Page 1

Page 2

Page 3

OWNER’S MANUAL

WARNING

!

This appliance can be used by children aged from 8 years and above and any persons, provided

they have experience and knowledge regarding the use of the product, or supervision or instruction

regarding the use of the appliance in a safe way, and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be completed by children.

Attention!

If the appliance or the supply cord is damaged, it must be repaired by manufacturer, its service agent

or qualied person.

Meaning of crossed – out wheeled dustbin:

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities.

Contact you local government for information regarding the collection systems available.

Page 4

Contents

1. Applications

2. Model Description

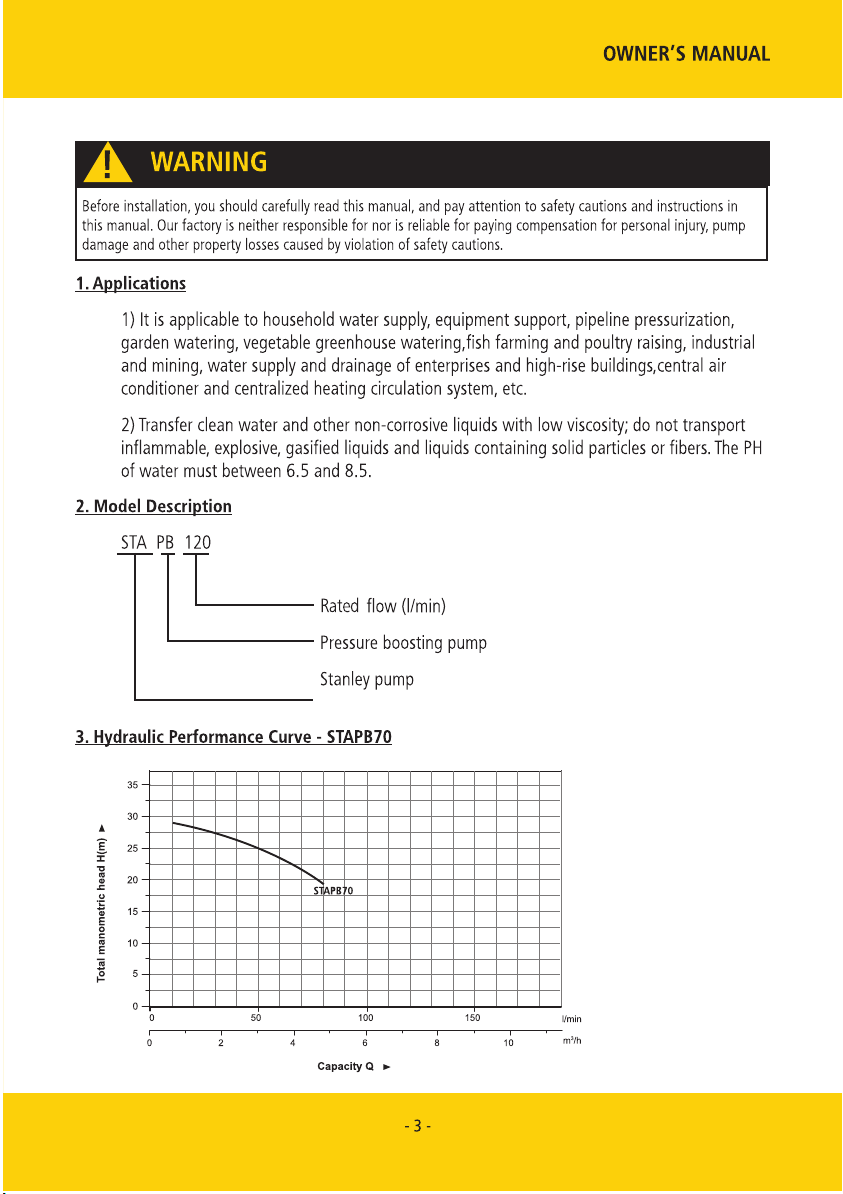

3. Hydraulic Performance Curve - STAPB70

4. Hydraulic Performance Curve - STAPB120

5. Safety Precautions

6. Product Structure

7. Dimension

8. Pipeline Installation

9. Electrical Connection

10. Start-up and Maintenance

11. Troubleshooting

- 2 -

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

8. Pipeline Installation

WARNING

!

This product should be installed and maintained by a qualied person, or someone who has read this manual and

understands the use requirements. Installation and operation should be in accordance with local regulations and

recognized operation standards. Install pipelines properly as stipulated in the manual, and conduct frost protection

measures for the pipeline.

