Page 1

SRR1200

English Page 05

Turkish Page 13

Russian Page 21

Ukrainian Page 31

Page 2

ENGLISH (Original instructions)

4

10

3

9

5

6

7

5

6

12

13

1

2

11

8

17

13

18

14

16

15

19

20

2

Page 3

FIG. H

(Original instructions) ENGLISH

22

9

23

30

10

29

28

9

7

30

9

28

25 26 24

7

7

3

Page 4

ENGLISH (Original instructions)

FIG. M FIG. N

FIG. O

FIG. P

*Router bit types, for reference only

4

Page 5

(Original instructions) ENGLISH

Intended use

Your Stanley SRR1200 plunge router has been designed for

routing wood and wood products. This tool is intended for

Professional use only.

SAFETY INSTRUCTIONS

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated

(cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered and dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of

electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock. NOTE: The term “residual current device

(RCD)” may be replaced by the term “ground fault circuit

interrupter (GFCI)” or “earth leakage circuit breaker

(ELCB)”.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e. Do not overreach. Keep proper footing and balance

at at all times. This enables better control of the power

tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices

can can reduce dust related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

5

Page 6

ENGLISH (Original instructions)

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

ADDITIONAL SAFETY INSTRUCTIONS FOR

ROUTERS

• Hold power tool by insulated gripping surfaces,

because the cutter may contact its own cord. Cutting

a “live” wire may make exposed metal parts of the power

tool “live” and shock the operator.

• Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding

the work by your hand or against the body leaves it

unstable and may lead to loss of control.

• Only use router bits with a shank diameter equal to the

size of the collet installed in the tool.

• Only use router bits suitable for the no-load speed of the

tool.

• Never use router bits with a diameter exceeding the

maximum diameter specified in the technical data

section.

• Do not use the tool in an inverted position.

• Do not attempt to use the tool in a stationary mode.

• Take special care when routing MDF or surfaces coated

with lead-based paint.

• Wear a dust mask specifically designed for protection

against lead paint dust and fumes and ensure that

persons within or entering the work area are also

protected.

• Do not let children or pregnant women enter the work

area.

• Do not eat, drink or smoke in the work area.

• Dispose of dust particles and any other debris safely.

• Always wear a dust mask.

• This appliance is not intended for use by young or infirm

persons without supervision. children must be supervised

to ensure they do not play with the appliance.

PERSONAL SAFETY

• No children or pregnant women should enter the work

rea where the paint sanding is being done until all

cleanup is completed.

• A dust mask or respirator should be worn by all persons

entering the work area. The filter should be replaced

daily or whenever the wearer has difficulty breathing.

Note: only those dust masks suitable for working with

lead paint dust and fumes should be used. Ordinary

painting masks do not offer this protection. See your

local hardware dealer for the NIOSH approved proper

mask.

LABELS ON TOOL

The label on your tool may include the following symbols

along with date code:

WARNING! To reduce the risk of injury, the user

must read the instruction manual before use.

Wear ear protection.

Wear safety glasses or goggles.

V Volts

A Amperes n

Hz Hertz

W Watts

min minutes

Alternating

Current

Direct Current

No-Load Speed

0

Class II Construction

Earthing Terminal

Safety Alert Symbol

Revolutions or

/min.

Reciprocation per

minute

6

Page 7

(Original instructions) ENGLISH

Position of Date Code (Fig. A)

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2016 XX JN

Year of manufacturing

PACKAGE CONTENTS

The package contains:

1 Router

3 Collets: 6mm,6.35mm, 8mm

1 Edge guide

2 Edge guide bars

1 Dust extraction adapter

1 Spanner

6 Router bits (optional, may not be available in all models)

1 Instruction Manual

• Check for damage to the tool, parts or accessories which

may have occurred during transport.

• Take the time to thoroughly read and understand this

manual prior to operation.

