Page 1

STGS9115

STGS9125

English Page 4

Русский Page 14

Українська Page 24

Ukrainian Page 35

Page 2

ENGLISH (Original instructions)

3

(Original instructions) ENGLISH

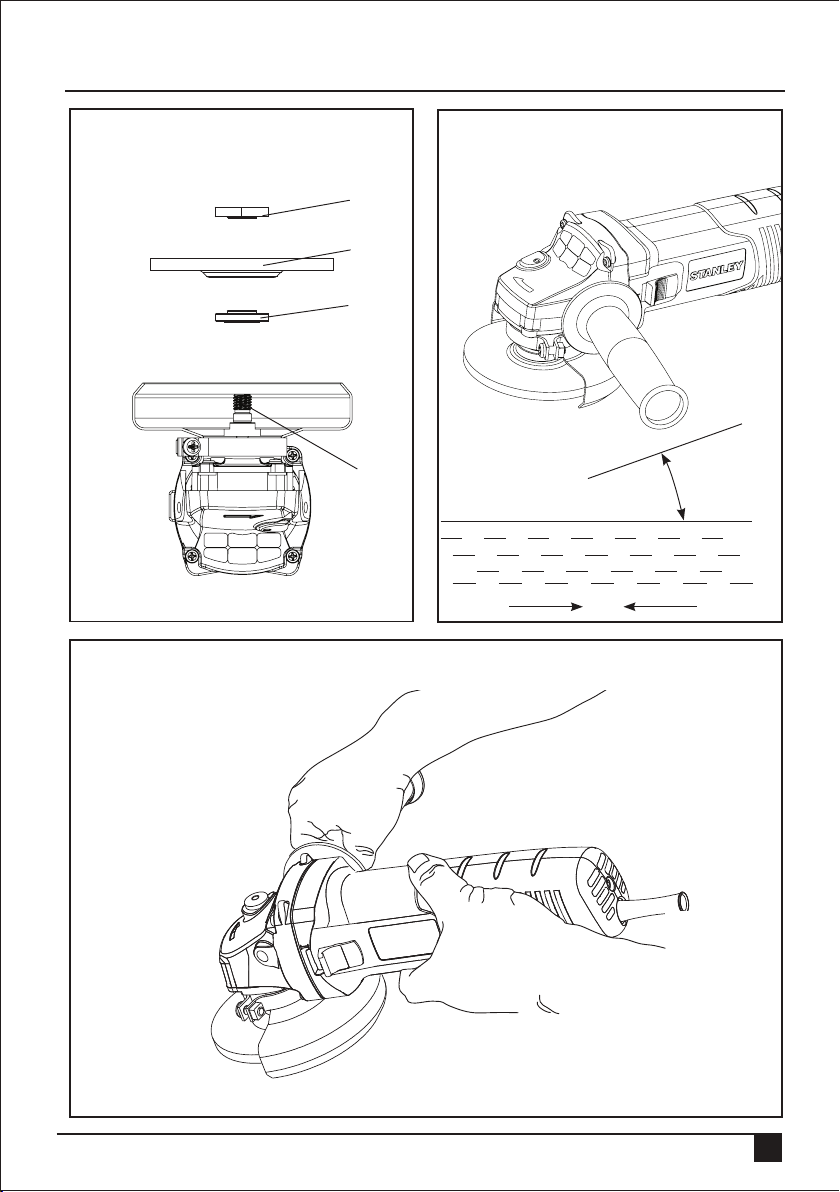

Figure 5

Figure 6

Figure 4

h

f

d

e

15o-30

o

A B

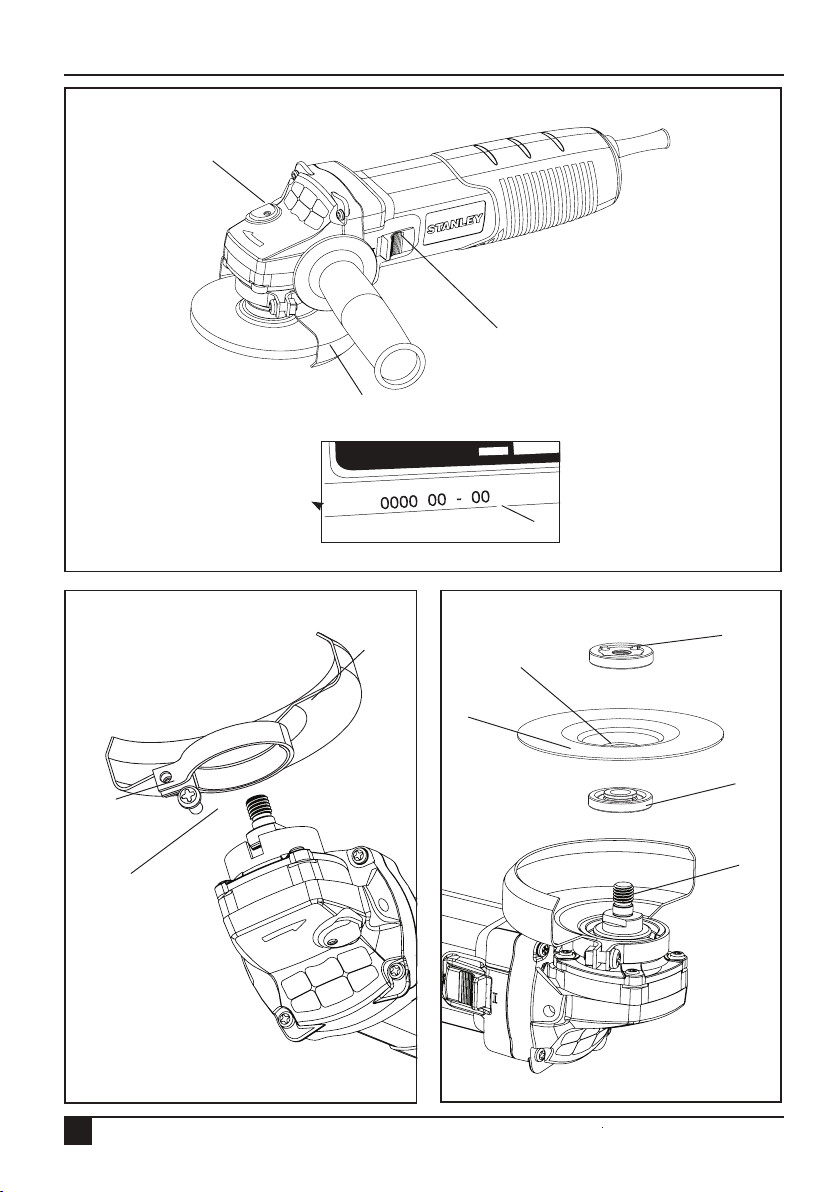

Figure 1

b

a

c

Figure 2 Figure 3

c

f

k

i

n

g

h

d

e

2

Page 3

(Original instructions) ENGLISH

Figure 4

Figure 6

Figure 5

h

f

d

e

15o-30

o

A B

3

Page 4

ENGLISH (Original instructions)

Intended Use

Your STANLEY angle grinder STGS9115-STGS9125 has

been designed for grinding metal using the appropriate type

of grinding disc. This tool is intended for professional use.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to

these symbols.

Danger: Indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

Warning: Indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

Caution: Indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

Notice: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

Denotes risk of electric shock.

Denotes risk of fire.

Warning: To reduce the risk of injury, read the

instruction manual.

General Power Tool Safety Warnings

Warning! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future reference

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b) Do not operate power tools in explosive

4

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

Page 5

(Original instructions) ENGLISH

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool.Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

toolin unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices

can reduce dust related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools.Such preventive safety measures reduce

the risk of starting the power tool accidentally

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc., in

accordance with these instructions, takinginto

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Additional specific safety rules

Safety Instructions for All Operations

Safety Warnings Common for Grinding

a) This power tool is intended to function as a grinder.

Read all safety warnings, instructions, illustrations

and specifications provided with this power tool.

