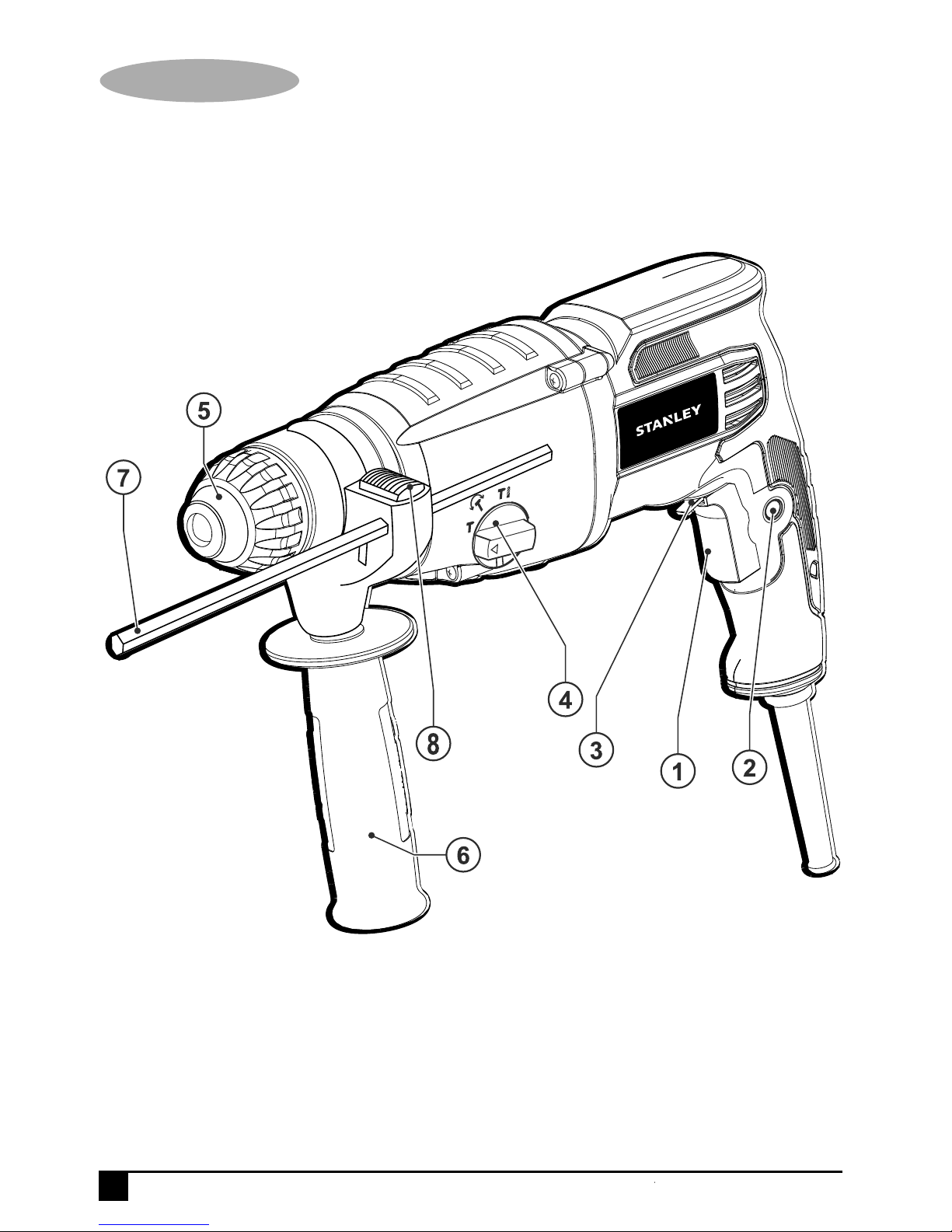

Features

This tool includes some or all of the following features.

1. Variable speed switch

2. Lock-on button

3. Forward/reverse switch

4. Drilling mode selector

5. Tool holder

6. Side handle

7. Depth stop

8. Depth stop lock button

Assembly

Warning! Before assembly, make sure that the tool

is switched off and unplugged.

