Page 1

STGL2023

STGL2223

English Page 5

Turkish Page 14

Page 2

2

ENGLISH (Original instructions)

A

C1

B

4

3

1

2

20

3

6

7

5

Page 3

3

(Original instructions) ENGLISH

C2 C3

E

D

10

8

9

7

6

3

10

8

6

7

10

8

6

7

4

10

10

11

90

o

Page 4

4

ENGLISH (Original instructions)

F

G

15o-30

o

A B

Page 5

5

(Original instructions) ENGLISH

Intended Use

Your STANLEY STGL2023, STGL2223, angle grinder has

been designed for grinding metal using the appropriate type

of grinding disc.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to

these symbols.

Danger: Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

Warning: Indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

Caution: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

Notice: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

Denotes risk of electric shock.

Denotes risk of fire.

Warning: To reduce the risk of injury, read the

instruction manual.

General power tool safety warnings

Warning! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

Page 6

6

ENGLISH (Original instructions)

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure the switch is

in the off position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous

situation.

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Additional specific safety rules

Safety instructions for all operations

Safety warnings common for grinding

a) This power tool is intended to function as a grinder.

Read all safety warnings, instructions, illustrations

and specifications provided with this power tool.

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury.

b) Operations such as cutting-off , sander, wire brush

or polisher are not recommended to be performed

with this power tool. Operations for which the power

tool was not designed may create a hazard and cause

personal injury.

c) Do not use accessories which are not specifically

designed and recommended by the tool

manufacturer. Just because the accessory can be

attached to your power tool, it does not assure safe

operation.

d) The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated speed

can break and fly apart.

e) The outside diameter and the thickness of your

accessory must be within the capacity rating of your

power tool. Incorrectly sized accessories cannon be

adequately guarded or controlled.

Page 7

7

(Original instructions) ENGLISH

f) The arbour size of wheels, flanges, backing pads or

any other accessory must properly fit the spindle of

the power tool. Accessories with arbour holes that do

not match the mounting hardware of the power tool will

run out of balance, vibrate excessively and may cause

loss of control.

g) Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheel for

chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires.

If power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After

inspecting and installing an accessory, position

yourself and bystanders away from the plane of the

rotating accessory and run the power tool at

maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test

time.

h) Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of

stopping small abrasive or workpiece fragments.

The eye protection must be capable of stopping flying

debris generated by various operations. The dust mask

or respirator must be capable of filtrating particles

generated by your operation. Prolonged exposure to

high intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of

workpiece or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

j) Hold the power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring or its

own cord. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

k) Position the cord clear of the spinning accessory. If

you lose control, the cord may be cut or snagged and

your hand or arm may be pulled into the spinning

accessory.

l) Never lay the power tool down until the accessory

has come to a complete stop. The spinning accessory

may grab the surface and pull the power tool out of your

control.

m) Do not run the power tool while carrying it at your

side. Accidental contact with the spinning accessory

could snag your clothing, pulling the accessory into your

body.

n) Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause

electrical hazards.

o) Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

p) Do not use accessories that require liquid coolants.

Using water or other liquid coolants may result in

electrocution or shock.

Further safety instructions for all operations

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory.

Pinching or snagging causes rapid stalling of the rotating

accessory which in turn causes the uncontrolled power tool

to be forced in the direction opposite of the accessory’s

rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by

the workpiece, the edge of the wheel that is entering into the

pinch point can dig into the surface of the material causing

the wheel to climb out or kick out. The wheel may either

jump toward or away from the operator, depending on

direction of the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these conditions.

Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be avoided by

taking proper precautions as given below:

a) Maintain a firm grip on the power tool and position

your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction

during start up. The operator can control torque

reaction or kickback forces, if proper precautions are

taken.

b) Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

c) Do not position your body in the area where power

tool will move if kickback occurs. Kickback will propel

the tool in direction opposite to the wheel’s movement at

the point of snagging.

d) Use special care when working corners, sharp edges

etc. Avoid bouncing and snagging the accessory.

Corners, sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of control or

kickback.

Page 8

8

ENGLISH (Original instructions)

e) Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety Warnings Specific for Grinding

Operations

a) Use only wheel types that are recommended for

your power tool and the specific guard designed for

the selected wheel. Wheels for which the power tool

was not designed cannot be adequately guarded and

are unsafe.

b) The guard must be securely attached to the power

tool and positioned for maximum safety, so the least

amount of wheel is exposed towards the operator.

The guard helps to protect operator from broken wheel

fragments and accidental contact with wheel and sparks

that could ignite clothing.

c) Wheels must be used only for recommended

applications. For example: do not grind with the side

of cut-off wheel. Abrasive cut-off wheels are intended

for peripheral grinding, side forces applied to these

wheels may cause them to shatter.

d) Always use undamaged wheel flanges that are of

correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing

the possibility of wheel breakage. Flanges for cut-off

wheels may be different from grinding wheel flanges.

e) Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and may

burst.

Residual Risks

In spite of the application of the relevant safety regulations

and the implementation of safety devices, certain residual

risks cannot be avoided. These are:

– Impairment of hearing

– Risk of personal injury due flying particles.

– Risk of burns due to accessories becoming hot during

operation.

– Risk of personal injury due to prolonged use.

– Risk of dust from hazardous substances.

Labels on tool

The label on your tool may include the following

symbols

along with the date code:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Package Content

This product package includes:

1 Angle grinder

1 Guard

1 Flange set

1 Spanner

1 Handle

1 Instruction manual

• Check the tool, parts, and accessories to see if they are

damaged during transportation.

• Take a few moments to read and understand this manual

before using the tool.

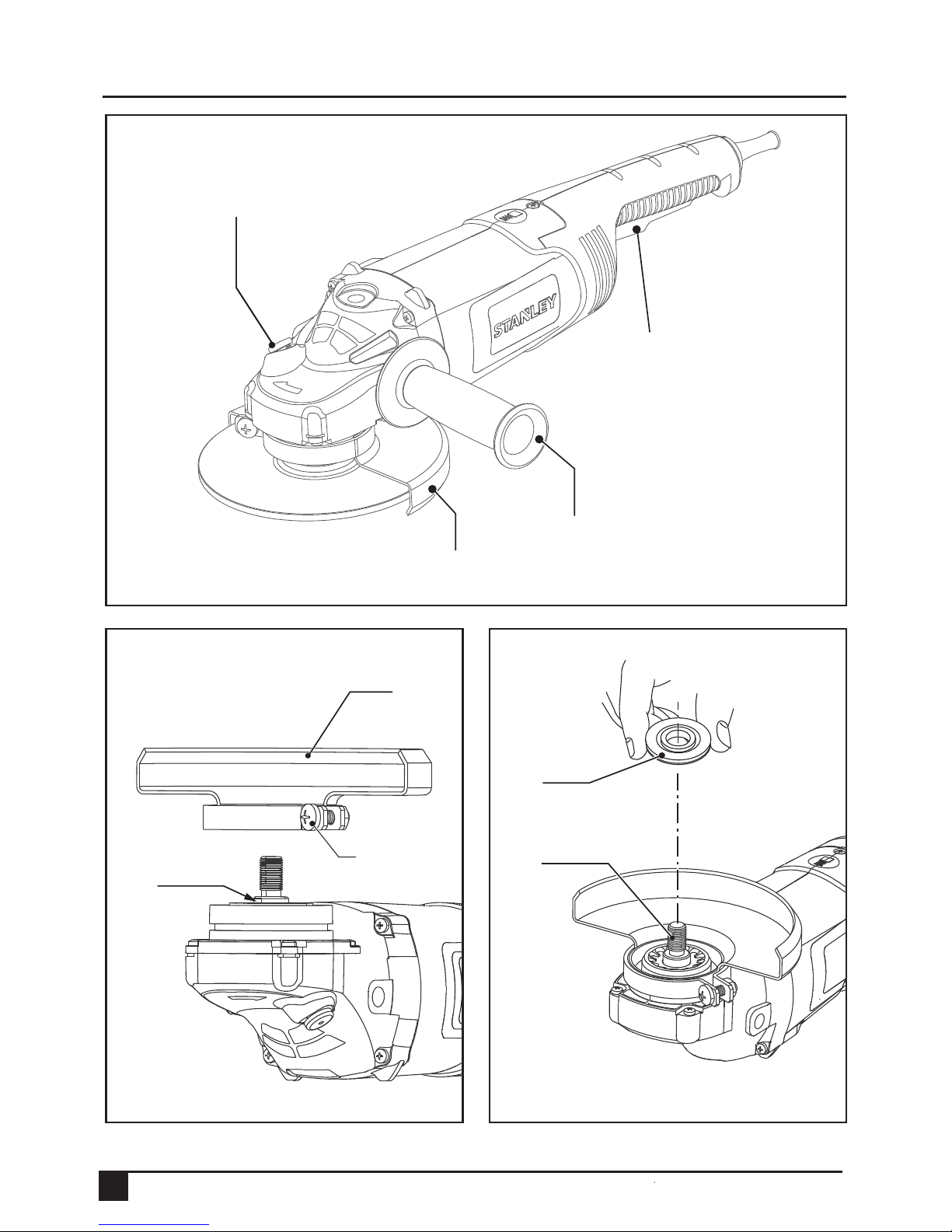

Description (Fig. 1)

Warning: Never modify the power tool or any part

of the tool, otherwise it may cause damage to the

tool or result in personal injury.

a. ON/OFF switch

b. Spindle lock

c. Guard

Purpose of design

This angle grinder is designed especially for grinding.