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury.

b) Operations such as cutting-off , sander, wire brush

or polisher are not recommended to be performed

with this power tool. Operations for which the power

tool was not designed may create a hazard and cause

personal injury.

c) Do not use accessories which are not specifically

designed and recommended by the tool

manufacturer. Just because the accessory can be

attached to your power tool, it does not assure safe

operation.

d) The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated speed

can break and fly apart.

5

Page 6

ENGLISH (Original instructions)

e) The outside diameter and the thickness of your

accessory must be within the capacity rating of your

power tool. Incorrectly sized accessories cannon be

adequately guarded or controlled.

f) Threaded mounting of accessories must match the

grinder spindle thread. For accessories mounted by

flanges, the arbour hole of the accessory must fit the

locating diameter of the flange. Accessories that do

not match the mounting hardware of the power tool will

run out of balance, vibrate excessively and may cause

loss of control.

g) Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheel for

chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires.

If power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After

inspecting and installing an accessory, position

yourself and bystanders away from the plane of the

rotating accessory and run the power tool at

maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test

time.

h) Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of

stopping small abrasive or workpiece fragments. The

eye protection must be capable of stopping flying debris

generated by various operations. The dust mask or

respirator must be capable of filtrating particles

generated by your operation. Prolonged exposure to

high intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of

workpiece or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

j) Hold the power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring or its

own cord. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

k) Position the cord clear of the spinning accessory. If

you lose control, the cord may be cut or snagged and

your hand or arm may be pulled into the spinning

accessory.

l) Never lay the power tool down until the accessory

has come to a complete stop. The spinning accessory

may grab the surface and pull the power tool out of your

control.

m) Do not run the power tool while carrying it at your

side. Accidental contact with the spinning accessory

could snag your clothing, pulling the accessory into your

body.

n) Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause

electrical hazards.

o) Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

p) Do not use accessories that require liquid coolants.

Using water or other liquid coolants may result in

electrocution or shock.

Further safety instructions for all operations

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory.

Pinching or snagging causes rapid stalling of the rotating

accessory which in turn causes the uncontrolled power tool

to be forced in the direction opposite of the accessory’s

rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by

the workpiece, the edge of the wheel that is entering into the

pinch point can dig into the surface of the material causing

the wheel to climb out or kick out. The wheel may either

jump toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching.Abrasive wheels may also break under these

conditions.

Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be avoided by

taking proper precautions as given below:

6

Page 7

(Original instructions) ENGLISH

a) Maintain a firm grip on the power tool and position

your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction

during start up. The operator can control torque

reaction or kickback forces, if proper precautions are

taken.

b) Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

c) Do not position your body in the area where power

tool will move if kickback occurs. Kickback will propel

the tool in direction opposite to the wheel’s movement at

the point of snagging.

d) Use special care when working corners, sharp edges

etc. Avoid bouncing and snagging the accessory.

Corners, sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of control or

kickback.

e) Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety warnings specific for grinding

operations

a) Use only wheel types that are recommended for your

power tool and the specific guard designed for the

selected wheel. Wheels for which the power tool was

not designed cannot be adequately guarded and are

unsafe.

b) The guard must be securely attached to the power

tool and positioned for maximum safety, so the least

amount of wheel is exposed towards the operator.

The guard helps to protect operator from broken wheel

fragments and accidental contact with wheel and sparks

that could ignite clothing.

c) Wheels must be used only for recommended

applications. For example: do not grind with the side

of cut-off wheel. Abrasive cut-off wheels are intended

for peripheral grinding, side forces applied to these

wheels may cause them to shatter.

d) Always use undamaged wheel flanges that are of

correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing

the possibility of wheel breakage. Flanges for cut-off

wheels may be different from grinding wheel flanges.

e) Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and may

burst.

f) The grinding surface of centre depressed wheels

must be mounted below the plane of the guard lip. An

improperly mounted wheel that projects through the

plane of the guard lip cannot be adequately protected.

Residual Risks

In spite of the application of the relevant safety regulations

and the implementation of safety devices, certain residual

risks cannot be avoided.

These are:

– Impairment of hearing

– Risk of personal injury due flying particles.

– Risk of burns due to accessories becoming hot during

operation.

– Risk of personal injury due to prolonged use.

– Risk of dust from hazardous substances.

Labels on tool

The label on your tool may include the following symbols

along with date code

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

....... No-Load

0

Speed

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation p er

minute

7

Page 8

ENGLISH (Original instructions)

Package Content

This product package includes:

1 Angle grinder

1 Guard

1 Flange set

1 Spanner

1 Handle

1 Instruction manual

• Check t he tool, parts, and accessories to see if they are

damaged during transportation.

• Take a f ew moments to read and understand this

manual before using the tool.

Description (Fig. 1)

Warning: Never modify the power tool or any

part of the tool, otherwise it may cause damage

to the tool or result in personal injury.

Do not allow children to come in contact with this tool.

Inexperienced operators are required to use this tool under

supervision.

No-Volt

The No-volt function stops the grinder restarting without the

switch being cycled if there is a break in the power supply.

Electrical Equipment Safety

Only one voltage is applicable to this tool. Be sure to check

that the power suuply corresponds to the voltage on the

rating plate.

Your Stanley tool is equipped with double

insulation, hence, it does not require to be

earthed.

When the power cord is damaged, have it sent to a Stanley

service center for replacement to specially prepared cables.

Using Extension Cords

If an extension cord is required, please select a 3-phase

extension cord that has been inspected and matches the

input power (see Technical Data) of this tool. The minimum

conductor size is 1.5mm2, maximum length is 30 meters.

When using a cable reel, be sure to pull out all the cables.

a. ON/OFF switch

b. Spindle lock

c. Guard

Purpose of Design

This angle grinder is designed especially for grinding.

Do not use sandpaper discs and grinding wheels other than

those with depressed center.

Do not use the tool in wet conditions or environments in the

presence of flammable liquids or gases.

This heavy-duty angle grinder is a professional power tool.

8

Assembly and Adjustment

Warning: To minimize the danger of serious

personal injury, please switch off the tool

power and disconnect all plugs before adjusting or

removing/installing any accessory. Before reassembling

the tool, press and release the trigger switch to make sure

the tool is already switched off.

Attaching and Removing the Wheel Guard

(Fig. 2)

Warning: To minimize the danger of serious personal

injury, please switch off the tool power and disconnect

all plugs before adjusting or removing/installing any

accessory. Before reassembling the tool, press and release

the trigger switch to make sure the tool is already switched

off.

Page 9

(Original instructions) ENGLISH

Attaching the Guard

1. Place the angle grinder on a work bench, groove facing

up.

2. Bring the flange of the guard (c) collar over the groove (i)

of the gear housing.

3. Turn the guard (c) counterclockwise by 150 degrees.

4. Make sure that the screws (k) are tightened.

Removing the Guard

1. Loosen the screws (k) on the guard collar.

2. Pull up the guard (c).

Warning: Do not operate the tool when the

safety guard is not in place.

Note: Refer to the grinding accessories chart at the end of

this section for accessories that can be used together with

this angle grinder.

Attaching and Removing Grinding Wheels

(Fig. 3, 4)

Warning: Do not use damaged grinding wheels.

1. Place the tool on a work bench, groove facing up.

2. Attach the inner flange (d) correctly on the output shaft

(e) (Fig. 3).

3. Place the grinding wheel (f) on the inner flange (d).

When attaching a grinding wheel with a raised center,

make sure that the raised center (g) faces the inner

flange (d).

4. Tighten the outer flange (h) until the output shaft (e) (Fig.

4). When attaching the grinding wheel, the ring on top of

the outer flange (h) must face the wheel.

5. Press the spindle lock (b) and prevent the spindle (e)

from rotating until it locks in place.

6. Use the pin spanner to tighten the outer flange (h).

Preparation Before Use

• Attach the safety guard and appropriate abrasive or

grinding wheels. Do not use abrasive or grinding wheels

that are overly worn.

• Make sure that the inner and outer flanges are attached

correctly.