1. For the pump installation, the inlet pipe

should be as short as possible with the least

turnings. The pump should be installed in a

ventilated and dry environment. It could be

installed outside, provided having proper

covering to prevent rain and wind.

2. For pipeline use, valves should be installed

on inlet and outlet pipelines and the inlet

pipeline should be installed with a check valve.

- 8 -

Page 11

A:

OWNER’S MANUAL

1. Foot valve

2. Inlet pipe

3. Tie-in

5. Drain plug

6. Electric pump

7. Valve

4. Filling plug

B: Installation precautions for inlet pipelines

1. While installing the electric pump, do not use too

soft rubber tube for the inlet pipeline. This avoids

it being sucked at.

2. The foot valve should be vertically placed and

installed 30cm from water bottom to avoid

sucking in sands and stones (B2);

3. Joints of the inlet pipelines should be sealed with

the least elbows, so no water can be sucked.

4. Diameter of the inlet pipe should be at least in

accordance with that of the water inlet, so as to

avoid too much water loss which will inuence

outlet performance.

5. Pay attention to drop of water level while using.

The foot valve should not be above the water

surface (B1).

6. In case the inlet pipe is longer than 10m or its

lifting height exceeds 4m, the pipe diameter

should exceed diameter of water inlet of the

pump.

7. Ensure the pump will not be affected by pipeline

pressures while installing the pipelines.

8. Filter should be installed in inlet pipelines so as

to avoid solid particles to enter into the electric

pump.

C: Installation Precautions of the outlet

pipeline

Pipe diameter of the outlet pipeline should be at

least in accordance with that of the water outlet,

so as to reduce its voltage drop, ow rate issues

and to reduce the noise emitted by the pump.

- 9 -

Page 12

9. Electrical Connection

WARNING

!

Unless the power is off, do not touch the wiring in the junction box.

The electric pump should have reliable grounding to prevent current leakage with leakage protection switch

being equipped.

1. Electrical connection and protection should be conducted according to stipulations. Specication

of working voltage is marked on the nameplate; please ensure the motor is in accordance with

power supply.

2. In case the working area of the electric pump is too far from the power supply, power

transmission lines should be of a heavier gauge, otherwise the electric pump cannot work

normally because the voltage drop is too dramatic.

3. In case the electric pump is used outdoor, extended lines should apply rubber cables for outdoor

use.

4. Check rotation of the motor (three-phase motor)

5. Check whether operation of the electric pump is normal, rotation is correct, which could be

observed from the fan blade terminal, e.g. clockwise rotation means correct direction. In case the

rotation is incorrect, cut off power and exchange the two power leads.

- 10 -

Page 13

10. Start-up and Maintenance

WARNING

!

Do not start up the pump before the pump chamber is lled with water.

Do not touch the electric pump unless its power has been cut off for at least 5 minutes.

Do not dismount the pump body unless water in the pump chamber is emptied.

Rotate the fan blade before startup, check

whether the pump rotation is exible and then

unscrew the water-lling plug, ll the pump

chamber with clean water from the water

injection hole, then tighten the plug screw

after gas has been completely discharged The

valve should be shut tightly while starting up

the pump. After the pump discharges water

and operates normally, adjust the valve to the

required ow (ow and lift will be displayed on

the nameplate).

OWNER’S MANUAL

Attention:

1. In case no water is discharged after being started for more than 5 minutes with the water lled,

turn off the electric pump, re-ll water or check whether the inlet pipeline has leakages.

2. In case of any frost and ice damages, please open the drain plug to empty water in the pump

chamber. When start up the pump again, open the drain plug, ll water and tighten it and then

the pump is usable.

3. In case not use for a long time, water in the pump should be emptied. The pump body, impeller

and support should be cleaned and coated with anticorrosive oil before they are put in a

ventilated and dry place for use.

4. In case the pump is halted for a long time, start it up again according to above diagram.

5. In summer or when the ambient temperature is high, pay attention to ventilation, avoid dew on

electrical parts which will result in electrical faults.

6. In case the motor is hot or abnormal, cut off the power immediately and check faults according to

the following table.

- 11 -

Page 14

11. Troubleshooting

WARNING

!

Check the pump after power cut-off.

- 12 -

Page 15

OWNER’S MANUAL

- 13 -

Page 16

Loading...

Loading...