Page 1

STHM10

English Page 4

Page 2

2

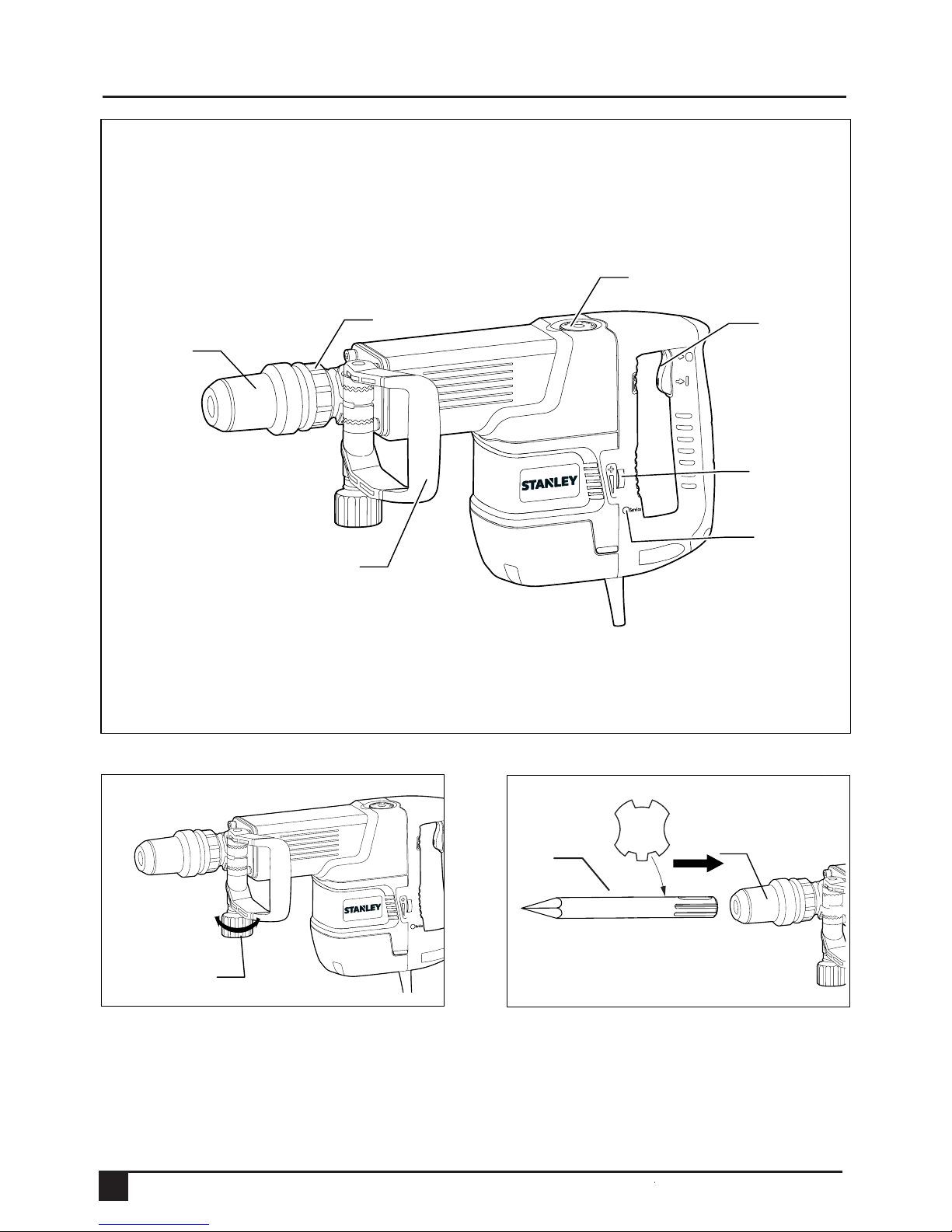

FIG A

FIG A1

FIG A2

6

2

1

4

3

10

5

A

7

8

6

B

ENGLISH (Original instructions)

