Page 1

STDR5206

English Page 3

Russian Page 13

Ukrainian Page 23

Page 2

ENGLISH

(Original instructions)

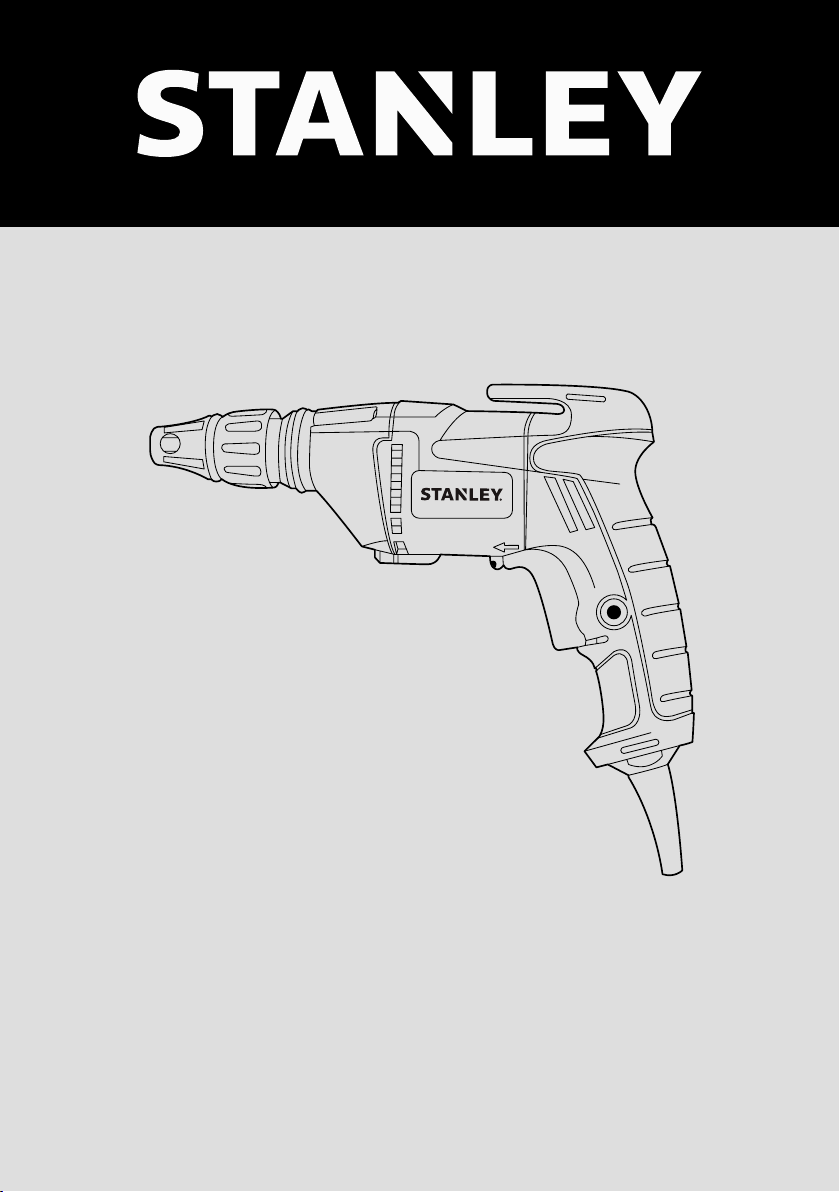

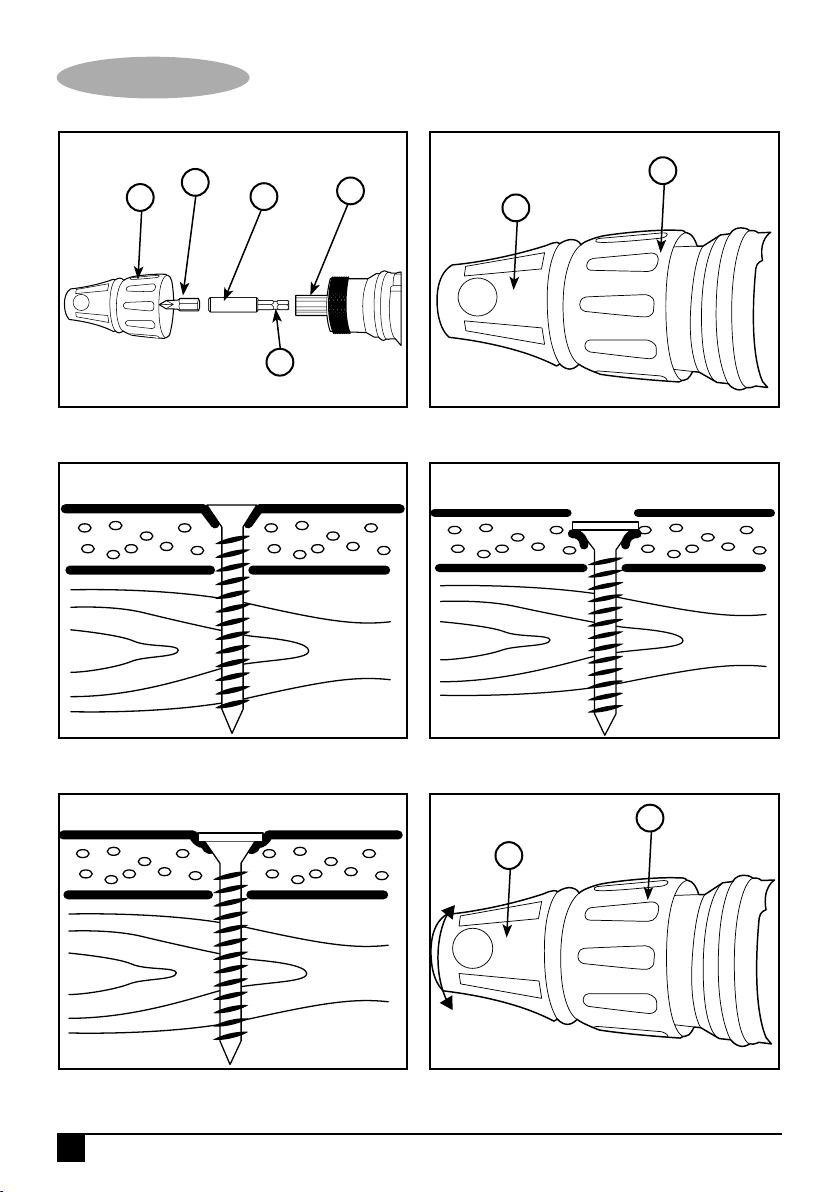

FIG. A

1

2

4

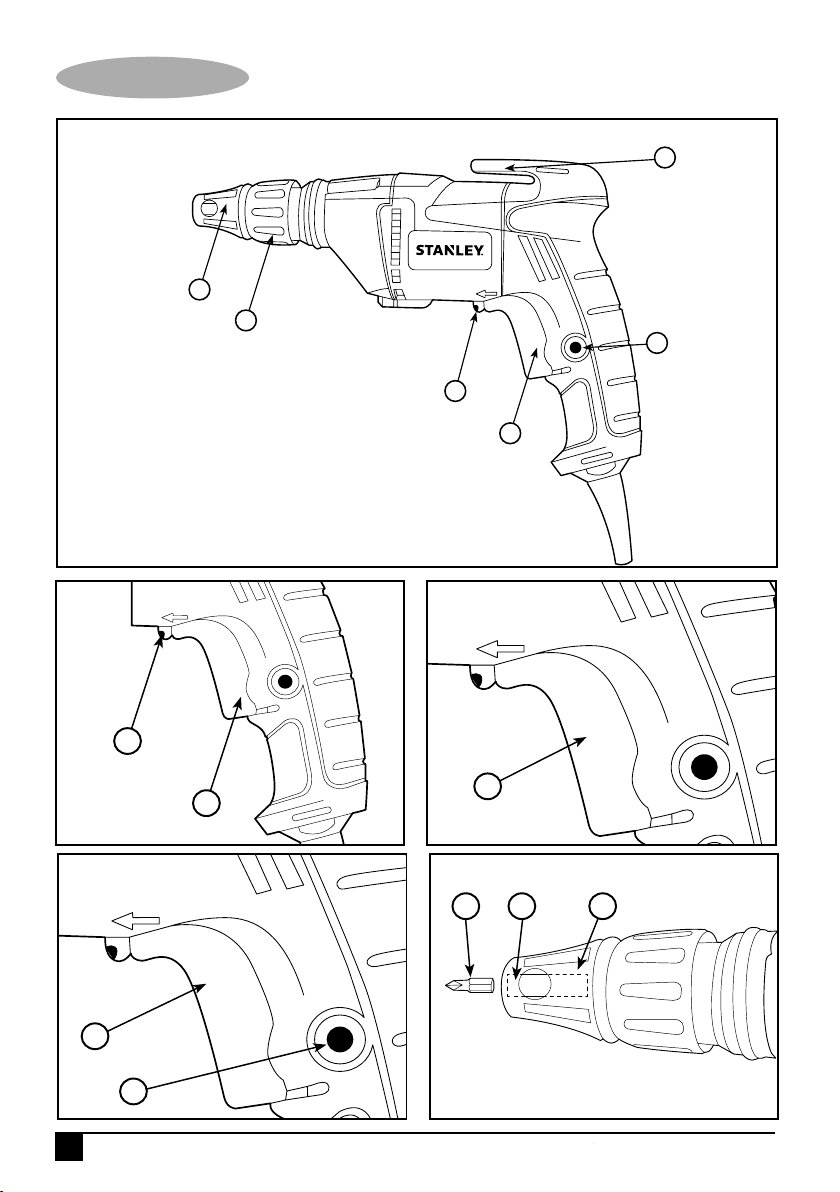

FIG. B FIG. C

3

6

5

4

5

FIG. D FIG. E

7

5

6

2

5

8

1

Page 3

(Original instructions)

