Page 1

Errigal Solid Fuel Boiler/Non Boiler Range

SAFETY NOTICE

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW COOK STOVE. FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE,

BODILY INJURY OR EVEN DEATH. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

IF THIS APPLIANCE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. FOR YOUR SAFETY,

FOLLOW THE INSTALLATION DIRECTIONS. CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT

RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN YOUR AREA.

THIS APPLIANCE MUST BE CONNECTED TO A LISTED, HIGH-TEMPERATURE RESIDENTIAL TYPE AND

BUILDING HEATING APPLIANCE CHIMNEY OR AN APPROVED MASONRY CHIMNEY WITH FLUE LINER.

THE COMPLETE INSTALLATION MUST BE DONE IN ACCORDANCE WITH CURRENT STANDARDS AND

LOCAL CODES. IT SHOULD BE NOTED THAT THE REQUIREMENTS AND THESE PUBLICATIONS MAY

BE SUPERSEDED DURING THE LIFE OF THIS MANUAL.

MANUFACTURED BY: WATERFORD STANLEY (MARKETING) LTD., BILBERRY, WATERFORD,

IRELAND.

ASSEMBLY INSTALLATION AND OPERATING INSTRUCTIONS

Page 2

1

TABLE OF CONTENTS

PAGE

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Pre-Installation Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Top Flue Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7. Rear Flue Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8. Flues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

9. Flue Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

10. Flue Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

11. Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

12. Use of Existing Flues & Chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

13. Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

14. Floor Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

15. Clearance to Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

16. Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

17. Smoke Spillage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

18. Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

19. Heating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

20. Boiler Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

21. Gravity Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

22. Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

23. Pipe Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

24. Water Circuit Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

25. Care For Your Central Heating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

26. Injector Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

27. Draining. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

28. General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

29. Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

30. Lighting The Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

31. Refuelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

32. Controlling The Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

33. Overnight Burning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

34. De-Ashing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

35. Disposal of Ashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

36. Main Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

37. The Hotplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

38. Use of Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

39. Hints on Fire Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

40. Over Firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

41. Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

42. Cleaning of Mild Steel Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

43. Cleaning The Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

44. Cleaning The Hotplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

45. Vitreous Enamel Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

46. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 3

INTRODUCTION

Congratulations on purchasing this fine Irish made Solid Fuel cooker which is built to exacting standards.

Please read the following information before operating this product.

This appliance is hot while in operation and retains its heat for a long period of time after use. Children,

aged or infirm persons should be supervised at all times and should not be allowed to touch the hot

working surfaces while in use or until the appliance has thoroughly cooled.

As manufacturers and suppliers of cooking and heating appliances, we take every possible care to ensure as

reasonably practicable, that these appliances are so designed and constructed as to meet the general safety

requirement when properly used and installed.

The complete installation must be done in accordance with current Standards and Local Codes. It should be

noted that the requirements and these publications may be superseded during the life of this manual.

IMPORTANT NOTICE: Any alteration to this appliance that is not approved in writing by Waterford Stanley will

render the guarantee void.

