Page 1

STGB3715

English Page 3

Turkish Page 11

Page 2

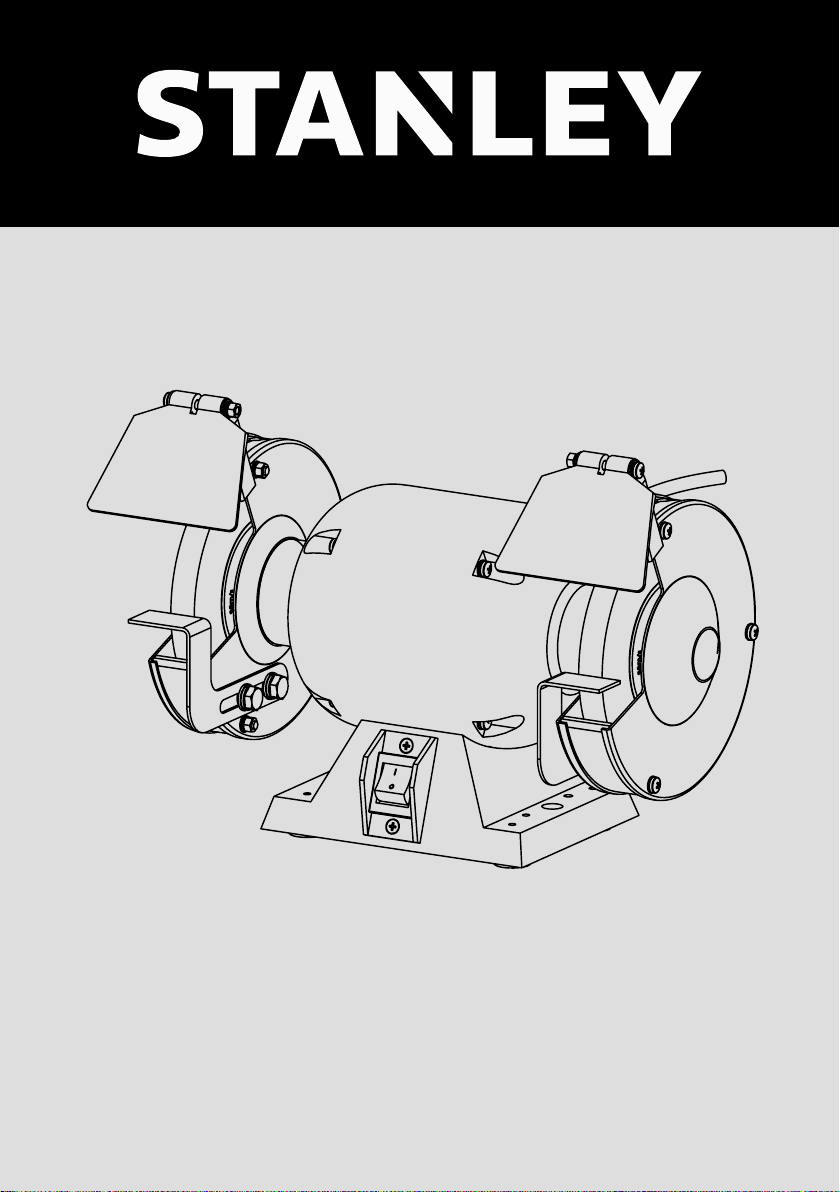

FIG. 1

FIG. 2

ENGLISH

(Original instructions)

