Page 1

STDH7213C

English Page 4

Turkish Page 14

Page 2

ENGLISH

2

(Original instructions)

B

A

0000 00-00

5

2

4

3

13

1

10

6

9

7

8

4

Page 3

3

ENGLISH

(Original instructions)

C

D

12

E

6

7

Page 4

Intended use

Your STANLEY impact drill has been designed for drilling in

wood, metal and concrete. This tool is intended for

consumer use only.

General Power tool Safety Warnings

Warning! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

ENGLISH

4

(Original instructions)

Page 5

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool's

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Additional Power Tool Safety Warnings

Warning! Additional safety warnings for drills and

impact drills

Drill Safety Warnings

• Wear ear protectors when impact drilling. Exposure

to noise can cause hearing loss.

• Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

• Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live" and

could give the operator an electric shock.

• Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding the

work by hand or against your body leaves it unstable and

may lead to loss of control.

• Before drilling into walls, floors or ceilings, check for the

location of wiring and pipes.

• Avoid touching the tip of a drill bit just after drilling, as it

may be hot.

• This tool is not intended for use by persons(including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety. Children should be supervised to ensure

that they do not play with the appliance.

• The intended use is described in this instruction manual.

The use of any accessory or attachment or performance

of any operation with this tool other than those

recommended in this instruction manual may present a

risk of personal injury and/or damage to property.

Safety of others

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

• Children should be supervised to ensure that they do not

play with the appliance

5

ENGLISH

(Original instructions)

Page 6

6

ENGLISH

Residual risks

Additional residual risks may arise when using the tool which

may not be included in the enclosed safety warnings. These

risks can arise from misuse, prolonged use etc. Even with

the application of the relevant safety regulations and the

implementation of safety devices, certain residual risks can

not be avoided. These include:

• Injuries caused by touching any rotating/moving parts.

• Injuries caused when changing any parts, blades or

accessories.

• Injuries caused by prolonged use of a tool. When using

any tool for prolonged periods ensure you take regular

breaks.

• Impairment of hearing.

• Health hazards caused by breathing dust developed

when using your tool (example:- working with wood,

especially oak, beech and MDF.)

Electrical safety

Double insulation measures are taken in this power

tool, so no grounding is needed. Please check

whether the voltage of power supplied is consistent with the

voltage on the nameplate or not.

• If the wire is damaged, it should be replaced by the

manufacturer or a service center authorized by

STANLEY, to avoid danger.

Using an extension cable

• If an extension cable is requred, use an approved

extension cable suitable for the power input of this tool

(see technical data). The minimum conductor size is

1.5 mm2.

When using a cable reel, always unwind the cable

completely.

Also refer to the table below.

(Original instructions)

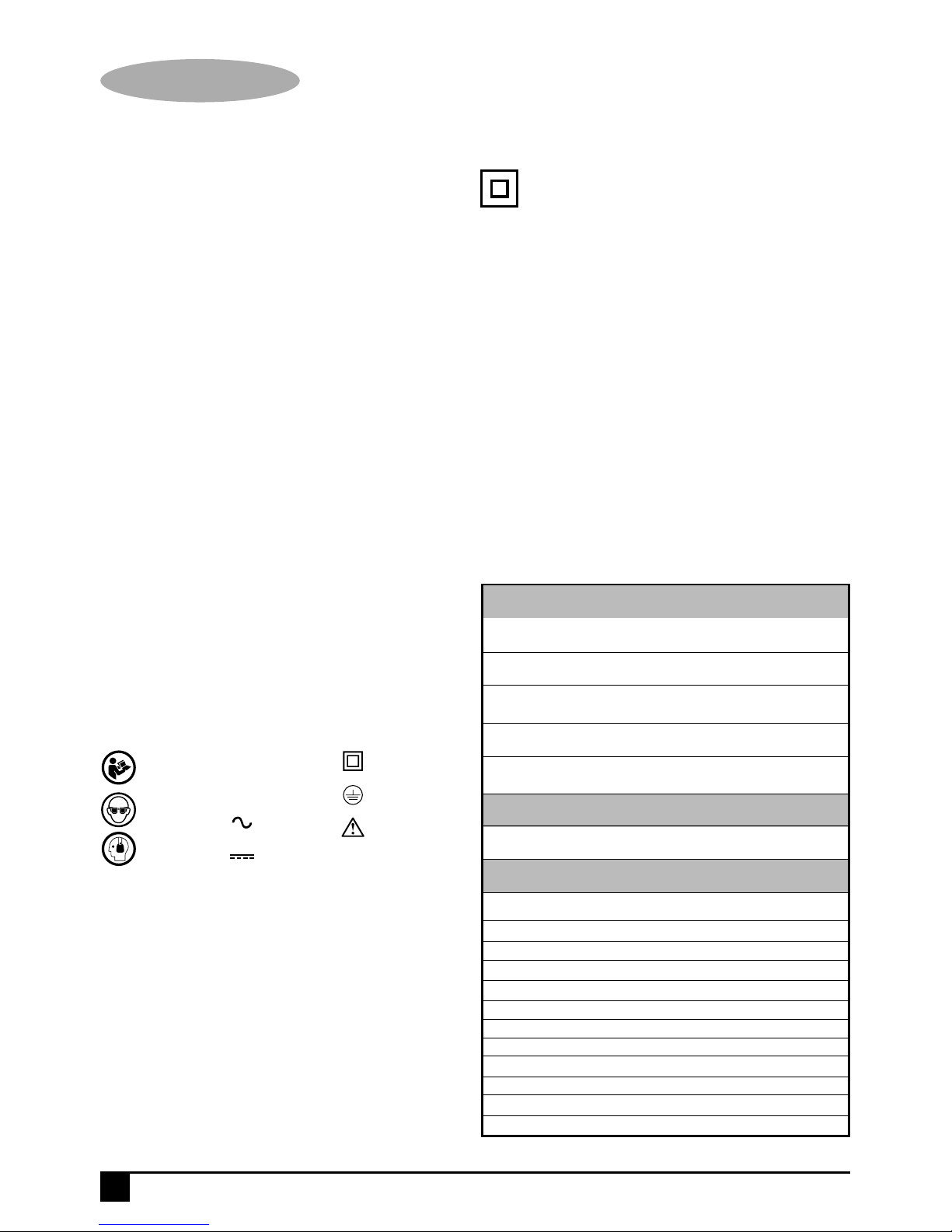

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hz ....... Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

0

....... No-Load

Speed

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

Labels on tool

The label on your tool may include the following symbols:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Conductor size (mm2) Cable rating (Amperes)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - 230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

Page 7

• Check for damage to the tool, parts or accessories which

may have occurred during transport.

• Take the time to thoroughly read and understand this

manual prior to operation.