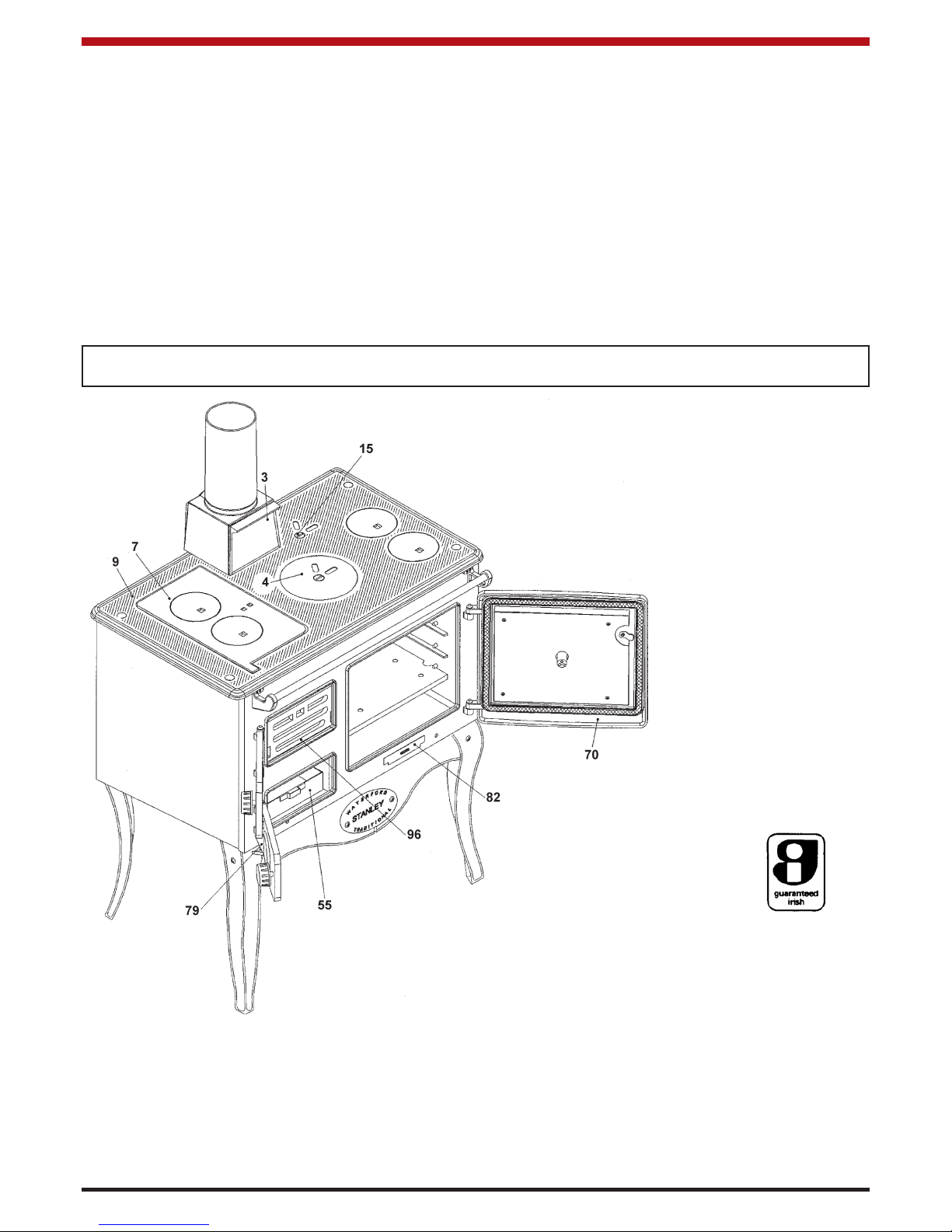

Fig.1

2

3. Bonnet Door

7. Hot Plate

9. Hob

15. Direct Damper

18. Oven Damper

55. Ash Pan

70. Oven Door

79. Spin Valve

82. Base Cleaning Door

96. Fire Fence

Page 4

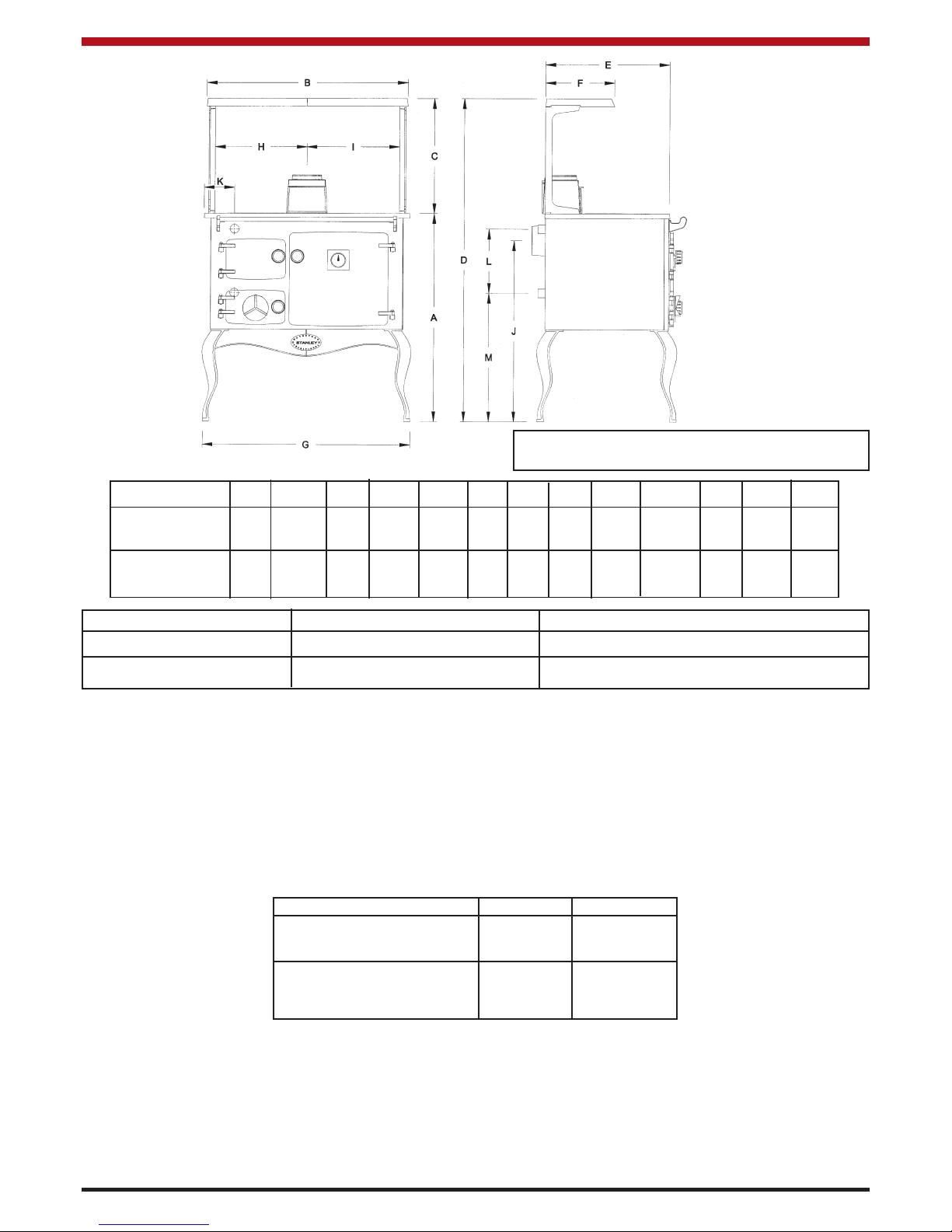

DIMENSIONS ABCDEFGHIJKLM

METRIC 880 905 508 1388 565 290 950 452 452 725 130 260 565

(millimetre)

IMPERIAL

34

5

/8 355/8 20 545/8 221/4 111/2 372/5 173/4 173/4 2811/20 5

1

/8

10

1

/4 221/4

(inches)

FEATURE METRIC IMPERIAL

HOT PLATE 911.25 cm

2

144 in

2

OVEN 400W x 330H x 400D 15

3

/4W x 13H x 153/4D

TECHNICAL DATA

CHIMNEY DRAUGHT: 0.06” - 0.10” wg. (1.52mm - 2.54mm)

FLUE DIAMETER: 5” (127mm)

BOILER TAPPINGS: 1” BSP (28mm)

TEST PRESSURE OF BOILER (Where applicable): 40 PSI (2.75 Bar)

OPERATING TEMPERATURE LIMIT: 96

0

C 2050F

COOKER WEIGHT: 263 Kgs (579 lbs)

SPACE HEATING: 3 kW’s (10, 000) Btu’s

Fig.2

NOTE: Dimensions stated below may be subject

to a slight +/- variation.

