Page 1

STCT224/250

Page 2

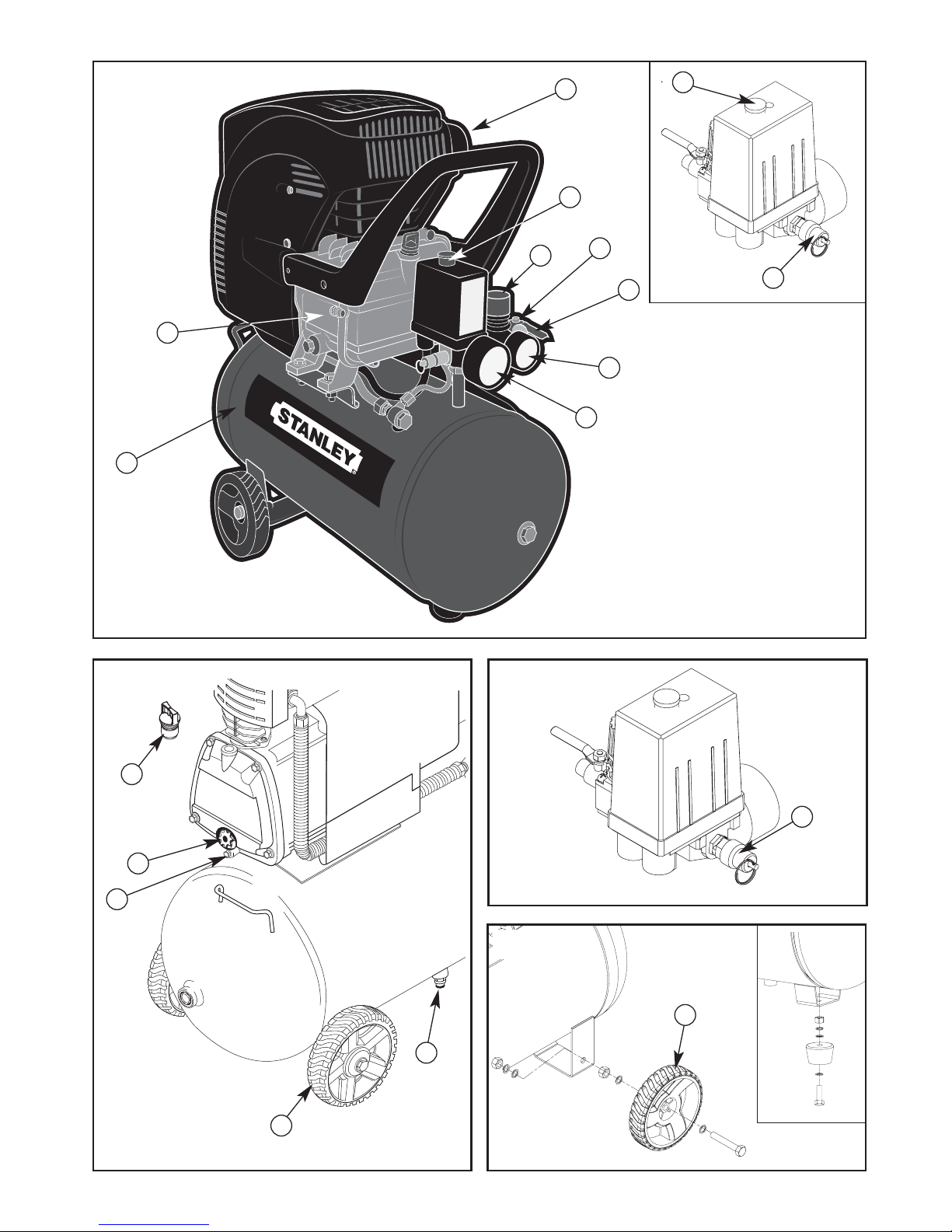

1

9

8

5

4

6

7

3

14

13

12

15

11

10

10

15

9

FIG. A

2

FIG. B FIG. C

FIG. D

Page 3

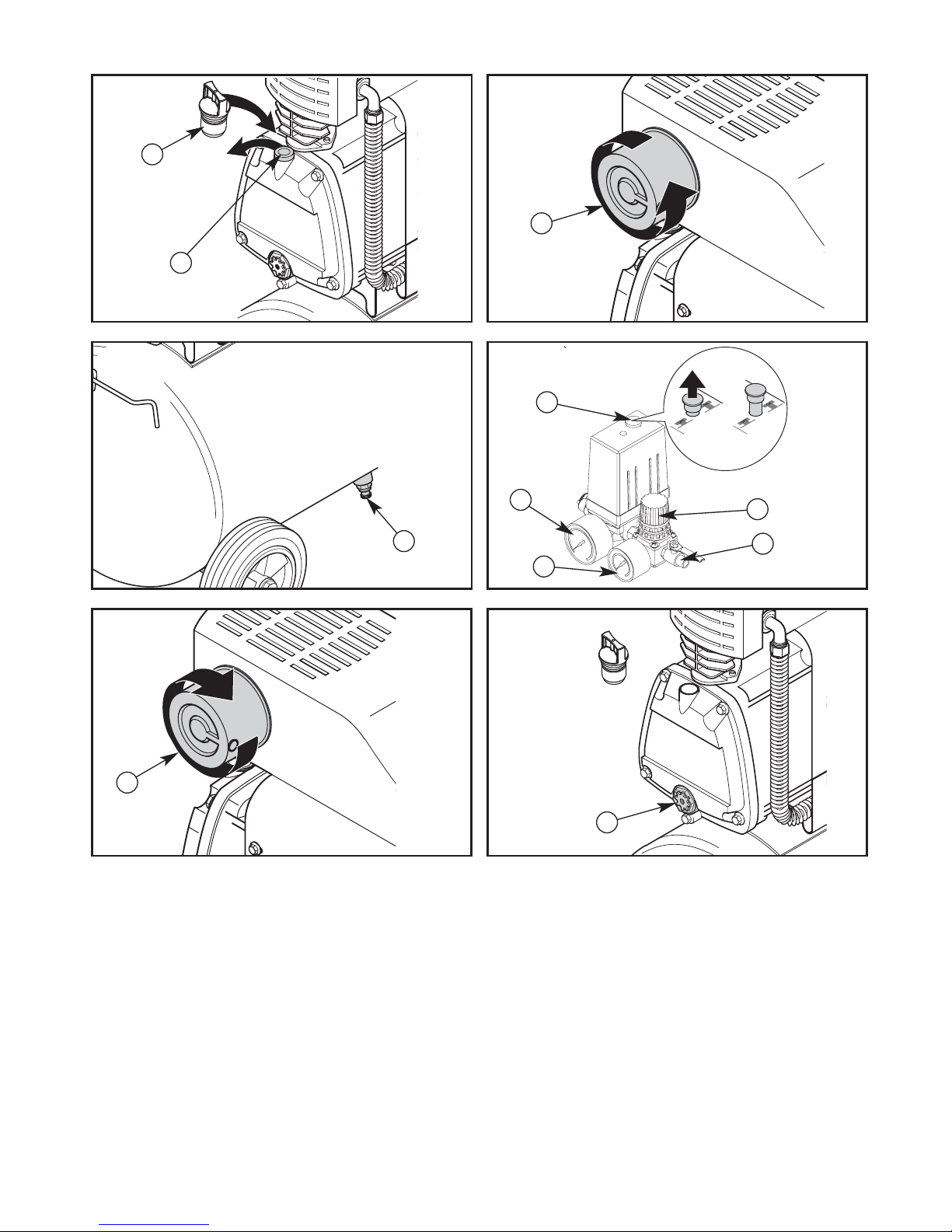

FIG. E

FIG. G

FIG. I

FIG. F

FIG. H

FIG. J

14

11

7

8

5

9

1

6

13

1

12

Page 4

4 • ENGLISH

IMPORTANT

This instruction manual provides important installation, use,

maintenance and safety information and must be at hand at all

times. Before operating this equipment, read this manual and

make sure you understand all of its instructions in order to

avoid personal injuries or damage to your piston compressor.