Do not use sandpaper discs and grinding wheels other than

those with depressed center.

Do not use the tool in wet conditions or environments in the

presence of flammable liquids or gases.

This heavy-duty angle grinder is a professional power tool.

Do not allow children to come in contact with this tool.

Inexperienced operators are required to use this tool under

supervision.

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

0

....... No-Load

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

Page 9

9

(Original instructions) ENGLISH

Electrical Equipment Safety

Only one voltage is applicable to this tool. Be sure

to check that the power suuply corresponds to the

voltage on the rating plate. Your STANLEY tool is

equipped with double insulation, hence, it does not require

to be earthed.

When the power cord is damaged, have it sent to a

STANLEY service center for replacement to specially

prepared cables.

Using Extension Cords

If an extension cord is required, please select a 3-phase

extension cord that has been inspected and matches the

input power (see Technical Data) of this tool. The minimum

conductor size is 1.5mm

2

, maximum length is 30 meters.

When using a cable reel, be sure to pull out all the cables.

Assembly and Adjustment

Warning: To minimize the danger of serious

personal injury, please switch off the tool

power and disconnect all plugs before

adjusting or removing/installing any accessory. Before

reassembling the tool, press and release the trigger switch

to make sure the tool is already switched off.

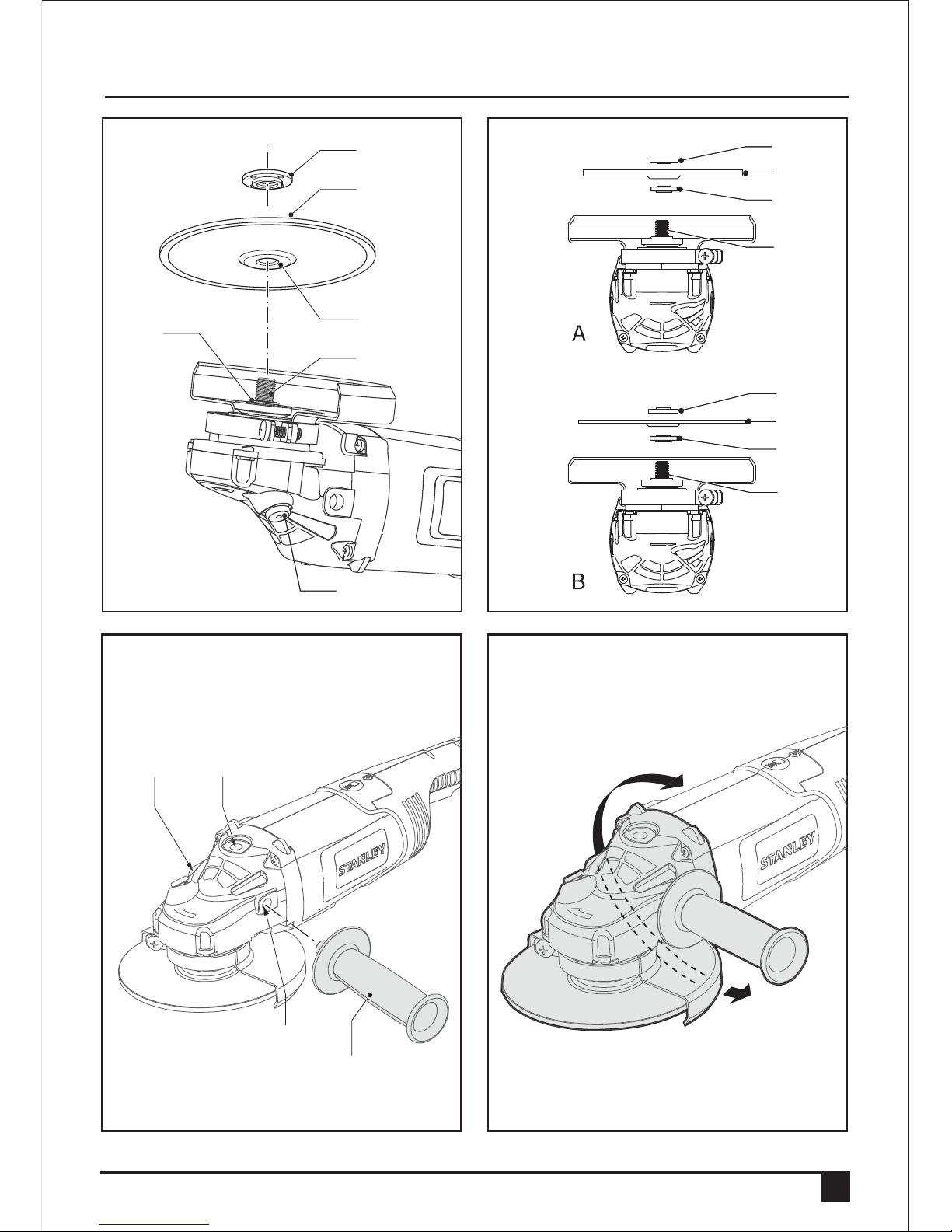

Attaching and Removing the Wheel Guard (Fig. B)

Warning To minimize the danger of serious

personal injury, please switch off the tool power

and disconnect all plugs before adjusting or

removing/installing any accessory. Before reassembling

the tool, press and release the trigger switch to make sure

the tool is already switched off.

Attaching the guard

1. Place the angle grinder on a work bench, groove facing

up.

2. Bring the flange of the guard (3) collar over the groove

(11) of the gear housing.

3. Turn the guard (4) counterclockwise by 150 degrees.

4. Make sure that the screws (20) are tightened.

Removing the guard

1. Loosen the screws (20) on the guard collar.

2. Pull up the guard (3).

Warning: Do not operate the tool when the safety

guard is not in place.

Fitting and removing a grinding (Fig. C1, C2, C3)

Warning: Do not use damaged grinding wheels.

1. Place the tool on a work bench, guard up.

2. Fit the inner flange (6) correctly onto the spindle (7)

(Fig. C1).

3. Place the disc (8) on the flange (6) (Fig.C2). When fitting

a disc with a raised center, make sure that the raised

centre (9) is facing the flange (6).

4. Screw the out flange (10) onto the spindle (7) (Fig. C3)

- the ring on the flange (10) must fae towoards the disc

when fitting a grinding disc (A)

- the ring on the flange (10) must face away from the

disc when fitting a cutting disc (B)

5. Press the spindle lock (2) and rotate the spindle (7) until

it locks in position (Fig. C2).

6. Tighten the flange (10) with the two-pin spanner

supplied.

7. Release the spindle lock.

8. To remove the disc, loosen the flange (10) with the

two-pin spanner.

Warning: Do not use a damaged disc.

Mounting the side handle (Fig.D)

• For grinding, screw the side handle (4) tightly into one of

the holes (11) or (12) on either side of the gear case.

Preparation Before Use

• Attach the safety guard and appropriate abrasive or

grinding wheels. Do not use abrasive or grinding wheels

that are overly worn.

• Make sure that the inner and outer flanges are attached

correctly.

• Make sure that the abrasive or grinding wheels are

rotating in the direction of the arrows on the accessories

and tool.