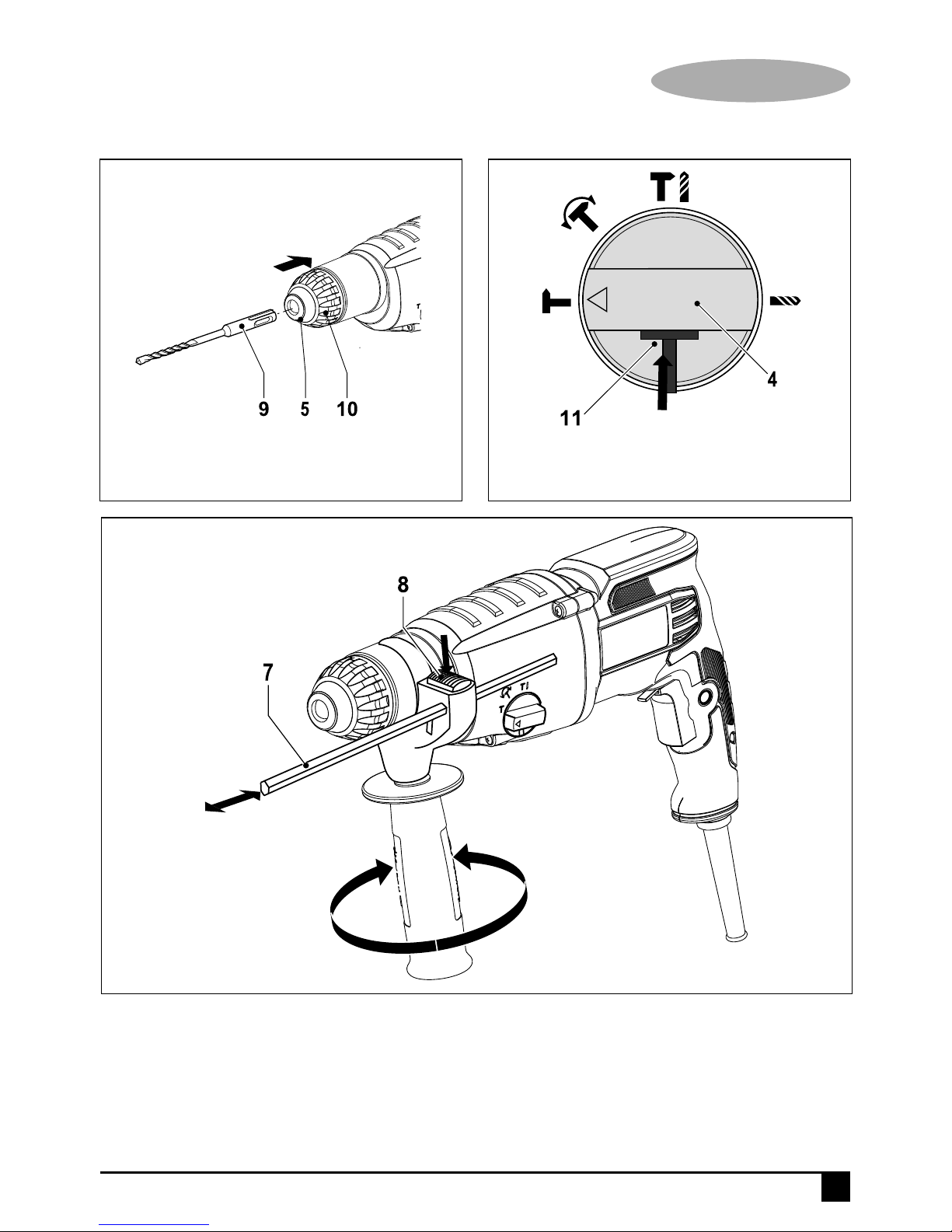

Fitting the side handle

• Turn the grip counterclockwise until you can slide the

side handle (6) onto the front of the tool.

• Rotate the side handle into the desired position.

• Tighten the side handle by turning the grip clockwise.

Fitting an accessory (fig. A)

• Clean and grease the shank (9) of the accessory.

• Pull back the sleeve (10) and insert the shank into the

tool holder (5).

• Push the accessory down and turn it slightly until it fits

into the slots.

• Pull on the accessory to check if it is properly locked.

The hammering function requires the accessory to be

able to move axially several centimetres when locked in

the tool holder.

• To remove the accessory, pull back the sleeve (10) and

pull out the accessory.

Use

Wear a dust mask

Warning! Let the tool work at its own pace. Do not

overload.

Warning! Before drilling into walls, floors or ceilings,

check for the location of wiring and pipes

Selecting the operating mode (fig. B)

The tool can be used in three operating modes. Press in the

button (11) and rotate the drilling mode selector (4) towards

the required position, as indicated by the symbols.

Drilling

• For drilling in steel, wood and plastics, set the operating

mode selector (4) to the position.

Hammer drilling

• For hammer drilling in masonry and concrete, set the

operating mode selector (4) to the position

• When hammering, the tool should not bounce and run

smoothly. If necessary, increase the speed.

(Original instructions)

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

0

....... No-Load

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

Labels on tool

The label on your tool may include the following symbols:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Page 7

7

ENGLISH

Hammering

• This function is included on only certain models with 3

modes(STHR263K)

• For hammering with spindle lock, and for light chiselling

and chipping, set the operating mode selector (4) to the

position.

• Make sure the forward/reverse switch is in the forward

position.

• When changing from hammer drilling to chiselling, turn

the chisel to the desired position. If resistance is felt

during mode change, slightly turn the chisel to engage

the spindle lock.

• When hammering with spindle lock, the angle of the bit

may be changed. Set the operating mode selector (4) to

the position, the angle of the bit may now be

changed by rotating the tool holder (6). Set the operating

mode selector (4) to the position, before continuing.

Selecting the direction of rotation

For drilling, and for chiselling, use forward (clockwise)

rotation. For removing a jammed drill bit, use reverse

(counterclockwise) rotation.

• To select forward rotation, push the forward/reverse

slider (3) to the left.

• To select reverse rotation, push the forward/reverse

slider to the right.

Warning! Never change the direction of rotation while the

motor is running.