Page 3

3

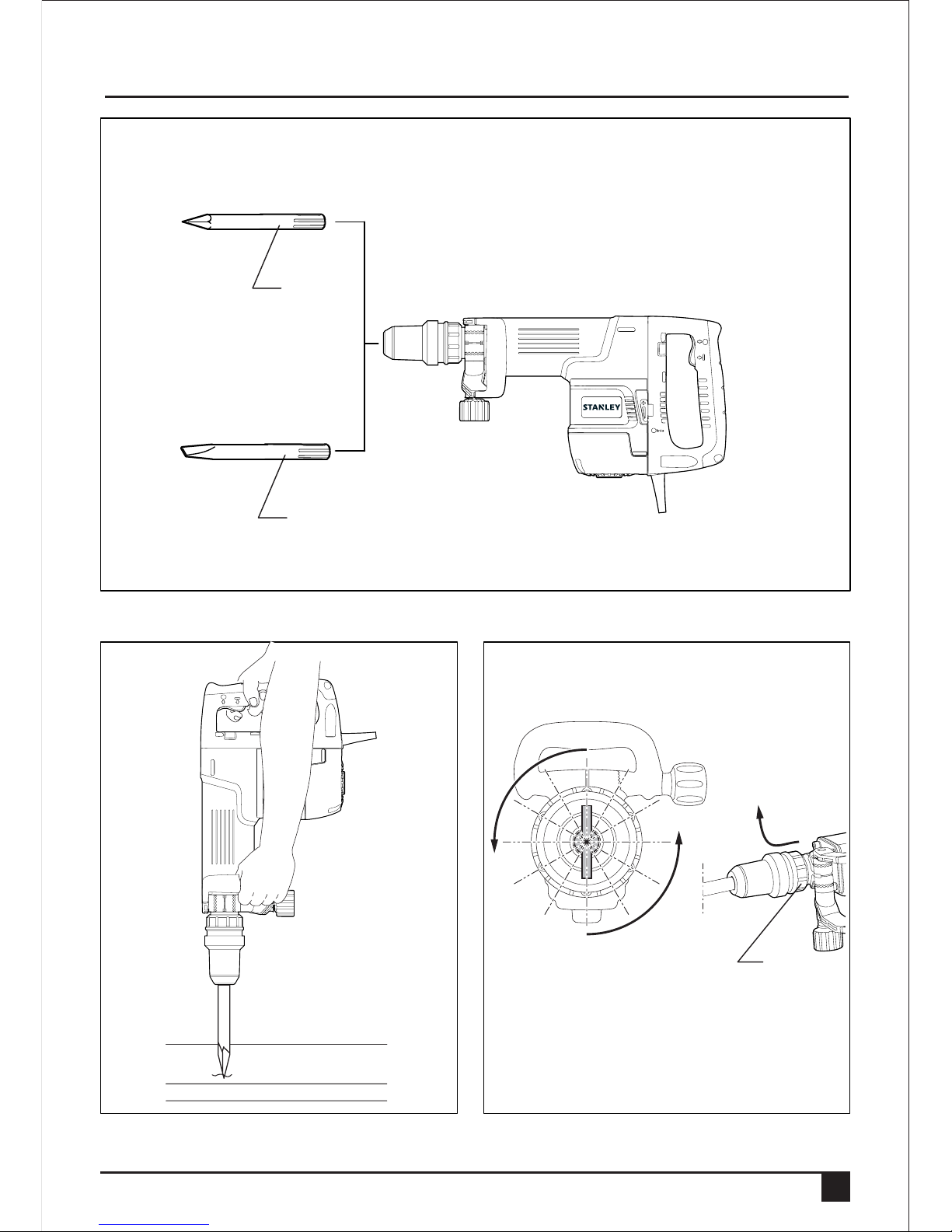

FIG B

FIG C FIG D

8

9

4

(Original instructions) ENGLISH

Page 4

4

Intended use

Your Stanley Demolition Hammer has been designed for

professional light or medium chipping, chiselling and

demolition applications in concrete, brick and masonry.

Safety instructions

General power tool safety warnings

WARNING! Read all safety warnings and instructions.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future reference

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

ENGLISH (Original instructions)

Page 5

5

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Additional safety warnings for hammers

• Wear ear protectors. Exposure to noise can cause

hearing loss.

• Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

• Hold power tool by insulated gripping surfaces

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live" and

could give the operator an electric shock.

• Be certain that the material being drilled does not

conceal electric or gas service and that their locations

have been verified with the utility companies.