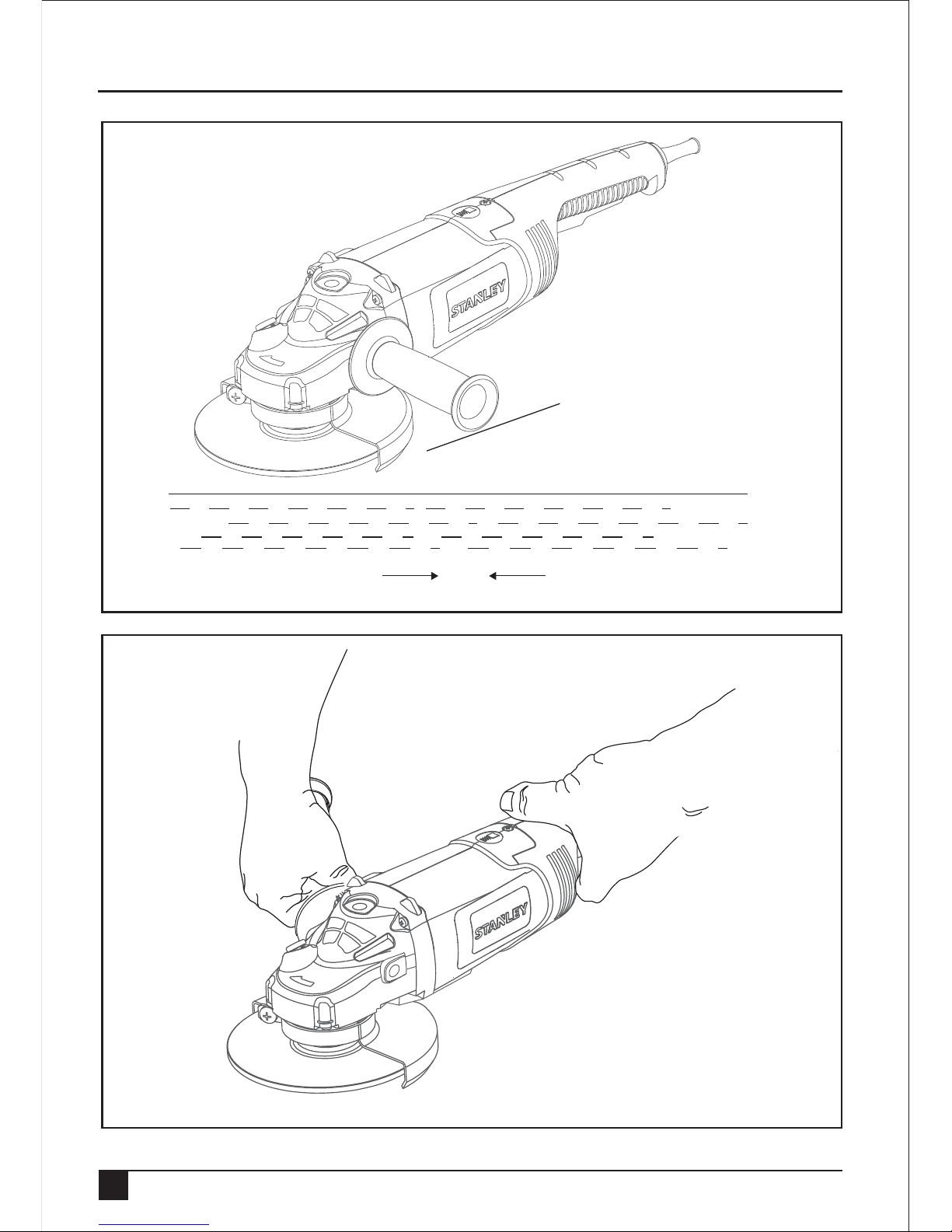

Operation (Fig. F)

Instructions

Warning: Always observe the safety instructions

and applicable regulations.

Page 10

10

ENGLISH (Original instructions)

Warning: To minimize the danger of serious

personal injury, please switch off the tool

power and disconnect all plugs before

adjusting or removing/installing any accessory. Before

reassembling the tool, press and release the trigger switch

to make sure the tool is already switched off.

Warning:

• Make sure all materials to be grinded are secured in

position.

Use clamps or a vice to hold and support the workpiece to a

stable platform. It is important to clamp and support the

workpiece securely to prevent the movement of the

workpiece and loss of control. Movement of the workpiece

or loss of control may create a hazard and cause personal

injury

• Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more secure than

by hand.

• Support panels or any oversized workpiece to minimize

the risk of wheel pinching and kickback. Large

workpieces tend to sag under their own weight. Supports

must be placed under the workpiece near the line of cut

and near the edge of the workpiece on both sides of the

wheel.

• Apply slight pressure to the tool. Do not apply side

pressure to the abrasive disc.

• Avoid overloading. If the tool becomes hot, let it spin for

a few minutes with no load.

1. Be sure to hold the tool tightly with both hands (one

hand on housing, the other on side handle). Start the

tool and bring the grinding wheel on the workpiece.

2. Keep the edge of the wheel tilted at angle from 15 to 30

degrees against the surface of the workpiece.

3. When using a new grinding wheel, do not operate the

wheel in the B direction, otherwise, it will cut into the

workpiece. When the edge of wheel has been rounded

off, you are free to operate the grinder in either the A or

B direction.

Starting and Stopping (Fig. A)

Warning: Before using the tool, check whether the

handle is tightened securely. Check whether the

ON/OFF switch is working normally.

Before plugging in the tool to the power supply, check

whether the switch is in the OFF position when pressing the

rear end of the switch.

To start the tool, press the rear end of the switch and slide it

forward. Press the rear end of the switch to stop the tool.

Warning: Do not switch the tool on or off while

under load conditions.

Proper Hand Position (Fig. G)

Warning: To reduce the risk of serious personal

injury, ALWAYS use proper hand position as shown.

Warning: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

sudden reaction.

Proper hand position requires one hand on the side handle

(figure A), with the other hand on the body of the tool, as

shown in figure G.

Switches

Caution: Hold the body of the tool firmly to

maintain control of the tool at start up and during

use and until the wheel or accessory stops rotating. Make

sure the wheel has come to a complete stop be fore laying

the tool down.

Note: To reduce unexpected tool movement, do not switch

the tool on or off while under load conditions. Allow the

grinder to run up to full speed before touching the work

surface. Lift the tool from the surface before turning the tool

off. Allow the tool to stop rotating before putting it down.

ON/OFF switch (1) Fig. A)

Warning: Before connecting the tool to a power

supply, be sure the slider switch is in the off position

by pressing the front part of the switch and releasing. Ensure

the slider switch is in the off position as described above

after any interruption in power supply to the tool, such as the

activation of a ground fault interrupter, throwing of a circuit

breaker, accidental unplugging, or power failure.

To start the tool, slide the slider switch 1 toward the front of

the tool and press, the tool will keep running. Release

pressure from the switch and the tool will stop.

Feature of the ON/OFF switch

Slide slider switch 1 to the front of the tool and press, and

the tool will start. Keep the switch pressed down and the tool

will keep running. To turn off the tool, release it. The switch

will spring up, which means that the tool is in the off-state.

Explanation: Before coming into contact with the object you

are working on, make sure the abrasive wheel is turning at

maximum speed. Before turning off the tool, lift the tool up

from the object you are working on.

Caution: Make sure the abrasive wheel is completely

stopped before putting down the tool.

Page 11

11

(Original instructions) ENGLISH

Rotating the Gear Case (fig. E)

The gear case is mounted onto the tool casing, and it can

be rotated to give the user a more comfortable experience

while cutting.

The rotating gear case can be turned 90 degrees, 180

degrees, and 270 degrees to the left or to the right.

• Loosen the four screws on the gear case.

• Rotate the gear case till it reaches its ideal location.

• Tighten the four screws on the gear case.

• Ensure that the rotating mechanism is locked.

Warning: Do NOT use the tool when the gear case

is unlocked.

Application on Metals

When applying the tool on metals, make sure that a

residual-current device (RCD) is inserted to prevent danger

from metal chips.

If the RCD causes power disconnection, have the tool sent

to an authorized STANLEY dealer for repair.

Warning: Under extreme working conditions,

conductive dust and grit may accumulate on the

housing interior when handling metal workpieces.

This could create an electric shock hazard as it weakens the

protective insulation in the grinder.

To avoid accumulation of metal chips in the interior of the

grinder, we recommend cleaning the ventilation ducts daily.

Refer to Maintenance.

Using Grinding Wheels

Warning: Metal powder accumulates. Excessive

use of the grinding wheel on metals may increase

the risk of electric shock. To reduce the risk, insert the RCD

before use and clean the ventilation ducts daily. Follow the

maintenance instructions below to blow dry compressed air

into the ventilation ducts.

Maintenance

STANLEY power tools have been designed to operate over

a long period of time with minimal maintenance. Continuous

satisfactory operation depends upon proper tool care and

regular cleaning.

Warning: To minimize the danger of serious

personal injury, please switch off the tool

power and disconnect all plugs before

adjusting or removing/installing any accessory. Before

reassembling the tool, press and release the trigger switch

to make sure the tool is already switched off.

Lubrication

This power tool does not require separate lubrication.

Cleaning

Warning: Once visible dust accumulates on the

ventilation ducts and the surrounding, immediately

use dry air to blow away dust and grit out of the interior of

the housing. You need to wear approved eye and facial

protective gear when performing this process.

Warning: Never use solvents or harsh chemicals to

clean non-metal parts of the tool. These chemicals

may weaken the material of the parts. Use only mild soap

and damp cloth to clean the tool. Never let any liquid get

inside the tool; never immerse any part of the tool into liquid.

Accessories

Warning: Excluding accessories provided by

STANLEY, all other accessories have not been

tested for product compatibility. Using such accessories

together with this tool may cause safety hazards. To

minimize the risk of personal injury, we recommend you to

use only STANLEY accessories with this product. Please

inquire at your dealer for more information regarding suitable

accessories.

Remarks

• STANLEY's policy is one of continuous improvement to

our products and as such, we reserve the right to modify

product specifications without prior notice.

• Standard equipment and accessories may vary by

country.

• Product specifications may differ by country.

• Complete product range may not be available in all

countries. Contact your local STANLEY dealers for

range availability.

Page 12

12

ENGLISH (Original instructions)

KWA (sound power uncertainty) dB(A) 3

Vibration emission value ah (surface grinder ) ah,AG = m/s²

8,2

Uncertainty K = m/s² 1.5

Service Information

STANLEY offers a full network of authorized service

locations. All STANLEY Service Centers are staffed with

trained personnel to provide customers with efficient and

reliable power tool service. For more information about our

authorized service centers and if you need technical advice,

repair, or genuine factory replacement parts, contact the

STANLEY location nearest you.