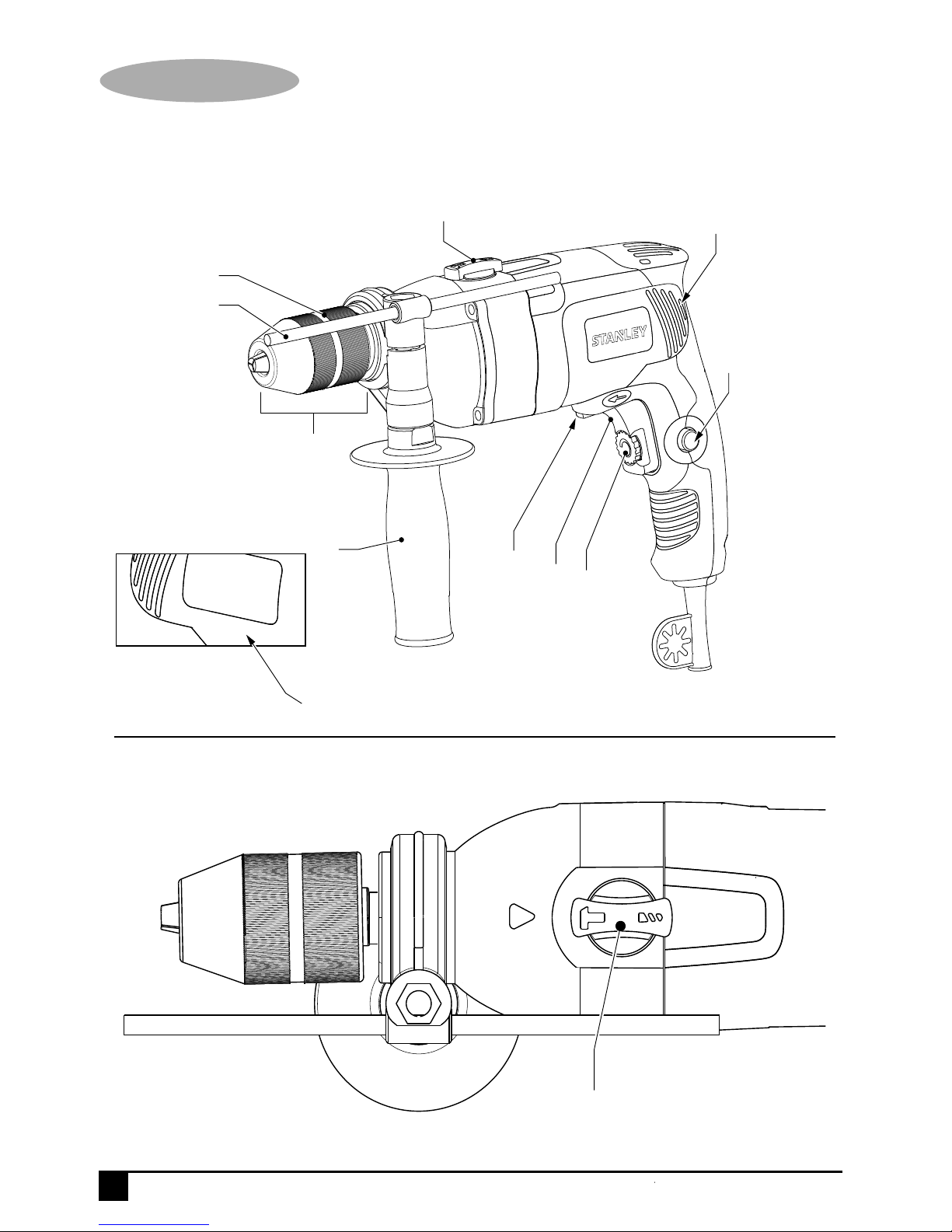

Description (fig. A)

1. Variable speed switch

2. Lock-on button

3. Forward/reverse slider

4. Mode selector

5. Ventilation slots

6. Side handle

7. Depth adjustment rod

8. Keyless chuck

9. Sleeve

10. Speed dail

Assembly

Warning! Before assembly, please ensure that the power

tool is powered off and the power plug of the tool is

unplugged from the power source.

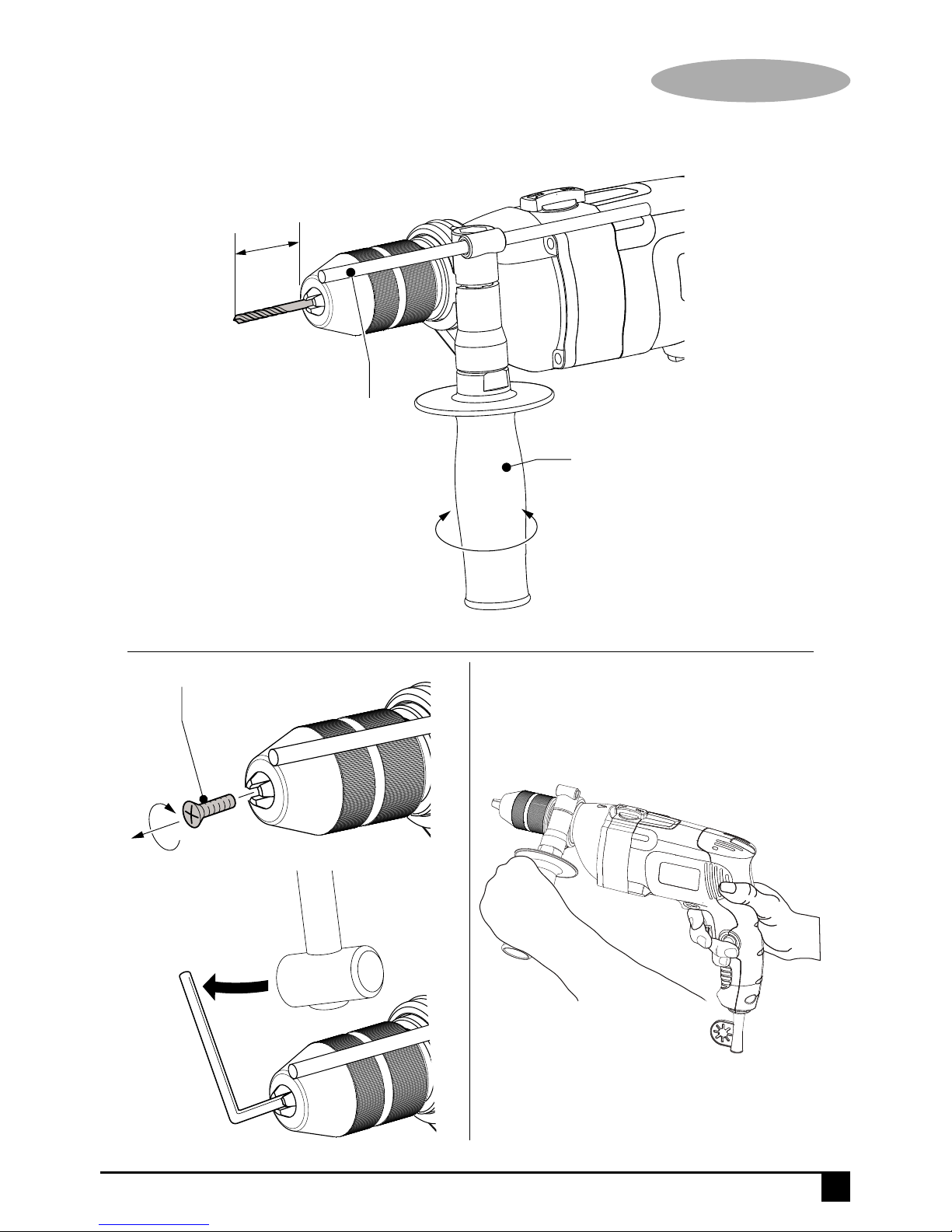

Selecting the operating mode (fig. B) The tool can be used in

two operating modes:

Rotary drilling:

for steel, wood and plastics.