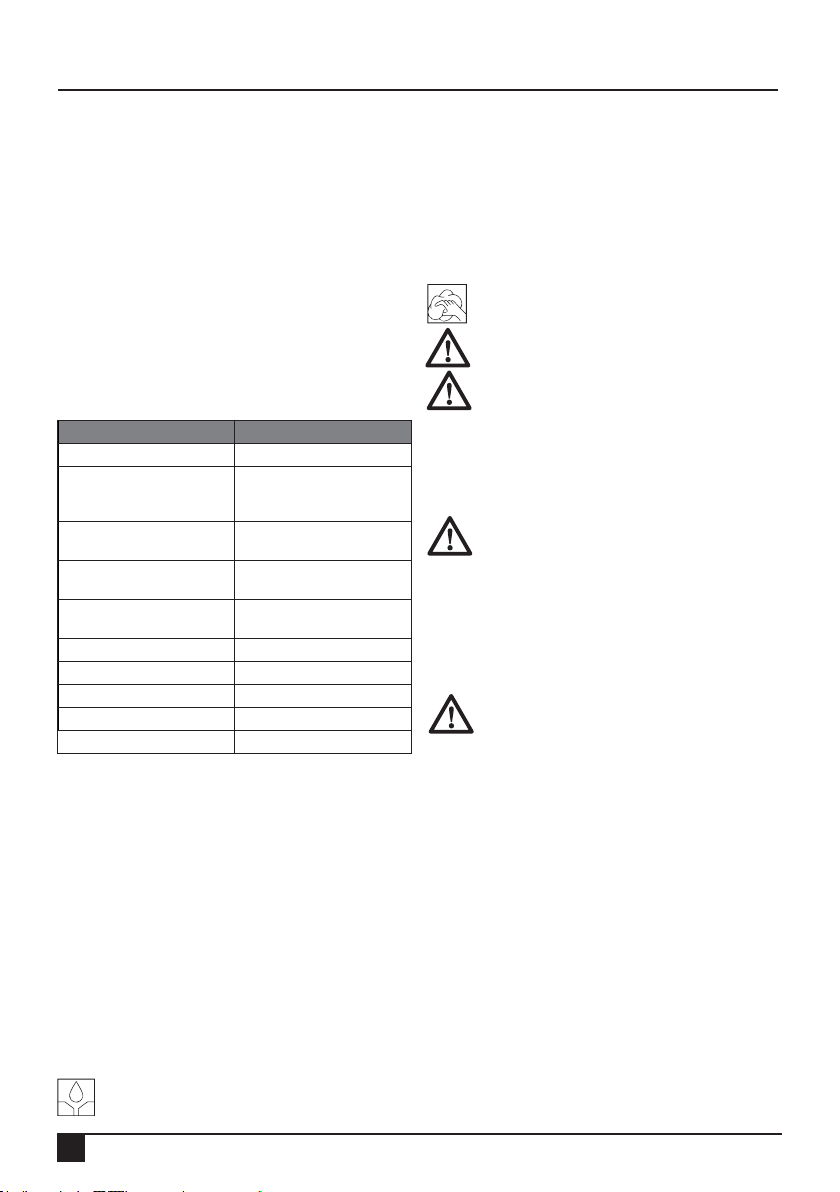

ELECTRICAL SAFETY

Your tool is double insulated; therefore no earth

wire is required. Always check that the main

voltage corresponds to the voltage on the rating

plate.

WARNING! If the power cord is damaged, it

must be replaced by the manufacturer,

authorized Stanley Service Center or an equally

qualified person in order to avoid damage or

injury. If the power cord is replaced by an equally

qualified person, but not authorized by Stanley,

the warranty will not be valid.

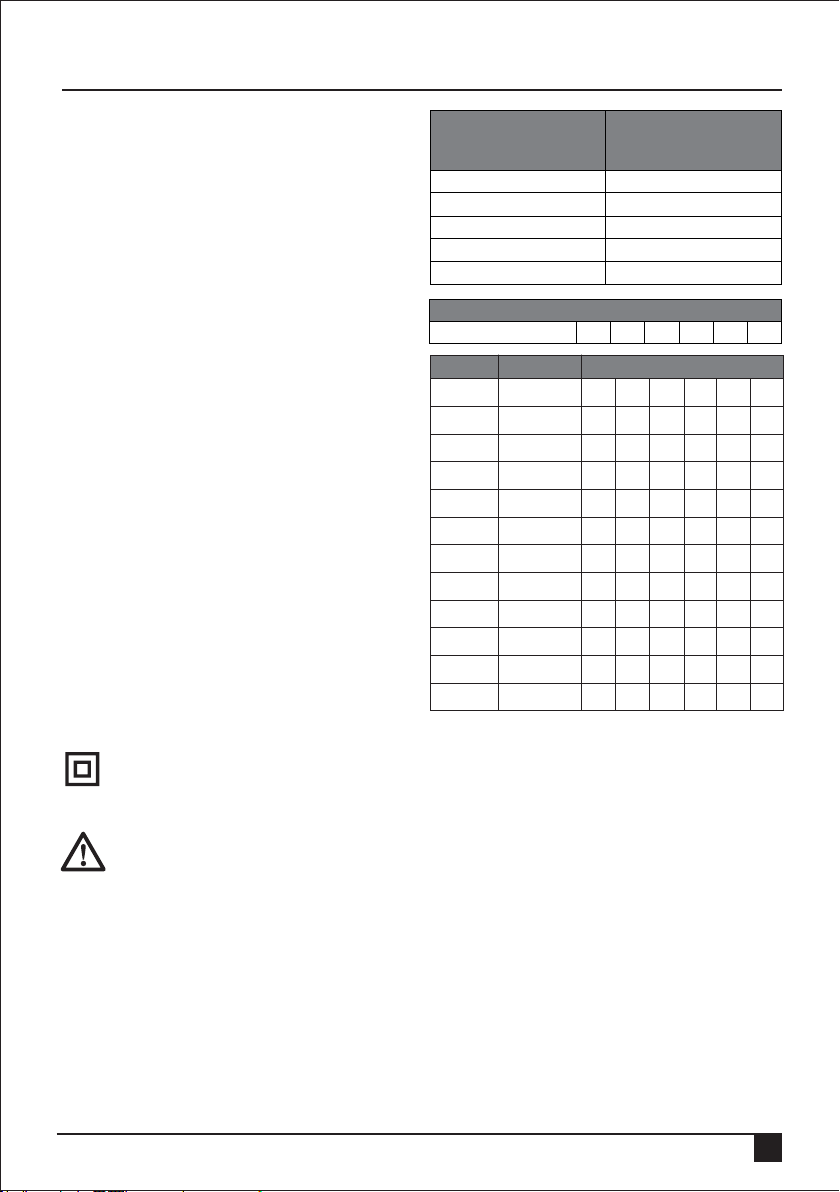

USING AN EXTENSION CABLE

If it is necessary to use an extension cable, please used an

approved extension cable that fits the tool’s power input

specifications. The minimum cross-sectional area of the

conducting wire is 1.5 sq. mm. Cables should be untangled

before reeling up.

Cable cross-sectional

area (mm2) Cable rated

current (Ampere)

0,75 6

1,00 10

1,50 15

2,50 20

4,00 25

Voltage Amperes Cable rated current (Ampere)

110-127 0 - 2,0 6 6 6 6 6 10

2,1 - 3,4 6 6 6 6 15 15

3,5 - 5,0 6 6 10 15 20 20

5,1 - 7,0 10 10 15 20 20 25

7,1 - 12,0 15 15 20 25 25 -

12,1 - 20,0 20 20 25 - - -

220-240 0 - 2,0 6 6 6 6 6 6

2,1 - 3,4 6 6 6 6 6 6

3,5 - 5,0 6 6 6 6 10 15

5,1 - 7,0 10 10 10 10 15 15

7,1 - 12,0 15 15 15 15 20 20

12,1 - 20,0 20 20 20 20 25 -

Cable cross-sectional

area (mm2) Cable rated

current (Ampere)

Cable length (m)