All technical data are taken under laboratory conditions and may vary in use, flue draught conditions will effect

performance

SPECIFICATION

BOILER TYPE 47K DHW

BOILER CAPACITY: 7.5 LTRS 3.2 LTRS

MAX OUTPUT TO WATER: 47,000 Btu 10,000 Btu

(13.77 kW) (2.9 kW)

INSTALLATION

When installing, operating and maintaining a solid fuel heater, respect basic standards of fire safety. Read

these instructions carefully before commencing the installation. Failure to do so may result in damage to persons and property. Consult your local municipal office, Fire Department and your insurance representative to

determine what regulations are in force.

3

Page 5

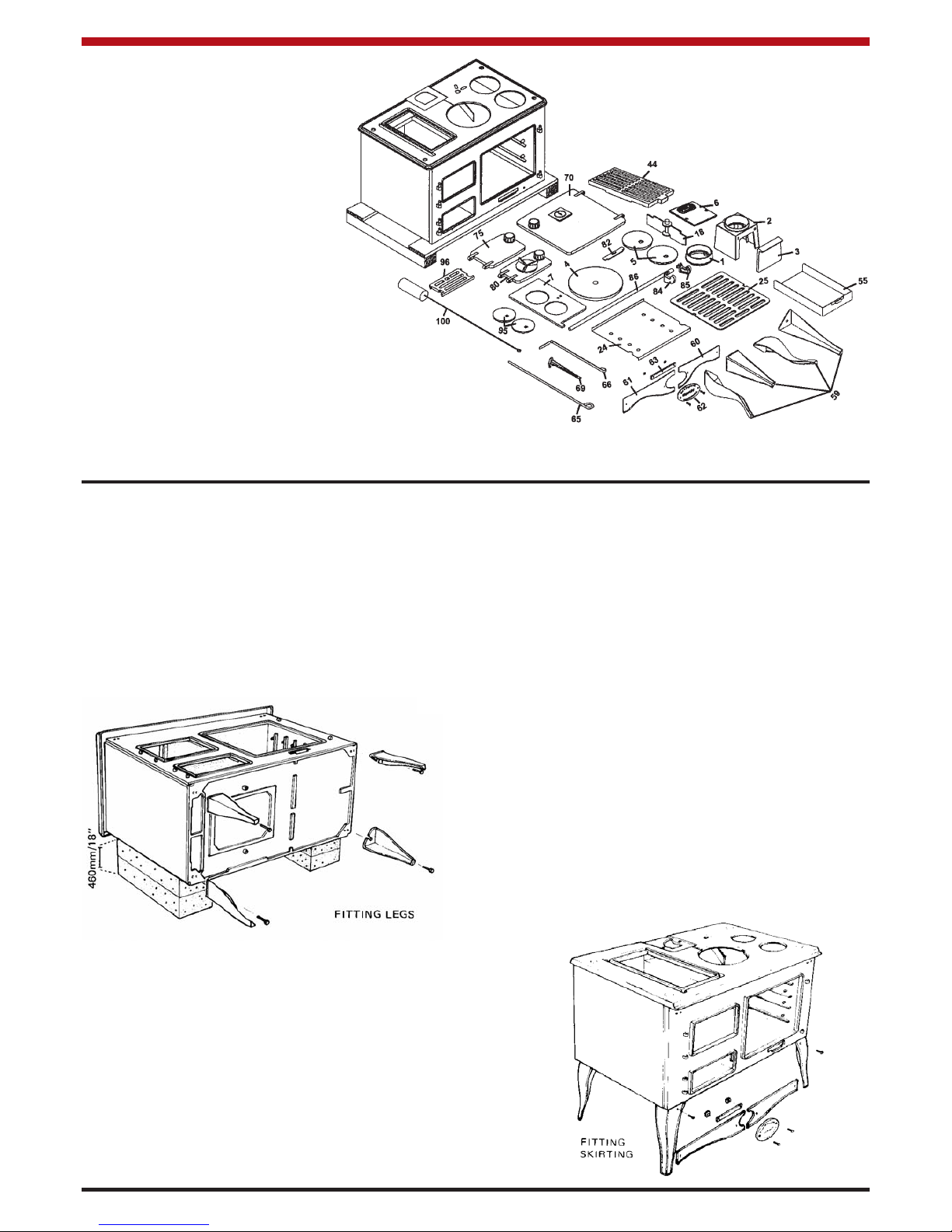

1. Remove packing strip from the top of

the range. Place the sheet steel back

plate to one side. Remove all loose

components from the top of the range

and firebox and the oven. Remove the

oven door. Spread the components on

the floor so you can identify them easily.

2. Place strong supports about 458mm (13”)

high behind the range. Space the supports

behind it and lay the cooker on its back.

(See Fig.4)

3. Fit the four legs (Part no. 59) to the four base

corners (Part no. 58) using the hexagon-head

bolts and washers. Note that each of the front

legs has a screw hole in the front.

4. Lift the range off the supports. Stand it upright

without putting any strain on the legs.