Impact drilling:

simultaneous rotating and impacting for concrete and

masonry drilling operations.

• Select the required operating mode by rotating the mode

selector (4) to the required position.

Inserting and removing a bit (fig. A,D)

Keyless chuck

The STDH7213 features a keyless chuck (d) for greater

convenience.

To Insert A Drill Bit Or Other Accessory.

• Grasp the rear half of the chuck with one handand use

your other hand to rotate the front half counterclockwise,

as shown in Figure 6. Rotate far enough so that the

chuck opens sufficiently to accept the desired accessory.

• Insert the bit or other accessory about 19 mm (3/4") into

the chuck and tighten securely by holding the rear half of

the chuck and rotating the front portion in the clockwise

direction. When the chuck is nearly tightened, you will

hear a clicking sound. After 4–6 clicks, the chuck is

securely tightened around the accessory.

• To release the accessory, repeat step 1 listed above.

Warning! Do not attempt to tighten drill bits (or any other

accessory) by gripping the front part of the chuck and

turning the tool on. Damage to the chuck and personal injury

may result.

Keyless Chuck Removal (Fig. D)

Tighten the chuck around the shorter end of a hex key (not

supplied). Using a soft hammer or piece of wood, strike the

longer end in the counterclockwise direction. This will loosen

the chuck so that it can be unscrewed by hand.

Keyless Chuck Installation (Fig. D)

Screw the chuck on by hand as far as it will go. Tighten the

chuck around the shorter end of a hex key (not supplied)

and strike the longer end in the clockwise direction with a

soft hammer.

Fitting the side handle (fig. A)

The side handle (6) can be fitted to suit both RH- and

LH-users.

Always use the drill with the side handle properly

assembled.

• Loosen the side handle.

• For RH-users, slide the side handle clamp overthe collar

behind the chuck, handle at the left.

• For LH-users, slide the side handle clamp colar behind

the chuck, handle at the right.

• Rotate the side handle to the desired positionand tighten

the handle.

Setting the drilling depth (fig. C)

• Insert the required drill bit into the chuck.

• Slacken the side handle (6).

• Fit the depth adjustment rod (7) through the hole in the

side handle clamp.

• Adjust the drilling depth as shown.

• Tighten the side handle.

Forward/reverse slider (fig. A)

• To select forward or reverse rotation, use the

forward/reverse-switch (3) (see arrow on tool).

Always wait until the motor has come to a

complete standstill before changing the direction of

rotation.

7

ENGLISH

(Original instructions)

Page 8

8

ENGLISH

(Original instructions)

Instructions for use

• Always observe the safety instructions and applicable

regulations.

• Be aware of the location of pipework and wiring.

• Apply only a gentle pressure to the tool. Excessive force

does not speed up drilling but decreases tool

performance and may shorten tool life.

• Wear ear protectors with impact drills.Exposure to noise

can cause hearing loss.

• Use auxiliary handles supplied with the tool. Loss of

control can cause personal injury.

• Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting

accessory contacting a "live" wire may make exposed

metal parts of the power tool "live" and shock the

operator.

• If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

Prior to operation

• Insert the appropriate bit.

• Mark the spot where the hole is to be drilled.

Proper Hand Position (fig. A, E)

Warning: To reduce the risk of serious personal

injury, ALWAYS use proper hand position as

shown.

Warning: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

sudden reaction.

Proper hand position requires one hand on the side handle

(6), with the other hand on the main handle.

Switching on and off

• To switch the tool on, press the variable speed switch

(1). The tool speed depends on how far you press the

switch.

• For continuous operation, press the lock-on button (2)

and release the variable speed switch. This option is

available only at full speed.

• To switch the tool off, release the variable speed switch.

To switch the tool off when in continuous operation,

press the variable speed switch once more and release

it.

• Based on the different applications, turn around the

speed dial (10) to control the maximum speed.

Drilling in metal

Start drilling with slow speed and increase to full power while

applying firm pressure on the tool. A smooth even flow of

metal chips indicates the proper drilling rate. Use a cutting

lubricant when drilling metals. The exceptions are cast iron

and brass which should be drilled dry.

Note: Large [5/16" (8 mm) to 1/2" (13 mm)] holes in steel

can be made easier if a pilot hole [5/32" (4 mm) to 3/16" (5

mm)] is drilled first.

Drilling in wood

Start drilling with slow speed and increase to full power while

applying firm pressure on the tool. Holes in wood can be

made with the same twist drills used for metal. These bits

may overheat unless pulled out frequently to clear chips

from the flutes. Work that is apt to splinter should be backed

up with a block of wood.

Drilling in masonry

When drilling in masonry, use carbide-tipped bits rated for

Impact drilling and be certain that the bits are sharp. Use a

constant and firm force on the tool to drill most effectively. A

smooth, even flow of dust indicates the proper drilling rate.

Screwdriving

• Select forward or reverse rotation.

Impact drilling (fig. A)

• Select the Impact mode.

• Press the switch (1).

Rotary drilling (fig. A)

• Select the rotary drilling mode.

• Proceed as described for Impact drilling.

Consult your dealer for further information on the

appropriate accessories.

Accessories

The performance of an electric tool depends on its

accessories. STANLEYaccessories are designed according

to high quality standards, to enhance the performance of

electric tool. The use of these accessories can help you

conveniently operate the tool.

Page 9

9

ENGLISH

(Original instructions)

Maintenance

The STANLEYcord / cordless appliance / tools are of

sophisticated design, can be used for a long time, and only

little maintenance is needed. To obtain consistent

satisfactory use, proper maintenance and regular cleaning of

the tools are necessary.

Warning! Before performing any maintenance work on the

cord / cordless electric tools, the following points must be

implemented:

• Switch off the power of the equipment / tools and pull off

the plug;

• If the equipment / tools are equipped with independent

battery pack, please turn off the power and remove the

battery pack from the equipment / tools.

• If the equipment / tools are equipped with an integrated

battery, please run out the battery, before turning off its

power.

• Before the cleaning, unplug the charger plug from the

power source. In addition, except the regular cleaning on

your charger, no other maintenance is needed.

• Regularly use the soft brush or dry cloth to clean the

ventilation slot of the equipment / tools / charger.

• Regularly use a damp cloth to clean the motor housing.

Please do not use any abrasive cleaning agents or

solvent-based cleansing agents.

• Regularly open the clamping chuck and tap it gently to

remove any internal dust (after installation).

Cleaning

Warning! Once the visible dust build-up is found

at and/or around the ventilating ports,

immediately flush the dust and powder within the

host shell with clean dry air. To perform this procedure, wear

the approved safety equipment and dust mask.