Setting the drilling depth (fig. C)

• Press in the depth lock button (8).

• Set the depth stop (7) to the desired position. The

maximum drilling depth is equal to the distance between

the tip of the drill bit and the front end of the depth stop.

• Release the depth lock button.

Switching on and off

• To switch the tool on, press the variable speed switch

(1). The tool speed depends on how far you press the

switch.

• As a general rule, use low speeds for large diameter drill

bits and high speeds for smaller diameter drill bits.

• For continuous operation, press the lock-on button (2)

and release the variable speed switch. This option is

available only in forward (clockwise) rotation.

• To switch the tool off, release the variable speed switch.

To switch the tool off when in continuous operation, press

the variable speed switch once more and release it.

Accessories

The performance of your tool depends on the accessory

used. STANLEY accessories are engineered to high quality

standards and designed to enhance the performance of your

tool. By using these accessories you will get the very best

from your tool.

Maintenance

Your STANLEY corded/cordless appliance/tool has been

designed to operate over a long period of time with a

minimum of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

Warning! Before performing any maintenance on corded/

cordless power tools:

• Switch off and unplug the appliance/tool.

• Or switch off and remove the battery from the appliance/

tool if the appliance/tool has a separate battery pack.

• Or run the battery down completely if it is integral and

then switch off.

• Unplug the charger before cleaning it. Your charger does

not require any maintenance apart from regular cleaning.

• Regularly clean the ventilation slots in your

appliance/tool/ charger using a soft brush or dry cloth.

• Regularly clean the motor housing using a damp cloth.

Do not use any abrasive or solvent-based cleaner.

• Regularly open the chuck and tap it to remove any dust

from the interior (when fitted).v

(Original instructions)

STHR263

Power input W 800

No-load speed /min 0-1,050

Impact rate BPM 0-5,200

Impact energy J 2.7

Modes 3

Max capacitry mm 26

Weight kg 2.8

Technical data

Page 8

8

ENGLISH

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Stanley product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Stanley provides a facility for the collection and recycling of

Stanley products once they have reached the end of their

working life. To take advantage of this service please return

your product to any authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Stanley office at the address

indicated in this manual. Alternatively, a list of authorised

Stanley repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com

(Original instructions)

The declared vibration emission values stated in the

technical data and the declaration of conformity have been

measured in accordance with a standard test method

provided by EN 60745 and may be used for comparing one

tool with another. The declared vibration emission value

may also be used in a preliminary assessment of exposure.

Warning: The vibration emission value during

actual use of the power tool can differ from the

declared value depending on the ways in which

the tool is used. The vibration level may increase above the

level stated.

When assessing vibration exposure to determine safety

measures required by 2002/44/EC to protect persons

regularly using power tools in employment, an estimation of

vibration exposure should consider, the actual conditions of

use and the way the tool is used, including taking account of

all parts of the operating cycle such as the times when the

tool is switched off and when it is running idle in addition to

the trigger time.

LpA (sound pressure) dB(A) 90

K

pA

(sound pressure uncertainty) dB(A) 3

LWA (sound power) dB(A) 101

KWA (sound power uncertainty) dB(A) 3

Vibration emission value a

h

Check

a

h, HD

(Hammer Drilling into concrete) = m/s² 16,3

Uncertainty K = m/s² 1,5

a

h, CHeq

(Chiselling) = m/s

2

13,5

Uncertainty K =

m/s

2

1,5

Page 9

9

ENGLISH

Two years full warranty

If your Stanley product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, Stanley Europe guarantees to replace all defective

parts free of charge or – at our discretion – replace the unit

free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The Stanley product is returned complete with all original

components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised Stanley repair agent in

the Stanley catalogue or contact your local Stanley office at

the address indicated in this manual. A list of authorised

Stanley repair agents and full details of our after sales

service is available on the internet at:www.stanleytools.com

(Original instructions)

STANLEY declares that these products described under

"technical data" are in compliance with:

2006/42/EC, EN 60745-1, EN 60745-2-6

These products also comply with Directive

2014/30/EU and 2011/65/EU. For more information, please

contact STANLEY at the following address or refer to the

back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

STANLEY.

R.Laverick

Engineering Manager

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2015

EC declaration of conformity

MACHINERY DIRECTIVE

STHR263

Page 10

10

TÜRKÇE

(Orijinal talimatlar)

Page 11

11

TÜRKÇE

(Orijinal talimatlar)

C

BA

* Yukarıda gösterilen çizim ile alet arasında farklılıklar olabilir.

Page 12

12

TÜRKÇE

(Orijinal talimatlar)

Kullanım amacı

STANLEY SDS plus pnömatik matkabınız ahşap, metal,

plastik ve duvar delme işleri ve ayrıca basit kırma

uygulamaları için tasarlanmıştır.

Güvenlik talimatları

Genel elektrikli alet güvenlik uyarıları

UYARI! Bütün güvenlik uyarılarını ve

talimatlarını mutlaka okuyun. Aşağıda yer alan

uyarılar ve talimatların herhangi birisine uyulmaması elektrik

çarpması, yangın ve/veya ciddi yaralanma riskine neden

olabilir.