5. Join the two sections of the front plinth together (Part Nos. 60 and 61) by screwing the name

plate (Part No. 62) and the plinth joining clip

(Part No. 63) into position between the two

sections and secure the two sections tightly to

the name plate.

6. Fit the complete plinth under the front of the

range inside the front legs using a screw and nut

to secure it to each leg. (See Fig.5)

7. Move the range into position for installation.

CAREFUL: Do not break a leg! Consult the

Chimney & Location Sections before finalising

the position for the range.

4

ASSEMBLY

Fig.3

Fig.4

Fig.5

PRE-INSTALLATION ASSEMBLY

1. Bonnet Ring

2. Bonnet

3. Bonnet Door

4. Simmering Plate

5. Cleaning Cup (2)

6. Hob Sealing Plate

7. Hot Plate

18. Oven Damper

24. Oven Shelf (Sheet Iron)

25. Oven Shelf (Cast Iron)

44. Riddling Grate

55. Ash Pan

59. Leg (4)

60. Plinth RHS

61. Plinth LHS

62. Nameplate

63. Plinth Joining Clip

65. Poker

66. Scraper

69. Riddling/Operating Tool

70. Oven Door

75. Fire Door

80. Ashpit Door

82. Base Cleaning Door

84. Towel Rail Bracket RH

85. Towel Rail Bracket LH

86. Towel Rail

95. Hotplate Cleaning Cups

96. Fire Fence

100. Cleaning Brush

Page 6

8. Place the oven damper in position (Part No.

18) on top of the oven and place the simmering

plate (Part No. 4) in position above it. Place

the oblong hotplate (Part No. 7) and the two

round cleaning cups (Part No.5) in position to

complete the cooker top.

9. Place the bonnet (Part No. 2) in position and fit

its front cleaning door (Part no. 3) in position.

10. Screw the towel rail brackets (Part Nos. 84 and

85) to the top front of the range (Part No. 87)

and fix the towel-rail (Part No.86) in position

between the brackets. Tighten up the screws.

11. Hang the fire door (Part No. 75) and the ashpit

door (Part No. 80) on their hinges.

12. Place the oven shelves in position (Part No.25)

the cast iron shelf below the sheet steel shelf.

13. Place the base cleaning door (Part No. 82) in

position beneath the oven door (Part No. 70).

14. Screw the optional splashback (Part No.91)

to its two supports (Part Nos. 88 & 89) keeping

the folded end to the bottom. Screw the platerack (Part No. 90) to the splashback. Screw the

complete assembly on to the cooker hob (Part

No. 9). (See Fig.8)

Note: The Platerack and splashback are an optional extra, not supplied as standard.

TOP FLUE EXIT

With the bonnet (Part No 2) in position on the hob,

connect the bonnet ring (Part No 1) onto the top of

the bonnet. The flue pipe is then connected to the

bonnet ring as shown in Fig.6. Seal all joints using

approved fire cement, ensuring that no cement

blocks the flue passageway.

5

Fig.6

FLUES

Flues should be vertical wherever possible and

where a bend is necessary it should not make an

angle of more than 37.5

o

with the vertical.

Horizontal flue runs should be avoided except in the

case of a back outlet appliance, when the length of

the horizontal section should not exceed 300mm.

FLUE PIPES

A flue pipe should only be used to connect an appliance to a chimney and should not pass through any

roof space.

Flue pipes may be of any of the following materials:

(a) Cast iron as described in BS 41:1973 (1981)

(b) Mild steel with a wall thickness of at least

3mm.

REAR FLUE EXIT

Replace the bonnet (Part No 2) with the hob sealing

plate (Part No 6), using approved fire cement to seal

the hob sealing plate to the hob. Remove the back

Fig.7

Fig.8

sealing plate (Part No 33) and fit the rear outlet spigot (Part No 94) to the flue back (Part No 32).

Connect the flue pipe to the rear flue spigot (see Fig

7). Seal all joints with fire cement ensuring that no

cement blocks the flue passageways.

Page 7

Before connecting this appliance to a chimney or

flue pipe which has previously been used with

another fuel, the chimney or flue pipe must be thoroughly swept and/or lined accordingly.

All register plates, restrictor plates and dampers etc.

which could obstruct the flue at a future date must

be removed before connecting this appliance.

The combustion products from this appliance will

have a descaling effect on hardened soot deposits

left from burning solid fuels.

ALTHOUGH THE CHIMNEY MAY HAVE BEEN

CLEANED OF LOOSE SOOT PRIOR TO INSTALLATION, IT IS IMPERATIVE THAT THE CHIMNEY

IS INSPECTED FOR SCALED SOOT PARTICLES

AFTER THE FIRST MONTH OF OPERATION AND

ANY LOOSE MATERIALS REMOVED TO AVOID

BLOCKAGE.

LOCATION

There are several conditions to be considered in

selecting a location for your Waterford Stanley Solid

Fuel Range.

a. Position in the area to be heated - central

locations are usually best.

b. Allowances for proper clearances to com-

bustibles.

FLOOR PROTECTION

When installing the Waterford Stanley Solid Fuel

Range on a combustible floor, a floor protector consisting of a layer of non-combustible material at least

3/8” (9mm) thick, or of at least 1/4” (6mm) thick covered with a 1/8” (3mm) sheet of metal is required to

cover the area under the heater and to extend to at

least 18” (460mm) at the front and 8” (200mm) to the

sides and back of stove. This will provide protection

from sparks and embers which may fall out from the

door when stoking or refuelling.

(c) Stainless steel with a wall thickness of

at least 1mm and as described in BS

EN 10095:1999 specification for

stainless and heat resisting steel plate,

sheet and strip, for grade 316 S11, 316

S13, 316 S16, 316 S31, 316 S33, or the

equivalent Euronorm 88-77 designation.