Warning! Read and understand all instructions. Failure to

follow all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

SAFETY INSTRUCTIONS

If an Air Compressor is improperly used it may

cause physical and material harm. In order to avoid

them, follow the recommendations below:

1. This equipment:

►Has hot, electric and moving parts;

►When connected to electric power, it may turn on

or turn off automatically due to tank’s pressure or

to the tripping of electric protectionelements;

►May cause mechanical or electric interferences

in nearby equipment;

►Must not work in places where non authorized

people, children or animals may have access;

►Requires an authorized person to supervise its

use and maintenance as well as the use of ad

equate individual protection equipment.

►Must be installed and operated in well ventilated

areas and protected against humidity or water

leakage.

2. Never exceed the maximum pressure indicated in

the compressor’s identification tag/sticker.

3. Do not change the pressure switch safety valve factory

adjustment. If any adjustment to the pressure switch is

needed, call the nearest StanleyBlack&Decker Authorized

ServiceCenter.

4. Never weld or carry out maintenance jobs on the

tank, once they may affect its resistance or may hide

more serious problems. In case of leakage, cracks

or deterioration caused by corrosion, stop using

the equipment immediately and get in touch with the

nearest StanleyBlack&Decker Authorized Service Center.

5. Never run the tank above the maximum pressure indicated

on its identification tag.

6. The end user must provide a new inspection of the

Pressure Vessel (tank) to be carried out after 5 (five)

years from the manufacturing date shown in its

identification tag, or when there is chemical or mechanical

damage that may endanger its resistance. The inspection

must be carried out and approved by a duly qualified

engineer (skilled professional), according to local

technical standards and legislation. The next period for

testing will be determined by the responsible engineer

himself. We recommend that the Pressure Vessel (tank)

be exchanged for a new one every 10 (ten) years, or

according to the responsible engineer’s judgment.

7. Air compression is a heat generating process and

parts and accessories are subject to high

temperatures. Therefore, one must be careful

when handling them in order to avoid burns.

8. The produced compressed air is not adequate for

human consumption. To use it for this purpose, it

is necessary to install special filters. Please contact

StanleyBlack&Decker for aditional information.

9. Do not carry out any maintenance while the

compressor is on. Do not clean or touch the

electric components without unplugging the

compressor from the outlet.

10. The refrigeration air intake protecting screen must be

always clean to prevent the propeller from pulling in impurities.

11. Never clean the compressor’s external surface with solvent

(thinner). Always use neutral detergent.

12. Avoid the accumulation of solvents, paints or

other chemicals that may cause damage or

explosion risk to the compressor.

13. Always use an electric extension cord according

to specifications (see Table 2 - Page 21) which

must not be amended. If these recommendations

are not followed, the user may be injured and the

compressor’s electric components may be

damaged, violating the warranty. When necessary,

use a longer air hose.

14. If the equipment presents any irregularities, stop its use

immediately and call the nearest StanleyBlack&Decker

Authorized Service Center.

WELCOME

You have purchased another product with StanleyBlack&Decker

quality standards.

The design, inspection and manufacturing of your

StanleyBlack&Decker tank is based on EN286-1 1998

Attachment 1.It is a mix of high technology and easy use.

INTRODUCTION

WE RECOMMEND READING THIS MANUAL PRIOR

TO USING THIS PRODUCT.

It will help you to optimize product performance, guarantee

safe use and guide you in preventive maintenance.

If there is any problem that cannot be solved by the

information provided in this manual, please contact the

nearest StanleyBlack&Decker Authorized Service Center.

In order to extend the useful life of this coaxial air compressor,

the use of mineral lubricant oil and original parts are highly

recommended.

GENERAL SAFETY RULES

SAVE THESE INSTRUCTIONS

INTRODUCTION

Page 5

ENGLISH • 5

The pressure vessel quality certificate must be presented to

authorities, in case of inspection. Keep it in a safe place along

with the instruction manual.

COMPRESSOR INSPECTION

Inspect for signs of obvious or concealed freight damage.

Report any damage to the delivering freight carrier

immediately. Be sure that all damaged parts are replaced and

any mechanical problems are corrected prior to the operation

of the air compressor. The air compressor serial number is

located on the pump or tank. Please write the serial number in

the space provided in the service section for future reference.

Warning! When using electric product, basic

safety precautions should always be followed to

reduce risk of fire, electric shock, and personal

injury.