B

A

MAX 2 mm

MAX 2 mm

C

2

Page 3

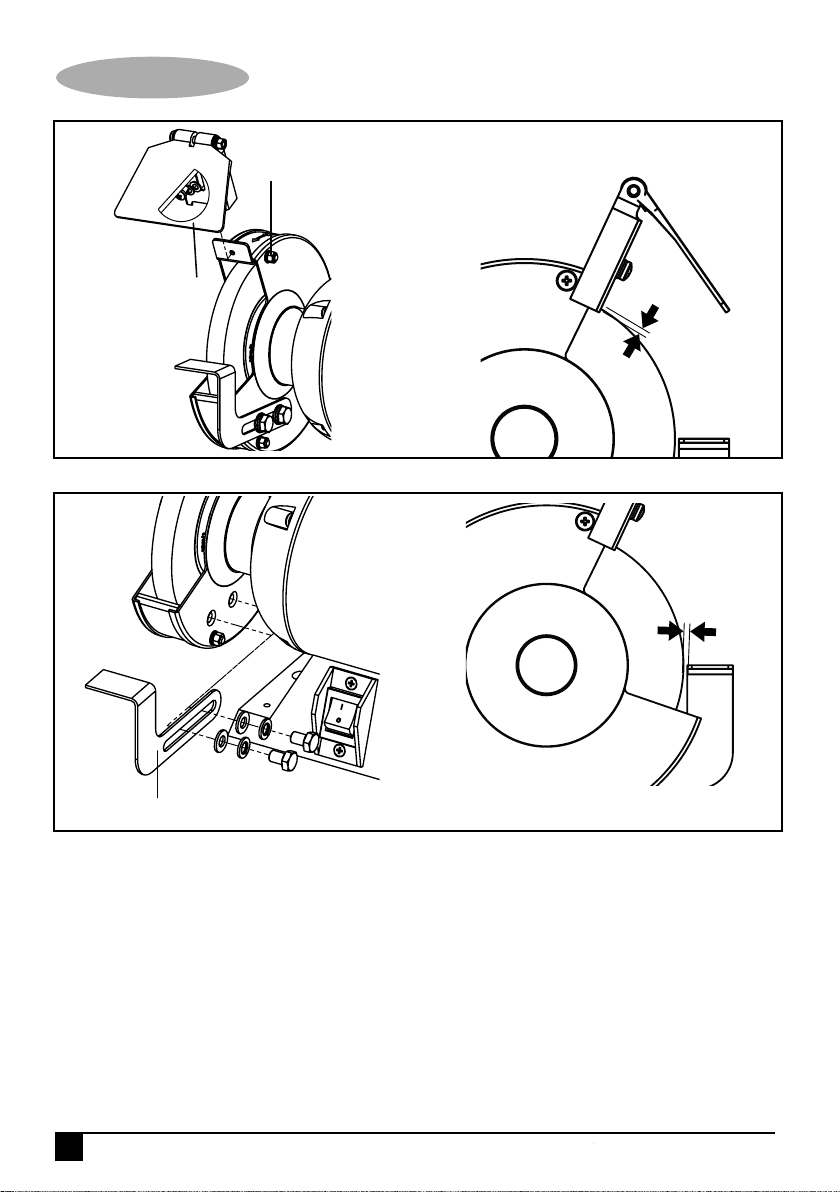

FIG. 3

(Original instructions)

D E F

ENGLISH

3

Page 4

ENGLISH

(Original instructions)

DO NOT RETURN THIS PRODUCT TO THE STORE,

first contact your local STANLEY Office

or nearest authorized service center.

Intended use

This tool is intended as a stationary machine for sharpening

of hand tools as well as for grinding and deburring metal

General Safety Rules

Warning! Read and understand all instructions.

Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

Safety instructions

General power tool safety warnings

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions listed below may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock. Note: The term “Residual Curent Device

(RCD)” can be replaced by “Ground Fault Circuit

Interrupter (GFCI)” or by “Earth Leakage Circuit Breaker

(ELCB)”.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

4

Page 5

(Original instructions)

ENGLISH

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is mainta

Additional Safety Rules For Bench Grinders

• Always use proper guard with grinding wheel. A guard

protects operator from broken wheel fragments.

• Accessories must be rated for at least the speed

recommended on the tool warning label.Wheels and

other accessories running over the rated speed can fly

apart and cause injury.

• Before using, inspect recommended accessory for

cracks or flaws. If such a crack or flaw is evident, discard

the accessory. DO NOT USE A GRINDING WHEEL

THAT IS CRACKED OR FLAWED IN ANY WAY.

• When starting the tool, let it run for one minute. Never

start the tool with a person in line with the wheel. This

includes the operator.

• Do not grind on the sides of grinding wheels unless they

are specifically designed for that purpose.

• Do not overtighten wheel clamp nut. This may crack the

grinding wheel.

• Clean the cavity around the grinding wheel periodically.

Warning! Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products, and arsenic and chromium from

chemically-treated lumber. (CCA)

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: Work in a well ventilated area, and work

with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

• Wear protective glasses;

• Do not use damaged or unshaped wheels;

• The adjustment of the spark arrestor shall be made

frequently, so as to compensate the wear of the wheel,

keeping the distance between the guard and the wheel

as small as possible, but in any case not greater than

2mm;

5

Page 6

ENGLISH

(Original instructions)

• The adjustment of the work rest shall be done gradually

so as to compensate the wear of the wheel, keeping the

distance between the work rest and the wheel as small

as possible, but in any case not greater than 2mm;

• Allow the tool to cool down after a continuous use of 20

minutes (S2 20min)

• Basic information on grinding wheels

1. Put grinding wheel in individual package, and keep in a

dry and well-ventilated place.

2. Various shortcomings during installation and operation

can lead to bursting of grinding wheels.

3. Ordinary grinding wheels are generally not designed to

withstand a greater lateral load.

4. Tap off cutting debris from the grinding wheel always

leads to damage of the grinding wheel.

5. Grinding wheels which may have an imbalance burst

easily.

6. An unbalance of a grinding wheel can not be completely

removed by withdrawing with a diamond dresser.

7. Incorrectly stored grinding wheels can burst immediately

after switching on, or individual small fragments fly away

like a bullet.

• Releasing jammed accessories. Release the pressure

on work piece, grinding wheels will return running.

6. Labels on tool

The label on your tool may include the following symbols:

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

....... No-Load

0

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Package Contents

The package contains:

1 Bench Grinder

2 Tool Rests

2 Eye Shields

2 Mounting Brackets

1 Instruction Manual

Features

This tool includes some or all of the following features.

• Lifting and transportation. Stop and disconnect machine.

Use two hands to lift up machine from two sides of

bottom of bearing housing.

• The work piece should be suitable for opening size

between wheels and plate. The machine is designed

and manufactured exclusively for grinding metals using

properly authorized grinding wheels. The grinding

machine must be used exclusively for this purpose.

6

A. Spark Guard

B. Screw

C. Tool Rest

D. Flange

E. Clamping Nut

F. Protective Cover

Page 7

(Original instructions)

ENGLISH

7. Electrical safety

Warning! If the power cord is damaged, it must

be replaced by the manufacturer, authorized

STANLEY Service Center or an equally qualified

person in order to avoid damage or injury. If the power cord

is replaced by an equally qualified person, but not

authorized by STANLEY, the warranty will not be valid.

Bench Mounting

1. The grinder should be unplugged.

2. Position grinder on workbench. Check for the availability

of power for the grinder. Mark location of holes for

drilling.