(d) Vitreous enamelled steel complying with

BS 6999: 1989.

FLUE CLEANING

The flue pipe must be fitted with a cleaning pipe.

The flue must be inspected twice annually and

cleaned when necessary.

CHIMNEY

The Waterford Stanley Solid Fuel Range must be

connected to a Factory-Built Chimney, installed in

accordance with the manufacturer’s instructions or a

lined masonry chimney, acceptable to the authority

having jurisdiction. An existing masonry chimney

should be inspected and if necessary repaired by a

competent mason or be relined using an approved

relining system.

THE CHIMNEY SERVING THIS WATERFORD

STANLEY SOLID FUEL RANGE SHOULD NOT

SERVE ANY OTHER APPLIANCES. If you intend

to use a fireplace chimney, the fireplace opening

must be sealed. The overall height of the chimney,

measured from the floor on which the Range is

installed must be at least 4.572 meters (15ft). Do

not use more than two elbows.

Chimneys for use with solid fuel appliances should

be capable of withstanding a temperature of 1100oC

without any structural change which would impair

the stability or performance of the chimney.

USE OF EXISTING FLUES AND CHIMNEYS

When connecting to an existing chimney it is necessary to line the flue using either 5” (125mm) rigid or

flexible stainless steel flue liner.

An existing flue pipe or chimney that has proved to

be satisfactory when used for solid fuel can normally be used for this appliance provided that its construction, condition and dimensions are acceptable.

Flues that have proven to be unsatisfactory, particularly with regard to down draught, must not be considered for venting this appliance until they have

been examined and any faults corrected. If there is

any doubt about an existing chimney, a smoke test

should be carried out.

Fig.9

(200mm)

(200mm)

(200mm)

(460mm)

6

Page 8

7

there is combustion present.

2. Existing fuel-fired equipment in the house

such as fireplaces or other heating appliances, smell, do not operate properly, suffer

smoke roll-out when opened, or back-draft

whether or not there is combustion present.

3. Opening a window slightly on a calm

(windless) day alleviates any of the above

symptoms.

4. The house is equipped with a well-sealed

vapour barrier and tight fitting windows

and/or has any powered devices that

exhaust house air.

5. There is excessive condensation on win-

dows in the winter.

6. A ventilation system is installed in the house.

If these or other indications suggest that ventilation

air is inadequate, additional combustion air should

be provided from the outdoors. Outside combustion

air can be provided to the appliance by the following

means:

1. Indirect method: for an appliance not

certified for direct connection of outside

combustion air, the outside air is ducted to a

point no closer than (12”) 300mm from the

appliance, to void affecting the performance

of the appliance.

2. A mechanical ventilation system: if the

house has a ventilation system (air change

or heat recovery):

a. The ventilation system may be able

to provide sufficient combustion make-up

air for the solid-fuel-fired appliance.

b. The householder should be informed that

the ventilation system might need to be

re-balanced by a ventilation technician

after installation of the appliance.

SMOKE SPILLAGE TEST

In all installations a spillage test should be carried

out to ensure there is sufficient combustion and the

flue system is adequate.

The spillage test is carried out as follows:

1. Light/burn appliance under normal condi-

tions in accordance with this installation

manual.

2. Close all doors and windows.

3. Operate all appliances requiring air at full

rate (eg. extraction hoods, tumble dryers

etc).

4. Check for smoke spillage.

CLEARANCES TO COMBUSTIBLES

Maintain at least the following clearances to all

combustible material:

Front 1220mm (36”)

Back 400mm (16”)

Oven Side 150mm (6”)

Oven Side with

Optional Shelf Fitted 250mm (10”)

Firebox Side 300mm (12”)

The minimum clearance to non-combustible materials should be maintained at least 50mm (2”) from the

back of the range.

Never obstruct free air circulation from around or

entering the cooker grills.

Where the flue passes through a combustible material a twin wall solid packed insulated chimney connector must be used and come flush with the outer

surface material and run all the way to the masonry

chimney or to the point of termination of the factory

made chimney. (see Fig. 10).

Fig.10

VENTILATION & COMBUSTION AIR

REQUIREMENTS

Provision for outside combustion air may be necessary to ensure that fuel-burning appliances do not

discharge products of combustion into the house.

Guidelines to determine the need for additional combustion air may not be adequate for every situation.

If in doubt, it is advisable to provide additional air.

Outside combustion air may be required if:

1. The solid-fuel-fired appliance does not draw

steadily, smoke rollout occurs, fuels burns

poorly, or back drafts occur whether or not

Page 9

PLUMBING

Diagrams illustrate the basic principles of water systems and are not to be regarded as working drawings.

NOTE: We strongly advise the use of pipe lagging

and also the use of a frost thermostat if the installation is likely to be exposed to situations where the

temperatures will drop to a level consistent with

frost.

Central Heating and Indirect Domestic Hot

Water.

Recommended indirect cylinder 135 litres, depending on domestic requirements with a 28mm flow and

return pipes not exceeding 7.8m each in length.

Cylinder and pipework should be lagged to minimise

heat losses.

HEATING SYSTEM

The system must include a gravity circuit with

expansion pipe, open to the atmosphere. The central heating must be pump-driven as with other types

of boilers. The primary air valve controls the heating

rate of the boiler, Closed = minimum, Open = maximum output. (See operating instructions).

BOILER OUTPUT (Central Heating)

High output cannot be maintained unless fuel is

being burned at a rate of 2.7 kg. per hour of coal.

When burning wood or peat, reduced outputs

will apply because of the lower calorific value of

the fuels.