Vibration

The declared vibration emission values stated in the

technical data and the declaration of conformity have been

measured in accordance with a standard test method

provided by EN 60745 and may be used for comparing one

tool with another. The declared vibration emission value

may also be used in a preliminary assessment of exposure.

Warning! The vibration emission value during actual use of

the power tool can differ from the declared value depending

on the ways in which the tool is used. The vibration level

may increase above the level stated.

When assessing vibration exposure to determine safety

measures required by 2002/44/EC to protect persons

regularly using power tools in employment, an estimation of

vibration exposure should consider, the actual conditions of

use and the way the tool is used, including taking account of

all parts of the operating cycle such as the times when the

tool is switched off and when it is running idle in addition to

the trigger time.

Level of sound pressure according to EN 60745:

STGL2023

LpA (sound pressure) dB(A) 92,5

KpA (sound pressure uncertainty) dB(A) 3

LWA (sound power) dB(A) 103,5

KWA (sound power uncertainty) dB(A) 3

Vibration emission value ah (surface grinder ) ah,AG = m/s²

8,0

Uncertainty K = m/s² 1.5

STGL2223

LpA (sound pressure) dB(A) 93,0

KpA (sound pressure uncertainty) dB(A) 3

LWA (sound power) dB(A) 104,0

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your STANLEY product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent environmental

pollution and reduces the demand for raw materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

STANLEY provides a facility for the collection and recycling

of STANLEY products once they have reached the end of

their working life. To take advantage of this service please

return your product to any authorised repair agent who will

collect them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Stanley office at the address

indicated in this manual. Alternatively, a list of authorised

STANLEY repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com

STGL2023 STGL2223

Input voltage V

AC 220-240 220-240

Power input W 2000 2200

Frequency Hz 50/60 50/60

No-load speed min-1 6500 6500

Wheel diameter mm 230 230

Spindle size M14 M14

Max disc thickness

Grinding discs mm 6.6 6.6

Weight kg 5.0 6.0

Specifications

Page 13

13

(Original instructions) ENGLISH

Two years full warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY Europe guarantees to replace all

defective parts free of charge or – at our discretion – replace

the unit free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

EC declaration of conformity

MACHINERY DIRECTIVE

STGL2023, STGL2223 - Angle Grinder

STANLEY declares that these products described under

"technical data" are in compliance with 2006/42/EC, EN

60745-1:2009 + A11:2010, EN 60745-2-3:2011

These products also comply with Directive 2004/108/EC

(until 19/04/2016) 2014/30/EU (from 20/04/2016) and

2011/65/EU. For more information, please contact STANLEY

at the following address or refer to the back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

STANLEY

R.Laverick

Engineering Manager

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

07.2015

Page 14

14

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

Kullanım amacı

STANLEY STGL2023, STGL2223 taşlama

makineniz uygun tipte taşlama diskini kullanarak

metal taşlanması için tasarlanmıştır.

Tanımlar: Güvenlik talimatları

Aşağıdaki tanımlar her işaret sözcüğü ciddiyet

derecesini gösterir. Lütfen kılavuzu okuyunuz ve

bu simgelere dikkat ediniz.

Tehlike: Engellenmemesi halinde ölüm veya

ciddi yaralanma ile sonuçlanabilecek çok yakın

bir tehlikeli durumu gösterir.

Uyarı: Engellenmemesi halinde ölüm veya ciddi

yaralanma ile sonuçlanabilecek potansiyel bir

tehlikeli durumu gösterir.

Uyarı: Engellenmemesi halinde önemsiz

veya orta dereceli yaralanma ile

sonuçlanabilecek potansiyel bir tehlikeli

durumu gösterir.

İkaz: Engellenmemesi halinde maddi

hasara neden olabilecek, yaralanma ile

ilişkisi olmayan durumları gösterir.

Elektrik çarpması riskine işaret eder.

Yangın riskini belirtir.

Uyarı: Yaralanma riskini azaltmak için, kullanım

kılavuzunu okuyun.

Genel elektrikli alet güvenlik uyarıları

Uyarı! Bütün güvenlik uyarılarını ve

talimatlarını mutlaka okuyun. Bu

uyarılar ve talimatların herhangi birisine

uyulmaması elektrik çarpması, yangın

ve/veya ciddi yaralanma riskine neden

olabilir.

Bütün uyarı ve güvenlik talimatlarını

ileride bakmak üzere saklayın

Uyarılarda yer alan «elektrikli alet»

terimi şebeke elektriğiyle (kablolu) veya

akü/pille (şarjlı) çalışan elektrikli aletinizi ifade

etmektedir.

1) Çalışma alanının

güvenliği

a) Çalışma alanını temiz ve aydınlık tutun.

Karışık veya karanlık alanlar kazaya davetiye

çıkartır.

b) Elektrikli aletleri, yanıcı sıvılar, gazlar ve

tozların bulunduğu yerler gibi yanıcı

ortamlarda çalıştırmayın. Elektrikli aletler,

toz veya dumanları ateşleyebilecek kıvılcımlar

çıkartır.

c) Bir elektrikli aleti çalıştırırken çocuklardan

ve etraftaki kişilerden uzak tutun. Dikkatinizi

dağıtıcı şeyler kontrolü kaybetmenize neden

olabilir.

2) Elektrik güvenliği

a) Elektrikli aletlerin fişleri prizlere uygun

olmalıdır. Fiş üzerinde kesinlikle hiçbir

değişiklik yapmayın. Topraklı elektrikli

aletlerde hiçbir adaptör fişi kullanmayın.

Değiştirilmemiş fişler ve uygun prizler elektrik

çarpması riskini azaltacaktır.

b) Borular, radyatörler, ocaklar ve

buzdolapları gibi topraklanmamış

yüzeylerle vücut temasından kaçının.

Vücudunuzun topraklanması halinde yüksek

bir elektrik çarpması riski vardır.

c) Elektrikli aletleri yağmura maruz

bırakmayın veya ıslatmayın. Elektrikli alete

su girmesi elektrik çarpması riskini

arttıracaktır.

d) Elektrik kablosunu uygun olmayan

amaçlarla kullanmayın. Elektrikli aleti

kesinlikle kablosundan

tutarak taşımayın,

çekmeyin veya prizden çıkartmayın.

Kabloyu sıcaktan, yağdan, keskin

kenarlardan veya hareketli parçalardan

uzak tutun. Hasarlı veya dolaşmış kablolar

elektrik çarpması riskini arttırır.

e) Elektrikli bir aleti açık havada

çalıştırıyorsanız, açık havada kullanıma

uygun bir uzatma kablosu kullanın. Açık

havada kullanıma uygun bir kablonun

kullanılması elektrik çarpması riskini azaltır.

Page 15

15

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

f) Eğer bir elektrikli aletin nemli bir bölgede

çalıştırılması zorunluysa, bir artık akım

aygıtı (RCD) korumalı bir kaynak kullanın.

Bir RCD kullanılması elektrik şoku riskini

azaltır.

3) Kişisel güvenlik

a) Elektrikli bir aleti kullanırken her zaman

dikkatli olun, yaptığınız işe yoğunlaşın ve

sağduyulu davranın. Elektrikli bir aleti

yorgunken veya ilaç ya da alkolün etkisi

altındayken kullanmayın. Elektrikli aletleri

kullanırken bir anlık dikkatsizlik ciddi kişisel

yaralanmayla sonuçlanabilir.

b) Kişisel koruyucu ekipmanları mutlaka

kullanın. Daima koruyucu gözlük takın.

Koşullara uygun toz maskesi, kaymayan

güvenlik ayakkabıları, baret veya kulaklık gibi

koruyucu donanımların kullanılması kişisel

yaralanmaları azaltacaktır.

c) İstem dışı çalıştırılmasını önleyin. Aleti güç

kaynağına ve/veya aküye bağlamadan,

yerden kaldırmadan veya taşımadan önce

düğmenin kapalı konumda olduğundan

emin olun. Aleti, parmağınız düğme üzerinde

bulunacak şekilde taşımak veya açık

konumdaki elektrikli aletleri elektrik

şebekesine bağlamak kazaya davetiye

çıkartır.

d) Elektrikli aleti

açmadan önce tüm ayarlama

anahtarlarını çıkartın. Elektrikli aletin

hareketli bir parçasına takılı kalmış bir anahtar

kişisel yaralanmaya neden olabilir.

e) Ulaşmakta zorlandığınız yerlerde

kullanmayın. Daima sağlam ve dengeli

basın. Bu, beklenmedik durumlarda elektrikli

aletin daha iyi kontrol edilmesine olanak tanır.

f) Uygun şekilde giyinin. Bol elbiseler

giymeyin ve takı takmayın. Saçınızı,

elbiselerinizi ve eldivenlerinizi hareketli

parçalardan uzak tutun. Bol elbiseler ve

takılar veya uzun saç hareketli parçalara

takılabilir.

g) Eğer kullandığınız üründe toz emme ve

toplama özellikleri olan ataşmanlar varsa

bunların bağlı olduğundan ve doğru

şekilde kullanıldığından emin olun. Bu toz

toplama ataşmanların kullanılması tozla ilgili

tehlikeleri azaltabilir.