3. Drill appropriate sized holes.

4. Insert 1/4” (6mm) Hex head bolts through washers and

the holes. You may want to use washers on the

underside of the bench as well.

5. Tighten the nuts. Do not overtighten. Allow the rubber

feet to absorb the vibration when the grinder is running.

Installing eye shields and mounting of spark guard

(Fig. 1)

Turn off tool and disconnect from power supply. Adjust

the eye shields so they are between the wheels and your

eyes.

Note: Eye shields are not designed to replace safety

glasses.

• Mounting of spark guard

- loosen screw B (do not remove it)

! regularly check the distance between spark guard A

and the grinding wheel (max. 2 mm) and re-adjust, if

necessary

- replace the grinding wheel, if it is worn down to the point

where spark guard A can no longer be adjusted to the

maximum distance of 2 mm

Installing tool rests (Fig. 2)

Turn off power and disconnect from power supply. Use

the bolts, washers, spacers and lock nuts from the plastic

bag to secure the brackets and tool rests in place.

Caution: Use the washers and screws supplied.

Longer screws may interfere with the movement

of the grinding wheel.

! regularly check the distance between tool rest C and the

grinding wheel (max. 2 mm) and re-adjust, if necessary

• Mounting tool on working surface

Operation

Never use a bench grinder if it is not firmly fastened to a

work bench or rigid frame. Before turning the grinder on,

put on safety glasses. Turn on the grinder and allow it to

reach full speed ( 2950 /min) . Hold the workpiece firmly and

against the tool rest. Hold very small pieces with pliers or

other suitable clamps. Feed the work smoothly and evenly

into the grinding wheel. Move the work slowly and avoid

jamming the work against the wheel. As the wheel tends to

slow down you should occasionally release the pressure to

let the wheel return to full speed.

Grind only on the face of the grinding wheel and never on

the side. (Some wheels are designed for side grinding and

will say so on their instruction sheets).

Caution: Prolonged grinding will cause most

materials to become hot. Handle them with

pliers.

Switch

The switch is located on the front of the grinder, on the base.

To turn the tool on depress the side of the rocker switch on

the right side, marked “1”. To turn off the grinder, depress the

left side of the rocker switch, marked “ O ”.

Changing Accessories

Turn off the tool and disconnect from power supply. Use only

wheels that measure 152mm in diameter. This tool has

13mm arbors on both sides. Follow the steps below to

remove and replace an accessory.

Replacing grinding wheels (FIG.3)

! disconnect the plug

! use only grinding wheels with an allowable speed

7

Page 8

ENGLISH

(Original instructions)

matching at least the highest no-load speed of the tool

! use only original Stanley grinding wheels

- remove protective cover F by loosening (not removing)

the 3 screws B

- unscrew clamping nut E with a spanner

- remove clamping flange D and grinding wheel

- for mounting new grinding wheel handle in reversed

order

! perform a sound-test on new grinding wheels and test-run

them without load for at least 5 minutes (stay out of danger

area)

Maintenance

Your tool has been designed to operate over a long period of

time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and

regular cleaning.

Warning! Before performing any maintenance, switch off

and unplug the tool.

• Regularly clean the ventilation slots in Your tool using a

soft brush or dry cloth.

• Regularly clean the motor housing using a damp cloth.

Do not use any abrasive or solvent-based cleaner.

Cleaning

Blowing dust and grit out of the wheel guards using

compressed air is a necessary regular maintenance

procedure. Dust and grit containing metal particles often

accumulate on interior surfaces and could create an

electrical shock hazard if not frequently cleaned out.

ALWAYS WEAR SAFETY GLASSES.

Caution! Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. Use clean, dry rag

only.

Accessories

The performance of your tool depends on the accessory

used. STANLEY accessories are engineered to high quality

standards and designed to enhance the performance of your

tool. By using these accessories you will get the very best

from your tool.

Specifications

STGB3715

Voltage 230V

Frequency 50Hz

Power 373W

No-load speed 2950/min (rpm)

Wheel diameter 152mm (6”)

Cord 1m

Weight 8.6kg

Service Information

STANLEY offers a full network of company-owned and

authorized service locations. All STANLEY Service Centers

are staffed with trained personnel to provide customers with

efficient and reliable power tool service. For more

information about our authorized service centers and if you

need technical advice, repair, or genuine factory

replacement parts, contact the STANLEY location nearest

you.

LpA (sound pressure) dB(A) 58,0

K

(sound pressure uncertainty) dB(A) 3

pA

LWA (sound power) dB(A) 72.5

KWA (sound power uncertainty) dB(A) 3

8

Page 9

(Original instructions)

ENGLISH

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Stanley product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Stanley provides a facility for the collection and recycling of

Stanley products once they have reached the end of their

working life. To take advantage of this service please return

your product to any authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Stanley office at the address

indicated in this manual. Alternatively, a list of authorised

Stanley repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com

EC declaration of conformity

MACHINERY DIRECTIVE

STGB3715

STANLEY declares that these products described under

"technical data" are in compliance with:

2006/42/EC, EN 61029-1, EN 61029-2-4

These products also comply with Directive

2014/30/EU and 2011/65/EU. For more information, please

contact STANLEY at the following address or refer to the

back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

STANLEY.