• Keep a firm grip on the tool at all times. Do not

attempt to operate this tool without holding it with

both hands. Operating this tool with one hand will result

in loss of control. Breaking through or encountering hard

materials such as re-bar may be hazardous as well.

Tighten the side handle securely before use.

• Ensure the chisel is secured in place before operating

the tool.

• In cold-weather conditions or when the tool has not been

used for a longer period of time, let the tool run with no

load for several minutes before use.

• When working above ground level ensure the area below

is clear.

• Do not touch the chisel or the parts close to the chisel

immediately after operation, as they may be extremely

hot and cause burns to the skin.

• Always direct the power cable to the rear, away from the

chisel.

• Do not operate this tool for long periods of time.

Vibration caused by hammer action may be harmful to

your hands and arms. Use gloves to provide extra

cushion and limit exposure by taking frequent rest

periods.

Residual risks

Additional residual risks may arise when using the tool which

may not be included in the enclosed safety warnings. These

risks can arise from misuse, prolonged use etc. In spite of

the application of the relevant safety regulations and the

implementation of safety devices, certain risks cannot be

avoided.

These are:

• Injuries caused by touching any rotating/moving parts.

• Injuries caused when changing any parts, blades or

accessories.

• Injuries caused by prolonged use of a tool. When using

any tool for prolonged periods ensure you take regular

breaks.

• Impairment of hearing.

• Health hazards caused by breathing dust developed

when using your tool (example:- working with wood,

especially oak, beech and MDF.)

(Original instructions) ENGLISH

Page 6

6

Vibration

The declared vibration emission values stated in the

technical data and the declaration of conformity have been

measured in accordance with a standard test method

provided by EN 60745 and may be used for comparing one

tool with another. The declared vibration emission value may

also be used in a preliminary assessment of exposure.

Warning! The vibration emission value during actual use of

the power tool can differ from the declared value depending

on the ways in which the tool is used. The vibration level

may increase above the level stated.

When assessing vibration exposure to determine safety

measures required by 2002/44/EC to protect persons

regularly using power tools in employment, an estimation of

vibration exposure should consider, the actual conditions of

use and the way the tool is used, including taking account of

all parts of the operating cycle such as the times when the

tool is switched off and when it is running idle in addition to

the trigger time.

Electrical safety

This tool is double insulated; therefore no earth

wire is required. Always check that the power

supply corresponds to the voltage on the rating

plate.

• If the supply cord is damaged, it must be replaced by the

manufacturer or an authorised Stanley Service Centre in

order to avoid a hazard.

ﹺEﹺlectronic impact energy control

The electronic impact energy control (c) offers the following

advantages:

• Use of smaller accessories without risk of breakage

• Minimised break-out when chiselling soft or brittle

materials

• Optimal tool control for precise chiselling

Service reminder light

When the service reminder light (j) lights up or blinks, this

will indicate that the cut-out carbon brushes will switch off

the tool in approximately 8 hours. After that period, the light

will go off and the tool will stop running.The tool must then

be sent to a service center for service.

Soft start feature

The soft start feature allows the impact rate to build up more

slowly, thus preventing the chisel or point from "bouncing"

around on the masonry when starting up.

Using an extension cable

If it is necessary to use an extension cable, please used an

approved extension cable that fits the tool’s power input

specifications (please refer to the technical data). The

minimum cross-sectional area of the conducting wire is 1.5

sq. mm. Cables should be untangled before reeling up.

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

0

....... No-Load

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

Labels on tool

The label on your tool may include the following symbols:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Voltage Amperes Cable rated current (Ampere)

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - -

230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

Cable cross-sectional area (mm

2

) Cable rated current (Ampere)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

ENGLISH (Original instructions)

Page 7

7

Features

This tool includes some or all of the following features.

1. Side Handle

2. Switch

3. Electronic impact energy control dial

4. Chisel position index collar

5. Lube oil-injection inlet

6. Tool holder / sleeve

7. Service indicator

Assembly and adjustments

WARNING: To reduce the risk of injury, turn unit

off and disconnect machine from power source

before installing and removing accessories,

before adjusting or changing set-ups or when making

repairs. Be sure the trigger switch is in the OFF position. An

accidental start-up can cause injury.