ENGLISH

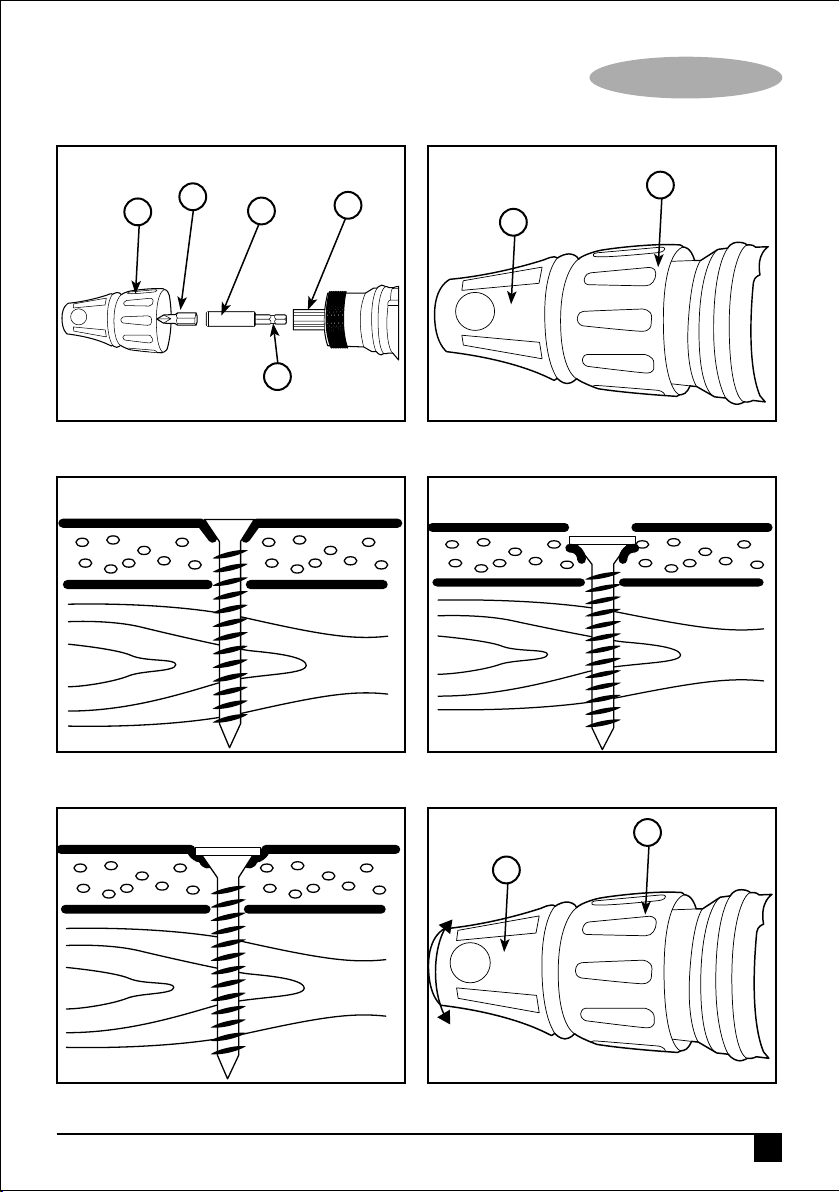

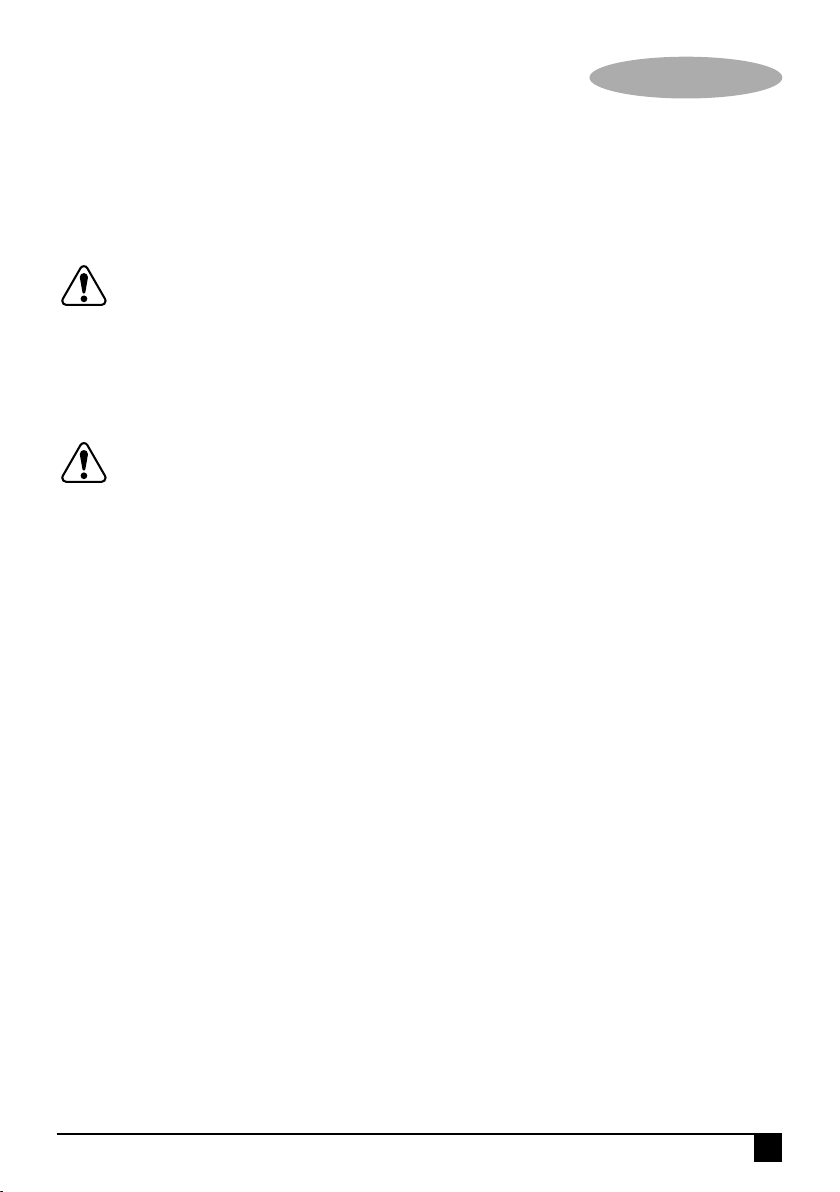

FIG. F

FIG. H

FIG. G

7

2

8

9

1

2

10

FIG. I

FIG. J

FIG. K

2

1

3

Page 4

ENGLISH

(Original instructions)

DO NOT RETURN THIS PRODUCT TO THE STORE,

first contact your local STANLEY Office

or nearest authorized service center.

Intended Use

This STANLEY screwdriver has been designed for driving

drywall fasteners through drywall board into timber or metal

framing studs.

General Safety Rules

Warning! Read and understand all instructions.

Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious

personal injury.

Save These Instructions

Safety instructions

General power tool safety warnings

Warning! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions listed below may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock. Note: The term “Residual Curent Device

(RCD)” can be replaced by “Ground Fault Circuit

Interrupter (GFCI)” or by “Earth Leakage Circuit Breaker

(ELCB)”.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

4

Page 5

(Original instructions)

ENGLISH

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Screwdriver safety warnings

Hold power tool by insulated gripping surfaces, when

performing an operation where the fastener may

contact hidden wiring or its own cord. Fasteners

contacting a "live" wire may make exposed metal parts of

the power tool "live" and could give the operator an electric

shock.

6. Labels on tool

The label on your tool may include the following symbols:

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

....... No-Load

0

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation p er

minute

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

7. Electrical safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main

voltage corresponds to the voltage on the rating

plate.

Warning! If the power cord is damaged, it must be

replaced by the manufacturer, authorized

STANLEY Service Center or an equally qualified person in

order to avoid damage or injury. If the power cord is replaced

by an equally qualified person, but not authorized by

STANLEY, the warranty will not be valid.

Features (Fig. A)

1. Depth stop

2. Depth adjuster

3. Belt clip

4. Forward/Reverse switch

5. Variable speed trigger switch

6. Lock-on button

Specific Safety Rules

Warning! Know your drywall screwdriver. Do not

plug the tool into the power source until you have

read and understand this Instruction Manual.

well as the specific potential hazards related to this tool.

• Following this rule will reduce the risk of electric shock,

Learn the tool’s applications and limitations, as

fire, or serious injury.

5

Page 6

ENGLISH

(Original instructions)

• Always wear eye protection. Any power tool can throw

foreign objects into your eyes and cause permanent eye

damage. ALWAYS wear safety goggles (not glasses) that

comply with ANSI safety standard Z87.1. Everyday

glasses have only impact resistant lenses. They ARE

NOT safety glasses

Warning! Glasses or goggles not in compliance

with ANSI Z87.1 could cause serious injury when

they break.

• Never use the drywall screwdriver to drive screws other

than drywall screws. The drywall screwdriver and the

screwdriver bits are designed specifically for driving

drywall screws.

• Only use screwdriver bits that are designed for use with

this tool.

• Always keep hands out of the path of the drywall screw.

Avoid awkward hand positions where a sudden slip could

cause your hand to move into the path of the saw blade.

• Make sure there are no nails or foreign objects in the

part of the workpiece to be cut or sanded.

• To avoid injury from accidental starting, always remove

the plug from the power source before installing or

removing a screwdriver bit or when adjusting the depth

control.

• Always check the wall area where screws will be driven

to be sure there are no hidden electrical wires in the

area.