4) Elektrikli aletlerin kullanımı ve bakımı

a) Elektrikli aleti zorlamayın. Uygulamanız

için doğru elektrikli aleti kullanın. Doğru

elektrikli alet, belirlendiği kapasite ayarında

kullanıldığında daha iyi ve güvenli

çalışacaktır.

b) Düğme açmıyor ve kapatmıyorsa elektrikli

aleti kullanmayın. Düğmeyle kontrol

edilemeyen tüm elektrikli aletler

tehlikelidir ve

tamir edilmesi gerekmektedir.

c) Herhangi bir ayarlama, aksesuar değişimi

veya elektrikli aletlerin saklanması

öncesinde fişi güç kaynağından çekin

ve/veya aküyü elektrikli aletten ayırın. Bu

tür önleyici güvenlik tedbirleri aletin istem dışı

olarak çalıştırılması riskini azaltacaktır.

d) Elektrikli aleti, çocukların ulaşamayacağı

yerlerde saklayın ve elektrikli aleti

tanımayan veya bu talimatları bilmeyen

kişilerin elektrikli aleti kullanmasına izin

vermeyin. Elektrikli aletler, eğitimsiz

kullanıcıların elinde tehlikelidir.

e) Elektrikli aletleri iyi durumda muhafaza

edin. Hareketli parçalardaki hizalama

hatalarını ve tutuklukları, parçalardaki

kırılmalar ve elektrikli aletin çalışmasını

etkileyebilecek tüm diğer koşulları kontrol

edin. Hasarlı ise, elektrikli aleti

kullanmadan önce tamir ettirin. Kazaların

çoğu, elektrikli aletlerin bakımının yeterli

şekilde yapılmamasından kaynaklanır.

f) Kesim aletlerini keskin ve temiz tutun.

Bakımı uygun şekilde yapılmış keskin kesim

uçlu kesim aletlerinin sıkışma ihtimali daha

düşüktür ve kontrol edilmesi daha kolaydır.

Page 16

16

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

g) Elektrikli aleti, aksesuarlarını ve aletin

diğer parçalarını kullanırken bu talimatlara

mutlaka uyun ve çalışma ortamının

koşullarını ve yapılacak işin ne olduğunu

göz önünde bulundurun. Elektrikli aletin

öngörülen işlemler dışındaki işlemler için

kullanılması tehlikeli durumlara neden olabilir.

5) Servis

a) Elektrikli aletinizi, sadece orijinal yedek

parçaların kullanıldığı yetkili servise tamir

ettirin. Bu, elektrikli aletin güvenliğinin

muhafaza edilmesini sağlayacaktır.

Özel ek güvenlik talimatları

Bütün uygulamalar için güvenlik talimatları

Taşlama uygulamaları için güvenlik talimatları

a) Bu elektrikli alet bir taşlama makinesi

olarak kullanılmak üzere tasarlanmıştır. Bu

elektrikli alet ile verilen tüm güvenlik

uyarıları, talimatlar, resimli açıklamalar ve

teknik özellikleri okuyun. Aşağıda belirtilen

tüm talimatların herhangi birisine uyulmaması

elektrik çarpması, yangın ve/veya ciddi

yaralanma riskine neden olabilir.

b) Zımparalama, fırçalama, polisaj veya

kesme işleri bu elektrikli alet ile yapılması

tavsiye edilmez. Elektrikli aletin tasarlanma

amacı dışındaki işlemler tehlike ve kişisel

yaralanmalara neden olabilir.

c) Üretici firma tarafından özel olarak

tasarlanmamış ve tavsiye edilmemiş

aksesuarları kullanmayın. Aksesuarın

elektrikli aletinize takılabilir olması güvenli bir

çalışma temin edeceği anlamına

gelmemektedir.

d) Aksesuarın nominal hızı en az elektrikli

alet üzerinde yazan maksimum hıza eşit

olmalıdır. Nominal hızından daha hızlı

çalışan aksesuarlar kırılabilir ve etrafa

saçılabilir.

e) Aksesuarınızın dış çapı ve kalınlığı

elektrikli aletinizin kapasite oranı içinde

olmalıdır. Yanlış ebatlı aksesuarlar yeteri

kadar korunamaz ve kontrol edilemez.

f) Disk, flanş, taban ya da diğer

aksesuarların mil çapı elektrikli aletin

miline tam olarak uymalıdır. Elektrikli aletin

montaj donanımına uymayan mil çapına sahip

aksesuarlar dengesiz çalışır, aşırı titreşim

yapar ve kontrolü kaybetmeye neden olabilir.

g) Hasar görmüş olan bir aksesuarı

kullanmayın. Her kullanımdan önce

aksesuarları inceleyin, örneğin diski talaş

ve çatlaklara karşı, tabanı çatlak, kopma ya

da aşırı kullanıma karşı, tel fırçayı gevşek

ya da kırık tellere karşı kontrol edin.

Elektrikli alet ya da aksesuar düşürülürse,

hasar olup olmadığını kontrol edin ya da

sağlam aksesuar takın. Aksesuarın

incelenmesi ve monte edilmesinden sonra

kendinizi ve etraftaki kişileri dönen

aksesuarın düzleminden uzakta yerleştirin

ve bir dakika boyunca elektrikli aleti boşta

ve maksimum hızda çalıştırın. Bu test

süresince hasarlı aksesuarlar normal olarak

kırılarak dağılacaktır.

h) Kişisel koruyucu ekipmanları mutlaka

kullanın. Uygulamaya bağlı olarak yüz

kalkanı, koruyucu gözlük ya da güvenlik

gözlükleri kullanın. Yeri geldiğinde küçük

aşındırıcı maddeleri ya da işleme tabi

tutulan parçaları durdurabilen toz maskesi,

kulaklık, eldiven ve iş önlüğü giyin. Göz

koruması, çeşitli işlemler sonucu açığa çıkan

uçan parçacıkları durdurabilmelidir. Toz

maskesi ya da gaz maskesi yaptığınız işlem

sonucu açığa çıkan parçacıkları

filtreleyebilmelidir. Uzun süreli yüksek şiddetli

gürültüye maruz kalınması işitme kaybına

neden olabilir.

i) Çevrede bulunan şahısları çalışma

alanından uzakta güvenli bir mesafede

tutun. Çalışma alanına giren şahıslar

kişisel koruyucu ekipman giymelidir.

İşleme tabi tutulan parçanın ya da kırık bir

aksesuarın parçacıkları fırlayabilir ve çalışma

alanının yakın çevresinde yaralanmalara

neden olabilir.

j) Kesme aksesuarının gizli kablolara veya

kendi kablosuna temas edebileceği

yerlerde çalışma yaparken elektrikli aleti

yalıtımlı kavrama yüzeylerinden tutun.

Kesme aksesuarının «akım taşıyan» bir

kabloya temas etmesi durumunda elektrikli

aletin metal kısımları da «akım taşır» hale

gelecek ve kullanıcının elektrik çarpılmasına

neden olabilir.

Page 17

17

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

k) Kabloyu dönen aksesuardan uzak tutun.

Kontrolü kaybederseniz kablo kesilebilir ya da

kopabilir ve eliniz ya da kolunuz dönen

aksesuar içine çekilebilir.

l) Aksesuar tamamen durmadıkça elektrikli

aleti asla yere koymayın. Dönen aksesuar

yüzeyi yakalayabilir ve elektrikli aleti

kontrolünüzden çıkarabilir.

m) Elektrikli aleti yanınızda taşırken

çalıştırmayın. Kaza ile temas halinde, dönen

aksesuar giysinize takılabilir, aksesuarı

vücudunuza doğru çekebilir.

n) Elektrikli aletin hava çıkışlarını düzenli

olarak temizleyin. Motor fanı, tozu muhafaza

içine çeker ve aşırı metal toplanması

elektriksel tehlike yaratabilir.

o) Elektrikli aleti yanıcı malzemelerin

yakınında çalıştırmayın. Kıvılcım bu

malzemeleri tutuşturabilir.

p) Sıvı soğutucu gerektiren aksesuarlar

kullanmayın. Su ya da diğer sıvı

soğutucuların kullanılması elektrik çarpması

ya da şok ile sonuçlanabilir.

Bütün uygulamalar için güvenlik

talimatları

Geri tepme ve ilgili uyarılar

Geri tepme, sıkışmış veya takılmış bir disk,

taban, fırça veya diğer aksesuarlara verilen ani

tepkidir. Sıkışma veya takılma dönen aksesuarın

aniden durmasına neden olur, bu daha sonra

temas noktasında elektrikli aletin kontrolsüzce,

aksesuarın dönme yönünün tersine doğru

zorlanmasına yol açar.