FEATURES (Fig. A and B)

1. Air intake filter housing

2. Compressor pump

3. Pressure vessel

4. Compressed air outlet (quick coupler), air not regulated

5. Compressed air outlet (quick coupler), air regulated

6. Outlet pressure gauge

7. Tank pressure gauge

8. Pressure regulator

9. On/Off switch

10. Safety valve

11. Condensate drain cock

12. Oil drain plug

13. Oil sight glass

14. Dip stick

15. Wheels

TECHNICAL SPECIFICATIONS

NOTE: The tank’s filling up time varies from ± 10%, according

to the installation.

1. Compressor (pump) Unit.- Pull in and compresses

the atmospheric air.

2. Air Tank.- Stores the compressed air.

3. Electric Motor.- Makes the compressor unit run.

4. Pressure Switch.- Controls the operation of compressor

to avoid that the maximum working pressure is surpassed.

See Installation and Electrical Connection Chapter.

5. Safety Valve.-Automatically exhausts the tank in case

the pressure is above the maximum allowed.

6. Check Valve.- Keeps the compressed air inside the tank

avoiding its return when the compressor unit stops.

7. Drain.- Removes the condensed water that accumulates

inside the tank.

8. Pressure Gauge.- Shows the pressure inside the tank

in psi or bar.

9. Pressure Regulator with Valve.- Used to adjust working

pressure on the indicator panel.

10. Protecting Screen.- Protects the rotating parts.

11. Intercooler.- Carries and cools down the compressed air.

12. Air Filter.- Filters atmospheric air impurities that are

sucked by the compressor.

13. Valve.- Controls the compressed air release, connects

KEY PARTS AND FUNCTIONS

CT224 CT250

Weight: 52,8 lbs 24 Kg 70,4 lbs 32 Kg

Height: 24,0 in 625 mm 28,7 in 775 mm

Length: 23,0 in 575 mm 27,1 in 325 mm

Width: 12,2 in 270 mm 12,2 in 730 mm

MODEL

CTS 224 CT250

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz 140 140

60 Hz 185 185

ROTATION

AIR TANK

psi

120 120

bar

8,4 8,4

rpm

50 Hz 2850 2850

60 Hz 3480 3480

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

Voltage (V)

120/127 or 220 120/127 or 220

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

220 220

50 Hz 1’57 3’55

60 Hz 1’38 3’25

STCT224 STCT250

Weight: 52,8 lbs 24 Kg 70,4 lbs 32 Kg

Height: 24,0 in 625 mm 28,7 in 775 mm

Length: 23,0 in 575 mm 27,1 in 325 mm

Width: 12,2 in 270 mm 12,2 in 730 mm

MODEL

STCT224 STCT250

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz 140 140

60 Hz 185 185

ROTATION

AIR TANK

psi

115 115

bar

8 8

rpm

50 Hz 2850 2850

60 Hz 3450 3450

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

Voltage (V)

120/127 or 230 120/127 or 230

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

300 300

50 Hz 1’57 3’55

60 Hz 1’38 3’25

CT224 CT250

MODEL

CTS

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz 140 140

ROTATION

AIR TANK

psi

120 120

bar

8,4 8,4

rpm

50 Hz 2850 2850

60 Hz 3480 3480

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

Voltage (V)

120/127 or 220 120/127 or 220

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Lbs

52,8 70,4

Volume (ml)

220 220

50 Hz 1’57 3’55

60 Hz 1’38 3’25

STCT224 STCT250

Weight:

Height:

Length:

Width:

MODEL

STCT224 STCT250

DISPLACEMENT

MAX. PRESSURE

l/min

50 Hz 140 140

ROTATION

AIR TANK

bar

8 8

rpm

50 Hz 2850 2850

Geom. Volume (L)

24 50

Filin

up time

ELETRIC MOTOR

SINGLE-PHASE

WITH THERMAL

PROTECTOR

230 230

HP

1,5 1,5

Max. HP

2,0 2,0

kW

1,1 1,1

Max. kW

Voltage (V)

1,5 1,5

OIL

CAPACITY

WEIGHT

COLOR REF:

ORANGE ORANGE

Kg

24 32

Volume (ml)

300 300

50 Hz 1’57 3’55

24 Kg

625 mm

575 mm

270 mm

32 Kg

775 mm

325 mm

730 mm

YELLOW YELLOW

Page 6

the hose nozzle.