R.Laverick

Engineering Manager

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2015

9

Page 10

ENGLISH

(Original instructions)

Two years full warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY Europe guarantees to replace all

defective parts free of charge or – at our discretion – replace

the unit free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

10

Page 11

FIG. 1

FIG. 2

(Orijinal talimatlar)

TÜRKÇE

B

A

MAX 2 mm

MAX 2 mm

C

11

Page 12

FIG. 3

TÜRKÇE

(Orijinal talimatlar)

D E F

12

Page 13

(Orijinal talimatlar)

TÜRKÇE

BU ÜRÜNÜ MAĞAZAYA İADE ETMEYİN;

önce en yakın STANLEY ofisine veya

yetkili servis merkezine başvurun.

Kullanım amacı

Bu alet tezgah tipi kullanılmak üzere, taşlama, metal pas

kazıma ve el aletlerinin keskinleştirilmesi için tasarlanmıştır.

Genel Güvenlik Kuralları

Uyarı! Bütün güvenlik uyarılarını ve talimatlarını

okuyun ve anlayın. Aşağıda belirtilen tüm

talimatların herhangi birisine uyulmaması elektrik

çarpması, yangın ve/veya ciddi yaralanma riskine neden

olabilir.

BU TALİMATLARI SAKLAYIN

Güvenlik talimatları

Genel elektrikli alet güvenlik uyarıları

UYARI! Bütün güvenlik uyarılarını ve talimatlarını

mutlaka okuyun. Aşağıda yer alan uyarılar ve

talimatların herhangi birisine uyulmaması elektrik çarpması,

yangın ve/veya ciddi yaralanma riskine neden olabilir.

Bütün uyarı ve güvenlik talimatlarını ileride bakmak

üzere saklayın.

Aşağıda yer alan uyarılardaki «elektrikli alet» terimi şebeke

elektriğiyle (kablolu) veya akü/pille (şarjlı) çalışan elektrikli

aletinizi ifade etmektedir.

1. Çalışma alanının güvenliği

Çalışma alanını temiz ve aydınlık tutun. Karışık veya

karanlık alanlar kazaya davetiye çıkartır.

Elektrikli aletleri, yanıcı sıvılar, gazlar ve tozların

bulunduğu yerler gibi yanıcı ortamlarda çalıştırmayın.

Elektrikli aletler, toz veya dumanları ateşleyebilecek

kıvılcımlar çıkartır.

Bir elektrikli aleti çalıştırırken çocuklardan ve etraftaki

kişilerden uzak tutun. Dikkatinizi dağıtıcı şeyler kontrolü

kaybetmenize neden olabilir.

2. Elektrik güvenliği

Elektrikli aletlerin fişleri prizlere uygun olmalıdır. Fiş

üzerinde kesinlikle hiçbir değişiklik yapmayın. Topraklı

elektrikli aletlerde hiçbir adaptör fişi kullanmayın.

Değiştirilmemiş fişler ve uygun prizler elektrik çarpması

riskini azaltacaktır.

Borular, radyatörler, ocaklar ve buzdolapları gibi

topraklanmamış yüzeylerle vücut temasından kaçının.

Vücudunuzun topraklanması halinde yüksek bir elektrik

çarpması riski vardır.

Elektrikli aletleri yağmura maruz bırakmayın veya

ıslatmayın. Elektrikli alete su girmesi elektrik çarpması

riskini arttıracaktır.

Elektrik kablosunu uygun olmayan amaçlarla

kullanmayın. Elektrikli aleti kesinlikle kablosundan

tutarak taşımayın, çekmeyin veya prizden çıkartmayın.

Kabloyu sıcaktan, yağdan, keskin kenarlardan veya hareketli

parçalardan uzak tutun. Hasarlı veya dolaşmış kablolar

elektrik çarpması riskini arttırır.

Elektrikli bir aleti açık havada çalıştırıyorsanız, açık

havada kullanıma uygun bir uzatma kablosu kullanın.

Açık havada kullanıma uygun bir kablonun kullanılması

elektrik çarpması riskini azaltır.

Eğer bir elektrikli aletin nemli bir bölgede çalıştırılması

zorunluysa, bir artık akım aygıtı (RCD) korumalı bir

kaynak kullanın. Bir RCD kullanılması elektrik şoku

riskini azaltır. Not: «Artık Akım Aygıtı (RCD)» tanımı,

«Kaçak Akım Koruma Cihazı (GFCI)» veya «Toprak Kaçağı

Devre Kesici (ELCB)» tanımları ile değiştirilebilir.

3. Kişisel güvenlik

Elektrikli bir aleti kullanırken her zaman dikkatli olun,

yaptığınız işe yoğunlaşın ve sağduyulu davranın.

Elektrikli bir aleti yorgunken veya ilaç ya da alkolün etkisi

altındayken kullanmayın. Elektrikli aletleri kullanırken bir

anlık dikkatsizlik ciddi kişisel yaralanmayla sonuçlanabilir.

Kişisel koruyucu ekipmanları mutlaka kullanın. Daima

koruyucu gözlük takın. Koşullara uygun toz maskesi,

kaymayan güvenlik ayakkabıları, baret veya kulaklık gibi

koruyucu donanımların kullanılması kişisel yaralanmaları

azaltacaktır.

İstem dışı çalıştırılmasını önleyin. Aleti güç kaynağına

ve/veya aküye bağlamadan, yerden kaldırmadan veya

taşımadan önce düğmenin kapalı konumda olduğundan

emin olun. Aleti, parmağınız düğme üzerinde bulunacak

şekilde taşımak veya açık konumdaki elektrikli aletleri

elektrik şebekesine bağlamak kazaya davetiye çıkartır.

Elektrikli aleti açmadan önce tüm ayarlama anahtarlarını

çıkartın. Elektrikli aletin hareketli bir parçasına takılı kalmış

bir anahtar kişisel yaralanmaya neden olabilir.