• Never leave the Lock-on button ON. Before plugging the

tool into the power source, make sure the lock-on button

is OFF.

General Safety Warnings

Warning! Wear a dust mask that is designed to be

used when operating a power tool in a dusty

environment.

Warning! Dust that is created by power sanding,

sawing, grinding, drilling, and other construction

activities may contain chemicals that are known to

cause cancer, birth defects, or other genetic abnormalities.

These chemicals include:

• Lead from lead-based paints

• Crystalline silica from bricks, cement, and other masonry

products

• Arsenic and chromium from chemically treate lumber

The level of risk from exposure to these chemicals varies,

according to how often this type of work is performed. In

order to reduce exposure to these chemicals, work in a

well-ventilated area, and use approved safety equipment,

such as a dust mask that is specifically designed to filter out

microscopic particles.

Safety Extension Cord

Warning! Keep the extension cord clear of the

working area. Position the cord so it will not get

caught on the workpiece, tools or any other obstructions

while you are working with the power tool.

Make sure any extension cord used with this tool is in good

condition. When using an extension cord, be sure to use one

of heavy enough gauge to carry the current the tool will

draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

Be sure your extension cord is properly wired and in good

condition. Always replace a damaged extension cord or

have it repaired by a qualified electrician before using it.

Protect your extension cord from sharp objects, excessive

heat and damp or wet areas.

Use a separate electrical circuit for your power tools. This

circuit must not be less than 14 gauge wire and should be

protected with either a 15 A time delayed fuse or circuit

breaker. Before connecting the power tool to the power

source, make sure the switch is in the OFF position and the

power source is the same as indicated on the nameplate.

Running at lower voltage will damage the motor.

Contents

Carefully unpack the drywall screwdriver. Compare the

contents against the “Drywall screwdriver components” chart

below.

Assembly and Operating

Warning! To avoid fire or toxic reaction, never use

gasoline, naphtha, acetone, lacquer thinner or

similar highly volatile solvents to clean the tool.

Forward/Reverse switch (Fig. B)

The forward/reverse switch (4) is conveniently mounted in

front of the variable speed trigger switch (5). To make the

screwdriver rotate clockwise for driving screws, push the

forward/reverse switch (4) to the left. To make the

screwdriver rotate counter-clockwise to remove screws,

push the forward/reverse switch (4) to the right.

6

Page 7

(Original instructions)

ENGLISH

Notes:

a. Never change the position of the forward/reverse switch

(4) while the screwdriver bit is turning.

b. The variable speed trigger switch (5) will NOT function

with the forward/reverse switch (4) in the middle

position.

Variable speed trigger switch (Fig. C)

This screwdriver is equipped with a variable speed On/Off

trigger switch.

1. To start screwdriver, gently squeeze the variable speed

trigger switch (5).

Note: The screwdriver will turn at its slowest speed when

the variable speed trigger switch is depressed slightly. The

screwdriver will turn at its fastest speed when the variable

speed trigger switch is fully depressed.

2. To stop the screwdriver, release the variable speed

trigger switch (5).

Lock-on button (Fig. D)

The lock-on button feature allows the trigger switch to be

locked in the ON position at full speed when continuous

operation for extended periods of time is required.

To lock the lock-on button in the ON position, pull back on

the variable speed trigger switch (5) to start the screwdriver

and push the lock-on button (6) into the screwdriver handle.

Release the variable speed trigger switch while holding the

lock-on button into the screwdriver handle. The screwdriver

will continue to run. To release the lock-on button, pull

variable speed trigger switch back (5) and then release the

trigger.

Note: Operating the screwdriver with the variable speed

trigger switch for an extended period of time may cause the

screwdriver motor to overheat. If the screwdriver gets hot,

stop driving screws and allow it to cool for at least 15

minutes.

Inserting a screwdriver bit (Fig. E)

This tool has a magnetic bit holder that provides convenient

bit changes. To install a bit, simply insert the hex bit shank

(7) into the magnetic bit holder (8) that is located inside the

depth stop (1). Push the bit into the magnetic bit holder until

the magnet holds the bit in place.

Notes:

a. Use only 1” (25 mm) long bits that are designed for use

in driving drywall screws.

b. Make sure the bit size is correct for the drywall screws

being driven. This will usually be a #2 size.

Replacing the magnetic bit holder (Fig. F)

If the magnetic bit holder becomes worn or damaged, it must

be replaced. The replacement bit holder must be of the

same dimensions as the original and have the ANSI

retention groove on the end that is inserted into the tool.

1. Remove the nosepiece (2) by turning it counter

clockwise.

Note: Do not use pliers on the nosepiece. Only use your

hand.

2. Grasp the screwdriver bit (7) with pliers and pull it out of

the magnetic bit holder (8).

3. Grasp the large end of the bit holder with pliers and pull

it straight out of the screwdriver spindle (9).

4. Reverse the process by inserting the replacement

magnetic bit holder into the tool.

Note: When inserting the replacement for magnetic bit

holder, gently tap it into place to make sure it is fully inserted.

Grasp the large end of the magnetic bit holder to ensure the

retention groove (10) is holding the magnetic bit holder in

place in the tool.

5. Reinstall the screwdriver bit and nose piece.

Safety Recommendations

Check the following every time you use the screwdriver:

1. Wear safety glasses or a mask.

2. Use hearing protection.

3. The screwdriver tip is the right size and it is in good

condition.

4. No power cables “live” where you are inserting the

screws.

Note: Failure to follow these safety rules will significantly

increase the risk of injury.

7

Page 8

ENGLISH

(Original instructions)

Adjusting the screwdrive bit depth (Fig. G)

It is important to control the depth to which the drywall screw

will be driven. Over driving the screw will drive the screw too

deep and break the outer paper layer of the drywall. Under

driving the screw will leave the screw head above the

drywall surface making it impossible to properly finish the

drywall.

The depth control system is made up of the depth stop (1)

and the depth adjuster (2).

Warning! The following adjustments should always

be verified using a scrap piece of drywall to avoid

damaging the “good” drywall sections.

1. Rotate the depth adjuster counter clockwise until

approximately 1/4” of the screwdriver bit extends beyond

the depth stop.

2. Place a drywall screw onto the screwdriver bit. The

magnetized bit will hold the screw onto the bit.

Note: Before driving the screw, press the screw point into

the drywall and make sure the screw is perpendicular to the

drywall.

3. Press the screw against the drywall with steady even

pressure and squeeze the trigger switch. The clutch in

the tool will engage and the screw will be driven to the

preset depth.

4. If the screw is not driven deep enough, the head of the

screw will not be recessed into the drywall (Fig. H). In

this case, turn the depth adjustment sleeve clockwise

until the correct depth has been achieved. If the screw is

driven too deep, it will be recessed too far into the

drywall and the outer paper of the drywall will be

fractured (Fig. I). In this case, turn the depth adjustment

sleeve counter clockwise until the correct depth has

been achieved. Fig. J illustrates the correct depth for the

screw to be driven.

Note: For each revolution the depth adjustment sleeve is

rotated, the depth will increase/decrease approximately

1/16” (1.6 mm).

Tips for driving drywall screws

ff Always drive the screws perpendicular to the drywall so

the heads are properly countersunk. They should never be

driven at an angle.

• Support the tool with both hands wherever possible.

This will provide better control over the tool help

eliminate screws being driven at an angle.

• Place the drywall screw on the screwdriver bit. The

magnetic bit holder will hold any steel screw for easy

starting.

• Press the screw against the drywall with steady even

pressure and squeeze the variable speed trigger switch.

The clutch in the tool will engage and the screw will be

driven to the preset depth. Once fully driven, the clutch

will make a chattering sound until the variable speed

trigger is released.

• When the screw is properly driven, the screw head will

be slightly countersunk into the drywall without breaking

the outer drywall paper. At this point, the clutch will

release to prevent over driving the screw. This will result

in minimum work to fill the holes and taping the seams.

• The belt clip allows you to conveniently attached the

screwdriver to your belt. This will allow you to use both

hands for positioning the drywall.

Removing drywall screws (Fig. K)

To remove drywall screws, remove the depth stop (1) to

expose the screwdriver bit.

Notes:

a. The depth stop is a press fit onto the depth adjuster (2).

Simply twist and pull outward to slide it off the depth

adjuster.

b. You can also turn the depth adjuster clockwise to expose

the screwdriver bit. This however will cause you to lose

the depth setting and you will have to re-set the depth.

Maintenance

Keep guards, air vents and the motor housing as clear as

possible of dust and dirt. Wipe with a clean cloth and blow

through with a low-pressure air supply. Excessive build-up of

metal dust can cause tracking of electrical current from the

internal parts to exposed metal parts. Do not overload your

angle grinder. Overloading causes a reduction in speed and

efficiency, causing your angle grinder to become too hot. If

this happens, operate your angle grinder under no load for

one or two minutes until it has cooled to normal operating

temperature. Switching your angle grinder off under load will

reduce the life of the switch.

8

Page 9

(Original instructions)

ENGLISH

Warning! When servicing, use only identical

replacement parts. The use of any other part may

create a hazard or cause product damage.

• DO NOT use solvents when cleaning plastic parts.

Plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use a clean cloth to remove dirt, dust, oil, grease etc.

Warning! Do not allow brake fluids, gasoline,

petroleum-based products, penetrating oils, etc. to

come into contact with plastic parts. They contain chemicals

that can damage, weaken or destroy plastic.

• Remove accumulated dust and debris regularly using a

SOFT and DRY brush.

Warning! Use safety goggles when using an air jet

to blow dust out of the tool. Keep air vents clean

and unobstructed to allow maximum airflow through the tool.

• DO NOT abuse power tools. Abusive practices can

damage the tool and the workpiece.