7,5 15 25 30 45 60

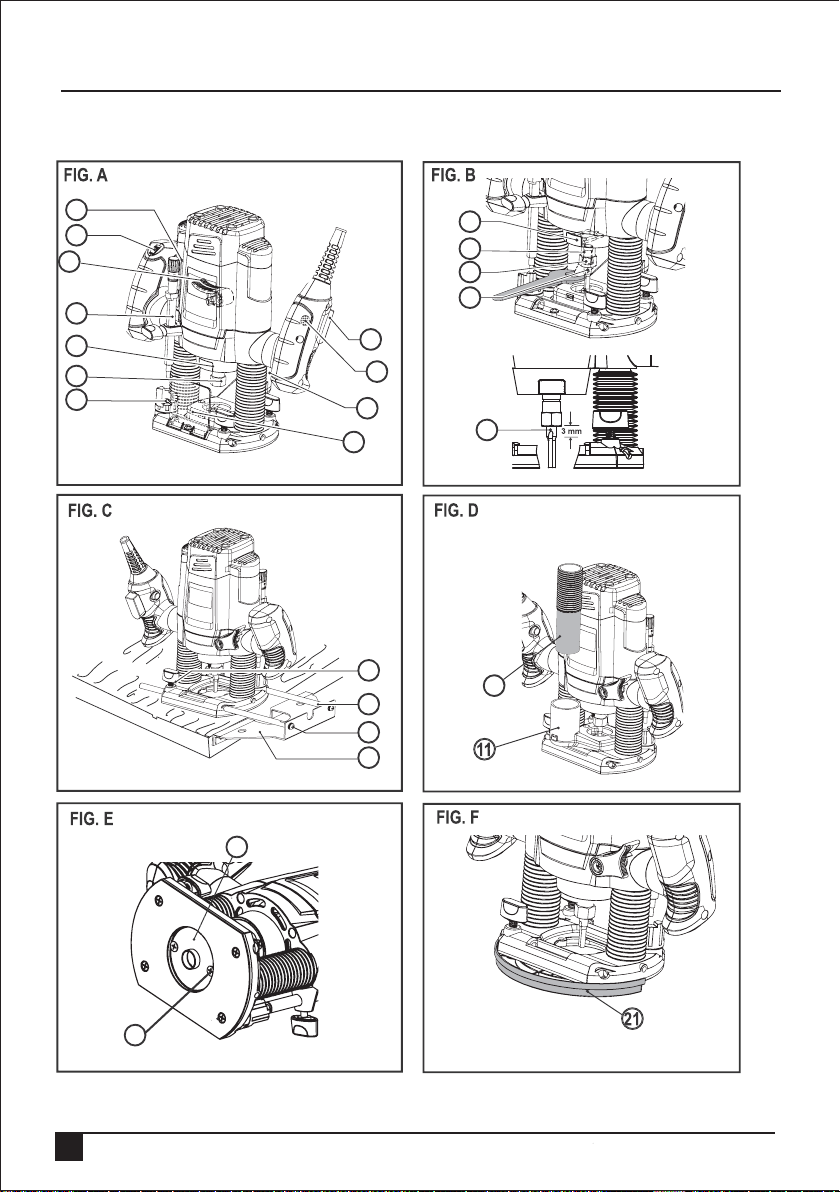

FEATURES (FIG. A)

This tool includes some or all of the following features.

1. On/Off switch

2. Lock-off button

3. Variable speed control knob

4. Plunge lock lever

5. Spindle lock button

6. Collet

7. Revolver depth stop

8. Chip deflector

9. Depth stop bar

10. Depth of cut scale

11. Dust extraction adaptor

7

Page 8

ENGLISH (Original instructions)

ASSEMBLY

WARNING! To prevent accidental operation, turn off and

unplug tool before performing the following operations.

Failure to do this could result in serious personal injury.

Fitting a router bit (Fig. B)

• Remove the chip reflector (8).

• Keep the spindle lock button (5) depressed and rotate

the spindle until the spindle lock fully engages.

• Loosen the collet nut (12) using the spanner provided.

• Insert the shank of the router bit (13) into the collet (6).

Make sure that the shank protrudes at least 3mm from

the collet as shown.

• Keep the spindle lock button (5) depressed and tighten

the collet nut (12) using the spanner provided.

Fitting the edge guide (Fig. C)

The edge guide helps to guide the tool parallel to an edge.

• Fit the bars (14) to the edge guide (15) using the two

screws (16) provided.

• Insert the bars (14) into the router base as shown.

• Set the edge guide to the required distance.

• Tighten the fixing screws (17).

Fitting the dust extraction adaptor (Fig. D)

The Dust extraction adaptor allows you to connect a vacuum

cleaner to the tool.

• Connect the hose (18) of the vacuum cleaner to the

adaptor (11).

Fitting the template guide (Fig. E)

(Template guide not included)

• Fit the template guide (19) to the base of the router, with

the flange to the bottom (workpiece) side.

• Insert the two long screws (20) from the bottom side

through the template guide and the holes in the base.

• Place a nut onto each of the screws and securely tighten

the nuts.

Fitting the distance piece (Fig. F)

(Distance piece not included)

• Fit the distance piece (21) to the base of the router using

the screws provided.

Fitting the centring pin (Fig. G)

(Centring pin not included)

• Fit the centring pin (22) to the workpiece side of the bars,

then tighten it with the steel knob(23) provided .