• Make sure that the abrasive or grinding wheels are

rotating in the direction of the arrows on the accessories

and tool.

Operation (Fig. 5)

Instructions

Warning: Always observe the safety instructions

and applicable regulations.

Warning: To minimize the danger of serious

personal injury, please switch off the tool power

and disconnect all plugs before adjusting or

removing/installing any accessory. Before reassembling the

tool, press and release the trigger switch to make sure the

tool is already switched off.

Warning:

• Make sure all materials to be grinded are secured in

position.

• Apply slight pressure to the tool. Do not apply side

pressure to the abrasive disc.

• Avoid overloading. If the tool becomes hot, let it spin for

a few minutes with no load.

1. Be sure to hold the tool tightly with both hands (one hand

on housing, the other on side handle). Start the tool and

bring the grinding wheel on the workpiece.

9

Page 10

ENGLISH (Original instructions)

2. Keep the edge of the wheel tilted at angle from 15 to 30

degrees against the surface of the workpiece.

3. When using a new grinding wheel, do not operate the

wheel in the B direction, otherwise, it will cut into the

workpiece. When the edge of wheel has been rounded

off, you are free to operate the grinder in either the A or B

direction.

Starting and Stopping (Fig. 1)

Warning: Before using the tool, check whether

the handle is tightened securely. Check whether

the ON/OFF switch is working normally.

Before plugging in the tool to the power supply, check

whether the switch is in the OFF (o) position when pressing

the rear end of the switch.

To start the tool, press the rear end of the switch and slide it

forward. Then press the front end of the switch to lock it.

Press the rear end of the switch to stop the tool.

Warning: Do not switch the tool on or off while

under load conditions.

Proper Hand Position (Fig. 6)

Warning: To reduce the risk of serious personal

injury, ALWAYS use proper hand position as

shown.

Warning: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

sudden reaction.

Proper hand position requires one hand on the side handle

(figure 1), with the other hand on the body of the tool, as

shown in figure 6.

Switches

Caution: Hold the body of the tool firmly to

maintain control of the tool at start up and during

use and until the wheel or accessory stops

rotating. Make sure the wheel has come to a

complete stop be fore laying the tool down.

Note: To reduce unexpected tool movement, do not switch

the tool on or off while under load conditions. Allow the

grinder to run up to full speed before touching the work

surface. Lift the tool from the surface before turning the tool

off. Allow the tool to stop rotating before putting it down.

Slider switch (Fig. 1)

Warning: Before connecting the tool to a power supply, be

sure the slider switch is in the off position by pressing the

rear part of the switch and releasing. Ensure the slider

switch is in the off position as described above after any

interruption in power supply to the tool, such as the

activation of a ground fault interrupter, throwing of a circuit

breaker, accidental unplugging, or power failure. If the slider

switch is locked on when the power is connected, the tool

will start unexpectedly..

To start the tool, slide the slider switch (a) toward the front of

the tool. To stop the tool, release the slider switch.For

continuous operation, slide the switch toward the front of the

tool and press the forward part of the switch inward. To stop

the tool while operating in continuous mode, press the rear

part of the slider switch and release.

Spindle lock (Fig. 1)

The spindle lock (b) prevents the output shaft from rotating

when attaching or removing the grinding wheel. Only use the

spindle lock when the tool is switched off, power is

unplugged, and wheel stops completely.

Note: To minimize tool damages, don't use the

spindle lock when the tool is operating.

Otherwise, it may damage the tool. The attached

accessories may come off and cause injury.

If using the spindle lock, press the spindle lock button and

rotate the output shaft until it stops.

Application on Metals

When applying the tool on metals, make sure that a

residual-current device (RCD) is inserted to prevent danger

from metal chips.

If the RCD causes power disconnection, have the tool sent

to an authorized Stanley dealer for repair.

10

Page 11

(Original instructions) ENGLISH

Warning: Under extreme working conditions,

conductive dust and grit may accumulate on the

housing interior when handling metal workpieces.

This could create an electric shock hazard as it weakens the

protective insulation in the grinder.

To avoid accumulation of metal chips in the interior of the

grinder, we recommend cleaning the ventilation ducts daily.

Refer to Maintenance.

Using Grinding Wheels

Warning: Metal powder accumulates. Excessive

use of the grinding wheel on metals may

increase the risk of electric shock. To reduce the

risk, insert the RCD before use and clean the ventilation

ducts daily. Follow the maintenance instructions below to

blow dry compressed air into the ventilation ducts.

Maintenance

Stanley power tools have been designed to operate over a

long period of time with minimal maintenance. Continuous

satisfactory operation depends upon proper tool care and

regular cleaning.

Warning: To minimize the danger of serious

personal injury, please switch off the tool

power and disconnect all plugs before

adjusting or removing/installing any accessory. Before

reassembling the tool, press and release the trigger switch

to make sure the tool is already switched off.

Lubrication

approved eye and facial protective gear when performing

this process.

Warning: Never use solvents or harsh chemicals

to clean non-metal parts of the material of the

parts. Use only mild soap and damp cloth to

clean the tool. Never let any liquid get inside the tool; never

immerse any part of the tool into liquid.

Accessories

Warning: Excluding accessories provided by

Stanley, all other accessories have not been

tested for product compatibility. Using such accessories

together with this tool may cause safety hazards. To

minimize the risk of personal injury, we recommend you to

use only Stanley accessories with this product.

Please inquire at your dealer for more information regarding

suitable accessories.

Technical Data

STGS9115 STGS9125

Input voltage V

Power input W 900 900

Frequency Hz 50/60 50/60

No-load speed min

Wheel diameter mm 115 125

Spindle size M14 M14

Max grinding

disc thickness

Type of wheel 27 27

Weight kg 2.2 2.3

AC

-1

mm 6 6

220-240 220-240

11000 11000

This power tool does not require separate lubrication.

Cleaning

Warning: Once visible dust accumulates on the

ventilation ducts and the surrounding,

immediately use dry air to blow away dust and

grit out of the interior of the housing. You need to wear

Level of sound pressure according to EN 60745:

Sound pressure (LpA) 88.5 dB(A), uncertainty (K) 3 dB(A)

Sound power (LWA) 99.5 dB(A), uncertainty (K) 3 dB(A)

Vibration emission value ah:

ah,AG = m/s² 8.2

Uncertainty K = m/s² 1.5

11

Page 12

ENGLISH (Original instructions)

Vibration

The vibration emission level given in this information sheet

has been measured in accordance with a standardised test

given in EN 60745 and may be used to compare one tool

with another. It may be used for a preliminary assessment of

exposure.

Warning: The declared vibration emission level

represents the main applications of the tool.

However if the tool is used for different

applications, with different accessories or poorly maintained,

the vibration emission may differ. This may significantly

increase the 1.5exposure level over the total working period.

An estimation of the level of exposure to vibration should

also take into account the times when the tool is switched

off or when it is running but not actually doing the job. This

may significantly reduce the exposure level over the total

working period.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and

the accessories, keep the hands warm, organisation of work

patterns.

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Stanley product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Stanley provides a facility for the collection and recycling of

Stanley products once they have reached the end of their

working life. To take advantage of this service please return

your product to any authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Stanley office at the address

indicated in this manual. Alternatively, a list of authorised

Stanley repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com

12

Page 13

(Original instructions) ENGLISH

EC declaration of conformity

MACHINERY DIRECTIVE

STGS9115-STGS9125 Angle Grinder

STANLEY declares that these products described under

"technical data" are in compliance with:

EN 60745-1:2009+A11:2010,

EN 60745-2-3:2011+A12:2014

These products also comply with Directive

2004/108/EC (until 19/04/2016) 2014/30/EU (from

20/04/2016) and 2011/65/EU. For more information, please

contact STANLEY at the following address or refer to the

back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

STANLEY.