Inserting and removing SDS-Max accessories (FIG. A1)

This tool uses SDS-Max chisels (refer to the inset in FIG A1

for a cross-section of a chisel shank). We recommend to

use professional accessories only.

1. Clean and grease the chisel shank.

CAUTION: Do not apply lubricant to the

machine.

2. Insert the chisel shank into the bit holder/tool sleeve (f).

Press and turn the chisel slightly until the sleeve snaps

into position.

3. Pull on the chisel to check if it is properly locked. The

hammering function requires the chisel to be able to

move axially several centimetres when locked in the tool

holder.

4. To remove a chisel, pull back the tool holder/ sleeve (f)

and pull the chisel out of the tool holder.

WARNING: Always wear gloves when you

change accessories. The exposed metal parts

on the tool and accessory may become extremly hot during

operation.

Indexing the chisel position (FIG. D)

The chisel can be indexed and locked into 12 different

positions.

1. Insert the chisel as described above.

2. Pull forward and rotate the chisel position collar (d) in the

direction of the arrow until the chisel is in the desired

position.

Setting the electronic impact power control dial (FIG. A)

Turn the dial (c) to the desired level. The higher the number,

the greater the impact energy. With dial settings from «1»

(low) to «6» (full power) the tool is extremely versatile and

adaptable for many different applications. The required

setting is a matter of experience, for example:

• When chiselling soft, brittle materials or when minimum

break-out is required, set the dial to «1» or «2» (low);

• When breaking harder materials, set the dial to «6» (full

power).

Fitting the side handle (FIG. A)

The side handle (a) can be mounted on the front of the

machine to suit both right hand and left hand users.

WARNING: Always operate the machine with

the side handle properly mounted..

1. Unscrew the side handle clamp knob (g).

2. Adjust the side handle (a) to the desired angle.

3. Slide and rotate the side handle to the desired position.

4. Lock the side handle in place by tightening the clamp

knob (g).

Operation instructions for use

WARNING:

• Always observe the safety instructions and applicable

regulations.

(Original instructions) ENGLISH

Page 8

8

• Be aware of the location of pipework and wiring.

• Apply a pressure of approx. 20 - 30 kg to the tool.

Excessive force does not speed up chiselling but

decreases tool performance and may shorten tool life.

• Always hold the tool firmly with both hands and ensure a

secure stance (FIG. C). Always operate the tool with the

side handle properly mounted.

Proper hand position (FIG. C)

Warning: To reduce the risk of serious

personal injury, ALWAYS use proper hand

position as shown.

Warning: To reduce the risk of serious

personal injury, ALWAYS hold securely in

anticipation of a sudden reaction.

Proper hand position requires one hand on the side handle

(a), with the other hand on the main handle.

Switching on and off (FIG. A)

1. To run the tool, press the switch (b) and turn it in 'ON'

position.

2. To stop the tool, turn it in 'OFF' position and release the

switch (b).

Demolition, chiseling and channelling (FIG. A)

1. Select the appropriate chisel, and clean and grease its

shank.

2. Insert the chisel and check whether it is properly locked.

3. Set the desired impact energy level.

4. Fit and adjust the side handle (a) and make sure it is

firmly tightened.

5. Hold the tool at main handle and side handle (a) and

switch on. The tool now runs in continuous operation.

6. Always switch off the tool when work is finished and

before unplugging.

Various types of chisels are available as an option. Only

Stanley recommended accessories should be used with this

product.

Warning:

• Do not use this tool to mix or pump easily combustible or

explosive fluids (benzine, alcohol, etc.).

• Do not mix or stir inflammable liquids labelled

accordingly.

Accessory maintenance (FIG. B)

Accessory maintenance at the right time guarantees optimal

results in application and a long and efficient accessory life.

Grind the chisels on grinding discs. Refer to FIG B for the

appropriate angles of the following chisels:

Pointed chisel (h)

Flat chisel (i)

Warning: These chisels can be reground only a

limited number of times. If in doubt, contact your

dealer for recommendations.

Warning: Ensure that the cutting edge does not

show discolouration caused by too much

pressure. This may impair the hardnessof the

accessory.