Warning! DO NOT attempt to modify tools or

create accessories. Any such alteration or

modification is misuse and could result in a hazardous

condition leading to possible serious injury. It will also void

the warranty.

Lubrication

All of the bearings in this tool are lubricated with a sufficient

amount of high-grade lubricant for the life of the unit under

normal conditions. Therefore, no further lubrication is

required.

Cleaning

Use only mild soap and a slightly damp cloth to clean your

angle grinder. Many household cleaners contain chemicals

which could seriously damage the plastic. Also, do not use

petrol, turpentine, lacquer or paint thinners or similar

products. Never let any liquid get inside the tool and never

immerse any part of the tool into liquid.

Specifications

STDR5206

Power 520W

Voltage 220-240V

Frequency 50/60Hz

No-load speed 0-4500/min (rpm)

Weight 3.3lb (1.45kg)

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Stanley product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

Stanley provides a facility for the collection and recycling of

Stanley products once they have reached the end of their

working life. To take advantage of this service please return

your product to any authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local Stanley office at the address

indicated in this manual. Alternatively, a list of authorised

Stanley repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com

Important! To assure product SAFETY and

RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be

performed by authorized service centers or other qualified

service personnel, always using identical replacement parts.

9

Page 10

ENGLISH

(Original instructions)

Two year full warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY Europe guarantees to replace all

defective parts free of charge or – at our discretion – replace

the unit free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

10

Page 11

(Оригинальные инструкции)

РУССКИЙ

FIG. A

1

2

4

FIG. B FIG. C

3

6

5

4

5

FIG. D FIG. E

7

5

6

5

8

1

11

Page 12

РУССКИЙ

(Оригинальные инструкции)

FIG. F

FIG. H

FIG. G

7

2

8

9

1

2

10

FIG. I

FIG. J

12

FIG. K

2

1

Page 13

(Оригинальные инструкции)

РУССКИЙ

НЕ ВОЗВРАЩАЙТЕ ЭТО ИЗДЕЛИЕ В МАГАЗИН,

сначала обратитесь в ваш местный офис STANLEY или

в ближайший авторизованный сервисный центр.

Назначение

Это отвертка Стэнли разработан для управления

гипсокартона крепеж через гипсокартон борту в

деревянных или металлического каркаса шпильки.

Общие правила техники безопасности

Внимание! Прочитайте и поймите все

инструкции. Несоблюдение любых

поражению электрическим током, пожару и/или

серьезной травме.

инструкций, указанных ниже, может привести к

СОХРАНИТЕ ЭТИ ИНСТРУКЦИИ

Правила техники безопасности

Общие предупреждения по технике безопасности

электроинструментов

Внимание! Ознакомьтесь со всеми

правилами безопасности и инструкциями.

указанных ниже, может привести к поражению

электрическим током, пожару и/или серьезной травме.

Сохраните все предупреждения и инструкции для

будущего использования.

Термин "электроинструмент" во всех предупреждениях,

указанных ниже, относится к вашему сетевому (с

кабелем) электроинструменту или аккумуляторному

электроинструменту (без кабеля питания).

1. Безопасность рабочего места

а. Содержите рабочее место в чистоте и хорошо

b. Не работайте с электроинструментом в месте

с. Дети и посторонние лица должны находиться как

2. Электробезопасность

а. Вилка электроинструмента должна

b. Избегайте контакта тела с заземленными

Несоблюдение предупреждений и инструкций,

освещенным. Беспорядок на рабочем месте или

отсутствие освещения рабочего места может

привести к аварии.

хранения взрывоопасных материалов,

например, в присутствии огнеопасных

жидкостей, газов или пыли. Электрические

инструменты создают искры, которые могут

воспламенить пыль или пары.

можно дальше во время работы с

электроинструментом. Вы можете отвлечься и

потерять контроль.

соответствовать розетке. Никогда не

модифицируйте вилку каким-либо образом. Не

используйте никакие вилки-переходники с

заземленными (замкнутыми на землю)

электроинструментами. Вилки и розетки, которые

не подвергались никаким изменениям снижают риск

поражения электрическим током.

поверхностями, такими как трубы, радиаторы,

плиты и холодильники. Существует повышенный

риск поражения электрическим током, если ваше

тело заземлено.

с. Избегайте любого воздействия дождя или влаги

на электроинструменты. Вода, попавшая в

электроинструмент, увеличивает риск поражения

электрическим током.

d. Аккуратно обращайтесь со шнуром питания.

Никогда не используйте шнур питания для

переноски, перемещения или извлечения вилки

из розетки. Держите шнур вдали от источников

тепла, масла, острых краев или движущихся частей.

Поврежденные или запутанные шнуры увеличивают

риск поражения электрическим током.

е. При работе с электроинструментом на улице,

используйте удлинитель, подходящий для

наружного использования. Использование кабеля,

пригодного для использования на открытом воздухе,

снижает риск поражения электрическим током.

f. При необходимости работы с

электроинструментом во влажной среде,

используйте устройство защитного отключения

(УЗО). Использование УЗО снижает риск поражения

электрическим током. Примечание: Термин

“устройство защитного отключения (УЗО)” может

быть заменен на "аварийный прерыватель

заземления" или "автоматический выключатель тока

утечки".

3. Личная безопасность

a. Будьте внимательны, смотрите, что вы делаете,

используйте здравый смысл при работе с

электроинструментом. Не используйте

электроинструмент, если вы устали или находитесь

под влиянием наркотиков, алкоголя или лекарств.

Малейшая неосторожность при работе с

электроинструментом может привести к серьезным

травмам.

b. Используйте средства индивидуальной защиты.

Всегда надевайте защитные очки. Другое

защитное оборудование, включая респиратор,

ботинки на нескользящей подошве, защитный

шлем или средства защиты органов слуха,

используемые в надлежащих условиях, уменьшат

риск получения травмы.

с. Для предотвращения случайного запуска,

убедитесь, что переключатель находится в

выключенном положении перед подключением к

источнику питания и/или аккумуляторной

батарее, поднятия или переноски инструмента. Не

переносите электроинструмент с пальцем на

выключателе и не включайте питание на инструмент

с включенным выключателем, что может привести к

несчастному случаю.

d. Перед включением электроинструмента снимайте

регулировочный или гаечный ключ. Гаечный или

регулировочный ключ, оставленный на

вращающейся части электроинструмента, может

привести к травме.

е. Не тянитесь. Сохраняйте правильную стойку и

баланс все время. Это позволяет лучше

контролировать инструмент в неожиданных

ситуациях.

13

Page 14

РУССКИЙ

(Оригинальные инструкции)

f. Одевайтесь правильно. Не надевайте свободную

одежду или украшения. Держите волосы, одежду

и перчатки вдали от движущихся частей.

Свободная одежда, украшения или длинные

волосы могут попасть в движущиеся части.

g. Если имеются устройства для подключения

пылесборника или вытяжки, убедитесь в том,

что они подсоединены и используются

правильно. Использование пылесборника снижает

вероятность возникновения рисков, связанных с

пылью.

4. Использование и уход за электроинструментом

a. Не перегружайте электроинструмент.

Используйте подходящий электрический

инструмент для соответствующего применения.

Правильно подобранный электроинструмент

позволит выполнить работу лучше и безопаснее при

скорости, для которой он был разработан.

b. Не используйте электроинструмент, если

переключатель не может его включить и

выключить. Любой электроинструмент, который

нельзя контролировать с помощью переключателя,

опасен и должен быть отремонтирован.

c. Отключите кабель питания от источника питания

и/или аккумуляторный блок от электрического

инструмента перед выполнением любых

регулировок, замены принадлежностей или при

хранении электроинструмента. Такие

профилактические меры безопасности уменьшают

риск непреднамеренного запуска электрического

инструмента.

d. Храните неиспользуемые электроинструменты в

недоступном для детей месте и не позволяйте

лицам, не знакомым с электроинструментом или

данными инструкциями, работать с

электроинструментом. Электроинструменты опасны

в руках неопытных пользователей.

е. Поддержание электроинструмента. Проверяйте

разрегулированность или cоединение

подвижных частей, поломки частей и любые

другие условия, которые могут повлиять на

работу электроинструмента. При наличии

повреждения, отремонтируйте

электроинструмент перед использованием.

Многие несчастные случаи являются следствием

плохого ухода за электроинструментом.

f. Держите режущий инструмент острым и чистым.

Хорошо ухоженный режущий инструмент с острыми

режущими кромками легче контролировать.

5. Обслуживание

а. Обеспечьте, чтобы обслуживание и ремонт

вашего электроинструмента проводился в

авторизованном сервисном центре по ремонту с

использованием только оригинальных запасных

частей. Это станет гарантией безопасности

электроинструмента.

14

Указания по технике безопасности для шуруповерта

Держите инструмент за изолированные поверхности

захвата при выполнении операций, когда режущий

инструмент может контактировать со скрытой

проводкой или собственным кабелем. Крепёжные

элементы, контактирующие с проводом под

напряжением, могут подать напряжение на открытые

металлические части электроинструмента и это может

привести к поражению оператора электрическим током.

6. Этикетки на инструменте

Этикетка на вашем инструменте может включать

следующие символы:

Читайте

инструкции по

эксплуатации

Используйте

средства

защиты глаз

Используйте

средства

защиты

органов слуха

В ........ Вольт

A ........ Ампер

Гц ....... Герц

Вт ........ Ватт

мин...... минуты

Перемен-

.....

ный ток

Постоян-

.....

ный ток

Скорость

n

.......

0

без нагрузки

Конструкция

......

класса II

Терминал

....

заземления

Символ

предупреж-

....

дения об

опасности

обороты или

...мин..

возвратнопоступательное движение

в минуту

Положение даты штрих-кода

Дата кода, который также включает год изготовления,

печатается на корпусе.