Ulaşmakta zorlandığınız yerlerde kullanmayın. Daima

sağlam ve dengeli basın. Bu, beklenmedik durumlarda

elektrikli aletin daha iyi kontrol edilmesine olanak tanır.

Uygun şekilde giyinin. Bol elbiseler giymeyin ve takı

takmayın. Saçınızı, elbiselerinizi ve eldivenlerinizi hareketli

parçalardan uzak tutun. Bol elbiseler ve takılar veya uzun

saç hareketli parçalara takılabilir.

13

Page 14

ENGLISH

(Original instructions)

Eğer kullandığınız üründe toz emme ve toplama

özellikleri olan ataşmanlar varsa bunların bağlı

olduğundan ve doğru şekilde kullanıldığından emin

olun. Bu toz toplama ataşmanların kullanılması tozla ilgili

tehlikeleri azaltabilir.

4. Elektrikli aletlerin kullanımı ve bakımı

Elektrikli aleti zorlamayın. Uygulamanız için doğru

elektrikli aleti kullanın. Doğru elektrikli alet, belirlendiği

kapasite ayarında kullanıldığında daha iyi ve güvenli

çalışacaktır.

Düğme açmıyor ve kapatmıyorsa elektrikli aleti

kullanmayın. Düğmeyle kontrol edilemeyen tüm elektrikli

aletler tehlikelidir ve tamir edilmesi gerekmektedir.

Herhangi bir ayarlama, aksesuar değişimi veya elektrikli

aletlerin saklanması öncesinde fişi güç kaynağından

çekin ve/veya aküyü elektrikli aletten ayırın. Bu tür

önleyici güvenlik tedbirleri aletin istem dışı olarak

çalıştırılması riskini azaltacaktır.

Elektrikli aleti, çocukların ulaşamayacağı yerlerde

saklayın ve elektrikli aleti tanımayan veya bu talimatları

bilmeyen kişilerin elektrikli aleti kullanmasına izin

vermeyin. Elektrikli aletler, eğitimsiz kullanıcıların elinde

tehlikelidir.

Elektrikli aletleri iyi durumda muhafaza edin. Hareketli

parçalardaki hizalama hatalarını ve tutuklukları,

parçalardaki kırılmalar ve elektrikli aletin çalışmasını

etkileyebilecek tüm diğer koşulları kontrol edin. Hasarlı

ise, elektrikli aleti kullanmadan önce tamir ettirin. Kazaların

çoğu, elektrikli aletlerin bakımının yeterli şekilde

yapılmamasından kaynaklanır.

Kesim aletlerini keskin ve temiz tutun. Bakımı uygun

şekilde yapılmış keskin kesim uçlu kesim aletlerinin sıkışma

ihtimali daha düşüktür ve kontrol edilmesi daha kolaydır.

Elektrikli aleti, aksesuarlarını ve aletin diğer parçalarını

kullanırken bu talimatlara mutlaka uyun ve çalışma

ortamının koşullarını ve yapılacak işin ne olduğunu göz

önünde bulundurun. Elektrikli aletin öngörülen işlemler

dışındaki işlemler için kullanılması tehlikeli durumlara neden

olabilir.

5. Servis

Elektrikli aletinizi, sadece orijinal yedek parçaların

kullanıldığı yetkili servise tamir ettirin. Bu, elektrikli aletin

güvenliğinin muhafaza edilmesini sağlayacaktır.

Taş motorları için ek güvenlik talimatları

Taşlama diski ile daima uygun koruyucu siperliği veya

kalkanı kullanın. Siperlik veya kalkan, kullanıcının kırılan disk

parçacıklarından korunmasına yardımcı olur.

Aksesuarlar, aletin uyarı etiketinde tavsiye edilen veya daha

yüksek hız seviyeli olmalıdır. Nominal hızından daha hızlı

çalışan diskler ve diğer aksesuarlar etrafa saçılabilir ve

yaralanmalara neden olabilir.

Kullanmadan önce, tavsiye edilen aksesuarda herhangi bir

çatlak ya da yarık olup olmadığını kontrol edin. Üzerinde

çatlak ya da yarık olan aksesuarı atın. ÇATLAMIŞ VEYA

HERHANGİ BİR ŞEKİLDE KUSURLU OLAN TAŞLAMA

DİSKLERİNİ KULLANMAYIN.

Aleti çalıştırırken bir dakika boyunca çalışmasına izin verin.

Disk ile aynı hizada insanlar varsa, aleti asla çalıştırmayın.

Bu koşul kullanıcı için de geçerlidir.

Özellikle bu amaç için tasarlanmış değil ise taşlama diskin

yanları ile taşlama etmeyin.

Disk sıkıştırma somununu aşırı sıkmayın. Bu, taşlama diskini

çatlatabilir.

Taşlama diski etrafındaki boşluğu düzenli olarak temizleyin.

Uyarı! Güçlü zımparalama, kesme, taşlama, delme ve diğer

inşaat faaliyetleri sırasında oluşturulan bazı tozlar, kansere,

doğum kusurlarına ve başka yeniden oluşabilen zararlara

sebep olduğu bilinen kimyasalları içerir. Bu kimyasal

maddelerin bazı örnekleri şunlardır:

Kurşun bazlı boyalardan kurşun,

tuğla, çimento ve diğer duvarcılık ürünlerinden silika

kristaline, ve kimyasal olarak işlenmiş keresteden arsenik ve

krom.