Warning! It is strictly forbidden to clean the

non-metallic parts of the tool with the solvents or

other irritant chemicals. These chemicals may

weaken the materials of these components. Use a cloth

moistened with a mild soapy water to clean it. Do not let any

substance permeate into the tool and.do not immerse any

part of the tool into a liquid.

Service Information

STANLEY offers a full network of company-owned and

authorized service locations throughout Asia. All STANLEY

Service Centers are staffed with trained personnel to provide

customers with efficient and reliable power tool

service.Whether you need technical advice, repair, or

genuine factory replacement parts, contact the STANLEY

location nearest to you.

Notes

• STANLEY’s policy is one of continuous improvement to

our products and, as such, we reserve the right tochange

product specifications without prior notice.

• Standard equipment and accessories may vary by

country.

• Product specifications may differ by country.

• Complete product range may not be available in all

countries. Contact your local STANLEY dealers for range

availability.

Impact Drill STDH7213C

Voltage V 220-240

Frequency Hz 50/60

Power input W 720

No-load speed /min 0-3000

Impact rate IPM 0-54000

Reverse/Forward rotation Yes

Chuck capacity mm 1.5-13

Max capacity

Concrete mm 16

Metal mm 13

Wood mm 32

Weight kg 2.5

Technical data

LpA (sound pressure) dB(A) 100,5

K

pA

(sound pressure uncertainty) dB(A) 3

LWA (sound power) dB(A) 111,5

KWA (sound power uncertainty) dB(A) 3

Vibration emission value a

h

Check (chiselling)

a

h,ID

= m/s² 15,0

a

h,D

= m/s² 6,1

Uncertainty K = m/s² 1.5

Page 10

10

ENGLISH

(Original instructions)

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your STANLEY product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for raw

materials.

Local regulations may provide for separate collection of

electrical products from the household, at municipal waste

sites or by the retailer when you purchase a new product.

STANLEY provides a facility for the collection and recycling

of STANLEY products once they have reached the end of

their working life. To take advantage of this service please

return your product to any authorised repair agent who will

collect them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local STANLEY office at the

address indicated in this manual. Alternatively, a list of

authorised STANLEY repair agents and full details of our

after-sales service and contacts are available on the Internet

at: www.2helpU.com

The vibration emission level given in this information sheet

has been measured in accordance with a standardised test

given in EN 60745 and may be used to compare one tool

with another. It may be used for a preliminary assessment of

exposure.

Warning: The declared vibration emission

level represents the main applications of the

tool. However if the tool is used for different

applications, with different accessories or poorly maintained,

the vibration emission may differ. This may significantly

increase the 1.5exposure level over the total working period.

An estimation of the level of exposure to vibration should

also take into account the times when the tool is switched

off or when it is running but not actually doing the job. This

may significantly reduce the exposure level over the total

working period.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and

the accessories, keep the hands warm, organisation of work

patterns.

Page 11

Two years full warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY Europe guarantees to replace all

defective parts free of charge or – at our discretion – replace

the unit free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

11

ENGLISH

(Original instructions)

STANLEY declares that these products described under

"technical data" are in compliance with:

2006/42/EC, EN 60745-1, EN 60745-2-6

These products also comply with Directive

2014/30/EU and 2011/65/EU. For more information, please

contact STANLEY at the following address or refer to the

back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

STANLEY.

R.Laverick

Engineering Manager

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2015

EC declaration of conformity

MACHINERY DIRECTIVE

STDH7213C

Page 12

12

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

B

A

0000 00-00

5

2

4

3

13

1

10

6

9

7

8

4

Page 13

13

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

C

D

12

E

6

7

Page 14

14

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Kullanım amacı

STANLEY darbeli matkabınız, ahşap, metal ve beton delme

için tasarlanmıştır. Bu alet sadece tüketici kullanımı için

tasarlanmıştır.

Güvenlik talimatları

Genel elektrikli alet güvenlik uyarıları

Uyarı! Bütün güvenlik uyarılarını ve tüm

talimatları okuyun. Aşağıda yer alan uyarılar ve

talimatlara uyulmaması elektrik çarpması, yangın

ve/veya ciddi yaralanmalara neden olabilir.

Bütün uyarı ve talimatları ileride bakmak üzere saklayın.

Aşağıda listelenen tüm uyarılarda kullanılan "elektrikli alet"

terimi şebeke elektriği ile (kablolu) veya aküyle (kablosuz)

çalışan elektrikli aleti ifade etmektedir.

1. Çalışma alanının güvenliği

a. Çalışma alanını temiz ve aydınlık tutun. Dağınık ve

karanlık alanlar kazaya davetiye çıkarır.

b. Elektrikli aletleri, yanıcı sıvılar, gazlar ve tozların

bulunduğu yerler gibi yanıcı ortamlarda

çalıştırmayın. Elektrikli aletler, toz veya dumanları

ateşleyebilecek kıvılcımlar çıkarır.

c. Bir elektrikli aleti çalıştırırken çocuklardan ve

etraftaki kişilerden uzak tutun. Dikkatinizi dağıtıcı

şeyler kontrolü kaybetmenize neden olabilir.

2. Elektrik güvenliği

a. Elektrikli aletlerin fişleri prizlere uygun olmalıdır. Fiş

üzerinde kesinliklehiçbir değişiklik yapmayın.

Topraklı (topraklanmış) elektrikli aletlerde hiçbir

adaptor fişi kullanmayın. Değiştirilmemiş fişler ve

uygun prizler elektrik çarpması riskini azaltacaktır.

b. Borular, radyatörler, ocaklar ve buzdolapları gibi

topraklanmış yüzeylerle vücut temasından kaçının.

Vücudunuzun topraklanması halinde yüksek elektrik

çarpma riski vardır.

c. Elektrikli aletleri yağmura maruz bırakmayın veya

ıslatmayın. Elektrikli alete su girmesi, elektrik çarpması

riskini artıracaktır.

d. Kablosuna zarar vermeyin. Elektrikli aleti kesinlikle

kablosundan tutarak taşımayın, çekmeyin veya

prizden çıkarmayın. Kabloyu sıcaktan, yağdan,

keskin kenarlardan veya hareketli parçalardan uzak

tutun. Hasarlı veya dolaşmış kablolar elektrik çarpma

riskini arttırır.

e. Elektrikli aleti açık havada kullanırken, açık hava

kullanımına uygun bir uzatma kablosu kullanın. Açık

havada kullanıma uygun bir kablonun kullanılması

elektrik çarpma riskini azaltır.

f. Eğer bir elektrikli aleti nemli bir bölgede çalıştırması

zorunluysa, bir artık akım aygıtı (RCD) korumalı bir

kaynak kullanın. Bir RCD kullanılması elektrik çarpma

riskini azaltır.

3. Kişisel güvenlik

a. Elektrikli bir alet kullanırken her zaman dikkatli olun,

yaptığınız işe yoğunlaşın ve sağduyulu davranın.