14. Oil Drain Plug.- Allows the removal of lubricant oil.

15. Oil Gauge Dipstick.- Shows the oil level and allows its

replacement.

16. Identification Tag/Information Sticker.- Shows the

compressor’s technical data.

17. Tank’s Identification Tag.- Shows the tank’s technical data.

18. Wire with Plug (2P+GR).- Used to connect the

compressor to the electric supply.

19. On/Off Button.- Starts/Shuts off the compressor.

20. Rubber Feet.- Used for the support of the compressor set.

21. Wheels.- Help to move the compressor.

22. Hose Nozzle.- Used to connect the hose to the

compressor, to accessories or hose nozzle (not shown).

Safety Devices (Fig. C)

Safety Valve

The spring safety valve (10) is incorporated into the pressure

switch unit. The safety valve opens if the max. permissible

pressure is exceeded.

OPERATION

Prior to Initial Operation

Install Wheels (Fig. D)

1. Install wheels (15) as illustrated.

2. Install rubber feet as illustrated.

Insert Dip Stick (Fig. E)

1. Remove the plug (12) from the crankcase.

2. Substitute the plug with the dip stick (14) supplied.

The plug prevents oil from leaking from the crankcase during

shipping. Keep plug for future use.

Install Air Intake Filter (Fig. F).

1. Remove plug from air intake of compressor pump housing.

Keep plug for future use.

2. Screw air filter (1) supplied on air intake.

Check Condensate Drain (Fig. G)

► Check to see that the condensate drain's screw (11)

is closed.

INSTALLATION OF THE AIR NETWORK

1. Assembly: Remove the product from the packaging and

rubber feet.

2. Location: Install the compressor in a covered, well ventilated

area, free of dust, gases, toxic gases, humidity or any other

kind of pollution. The ambient temperature recommended

during work is: minimum of 5°C (41°F) and maximum of

40°C (104°F). In order to avoid damage to the compressor,

operate it on a level foundation.

2.1 Compressor’s Installation: When this compressor

model is coupled to a compressed air network, the

connection must be made by a hose or expandable

joints so that the charges, thermal expansion, piping’s

weight, mechanical and thermal shocks or obstructions

are not transmitted to the air receiver. The air receiver

may be damaged if these warnings are not observed.

3. Position: Keep a minimum distance of 800 mm (32") from

any obstacle, to allow good ventilation during operation and

to make maintenance easier.

4. Quality of Compressed Air: For services in which the air

must be free of oil or dust particles, the installation of special

air filters. Please contact the nearest StanleyBlack&Decker

Authorized Service Center for information.

5. Electrical Connection:

5.1 Look for a specialized technician to evaluate

the electrical supply and to select the adequate protection

and input devices Electrical Wiring Diagram.

Electrical Wiring Diagram

Grounding Instructions: This product must be grounded

to reduce the risk of an electric shock.

Warning! The incorrect installation of the grounding wire

connector may result in an electric shock. If it is necessary to

replace or repair both the cable and the connector, do not

connect the grounding wire to the terminal of the flat blade.

The green cable, with or without yellow stripes, is the rounding

cable. In case of doubts regarding the grounding information

or whether the product is properly grounded, make sure you

contact a qualified electrician to verify the connections.

6 • ENGLISH

P

F1

GROUND

Tension

Supplies

PLUG2P+GR

OR WIRE

Customer's responsibility

M

1~

Phase

N

Neutral

F1 Fuse type "D" or "NH"

(See Table 2 - Page 5)

P Pressure switch

M Electric motor

ENCHUFE CON

ATERRAMENTO

ENCHUFE

A TIERRA

ESPIGA

A TIERRA

ESPIGAS DE

ATERRAMENTO

ESPIGAS DE ATERRAMENTO

GROUNDED

OUTLET

GROUNDED OUTLET

GROUNDED

OUTLET

GROUNDING

PIN

GROUNDING

PIN

GROUNDING PIN

TOMADA COM

CONEXÃO DE

ATERRAMENTO

PINO DE

ATERRAMENTO

Page 7

6. Important: A compressor with good dimensions (with

pressure switch) will have roughly six (6) starts per hour.