Bütün uyarı ve güvenlik talimatlarını ileride bakmak

üzere saklayın.

Aşağıda yer alan uyarılardaki «elektrikli alet» terimi şebeke

elektriğiyle (kablolu) veya akü/pille (şarjlı) çalışan elektrikli

aletinizi ifade etmektedir.

1. Çalışma alanının güvenliği

Çalışma alanını temiz ve aydınlık tutun. Karışık veya

karanlık alanlar kazaya davetiye çıkartır.

Elektrikli aletleri, yanıcı sıvılar, gazlar ve tozların

bulunduğu yerler gibi yanıcı ortamlarda çalıştırmayın.

Elektrikli aletler, toz veya dumanları ateşleyebilecek

kıvılcımlar çıkartır.

Bir elektrikli aleti çalıştırırken çocuklardan ve etraftaki

kişilerden uzak tutun. Dikkatinizi dağıtıcı şeyler kontrolü

kaybetmenize neden olabilir.

2. Elektrik güvenliği

Elektrikli aletlerin fişleri prizlere uygun olmalıdır. Fiş

üzerinde kesinlikle hiçbir değişiklik yapmayın. Topraklı

elektrikli aletlerde hiçbir adaptör fişi kullanmayın.

Değiştirilmemiş fişler ve uygun prizler elektrik çarpması

riskini azaltacaktır.

Borular, radyatörler, ocaklar ve buzdolapları gibi

topraklanmamış yüzeylerle vücut temasından kaçının.

Vücudunuzun topraklanması halinde yüksek bir elektrik

çarpması riski vardır.

Elektrikli aletleri yağmura maruz bırakmayın veya

ıslatmayın. Elektrikli alete su girmesi elektrik çarpması

riskini arttıracaktır.

Elektrik kablosunu uygun olmayan amaçlarla

kullanmayın. Elektrikli aleti kesinlikle kablosundan

tutarak taşımayın, çekmeyin veya prizden çıkartmayın.

Kabloyu sıcaktan, yağdan, keskin kenarlardan veya hareketli

parçalardan uzak tutun. Hasarlı veya dolaşmış kablolar

elektrik çarpması riskini arttırır.

Elektrikli bir aleti açık havada çalıştırıyorsanız, açık

havada kullanıma uygun bir uzatma kablosu kullanın.

Açık havada kullanıma uygun bir kablonun kullanılması

elektrik çarpması riskini azaltır.

Eğer bir elektrikli aletin nemli bir bölgede çalıştırılması

zorunluysa, bir artık akım aygıtı (RCD) korumalı bir

kaynak kullanın. Bir RCD kullanılması elektrik şoku riskini

azaltır.

3. Kişisel güvenlik

Elektrikli bir aleti kullanırken her zaman dikkatli olun,

yaptığınız işe yoğunlaşın ve sağduyulu davranın.

Elektrikli bir aleti yorgunken veya ilaç ya da alkolün

etkisi altındayken kullanmayın. Elektrikli aletleri

kullanırken bir anlık dikkatsizlik ciddi kişisel yaralanmayla

sonuçlanabilir.

Kişisel koruyucu ekipmanları mutlaka kullanın. Daima

koruyucu gözlük takın. Koşullara uygun toz maskesi,

kaymayan güvenlik ayakkabıları, baret veya kulaklık gibi

koruyucu donanımların kullanılması kişisel yaralanmaları

azaltacaktır.

İstem dışı çalıştırılmasını önleyin. Aleti güç kaynağına

ve/veya aküye bağlamadan, yerden kaldırmadan veya

taşımadan önce düğmenin kapalı konumda olduğundan

emin olun. Aleti, parmağınız düğme üzerinde bulunacak

şekilde taşımak veya açık konumdaki elektrikli aletleri

elektrik şebekesine bağlamak kazaya davetiye çıkartır.

Elektrikli aleti açmadan önce tüm ayarlama anahtarlarını

çıkartın. Elektrikli aletin hareketli bir parçasına takılı kalmış

bir anahtar kişisel yaralanmaya neden olabilir.

Ulaşmakta zorlandığınız yerlerde kullanmayın. Daima

sağlam ve dengeli basın. Bu, beklenmedik durumlarda

elektrikli aletin daha iyi kontrol edilmesine olanak tanır.

Uygun şekilde giyinin. Bol elbiseler giymeyin ve takı

takmayın. Saçınızı, elbiselerinizi ve eldivenlerinizi hareketli

parçalardan uzak tutun. Bol elbiseler ve takılar veya uzun

saç hareketli parçalara takılabilir.

Eğer kullandığınız üründe toz emme ve toplama

özellikleri olan ataşmanlar varsa bunların bağlı

olduğundan ve doğru şekilde kullanıldığından emin

olun. Bu toz toplama ataşmanların kullanılması tozla ilgili

tehlikeleri azaltabilir.

Page 13

13

TÜRKÇE

(Orijinal talimatlar)

4. Elektrikli aletlerin kullanımı ve bakımı

Elektrikli aleti zorlamayın. Uygulamanız için doğru

elektrikli aleti kullanın. Doğru elektrikli alet, belirlendiği

kapasite ayarında kullanıldığında daha iyi ve güvenli

çalışacaktır.