Elektrikli bir aleti yorgunken veya ilaç ya da alkolün

etkisi altındayken kullanmayın. Elektrikli aletleri

kullanırken bir anlık dikkatsizlik ciddi yaralanmalara yol

açabilir.

b. Kişisel koruyucu ekipmanları mutlaka kullanın. Daima

koruyucu gözlük takın. Koşullara uygun toz maskesi,

kaymayan ayakkabılar, baret veya kulaklık gibi koruyu

cu

donanımların kullanılması kişisel yaralanmaları

az

altacaktır.

c. İstem dışı çalıştırılmasını önleyin. Cihazı güç

kaynağına ve/veya aküye bağlamadan, kaldırmadan

veya taşımadan önce düğmenin kapalı konumda

olduğundan emin olun. Aleti, parmağınız düğme

üzerinde bulunacak şekilde taşımak veya açık

konumdaki elektrikli aletleri elektrik şebekesine bağlamak

kazaya davetiye çıkarır.

d. Elektrikli aleti çalıştırmadan önce herhangi bir

ayarlama anahtarını veya vida anahtarını çıkarın.

Elektrikli aletin hareketli parçasına takılı bırakılan bir vida

anahtarı veya anahtar, kişisel yaralanmaya neden

olabilir.

e. Ulaşmakta zorlandığınız yerlerde kullanmayın. Her

zaman sağlam ve dengeli basın. Bu, beklenmedik

durumlarda elektrikli aletin daha iyi kontrol edilmesine

olanak tanır.

f. Uygun şekilde giyinin. Bol giysiler giymeyin ve takı

takmayın. Saçınızı, giysinizi ve eldivenlerinizi

hareketli parçalardan uzak tutun. Bol giysiler, takılar

veya uzun saçlar hareketli parçalara takılabilir.

g. Eğer kullandığınız üründe toz emme ve toplama

özellikleri olan ataşmalar varsa bunların bağlı

olduğundan ve doğru şekilde kullanıldığından emin

olun. Bu toz toplama ataşmanların kullanılması tozla ilgili

tehlikeleri azaltabilir.

Page 15

15

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

4. Elektrikli aletlerin kullanımı ve bakımı

a. Elektrikli aleti zorlamayın. Uygulamanız için doğru

elektrikli aleti kullanın. Doğru elektrikli alet, belirlendiği

kapasite ayarında kullanıldığında daha iyi ve güvenli

çalışacaktır.

b. Düğme açmıyor ve kapatmıyorsa elektrikli aleti

kullanmayın. Düğmeyle kontrol edilemeyen tüm

elektrikli aletler tehlikelidir ve tamir edilmesi

gerekmektedir.

c. Herhangi bir ayarlama, aksesuar değişimi veya

elektrikli aletlerin saklanması öncesinde fişi güç

kaynağından çekin. Bu tür önleyici güvenlik tedbirleri

aletin istem dışı çalıştırılması riskini azaltır.

d. Elektrikli aleti, çocukların ulaşamayacağı yerlerde

saklayın ve elektrikli aleti tanımayan veya bu

talimatları bilmeyen kişilerin elektrikli aleti

kullanmasına izin vermeyin. Elektrikli aletler, eğitimsiz

kullanıcıların elinde tehlikelidir.

e. Elektrikli aletlerin bakımını yapın. Hareketli

parçalardaki hizalama hatalarını ve tutuklukları,

parçalardaki kırılmalar ve elektrikli aletin çalışmasını

etkileyebilecek tüm koşulları kontrol edin. Hasarlı

ise, elektrikli aleti kullanmadan önce tamir ettirin.

Kazaların çoğu, elektrikli aletlerin bakımının yeterli

şekilde yapılmamasından kaynaklanır.

f. Kesim aletlerini keskin ve temiz tutun. Bakımı uygun

şekilde yapılmış keskin kesim uçlu kesim aletlerinin

sıkışma ihtimali daha düşüktür ve kontrol edilmesi

kolaydır.

g. Elektrikli aleti, aksesuarlarını ve aletin diğer

parçalarını vs. kullanırken bu talimatlara mutlaka

uyun ve elektrikli alet türü için öngörüldüğü şekilde,

çalışma ortamının koşullarını ve yapılacak işin ne

olduğunu göz önünde bulundurun. Elektrikli aletin

öngörülen işlemler dışındaki işlemler için kullanılması

tehlikeli durumlara neden olabilir.

5. Servis

a. Elektrikli aletinizi, sadece orijinal yedek parçaların

kullanıldığı yetkili servise tamir ettirin. Bu, elektrikli

aletin güvenliğinin muhafaza edilmesini sağlayacaktır.

Elektrikli alet için ek güvenlik talimatları

Uyarı! Matkaplar ve darbeli matkaplar için ek

güvenlik talimatları

Matkap Güvenlik Uyarıları

• Darbeli matkapla kulaklık takın. Yüksek sese maruz

kalmak işitme kaybına yol açabilir.

• Aletle birlikte verilmiş olan yardımcı tutma kollarını

kullanın. Kontrol kaybı kişisel yaralanmalara neden

olabilir.

• Kesme aksesuarlarının gizli kablolara temas

edebileceği yerlerde çalışma yaparken elektrikli aleti

yalıtımlı kavrama yüzeylerinden tutun. Kesme

aksesuarlarının "akım taşıyan" bir kabloya temas etmesi

durumunda elektrikli aletin metal kısımları da "akım taşır"

hale gelebilir ve kullanıcının çarpılmasına neden olabilir.

• Tutturucunun gizli kablolara temas edebileceği bir

işlemi gerçekleştirirken, elektrikli aleti yalıtımlı

kavrama yüzeylerinden tutun. Tutturucuların "akım

taşıyan" bir kabloya temas etmesi durumunda elektrikli

aletin metal kısımları da "akım taşır" hale gelebilir ve

kullanıcının çarpılmasına neden olabilir.

• Üzerinde çalıştığınız parçayı sabitlemek ve

desteklemek için kelepçeler veya başka pratik

yöntemler kullanın. Parçayı elle tutmanız veya

vücudunuza dayamanız, dengesiz bırakır ve kontrol

kaybına yol açabilir.

• Duvar, zemin veya tavanda delik açmadan önce kablo ve

boruların konumunu kontrol edin.

• Delme işleminin hemen ardından matkap ucuna

dokunmaktan kaçının, sıcak olabilir.

• Bu alet fiziksel, zihinsel veya algılama gücü azalmış

veya yeterince deneyim ve bilgisi bulunmayan kişiler

(çocuklar dahil) tarafından kullanılmak üzere

üretilmemiştir, bu tür kişiler aleti ancak güvenliklerinden

sorumlu bir kişi tarafından cihazın kullanımıyla ilgili

talimatları verilmesi veya sürekli kontrol altında tutulması

ile kullanabilir. Çocuklar, aletle oynamalarını önlemek

amacıyla kontrol altında tutulmalıdır.

• Kullanım amacı bu kullanım kılavuzunda açıklanmıştır.

Herhangi bir aksesuarın veya bağlantının ya da işlemin,

bu kılavuzda tavsiye edilen şekilden başka bir şekilde

kullanılması şahısların yaralanmalarına ve/veya mal

kaybına yol açabilir.