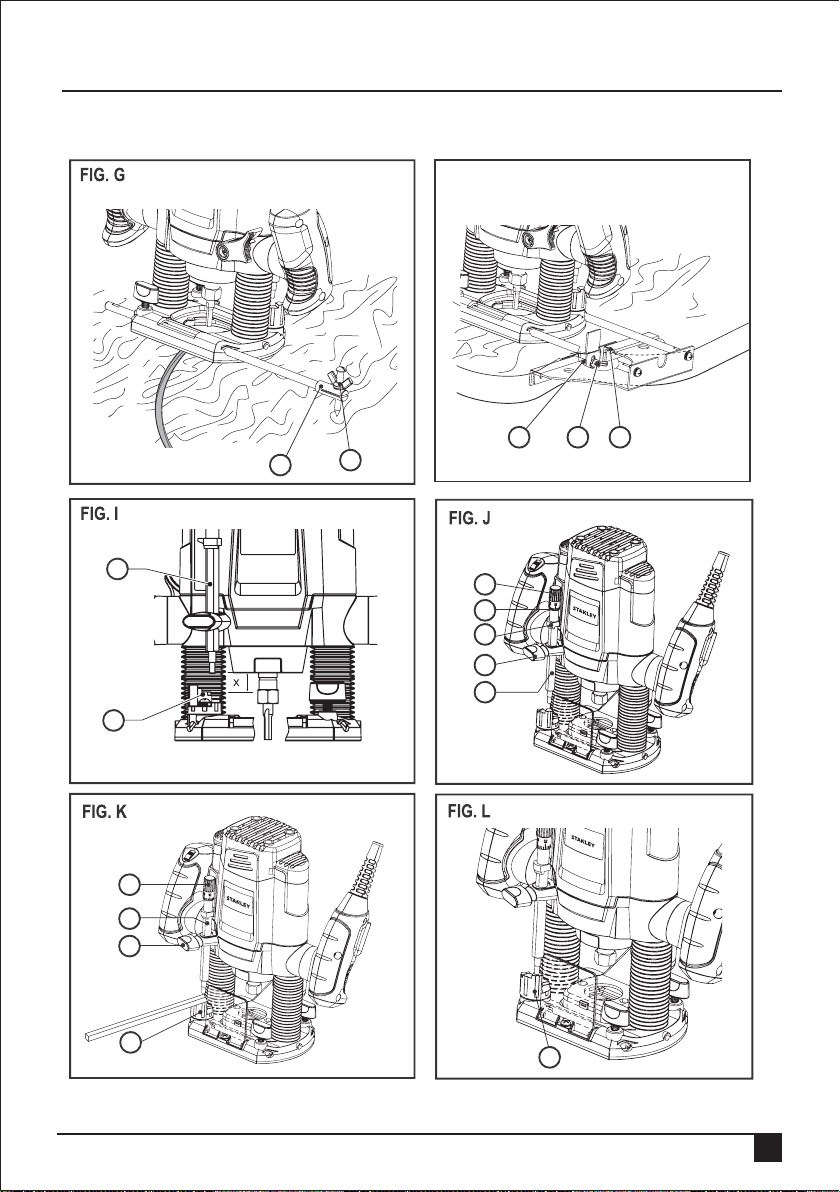

Fitting the copy follower (Fig. H)

(Copy follower not included)

• Fit the edge guide to the router as shown in Fig. C.

• Fit the bar (24) to the upper side of the edge guide using

the two screws and nuts provided.

• Adjust the rotating attachment (25) on the bar with the

wing knob (26).

OPERATION

WARNING! Let the tool work at its own pace. Do not

overload.

• Carefully guide the cable in order to avoid accidentally

cutting it.

Adjusting the depth of cut (FIG. I, J and K)

• The depth of cut is the distance X between the depth

stop bar (9) and the depth stop (7).

• The depth of cut can be set in two different ways as

described below.

Adjusting the depth of cut using the scale

(FIG. J)

• Fit the router bit as described above.

• Loosen the locking screw (28).

• Pull the plunge lock lever (4) up.

• Plunge the router down until the router bit touches the

workpiece.

• Push the plunge lock lever (4) down.

• Move the pointer (29) in the zero position on the scale

(10).

• Add the disered depth of cut to the starting position.

• Move the depth stop bar (9) to the calculated position on

the scale.

• Tighten the locking screw (28).

• Fine adjust using the adjusting knob (30).

• Pull the plunge lock lever (4) up and let the router return

to its original position.

8

Page 9

(Original instructions) ENGLISH

• After switching the router on, plunge it down and make

the desired cut.

Adjusting the depth of cut using a piece of

wood (FIG. K)

• Fit the router bit and plunge the router down as

described above.

• Pull the depth stop ba (9) up.

• Place a piece of wood with a thickness equal to the

desired depth of cut between the depth stop (7) and the

depth stop bar (9).

• Tighten the locking screw (28).

• Fine adjust using the adjusting knob (30).

• Remove the piece of wood.

• Pull the plunge lock lever (4) up and let the router return

to its original position.

• After switching the router on, plunge it down and make

the desired cut.

Adjusting the revolver depth stop (FIG. L)

After turning the revolver depth stop to the desired setting,

you can fine-adjust the depth stop to be used. If you want to

make several cuts with a different depth of cut, adjust each

of the depth stops.

Setting the speed

Set the speed control knob (3) to the required speed. Use a

high speed for small diameter router bits. Use a low speed

for large diameter router bits.