Yukarıdakilere maruz kalma riskiniz bu tip işleri ne kadar

sıklıkla yaptığınıza göre değişir. Bu kimyasallara maruz

kalma olasılığınızı azaltmak için: Aleti iyi havalandırmalı bir

yerde kullanın ve çalışırken özel mikroskobik partikülleri

filtrelemek için tasarlanmış olan toz maskesi gibi onaylı

koruyucu ekipmanları kullanın.

Koruyucu gözlük takın;

Hasar görmüş olan veya şekilsiz taşlama disklerini

kullanmayın.

Kıvılcım kalkanı ayarı sık sık yapılmalıdır; bu, disk

aşınmasını azaltacak ayrıca disk ve kalkan arasındaki

mesafeyi mümkün olduğu kadar düşük (ancak 2 mm’den

daha fazla değil) bırakır.

14

Page 15

(Original instructions)

ENGLISH

Iş parçası desteği ayarı kademeli olarak yapılmalıdır; bu,

disk aşınmasını azaltacak ayrıca disk ve iş parçası desteği

arasındaki mesafeyi mümkün olduğu kadar düşük (ancak 2

mm’den daha fazla değil) bırakır;

20 dakikalık (S2 20min) kesintisiz bir kullanımdan sonra

aletin soğumasını bekleyin)

Taşlama diskleri hakkında temel bilgiler

Taşlama diskini ayrı ambalaja koyun ve kuru ve iyi

havalandırılan bir alanda saklayın.

Montaj ve kullanım sırasında çeşitli kusurlar taşlama

disklerinin patlamasına yol açabilmektedir.

Sıradan taşlama diskleri genellikle daha büyük bir yanal

yüke dayanacak şekilde tasarlanmış değildir.

Kesim talaşını temizlemek için taşlama diskine vurmak

taşlama diskine her zaman zarar verir.

Bir dengesizliği olabilen taşlama diskleri kolayca

patlayabililer.

Taşlama diskinin balanssızlığı elmas yontma ile tamamen

giderilemez.

Yanlış bir şekilde saklanan taşlama diskleri alet açıldıktan

hemen sonra patlayabilir ya da küçük parçaları mermi gibi

tek tek uçar.

Sıkışmış aksesuarlarının çıkartılması. İş parçasına

uygulanan baskıyı azaltın ve taşlama diskleri yeniden

dönmeye başlayacaktır.

Kaldırma ve taşıma. Aleti durdurun ve yerinden sökün. Aleti,

rulman gövdesini alttan iki taraftan ve iki elinizi de kullanarak

kaldırın.

Iş parçası, diskler ve taban arasındaki boyut açılması için

uygun olmalıdır. Alet, usulüne uygun olarak üretilmiş

taşlama disklerini kullanarak metal zımparalama için özel

olarak tasarlanmış ve üretilmiştir. Taş motoru sadece bu

işler için kullanılmalıdır.

6. Alet üzerindeki etiketler

Alet üzerinde aşağıdaki semboller bulunabilir:

Kullanım

Kılavuzunu

Okuyun

Koruyucu

Gözlük kullanın

Kulaklık

Kullanın

V ........ Volt

A ........ Amper

Hz ....... Hertz

W ........ Vat

dak ..... dakika

Alternatif

.....

Akım

Direkt

.....

Akım

boş .......

Yüksüz

Hız

......

....

....

.../min..

Sınıf II

İnşaat

Topraklama

Terminal

Güvenlik

uyarısı

Sembolü

Dakikada

devir veya

gel git sayısı

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Ambalajın İçeriği

Ambalaj, aşağıdaki parçaları içermektedir:

1 Taş motoru

2 İş parçası desteği

2 Koruyucu siperlik

2 Montaj braketi

1 Kullanım kılavuzu

ÖZELLİKLER

Bu alet, aşağıdaki özelliklerin bir kısmını veya tümünü

içermektedir.

A. Kıvılcım muhafazası

B. Vida

C. İş parçası desteği

D. Flanş

E. Sıkıştırma somunu

F. Koruyucu kapak

15

Page 16

ENGLISH

(Original instructions)

7. Elektrik güvenliği

Uyarı! Elektrik kablosu hasarlı ise, bir tehlike

oluşmasını önlemek için üretici ya da yetkili

STANLEY Servis Merkezi tarafından

değiştirilmelidir. Elektrik kablosu STANLEY yetkili servisi

haricinde değiştirilirse, garanti geçerli olmayacaktır.

Tezgaha montajı

Taş motorunun fişi prizden çekilmiş olmalıdır.

Taş motorunu tezgah üzerinde yerleştirin. Taş motorun

kullanabileceği güç kaynağını kontrol edin. Delinecek delik

yerlerini işaretleyin.

Uygun çapta delikleri delin.

Pullara ve deliklere 6 mm altıgen başlı cıvataları sokun.

Ayrıca pulları tezgahın alt tarafından da kullanabilirsiniz.

Somunları sıkın. Aşırı sıkmayın. Taş motoru çalışma

sırasında lastik ayaklara titreşimi emmeye izin verin.

Koruyucu siperliklerin ve kıvılcım kalkanının takılması

(Şekil 1)

Aleti kapatın ve fişini şebekeden çekin. Koruyucu siperlikleri,

gözleriniz ve disklerin arasında olacak şekilde ayarlayın.

Not: Siperlikler koruyucu gözlük yerine kullanılması için

tasarlanmış değildir.

Kıvılcım kalkanının takılması

Vidayı B gevşetin (ama çıkartmayın).