Düğme açmıyor ve kapatmıyorsa elektrikli aleti

kullanmayın. Düğmeyle kontrol edilemeyen tüm elektrikli

aletler tehlikelidir ve tamir edilmesi gerekmektedir.

Herhangi bir ayarlama, aksesuar değişimi veya elektrikli

aletlerin saklanması öncesinde fişi güç kaynağından

çekin ve/veya aküyü elektrikli aletten ayırın. Bu tür

önleyici güvenlik tedbirleri aletin istem dışı olarak

çalıştırılması riskini azaltacaktır.

Elektrikli aleti, çocukların ulaşamayacağı yerlerde

saklayın ve elektrikli aleti tanımayan veya bu talimatları

bilmeyen kişilerin elektrikli aleti kullanmasına izin

vermeyin. Elektrikli aletler, eğitimsiz kullanıcıların elinde

tehlikelidir.

Elektrikli aletleri iyi durumda muhafaza edin. Hareketli

parçalardaki hizalama hatalarını ve tutuklukları,

parçalardaki kırılmalar ve elektrikli aletin çalışmasını

etkileyebilecek tüm diğer koşulları kontrol edin. Hasarlı

ise, elektrikli aleti kullanmadan önce tamir ettirin. Kazaların

çoğu, elektrikli aletlerin bakımının yeterli şekilde

yapılmamasından kaynaklanır.

Kesim aletlerini keskin ve temiz tutun. Bakımı uygun

şekilde yapılmış keskin kesim uçlu kesim aletlerinin sıkışma

ihtimali daha düşüktür ve kontrol edilmesi daha kolaydır.

Elektrikli aleti, aksesuarlarını ve aletin diğer parçalarını

kullanırken bu talimatlara mutlaka uyun ve çalışma

ortamının koşullarını ve yapılacak işin ne olduğunu göz

önünde bulundurun. Elektrikli aletin öngörülen işlemler

dışındaki işlemler için kullanılması tehlikeli durumlara neden

olabilir.

5. Servis

Elektrikli aletinizi, sadece orijinal yedek parçaların

kullanıldığı yetkili servise tamir ettirin. Bu, elektrikli aletin

güvenliğinin muhafaza edilmesini sağlayacaktır.

Elektrikli el aletleri için ek güvenlik

talimatları

Uyarı! Matkaplar ve darbeli matkaplar için ek

güvenlik talimatları

Kulaklık takın. Yüksek sese maruz kalmak işitme kaybına

yol açabilir.

Aletle birlikte verilmiş olan yardımcı tutma kollarını

kullanın. Kontrol kaybı kişisel yaralanmalara neden olabilir.

Kesme aksesuarının gizli kablolara veya kendi

kablosuna temas edebileceği yerlerde çalışma yaparken

elektrikli aleti yalıtımlı kavrama yüzeylerinden tutun.

Kesme aksesuarının «akım taşıyan» bir kabloya temas

etmesi durumunda elektrikli aletin metal kısımları da «akım

taşır» hale gelecek ve kullanıcının elektrik çarpılmasına

neden olabilir.

Hiçbir zaman dönme konumunda kırıcı uç kullanmayın.

Aksesuar malzeme içinde sıkışacak ve matkabı

döndürecektir.

Üzerinde çalıştığınız parçayı sabitlemek ve desteklemek için

kelepçeler veya başka pratik yöntemler kullanın. Parçayı elle

veya vücudunuza dayamanız dengesiz durmasına neden

olacaktır ve aletin kontrolünü kaybetmenize yol açabilir.

Duvar, zemin veya tavanda delik açmadan önce kablo ve

boruların konumunu kontrol edin.

Delme işleminin hemen ardından matkap ucuna

dokunmaktan kaçının; sıcak olabilir.

Kullanım amacı bu kullanım kılavuzunda açıklanmıştır.

Herhangi bir aksesuarın veya bağlantının ya da işlemin, bu

kılavuzda tavsiye edilen şekilden başka bir şekilde

kullanılması şahısların yaralanmalarına ve/veya mal kaybına

yol açabilir.

Diğer kişilerin güvenliği

Bu alet fiziksel ve zihinsel kapasitesinin yanı sıra algılama

gücü azalmış olan veya yeterince deneyim ve bilgisi

bulunmayan kişiler (çocuklar dahil) tarafından kullanılmak

üzere üretilmemiştir. Bu tür kişiler aleti ancak

güvenliklerinden sorumlu bir kişi tarafından aletin

kullanımıyla ilgili talimatların verilmesi veya sürekli kontrol

altında tutulması durumunda kullanabilir.

Çocuklar, aletle oynamalarını önlemek amacıyla kontrol

altında tutulmalıdır.

Diğer tehlikeler

Aletin kullanımıyla ilgili ekte sunulan güvenlik uyarılarına

dahil olmayan ilave kalıcı riskler ortaya çıkabilir. Bu riskler,

hatalı, uzun süreli kullanım vb. dolayısıyla ortaya çıkabilir.