R.Laverick

Engineering Manager

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2016

TWO YEAR WARRANTY

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY guarantees to replace all defective

parts free of charge or – at our discretion – replace the unit

free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual;

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorized

persons;

• Proof of purchase is produced;

• The STANLEY product is returned complete with all

original components;

• The product hasn’t been used for hire purposes.

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet at:

www.2helpU.com

13

Page 14

Русский язык (Перевод с оригинала инструкции)

Область застосування

Ваша кутова шліфувальна машина STANLEY

STGS9115-STGS9125 була розроблена для робіт по різу /

шліфуванню металу з використанням рекомендованого типу

диска. Інструмент призначений для професійого викомалтання.

Определения: Правила техники

безопасности

Приведенные ниже определения описывают уровень

важности каждого сигнального слова. Пожалуйста,

прочтите инструкцию и обратите внимание на эти

символы.

Опасность: Указывает на потенциально

опасную ситуацию, которая, если ее не

избежать, приведет к смерти или серьезным

травмам.

Предупреждение: Указывает на

потенциально опасную ситуацию, которая,

если ее не избежать, могла бы привести к

смерти или серьезным травмам.

Предостережение: Указывает на

потенциально опасную ситуацию, которая,

если ее не избежать, может привести к легкой

или средней травме.

Примечание: Указывает на ситуацию, не связанную с

производственной травмой, которая, если ее не

предотвратить, может привести к материальному

ущербу.

Обозначает опасность поражения

электрическим током.

Обозначает опасность возгорания.

Предупреждение: Чтобы уменьшить риск

получения травмы, ознакомьтесь с

инструкциями по эксплуатации.

Общие предупреждения по технике

безопасности электроинструментов

Внимание! Ознакомьтесь со всеми правилами

безопасности и инструкциями. Несоблюдение

предупреждений и инструкций, указанных ниже, может

привести к поражению электрическим током, пожару

и/или серьезной травме.

Сохраните все предупреждения и инструкции для

будущего использования.

Термин "электроинструмент" во всех предупреждениях,

указанных ниже, относится к вашему сетевому (с

кабелем) электроинструменту или аккумуляторному

электроинструменту (без кабеля питания).

1. Безопасность рабочего места

а. Содержите рабочее место в чистоте и хорошо

освещенным. Беспорядок на рабочем месте или

отсутствие освещения рабочего места может

привести к аварии.

b. Не работайте с электроинструментом в месте

хранения взрывоопасных материалов, например,

в присутствии огнеопасных жидкостей, газов или

пыли. Электрические инструменты создают искры,

которые могут воспламенить пыль или пары.

с. Дети и посторонние лица должны находиться как

можно дальше во время работы с

электроинструментом. Вы можете отвлечься и

потерять контроль.

2. Электробезопасность

а. Вилка электроинструмента должна

соответствовать розетке. Никогда не

модифицируйте вилку каким-либо образом. Не

используйте никакие вилки-переходники с

заземленными (замкнутыми на землю)

электроинструментами. Вилки и розетки, которые

не подвергались никаким изменениям снижают риск

поражения электрическим током.

b. Избегайте контакта тела с заземленными

поверхностями, такими как трубы, радиаторы,

плиты и холодильники. Существует повышенный

риск поражения электрическим током, если ваше

тело заземлено.

с. Избегайте любого воздействия дождя или влаги

на электроинструменты. Вода, попавшая в

электроинструмент, увеличивает риск поражения

электрическим током.

d. Аккуратно обращайтесь со шнуром питания.

Никогда не используйте шнур питания для

переноски, перемещения или извлечения вилки

из розетки. Держите шнур вдали от источников

тепла, масла, острых краев или движущихся частей.

Поврежденные или запутанные шнуры увеличивают

риск поражения электрическим током.

14

Page 15

Русский язык (Перевод с оригинала инструкции)

е. При работе с электроинструментом на улице,

используйте удлинитель, подходящий для

наружного использования. Использование кабеля,

пригодного для использования на открытом воздухе,

снижает риск поражения электрическим током.

f. При необходимости работы с

электроинструментом во влажной среде,

используйте устройство защитного отключения

(УЗО). Использование УЗО снижает риск поражения

электрическим током.

3. Личная безопасность

a. Будьте внимательны, смотрите, что вы делаете,

используйте здравый смысл при работе с

электроинструментом. Не используйте

электроинструмент, если вы устали или находитесь

под влиянием наркотиков, алкоголя или лекарств.

Малейшая неосторожность при работе с

электроинструментом может привести к серьезным

травмам.

b. Используйте средства индивидуальной защиты.

Всегда надевайте защитные очки. Другое

защитное оборудование, включая респиратор,

ботинки на нескользящей подошве, защитный

шлем или средства защиты органов слуха,

используемые в надлежащих условиях, уменьшат

риск получения травмы.

с. Для предотвращения случайного запуска,

убедитесь, что переключатель находится в

выключенном положении перед подключением к

источнику питания и/или аккумуляторной

батарее, поднятия или переноски инструмента.

Не переносите электроинструмент с пальцем на

выключателе и не включайте питание на инструмент

с включенным выключателем, что может привести к

несчастному случаю.

d. Перед включением электроинструмента

снимайте регулировочный или гаечный ключ.

Гаечный или регулировочный ключ, оставленный на

вращающейся части электроинструмента, может

привести к травме.

е. Не тянитесь. Сохраняйте правильную стойку и

баланс все время. Это позволяет лучше

контролировать инструмент в неожиданных

ситуациях.

f. Одевайтесь правильно. Не надевайте свободную

одежду или украшения. Держите волосы, одежду

и перчатки вдали от движущихся частей.

Свободная одежда, украшения или длинные волосы

могут попасть в движущиеся части.

g. Если имеются устройства для подключения

пылесборника или вытяжки, убедитесь в том, что

они подсоединены и используются правильно.

Использование пылесборника снижает вероятность

возникновения рисков, связанных с пылью.

4. Использование и уход за электроинструментом

a. Не перегружайте электроинструмент.

Используйте подходящий электрический

инструмент для соответствующего применения.

Правильно подобранный электроинструмент

позволит выполнить работу лучше и безопаснее при

скорости, для которой он был разработан.

b. Не используйте электроинструмент, если

переключатель не может его включить и

выключить. Любой электроинструмент, который

нельзя контролировать с помощью переключателя,

опасен и должен быть отремонтирован.

c. Отключите кабель питания от источника питания

и/или аккумуляторный блок от электрического

инструмента перед выполнением любых

регулировок, замены принадлежностей или при

хранении электроинструмента. Такие

профилактические меры безопасности уменьшают

риск непреднамеренного запуска электрического

инструмента.

d. Храните неиспользуемые электроинструменты в

недоступном для детей месте и не позволяйте

лицам, не знакомым с электроинструментом или

данными инструкциями, работать с

электроинструментом. Электроинструменты опасны

в руках неопытных пользователей.

е. Поддержание электроинструмента. Проверяйте

разрегулированность или cоединение

подвижных частей, поломки частей и любые

другие условия, которые могут повлиять на

работу электроинструмента. При наличии

повреждения, отремонтируйте

электроинструмент перед использованием.

Многие несчастные случаи являются следствием

плохого ухода за электроинструментом.

15

Page 16

Русский язык (Перевод с оригинала инструкции)

f. Держите режущий инструмент острым и чистым.

Хорошо ухоженный режущий инструмент с острыми

режущими кромками легче контролировать.

g. Используйте электроинструмент, аксессуары и

насадки в соответствии с данными

инструкциями, принимая внимание условия

работы и те работы, которые должны быть

выполнены. Использование электроинструмента

для операций, отличающихся от тех, для которых он

предназначен, может привести к опасной ситуации.

5. Обслуживание

а. Обеспечьте, чтобы обслуживание и ремонт

вашего электроинструмента проводился в

авторизованном сервисном центре по ремонту с

использованием только оригинальных запасных

частей. Это станет гарантией безопасности

электроинструмента.

Дополнительные указания по конкретным

правилам безопасной работы

Правила техники безопасности для всех операций

Общие меры предосторожности для шлифования

а. Данный электроинструмент предназначен для

работы в качестве шлифовального станка.