Maintenance

Your Stanley corded/cordless appliance/tool has been

designed to operate over a long period of time with a

minimum of maintenance. To ensure satisfactory operations,

the tool must be maintained and cleaned regularly

• This machine is not user-serviceable. Take the tool to an

authorised Stanley repair agent after approximately 100

hours of use. If problems occur before this time contact

an authorised Stanley repair agent.

Lubrication

• Open the cap of the lube oil-injection inlet(e), check the

lube oil in the gearbox, if the lube oil is dirty or

insufficient, replace or add the adequate amount of lube

oil provided by the company.

Cleaning

Warning: Blow dirt and dust out of the main

housing with dry air as often as dirt is seen

collecting in and around the air vents. Wear

approved eye protection and approved dust mask when

performing this procedure.

ENGLISH (Original instructions)

Page 9

9

Warning: Never use solvents or other harsh

chemicals for cleaning the non-metallic

parts of the tool. These chemicals may weaken the material

of the parts. Use only mild soap and damp cloth to clean the

tool. Never let any liquid get inside the tool; never immerse

any part of the tool into liquid.

Optional accessories

Warning: Since accessories, other than those

offered by Stanley, have not been tested with

this product, use of such accessories with this

tool could be hazardous. To reduce the risk of injury, only

Stanley recommended accessories should be used with this

product.

Consult your dealer for further information on the

appropriate accessories.

Notes

• STANLEY's policy is one of continuous improvement to

our products and, as such, we reserve the right to

change product specifications without prior notice.

• Standard equipment and accessories may vary by

country.

• Product specifications may differ by country.

• Complete product range may not be available in all

countries.

• Contact your local STANLEY dealers for range

availability.

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Stanley product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Stanley provides a facility for the collection and recycling of

Stanley products once they have reached the end of their

working life. To take advantage of this service please return

your product to any authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Stanley office at the address

indicated in this manual. Alternatively, a list of authorised

Stanley repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com

Technical data

SPECIFICATION STHM10

Voltage V 220-240

Frequency Hz 50/60

Power W 1600

Impact rate bpm 900-1890

Impact energy J 5-25

Chisel positions 12

Tool holder SDS-Max

Weight kg 10.5

(Original instructions) ENGLISH

Page 10

Service Information

STANLEY offers a full network of authorized service

locations. All STANLEY Service Centers are staffed with

trained personnel to provide customers with efficient and

reliable power tool service. For more information about our

authorized service centers and if you need technical advice,

repair, or genuine factory replacement parts, contact the

STANLEY location nearest you.

One year full warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 12 months from the date of

purchase, STANLEY guarantees to replace all defective

parts free of charge or – at our discretion – replace the unit

free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

10

ENGLISH (Original instructions)

Page 11

N435540 01/2015

Page 12

ALGERIA: Sarl Outillage Corporation, 08 Rue Med Boudiaf - Cheraga - Algiers, Algeria. Tel: (213-21) 375130, Fax: (213-21) 369667. ANGOLA: Angoferraria,

Lda., Rua Robert Shields, No. 61, Luanda, Angola, Tel: 00244-222-395837 / 222-395034, Fax: 00244-222-394790. AZERBAIJAN: Royalton Holdings Ltd. 41

Khagani St. Apt. 47 AZ 1001, Baku. Tel: (994-12) 4935544, Fax: (994-12) 5980378. BAHRAIN: Kavalani & Sons W.L.L., P.O. Box 71, Sitra, Manama, Tel: (973)

17732888, Fax: (973) 17737379. Alfouz Services Co. WLL., P.O. Box 26562, Tubli, Manama. Tel: (973) 17783562, Fax: (973) 17783479. EGYPT: El Farab

S.A.E., 15-Nabil El Wakkad Street, Dokki, Giza, Egypt, Tel: 00202-37603946 / 002-010-2582544, Fax: 00202-33352796. ETHIOPIA: Seif Tewfik Sherif, Arada

Sub-City, Kebele 01/02, Global Insurance Building, 2nd Floor, Room 43, P.O. Box 2525, Addis Ababa, Ethiopia. Tel: (251-11) 1563968/ 1563969, Fax: (251-11)

1558009. IRAQ: Financial Links, Kazzaz Building Arasat Al-Hindia Block No: 629 Street: 31Building No: 1 Baghdad – Iraq. Tel: 00964 (0)780 195 2223/ 00964