Пример:

2014 XX JN

Год изготовления

7. Электрическая безопасность

Ваш инструмент имеет двойную изоляцию,

именно в этой связи заземляющий провод не

требуется. Всегда проверяйте, что напряжение

сети соответствует напряжению, указанному на

заводской табличке.

Внимание! Если шнур питания поврежден, он

должен быть заменен производителем в

авторизованном сервисном центре STANLEY

или квалифицированным специалистом для того, чтобы

избежать повреждения или травмы. Если шнур питания

заменен квалифицированным специалистом, не

уполномоченным STANLEY, гарантия не будет

действовать.

Опции (Рис. A)

1. Ограничитель глубины

2. Регулятор глубины

3. Зажим для крепления к поясному ремню

4. Переключатель вперед/назад

5. Вариатор скорости

6. Кнопка фиксации

Page 15

(Оригинальные инструкции)

РУССКИЙ

Определенные правила техники

безопасности

Осторожно! Изучите ваш шуруповёрт для

гипсокартона. Не подключайте инструмент к

источнику питания, пока вы не прочли и поняли

данную инструкцию по эксплуатации Узнайте о сфере

применения инструмента и ограничениях, а также

определенных потенциальных опасностях, связанных с

этим инструментом.

• Выполнение этого правила снизит риск поражения

электрическим током, возникновения огня или

серьезной травмы.

• Всегда надевайте защитные очки. Любой

электроинструмент может стать причиной попадания

посторонних объектов в ваши глаза и привести к

необратимому повреждению глаз. Всегда надевайте

защитные очки (не очки для коррекции зрения ),

которые соответствуют стандарту стандарту

безопасности ANSI Z87.1. Повседневные очки

снабжены только ударопрочными линзами. Они НЕ

ЯВЛЯЮТСЯ защитными очками

Осторожно! Очки для коррекции зрения или

солнцезащитные очки, не в соответствующие

требованиям ANSI Z87.1, могут привести к

серьезным травмам, если они ломаются.

• Никогда не используйте шуруповёрт для

гипсокартона для закручивания шурупов иного типа,

чем саморезы. Шуруповёрт для гипсокартона и

насадки для шуруповёрта предназначены именно

для закручивания саморезов.

• Используйте насадки для шуруповёрта, которые

предназначены для использования с данным

инструментом.

• Всегда держите руки подальше от пути самореза.

Избегайте неудобных положений рук, кода внезапное

скольжение может привести вашу руку на путь

движения пильного диска.

• Убедитесь в отсутствии гвоздей или посторонних

предметов в части детали, которая будет

подвергаться резанию или шлифованию.

• Во избежание травм от случайного включения,

всегда вынимайте вилку из розетки, прежде чем

устанавливать или извлекать насадку для

шуруповёрта или во время регулировки глубины.

• Всегда проверяйте зону стены, куда будут

вкручиваться шурупы, чтобы убедиться в отсутствии

каких-либо скрытых электрических проводов в

данной зоне.

• Никогда не оставляйте кнопку фиксации в положении

ВКЛ. Перед подключением инструмента к источнику

питания, убедитесь, что кнопку фиксации в

положении ВЫКЛ.

Указания по технике безопасности общего

характера

Осторожно! Одевайте противопылевой

респиратор, который предназначен для

использования при работе с

электроинструментом в пыльной среде.

Осторожно! Пыль, которая создается при

механической шлифовке, распиле, шлифовании,

сверлении и других строительных работах

может содержать вещества, которые, как

известно, вызывают рак, врожденные дефекты или

другие генетические аномалии. К ним относятся:

• Свинец из свинцовых красок

• Кристаллический кремнезем из кирпичей, цемента и

других стеновых блоков

• Мышьяк и хром из химически обработанных

пиломатериалов

Уровень риска от воздействия этих веществ колеблется,

в связи с тем, как часто выполняется этот тип работы.

Для того, чтобы сократить воздействие этих химических

веществ, работайте в хорошо проветриваемом

помещении и используйте одобренные технические

средства обеспечения безопасности, например,

респиратор, который предназначен именно для

фильтрования микроскопических частиц.

Безопасный удлинитель

Осторожно! Избегайте попадания удлинителя в

рабочую зону. Расположите шнур, чтобы он не

попадал на заготовку, инструменты или любые

другие препятствия, пока вы работаете с

электроинструментом.

Убедитесь в хорошем состоянии любого удлинителя,

использующегося с этим инструментом. При

использовании удлинителя убедитесь, что используете

провод достаточного сечения, способный выдержать

рабочий ток инструмента. Шнур недостаточного сечения

может вызвать падение сетевого напряжения, что

приводит к потере мощности и перегреву.

Убедитесь, что ваш удлинитель правильно ли

подключен и находится в хорошем состоянии. Всегда

заменяйте поврежденный удлинитель или перед его

использованием отдайте его в ремонт

квалифицированному электрику. Защищайте свой

удлинитель от острых предметов, высоких температур и

воздействия сырости или влаги.

Используйте отдельную электрическую цепь для ваших

электроинструментов. В этой цепи должны

использоваться провода не менее 14 калибра, также они

должны быть защищены или предохранителями (15 А) с

временной задержкой или автоматом защиты цепи.

Перед подключением электроинструмента к источнику

питания, убедитесь, что переключатель находится в

положении ВЫКЛ и источник питания соответствует

указанному на паспортной табличке. Запуск при

пониженном напряжении может привести к повреждению

двигателя.

15

Page 16

РУССКИЙ

(Оригинальные инструкции)

Содержимое упаковки

Осторожно распакуйте шуруповерт для гипсокартона.

Сравните содержимое с таблицей компонентов

шуруповерта для гипсокартона.

Монтаж и эксплуатация

Осторожно! Чтобы избежать возникновения огня или

токсической реакции, для очистки инструмента

никогда не используйте бензин, керосин, ацетон,

растворитель для лака и подобные

легколетучие растворители.

Переключатель вперед/назад (Рис. В)

Переключатель "вперед/назад" (4) удобно

установленный в передней части вариатора скорости

(5). Для того, чтобы шуруповерт вращался по часовой

стрелке для вкручивания шурупов, передвиньте

переключатель "вперед/назад" (4) влево. Для того,

чтобы шуруповерт вращался против часовой стрелки

для выкручивания шурупов, передвиньте

переключатель "вперед/назад" (4) вправо.

Примечания:

a. Никогда не меняйте положение переключатель

"вперед/назад" (4) пока шуруповерт вращается.

b. Вариатор скорости (5) НЕ БУДЕТ работать, если

переключатель "вперед/назад" (4) находится в

среднем положении.

Вариатор скорости (Рис. C)

Шуруповерт снабжен вариатором скорости Вкл\Выкл

(On/Off).

1. Чтобы запустить шуруповерт, аккуратно нажмите на

вариатор скорости (5).

Примечание: Если вариатор скорости слегка нажат, то

шуруповерт будет работать на самой медленной

скорости. Если вариатор скорости нажат сильно, то

шуруповерт будет работать на самой быстрой скорости.

2. Чтобы остановить шуруповерт, отпустите вариатор

скорости (5).

Кнопка фиксации (Рис. D)

Кнопка фиксации позволяет зафиксировать курковый

выключатель в положении ВКЛ на полной скорости,

когда необходима непрерывная работа в течение

длительного периода времени.

Чтобы зафиксировать кнопку фиксации в положении

ВКЛ, потяните назад вариатор скорости (5), чтобы

запустить шуруповерт и вдавите кнопку фиксации (6) в

рукоятку шуруповерта. Отпустите вариатор скорости,

удерживая кнопку фиксации в рукоятке шуруповерта.

Шуруповерт продолжит работать. Чтобы отпустить

кнопку фиксации, потяните назад вариатор скорости (5) и

затем отпустите вариатор.

Примечание: Эксплуатация шуруповерта с вариатором

скорости в течение длительного периода времени может

привести к перегреву двигателя шуруповерта. Если

шуруповерт нагревается, прекратите вкручивание и

дайте ему остыть в течение, по крайней мере, 15 минут.

Установка насадки шуруповерта (Рис. E)

Этот инструмент снабжен магнитным держателем

насадки, что обеспечивает удобство замены насадки.

Чтобы установить насадку, просто вставьте

шестигранный хвостовик насадки (7) в магнитный

держатель насадки (8), который находится внутри

ограничителя глубины (1). Вожмите немного насадку в

магнитный держатель насадки, пока магнит не

зафиксирует насадку на месте.

Примечания:

a. Используйте только насадки длиной 1 "(25 мм),

которые предназначены для закручивания

саморезов.

b. Убедитесь, что размер правильно подобран

для.саморезов. Обычно это размер № 2.

Замена магнитного держателя насадки (Рис. F)

Если магнитный держатель насадки изношен или

поврежден, он должен быть заменен. Держатель

насадки должен быть из тех же размеров, как и

оригинал, с удерживающей канавкой ANSI канавкой

на конце, которая вставлена в инструмент.

1. Снимите наконечник (2), повернув его против

часовой стрелки.

Примечание: Не используйте плоскогубцы при

обращении с насадкой. Используйте только руки.

2. Возьмите насадку шуруповерта (7) плоскогубцами и

вытяните его из магнитного держателя насадки (8).

3. Возьмитесь за большой конец держателя насадки

плоскогубцами и вытяните ее из шпинделя

шуруповерта (9).

4. Выполните процесс в обратном порядке, вставив

магнитный держатель насадки в инструмент.

Примечание: При замене магнитного держателя

насадки, мягко посадите его на место, чтобы убедиться,

что он полностью вставлен. Возьмитесь за большой

конец держателя насадки плоскогубцами, чтобы

гарантировать удерживание удерживающей канавкой

(10) магнитного держателя насадки в инструменте на

необходимом месте.