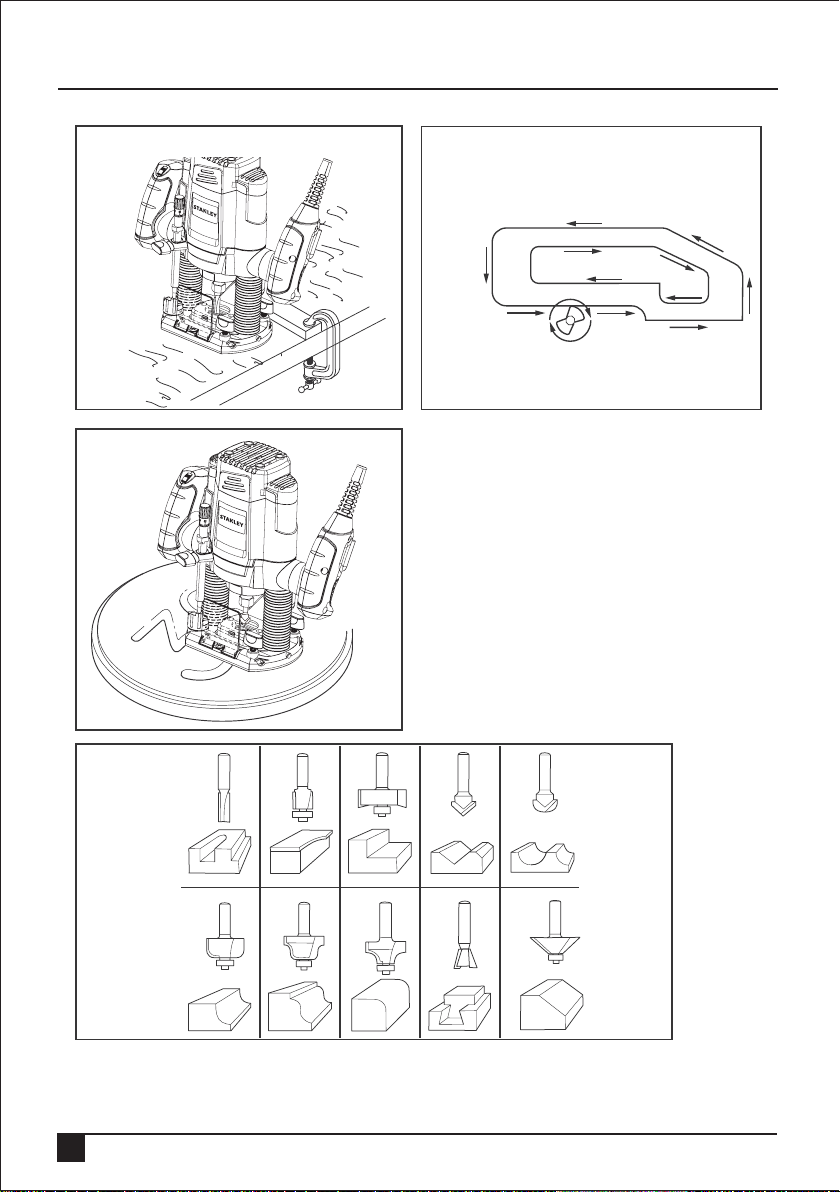

Fitting The Dust Extraction Adaptor (Fig. M)

When it is not possible to use the edge guide, for example

when routing grooves in the back panel of a bookcase to

support shelves, proceed as follow:

• Select a piece of wood with a straight edge to use as a

batten.

• Place the batten onto the workpiece.

• Move the batten until it is in the correct position to guide

the tool.

• Securely clamp the batten to the workpiece.

Using the template guide (FIG. E)

The template guide can be used to make a cutout shape

from a template, for instance a letter.

• Secure the template over the workpiece with

doublesided tape or ‘G’ clamps.

• The router bit must extend below the flange of the

template guide, to cut the workpiece in the shape of the

template.

Using the distance piece (FIG. F)

(Distance piece not Included)

The distance piece can be used for trimming wooden or

laminate vertical projections.

Using the centring pin (FIG. G)

(Centring pin not included)

The centring pin can be used to cut out circular patterns.

• Drill a hole for the point of the centring pin in the center

of the circle to be cut.

• Place the router on the workpiece with the point of the

centring pin in the drilled hole.

• Adjust the radius of the circle with the bars.

• The router can now be moved over the workpiece to cut

out the circle.

Using the copy follower (FIG. H)

(Copy follower not included)

The copy follower helps to maintain an equal cutting

distance along the edge of irregularly shaped workingpieces.

• Place the router on the workpiece at the desired distance

from the edge to be copied.

• Adjust the bars of the edge guide until the wheel is in

contact with the workpiece.

Switching On and Off

Switching On

• Keep the lock-off button (2) depressed and press the

On/Off switch (1).

• Release the lock-off button.

Switching Off

• Realese the On/Off switch.

WARNING! Always operate the tool with both hands.TION

9

Page 10

ENGLISH (Original instructions)

Helpful Hints

• When working on outside edges, move the tool

counterclockwise (Fig. M). When working on inside

edges, move the tool clockwise.

• Use HSS router bits for softwood.

• Use TCT router bits for hardwood.

• You can use the tool without a guide (Fig. O). This is

useful for signwritting and creative work. Only make

shallow cuts.

• Refer to the table below for common types of router bits.

Router bits (Optional) (FIG. P)

Description Application

Straight bit (1) Grooves and rebates

Trimming laminates or

Trimming bit (2)

Rebating bit (3)

V-grooving bit (4)

Core box bit (5)

Core bit (6) Decorative edge moulding

Ogee moulding bit (7) Decorative edge moulding

Rounding over bit (8) Rounding over edges

Dovetail bit (9) Dovetail joints

Chamfer bit (10) Chamfer edges

hardwood; accurate

profiling using a template

Rebates on straight or

curved workpieces

Grooves, engraving and

decorative edge moulding

Fluting, engraving and

decorative edge moulding

MAINTENANCE

Your Stanley tool has been designed to operate over a long

period of time with a minimum of maintenance. continuous

satisfactory operation depends upon proper tool care and

regular cleaning.

WARNING! To minimize the danger of serious personal

injury, please switch off the tool power and disconnect

all plugs before adjusting or removing/ installing any

accessory. Before reassembling the tool, press and release

the trigger switch to make sure the tool is already switched

off.

WARNING! Before performing any maintenance on corded/

cordless power tools:

Lubrication

Stanley tools are properly lubricated at the factory and are

ready for use.

Tools should be lubricated regularly every year depending on

usage. (Tools used on heavy duty jobs and tools exposed to

heat may require more frequent lubrication.) This lubrication

should be attempted only by trained power tool

repairperson’s such as those at Stanley service centers or in

other qualified service personnel.

Cleaning

WARNING! Regularly clean the ventilation slots

in your tool using a soft brush or dry cloth.

WARNING! Never use solvents or harsh

chemicals to clean non-metal parts of the tool.