(0)781 3763044. Al Sard Co. for General Trading Ltd. Jbara Bldg. 3Flr, Al Rasheed St. Bagdad. Tel: (964) 18184102. Sakhar Group, Arrassat al-hindya Al

Masbah, Bagdad. (964) 7400144446. JORDAN: Palestine Bldg. Matl. (Bashiti Hardware), 93 King Abdullah 2nd Street, Opp. ELBA House, P.O. Box 3005,

Amman 11953, Tel: (962-6) 5349098, Fax: (962-6) 5330731. KENYA: Dextron Tools Ltd., P.O. Box 20121-00200, Shariff House, Kimathi Street, Nairobi. Tel:

(254-20) 6905000/ 2358021, Fax: (254-20) 6905111/ 6905112. KUWAIT: Al Omar Technical Co., P.O. Box 4062, 13041 Safat, Kuwait. Tel: (965) 24848595/

24840039, Fax: (965) 24845652. Fawaz Al Zayani Establishment, P.O. Box 42426, Shop No. 18, Al Humaizi Commercial Complex, Khalifa Al Jassim,

Shuwaikh, Kuwait. Tel: (965) 24828710, Fax: (965) 24828716. Fawaz Al Zayani Establishment, P.O. Box 42426, Shop No.18, Al Humaizi Commercial

Complex, Khalifa Al Jassim, Shuwaikh, Kuwait, Tel: (965) 24828710, Fax: (965) 24828716. Fawaz Al Zayani Establishment, Fahaheel Industrial Area, Main St.,

Sanaya, Kuwait, Tel: (965) 23925830, Fax: (965) 24828716. LEBANON: Est. Shaya & Azar S.A.R.L., Boulvard Jdeideh - Mar Takla - Bouchrieh .P.O. Box

90545 Jdeideh.Beirut - Lebanon, Tel: 00961 1 872305 / 306 , Fax: 00961 1 872303. LIBYA: North Africa Trading ( El Ghoul Brothers), AlHilal Service Center

Tawergha St. Misurata, Tel: 00218-091-3221408. (Benghazi) Sniydel st., Amr Ibn EL-Aas Rd. Tel: (+218) 92 5771120. (Tripoli) Al Barniq Service Center,

Mokhazin elsukar st., ElFallah. Tel: (+218) 21 4808019. (Misrata) Al Hilal Service Center, Tawergha st. Tel: (+218) 51 2626743. MAURITIUS: Robert Le Marie

Limited, Old Moka Road, Bell Village, P.O. Box 161, Port Louis, Tel: 00230-212 1865/ 212 2847, Fax: 00230-2080843. MOROCCO: Ets Louis Guillaud & Cie,

149, Quartier Industriel, Moulay Rachid, Casablanca, Postal Code 20450, Morocco, Tel: 00212-522729233, Fax: 00212-522729096. NIGERIA: Meridian

Power Tools Ltd., Gr.Floor, #1 Alhaji Masha Rd, Next toTeslim Balogun Stadium, Near National Stadium Surulere, Lagos, Nigeria, Tel: 00234-1-7740431 /

7740410, Fax: 00234-1-7913798. OMAN: Al Jizzi Company LLC, P.O. Box 1704,PC 112 Ruwi, Oman, Tel: (968) 24832618/ 24835153, Fax: (968)

24831334/24836460. Al Hassan Technical & Construction Supplies Co. LLC, P.O. Box 1948, P.C. 112, Ruwi, Tel: (968) 24810575 / 24837054, Fax: (968)

24810287/ 24833080. Oman Hardware Co. LLC, P.O. Box 635, Ruwi Postal Code 112, Te: (968) 24815131, Fax: (968) 24816491. Khimji Ramdas, P.O. Box

19, Post Code 100, Ghala, Muscat, Oman. Tel: (968) 24595906/ 907, Fax: (968) 24852752. Oman Marketing & Service Co. (Omasco), P.O. Box 2734, Behind

Honda Showroom, Wattayah, Oman. Tel: (968) 24560232/ 24560255, Fax: (968) 24560993. Oman Marketing & Service Co. (Omasco), Al Ohi, Sohar, Oman.

Tel: (968) 26846379, Fax: (968) 26846379. Oman Marketing & Service Co. (Omasco), Sanaya, Salalah, Oman. Tel: (968) 23212290, Fax: (968) 23210936.