5. Установите на место насадку шуруповерта и головку.

16

Page 17

(Оригинальные инструкции)

РУССКИЙ

Рекомендации по технике безопасности

Проверяйте следующее каждый раз, когда вы

используете шуруповерт:

1. Одевайте защитные очки или маску.

2. Используйте средство защиты слуха.

3. Размер насадки шуруповерта соответствует и она в

хорошем состоянии.

4. Там, где вы вкручиваете саморезы отсутствуют

провода под напряжением.

Примечание: Несоблюдение этих правил

техники безопасности значительно повышает

риск получения травмы.

Регулировка глубины насадки шуруповерта (Рис. G)

Важно контролировать глубину, на которую саморез

вкручивается в гипсокартон. Слишком глубокое

вкручивание самореза разрушит внешний слой бумаги

гипсокартона. При недостаточной глубине вкручивания

головка самореза будет выступать над поверхностью

гипсокартона, что делает невозможным последующую

обработку поверхности гипсокартона.

Система контроля глубины состоит из ограничителя

глубины (1) и регулятора глубины (2).

Осторожно! Следующие настройки всегда должны быть

проверены при помощи куска гипсокартона, чтобы

избежать повреждения "хороших" листов гипсокартона.

1. Поверните регулятор глубины против часовой

стрелки пока примерно 1/4" насадки шуруповерта

выйдет за пределы ограничителя глубины.

2. Поместите саморез в насадку шуруповерта.

Намагниченная насадка будет удерживать саморез

на насадке.

Примечание: Перед началом ввинчивания

шурупа, вдавите кончик шурупа в гипсокартон и

убедитесь, что шуруп перпендикулярен

гипсокартона.

3. Вдавите шуруп в гипсокартон, оказывая

равномерное давление и нажмите курковый

выключатель. Муфта инструмента запустится и

шуруп будет ввинчен на заданную глубину.

4. Если шуруп не будет вкручен достаточно глубоко,

головка шуруповерта не утопится в гипсокартон (Рис.

H). В этом случае поверните регулировочную втулку

по часовой стрелке до достижения необходимой

глубины. Если шуруп вкручен слишком глубоко, он

будет слишком утоплен в гипсокартон и внешний

слой бумаги гипсокартона будет разрушен (Рис. I) В

этом случае, поверните регулировочную втулку

против часовой стрелки до тех пор, пока не будет

достигнута соответствующая глубина. Рис. J

иллюстрирует соответствующую глубину

закручивания шурупа.

Примечание: При каждом обороте регулировочной

втулки глубина увеличится / уменьшится примерно на

1/16 "(1,6 мм).

Советы по закручиванию саморезов

Всегда закручивайте винты перпендикулярно

гипсокартону так, чтобы головки прятались в потай

должным образом. Они никогда не должны

закручиваться под углом.

• Поддерживайте инструмент обеими руками, когда

это возможно. Это обеспечит лучший контроль над

инструментом, помогая избежать закручивания

шурупов под углом.

• Поместите саморез в насадку шуруповерта.

Магнитный держатель насадки удерживает любой

стальной шуруп, облегчая запуск.

• Вдавливайте шуруп в гипсокартон, оказывая

равномерное давление и нажмите вариатор

скорости. Муфта инструмента запустится и шуруп

будет ввинчен на заданную глубину. После полного

закручивания, муфта производит стучащие звуки,

пока не будет отпущен вариатор скорости.

• Когда шуруп правильно закручен, головка шурпа

будет слегка утоплена в гипсокартона, не разрывая

внешний слой бумаги гипсокартона. В этот момент

муфта отпустит, чтобы избежать чрезмерного

закручивания шурупа. Это приведет к тому, что

работа по заполнению отверстий и оклеиванием

лентой швов будет минимальной.

• Зажим для крепления к поясному ремню позволяет

удобно крепить шуруповерт на ремне. Это позволит

вам использовать обе руки для позиционирования

гипсокартона.

Удаление саморезов (Рис. K)

Для удаления саморезов, снимите ограничитель глубины

сверления (1), чтобы открыть доступ к насадке

шуруповерта.

Примечания:

a. Ограничитель глубины является запрессованным

элементом регулятора глубины (2). Чтобы снять его

просто крутите и стягивайте регулятор глубины.

b. Вы также можете поворачивать регулятор глубины

по часовой стрелке, чтобы освободить насадку

шуруповерта. Это, однако, приведет к тому, что

настройка глубины собьется и вам придется

повторно устанавливать глубину.

17

Page 18

РУССКИЙ

(Оригинальные инструкции)

Обслуживание

Очищайте, насколько это возможно, пыль и грязь с

предохранительных щитков, вентиляционных отверстий

и корпуса двигателя. Протрите чистой тканью и

продуйте воздухом низкого давления. Чрезмерное

накопление металлической пыли может привести к

разрядам электрического тока от внутренних частей к

открытым металлическим частям. Не перегружайте

угловую шлифовальную машину. Перегрузка приводит к

снижению скорости и эффективности, в результате чего

ваш угловая шлифовальная машина перегревается.

Если это произойдет, позволь угловой шлифовальной

машине работать на холостом ходу в течение одной или

двух минут, пока она не остынет до нормальной рабочей

температуры. Выключение вашей угловой

шлифовальной машины под нагрузкой может сократить

срок службы выключателя.

Осторожно! При выполнении технического

обслуживания используйте только идентичные

запасные части. Использование любой другой детали

может стать причиной возникновения опасности или

повреждения оборудования.

• НЕ используйте растворители для очистки

пластмассовых деталей. Пластмассы могут быть

повреждены при использовании различных типов

растворителей, доступных в торговой сети.

Используйте чистую ткань, чтобы удалить грязь,

пыль, масло, жир и т.д.

Осторожно! Не допускайте контакта

пластиковых деталей с тормозной жидкостью,

бензином, продуктами на основе нефти, проникающими

маслами и т.д. Они содержат химические вещества,

которые могут повредить, ослабить или разрушить

пластик.

• Регулярно удаляйте скопившуюся пыль и мусор,

используя МЯГКУЮ и СУХУЮ кисть.

Осторожно! Используйте защитные очки при помощи

воздушной струи, чтобы выдуть пыль из инструмента.

Содержите вентиляционные отверстия в чистоте и

незасоренными для обеспечения максимального

воздушного потока через инструмент.

• НЕ эксплуатируйте электроинструменты с

нарушением установленных режимов.

Ненадлежащие действия могут привести к

повреждению инструмента и заготовки.

Осторожно! НЕ пытайтесь модифицировать

инструменты или зарегистрироваться насадки.

Любое такое изменение или модификация является

ненадлежащим использованием и может привести к

опасной ситуации, ведущей к возможной серьезной

травме. Это также приведет к аннулированию гарантии.

Смазка

Все подшипники в этом инструменте смазываются

достаточным количеством высокосортной смазки для

эксплуатации устройства при нормальных условиях.

Дополнительная смазка не требуется.

Очистка

Используйте только мягкое мыло и влажную ткань,

чтобы очистить вашу угловую шлифовальную машину.

Многие бытовые чистящие средства содержат

химические вещества, которые могут серьезно

повредить пластик. Кроме того, не используйте бензин,

скипидар, лак или растворители для краски или

подобные продукты. Никогда не допускайте попадания

жидкости внутрь инструмента и никогда не опускайте

какую-либо деталь инструмента в жидкость.

Важно! Чтобы гарантировать БЕЗОПАСНОСТЬ

и НАДЕЖНОСТЬ, ремонт, техническое

обслуживание и регулировка (кроме тех,

которые перечислены в настоящем руководстве)

должны выполняться авторизованными сервисными

центрами или другим квалифицированным

обслуживающим персоналом всегда с использованием

идентичных запасных частей.

Характеристики

STDR5206

Мощность 520 Вт

Напряжение 220-240 В

Частота 50/60 Гц

Число оборотов 0-4500/мин

холостого хода (оборотов в минуту)

Вес 3,3 фунтов (1,45 кг)

18

Page 19

(Оригинальные инструкции)

РУССКИЙ

Защита окружающей среды

Раздельный сбор. Данное изделие нельзя

утилизировать вместе с обычными бытовыми

отходами.

Если однажды Вы захотите заменить Ваше изделие

Stanley или Вы больше в нем не нуждаетесь, не

выбрасывайте его вместе с бытовыми отходами.

Отнесите изделие в специальный приёмный пункт.

Раздельный сбор изделий с истекшим сроком

службы и их упаковок позволяет пускать их в

переработку и повторно использовать. Использование

переработанных материалов помогает защищать

окружающую среду от загрязнения и снижает расход

сырьевых материалов.

Местное законодательство может обеспечить сбор

старых электрических продуктов отдельно от бытового

мусора на муниципальных свалках отходов, или Вы

можете сдавать их в торговом предприятии при покупке

нового изделия. Фирма Stanley обеспечивает прием и

переработку отслуживших свой срок изделий Stanley.

Чтобы воспользоваться этой услугой, Вы можете сдать

Ваше изделие в любой авторизованный сервисный

центр, который собирает их по нашему поручению.

Вы можете узнать место нахождения Вашего

ближайшего авторизованного сервисного центра,

обратившись в Ваш местный офис Stanley по адресу,

указанному в данном руководстве по эксплуатации.

Кроме того, список авторизованных сервисных центров

Stanley и полную информацию о нашем послепродажном

обслуживании и контактах Вы можете найти в интернете

по адресу: www.2helpU.com

Два года полной гарантии

При повреждении продукта STANLEY в течение 24

месяцев со дня покупки, произошедшего вследствие

дефекта материалов или производственного брака,

STANLEY гарантирует замену всех неисправных частей

без взимания платы или, по нашему усмотрению,

бесплатную замену самого инструмента, при условии,

что:

• Продукт использовался без нарушения правил

эксплуатации в соответствии с руководством по

эксплуатации.