These chemicals may weaken the material of the

parts. Use only mild soap and damp cloth to

clean the tool. Never let any liquid get inside the

tool; never immerse any part of the tool into

liquid.

IMPORTANT! To ensure product SAFETY and

RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this

manual) should be performed by authorized

service centers or other qualified organizations,

always using identical replacement parts. Unit

contains no user service able parts inside.

Optional Accessories

WARNING! Since accessories, other than those

offered by Stanley, have not been tested with this

product, use of such accessories with this tool

could be hazardous. To reduce the risk of injury, only

Stanley, recommended accessories should be used with this

product.

The performance of any power tool is dependent upon the

accessory used. Stanley accessories are engineered to high

quality standards and are designed to enhance the

performance of power tool. By using Stanley accessories will

ensure that you get the very best from your Stanley tool.

Stanley offers a large selection of accessories available at

our local dealer or authorized service center at extra cost.

Remarks

Stanley’s policy is one of continuous improvement to our

products and, as such, we reserve the right to change

product specifications without prior notice. Standard

equipment and accessories may vary by country. Product

specifications may differ by country. Complete product range

may not be available in all countries. Contact your local

Stanley dealers for range availability.

10

Page 11

(Original instructions) ENGLISH

Protecting the Environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your STANLEY product needs

replacement, or if it is of no further use to you, do not

dispose of it with household waste. Make this product

available for separate collection.

STANLEY provides a facility for the collection and

recycling of STANLEY products once they have

reached the end of their working life. To take

advantage of this service please return your product to any

authorised repair agent who will collect them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local STANLEY office at the

address indicated in this manual. Alternatively, a list of

authorised STANLEY repair agents and full details of our

after-sales service and contacts are available on the Internet

at: www.2helpU.com.

SERVICE INFORMATION

STANLEY offers a full network of company-owned and

authorized service locations. All STANLEY Service Centers

are staffed with trained personnel to provide customers with

efficient and reliable power tool service. For more

information about our authorized service centers and if you

need technical advice, repair, or genuine factory

replacement parts, contact the STANLEY location nearest

you.

TECHNICAL DATA

ROUTER SRR1200

Voltage V 220-240

Frecuency Hz 50/60

Power W 1200

No-load Speed /min (RPM) 8000 - 27000

Collet Size mm 6mm, 6.35mm, 8mm

Cord m 3

The declared vibration emission values stated in the

technical data and the declaration of conformity have been

measured in accordance with a standard test method

provided by EN 60745 and may be used for comparing one

tool with another. The declared vibration emission value may

also be used in a preliminary assessment of exposure.

Warning: The vibration emission value during

actual use of the power tool can differ from the

declared value depending on the ways in which

the tool is used. The vibration level may increase above the

level stated.

When assessing vibration exposure to determine safety

measures required by 2002/44/EC to protect persons

regularly using power tools in employment, an estimation of

vibration exposure should consider, the actual conditions of

use and the way the tool is used, including taking account of

all parts of the operating cycle such as the times when the

tool is switched off and when it is running idle in addition to

the trigger time.

EC declaration of conformity

MACHINERY DIRECTIVE

SRR1200 - Plunge Router

Stanley Europe declares that these products described

under "technical data" are in compliance with: 2006/42/EC,

EN 60745-1:2009 + A11:2010, EN 60745-2-17:2010

These products also comply with Directive 2014/30/EU and

2011/65/EU.

For more information, please contact Stanley Europe at the

following address or refer to the back of the manual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of Stanley

Europe.

Level of sound pressure according to EN 60745:

Sound pressure (LpA) 91,5 dB(A), uncertainty (K) 3 dB(A)

Sound power (LWA) 102,5 dB(A), uncertainty (K) 3 dB(A)

Vibration emission value ah:

ah = 4,0 m/s²

uncertainty (K) = 1,5 m/s²

R.Laverick

Engineering Manager

Stanley Europe, Egide Walschaertsstraat 14-18,

2800 Mechelen, Belgium

01.2017

11

Page 12

ENGLISH (Original instructions)

TWO YEARS WARRANTY

If your STANLEY product becomes defective due to faulty

materials or workmanship within 24 months from the date of

purchase, STANLEY guarantees to replace all defective

parts free of charge or – at our discretion – replace the unit

free of charge provided that:

• The product has not been misused and has been used

in accordance with the instruction manual;

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorized

persons;

• Proof of purchase is produced.

• The STANLEY product is returned complete with all

original components

• The product hasn’t been used for hire purposes

If you wish to make a claim, contact your seller or check the

location of your nearest authorised STANLEY repair agent in

the STANLEY catalogue or contact your local STANLEY

office at the address indicated in this manual. A list of

authorised STANLEY repair agents and full details of our

after sales service is available on the internet at:

www.2helpU.com

12

Page 13

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Kullanım amacı

Stanley SRR1200 el frezeniz ahşap ve ahşap ürünlerini

frezelemek için tasarlanmıştır. Bu alet profesyonel kullanım

içindir.

GÜVENLİK TALİMATLARI

Elektrikli el aletleri için genel güvenlik talimatları

UYARI! Bütün güvenlik uyarılarını ve

talimatlarını mutlaka okuyun. Bu uyarılar ve

talimatların herhangi birisine uyulmaması elektrik

çarpması, yangın ve/veya ciddi yaralanma

riskine neden olabilir.

Bütün uyarı ve güvenlik talimatlarını ileride bakmak

üzere saklayın. Uyarılarda yer alan «elektrikli alet» terimi

şebeke elektriğiyle (kablolu) veya akü/pille (şarjlı) çalışan

elektrikli aletinizi ifade etmektedir.

1. Çalışma alanının güvenliği

a. Çalışma alanını temiz ve aydınlık tutun. Dağınık ve

karanlık alanlar kazaya davetiye çıkarır.

b. Elektrikli aletleri, yanıcı sıvılar, gazlar ve tozların

bulunduğu yerler gibi yanıcı ortamlarda

çalıştırmayın. Elektrikli aletler, toz veya dumanları

ateşleyebilecek kıvılcımlar çıkarır.

c. Bir elektrikli aleti çalıştırırken çocuklardan ve

etraftaki kişilerden uzak tutun. Dikkatinizi dağıtıcı

şeyler kontrolü kaybetmenize neden olabilir.