Kıvılcım kalkanı A ve taşlama diski arasındaki mesafeyi

düzenli olarak kontrol edin (maks. 2 mm), gerekirse

ayarlama yapın.

Kıvılcım kalkanı A en fazla 2 mm'lik azami mesafe

ayarlanabilir noktasına aşınmış ise, taşlama diskini

değiştirin.

İş parçası desteklerinin takılması (Şekil 2)

Aleti kapatın ve fişini şebekeden çekin. Braketleri ve iş

parçası desteklerini yerinde sabitlemek için plastik poşette

bulunan cıvataları, pulları, destek parçalarını ve sıkıştırma

somunları kullanın.

Uyarı: Aletle birlikte verilmiş olan pulları ve

vidaları kullanın. Daha uzun vidalar taşlama

diskin dönmesine engel olabilir.

İş parçası desteği C ve taşlama diski arasındaki mesafeyi

düzenli olarak kontrol edin (maks. 2mm), gerekirse ayarlama

yapın.

İş parçasını çalışma alanında yerleştirin.

Kullanım

Sıkıca bir tezgah ya da sert çerçeveye sabitlenmiş değilse

bir taş motorunu asla kullanmayın. Taş motorunu

çalıştırmadan önce koruyucu gözlük takın. Taş motorunu

çalıştırın ve tam hıza ulaşmasını bekleyin (2950 dev./dak.).

İş parçasını destek üzerinde sıkı tutun. Çok ufak iş parçaları

pense veya diğer uygun kelepçeler ile sabitleyin. İş parçasını

yumuşak ve eşit bir şekilde taşlama diskine yaklaştırın. İş

parçasını yavaşça hareket ettirin ve taşlama diskinde

sıkışmasından kaçının. Disk yavaşlama eğilimine girmiş

olduğunda baskıyı azaltın ve diskin tam hızına ulaşmasına

izin verin.

Taşlama işleri sadece disk yüzeğinde yapın; diskin yan

taraflarını asla kullanmayın. (Bazı diskler yan taşlama için

tasarlanmıştır; bu onların kullanım talimatlarında yazılmıştır).

Uyarı: Uzun süreli taşlama çoğu malzemelerin

sıcak hale gelmesine neden olabilir. Bu

malzemeleri pense yardımı ile tutun.

Tetik

Açma/kapama tetiği taş motorunun tabanında ön tarafta

bulunmaktadır. Aleti açmak için, açma/kapama tetiğinin «I»

işaretli sağ kısmına basın. Aleti kapatmak için, açma/kapama

tetiğinin «O» işaretli sol kısmına basın.

Aksesuarları değiştirme

Aleti kapatın ve fişini şebekeden çekin. Sadece 152 mm çapı

olan diskleri kullanın. Bu aletin iki tarafında 13 mm çapında

göbekler vardır. Aksesuarı çıkartmak ve yeniden takmak için

aşağıdaki talimatlara uyun.

Taşlama disklerinin takılması (ŞEKİL 3)

Aletin fişini şebekeden çıkarın

Sadece uygun olan maksimum hız, her zaman aletin

üzerindeki etikette belirtilen yüksüz hıza eşit veya bu hızdan

daha yüksek olan diskleri kullanın

16

Page 17

(Orijinal talimatlar)

TÜRKÇE

Sadece orijinal Stanley taşlama disklerini kullanın.

3 vidayı B gevşetin (ama çıkartmayın) ve koruyucu kapağı F

çıkartın.

Anahtar kullanarak sıkıştırma somunu E sökün.

Sıkıştırma flanşı D ve taşlama diskini çıkartın.

Ters sırayla yeni taşlama diskini takın.

Yeni taşlama disk ile ses testi yapın ve tehlikeli alanın

dışında kalarak aletin en az 5 dakika süre ile yüksüz

çalışmasına izin verin)

Bakım

Aletiniz minimum bakımla uzun bir süre çalışacak şekilde

tasarlanmıştır. Kesintisiz olarak memnuniyet verici bir şekilde

çalışması gerekli özenin gösterilmesine ve düzenli temizliğe

bağlıdır.

Uyarı! Bakımdan önce aletin kapalı ve fişinin çekilmiş

olduğundan emin olun.

Aletinizdeki havalandırma deliklerini yumuşak bir fırça veya

kuru bir bezle düzenli olarak temizleyin.

Motor muhafazasını düzenli olarak nemli bir bezle silin.

Aşındırıcı veya çözücü bazlı temizleyiciler kullanmayın.

Temizleme

Basınçlı havayı kullanarak disk muhafızların toz ve kum

temizlemesi gerekli düzenli bir bakım işlemidir. Metal içeren

toz ve parçacıklar sıkça iç yüzeylerde birikir ve düzenli

olarak temizlenmezse elektrik şoku tehlikesine neden

olabilir.

HER ZAMAN KORUYUCU GÖZLÜK TAKIN.

Uyarı! Aletin metalik olmayan parçalarını temizlemek için

asla çözücü veya başka sert kimyasal kullanmayın. Sadece

temiz ve kuru bez kullanın.

Aksesuarlar

Aletinizin performansı kullanılan aksesuara bağlıdır.

STANLEY aksesuarları, yüksek kalite standartlarına göre

üretilmiş ve aletinizin performansını arttıracak şekilde

tasarlanmıştır. Bu aksesuarları kullanarak, aletinizden en iyi

verimi alacaksınız.