Diğer kişilerin güvenliği

• Bu alet fiziksel, zihinsel veya algılama gücü azalmış

veya yeterince deneyim ve bilgisi bulunmayan kişiler

(çocuklar dahil) tarafından kullanılmak üzere

üretilmemiştir, bu tür kişiler aleti ancak güvenliklerinden

sorumlu bir kişi tarafından cihazın kullanımıyla ilgili

talimatları verilmesi veya sürekli kontrol altında tutulması

ile kullanabilir.

• Çocuklar, aletle oynamalarını önlemek amacıyla kontrol

altında tutulmalıdır.

Page 16

16

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Diğer tehlikeler.

Aleti kullanırken ekteki güvenlik uyarılarına dahil olmayan

bazı başka riskler ortaya çıkabilir. Bu riskler yanlış kullanım,

uzun süreli kullanım vs. ortaya çıkabilirler. Hatta, ilgili

güvenlik düzenlemeleri ve güvenlik cihazlarının

uygulanmasına rağmen, belirli risklerden kaçınılması

mümkün değildir: Bunların dahilinde:

• Herhangi bir dönen/hareketli parçanın temas etmesi ile

yaralanmalar.

• Herhangi bir parçayı, bıçak veya aksesuarı değiştirirken

meydana gelen yaralanmalar.

• Aletin uzun süreli kullanılması sonucu ortaya çıkan

yaralanmalar. Herhangi bir aletin uzun süreli

kullanımında düzenli olarak çalışmanıza ara verin.

• Duyma bozukluğu.

• Aleti kullanırken toz soluması sonucu ortaya çıkan sağlık

sorunları (örneğin:- ahşapta çalışma, özellikle meşe,

kayın ve MDF.)

Elektrik güvenliği

Bu alette çift yalıtım kullanılmıştır, bu nedenle

topraklamaya gerek yoktur. Şebeke geriliminin aletin

üretim etiketinde belirlenmiş değerlere uyup uymadığını lütfen

kontrol edin.

• Kablo hasarlı ise, tehlike oluşmasını önlemek için üretici

ya da yetkili bir STANLEY merkez servisi tarafından

değiştirilmelidir.

Uzatma kablosu kullanılması

• Bir uzatma kablosu kullanılması gerekiyorsa, bu aletin elektrik

girişine uygun onaylı uzatma kablosu olması gerekiyor (teknik

ver

ilere b

akın). Minimum iletken boyutu 1.5 mm2 dir.

Bir kablo makarası kullanırken, kabloyu daima sonuna kadar açın.

İletken boyut (mm2) Kablo gücü (Amper)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Kablo uzunluğu (m)

7.5 15 25 30 45 60

Voltaj Amper Kablo gücü (Amper)

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - 230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

V ........ Volt

A ........ Amper

Hz ....... Hertz

W ........ Vat

dak ..... dakika

.....

.....

boş .......

......

....

....

.../min..

Alet üzerindeki etiketler

Alet üzerinde aşağıdaki semboller bulunabilir:

Kullanım

Kılavuzunu

Okuyun

Koruyucu

Gözlük kullanın

Kulaklık

Kullanın

Alternatif

Akım

Direkt

Akım

Yüksüz

Hız

Sınıf II

İnşaat

Topraklama

Terminal

Güvenlik

uyarısı

Sembolü

Dakikada

devir veya

gel git sayısı

Tarih kodu konumu

İmalat yılını da içeren Tarih Kodu gövdeye basılıdır.

Örnek:

2014 XX JN

İmalat Yılı

Page 17

17

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

• Alette, parçalarda veya aksesuarlarda nakliye sırasında

meydana gelmiş olabilecek hasarı kontrol edin.

• Aleti çalıştırmadan önce, bu kullanım kılavuzunu baştan

sona okumak ve

anlamak için zamanı ayırın.

Açıklama (şekil. A)

1. Değişken hız anahtarı

2. Kesintisiz çalıştırma düğmesi

3. İleri/geri sürgüsü

4. Mod seçici

5. Havalandırma delikleri

6. Yan kol

7. Derinlik ayarlama çubuğu

8. Anahtarsız mandren

9. Kol

10. Hız çevirme

Montaj

Uyarı! Montaj yapmadan önce, aletin kapalı ve bütün

fişlerinin güç kaynaklarından çekilmiş olduğundan emin

olun.

Çalışma modunun seçilmesi (şekil B) Alet, iki çalışma

modunda kullanılabilir:

Darbesiz delme:

çelik, ahşap ve plastikler için.

Darbeli delme:

eşzamanlı döner ve beton ve yığma delme

işlemleri için etkilidir.

• Gereken çalışma modunu seçmek için, mod seçme

düğmesini (4) istenen konuma döndürün.

Matkap ucunun takılması ve çıkartılması (şekil A,D)

Anahtarsız mandren

STDH7213’de büyük kolaylık için anahtarsız mandren (d)

bulunmaktadır.

Bir Matkap Ucu Veya Diğer Aksesuarların Takılması.

• Bir elinizle mandrenin arka yarısını kavrayın ve diğer

elinizi kullanarak ön yarısını saatin tersi yönünde çevirin,

şekil 6’da gösterildiği gibi. İstenen aksesuarın

yerleştirilmesine olanak tanıyacak kadar döndürün.

• Mandrenin içine ucu veya diğer aksesuarları yaklaşık 19

mm (3/4") yerleştirin ve mandrenin arka yarısını tutup ön

kısmını saat yönünde sıkışana kadar dikkatlice çevirin.

Mandren sıkışmaya başladığında, bir klik sesi

duyacaksınız. 4–6 klik sesinden sonra, manderen

aksesuarın etrafına sıkıca oturmuş olacak.

• Akesuarı çıkarmak için, 1. adımı yenileyin.

Uyarı! Matkabın ucunu (veya diğer aksesuarları) mandrenin

önünü kavrayarak ve aleti çalıştırarak sıkılaştırmaya

çalışmayın. Mandrende hasar kişisel yaralanmaya neden

olabilir.

Anahtarsız Mandren Çıkartma (Şekil D)

Bir altıgen anahtarın (birlikte verilmez) kısa ucunu mandrene

sıkıştırın. Yumuşak bir çekiç veya bir tahta parçası kullanarak,

uzun ucuna saat yönünün tersine vurun. Bu mandreni

gevşetir, böylece el ile sökebilirsiniz.

Anahtarsız Mandren Montajı (Şekil D)

Mandreni gidebildiği kadar elle vidalayın. Bir altıgen anahtarın

(birlikte verilmez) kısa ucunu mandrene sıkıştırın ve

anahtarın uzun ucuna yumuşak bir çekiçle saat yönünde

vurun.

Yan kolun takılması (şekil A

)

Yan kol (6), hem Sağ El hem de Sol El kullanıcıları için

donanıma uygun takılabilir.

Daima, yan kolu uygun şekilde monte ettikten sonra

matkapı kullanın.

• Yan kol

u gevşetin.

• Sağ El kullanıcıları için, yan yol kelepçesini mandren

arkasındaki bileziğin üzerine kaydırın, soldan tutun.

• Sol El kullanıcıları için, yan yol kepçesini mandrenin

arkasındaki bileziğe kaydırın, sağdan tutun.