• Продукт пришел в негодность вследствие

нормального износа;

• Ремонт продукта не производился посторонними

лицами.

• Имеется подтверждение факта совершения покупки.

• Продукт STANLEY возвращен в полной комплектации

и с наличием всех оригинальных составных частей.

Если Вы хотите подать заявку на гарантийное

обслуживание, обратитесь к Вашему продавцу, в один из

авторизованных сервисных центров STANLEY, список

которых приведен в каталоге продукции STANLEY, или в

ближайший сервисный центр STANLEY с по адресу,

указанному на упаковке продукта или в данном

руководстве по эксплуатации. Список авторизованных

сервисных центров STANLEY и полную информацию о

нашем послепродажном обслуживании Вы можете найти

в интернете по адресу: www.stanleytools.com

19

Page 20

РУССКИЙ

(Оригинальные инструкции)

Гарантийные условия

Уважаемый покупатель!

1. Поздравляем Вас с покупкой высококачественного

изделия STANLEY и выражаем признательность за Ваш

выбор.

2. При покупке изделия требуйте проверки его комплектности

и исправности в Вашем присутствии, инструкцию по

эксплуатации и заполненный гарантийный талон на

русском языке.

В гарантийном талоне должны быть внесены: модель,

дата продажи, серийный номер, дата производства

инструмента; название, печать и подпись торговой

организации. При отсутствии у Вас правильно заполненного гарантийного талона, а также несоответствия

указанных в нем данных мы будем вынуждены откло- нить

Ваши претензии по качеству данного изделия.

3. Во избежание недоразумений убедительно просим Вас

перед началом работы с изделием внимательно

ознакомиться с инструкцией по его эксплуатации.

Правовой основой настоящих гарантийных условий

является действующее Законодательство. Гарантийный

срок на данное изделие составляет 24 месяца и

исчисляется со дня продажи. В случае устранения

недостатков изделия, гарантийный срок продлевается на

период его нахождения в ремонте. Срок службы изделия

составляет 5 лет со дня продажи.

4. В случае возникновения каких-либо проблем в про- цессе

эксплуатации изделия рекомендуем Вам обра- щаться

только в уполномоченные сервисные центры STANLEY,

адреса и телефоны которых Вы сможете найти в

гарантийном талоне, на сайте www.2helpU.com или узнать

в магазине. Наши сервисные станции - это не только

квалифицированный ремонт, но и широкий ассортимент

запчастей и принадлежностей.

5. Производитель рекомендует проводить периодическую

проверку и техническое обслуживание изделия в

уполномоченных сервисных центрах.

Изготовитель

Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

6. Наши гарантийные обязательства распространяются

только на неисправности, выявленные в течение гарантийного срока и вызванные дефектами производства и \

или материалов.

7. Гарантийные условия не распространяются на

неисправности изделия, возникшие в результате:

7.1. Несоблюдения пользователем предписаний инструкции по

эксплуатации изделия, применения изделия не по

назначению, неправильном хранении, использования

принадлежностей, расходных материалов и запчастей, не

предусмотренных производителем.

7.2. Механического повреждения (сколы, трещины и разрушения) внутренних и внешних деталей изделия,

основных и вспомогательных рукояток, сетевого электрического кабеля, вызванного внешним ударным или

любым иным воздействием

7.3 Попадания в вентиляционные отверстия и проникновение внутрь изделия посторонних предметов,

материалов или веществ, не являющихся отходами,

сопровождающими применение изделия по назначению,

такими как: стружка, опилки, песок, и пр.

7.4. Воздействий на изделие неблагоприятных атмосферных и

иных внешних факторов, таких как дождь, снег,

повышенная влажность, нагрев, агрессивные среды,

несоответствие параметров питающей электросети,

указанных на инструменте.

7.5. Стихийного бедствия. Повреждение или утрата изделия,

связанное с непредвиденными бедствиями, стихийными

явлениями, в том числе вследствие действия

непреодолимой силы (пожар, молния, потоп и другие

природные явления), а так же вследствие перепадов напряжения в электросети и другими причинами, которые

находятся вне контроля производителя.

8. Гарантийные условия не распространяются:

8.1. На инструменты, подвергавшиеся вскрытию, ремонту или

модификации вне уполномоченного сервисного центра.

8.2. На детали и узлы, имеющие следы естественного износа,

такие как:

приводные ремни и колеса, угольные щетки, смазка,

подшипники, зубчатое зацепление редукторов, резиновые уплотнения, сальники, направляющие ролики,

муфты, выключатели, бойки, толкатели, стволы, и т.п.

8.3. На сменные части: патроны, цанги, зажимные гайки и

фланцы, фильтры, аккумуляторные батареи, ножи,

шлифовальные подошвы, цепи, звездочки, пильные шины,

защитные кожухи, пилки, абразивы, пильные и

абразивные диски, фрезы, сверла, буры и т.п.

8.4. На неисправности, возникшие в результате перегрузки

инструмента (как механической, так и электрической),

повлекшей выход из строя одновременно двух и более

деталей и узлов, таких как: ротора и статора, обеих

обмоток статора, ведомой и ведущей шестерни редуктора или других узлов и деталей. К безусловным

признакам перегрузки изделия относятся, помимо прочих:

появление цветов побежалости, деформация или

оплавление деталей и узлов изделия, потемнение или

обугливание изоляции проводов электродвигателя под

воздействием высокой температуры.

20

Page 21

(Оригінальні інструкції)

УКРАЇНСЬКА

FIG. A

1

2

4

FIG. B FIG. C

3

6

5

4

5

FIG. D FIG. E

7

5

6

5

8

1

21

Page 22

УКРАЇНСЬКА

(Оригінальні інструкції)

FIG. F

FIG. H

FIG. G

7

2

8

9

1

2

10

FIG. I

FIG. J

22

FIG. K

2

1

Page 23

(Оригінальні інструкції)

УКРАЇНСЬКА

НЕ ПОВЕРТАЙТЕ ЦЕЙ ВИРІБ В МАГАЗИН,

спочатку зверніться у місцевий офіс STANLEY або в

найближчий авторизований сервісний центр.

призначення

Це викрутка Стенлі розроблений для управління

гіпсокартону кріплення через гіпсокартон борту в

дерев'яних або металевого каркаса шпильки.

Загальні правила техніки безпеки

Увага! Прочитайте і зрозумійте всі інструкції.

Недотримання будь-яких інструкцій,

зазначених нижче, може призвести до

ураження електричним струмом, пожежі та/або

серйозної травми.

ЗБЕРЕЖІТЬ ЦІ ІНСТРУКЦІЇ

Правила техніки безпеки

Загальні попередження з техніки безпеки

електроінструментів

Увага! Ознайомтеся з усіма правилами

безпеки та інструкціями. Недотримання

попереджень та інструкцій, зазначених нижче,

може призвести до ураження електричним струмом,

пожежі та/або серйозної травми.

Збережіть всі попередження та інструкції для

майбутнього використання.

Термін "електроінструмент" у всіх попередженнях,

зазначених нижче, відноситься до мережевого (з

кабелем) електроінструменту або акумуляторної батареї

(без кабелю живлення).

1. Безпека робочого місця

а. Утримуєте робоче місце в чистоті і добре

освітленим. Безлад на робочому місці або

відсутність освітлення робочого місця може

призвести до аварії.

b. Не працюйте з електроінструментом в місці

зберігання вибухонебезпечних матеріалів,

наприклад, у присутності легкозаймистих рідин,

газів або пилу. Електричні інструменти створюють

іскри, що можуть запалити пил або пари.

с. Діти і сторонні особи повинні знаходитися

якнайдалі під час роботи з електроприладами. Ви

можете відволіктися і втратити контроль.

2. Електробезпека

а. Вилка електроінструмента повинна відповідати

розетці. Ніколи не змінюйте вилку будь-яким

чином. Не використовуйте ніякі

вилки-перехідники з заземленими (замкнутими на

землю) електроінструментами. Вилки і розетки, які

не піддавалися ніяким змінам знижують ризик

ураження електричним струмом.

b. Уникайте контакту тіла з заземленими

поверхнями, такими як труби, радіатори, плити та

холодильники. Існує підвищений ризик ураження

електричним струмом, якщо ваше тіло заземлене.

с. Уникайте будь-якого впливу дощу або вологи на

електроінструменти. Вода, що потрапила в

електроінструмент, збільшує ризик ураження

електричним струмом.

d. Обережно поводьтеся зі шнуром живлення.

Ніколи не використовуйте шнур живлення для

перенесення, переміщення або вилучення вилки з

розетки. Тримайте шнур подалі від джерел тепла,

масла, гострих країв або рухомих частин.

Пошкоджені або заплутані шнури збільшують ризик

ураження електричним струмом.

е. При роботі з електроінструментом на вулиці,

використовуйте подовжувач, відповідний для

зовнішнього використання. Використання кабелю,

придатного для використання на відкритому повітрі,

знижує ризик ураження електричним струмом.

f. При необхідності роботи з електроінструментом у

вологому середовищі, використовуйте пристрій

захисного відключення (ПЗВ). Використання ПЗВ

знижує ризик ураження електричним струмом.

Примітка: Термін "пристрій захисного відключення

(ПЗВ)" може бути замінений на "аварійний переривач

заземлення" або "автоматичний вимикач струму

витоку".

3. Особиста безпека

a. Будьте уважні, дивіться, що ви робите,

використовуйте здоровий глузд при роботі з

електроприладами. Не використовуйте

електроінструмент, якщо ви втомилися або

перебуваєте під впливом наркотиків, алкоголю або

ліків. Найменша необережність при роботі з

електроінструментом може призвести до серйозних

травм.

b. Використовуйте засоби індивідуального захисту.