Emniyet tedbirlerini düzenleyen yönetmeliğin uygulanmasına

ve emniyet sağlayıcı aygıtların kullanılmasına rağmen,

başka belirli risklerden kaçınılamaz. Bunlar:

Aletin dönen ve hareket eden parçalarına dokunma

sonucu ortaya çıkan yaralanmalar.

Herhangi bir parçayı, bıçak veya aksesuarı değiştirirken

ortaya çıkan yaralanmalar.

Page 14

14

TÜRKÇE

(Orijinal talimatlar)

Aletin uzun süreli kullanılması sonucu ortaya çıkan

yaralanmalar. Herhangi bir aleti uzun sürelerle

kullanacaksanız düzenli olarak çalışmanıza ara verin.

Duyma bozukluğu.

Aleti kullanırken ortaya çıkan tozun solunması sonucu ortaya

çıkan sağlık sorunları (örnek: ahşapta çalışırken, özellikle

meşe, akgürgen ve MDF).

Elektrik güvenliği

Bu alet çift yalıtımlıdır. Bu yüzden hiçbir topraklama

kablosuna gerek yoktur. Her zaman şebeke geriliminin aletin

üretim etiketinde belirlenmiş değerlere uyup uymadığını

kontrol edin.

Elektrik kablosu hasarlı ise, bir tehlike oluşmasını

önlemek için üretici ya da yetkili STANLEY Servis

Merkezi tarafından değiştirilmelidir.

ÖZELLİKLER

Bu alet, aşağıdaki özelliklerin bir kısmını veya tümünü

içermektedir.

1. Değişken hız ayarlı tetik

2. Kesintisiz çalıştırma düğmesi

3. İleri/geri sürgüsü

4. Delme modu seçicisi

5. Uç tutucu

6. Yan kol

7. Derinlik çubuğu

8. Derinlik çubuğu düğmesi

Montaj

Uyarı! Montajdan önce aletin kapalı ve fişinin

çekilmiş olduğundan emin olun.

Yan kolun takılması

Tutamağı, yan kol (6) aletin ön kısmının üzerine kaydırabilir

duruma gelene kadar saatin ters yönünde çevirin.

Yan kolu istediğiniz konuma çevirin.

Tutamağı saat yönünde çevirerek yan kolu sıkın.

Aksesuar takılması (Şekil A)

Aksesuarın sap kısmını (9) temizleyip yağlayın.

Kovanı (10) geri çekip sap kısmını uç tutucunun (5) içine

sokun.

Aksesuarı aşağı bastırın ve yuvaların içine oturana kadar

hafifçe çevirin.

Uygun şekilde kilitlenip kilitlenmediğini kontrol etmek için

aksesuarı çekin. Darbeleme fonksiyonu, aksesuarın uç

tutucuya kilitlendikten sonra yukarı aşağı birkaç santimetre

hareket edebilmesini gerektirir.

Aksesuarı çıkartmak için, kovanı (10) geri çekin ve

aksesuarı çekip çıkartın.

Kullanımı

Toz maskesini kullanılması tavsiye edilir.

Uyarı! Aletin kendi hızında çalışmasına izin verin.

Aşırı yüklenmeyin.

Uyarı! Duvar, zemin veya tavanda delik açmadan

önce kablo ve boruların konumunu kontrol edin

Çalışma modunun seçilmesi (Şekil B)

Alet üç çalışma modunda kullanılabilir. Düğmeye (11) basın

ve çalışma modu seçicisini (4) sembollerle gösterildiği

şekilde gerekli konuma çevirin.

Delme

Çelik, ahşap ve plastiği delmek için çalışma modu seçicisini

(4) konumuna getirin.

Darbeli delme

Duvar ve betonda darbeli delme için çalışma modu seçicisini

(4) konumuna getirin.

Darbeli delme sırasında, alet sağa sola kaymamalı ve

düzenli çalışmalıdır. Gerekirse hızı arttırın.

V ........ Volt

A ........ Amper

Hz ....... Hertz

W ........ Vat

dak ..... dakika

.....

.....

boş .......

......

....

....

.../min..

Alet üzerindeki etiketler

Alet üzerinde aşağıdaki semboller bulunabilir:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Kullanım

Kılavuzunu

Okuyun

Koruyucu

Gözlük kullanın

Kulaklık

Kullanın

Alternatif

Akım

Direkt

Akım

Yüksüz

Hız

Sınıf II

İnşaat

Topraklama

Terminal

Güvenlik

uyarısı

Sembolü

Dakikada

devir veya

gel git sayısı

Page 15

15

TÜRKÇE

(Orijinal talimatlar)

Kırma

Bu fonksiyon sadece 3 çalışma modu olan belirli modellerde

bulunur (STHR263K).

Mil kilidi ile kırma ve keskileme işleri için çalışma modu

seçicisini (4) konumuna getirin.

İleri/geri sürgüsünün ileri konumunda olduğundan emin

olun.

Darbeli delmeden kırıcı moduna geçmek için kırıcı ucunu

istediğiniz konuma çevirin. Mod değişimi sırasında direnç

hissederseniz, mil kilidini devreye sokmak için kırıcı ucunu

hafifçe çevirin.

Mil kilitli haldeyken darbeleme uç açısı değiştirilebilir.