See “Instruction Troubleshooting Guide” (page. 9).

7. Electric Motor Warranty: The electric motor warranty will

only be granted if the installation instruction are followed

according to diagram “Electrical Wiring Diagram”.

8. Before plugging the equipment to the electric supply, check

if voltage indicated in the supply wire’s tag matches the

local voltage.

Table 2.- Orientation Data for Conductors and Fuses

Note:

► The energy supply must not present voltage changes

over ± 10%.

► Voltage drop caused by start up must not be over 10%

► For your safety, the installation must have a grounding

conductor to avoid electric shocks.

► INSTALLATION EXPENSES ARE THE PURCHASER’S

RESPONSIBILITY.

Generating Compressed Air (Fig. H)

1. Start compressor (9) and wait until the max. tank pressure

is reached (compressor shuts off).

The tank pressure is indicated by the tank pressure gauge (7).

2. Set pressure regulator (8) to required working pressure.

The current working pressure is indicated by the regulated

pressure gauge (6).

Caution! The regulated pressure may not be set higher

than the max. working pressure of the connected air tools.

3. Connect air hose to compressed air outlet (5).

4. Connect air tool. You are now ready to work with the air tool.

5. Switch the compressor OFF (9), if you do not continue

working immediately afterwards. Unplug after switching OFF.

CARE AND MAINTENANCE

Danger! Prior to all servicing:

► Switch Off.

► Unplug.

► Wait until the compressor has come to a complete stop.

► Ensure the compressor and all air tools and accessories

connected to it are relieved from pressure.

► Let the device and all air tools and accessories used cool off.

After all servicing:

► Check to see that all safety devices are operational.

► Make sure that no tools or other parts remain on

or in the machine.

► Repair and maintenance work other than described in this

section must only be carried out by qualified specialists.

Periodic Maintenance

Prior to Each Use:

► Check air hoses for damage, replace if necessary.

► Check all screwed connections for tightness, tighten

if necessary.

► Check power supply cable for damage, if necessary have

replaced by a qualified electrician.

Every 50 Operating Hours (Fig. G, I and J)

► Check air filter element (1) of compressor pump,

clean if necessary.

► Check oil level of pump at oil sight glass (14),

top up oil if necessary.

► Drain condensate from pressure vessel (11).

Every 250 Operating Hours

► Replace air intake filter element of compressor pump.

Every 500 Operating Hours

► Drain oil and fill with fresh oil.

Every 1000 Operating Hours

► Have unit serviced by an authorized service station.

This will extent the compressor's service life considerably.

Machine Storage

1. Switch unit OFF and unplug.

2. Release pressure from tank and all connected air tools.

3. Store machine in such way that it cannot be started

by unauthorized persons.

Caution! Do not store machine unprotected outdoors or in

damp environment.

Do not lay device on its side for transportation or storing.

MAINTENANCE

Your tool has been designed to operate over a long period of

time with a minimum of maintenance. Continuous satisfactory

operation depends upon proper tool care and regular cleaning.

Warning! Before performing any maintenance, switch off

and unplug the tool.

► Regularly clean the ventilation slots in your tool using

a soft brush or dry cloth.

► Regularly clean the motor housing using a damp cloth.

Do not use any abrasive or solvent-based cleaner.

PROTECTING THE ENVIRONMENT

Separate collection. This product must not be

disposed of with normal household waste. Should

you find one day that your Black & Decker product

needs replacement, or if it is of no further use to you,

ENGLISH • 7

MOTOR

POWER

(HP)

ELECTRICAL

VOLTAGE

(V)

CONDUCTOR

(mm)

2

FUSE

(A)

MAX. DIST. (m/in)

VOLTAGE DROP (%)

35207 / 273

27 / 1053

2.5

mm

2

AWG

1.51315

120/127

230

2.0 MAX.

POTENCIA

MOTOR

(HP)

TENSIÓN

RED

(V)

CONDUCTOR

(mm)

2

FUSIBLE

(A)

DIST. MÁX. (m)

CAIDA TENSIÓN (%)

35

20

7

27

2,5

1,5

120/127

220

2,0 Máx.