Ознакомьтесь со всеми мерами

предосторожности, инструкциями,

иллюстрациями и спецификациями,

поставляемыми с инструментом. Несоблюдение

всех инструкций, указанных ниже, может привести к

поражению электрическим током, пожару и/или

серьезной травме.

b. Такие операции, как резание, пескоструйная

очистка, чистка проволочной щеткой или

полировка не рекомендуется выполнять с

помощью этого электроинструмента. Операции,

для которых электроинструмент не предназначен,

могут создать опасность и причинить травму.

c. Не используйте принадлежности, которые не

были специально разработаны и

рекомендованы изготовителем инструмента. Тот

факт, что аксессуар может быть подключен к

электроинструменту, не гарантируют безопасную

работу.

d. Номинальная частота вращения аксессуара

должны быть по меньшей мере равна

максимальной скорости, обозначенной на

инструменте. Аксессуары работающие быстрее, чем

их номинальная скорость, могут сломаться и

разлететься.

e. Наружный диаметр и толщина аксессуара должна

быть в пределах номинальных мощностей

вашего инструмента. Аксессуар неправильного

размера не может быть адекватно защищен или

контролироваться.

f) Резьбовый крепеж аксессуаров должен

соответствовать резьбе шпинделя

шлифовального станка. Для аксессуаров,

монтируемых при помощи фланцев, отверстие

шпинделя аксессуара должно соответствовать

местоположению диаметра фланца. Из-за

аксессуаров, которые не соответствуют монтажному

оборудованию электроинструмента, можно потерять

равновесие, испытать чрезмерную вибрацию или

потерять управление.

g. Не используйте поврежденные принадлежности.

Перед каждым применением проверяйте

вспомогательное оборудование - абразивный

круг на наличие сколов и трещин, шлифовальный

диск на наличие трещин, повреждения или

чрезмерный износ, болтающиеся или

поврежденные провода. Если электроинструмент

или аксессуар упал, проверьте его на наличие

повреждений или установите неповрежденный

аксессуар. После проверки и установки аксессуара,

встаньте вдали от плоскости вращения аксессуара и

запустите электроинструмент на максимальной

скорости без нагрузки в течение одной минуты.

Поврежденные аксессуары, как правило,

распадаются в течение этого времени испытаний.

h. Наденьте средства индивидуальной защиты. В

зависимости от применения, используйте

защитную маску, или защитные очки. В случае

необходимости, наденьте защитную маску,

используйте средства для защиты слуха,

перчатки и рабочий фартук, способные

остановить мелкие абразивы или фрагмены

деталей. Средства защиты глаз должны быть

способны остановить летящий мусор во время

различных операций. Маска или респиратор должны

быть способны фильтровать частицы, образуемые во

время вашей работы. Длительное воздействие шума

высокой интенсивности может привести к потере

слуха.

i. Держите людей на безопасном расстоянии от

места работы. Любой человек, входящий в

рабочую зону, должен быть одет в средства

индивидуальной защиты. Фрагменты деталей или

разбитый аксессуар может улететь и причинить

травму за пределами непосредственной близости от

места работы.

16

Page 17

Русский язык (Перевод с оригинала инструкции)

j. Во время работы держите электроинструмент

только за изолированные части, во время

работы режущий инструмент может задеть

скрытую проводку или собственный кабель.

Режущий аксессуар при контакте с проводом под

наряжением может стать причиной удара

электрическим током.

k. Расположите шнур вдали от вращающегося

аксессуара. Если вы теряете контроль, шнур может

быть разрезан или зацеплен, и ваша рука или руки

могут быть втянуты в вращающийся аксессуар.

l. Никогда не кладите электроинструмент, пока

аксессуар полностью не остановился.

Вращающийся инструмент может захватить

поверхность, и электроинструмент выйдет из под

вашего контроля.

m. Не запускайте электроинструмент во время его

переноски. Случайный контакт с вращающимся

аксессуаром может затянуть вашу одежду и

поранить ваше тело.

n. Регулярно очищайте вентиляционные прорези

электроинструмента. Вентилятор двигателя будет

выдувать пыль внутри корпуса и предотвращать от

чрезмерного накопления металлических порошков,

которые могут вызвать поражение электрическим

током.

o. Не используйте электроинструмент вблизи

легковоспламеняющихся материалов. Искры

могут воспламенить эти материалы.

p. Не используйте аксессуары, которые требуют

охлаждающих жидкостей. Использование воды или

других охлаждающих жидкостей может привести к

поражению электротоком.

Дальнейшие инструкции по технике

безопасности для всех операций

Отдача и связанные с ней предупреждения

Отдача является внезапной реакцией на защемление

или зацепление вращающегося круга, шлифовального

диска или любого другого аксессуара. Сжатие или

зацепление вызывает быстрый срыв вращающегося

аксессуара, который в свою очередь поворачивает

неконтролируемый электроинструмент в направлении,

противоположном направлению вращения аксессуара в

точке привязки. Например, если абразивный круг

зацепил или защемил заготовку, край круга, который

попадает в точку защемления может вбуриваться в

поверхность материала, в результате чего круг

выбирается из защемления. Круг может выскочить либо

к или от оператора, в зависимости от направления

вращения круга в точке защемления. Абразивные круги

могут также ломаться в этих условиях. Отдача является

результатом неправильного использования инструмента

и/или неправильных действий оператора и условий,

которых можно избежать путем принятия надлежащих

мер предосторожности, как указано ниже:

a. Крепко держите электроинструмент. Положение

вашего тела и рук должно позволить вам

противостоять воздействию отдачи. Всегда

используйте вспомогательную рукоятку, если это

предусмотрено, для максимального контроля над

отдачей или реактивным крутящим моментом во

время запуска. Оператор может управлять

реактивным крутящим моментом или отдачей, если

приняты соответствующие меры предосторожности.

b. Никогда не помещайте руки вблизи

вращающегося аксессуара. Аксессуар может дать

отдачу по вашей руке.

c. Не стойте там, где будет двигаться

электроинструмент если произойдет случай

отдачи. Отдача будет двигать инструмент в

направлении, противоположном движению кругов в

точке зацепления.

d. Используйте особую осторожность при

обработке углов, острых кромок и т.д. Избегайте

отскока и зацепления аксессуара. Углы, острые

края или отскоки, как правило, могути привести к

потере управления над вращающимся аксессуаром

или к отдаче.

е. Не подключайте лезвие пильной цепи для

резьбы по дереву или зубчатые пилы. Такие

лезвия создают частую отдачу и потерю контроля.

Предупреждения по технике

безопасности, специфичные для

операций шлифования

a) Используйте только те типы кругов, которые

рекомендованы для вашего электроинструмента

и конкретного кожуха, предназначенного для

выбранного круга. Круги, не предназначенные для

данного электроинструмента, использовать

небезопасно.

b) Кожух должен быть надежно прикреплен к

электроинструменту и расположен с учетом

максимальной безопасности, так, чтобы как

можно меньшая часть круга была открыта для

оператора. Кожух помогает защитить оператора от

сломанных фрагментов круга и случайного контакта с

кругом, а также искр, которые могут воспламенить

одежду.

17

Page 18

Русский язык (Перевод с оригинала инструкции)

c) Круги должны быть использованы только для

рекомендованных приложений. Например: не

шлифовать боковой частью отрезного круга.

Абразивные отрезные круги предназначены для

периферийного шлифования, боковая сила,

применяемая к этим кругам может привести к их

разрушению.

d) Всегда используйте неповрежденные круговые

фланцы, которые имеют правильный размер и

форму для выбранного круга. Собственные

круговые фланцы поддерживают круг, таким

образом, уменьшая возможность поломки круга.

Фланцы для отрезных кругов могут отличаться от

фланцев для шлифовальных кругов.

e) Не используйте изношенные круги от более

крупных электроинструментов. Круги

предназначенные для электроинструмента большего

размера не подходят для более высокой скорости

меньшего инструмента и могут лопнуть.

f) Поверхность шлифования круга с утопленным

центром должна быть установлена ниже края

кожуха. Неправильно установленный круг, который

проецируется по плоскости края кожуха, не может

быть защищен надлежащим образом.