Teknik özellikler

STGB3715

Voltaj 230 V

Frekans 50 Hz

Güç 373 W

Yüksüz hızı 2950 dev/dak

Disk çapı 152 mm

Kablo uzunluğu 1 m

Ağırlık 8,6 kg

Servis bilgileri

STANLEY, kendisine ait ve yetkili servisler ile tam bir servis

ağı sunmaktadır. Tüm STANLEY Servis Merkezleri

müşterilere etkili ve güvenilir elektrikli el aleti hizmeti sunmak

için eğitimli personel ile donatılmıştır. Yetkili servis

merkezlerimiz hakkında daha fazla bilgi almak istiyorsanız

veya teknik danışmanlık, onarım ya da orijinal fabrika yedek

parçası ihtiyacınız varsa, size en yakın STANLEY satış

noktasına başvurun.

LpA (ses basıncı) dB(A) 58,0

KpA (ses basıncı belirsizlii) dB(A) 3

LWA (akustik güç) dB(A) 72,5

KWA (akustik gücü belirsizlii) dB(A) 3

17

Page 18

TÜRKÇE

(Orijinal talimatlar)

Çevrenin korunması

Ayrı olarak atın. Bu ürün, normal evsel atıklarla

birlikte atılmamalıdır.

STANLEY ürününüzün değiştirilmesi gerektiğini düşünmeniz

veya artık kullanılamaz durumda olması halinde onu, evsel

atıklarla birlikte atmayın. Bu ürünü, ayrı olarak toplanacak

şekilde atın.

Kullanılmış ürünlerin ve ambalajların ayrı olarak

toplanması bu maddelerin geri dönüşüme sokularak

yeniden kullanılmasına olanak tanır. Geri dönüşümlü

maddelerin tekrar kullanılması çevre kirliliğinin önlenmesine

yardımcı olur ve ham madde ihtiyacını azaltır.

Yerel yönetmelikler, elektrikli ürünlerin evlerden toplanıp

belediye atık tesislerine aktarılması veya yeni bir ürün satın

alırken perakende satıcı tarafından toplanması yönünde

hükümler içerebilir. STANLEY, hizmet ömrünün sonuna

ulaşan STANLEY ürünlerinin toplanması ve geri dönüşüme

sokulması için bir imkân sunmaktadır. Bu hizmetin

avantajlarından faydalanmak için, lütfen, ürününüzü bizim

adımıza teslim alacak herhangi bir yetkili servise iade edin.

Bu kılavuzda belirtilen listeden size en yakın STANLEY

yetkili tamir servisinin yerini öğrenebilirsiniz. Ya da, alternatif

olarak internet’ten STANLEY yetkili tamir servislerinin

listesini ve satış sonrası hizmetlerimizle ilgili tüm bilgiler ve

temas bilgilerine aşağıdaki siteden ulaşabilirsiniz.

www.2helpU.com

AT Uygunluk Beyanatı

MAKİNE DİREKTİFİ

STGB3715

STANLEY, «teknik özellikleri» bölümünde açıklanan bu

ürünlerin aşağıda belirtilen yönergelere uygun olduğunu

beyan eder: 2006/42/EC, EN 61029-1, EN 61029-2-4

Bu ürünler ayrıca 2014/30/EU ve 2011/65/EU Direktiflerine

de uygundur. Daha fazla bilgi için, lütfen aşağıdaki adresten

STANLEY ile irtibata geçin veya kılavuzun arkasına bakın.

Bu belge altında imzası bulunan yetkili, teknik dosyanın

derlenmesinden sorumludur ve bu beyanı STANLEY adına

vermiştir.

R.Laverick

Mühendislik Bölümü Müdürü

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2015

18

Page 19

İki yıl tam garanti

Sahip olduğunuz STANLEY ürünü satın alma tarihinden

itibaren 24 ay içinde hatalı malzeme veya işçilik nedeniyle

bozulursa, STANLEY Europe aşağıdaki şartlara uyulması

koşuluyla ücretsiz olarak tüm kusurlu parçaların

yenilenmesini veya -kendi inisiyatifine bağlı olarak- satın

alınan ürünün değiştirilmesini garanti eder:

Ürün, hatalı kullanılmamış kullanım kılavuzuna uygun

kullanılmıştır.

Ürün yıpranmamış, hırpalanmamış ve aşınmamıştır;

Yetkili olmayan kişilerce tamire çalışılmamıştır.

Satın alma belgesi (fatura) ibraz edilmiştir.

STANLEY ürünü, tüm orijinal parçaları ile birlikte iade

edilmiştir

Garanti talebinde bulunmak için, lütfen satıcıyla irtibata geçin

veya STANLEY katalogunda belirtilen size en yakın

STANLEY yetkili satıcı adresini kontrol edin veya ürünün

kılavuzunda belirtilen adresteki yerel STANLEY yetkili tamir

servisi ile temas kurun. İnternet’ten Stanley yetkili tamir

servislerinin listesine ve satış sonrası hizmetlerimizle ilgili

tüm bilgilerine aşağıdaki siteden ulaşabilirsiniz:

www.stanleytools.com

(Orijinal talimatlar)

TÜRKÇE

19

Page 20

Sanayi ve Ticaret Bakanlığı tebliğince kullanım ömrü 7 yıldır.

Türkiye Distribütörü

STANLEY BLACK&DECKER TURKEY ALET URETIM SAN. TIC. LTD.STI.

Kozyatağı Mh Değirmen Sk. Nida Kule No:18 Kat:6

34742 Kadıköy İstanbul

Tel: (0216) 665 29 00

Faks: (0216) 665 29 01

E-posta:

Loading...

Loading...