GRAVITY CIRCUIT

The gravity circuit consists of a domestic hot water

tank of 135 litres Indirect Cylinder for central Heating

units and Direct Cylinder for Domestic Hot Water

Unit fixed in an upright position, recommended for

hot water storage and it should be connected to the

boiler by 28mm diameter flow and return piping. The

pipes should not exceed 7.8m each in length and

anything in excess of 4.6m must be fully lagged.

The shorter the run of pipe work the more effective

the water heating efficiency and to this end, the

cylinder should be fully lagged. In the interest of

safety do not have any valves on this circuit.

HEATING

Care should be taken to ensure that the heating

installation is correctly installed and that it complies

with all relevant codes of practice. If this appliance

is being connected to an existing system, it is

strongly recommended to check the following.

(a) That the pipework is adequately insulated

(where applicable).

(b) Check all controls e.g. pump, pipe thermo-

stat etc, are operating satisfactorily and

are compatible with the requirements of the

cooker.

(c) Cleanse the system and add suitable

inhibitor.

Only competent personnel should be employed to

carry out your heating installation.

PIPE FITTINGS

Materials used for installation work should be fire

resistant, sound and should conform to the current

editions of the following or their equivalent:

1. Ferrous Materials

B.S. 1387: Steel Tubes

B.S. 4127: Stainless Steel Tubes

B.S. 1740: Steel Pipe Fittings

B. S. 6956: Jointing Materials

2. Non-Ferrous Materials

EN 29453: Soft Solder Alloys

B.S. 864: Compression Tube Fittings

B.S. 2871 & EN 1057: Copper & Copper

Alloys.

WATER CIRCUIT TEMPERATURE

The return water temperature must be maintained at

not less than 50º C so as to avoid condensation on

the boiler and return piping. Fitting a pipe thermostat to the return from the gravity circuit and wiring it

into the pump control will ensure than no cold water

will be returned from the central heating circuit

before the water from the gravity circuit has warmed

up the common return pipe and boiler. If this is not

sufficient to keep the boiler temperatures above the

Stanley

Solid Fuel

Range

Fig. 11

8

Page 10

DRAINING

Key - operated drain taps to B.S. 2879 should be

provided in accessible positions in all low parts of

the system. However it should be noted that there

may be short sections of pipework e.g. when passing under doorways that may be possible to drain.

GENERAL MAINTENANCE

It is important that the user is familiar with their heating system and that they ensure regular checks and

maintenance which can limit unnecessary breakdowns.

We recommend that you evaluate the overall insulation in your house, i.e. attic, external walls, windows,

external doors. Insulation and draught proofing can

greatly reduce running costs, while equally enhancing living conditions.

FUELS

The Cooker output levels are assessed on standard

House Coal of good quality. Reduced outputs will

result when fuels of low calorific values are used.

Wood logs up to 21cm long are suitable.

All fuel should be stored under cover and kept as dry

as possible prior to use.

FUEL CALORIFIC VALUES

Anthracite 25-50mm C.V.: 8.2 kW/Kg = 14,000 Btu’s/lb

House Coal 25-75mm C.V.: 7.2 kW/Kg = 12,300 Btu’s/lb

Timber - Firebox Size C.V.: 5.0 kW/Kg = 8,600 Btu’s/lb

Peat Briquettes C.V.: 4.8 kW/Kg = 8,300 Btu’s/lb

Bog Peat C.V.: 3.4 kW/Kg = 6,000 Btu’s/lb

9

required minimum, a three-way mixing valve may be

fitted to the flow pipe to divert some hot water

straight back into the return. Such a valve can be

operated either manually or electrically in conjunction with a return pipe thermostat.

CARE FOR YOUR CENTRAL HEATING SYSTEM

We strongly recommend the use of suitable corrosion inhibitors and anti-freeze solution in your heating system, in an effort to minimise black oxide,

sludge and scale build-up, which effects efficiency.

In hard water areas the use of a suitable limescale

preventer / remover is advised.

Use only quantities specified by the water treatment

product manufacturer. Only add to the heating system after flushing and finally refilling. Refer to BS

7953.

INJECTOR TEE (Central Heating)

Where the gravity and central heating circuits join

together to return to the Cooker we recommend the

use of an injector tee connection, situated as close

to the unit as possible. This type of tee encourages

a stable flow of hot water through both circuits and

helps to prevent priority being given to the stronger

flow, which is most commonly the pumped central

heating circuit. This way, there will be no shortage

of hot water to the taps when the heating is on.

Fig.12

Fig.13

LIGHTING THE FIRE

To access the firebox, after opening the firedoor

(Part No. 75) lift up and then tilt forward the firefence

(Part No 96). Lay a few crumpled sheets of paper

on the riddling grate (Part no. 44) then a few small

dry pieces of sticks or kindling. Open the spin valve

(Part no. 79) fully by rotating it in an anti-clockwise

direction. Turn the direct damper (Part no. 15) to

open by using the operating tool (Part No. 69). Now

light the paper, lift up the fire fence and close the fire

door (Part no. 75). When the kindling has caught

fire (allow 15 minutes for this to happen), add larger

pieces of dry wood, until the fire box is half filled.

When the larger pieces of wood have caught fire,

add fuel load.

Note: It is also possible to access the firebox by lifting the hotplate (Part No 7) (See Hotplate Section).

Page 11

10

IMPORTANT: UNDER NO CIRCUMSTANCES

SHOULD ANY FLAMMABLE LIQUID, GASOLINE

KEROSENE, LIGHTER FLUID OR CHARCOALSTARTERS BE USED TO LIGHT OR “FRESHEN

UP” THE FIRE. NEVER USE MANUFACTURED

LOGS. OPERATE APPLIANCE ONLY WITH

FUELLING DOOR AND ASHPIT DOOR CLOSED.