Остаточные риски

Несмотря на соблюдение соответствующих правил

техники безопасности и использование защитных

устройств, некоторые остаточные риски невозможно

избежать,

а именно:

– Плохой слух

– Риск получения травмы от летящих частиц

– Риск получения ожогов из-за того, что аксессуары во

время эксплуатации становятся горячими

– Риск получения травмы из-за длительного

использования.

– Риск пыли от опасных веществ.

Этикетки на инструменте

Наравне с кодом даты на инструменте могут

находиться следующие знаки:

Читайте

инструкции по

эксплуатации

Используйте

средства

защиты глаз

Используйте

средства

защиты

органов слуха

В ........ Вольт

A ........ Ампер

Гц ....... Герц

Вт ........ Ватт

мин...... минуты

Перемен-

.....

ный ток

Постоян-

.....

ный ток

Скорость

n

.......

0

без нагрузки

Конструкция

......

класса II

Терминал

....

заземления

Символ

предупреж-

....

дения об

опасности

обороты или

...мин..

возвратнопоступательное движение

в минуту

Положение даты штрих-кода

Дата кода, который также включает год изготовления,

печатается на корпусе.

Пример:

2014 XX JN

Год изготовления

Содержание упаковки

Данная упаковка включает в себя:

1 Угловую шлифовальную машину

1 Кожух

1 Набор фланцев

1 Гаечный ключ

1 Ручку

1 Руководство по эксплуатации

• Проверьте инструмент, запчасти и аксессуары,

чтобы понять не были ли они повреждены во время

транспортировки.

• Потратьте несколько минут, чтобы ознакомиться и

понять данную инструкцию перед использованием

инструмента.

Описание (рис. 1)

Предупреждение: Никогда не производите

никаких модификаций электроинструмента

это может привести к повреждению инструмента или

травме.

a) Переключатель ВКЛ./ВЫКЛ.

b) Блокировка шпинделя

c) Кожух

Цель дизайна

Данная угловая шлифовальная машина разработана

специально для шлифования.

Не используйте круги с наждачной бумагой и

шлифовальные круги кроме тех, которые имеют

утопленный центр.

Не используйте инструмент во влажных условиях или

условиях, где присутствуют легковоспламеняющиеся

жидкости или газы.

или какой-либо его части, в противном случае

18

Page 19

Русский язык (Перевод с оригинала инструкции)

Данная угловая шлифовальная машина для тяжелых

условий эксплуатации является профессиональным

электроинструментом.

Не допускайте детей к данному электроинструменту.

Неопытные операторы обязаны использовать этот

инструмент под наблюдением профессионалов.

Отключение при падении напряжения

Данная функция отключит шлифмашину без

последующего запуска при исчезновении или сильном

понижении напряжения.

Безопасность электротехнического

оборудования

Для данного инструмента применяется только одно

напряжение. Убедитесь, что электропитание

соответствует напряжению, указанному на заводской

табличке.

Ваш инструмент Stanley оснащен двойной

изоляцией, следовательно, не требует

заземления.

Если шнур питания поврежден, отправьте его в

сервисный центр Stanley для замены специально

подготовленных кабелей.

Использование удлинителей

Если требуется удлинитель, выберите 3-фазный

удлинитель, который был проверен и соответствует

входной мощности (см. Технические данные) этого

инструмента. Минимальный размер проводника

составляет 1,5 мм2, максимальная длина составляет 30

метров.

При использовании кабельного барабана, убедитесь,

что вы вытянули все кабели.

Монтаж и наладка

Предупреждение: Чтобы свести к

минимуму опасность получения

выключите питание инструмента и отсоедините все

вилки перед регулировкой или снятием/установкой

любого аксессуара. Перед сборкой инструмента

нажмите и отпустите курковый выключатель, чтобы

убедиться, что инструмент уже выключен.

серьезной травмы, пожалуйста,

Установка и снятие защитного кожуха

(рис. 2)

Предупреждение: Чтобы свести к минимуму

опасность получения серьезной травмы,

пожалуйста, выключите питание инструмента и

отсоедините все вилки перед регулировкой или

снятием/установкой любого аксессуара. Перед

сборкой инструмента нажмите и отпустите курковый

выключатель, чтобы убедиться, что инструмент уже

выключен.

Установка кожуха

1. Установите угловую шлифовальную машину на

рабочий стол пазом вверх.

2. Установите фланец воротника кожуха (с) через паз (i)

корпуса зубчатой передачи.

3. Поверните кожух (с) против часовой стрелки на 150

градусов.

4. Убедитесь, что винты (k) затянуты.

Снятие кожуха

1. Ослабьте винты (k) на вороте кожуха.

2. Поднимите кожух (с).

Предупреждение: Не используйте

инструмент, если защитный кожух не

находится на месте.

Примечание: Ознакомьтесь со шлифовальными

аксессуарами в конце этого раздела для аксессуаров,

которые могут быть использованы вместе с данной

угловой шлифовальной машиной.

Установка и снятие шлифовальных

кругов (рис. 3, 4)

Предупреждение: Не используйте

поврежденные шлифовальные круги.

1. Установите инструмент на рабочий стол пазом вверх.

2. Установите внутренний фланец (d) правильно на

выходном валу (е) (рис. 3).

3. Установите шлифовальный круг (f) на внутренний

фланец (d). При установке шлифовального круга с

приподнятым центром, убедитесь, что приподнятый

центр (g) смотрит на внутренний фланец (d).

4. Затяните внешний фланец (h) до выходного вала (е)

(рис. 4). При установке шлифовального круга, кольцо

поверх внешнего фланца (h) должно смотреть на

круг.

5. Нажмите на блокировку шпинделя (b) и

предотвратите шпиндель (е) от вращения пока он не

зафиксируется в нужном месте.

6. Используйте гаечный ключ, чтобы затянуть внешний

фланец (h).

19

Page 20

Русский язык (Перевод с оригинала инструкции)

Подготовка к использованию

• Прикрепите безопасний кожух и соответствующие

абразивные или шлифовальные круги. Не

используйте чрезмерно изношенные абразивные

или шлифовальные круги.

• Убедитесь в том, что внутренние и внешние фланцы

закреплены правильно.

• Убедитесь, что абразивные или шлифовальные

круги вращаются в направлении стрелок, указанных

на аксессуарах и инструменте.

Операция (рис. 5)

Инструкции

Предупреждение: Всегда соблюдайте

инструкции по технике безопасности и другие

правила.

Предупреждение: Чтобы свести к минимуму

опасность получения серьезной травмы,

пожалуйста, выключите питание инструмента

и отсоедините все вилки перед регулировкой или

снятием/установкой любого аксессуара. Перед сборкой

инструмента нажмите и отпустите курковый

выключатель, чтобы убедиться, что инструмент уже

выключен.

Предупреждение:

• Убедитесь, что все шлифуемые материалы

закреплены в правильном положении.

• Немного надавите на инструмент. Не применяйте

боковое надавливание на абразивный круг.

• Избегайте перегрузки. Если инструмент нагревается,

дайте ему повращаться в течение нескольких минут

без нагрузки.

1. Убедитесь, что держите инструмент плотно обеими

руками (одной рукой за корпус, другий за боковую

ручку). Запустите инструмент и проведите

шлифовальным кругом по заготовке.

2. Держите край колеса под углом от 15 до 30 градусов

по отношению к поверхности обрабатываемой

детали.

3. При использовании нового шлифовального круга,

20

круг не должен работать в направлении B, в

противном случае, он может разрезать заготовку.

Когда край круга был закруглен, вы можете

использовать шлифовальный станок как в

направлении А, так и в направлении В.

Запуск и остановка (рис. 1)

Предупреждение: Перед использованием

инструмента, проверьте, чтобы ручка была

надежно затянута. Убедитесь, что

переключатель ВКЛ./ВЫКЛ. работает нормально.