Завжди надягайте захисні окуляри. Інше захисне

обладнання, включаючи респіратор, черевики на

нековзній підошві, захисний шолом або засоби

захисту органів слуху, використовувані в належних

умовах, зменшать ризик отримання травми.

с. Для запобігання випадкового запуску,

переконайтеся, що перемикач знаходиться у

вимкненому положенні перед підключенням до

джерела живлення та/або акумуляторної батареї,

підняття або перенесення інструменту. Не

переносьте електроінструмент з пальцем на вимикачі

і не включайте електроживлення на інструмент з

увімкненим вимикачем, що може призвести до

нещасного випадку.

d. Перед включенням електроінструменту знімайте

регулювальний або гайковий ключ. Гайковий або

регулювальний ключ, залишений на обертовій частині

електроінструменту, може призвести до травми.

е. Не тягніться. Зберігайте правильну стійку і

баланс весь час. Це дозволяє краще контролювати

інструмент в несподіваних ситуаціях.

f. Одягайтеся правильно. Не надягайте вільний

одяг або прикраси. Тримайте волосся, одяг і

рукавички далеко від рухомих частин. Вільний

одяг, прикраси або довге волосся можуть потрапити в

рухомі частини.

23

Page 24

УКРАЇНСЬКА

(Оригінальні інструкції)

g. Якщо є пристрої для підключення пилозбірника

або витяжки, переконайтеся в тому, що вони

під'єднані і використовуються правильно.

Використання пилозбірника знижує ймовірність

виникнення ризиків, пов'язаних з пилом.

4. Використання та догляд за електроінструментом

a. Не перевантажуйте електроінструмент.

Використовуйте відповідний електричний

інструмент для відповідного застосування.

Правильно підібраний електроінструмент дозволить

виконати роботу краще і безпечніше при швидкості,

для якої він був розроблений.

b. Не використовуйте електроінструмент, якщо

перемикач не може його включити і вимкнути.

Будь-який електроінструмент, який не можна

контролювати за допомогою перемикача, є

небезпечний і повинен бути відремонтований.

c. Від'єднайте кабель живлення від джерела

живлення та/або акумулятора від електричного

інструменту перед виконанням будь-яких

регулювань, заміни приладдя або при зберіганні

електроінструменту. Такі профілактичні заходи

безпеки зменшують ризик ненавмисного запуску

електричного інструменту.

d. Зберігайте електроприлади в недоступному для

дітей місці і не дозволяйте особам, які не знайомі

з електричним інструментом або даними

інструкціями, працювати з електроприладами.

Електроінструменти небезпечні в руках

недосвідчених користувачів.

е. Підтримання електроінструменту. Перевіряйте

разрегульованість або з'єднання рухомих частин,

поломки частин і будь-які інші умови, які можуть

вплинути на роботу електроінструменту. При

наявності пошкодження, відремонтуйте

електроінструмент перед використанням. Багато

нещасних випадків є наслідком поганого догляду за

електроінструментом.

f. Тримайте ріжучий інструмент гострим і чистим.

Добре доглянутий ріжучий інструмент з гострими

ріжучими крайками легше контролювати.

5. Обслуговування

а. Забезпечте, щоб обслуговування і ремонт

вашого електроінструменту проводився в

авторизованому сервісному центрі по ремонту з

використанням тільки оригінальних запасних

частин. Це стане гарантією безпеки

електроінструменту.

Вказівки з техніки безпеки для шуруповерта

При виконанні операцій, під час яких ріжучий інструмент

може контактувати з прихованими кабелями чи власним

кабелем електроживлення тримайте електроінструмент

за спеціальні ізольовані поверхні. Кріпильні елементи,

що контактують з проводом під напругою можуть подати

напругу на відкриті металеві частини електроінструменту

і це може призвести до ураження оператора

електричним струмом.

Етикетки на інструменті

Етикетки на вашому інструменті можуть включати

такі символи:

Читайте

інструкції з

експлуатації

Використовуйте

засоби захисту

очей

Використовуйте

засоби захисту

органів слуху

В ........ Вольт

A ........ Ампер

Гц ....... Герц

Вт ........

мин .....

n

0

Ватт

хвилини

Змінний

.....

струм

Постійний

.....

струм

Швидкість

.......

без навантаження

......

....

....

хв..

Конструкція

класу II

Термінал

заземлення

Символ

попередження про

небезпеку

обороти або

зворотно

поступальний рух в

хвилину

Положення дати штрих-коду

Дата коду, який також включає рік виготовлення,

друкується на корпусі.

Приклад:

2014 XX JN

Рік виготовлення

7. Електрична безпека

Ваш інструмент має подвійну ізоляцію, саме в

цьому зв'язку заземлюючий провід не потрібен.

Завжди перевіряйте, що напруга мережі відповідає

напрузі, вказаній на табличці.

Увага! Якщо шнур живлення пошкоджений, він

повинен бути замінений виробником в

авторизованому сервісному центрі STANLEY або

кваліфікованим фахівцем для того, щоб уникнути

пошкодження або травми. Якщо шнур живлення

замінений кваліфікованим фахівцем, не уповноваженим

STANLEY, гарантія не діятиме.

Опції (Мал. A)

1. Обмежувач глибини

2. Регулятор глибини

3. Зажим для кріплення до поясного ременя

4. Перемикач вперед / назад

5. Варіатор швидкості

6. Кнопка блокіровки

Певні правила техніки безпеки

Обережно! Вивчіть ваш шуруповерт для

гіпсокартону. Не приєднуйте інструмент до

джерела живлення, поки ви не прочитали і зрозуміли цю

інструкцію з експлуатації. Дізнайтеся про сферу

застосування інструменту і обмеженнях, а також певних

потенційних небезпеки, пов'язані з цим інструментом.

24

Page 25

(Оригінальні інструкції)

УКРАЇНСЬКА

• Виконання цього правила знизить ризик ураження

електричним струмом, виникнення вогню або

серйозної травми.

• Завжди надягайте захисні окуляри. Будь-який

електроінструмент може стати причиною

потрапляння сторонніх об'єктів у ваші очі і призвести

до незворотного пошкодження очей. ЗАВЖДИ

надягайте захисні окуляри (не очки для корекції зору),

які відповідають стандарту безпеки ANSI Z87.1.

Повсякденні окуляри забезпечені тільки

удароміцними лінзами. Вони НЕ Є захисними

окулярами

Обережно! Окуляри для корекції зору або

сонцезахисні окуляри, що не відповідають

вимогам ANSI Z87.1, можуть призвести до

серйозних травм, якщо вони ламаються.

• Ніколи не використовуйте шуруповерт для

гіпсокартону для закручування шурупів іншого типу,

ніж саморізи. Шуруповерт для гіпсокартону та

насадки для шуруповерта призначені саме для

закручування саморізів.

• Використовуйте насадки для шуруповерта, які

призначені для використання з даним інструментом.

• Завжди тримайте руки подалі від шляху саморізу.

Уникайте незручних положень рук, коли раптове

ковзання може привести вашу руку на шлях руху

пилкового диска.

• Переконайтеся у відсутності цвяхів або сторонніх

предметів в частині деталі, яка буде піддаватися

різанню або шліфуванню.

• Щоб уникнути травм від випадкового включення,

завжди виймайте вилку з розетки, перш ніж

встановлювати або витягувати насадку для

шуруповерта або під час регулювання глибини.

• Завжди перевіряйте зону стіни, куди вкручуються

шурупи, щоб переконатися у відсутності будь-яких

прихованих електричних проводів в даній зоні.

• Ніколи не залишайте кнопку фіксації в положенні ВКЛ

(ON). Перед підключенням інструменту до джерела

живлення, переконайтеся, що кнопка фіксації в

положенні ВИКЛ (OFF).

Вказівки з техніки безпеки загального характеру

Обережно! Одягайте протипиловий респіратор,

який призначений для використання при роботі з

електроінструментом в запорошеному

середовищі.

Обережно! Пил, який створюється при

механічній шліфовці, розпилі, шліфуванні,

свердлінні та інших будівельних роботах може

містити речовини, які, як відомо, викликають рак,

вроджені дефекти або інші генетичні аномалії. До них

відносяться:

• Свинець з свинцевих фарб

• Кристалічний кремнезем з цегли, цементу та інших

стінових блоків

• Миш'як і хром з хімічно оброблених пиломатеріалів

Рівень ризику від впливу цих речовин коливається, у

зв'язку з тим, як часто виконується цей тип роботи. Для

того, щоб скоротити вплив цих хімічних речовин,

працюйте в добре провітрюваному приміщенні і

використовуйте схвалені технічні засоби забезпечення

безпеки, наприклад, респіратор, який призначений саме

для фільтрування мікроскопічних часток.

Безпечний подовжувач

Обережно! Уникайте потрапляння подовжувача

в робочу зону. Розташуйте шнур, щоб він не

потрапляв на заготовку, інструменти або будь-які

інші перешкоди, поки ви працюєте з електроприладами.

Переконайтеся в хорошому стані будь-якого

подовжувача, що використовується з цим інструментом.

При використанні подовжувача переконайтеся, що

використовуєте провід достатнього перетину, здатний

витримати робочий струм інструменту. Шнур

недостатнього перетину може викликати падіння

напруги, що призводить до втрати потужності і перегріву.

Переконайтеся, щодо вашого подовжувача чи правильно

він підключений і знаходиться у хорошому стані. Завжди

замінюйте пошкоджений подовжувач або перед його

використанням віддайте його в ремонт кваліфікованому

електрику. Захищайте свій подовжувач від гострих

предметів, високих температур і впливу вогкості або

вологи.