PAKISTAN: ZIT Co - Nasir & Bros., 2nd Floor, Qadri Center, Chowk Dalgran Railway Road, Lahore, Pakistan, Tel: 0092 42 37670839, Fax: 0092 42

37652989. Ammar Service & Spares, 60-Bank Arcade, Serai Road, Karachi, Pakistan. Tel: (92-21) 32426905, Fax: (92-21) 32427214. QATAR: Teyseer

Industrial Supplies & Services Co. WLL, 55, Al Wakalat St. (Between St. 18 & 19) Salwa Industrial Area, P.O. Box 40523 Doha,Qatar, Te: (974) 44581536, Fax:

(974) 44682024. Shaheen Electrical Works & Trading Co. WLL, Gate 34, St. 44 Industrial Area P.O. Box 9756, Doha, Tel: (974) 44600230 /44600525, Fax:

(974) 44601338. Al Muftah Service Centre, Al Wakrah Road, P.O. Box 875, Doha,Qatar, Tel: (974) 44650880/ 44650110/ 44446868, Fax: (974) 44441415 /

44662599. SAUDI ARABIA: (Al Bahr) Mohamed Ahmed Bin Afif Est., P.O. Box 530, Yanbu, Al Bahr. Tel: (966-4) 3222626/ 3228867, Fax: (966-4) 3222210.

(Al Khobar) Fawaz Ebrahim Al Zayani Trading Est., P.O. Box 76026, Al Khobar # 31952, Tel: (966-3) 8140914, Fax: (966-3) 8140824. MSS (Al-Mojil Supply &

Services) P.O. Box 450, Jubail 31951, Opp. Gulf Bridge Library & Riyadh House. Tel: (966-3) 3612850/ 3624487/ 3621729, Fax: (966-3) 3623589/ 3620783.

(Dammam) MSS (Al-Mojil Supply & Services), P.O. Box 450, Jubail 31951.Opp-Gulf Bridge Library & Riyadh House, Tel: (966-3) 3612850 / 3624487 /

3621729, Fax: (966-3) 3623589 / 3620783. Al Bawardi Tools & Hardware, P.O. Box 112, Dammam, Tel: (966-3) 8330780 Ext.24 / 8348585 Ext. 24 /

+966-3-8335555, Fax: (966-3) 8336303. (Al Hassa) Mutawa Trading & Gen. Services, Maliki road Hafuf city, Al Hassa, KSA. Tel: (966) 502846275 (Jeddah) Al

Bawardi Tools & Hardware, P.O. Box 16905, Jeddah 21474, Tel: (966-2) 6444547 / 6439035 / 6456095, Fax: (966-2) 6439024. EAC (Al Yousef Contg. & Trdg.

Est.), P.O. Box 30377, Jeddah -21477, Tel: (966-2) 6519912, Fax: (966-2) 6511153. (Madina) Garziz Trading for Bldg Mat & Decoration, P.O. Box 3364,

Madina, Tel: (966-4) 826 14 90 / 8227636, Fax: (966-4) 8265741. (Riyadh) Industrial Material Organization (IMO), P.O. Box 623, Rail Street ,Riyadh, Tel:

(966-1) 4028010 Ext 26 / 8001245757, Fax: (966-1) 4037970. Sultan Garment Factory (RSC), P.O. Box 29912, Riyadh 11467, KSA, Tel: (966-1) 4055148 /

4042889, Fax: (966-1) 4055148. Al Bawardi Tools & Hardware, P.O. Box 68, Riyadh 11411, Tel: (966-1) 4484999, Fax: (966-1) 4487877. (Yanbu) Fawaz

Ebrahim Al Zayani, Opposite to Al Fouzan, Jeddah highway or King Abdul Aziz road, Yanbu. Tel: (966-4) 3960980, Fax: (966-4) 3961980. Mohamed Ahmed

Bin Afif Est., P.O. Box 530, Yanbu, Al Bahr, Tel: (966-4) 3222626/ 3228867, Fax: (966-4) 3222210. SOUTH AFRICA: Stanley Black & Decker - RSA, 199