• Yan kolu istediğiniz

konuma döndürüp kolu sıkılayın.

Delme derinliğinin ayarlanması (şekil C)

• Gereken matkap ucunu takın.

• Yan kolu gevşetin (6).

• Derinlik ayarlama çubuğunu (7) yan yol kelepçesindeki

delikten geçirin.

• Delme derinliğini gösterildiği şekilde ayarlayın.

• Yan kolu sıkın.

İleri/geri kolu (şekil A)

• İleri veya geri rotasını seçmek için, ileri/geri anahtarını

kullanın (3) (alet üzerindeki oka bakın).

Dönme yönünü değiştirmeden önce, daima motor

tamamen durana kadar bekleyin.

Page 18

18

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Kullanım talimatları

• Her zaman güvenlik talimatlarını ve geçerli

yönetmelikleri uygulayın.

• Boru ve kablo tesisatının geçtiği yerlere dikkat edin.

• Alete yalnızca hafif bir baskı uygulayın. Aşırı kuvvet

uygulaması delmeyi hızlandırmak bir yana aletin

performansını düşürür ve ömrünü kısaltabilir.

• Darbeli matkap ile kulaklık kullanın. Aşırı gürültüye

maruz kalmak işitme kaybına yol açabilir.

• Aletin üzerindeki yardımcı kolları kullanın. Kontrol kaybı

kişisel yaralanmaya neden olabilir.

• Kesme aksesuarlarının gizli kablolara veya kendi

kablosuna temas edebileceği yerlerde çalışma yaparken

elektrikli aleti yalıtımlı kavrama yüzeylerinden tutun.

Kesme aksesuarlarının "akım taşıyan" bir kabloya temas

etmesi durumunda elektrikli aletin metal kısımları da

"akım taşır" hale gelebilir ve kullanıcının çarpılmasına

neden olabilir.

• Eğer bir elektrikli aletin nemli bir bölgede çalıştırılması

zorunluysa, bir artık akım aygıtı (RCD) korumalı bir

kaynak kullanın. Bir RCD kullanılması elektrik şoku

riskini azaltır.

Çalıştırmadan önce

• Uyg

un ucu takın.

• Delik delmede

n önce işaretleyin.

Uygun El Pozisyonu (şekil A, E)

Uyarı: Ciddi kişisel yaralanma riskini azaltmak için,

DAİMA gösterilen uygun el pozisyonunu kullanın.

Uyarı: Ciddi kişsel yaralanma riskini azaltmak için,

ani tepki ihtimaline karşı aleti DAİMA sıkıca tutun.

Uygun el pozisyonu için, bir el yan kolda (6), diğer el ana

kolda olmalı.

Açma ve kapatma

• Aleti

açmak için değişken hız düğmesine basın (1).

Aletin hızı düğmeye ne kadar bastığınıza bağlıdır.

• Sürekli çalışması için kesintisiz çalıştırma düğmesine

basın (2) ve değişken hız düğmesini bırakın. Bu seçenek

sadece tam hızda kullanılabilir.

• Aleti kapatmak için, değişken hız düğmesini bırakın.

Sürekli çalışma esnasında aleti kapatmak için, bir kez

değişken hız düğmesine basın ve bırakın.

• Farklı uygulamalar kapsamında, maksimum hızı kontrol

etmek için (10) hı

zlı çevirmeyi etrafında çevirin.

Metal delme

Alet üzerine sağlam bir baskı uygularken, yavaş hızda

delmeye başlayıp tam hızda çalışmaya getirin. Metal talaşının

düzgün bir şekilde çıkması uygun delme hızını gösterir. Metal

delerken bir kesme yağı kullanın. İstisnalar, kuru delinmesi

gereken demir ve pirinç dökümleridir.

Not: Önce bir pilot delik açılırsa [5/32" (4 mm) ila 3/16" (5

mm)], geniş [5/16" (8 mm) ila 1/2" (13 mm)] çelik delikler daha

kolay yapılabilir.

Ahşap delme

Alet üzerine sağlam bir baskı uygularken, yavaş hızda delmeye

başlayıp tam hızda çalışmaya getirin. Ahşap delikler metal için

kullanılan aynı burgulu matkap ucu ile yapılabilir. Bu uçlar, sık

sık yerlerinden çıkartılıp temizlenmezse aşırı derecede

ısınabilir. Küçük parçaların sıçramasına eğilimli çalışmalarda,

ahşap bir blokla desteklenmelidir.

Duvar delme

Duvar delme işlemi yaparken karbür-uçlu uc kullanının ve

uçların keskin olduğundan emin olun. En etkili delme için

matkap üzerinde sürekli ve sağlam bir güç uygulayın. Düzgün

bir toz akışının çıkması uygun delme hızını gösterir.

Vidalama

• İleri vey

a geri dö

ndürmeyi seçin.

Darbeli delme (şekil A)

• Darbeli

modu seçin.

• Düğmeye bas

ın (1).

Darbesiz delme (şekil A)

• Darbe

siz delme modunu seçin.

• Darbeli delme

için anlatıldığı gibi devam edin.

Uygun aksesuarlar hakkında daha fazla bilgi için bayinize

başvurun.

Aksesuarlar

Elektrikli aletinizin performansı kullanılan aksesuara bağlıdır.

STANLEY aksesuarları, yüksek kalite standartlarına göre

üretilmiş ve aletinizin performansını arttıracak şekilde

tasarlanmıştır. Bu aksesuarları kullanarak, aletinizden en iyi

verimi alacaksınız.

Page 19

19

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Bakım

STANLEY kablolu / kablosuz cihazların/aletlerin, sofistike

tasarımları vardır, sadece küçük bakımlarla uzun süre

kullanılabilirler. Kesintisiz olarak memnuniyet verici bir şekilde

çalışması, gerekli özenin gösterilmesine ve düzenli temizliğe

bağlıdır.

Uyarı! Kablolu / kablosuz elektrikli aletler üzerinde bakım

yapılmadan önce, aşağıdaki noktaların uygulanması gerekir:

• Ekipma

nın / aletlerin gücünü kapatın ve fişi çekin;

• Ekipman / aletler, bağımsız aküye sahip iseler, lütfen

gücü kapatın ve ekipman / aletlerden aküyü çıkartın.

• Ekipman / aletler, entegre aküye sahip iseler, lütfen gücü

kapatmadan önce akünün bitmesini bekleyin.

• Temizlemeden önce, şarj fişini güç kaynağından çekin.

Buna ek olarak, şarj cihazının düzenli temizliği haricinde

başka bakıma gerek yoktur.

• Düzenli olarak ekipman / aletler / şarj cihazının

havalandırma deliklerini temizlemek için yumuşak sabun

ve nemli bez kullanın.

• Düzenli olarak motor gövdesi temizlemek için nemli bir

bez kullanın. Lütfen herhangi bir aşındırıcı temizlik

maddeleri veya çözücü bazlı temizlik maddeleri

kullanmayın.

• Düzenli olarak

sıkıştırma mandrenini açın ve içindeki tozu

temizlemek için hafifçe vurun (kurulumdan sonra).