Çalışma modu seçicisini (4) konumuna getirdiğinizde uç

tutucuyu (6) çevirme sırasında ucun açısı artık

değiştirilebilir. Devam etmeden önce çalışma modu

seçicisini (4) konumuna getirin.

Dönme yönünün seçilmesi

Delik açma ve kırma uygulamaları için ileri (saat yönünde)

dönmeyi kullanın. Sıkışmış bir matkap ucunu çıkartmak için

geri (saatin ters yönünde) dönmeyi kullanın.

İleri dönmeyi seçmek için ileri/geri sürgüsünü (3) sola itin.

Geri dönmeyi seçmek için ileri/geri sürgüsünü sağa itin.

Uyarı! Dönme yönünü kesinlikle motor çalışır durumdayken

değiştirmeyin.

Delme derinliğinin ayarlanması (Şekil C)

Derinlik çubuğu düğmesine (8) basın.

Derinlik çubuğunu (7) istediğiniz konuma ayarlayın.

Maksimum delme derinliği, matkap ucunun uç kısmı ile

derinlik çubuğunun ön ucu arasındaki mesafeye eşittir.

Derinlik çubuğu düğmesini bırakın.

Açılması ve kapatılması

Aleti açmak için, değişken hız ayarlı tetiğine (1) basın. Aletin

hızı, tetiğe ne kadar bastığınıza bağlıdır.

Genel kural olarak, büyük çaplı uçlar için düşük hız, küçük

çaplı uçlar içinse yüksek hız seçin.

Sürekli çalışması için kesintisiz çalıştırma düğmesine (2)

basın ve değişken hız ayarlı tetiğini bırakın. Bu seçenek

sadece ileri (saat yönünde) dönme için geçerlidir.

Aleti kapatmak için, değişken hız ayarlı tetiğini bırakın.

Kesintisiz çalışma konumundayken aleti kapatmak için

değişken hız ayarlı tetiğine bir kez daha basın ve bırakın.

Aksesuarlar

Aletinizin performansı kullanılan aksesuara bağlıdır.

STANLEY aksesuarları, yüksek kalite standartlarına göre

üretilmiş ve aletinizin performansını arttıracak şekilde

tasarlanmıştır. Bu aksesuarları kullanarak, aletinizden en iyi

verimi alacaksınız.

Bakım

STANLEY elektrikli/şarjlı aletiniz minimum bakımla uzun bir

süre çalışacak şekilde tasarlanmıştır. Kesintisiz olarak

memnuniyet verici bir şekilde çalışması gerekli özenin

gösterilmesine ve düzenli temizliğe bağlıdır.

Uyarı! Elektrikli/şarjlı alet üzerinde herhangi bir bakım işlemi

gerçekleştirmeden önce:

Aleti kapatın ve fişten çekin.

Veya aletin çıkartılabilir aküsü varsa; aleti kapatın ve aküyü

aletten çıkartın.

Veya aletin dahili aküsü varsa, bitene kadar çalıştırın ve

sonra kapatın.

Şarj cihazını temizlemeden önce fişten çekin. Şarj cihazınız,

düzenli temizlik dışında herhangi bir bakım

gerektirmemektedir.

Aletinizdeki ve şarj cihazındaki havalandırma deliklerini

yumuşak bir fırça veya kuru bir bezle düzenli olarak

temizleyin.

Motor muhafazasını düzenli olarak nemli bir bezle silin.

Aşındırıcı veya çözücü bazlı temizleyiciler kullanmayın.

Mandreni düzenli olarak tamamen açın ve içindeki tozu

dökmek için hafifçe vurun (mandren alete takılıysa).

STHR263

Giriş gücü W 800

Yüksüz hızı dev/dak 0-1,050

Darbe oranı darbe/dak 0-5,200

Tek darbe gücü J 2,7

Çalışma modları 3

Maks. delme kapasitesi mm 26

Ağırlık kg 2,8

Teknik özellikleri

Page 16

16

TÜRKÇE

(Orijinal talimatlar)

Çevrenin korunması

Ayrı olarak atın. Bu ürün, normal evsel atıklarla

birlikte atılmamalıdır.

Stanley ürününüzün değiştirilmesi gerektiğini düşünmeniz

veya artık kullanılamaz durumda olması halinde onu, evsel

atıklarla birlikte atmayın. Bu ürünü, ayrı olarak toplanacak

şekilde atın.

Kullanılmış ürünlerin ve ambalajların ayrı olarak

toplanması bu maddelerin geri dönüşüme sokularak

yeniden kullanılmasına olanak tanır. Geri dönüşümlü

maddelerin tekrar kullanılması çevre kirliliğinin önlenmesine

yardımcı olur ve ham madde ihtiyacını azaltır.

Yerel yönetmelikler, elektrikli ürünlerin evlerden toplanıp

belediye atık tesislerine aktarılması veya yeni bir ürün satın

alırken perakende satıcı tarafından toplanması yönünde

hükümler içerebilir. Stanley, hizmet ömrünün sonuna ulaşan

Stanley ürünlerinin toplanması ve geri dönüşüme sokulması

için bir imkân sunmaktadır. Bu hizmetin avantajlarından

faydalanmak için, lütfen, ürününüzü bizim adımıza teslim

alacak herhangi bir yetkili servise iade edin.