2. Elektrik güvenliği

a. Elektrikli aletlerin fişleri prizlere uygun olmalıdır. Fiş

üzerinde kesinliklehiçbir değişiklik yapmayın.

Topraklı (topraklanmış) elektrikli aletlerde hiçbir

adaptor fişi kullanmayın. Değiştirilmemiş fişler ve

uygun prizler elektrik çarpması riskini azaltacaktır.

b. Borular, radyatörler, ocaklar ve buzdolapları gibi

topraklanmış yüzeylerle vücut temasından kaçının.

Vücudunuzun topraklanması halinde yüksek elektrik

çarpma riski vardır.

c. Elektrikli aletleri yağmura maruz bırakmayın veya

ıslatmayın. Elektrikli alete su girmesi, elektrik çarpması

riskini artıracaktır.

d. Kablosuna zarar vermeyin. Elektrikli aleti kesinlikle

kablosundan tutarak taşımayın, çekmeyin veya

prizden çıkarmayın. Kabloyu sıcaktan, yağdan,

keskin kenarlardan veya hareketli parçalardan uzak

tutun. Hasarlı veya dolaşmış kablolar elektrik çarpma

riskini arttırır.

e. Elektrikli aleti açık havada kullanırken, açık hava

kullanımına uygun bir uzatma kablosu kullanın. Açık

havada kullanıma uygun bir kablonun kullanılması

elektrik çarpma riskini azaltır.

f. Eğer bir elektrikli aleti nemli bir bölgede çalıştırması

zorunluysa, bir artık akım aygıtı (RCD) korumalı bir

kaynak kullanın. Bir RCD kullanılması elektrik şoku

riskini azaltır. NOT: «Artık Akım Aygıtı (RCD)» tanımı,

«Kaçak Akım Koruma Cihazı (GFCI)» veya «Toprak

Kaçağı Devre Kesici (ELCB)» tanımları ile değiştirilebilir.

3. Kişisel güvenlik

a. Elektrikli bir alet kullanırken her zaman dikkatli olun,

yaptığınız işe yoğunlaşın ve sağduyulu davranın.

Elektrikli bir aleti yorgunken veya ilaç ya da alkolün

etkisi altındayken kullanmayın. Elektrikli aletleri

kullanırken bir anlık dikkatsizlik ciddi yaralanmalara yol

açabilir.

b. Kişisel koruyucu ekipmanları mutlaka kullanın.

Daima koruyucu gözlük takın. Koşullara uygun toz

maskesi, kaymayan güvenlik ayakkabıları, baret veya

kulaklık gibi koruyucu donanımların kullanılması kişisel

yaralanmaları azaltacaktır.

c. İstem dışı çalıştırılmasını önleyin. Cihazı güç

kaynağına ve/veya aküye bağlamadan, kaldırmadan

veya taşımadan önce düğmenin kapalı konumda

olduğundan emin olun. Aleti, parmağınız düğme

üzerinde bulunacak şekilde taşımak veya açık

konumdaki elektrikli aletleri elektrik şebekesine bağlamak

kazaya davetiye çıkarır.

d. Elektrikli aleti çalıştırmadan önce herhangi bir

ayarlama anahtarını veya vida anahtarını çıkarın.

Elektrikli aletin hareketli parçasına takılı bırakılan bir vida

anahtarı veya anahtar, kişisel yaralanmaya neden

olabilir.

e. Ulaşmakta zorlandığınız yerlerde kullanmayın. Her

zaman sağlam ve dengeli basın. Bu, beklenmedik

durumlarda elektrikli aletin daha iyi kontrol edilmesine

olanak tanır.

f. Uygun şekilde giyinin. Bol giysiler giymeyin ve takı

takmayın. Saçınızı, giysinizi ve eldivenlerinizi

hareketli parçalardan uzak tutun. Bol giysiler, takılar

veya uzun saçlar hareketli parçalara takılabilir.

g. Eğer kullandığınız üründe toz emme ve toplama

özellikleri olan ataşmalar varsa bunların bağlı

olduğundan ve doğru şekilde kullanıldığından emin

olun. Bu toz toplama ataşmanların kullanılması tozla ilgili

tehlikeleri azaltabilir.

4. Elektrikli aletlerin kullanımı ve bakımı

13

Page 14

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

a. Elektrikli aleti zorlamayın. Uygulamanız için doğru

elektrikli aleti kullanın. Doğru elektrikli alet, belirlendiği

kapasite ayarında kullanıldığında daha iyi ve güvenli

çalışacaktır.

b. Düğme açmıyor ve kapatmıyorsa elektrikli aleti

kullanmayın. Düğmeyle kontrol edilemeyen tüm

elektrikli aletler tehlikelidir ve tamir edilmesi

gerekmektedir.

c. Herhangi bir ayarlama, aksesuar değişimi veya

elektrikli aletlerin saklanması öncesinde fişi güç

kaynağından çekin. Bu tür önleyici güvenlik tedbirleri

aletin istem dışı çalıştırılması riskini azaltır.

d. Elektrikli aleti, çocukların ulaşamayacağı yerlerde

saklayın ve elektrikli aleti tanımayan veya bu

talimatları bilmeyen kişilerin elektrikli aleti

kullanmasına izin vermeyin. Elektrikli aletler, eğitimsiz

kullanıcıların elinde tehlikelidir.

e. Elektrikli aletlerin bakımını yapın. Hareketli

parçalardaki hizalama hatalarını ve tutuklukları,

parçalardaki kırılmalar ve elektrikli aletin çalışmasını

etkileyebilecek tüm koşulları kontrol edin. Hasarlı

ise, elektrikli aleti kullanmadan önce tamir ettirin.