Örneğin, bir aşındırıcı disk, işleme tabi tutulan

parçaya takılır ya da sıkışırsa; sıkışma noktasına

giren disk kenarı malzemenin yüzeyine

saplanarak, diskin geri tepmesine ya da

fırlamasına neden olabilir. Disk, sıkışma

noktasındaki hareket yönüne bağlı olarak ya

kullanıcıya doğru ya da kullanıcıdan uzağa

fırlayabilir. Aşındırıcı diskler bu koşullar altında

kırılabilir.

Geri tepme, aletin yanlış kullanılmasından

ve/veya yanlış çalıştırma işlemleri veya

koşullarından kaynaklanır ve aşağıda da belirtilen

uygun tedbirler alınarak önlenebilir:

a) Elektrikli aleti sıkıca tutun, vücudunuzu ve

kolunuzu geri tepme gücüne karşı koyacak

şekilde konumlandırın. Geri tepmeye ya da

çalıştırma sırasındaki döndürme momenti

tepkisine karşı maksimum kontrol

sağlamak için eğer varsa yan tutma kolunu

kullanın. Doğru önlemler alınırsa döndürme

momenti tepkileri ya da geri tepmeler kullanıcı

tarafından kontrol edilebilir.

b) Döner aksesuar civarına asla elinizi

sokmayın. Aksesuar elinizde geri tepme etkisi

yapabilir.

c) Geri tepmenin meydana gelmesi

durumunda vücudunuzu elektrikli aletin

hareket edeceği alanda bulundurmayın.

Geri tepme hareketi aleti takılma noktasında

disk hareketine ters yönde itecektir.

d) Köşe, keskin kenarlar vb. yerlerle

çalışırken özellikle dikkatli olun.

Aksesuarın sekmesinden ve takılmasından

kaçının. Köşeler, keskin kenarlar ya da

sektirme hareketi döner aksesuarı engelleme

eğilimindedir ve kontrolün kaybedilmesine ya

da geri tepmeye neden olabilir

e) Zincirli testere zinciri, ahşap oyma bıçağı

ya da dişli daire/gönye testere bıçağı

takmayın. Bu tür bıçaklar sık sık geri tepme

ve kontrol kaybı oluşturur.

Taşlama uygulamalarına özel ilave

güvenlik uyarıları

a) Sadece elektrikli aletiniz için tavsiye edilen

disk türlerini ve seçilen disk için

tasarlanmış özel muhafazayı kullanın.

Elektrikli aletin birlikte kullanılmak için

tasarlanmadığı diskler yeteri kadar

korunamazlar ve güvenli değillerdir.

b) Muhafazanın elektrikli alete güvenli bir

şekilde bağlanması ve maksimum güvenlik

için konumlandırılması gerekir, böylece

diskin çok az bir kısmı kullanıcıya açık

olacaktır. Muhafaza, kullanıcının kırılan disk

parçacıklarından ve disk ile istenmeyen

temaslardan ve giysileri yakabilecek

kıvılcımlardan korunmasına yardımcı olur.

Page 18

18

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

c) Diskler sadece önerilen uygulamalar için

kullanılmalıdır. Örneğin: kesme diskinin

kenarı ile taşlama yapmayın. Aşındırıcı

kesici diskler çevresel aşındırma için

tasarlanmıştır, bu disklere uygulanan yan

kuvvetler diskleri parçalayabilir.

d) Her zaman seçilen disk için doğru ebat ve

şekilde, hasarsız flanşları kullanın. Uygun

flanşlar, diski destekler ve disk kırılması

olasılığını azaltır. Kesme diski flanşları

taşlama diski flanşlarından farklı olabilir.

e) Daha büyük çaplı taşlamaların yıpranmış

disklerini kullanmayın. Daha büyük elektrikli

aletler için tasarlanmış disk daha küçük bir

aletin yüksek hızları için uygun değildir ve

parçalanabilir.

Diğer tehlikeler

Emniyet tedbirlerini düzenleyen yönetmeliğin

uygulanmasına ve emniyet sağlayıcı aygıtların

kullanılmasına rağmen, başka belirli risklerden

kaçınılamaz. Bunlar:

- Duyma bozukluğu

- Sıçrayan parçacıklardan kaynaklanan

yaralanma riski.

- Çalışma sırasında ısınan aksesuarlardan

kaynaklanan yanık tehlikesi.

- Uzun süreli kullanımdan kaynaklanan

yaralanma riski.

- Tehlikeli maddeler içeren

tozun oluşması

riski.

İçindekiler

Ambalaj, aşağıdaki parçaları içermektedir:

1 Avuç taşlama makinesi

1 Muhafaza

1 Flanş seti

1 Anahtar

1 Yan kol

1 Kullanım kılavuzu

Alette, parçalarda veya aksesuarlarda nakliye

sırasında meydana gelmiş olabilecek hasarı

kontrol edin.

Aleti çalıştırmadan önce, bu kullanım kılavuzunu

baştan sonra okuyup anlamak için gerekli zamanı

ayırın.

Açıklama (Şekil 1)

Uyarı: Hiçbir zaman elektrikli aleti veya

herhangi bir parçasını değiştirmeyin. Bu,

kişisel yaralanmalara ya da alet hasarına

yol açabilir.

a. Açma/kapama düğmesi

b. Mil kilidi düğmesi

c. Muhafaza

Kullanım amacı

Bu avuç taşlama makinesi özellikle taşlama

uygulamaları için tasarlanmıştır.

Basık merkezli taşlama disklerinin dışında

taşlama ve zımpara disklerini kullanmayın.

Islak koşullarda veya yanıcı sıvı ya da gazların

mevcut olduğu ortamlarda kullanmayın.

Bu ağır hizmet tipi avuç taşlama makinesi

profesyonel bir elektrikli alettir.

Çocukların aleti ellemesine izin vermeyin. Bu alet

deneyimsiz kullanıcılar tarafından kullanılırken

nezaret edilmelidir

Elektrik güvenliği

Bu alet, sadece tek

bir gerilim ile çalışacak

şekilde ayarlanmıştır. Her zaman şebeke

geriliminin aletin üretim etiketinde belirlenmiş

değerlere uyup uymadığını kontrol edin.

STANLEY aletiniz çift yalıtımlıdır; bu yüzden

hiçbir topraklama kablosuna gerek yoktur.

Güç kablosu hasarlıysa, STANLEY yetkili

servisinden temin edilebilen özel olarak

hazırlanmış bir kabloyla değiştirilmelidir.

V ........ Volt

A ........ Amper

Hz ....... Hertz

W ........ Vat

dak ..... dakika

.....

.....

boş .......

......

....

....

.../min..

Alet üzerindeki etiketler

Aletin etiketinde aşağıdaki semboller bulunabilir:

Tarih kodu konumu

İmalat yılını da içeren Tarih Kodu gövdeye basılıdır.

Örnek:

2014 XX JN

İmalat Yılı

Kullanım

Kılavuzunu

Okuyun

Koruyucu

Gözlük kullanın

Kulaklık

Kullanın

Alternatif

Akım

Direkt

Akım

Yüksüz

Hız

Sınıf II

İnşaat

Topraklama

Terminal

Güvenlik

uyarısı

Sembolü

Dakikada

devir veya

gel git sayısı

Page 19

19

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Uzatma kablolarının kullanımı

Bir uzatma kablosu gerekli ise, bu aletin elektrik

girişine uygun (Teknik Özelliklere bakın), onaylı

bir 3 telli uzatma kablo kullanın. Minimum iletken

boyutu 1,5 mm2'dir; maksimum uzunluk 30 m’dir.

Bir kablo makarası kullanırken, kabloyu daima

sonuna kadar açın.

Montaj ve ayarlama

Uyarı: Ciddi yaralanma riskini azaltmak

için herhangi bir ayar yapmadan ya da

parça veya aksesuarları söküp takmadan

önce aleti kapatın ve güç kaynağından ayırın.

Aleti yeniden bağlamadan önce aletin kapalı

olduğundan emin olmak için tetik düğmesine

basıp bırakın.

Muhafazanın takılması ve çıkartılması

(Şekil B)

Uyarı: Ciddi yaralanma riskini azaltmak

için herhangi bir ayar yapmadan ya da

parça veya aksesuarları söküp takmadan

önce aleti kapatın ve güç kaynağından ayırın.

Aleti yeniden bağlamadan önce aletin kapalı

olduğundan emin olmak için tetik düğmesine

basıp bırakın.

Muhafazanın takılması

1. Taşlama makinesini, oluğu yukarı gelecek

şekilde bir çalışma tezgahına yatırın.

2. Muhafaza (3) desteğinin flan

şını vites

muhafazasının oluğunun (11) üzerine takın.

3. Muhafazayı (4) 150 derece saatin ters

yönünde çevirin.

4. Vidaların (20) sıkıldığından emin olun.

Muhafazanın çıkartılması

1. Muhafaza desteğindeki vidayı (20) gevşetin.

2. Muhafazayı (3) aletten çıkartın.

Uyarı: Muhafaza yerinde değilse aleti

kesinlikle kullanmayın.

Taşlama diskinin takılması ve çıkartılması

(Şekil C1, C2, C3)

Uyarı: Hasar görmüş olan taşlama

disklerini kullanmayın.

1. Muhafaza yukarı gelecek şekilde aleti bir

çalışma tezgahına yatırın.