Temizleme

Uyarı! Havalandırma kanallarında ve/veya

etrafında toz görünüyorsa, ana gövdede biriken bu

tozu ve kiri derhal kuru hava kullanarak temizleyin.

Bu işlemi yaparken onaylı güvenlik ekipmanları ve toz

maskesi kullanın.

Uyarı! Bu aletin metal olmayan parçalarını

çözücüler veya diğer tahriş edici kimyasal

maddelerle temizlemek kesinlikle yasaktır. Bu

kimyasallar, bu bileşenin malzemelerini zayıflatabilir.

Temizlemek için yumuşak

sabun ve nemli bez kullanın. Aletin içine herhangi bir

maddenin girmesine izin vermeyin ve herhangi bir parçasını

suya batirmayın.

Servis bilgileri

STANLEY Asya’da, şirket sahipleri ve servis konumlarının tam

ağını sunmaktadır. TÜM STANLEY Servis Merkezleri,

müşterilere etkili ve güvenilir hizmet sağlamak için eğitimli

personel kadrosuna sahiptir. İster teknik öneriye ve onarıma

isterse orjinal yedek parçaya ihtiyacınız olsun, size en yakın

STANLEY ile temasa geçin.

Notlar

• STANLE

Y’in politikalarından biri, ürünlerimizi sürekli

olarak iyileştiririz ve bu itibarla, ürün özelliklerini önceden

haber vermeden değiştirme hakkını saklı tutarız.

• Standart donanım ve aksesuarlar ülkeye göre farklılık

gösterebilir.

• Ürün özellikleri ülkeye göre farklılık gösterebilir.

• Tüm ürün yelpazesi tüm ülkelerde geçerli olmayabilir.

Kullanılabilir olanları öğrenmek için yerel STANLEY

satıcınıza başvur

un.

Darbeli Matkap STDH7213C

Voltaj V 220-240

Frekans Hz 50/60

Güç girişi W 720

Yüksüz hız /dak 0-3000

Darbe gücü IPM 0-54000

Geri/İleri döndürme Evet

Mandren kapasitesi mm 1.5-13

Max kapasite

Beton mm 16

Metal mm 13

Ahşap mm 32

Ağırlık kg 2.5

Teknik veri

LpA (sound pressure) dB(A) 100,5

K

pA

(sound pressure uncertainty) dB(A) 3

LWA (sound power) dB(A) 111,5

KWA (sound power uncertainty) dB(A) 3

Vibration emission value a

h

Check

(polishing

)

a

h,ID

= m/s² 15,0

a

h,D

= m/s² 6,1

Uncertainty K = m/s² 1.5

Page 20

20

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Bu bilgi sayfasında verilen titreşim emisyon düzeyi, EN

60745’te sağlanan standart teste uygun olarak ölçülmüştür

ve aletleri birbiriyle karşılaştırmak için kullanılabilir. Ön

maruziyet değerlendirmesi için kullanılabilir.

Uyarı: Beyan edilen titreşim emisyon düzeyi, aletin

ana uygulamalarını yansıtır. Ancak alet farklı

aksesuarlarla farklı uygulamalar için kullanılırsa veya bakımı

kötü yapılırsa, titreşim emisyonu değişebilir. Bu, toplam

çalışma süresindeki 1,5 maruziyet düzeyini önemli ölçüde

artırabilir.

Tahmini titreşim maruziyeti, aletin kapalı kaldığı veya

çalışmasına karşın iş görmediği zamanları da dikkate

almalıdır. Bu, toplam çalışma süresindeki maruziyet düzeyini

önemli ölçüde azaltabilir.

Kullanıcıyı titreşim etkilerinden korumak için belirtilen ek

güvenlik önlemlerini alın: aletin ve aksesuarların bakımını

yapın, elleri sıcak tutun, çalışma modellerini düzenleyin.

Çevrenin korunması

Ayrı olarak atın. Bu ürün, normal evsel atıklarla

birlikte atılmamalıdır.

STANLEY ürününüzün değiştirilmesi gerektiğini düşünmeniz

veya artık kullanılamaz durumda olması halinde onu, evsel

atıklarla birlikte atmayın. Bu ürünü, ayrı olarak toplanacak

şekilde atın.

Kullanılmış ürünlerin ve ambalajların ayrı olarak

toplanması bu maddelerin geri dönüşüme sokularak

yeniden kullanılmasına olanak tanır. Geri dönüşümlü

maddelerin tekrar kullanılması çevre kirliliğinin önlenmesine

yardımcı olur ve ham madde ihtiyacını azaltır.

Yerel yönetmelikler, elektrikli ürünlerin evlerden toplanıp

belediye atık tesislerine aktarılması veya yeni bir ürün satın

alırken perakende satıcı tarafından toplanması yönünde

hükümler içerebilir. STANLEY, hizmet ömrünün sonuna

ulaşan STANLEY ürünlerinin toplanması ve geri dönüşüme

sokulması için bir imkân sunmaktadır. Bu hizmetin

avantajlarından faydalanmak için, lütfen, ürününüzü bizim

adımıza teslim alacak herhangi bir yetkili servise iade edin.

Bu kılavuzda belirtilen listeden size en yakın STANLEY

yetkili tamir servisinin yerini öğrenebilirsiniz. Ya da, alternatif

olarak internet’ten STANLEY yetkili tamir servislerinin

listesini ve satış sonrası hizmetlerimizle ilgili tüm bilgiler ve

temas bilgilerine aşağıdaki siteden ulaşabilirsiniz.

www.2helpU.com

Page 21

21

TÜRKÇE

(Çevirisi orijinal talimatlardan yapılmıştır)

Two years full warranty

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY Europe guarantees to replace all

defective parts free of charge or – at our discretion – replace

the unit free of charge provided that:

• The product has not been misused and has been used in

accordance with the instruction manual.

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet

at:www.stanleytools.com

STANLEY, «teknik özellikleri» bölümünde açıklanan bu

ürünlerin aşağıda belirtilen yönergelere uygun olduğunu

beyan eder: 2006/42/EC, EN 60745-1, EN 60745-2-6

Bu ürünler ayrıca 2014/30/EU ve 2011/65/EU Direktiflerine

de uygundur. Daha fazla bilgi için, lütfen aşağıdaki adresten

STANLEY ile irtibata geçin veya kılavuzun arkasına bakın.

Bu belge altında imzası bulunan yetkili, teknik dosyanın

derlenmesinden sorumludur ve bu beyanı STANLEY adına

vermiştir.

R.Laverick

Mühendislik Bölümü Müdürü

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belgium

01.2015

AT Uygunluk Beyanatı

MAKİNE DİREKTİFİ

STDH7213C

Sanayi ve Ticaret Bakanlığı tebliğince kullanım ömrü 7 yıldır.

Türkiye Distribütörü

STANLEY BLACK&DECKER TURKEY ALET URETIM SAN. TIC. LTD.STI.

Kozyatağı Mh Değirmen Sk. Nida Kule No:18 Kat:6

34742 Kadıköy İstanbul

Tel : (0216) 665 29 00

Faks : (0216) 665 29 01

E-posta: info-tr@sbdinc.com

Page 22

N418785 01/2015

Loading...

Loading...