THIS APPLIANCE IS HOT WHILST IN OPERATION, KEEP CHILDREN, CLOTHING AND FURNITURE A SAFE DISTANCE AWAY.

“KEEP ALL SUCH LIQUIDS WELL AWAY FROM

STOVE WHILE IN USE”

OPERATE APPLIANCE ONLY WITH FUELLING

DOOR AND ASHPIT DOOR CLOSED.

REFUELLING

Before refuelling the range, open the direct damper

(Part No. 15). Add the fuel, and after refuelling

ensure that the direct damper is closed, otherwise

oven temperature will drop and the fire box may

overheat.

Note: Only the recommended fuels as outlined in

the section on fuels may be used during refuelling of

the range.

CONTROLLING THE FIRE

The direct damper (Part No 15) must be kept closed

except when initially lighting the fire or during refuelling. The burn rate is adjusted by controlling the

primary air using the spin valve (Part No. 79). The

primary air is increased by turning the spin valve

anticlockwise, and decreased by turning it clockwise

(see Fig.14). The oven damper (item 18) under the

round hot plate (Part No. 4) controls the chimney

draught which also adjusts the burn rate. (see

Fig.15)

Fig.15

Fig.14

You will get to know how to use the spin valve and

oven damper in conjunction for the optimum range

performance. Ensure that both the ashpit door (Part

No. 80) and the fire door (Part No. 75) are closed

securely during firing.

KEEP ALL COMBUSTIBLE MATERIALS AT

LEAST 1220mm (4 Feet) AWAY FROM THE

RANGE. They include rugs, fabrics, furnishings,

papers, firewood, etc. NEVER dry clothing on or

within 1220mm (4 Feet) of the range.

OVERNIGHT BURNING

Open the spin valve (Part No. 79) by a quarter turn

and close the oven damper (Part No. 18); riddle the

fire and refuel. In the morning open the air valve and

damper and riddle the fire; when it is again burning

brightly, refuel. If it is found that the fire is completely burned out then new settings should be tried

in respect of the spin valve. On the other hand if the

fire is out and the fuel unburned then the reverse

should apply.

DE-ASHING

The ash pan (Part No. 55) must be emptied regularly, otherwise ash will build up to a point where it

interferes with the natural flow of cool air through the

fire bars and as a consequence these will be damaged.

The ashpan is accessed by opening the ashpit door

(Part No. 80) and is removed using the riddling tool

(Part No. 69).

Note: The ashpan must be replaced in position

before the range is fired.

DISPOSAL OF ASHES

Ashes should be placed in a metal container with a

tight-fitting lid. The closed container of ashes should

be placed on a non-combustible floor or on the

ground well away from all combustible materials

pending final disposal. If the ashes are disposed of

by burial in soil or otherwise locally dispersed they

should be retained in the closed container until all

cinders have thoroughly cooled.

Page 12

MAIN OVEN

When baking or roasting, open the oven damper

and spin valve fully until the thermometer shows a

temperature about 50

o

F (10oC) higher than that

which is required. Then close the Spin Valve to a

point where the required temperature is sustained (a

little practice will soon show how much adjustment is

necessary). Much will also depend on the strength

of the chimney draught. Remember the direct flue

damper must be kept fully closed as a by-pass is

provided to allow waste gases through at all times.

When baking or roasting, if it is found that the surface of the food is cooking too quickly then position

the plain steel shelf in the top of the oven so as to

act as a heat shield which will protect the food on the

shelf beneath.

THE HOTPLATE

Use the hotplate and the cooking-top of the range

for boiling simmering, frying, grilling, braising, etc.

Best results can be obtained by using flat bottomed

utensils. The lacquer which was applied to protect

the surface-ground hotplates will burn off and give a

strong odour during the burn off process. Keep the

hotplates clean with a wire brush. Over a short period you will quickly adapt to the best ways and

means of using the cooker-top in order to obtain

utmost satisfaction and efficiency.

The firebox may also be accessed by lifting the hotplate (Part No. 7) using the hotplate lifter (Part No.

67). Before the hotplate is moved, the hotplate

cleaning cups (Part No. 95) must be locked in position by turning them clockwise, into the closed position as shown in Fig.16.

HINTS ON FIRE SAFETY

To provide reasonable fire safety the following

should be given serious consideration:

1. The installation of smoke detectors.

2. A conveniently located Class A fire

extinguisher.

3. A practical evacuation plan.

4. A plan to deal with chimney fire as follows

(a) Notify the fire department

(b) Prepare occupants for immediate

evacuation.

(c) Close all openings into the stove

(d) While awaiting fire department,

watch for ignition of adjacent com

bustibles from overheated stove pipe

or hot embers or sparks from the

chimney.

NOTE: Inspect the chimney flue weekly until a safe

frequency is established.

OVER-FIRING

When using anthracite, coke or coal avoid excessive

firing conditions. High temperatures are unnecessary and can only do serious harm to the cooker.

The first indication that overheating is taking place

will be the formation of Clinker (Melted Ash) in the

firebox and this should be removed immediately otherwise damage will occur not only to the cooker

components but also to the fire bricks and any damage here should be repaired without delay.

11

Fig.16

USE OF TOOLS

Fig.17

Ash Pan

Lifting Tool

Soot

Cleaning

Page 13

Remove the hotplates (Part No. 4 & 7), the bonnet

door (Part No. 3), the oven damper (Part No. 18)

and the cleaning cups (Part No. 5) from the top of

the cooker. See Fig. 18. If the flue is connected to

the back outlet configuration, the hob sealing plate

(Part No. 6) is removed instead of the bonnet door.