2. İç flanşı (6) mil (7) üzerine düzgünce takın

(Şekil C1).

3. Diski (8) iç flanş (6) üzerine yerleştirin (Şekil

C2). Yüksek merkezli bir disk takarken yüksek

merkezin (9) iç flanşa (6) baktığından emin

olun.

4. Dişli dış flanşı (10) mil (7) üzerine döndürerek

sabitleyin (Şekil C3).

- Taşlama diskini takarken dış flanştaki (10)

yüksek merkez diske bakmalıdır (A)

- Kesme diskini takarken dış flanştaki (10)

yüksek merkez diskin aksi yöne bakmalıdır (B)

5. Mil kilidi düğmesini (2) basılı tutun ve

mili (7)

yerinde kilitlenene kadar döndürün (Şekil C2).

6. Verilen çift pimli anahtarı kullanarak flanşı (10)

sıkın.

7. Mil kilidi düğmesini bırakın.

8. Diski çıkartmak için, flanşı (10) verilen iki pimli

anahtar ile gevşetin.

Uyarı: Hasarlı diski kullanmayın.

Yan kolun takılması (Şekil D)

• Taşlama için ikinci tutma kolunu (4) gövdenin

her iki tarafındaki deliklerden birine (11) veya

(12) iyice vidalayın.

Aleti kullanmadan önce

• Muhafazayı ve uygun bir aşındırıcı veya

taşlama diskini takın. Çok yıpranmış aşındırıcı

veya taşlama disklerini kullanmayın.

• İç ve dış flanşın düzgün takıldığından emin

olun.

• Aşındırıcı veya taşlama diskinin, aksesuar ve

aletin üzerindeki oklar yönünde dönmesine

dikkat edin.

Kullanımı (Şekil F)

Kullanım talimatları

Uyarı: Güvenlik talimatlarına ve geçerli

yönetmeliklere daima uyun.

Uyarı: Ciddi yaralanma riskini azaltmak

için herhangi bir ayar yapmadan ya da

parça veya aksesuarları söküp

takmadan önce aleti kapatın ve güç

kaynağından ayırın. Aleti yeniden bağlamadan

önce aletin

kapalı olduğundan emin olmak için

tetik düğmesine basıp bırakın.

Page 20

20

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

Uyarı:

• Taşlanacak tüm malzemelerin yerlerine sıkıca

sabitlendiklerinden emin olun.

Çalışma malzemesini sabit bir platforma

sabitlemek ve desteklemek için kelepçe veya

mengene kullanın. Parçanın hareket etmesini ve

kontrol kaybını önlemek için çalışma parçasını

sıkıştırmak ve sabitlemek çok önemlidir.

Parçanın hareket etmesi veya kontrol kaybı

zarara ve kişisel yaralanmaya yol açabilir.

• çalışma parçasını sabitleyin. Kelepçe veya

mengene ile sıkıştırılmış bir çalışma parçası

el ile tutulmaktan daha güvenli bir şekilde

tutulur.

• Kırılma ve geri tepmeyi en aza indirmek için

panel ve büyük boyutlu iş parçalarını

destekleyin. Geniş çalışma parçaları kendi

ağırlıkları ile bükülebilirler. Destekler çalışma

parçasında, kesme hattı yanına ve diskin her

iki tarafında parçanın kenarının yakınında

konumlandırılmalıdır.

• Alete yalnızca hafif bir baskı uygulayın.

Aşındırıcı diske yanal basınç uygulamayın.

• Aşırı yüklemeden kaçının. Alet çok fazla

ısındığında yüksüz durumdayken birkaç

dakika çalıştırın.

1. Aleti iki elinizle sıkıca tutun (bir el alet

gövdesinin, diğer el yan kolun üzerinde

olacak şekildedir). Aleti çalıştırın ve taşlama

diskini iş parçasının üzerine getirin.

2. İş parçasının yüzeyine karşı 15 ila 30 derece

arasında açı ile disk kenarını eğimli tutun.

3. Yeni bir taşlama diskini kullanırken B yönünde

çalışmayın, aksi taktirde disk iş parçasını

kesebilir. Diskin kenarı yuvarlanmış olduktan

sonra her yönünde, A ya da B, serbestçe

çalışabilirsiniz.

Açılması ve kapatılması (Şekil A)

Uyarı: Aleti kullanmadan önce yan kolun

iyice sıkıldığından emin olun.

Açma/kapama düğmesinin düzgün

çalıştığını kontrol edin.

Elektrik prizine takmadan önce açma/kapama

düğmesinin arka kısmına basarak aletin kapalı

olduğundan mutlaka emin olun.

Aleti çalıştırmak için, açma/kapama düğmesinin

arka kısmına basın ve öne doğru kaydırın. Aleti

kapatmak için açma/kapama düğmesinin arka

kısmına basın.

Uyarı: Aleti yük altındayken açıp

kapamayın.

Uygun el pozisyonu (Şekil G)

Uyarı: Ciddi yaralanma riskini azaltmak

için, DAİMA şekilde gösterilen uygun el

pozisyonunu kullanın.

Uyarı: Ciddi yaralanma riskini azaltmak

için, ani tepki ihtimaline karşı aleti DAİMA

sıkıca tutun.

Uygun el pozisyonu Şekil G’de gösterildiği gibi bir

elin yan kolunda (Şekil A) ve diğer elin aletin

gövdesinde olmasını gerektirir.

Anahtarlar

Uyarı: Daya iyi kontrol sağlamak için aleti

çalıştırırken, kullanımı sırasında ve diskin

veya aksesuarın dönmesi durana kadar

aletin gövdesini sıkı bir şekilde tutun. Disk

tamamen durmadıkça elektrikli aleti asla yere

koymayın.

Not: Beklenmeyen alet hareketini önlemek için

aleti yük altındayken açıp kapamayın.

Taşlama

makinesi iş yüzeyine dokunmadan önce tam hıza

kadar çalıştırın. Kapatmadan önce aleti iş

yüzeyinden kaldırın. Aleti elinizden bırakırken

mutlaka diskin durmasını bekleyin.

Açma/kapama düğmesi (1) (Şekil A)

Uyarı: Elektrik prizine takmadan önce

açma/kapama sürgülü düğmesinin ön

kısmını basıp bırakarak elektrikli aletin

kapalı olduğundan mutlaka emin olun. Kaçak

akım koruma cihazının ve devre kesicinin

çalışması, yanlışlıkla prizden çıkartma veya güç

kesintisi gibi herhangi bir elektrik kesintisi

sonrasında yukarıda açıklandığı gibi

açma/kapama sürgülü düğmesinin kapalı

olduğundan emin olun.

Aleti çalıştırmak için, açma/kapama sürgülü

düğmesini (1) aletin önüne doğru kaydırın ve

basın, alet çalışmaya başlayacaktır. Düğmeye

uygulanan baskı bırakıldığında alet duracaktır.

Açma/kapama düğmesinin özelliği

Aleti çalıştırmak için, açma/kapama sürgülü

düğmesini (1) aletin önüne doğru kaydırın ve

basın, alet çalışmaya başlayacaktır

.

Açma/kapama bastığınız sürece alet kesintisiz

çalışacaktır. Aleti kapatmak için açma/kapama

düğmesine basmayı bırakın. Alet derhal tepki

verir, bunun anlamı alet kapalı konuma geçmiştir.

Page 21

21

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Açıklama: Üzerinde çalıştığınız malzeme ile

temas etmeden önce, aşındırıcı diskin

maksimum hızda döndüğünden emin olun.

Kapatmadan önce aleti üzerinde çalıştığınız

malzemeden kaldırın.

Uyarı: Aleti yere bırakmadan önce

aşındırıcı diskin dönüşünün durduğundan

emin olun.

Döner vites kutusu (Şekil E)

Vites kutusu aletin gövdesi üzerine monte edilir

ve kesim esnasında kullanıcıya rahat bir deneyim

sunmak için döndürülebilir.

Döner vites kutusu sağa veya sola 90, 180 ve

270 derece dönebilir.

• Vites kutusu üzerindeki dört vidayı gevşetin.

• En uygun konuma ulaşına kadar vites

kutusunu döndürün.

• Vites kutusu üzerindeki dört vidayı sıkın.

• Dönme mekanizmasının kilitli olduğundan

emin olun.

Uyarı: Vites kutusu kilitli olmadığında aleti

KULLANMAYIN.

Metal uygulamalar

Aleti metal uygulamalarda kullanırken metal

talaşının neden olduğu kalıcı riskleri engellemek

için bir artık akım aygıtının (RCD) takılı

olduğundan emin olun.

Artık akım aygıtı güç kesilmesine neden olunca

aleti

yetkili STANLEY servis merkezine tamir için

getirin.

Uyarı: Uç çalışma koşullarında, metalle

çalışırken makine gövdesinde iletken toz

birikebilir. Bu ise makinenin içindeki

koruyucu izolasyonun bozulmasına ve olası

elektrik çarpması risklerine neden olabilir.

Aletin içinde metal toplanmasını önlemek için

havalandırma deliklerinin her gün temizlemesi

tavsiye edilir. «Bakım» kısmına bakın.