Перед включением инструмента в источник питания,

убедитесь в том, что переключатель находится в

положении ВЫКЛ. (о) при нажатии на заднюю часть

переключателя.

Для запуска инструмента, нажмите на заднюю часть

выключателя и сдвиньте его вперед. Затем нажмите на

переднюю часть выключателя, чтобы зафиксировать ее.

Нажмите на заднюю часть переключателя, чтобы

выключить инструмент.

Предупреждение: Не включайте и не

выключайте инструмент, когда он находится

под нагрузкой.

Правильное положение рук (рис. 6)

Предупреждение: Чтобы уменьшить риск

получения серьезной травмы,va ВСЕГДА

используйте правильное положение рук, как показано на

рисунке.

Предупреждение: Чтобы уменьшить риск

получения серьезной травмы, ВСЕГДА крепко

держите инструмент в ожидании возможной внезапной

реакции.

Правильное положение рук во время работы требует,

чтобы одна рука была на боковой рукоятке (рис 1), тогда

как другая на корпусе инструмента, как показано на

рисунке 6.

Выключатели

Предостережение: Крепко держите корпус

инструмента, сохраняя контроль над

инструментом при запуске и во время использования до

тех пор, пока круг или другой аксессуар не перестает

вращаться. Убедитесь, что круг полностью остановился,

прежде чем положить инструмент.

Page 21

Русский язык (Перевод с оригинала инструкции)

Примечание: Для уменьшения неожиданного движения

инструмента, не включайте и не выключайте инструмент

пока он находится под нагрузкой. Дайте

шлифовальному станку поработать на полную

мощность, прежде чем прикоснуться им к рабочей

поверхности. Поднимите инструмент от поверхности,

прежде чем выключить его. Дайте инструменту

остановиться прежде чем положить его.

Скользящий переключатель (рис. 1)

Предупреждение: Перед подключением инструмента к

источнику питания, убедитесь, что ползунок

переключателя находится в выключенном положении,

нажав на заднюю часть переключателя и освободив его.

Убедитесь, что скользящий переключатель находится в

выключенном положении, как описано выше, после

любого перерыва в подаче электропитания на

инструмент, например, активации прерывателя

замыкания на землю, автоматического выключения,

случайного отключения или сбоя питания. Если

положение переключателя заблокировано, когда

подключено питание, инструмент может включиться

неожиданно.

Для запуска инструмента сдвиньте скользящий

переключатель (а) в направлении передней части

инструмента. Для остановки инструмента, отпустите

ползунок переключателя. Для непрерывной работы,

переведите переключатель в сторону передней части

инструмента и нажмите на переднюю часть

выключателя внутрь. Для остановки инструмента при

работе в непрерывном режиме, нажмите на заднюю

часть скользящего переключателя и отпустите его.

Блокировка шпинделя (рис. 1)

Блокировка шпинделя (b) предотвращает выходной вал

от вращения при установке или удалении

шлифовального круга. Используйте только блокировку

шпинделя, когда инструмент выключен, питание

отключено, и круг полностью остановлен.

Примечание: Для уменьшения повреждений

инструмента, не используйте блокировку

шпинделя, когда инструмент работает. В

противном случае, это может привести к повреждению

инструмента. Прилагаемые аксессуары могут

оторваться и нанести травму.

При использовании блокировки шпинделя, нажмите

кнопку блокировки шпинделя и прокрутите выходной вал

до упора.

Применение по металлам

При применении инструмента на металлах, убедитесь,

что устройство защитного отключения (УЗО) встроено

для предотвращения опасности повреждения

металлической стружкой.

Если УЗО вызывает отключение питания, отправьте

инструмент для проверки и ремонта в авторизованный

центр Stanley.

Предупреждение: При экстремальных

условиях работы, токопроводящая пыль и

песок могут накапливаться внутри корпуса

при работе с металлическими деталями. Это может

создать опасность поражения электрическим током, так

как ослабляет защитную изоляцию шлифовального

станка.

Чтобы избежать накопления металлической стружки

внутри корпуса шлифовального станка, мы рекомендуем

ежедневно очищать вентиляционные каналы.

Ознакомьтесь с руководством по техническому

обслуживанию.

Использование шлифовальных кругов

Предупреждение: Металлический порошок

накапливается. Чрезмерное использование

шлифовального круга по металлу может

увеличить риск поражения электрическим током. Чтобы

уменьшить риск, вставьте УЗО перед использованием и

очищайте вентиляционные каналы ежедневно. Следуйте

инструкциям по техническому обслуживанию для чистки

вентиляционных каналов сухим сжатым воздухом.

Обслуживание

Электроинструменты Stanley были разработаны для

работы в течение длительного периода времени с

минимальным обслуживанием. Срок службы и

надежность обеспечиваются правильным уходом и

регулярной чисткой.

Предупреждение: Чтобы свести к

минимуму опасность получения

серьезной травмы, пожалуйста,

выключите питание инструмента и отсоедините все

пробки перед регулировкой или снятием/установкой

любого аксессуара. Перед сборкой инструмента

нажмите и отпустите курковый выключатель, чтобы

убедиться, что инструмент уже выключен.

21

Page 22

Русский язык (Перевод с оригинала инструкции)

Смазка

Этот электроинструмент не требует отдельной смазки.

Чистка

Предупреждение: Если вы можете видеть

осевшую пыль на вентиляционных каналах и

внутри корпуса, сразу же используйте сухой

воздух, чтобы сдуть пыль и песок из внутренней части

корпуса. Используйте средства защиты глаз и лица при

выполнении этого процесса.

Предупреждение: Никогда не используйте

растворители или агрессивные химические средства для

очистки неметаллических частей. Используйте только

мягкое мыло и влажную ткань, чтобы очистить

инструмент. Никогда не допускайте попадания жидкости

внутрь инструмента и никогда не погружайте любую

часть инструмента в жидкость.

Аксессуары

Предупреждение: За исключением

аксессуаров, поставляемых Stanley, все

другие аксессуары не были проверены на

совместимость с продуктом. Использование таких

аксессуаров с данным инструментом может привести к

опасной ситуации. Чтобы свести к минимуму риск

получения травмы, мы рекомендуем использовать

только аксессуары Stanley с этим продуктом.

Пожалуйста, получите дополнительную информацию о

подходящих аксессуарах у своего дилера.

Защита окружающей среды

Раздельный сбор и утилизация. Этот продукт

не следует утилизировать вместе с бытовым

мусором.

Если вы поймете, что ваш продукт Stanley нуждается в

замене, или если он не имеет никакого дальнейшего

применения для вас, не выбрасывайте его вместе с

бытовыми отходами. Предоставьте этот продукт для

раздельного сбора/утилизации.

Раздельный сбор продуктов и упаковок

позволяет осуществить их переработку и

использовать их повторно. Повторное

использование переработанных материалов помогает

защищать окружающую среду от загрязнения и снижает

расход сырьевых материалов.

Местное законодательство может обеспечить сбор

старых электроинструментов отдельно от бытового

мусора на муниципальных свалках отходов или в

торговом предприятии при покупке нового изделия.

Stanley обеспечивает возможность для сбора и

утилизации продуктов Stanley, как только они достигли

конца своего срока службы. Для того чтобы

воспользоваться этой услугой, вы можете сдать ваше

изделие в любой авторизованный сервисный центр,

который собирает их по нашему поручению.

Вы можете узнать место нахождения вашего

ближайшего авторизованного сервисного центра,

обратившись в местное отделение Stanley по адресу,

указанному в данном руководстве. Кроме того, список

авторизованных ремонтных агентов Stanley и полную

информацию о нашем послепродажном обслуживании и

контактах вы можете найти в Интернете:

www.2helpU.com

Технические характеристики

STGS9115 STGS9125

перем. тока

Напряжение питания В

Потребляемая мощность Вт 900 900

Частота тока Гц 50/60 50/60

Число оборотов без

нагрузки

Диаметр круга мм 115 125

Диаметр шпинделя M14 M14

Толщина

шлифовального круг

Тип круг 27 27

Вес кг 2.2 2.3

об/мин 11000 11000

22

220-240 220-240

мм 6 6

Page 23

Гарантийные условия

Уважаемый покупатель!