POTÊNCIA

MOTOR

(HP)

TENSÃO

REDE

(V)

CONDUTOR

(mm)

2

FUSÍVEL

(A)

DIST. MÁX. (m)

QUEDA TENSÃO (%)

35

20

7

27

2,5

1,5

120/127

220

2,0 Max.

MOTOR

POWER

(HP)

ELECTRICAL

VOLTAGE

(V)

CONDUCTOR

(mm)

2

FUSE

(A)

MAX. DIST. (m/in)

VOLTAGE DROP (%)

35

20

7 / 273

27 / 1053

2.5

mm

2

AWG

1.51315

120/127

230

2.0 MAX.

MOTOR

POWER

(HP)

ELECTRICAL

VOLTAGE

(V)

CONDUCTOR

(mm)

2

FUSE

(A)

MAX. DIST. (m/in)

VOLTAGE DROP (%)

mm

2

AWG

2027 / 10531.5 152302.0 MAX.

Page 8

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products and packaging

allows materials to be recycled and used again.

Re-use of recycled materials helps prevent

environmental pollution and reduces the demand for

raw materials. Local regulations may provide for

separate collection of electrical products from the

household, at municipal waste sites or by the retailer

when you purchase a new product.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned

and authorized service locations. All StanleyBlack&Decker

Service Centers are staffed with trained personnel to provide

customers with efficient and reliable power tool service.

For more information about our authorized service centers

and if you need technical advice, repair, or genuine factory

replacement parts, contact the StanleyBlack&Decker location

nearest you.

8 • ENGLISH

Air Flow Rate @ 40 PSI - 50Hz SCFM - L/min 3.7 - 105 3.7 - 105

Air Flow Rate @ 90 PSI - 50Hz SCFM - L/min 2.6 - 74 2.6 - 74

Air Flow Rate @ 115 PSI - 50Hz SCFM - L/min 2.4 - 68 2.4 - 68

Operating Pressure (Max.) Bar 8 8

Amounts of Cylinders 1 1

Number of Stages 1 1

Max. Service/Ambient Temperature ** °C + 40 + 40

Min. Service/Ambient Temperature ** °C + 5 + 5

Air Tank Volume L 24 50

Air Outlet Amounts 1 1

Rotation - 50Hz rpm 2850 2850

Engine Power - Max. HP 2 2

Connection Voltage - 50Hz V 2

30 230

Rated Current - 50Hz A 6.4 6.4

Fuse Protection See table 2 pg. 21

Max. Total Length When Extensions Are Used See table 2 pg. 21

Standard motor protection IP 20 20

Weight K g 23.8 32.5

Dimensions m m (H x W x L)

575 x 270 x 625 775 x 325 x 730

Amount of Oil for Change L approx. 0.3 approx. 0.3

Sound Level dB(A) 91 93

All technical data refers to an ambient temperature of 20 °C.

**)

The service life of some components, for instance the seal of the anti-surge valve, is substantially reduced when the compressor works

at high temperatures (max. and higher service/storage temperature).

**) There is the risk of freezing for the condensation in the pressure tank when temperatures are below the min. service/storage temperature.

SPECIFICATIONS

STCT224 STCT250

Page 9

COD

POSSIBLE CAUSE POSSIBLE SOLUTION

1

2

3

4

5

6

7

8

9

10

Voltage drop or electrical

supply is out.

Damaged electric motor.

Tank is full of air.

Installation fuse has burned out.

Check valve does not seal

because of impurities.

The demand is above

the compressor’s capacity.

Thermal protector tripped.

Filter clogged.

Air leakage in the compressor.

High ambient temperature

(Max. 40˚C or 104˚F)

Check the installation and/or wait

for the electrical supply stabil

ization.

Send it to the nearest

StanleyBlack&Decker

Authorized Service Center.

Electric motor will start

as soon as the pressure

in the tank decreases.

Find out the burning cause

Page. 21

Send the compressor to the

nearest

StanleyBlack&Decker

Authorized Service Center

Check the compressor’s capacity.

Turn compressor off, wait for 5 (five)

min. and reset the protector. If tripping

is frequent, look for the nearest

Replace it.

Re-fasten bolts and/or fitti

ngs.

Improve local conditions.

COD

POSSIBLE CAUSE POSSIBLE SOLUTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Voltage drop or electrical

supply is out.