Taşlama disklerinin kullanılması

Uyarı: Metal tozu toplanma riski.

Taşlama diskinin metalde yoğun

kullanılması elektrik çarpması riskini

arttıracaktır. Bu riski azaltmak için aleti

kullanmadan önce artık akım aygıtını (RCD) takın

ve her gün havalandırma deliklerini temizleyin.

Havalandırma deliklerinin basınçlı hava ile

temizlemesi için aşağıdaki bakım talimatlarını

izleyin.

Bakım

STANLEY elektrikli aletiniz minimum

bakımla uzun bir süre çalışacak şekilde

tasarlanmıştır. Kesintisiz olarak

memnuniyet verici bir şekilde çalışması gerekli

özenin gösterilmesine ve düzenli temizliğe

bağlıdır.

Uyarı: Ciddi yaralanma riskini azaltmak için

herhangi bir ayar yapmadan ya da parça veya

aksesuarları söküp takmadan önce aleti

kapatın ve

güç kaynağından ayırın. Aleti

yeniden bağlamadan önce aletin kapalı

olduğundan emin olmak için tetik düğmesine

basıp bırakın.

Yağlama

Elektrikli aletiniz ek bir yağlama

gerektirmemektedir.

Temizleme

Uyarı: Havalandırma deliklerinin içinde ve

çevresinde görünür toz toplanırken hemen

basınçlı hava ile aletin gövdesinde birikmiş

tozu temizleyin. Bu işlemi yaparken onaylanmış

koruyucu gözlük ve yüz maskesi takmalısınız.

Uyarı: Aletin metalik olmayan parçalarını

temizlemek için asla çözücü veya başka

sert kimyasal kullanmayın. Bu kimyasallar bu

parçalarda kullanılan malzemeleri güçsüzleştirir.

Aleti temizlemek için, sadece yumuşak sabun ve

nemli bir bez kullanın. Aletin içine sıvı kaçmasına

kesinlikle izin vermeyin; aletin herhangi bir

parçasını bir sıvı içine daldırmayın.

Page 22

22

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

Aksesuarlar

Uyarı: STANLEY tarafından sunulan

aksesuarlar hariç, bütün başka

aksesuarlar ürün uyumluluğu için test

edilmemiştir. Bu alet ile birlikte bu tür

aksesuarların kullanılması güvenlik sorunlarına

neden olabilir. Yaralanma riskini en aza indirmek

için bu alet ile sadece STANLEY aksesuarların

kullanılması tavsiye edilir.

Uygun aksesuarlarla ilgili daha fazla bilgi için

bayiinize danışın.

Notlar

• STANLEY politikası gibi, ürünlerimizi sürekli

iyileştirme amacıyla önceden haber vermeden

ürün özelliklerini değiştirme hakkını saklı

tutarız.

• Standart ekipman ve aksesuarlar ülkeye göre

değişebilir.

• Ürün özellikleri ülkelere göre farklı olabilir.

• Komple ürün çeşidi tüm ülkelerde geçerli

olmayabilir. Ürün çeşidi durumu hakkında

lütfen en yakın STANLEY yetkili servisiyle

temas kurun.

Titreşim

Teknik veriler ve uygunluk beyanatı içerisinde

belirtilen titreşim emisyon değerleri EN60745

tarafından belirlenen standart bir test yöntemine

uygun olarak ölçülmektedir ve diğer bir aletle

karşılaştırma yaparken kullanılabilir. Beyan

edilen titreşim emisyon değeri aynı zamanda

maruz kalmanın önceden değerlendirilmesinde de

kullanılabilir.

Uyarı! Elektrikli aletin mevcut kullanımı

sırasındaki titreşim emisyon değeri, aletin

kullanım yöntemine bağlı olarak, beyan edilen

değere göre farklılık sergileyebilir. Titreşim düzeyi

belirlenen seviyenin üzerinde artış gösterebilir.

İşyerinde düzenli olarak elektrikli alet kullanan

çalışanları korumak amacıyla 2002/44/EC

tarafından getirilen elektrik güvenliği önlemlerini

belirlemek üzere titreşime maruz kalmayı

değerlendirirken, çalışma döngüsü içerisinde

örneğin aletin kapalı olduğu ve aktif durumda

olmasının yanı sıra boşta çalıştığı zamanlar gibi,

bütün zaman dilimleri dahil olmak üzere mevcut

kullanım durumu ve aletin kullanım şekli göz

önünde bulundurularak değerlendirilmelidir.

STGL2023

LpA (ses basıncı) dB(A) 92,5

KpA (ses basıncı belirsizli_i) dB(A) 3

LWA (ses gücü) dB(A) 103,5

KWA (ses gücü belirsizli_i) dB(A) 3

Titreşim emisyon değeri ah (yüzey taşlama)

ah.AG = m/s² 8

Belirsizlik K = m/s² 1,5

STGL2223

LpA (ses basıncı) dB(A) 93,0

KpA (ses basıncı belirsizli_i) dB(A) 3

LWA (ses gücü) dB(A) 104,0

KWA (ses gücü belirsizli_i) dB(A) 3

Titreşim emisyon değeri ah (yüzey taşlama)

ah.AG = m/s² 8,2

Belirsizlik K = m/s² 1,5

Servis bilgileri

STANLEY, yetkili servisler ile tam bir servis ağı

sunmaktadır. Tüm STANLEY Servis Merkezleri

müşterilere etkili ve güvenilir elektrikli el aleti

hizmeti sunmak için eğitimli personel ile

donatılmıştır. Yetkili servis merkezlerimiz

hakkında daha fazla bilgi almak istiyorsanız veya

teknik danışmanlık, onarım ya da orijinal fabrika

yedek parçası ihtiyacınız varsa, size en yakın

STANLEY satış noktasına başvurun.

STGL2023 STGL2223

Voltaj V

AC

220-240 220-240

Giriş gücü W 2000 2200

Frekans Hz 50/60 50/60

Yüksüz hızı dev/dak 6500 6500

Disk çapı mm 230 230

Mil çapı M14 M14

Taşlama diski kalınlığı

Taşlama diskleri mm 6.6 6.6

Ağırlık kg 4.9 5.9

Teknik özellikler

Page 23

23

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

İki yıl garanti

Sahip olduğunuz STANLEY ürünü satın alma tarihinden

itibaren 24 ay içinde hatalı malzeme veya işçilik nedeniyle

bozulursa, STANLEY aşağıdaki şartlara uyulması koşuluyla

ücretsiz olarak tüm kusurlu parçaların yenilenmesini veya

-kendi inisiyatifine bağlı olarak- satın alınan ürünün

değiştirilmesini garanti eder:

• Ürün, hatalı kullanılmamış kullanım kılavuzuna uygun

kullanılmıştır.

• Ürün yıpranmamış, hırpalanmamış ve aşınmamıştır;

• Yetkili olmayan kişilerce tamire çalışılmamıştır.

• Satın alma belgesi (fatura) ibraz edilmiştir.

• STANLEY ürünü, tüm orijinal parçaları ile birlikte iade

edilmiştir

Garanti talebinde bulunmak için, lütfen satıcıyla irtibata

geçin veya STANLEY katalogunda belirtilen size en yakın

STANLEY yetkili satıcı adresini kontrol edin veya ürünün

kılavuzunda belirtilen adresteki yerel STANLEY yetkili tamir

servisi ile temas kurun. İnternet’ten STANLEY yetkili tamir

servislerinin listesine ve satış sonrası hizmetlerimizle ilgili

tüm bilgilerine aşağıdaki siteden ulaşabilirsiniz:

www.stanleytools.com

AT Uygunluk Beyanatı

MAKİNE DİREKTİFİ

STGL2023, STGL2223 - Büyük Taşlama

STANLEY, «teknik özellikleri» bölümünde açıklanan bu

ürünlerin aşağıda belirtilen yönergelere uygun olduğunu

beyan eder: 2006/42/EC, EN 60745-1:2009 + A11:2010, EN

60745-2-3:2011

Bu ürünler ayrıca 2004/108/EC (until 19/04/2016)

2014/30/EU (from 20/04/2016) ve 2011/65/EU Direktiflerine

de uygundur. Daha fazla bilgi için, lütfen aşağıdaki adresten

STANLEY ile irtibata geçin veya kılavuzun arkasına bakın.

Bu belge altında imzası bulunan yetkili, teknik dosyanın

derlenmesinden sorumludur ve bu beyanı STANLEY adına

vermiştir.

R.Laverick

Mühendislik Bölümü Müdürü

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

07.2015

Sanayi ve Ticaret Bakanlığı tebliğince kullanım ömrü 7 yıldır.

Türkiye Distribütörü

STANLEY BLACK&DECKER TURKEY ALET URETIM SAN. TIC. LTD.STI.

Kozyatağı Mh Değirmen Sk. Nida Kule No:18 Kat:6, 34742 Kadıköy İstanbul

Tel : (0216) 665 29 00, Faks : (0216) 665 29 01, E-posta: info-tr@sbdinc.com

Page 24

N446374 07/2015

Loading...

Loading...