1. Поздравляем Вас с покупкой высококачественного

изделия STANLEY и выражаем признательность за Ваш

выбор.

2. При покупке изделия требуйте проверки его комплектности

и исправности в Вашем присутствии, инструкцию по

эксплуатации и заполненный гарантийный талон на

русском языке.

В гарантийном талоне должны быть внесены: модель,

дата продажи, серийный номер, дата производства

инструмента; название, печать и подпись торговой

организации. При отсутствии у Вас правильно заполненного гарантийного талона, а также несоответствия

указанных в нем данных мы будем вынуждены откло- нить

Ваши претензии по качеству данного изделия.

3. Во избежание недоразумений убедительно просим Вас

перед началом работы с изделием внимательно

ознакомиться с инструкцией по его эксплуатации.

Правовой основой настоящих гарантийных условий

является действующее Законодательство. Гарантийный

срок на данное изделие составляет 24 месяца и

исчисляется со дня продажи. В случае устранения

недостатков изделия, гарантийный срок продлевается на

период его нахождения в ремонте. Срок службы изделия

составляет 5 лет со дня продажи.

4. В случае возникновения каких-либо проблем в про- цессе

эксплуатации изделия рекомендуем Вам обра- щаться

только в уполномоченные сервисные центры STANLEY,

адреса и телефоны которых Вы сможете найти в

гарантийном талоне, на сайте www.2helpU.com или узнать

в магазине. Наши сервисные станции - это не только

квалифицированный ремонт, но и широкий ассортимент

запчастей и принадлежностей.

5. Производитель рекомендует проводить периодическую

проверку и техническое обслуживание изделия в

уполномоченных сервисных центрах.

Изготовитель

Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

Русский язык (Перевод с оригинала инструкции)

6. Наши гарантийные обязательства распространяются

только на неисправности, выявленные в течение гарантийного срока и вызванные дефектами производства и \

или материалов.

7. Гарантийные условия не распространяются на

неисправности изделия, возникшие в результате:

7.1. Несоблюдения пользователем предписаний инструкции по

эксплуатации изделия, применения изделия не по

назначению, неправильном хранении, использования

принадлежностей, расходных материалов и запчастей, не

предусмотренных производителем.

7.2. Механического повреждения (сколы, трещины и разрушения) внутренних и внешних деталей изделия,

основных и вспомогательных рукояток, сетевого электрического кабеля, вызванного внешним ударным или

любым иным воздействием

7.3 Попадания в вентиляционные отверстия и проникновение внутрь изделия посторонних предметов,

материалов или веществ, не являющихся отходами,

сопровождающими применение изделия по назначению,

такими как: стружка, опилки, песок, и пр.

7.4. Воздействий на изделие неблагоприятных атмосферных и

иных внешних факторов, таких как дождь, снег,

повышенная влажность, нагрев, агрессивные среды,

несоответствие параметров питающей электросети,

указанных на инструменте.

7.5. Стихийного бедствия. Повреждение или утрата изделия,

связанное с непредвиденными бедствиями, стихийными

явлениями, в том числе вследствие действия

непреодолимой силы (пожар, молния, потоп и другие

природные явления), а так же вследствие перепадов напряжения в электросети и другими причинами, которые

находятся вне контроля производителя.

8. Гарантийные условия не распространяются:

8.1. На инструменты, подвергавшиеся вскрытию, ремонту или

модификации вне уполномоченного сервисного центра.

8.2. На детали и узлы, имеющие следы естественного износа,

такие как:

приводные ремни и колеса, угольные щетки, смазка,

подшипники, зубчатое зацепление редукторов, резиновые уплотнения, сальники, направляющие ролики,

муфты, выключатели, бойки, толкатели, стволы, и т.п.

8.3. На сменные части: патроны, цанги, зажимные гайки и

фланцы, фильтры, аккумуляторные батареи, ножи,

шлифовальные подошвы, цепи, звездочки, пильные шины,

защитные кожухи, пилки, абразивы, пильные и

абразивные диски, фрезы, сверла, буры и т.п.

8.4. На неисправности, возникшие в результате перегрузки

инструмента (как механической, так и электрической),

повлекшей выход из строя одновременно двух и более

деталей и узлов, таких как: ротора и статора, обеих

обмоток статора, ведомой и ведущей шестерни редуктора или других узлов и деталей. К безусловным

признакам перегрузки изделия относятся, помимо прочих:

появление цветов побежалости, деформация или

оплавление деталей и узлов изделия, потемнение или

обугливание изоляции проводов электродвигателя под

воздействием высокой температуры.

23

Page 24

Русский язык (Перевод с оригинала инструкции)

Приложение к руководству по эксплуатации

Угловые шлифмашины

Модели: STGS7115, STGS9115, STGS9125, STGS1125, STGL2223, STGL2123, STGL2023, STGL2218, STGL2018,

STGS9100, STGS5100, STGS5115, STGS7100, STGS5800, STGS5815, STGS8100, STGS8115, STDG5006, STGP1318,

FME811K, FME811, FME812, FME812K, FME841, FME841K, FMEK890. Сделано в Китае.

Сертификат №: RU C-DE.АГ49.B.03918

Действителен до: 12 марта 2018 г. Выдан: Общество с

ограниченной ответственностью "Гильдия Качества", адрес

местонахождения: 115088, город Москва,

Шарикоподшипниковская улица, дом 4, корпус 12, фактический

адрес: 248018, Калужская область, город Калуга, улица Карла

Либкнехта, дом 31, телефон: +7(4842) 22-02-81, факс:

+7(499)372-00-89, e-mail: gk.tr.ts@gmail.com.

Изготовитель: Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

Хранение.

Необходимо хранить в сухом месте, вдали от источников

повышенных температур и воздействия солнечных лучей. При

хранении необходимо избегать резкого перепада температур.

Хранение без упаковки не допускается

Срок службы.

Срок службы изделия составляет 5 лет. Не рекомендуется к

эксплуатации по истечении 5 лет хранения с даты

изготовления без предварительной проверки. Дата

изготовления (код даты) указана на корпусе инструмента.

Код даты, который также включает год изготовления,

отштампован на поверхности корпуса изделия.

Уполномоченное изготовителем юр.лицо:

ООО "Стэнли Блэк энд Деккер",117485, город Москва, улица

Обручева, дом 30/1, строение 2

Телефон: + 7 (495) 258-3981, факс: + 7 (495) 258-3984, E-mail:

inbox@dewalt.com

Сведения о импортере указаны в эксплуатационных

документах и/или на упаковке

Транспортировка.

Категорически не допускается падение и любые механические

воздействия на упаковку при транспортировке.

При разгрузке/погрузке не допускается использование любого

вида техники, работающей по принципу зажима упаковки.

Перечень критических отказов, возможные ошибочные

действия персонала.

Не допускается эксплуатация изделия:

-При появлении дыма из корпуса изделия

-При поврежденном и/ или оголенном сетевом кабеле

-при повреждении корпуса изделия, защитного кожуха, рукоятки

-при попадании жидкости в корпус

-при возникновении сильной вибрации

-при возникновении сильного искрения внутри корпуса

Пример:

2014 46 XX, где 2014 –год изготовления, 46-неделя

изготовления. Определить месяц изготовления по указанной

неделе изготовления можно согласно приведенной ниже

таблице.

Месяц Январь Февраль Март Апрель Май Июнь Июль Август Сентябрь Октябрь Ноябрь Декабрь Год производства

01 05 09 14 18 22 27 31 36 40 44 49

02 06 10 15 19 23 28 32 37 41 45 50

Неделя 03 07 11 16 20 24 29 33 38 42 46 51 2014

04 08 12 17 21 25 30 34 39 43 47 52