Winze Drive Stormill Ext 9 Roodepoort, Tel: (2711) 472 0454, Fax: (2711) 472 0482. Trevco Power Tool Service 14 Steenbok Street, Koedoespoort, 0186,

Pretoria, South Africa. Tel: (27-86) 1873826, Fax: (27-86) 5001771. TANZANIA: General Motors investment Ltd., P.O. Box 16541, 14 Nyerere Road,

Vingunguti, Dar-es-Salaam. Tel: (255 22) 2862661/ 2865022, Fax: (255 22) 2862667. TUNISIA: Societe Tunisienne De Maintenance (STM), Rue de la

Physique. Nouvelle Zone Industrielle Ben Arous., 2013 Ben Arous, Tunisia. Tel: (+216) 79 389687, Fax: (+216) 71 385154. UAE: (Abu Dhabi) Light House

Electrical, P.O. Box 120, Abu Dhabi, Tel: (971-2) 6726131, Fax: (971-2) 6720667. Galaxy Equipment Trading, Madinath Zayed (Baada Zaid), Abu Dhabi P.C.

58910, Tel: (971-2) 8844279, Fax: (971-2) 8844297 (Ajman) Al Sukoon Gen. Trdg. Co. LLC, P.O. Box 2975, Ajman. Tel: (971-6) 7435725/ 7438317, Fax:

(971-6) 7437350. Al Sukoon Gen. Trdg. Co. LLC, P.O. Box 2975, Ajman, Tel: (971-6) 7435725 / 7438317, Fax: (971-6) 7437350 (Al Ain) Zillion Equipment and

Spare Parts Trading LLC, P.O. Box 19740, Opp. Bin Sadal/ Trimix Redymix Sanaiya, Al Ain. Tel: (971-3) 7216690, Fax: (971-3) 7216103. (Dubai) Black &

Decker (Overseas) GmbH, P.O. Box 5420, Dubai, Tel: (971-4) 8127400/ 8127406, Fax: (971-4)2822765. Ideal Star Workshop Eqpt.Trading LLC, P.O. Box

37116, Al Quoz, Dubai, Tel: (971-4) 3474160, Fax: (971-4) 3474157, Fine Tools, P.O.Box 30139 , Al Quoz, Dubai, Tel: (971-4) 3385240, Fax: (971-4) 3385239,

Alebrah Engineering Service, P.O. Box 78954, Al Qusais , Dubai, Tel: (971-4) 2850044, Fax: (971-4) 2844802. (Musaffah) Light House Electrical, P.O. Box

120, Abu Dhabi, Tel: (971-2) 5548315, Fax: (971-2) 5540461. (Sharjah) Mc Coy Middle East LLC, P.O. Box 25793, Sharjah, Tel: (971-6) 5395931, Fax:

(971-6) 5395932. Burj Al Madeena, Industrial Area No.1, Opp. Pakistani Masjid, P.O. Box 37635, Sharjah. Tel: (971-6) 5337747, Fax: (971-6) 5337719. Burj Al

Madeena, , Industrial Area No 1,opp Pakistani Masjid P.O. Box 37635, Sharjah, Tel: (971-6) 5337747, Fax: (971-6) 5337719 (Ras Al Khaimah) Mc Coy Middle

East LLC, P.O. Box 10584, Ras Al Khaimah, Tel: (971-7) 2277095, Fax: (971-7) 2277096. UGANDA: The Building Center (U) Ltd., 52 Station Road, Kitgum

House, P.O. Box 7436, Kampala, Uganda. Tel: (256-41) 4234567/ 4259754, Fax: (256-41) 4236413. YEMEN: (Aden) Middle East Trad. Co. Ltd. (METCO),

Mualla Dakka, Aden, Yemen. Tel: (967-2) 222670, Fax: (967-2) 222670. (Sana'a) Middle East Trad. Co. Ltd. (METCO), Hayel St., Sana'a, Yemen. Tel: (967-1)

204201, Fax: (967-1) 204204. (Taiz) Middle East Trading Co. (METCO), P.O. Box 12363, 5th Flr, Hayel Saeed Anam Bldg, Al-Mugamma St. Taiz, Yemen. Tel:

(967-4) 213455, Fax: (967-4) 219869.

Names & Addresses for STANLEY Service Concessionaries - MIDDLE EAST & AFRICA

Loading...

Loading...