Damaged electric motor.

Tank is full of air.

Installation fuse has burned out.

Check valve does not seal

because of impurities.

The demand is above

the compressor’s capacity.

Thermal protector tripped.

Filter clogged.

Air leakage in the compressor.

High ambient temperature

(Max. 40˚C or 104˚F)

Valve plate joint is broken.

Wrong oil or low oil level.

Carbonized valve plate.

Deficient or inadequate

electrical supply.

Operating in a non-adequate

environment.

The oil change did not occur at

the recommended interval.

Loose fastening elements.

Continuous air leakage through

pressure switch’s relief valve when

compressor shuts off.

Excess water in the tank.

Too much dust and paint

on the compressor.

Check the installation and/or wait

for the electrical supply stabilization.

Send it to the nearest Black&Decker

Authorized Service Center.

Electric motor will start

as soon as the pressure

in the tank decreases.

Find out the burning cause

(See Table 2 - Pág. 21)

Send the compressor to the

nearest Black&Decker

Authorized Service Center

Check the compressor’s capac

ity.

Turn compressor off, wait for 5 (five)

min. and reset the protector. If tripping

is frequent, look for the nearest

Black&Decker Authorized Center.

Replace it.

Re-fasten bolts and/or fittings.

Improve local conditions.

Look for the nearest

StanleyBlack&Decker

Authorized Center.

Change oil.

Clean it every 1000 working hours

or 12 months at your nearest

Have a specialized technician

check it.

Improve local conditions.

See “Care and Maintenance”

Page 21

Find and re-fasten them.

Send compressor to the nearest

Drain the tank through the drain

as indicated in Fig. B - Page 2

Clean the compressor externally.

TROUBLESHOOTING GUIDE

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or

maintenance personnel can perform some corrective actions, and others may require the assistance of a qualified

StanleyBlack&Decker technician.

ENGLISH 9

Motor does not start or does not restart

(Do not insist to start the motor. Do it only after

you have discovered and eliminated the cause

of the problem)

1, 2, 3, 4, 5, 7, 14, 15, 22

Reduce air production

(Pressure gauge keeps showing a lower pressure

than that of the job)

6, 8, 9, 10, 11, 13, 16

The compressor unit overheats

5, 6, 10, 11, 12, 13, 16, 20, 25

Electric motor overheats

5, 7, 10

Premature wear of the compressor unit

internal parts

6, 9, 10, 12, 15, 16, 23

Abnormal noise or vibration

15, 16, 17

Tank pressure increases quickly or too frequent

starts (The normal number of starts is roughly

6 an hour)

19, 24

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

Problem

Code

High temperature of the compressed air

5, 6, 8, 9, 10, 11, 12, 13, 20

Compressor operate ininterruptedly

6, 8, 13, 25

Excessive consumption of lubricating oil

(Compressors usually use more oil in the first 200

working hours until rings are smoothly adjusted)

6, 10, 12

Lubricant oil with unusual color

10, 15, 16, 21

Insufficient pressure for required work

15, 18, 24

Air leakage through relief valve of pressure switch

or compressor unit (when assembled), with

compressor operating from more than 1 (one)

minute (valve closes above 20 psi (1.3 bar))

25

StanleyBlack&Decker Authorized Center

StanleyBlack&Decker Authorized Center

StanleyBlack&Decker Authorized

Service Center.

Page 10

10 ENGLISH

20

21

22

23

24

25

Too much dust and paint

on the compressor.

Water is mixed with the oil

(milky coloration).

Ambient temperature below minimum

recommended 5˚C (41˚F).

Operating too long below

pressure of 60 psi (4.0 bar).

Pressure regulator valve not adjusted

(Fig. H )

Relief valve not seal because

of impurities.

as indicated in Fig. B - Page 2

Clean the compressor externally.

Change the lubricant oil and run

your pressure compressor for

15 min, at a maximum pressure of

100 psi (7.0 bar). This will remove

any internal condensation signs

inside pump.

Run the equipment above 5˚C

(41˚F)

Compressed air consumption

higher than compressor’s flow.

Adjust it.

Send compressor to the nearest

StanleyBlack&Decker Authorized Center

Loading...

Loading...