To remove all the accumulated deposits, take off the

cleaning door (Part No. 82) situated immediately

under the oven on the front of the cooker and thoroughly clean out the residue from the side flue, back

flue and base plate using the scraper tool (Part No.

66). This operation is essential, otherwise the flow

of combustion gases will be obstructed or even

stopped, and satisfactory oven temperature will not

be maintained, apart from which such deposits will

cause smoking. See Fig.21.

Replace all loose parts which have been removed

making sure that all cooking surfaces have been

thoroughly cleaned on the underside. See Fig.22.

CLEANING INSTRUCTIONS

Fig.18

Fig.19

Fig.20

Fig.21

Fig.22

All deposits from the flue pipe and the top of the

oven may be brushed both into the firebox and down

the back flue passage way. See Fig. 19.

Deposits which have accumulated on the side of the

oven must also be brushed downward. (See Fig 20)

12

Direct Damper

Open

Cleaning

Brush

Flue

Passageway

SIDE FLUE PASSAGEWAY

Page 14

13

CLEANING THE MILD STEEL PARTS

The steel side panels and splash back must not be

cleaned with steel wool. Use only washing up liquid

in hot water with a lint free cloth. Dry off and apply

a coat of good quality furniture polish.

CLEANING THE OVENS

Grease spillages will burn off from the oven interior,

when the oven is hot and any other loose materials

can be wiped out with a cloth, when cold. Stubborn

stains in the oven and on the shelves in the oven

can be cleaned off with a paste of bread soda and

water.

CLEANING THE HOT PLATE

The hotplate may be cleaned using a small amount

of oil or fine steel wool to remove rust and cooking

stains. Dry off with a lint free cloth and apply a light

coat of cooking oil to preserve the finish.

VITREOUS ENAMEL CLEANING

General cleaning must be carried out when the

stove is cool.

If this stove is finished in a high gloss vitreous enamel, to keep the enamel in the best condition observe

the following tips:

1. Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.

2. For stubborn deposits a soap impregnated

pad can be carefully used on the vitreous

enamel.

3. Use only products recommended by the

Vitreous Enamel Association, these products carry the Vitramel label.

4. DO NOT USE ABRASIVE PADS OR OVEN

CLEANSERS CONTAINING CITRIC ACID

ON ENAMELLED SURFACES. ENSURE

THAT THE CLEANSER MANUFACTURERS INSTRUCTIONS ARE ADHERED TO.

Association

Page 15

14

EXPLODED VIEW

1. Bonnet Ring

2. Bonnet

3. Bonnet Door

4. Simmering Plate

5. Cleaning Cup (2)

6. Hob Sealing Plate

7. Hot Plate

8. Hot Plate Cord

9. Hob

10. Hob Protection Plate (Large)

11. Hob Protecting Plate (Small)

12. Flue Guide LH

13. Flue Guide RH

14. Back Flue Guide

15. Direct Damper

16. Steam Escape

17. Front Flue Guide

18. Oven Damper

19. Oven Top

20. Oven Back

21. Oven Side (LH)

22. Oven Side (RH)

23. Oven Bottom

24. Oven Shelf (Sheet Iron)

25. Oven Shelf (Cast Iron)

26. Oven End Flue Bottom

27. Oven End Flue Top

28. Stay Rods

29. Insulation

30. Sheet Iron Sides (2)

31. Sheet Iron Back (R.H)

32. Flue Back

33. Back Sealing Plate

34. Fire Box Back

35. Fire Box Back Sheet Iron

36. Sham Cheek

37. Fire Box Brick Back

38. Fire Box Brick L.H.S. Back

39. Fire Box Brick L.H.S. Front

40. Fire Box Brick Front Bottom

41. Fire Box Brick Front Top

42. Fire Box Brick R.H.S. Front

43. Fire Box Brick R.H.S. Back

44. Riddling Grate

50. Bottom Grate Rest

51. Ash Pit Back

52. Ash Pit L.H.S

53. Ash Pit R.H.S

54. Ash Pit Bottom

55. Ash Pan

56. Fire Box Blanking Plate

57. Flue Check

58. Base

59. Legs (4)

60. Plinth R.H.S

61. Plinth L.H.S

62. Nameplate

63. Plinth Joining Clip

64. S.I. Base Protection Plate

65. Poker

66. Scraper

67. Hotplate Lifter

68. Thermometer

69. Riddling/Operating Tool

70. Oven Door

71. Door Knob (3)

72. Door Catch (3)

73. Oven Door Rope

74. Oven Door Panel

75. Fire Door

76. Fire Door Millboard Panel

77. Fire Door Rope

78. Fire Door Protection Panel

79. Spin Valve

80. Ashpit Door

81. Ashpit Door Rope

82. Base Cleaning Door

83. Base Cleaning Door Clip

84. Towel Rail Bracket R.H.

85. Towel Rail Bracket L.H.

86. Towel Rail

87. Front

88. Plate Rack Standard L.H.

89. Plate Rack Standard R.H.

90. Plate Rack Shelf (2)

91. Splashback

92. Plate Rack Centre Piece

93. Centre Piece Blanking Plate

94. Rear Outlet Spigot

95. Hotplate Cleaning Cups

96. Fire Fence

100. Cleaning Brush

Boiler Options

97. 47 K Boiler

98. DHW Boiler

99. 21K Boiler

95

94

99

100

98

97

96

Page 16

N00076AXX DP 070830

15

Manufactured by

Waterford Stanley Ltd.,

Unit 210, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

Loading...

Loading...