Bu kılavuzda belirtilen listeden size en yakın Stanley etkili

tamir servisinin yerini öğrenebilirsiniz. Ya da, alternatif olarak

internet’ten Stanley yetkili tamir servislerinin listesini ve satış

sonrası hizmetlerimizle ilgili tüm bilgiler ve temas bilgilerine

aşağıdaki siteden ulaşabilirsiniz. www.2helpU.com

Teknik veriler ve uygunluk beyanatı içerisinde belirtilen

titreşim emisyon değerleri EN60745 tarafından belirlenen

standart bir test yöntemine uygun olarak ölçülmektedir ve

diğer bir aletle karşılaştırma yaparken kullanılabilir. Beyan

edilen titreşim emisyon değeri aynı zamanda maruz

kalmanın önceden değerlendirilmesinde de kullanılabilir.

Uyarı: Elektrikli aletin mevcut kullanımı

sırasındaki titreşim emisyon değeri, aletin

kullanım yöntemine bağlı olarak, beyan edilen

değere göre farklılık sergileyebilir. Titreşim düzeyi belirlenen

seviyenin üzerinde artış gösterebilir.

İşyerinde düzenli olarak elektrikli alet kullanan çalışanları

korumak amacıyla 2002/44/EC tarafından getirilen elektrik

güvenliği önlemlerini belirlemek üzere titreşime maruz

kalmayı değerlendirirken, çalışma döngüsü içerisinde

örneğin aletin kapalı olduğu ve aktif durumda olmasının yanı

sıra boşta çalıştığı zamanlar gibi, bütün zaman dilimleri dahil

olmak üzere mevcut kullanım durumu ve aletin kullanım

şekli göz önünde bulundurularak değerlendirilmelidir.

LpA (ses basıncı) dB(A) 90

KpA(ses basıncı belirsizlii) dB(A) 3

LWA (akustik güç) dB(A) 101

KWA (akustik gücü belirsizlii) dB(A) 3

Titreim emisyon deeri a

h

a

h, HD

(Betonda darbeli delme) = m/s² 16,3

Belirsizlik K = m/s² 1,5

a

h, CHeq

(Kırma) = m/s² 13,5

Belirsizlik K = m/s² 1,5

Page 17

17

TÜRKÇE

(Orijinal talimatlar)

İki yıl tam garanti

Sahip olduğunuz Stanley ürünü satın alma tarihinden itibaren

24 ay içinde hatalı malzeme veya işçilik nedeniyle bozulursa,

Stanley Europe aşağıdaki şartlara uyulması koşuluyla

ücretsiz olarak tüm kusurlu parçaların yenilenmesini veya

-kendi inisiyatifine bağlı olarak- satın alınan ürünün

değiştirilmesini garanti eder:

Ürün, hatalı kullanılmamış kullanım kılavuzuna uygun

kullanılmıştır.

Ürün yıpranmamış, hırpalanmamış ve aşınmamıştır;

Yetkili olmayan kişilerce tamire çalışılmamıştır.

Satın alma belgesi (fatura) ibraz edilmiştir.

Stanley ürünü, tüm orijinal parçaları ile birlikte iade edilmiştir

Garanti talebinde bulunmak için, lütfen satıcıyla irtibata geçin

veya Stanley katalogunda belirtilen size en yakın Stanley

yetkili satıcı adresini kontrol edin veya ürünün kılavuzunda

belirtilen adresteki yerel Stanley yetkili tamir servisi ile temas

kurun. İnternet’ten Stanley yetkili tamir servislerinin listesine

ve satış sonrası hizmetlerimizle ilgili tüm bilgilerine aşağıdaki

siteden ulaşabilirsiniz: www.stanleytools.com

STANLEY, «teknik özellikleri» bölümünde açıklanan bu

ürünlerin aşağıda belirtilen yönergelere uygun olduğunu

beyan eder: 2006/42/EC, EN 60745-1, EN 60745-2-6

Bu ürünler ayrıca 2014/30/EU ve 2011/65/EU Direktiflerine

de uygundur. Daha fazla bilgi için, lütfen aşağıdaki adresten

STANLEY ile irtibata geçin veya kılavuzun arkasına bakın.

Bu belge altında imzası bulunan yetkili, teknik dosyanın

derlenmesinden sorumludur ve bu beyanı STANLEY adına

vermiştir.

R.Laverick

Mühendislik Bölümü Müdürü

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2015

AT Uygunluk Beyanatı

MAKİNE DİREKTİFİ

STHR263

Sanayi ve Ticaret Bakanlığı tebliğince kullanım ömrü 7 yıldır.

Türkiye Distribütörü

STANLEY BLACK&DECKER TURKEY ALET URETIM SAN. TIC. LTD.STI.

Kozyatağı Mh Değirmen Sk. Nida Kule No:18 Kat:6

34742 Kadıköy İstanbul

Tel : (0216) 665 29 00

Faks : (0216) 665 29 01

E-posta: info-tr@sbdinc.com

Page 18

Loading...

Loading...