Kazaların çoğu, elektrikli aletlerin bakımının yeterli

şekilde yapılmamasından kaynaklanır.

f. Kesim aletlerini keskin ve temiz tutun. Bakımı uygun

şekilde yapılmış keskin kesim uçlu kesim aletlerinin

sıkışma ihtimali daha düşüktür ve kontrol edilmesi

kolaydır.

g. Elektrikli aleti, aksesuarlarını ve aletin diğer

parçalarını vs. kullanırken bu talimatlara mutlaka

uyun ve elektrikli alet türü için öngörüldüğü şekilde,

çalışma ortamının koşullarını ve yapılacak işin ne

olduğunu göz önünde bulundurun. Elektrikli aletin

öngörülen işlemler dışındaki işlemler için kullanılması

tehlikeli durumlara neden olabilir.

5. Servis

a. Elektrikli aletinizi, sadece orijinal yedek parçaların

kullanıldığı yetkili servise tamir ettirin. Bu, elektrikli

aletin güvenliğinin muhafaza edilmesini sağlayacaktır.

EL FREZELERİ İÇİN EK GÜVENLİK

TALİMATLARI

• Aletin kendi kablosuna temas edebileceği için

elektrikli el aletini yalıtımlı kavrama yüzeylerinden

tutun. «Akım taşıyan» bir teli kesmesi metal kısımları

«akım taşır» hale götürür ve operatörün çarpılmasına yol

açacaktır.

• Üzerinde çalıştığınız parçayı sabitlemek ve

desteklemek için kelepçeler veya başka pratik yöntemler

kullanın. Parçayı elle veya vücudunuza dayamanız

dengesiz durmasına neden olacaktır ve aletin kontrolünü

kaybetmenize yol açabilir.

• Daima alete takılı uç girişi ölçüsüne uygun bir sap çapına

sahip freze uçları kullanın.

• Daima yüksüz alet hızına uygun freze uçları kullanın.

• Hiçbir zaman çapı, teknik veri bölümünde belirtilen

maksimum çapı aşan freze uçlarını kullanmayın.

• Aleti hiçbir zaman ters yönde kullanmayın.

• Aleti sabit modda kullanmaya çalışmayın.

• MDF ve kurşun bazlı boyalı yüzeyleri frezelerken özel bir

dikkat gösterin.

• Kurşunlu boya tozu ve dumanlarına karşı korunma için

özel olarak tasarlanmış bir toz maskesi kullanın ve

çalışma alanına giren veya bu alanda bulunan kişilerin

de korunduğundan emin olun.

• Çocukların veya gebe kadınların çalışma alanına

girmesine izin vermeyin.

• Çalışma alanında bir şey yemeyin, herhangi bir içecek

veya sigara içmeyin.

• Toz partiküllerini ve diğer moloz kalıntılarını güvenli bir

şekilde atın.

• Daima toz maskesi takın.

• Bu alet genç veya kuvvetsiz kişilerin gözetimsiz

kullanmaları için tasarlanmamıştır. Çocuklar, aletle

oynamalarının önlemek amacıyla kontrol altında

tutulmalıdır.

KİŞİSEL GÜVENLİK

• Boya zımparasının yapıldığı çalışma alanına temizlik

tamamlanıncaya kadar hiçbir çocuk veya hamile kadın

girmemelidir.

• Calışma alanına giren herkes tarafından toz maskesi

veya solunum korumasını kullanılmalıdır. Filtre, her gün

veya kullanıcı nefes almakta zorlandığında

değiştirilmelidir.

Not: Yalnızca kurşun boya tozu ve dumanlar ile

çalışmaya uygun toz maskeleri kullanılmalıdır. Genel

boyama maskeleri bu korumayı sunmazlar. NIOSH

tarafından onaylanmış uygun maske için yerel

hırdavat satıcınıza başvurun.

14

Page 15

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

ALET ÜZERİNDEKİ ETİKETLER

Aletin etiketinde aşağıdaki semboller bulunabilir tarih koduna

göre:

UYARI! Yaralanma riskini en aza indirmek için

kullanıcı kullanım talimatlarını mutlaka okumalıdır.

Kulaklık takın.

Koruyucu gözlük takın.

V Volt

A Amper n

Hz Hertz

W Watt

min dakikalar

Dalgalı

akım

Tarih kodu konumu (Şekil A)

İmalat yılını da içeren Tarih Kodu gövdeye basılıdır.

Örnek:

2016 XX JN

Doğru akım

Yüksüz hızı

0

Çift yalıtım

Topraklı terminal

Güvenlik uyarı sembolü

Dakikada devir veya

/min.

darbe sayısı

İmalat Yılı

AMBALAJIN İÇERİĞİ

Ambalaj, aşağıdaki parçaları içermektedir:

1 El Frezesi

3 Uç girişi: 6mm, 6,35mm, 8mm

1 Kenar kılavuzu

2 Kenar kılavuzu çubuğu

1 Toz atma adaptörü

1 Anahtar

6 Freze ucu (ilave aksesuarlar, her model ile sunulmayabilir)

1 Kullanım kılavuzu

• Alette, parçalarda veya aksesuarlarda nakliye sırasında

meydana gelmiş olabilecek hasarı kontrol edin.

• Aleti çalıştırmadan önce, bu kullanım kılavuzunu baştan

sonra okuyup anlamak için gerekli zamanı ayırın.

ELEKTRİK GÜVENLİĞİ

Bu alet çift yalıtımlıdır. Bu yüzden hiçbir

topraklama kablosuna gerek yoktur. Her zaman

şebeke geriliminin aletin üretim etiketinde

belirlenmiş değerlere uyup uymadığını kontrol

edin.

UYARI! Elektrik kablosu hasarlı ise, bir tehlike

oluşmasını önlemek için üretici ya da yetkili

Stanley Servis Merkezi tarafından

değiştirilmelidir. Elektrik kablosu Stanley yetkili

servisi haricinde değiştirilirse, garanti geçerli

olmayacaktır.

UZATMA KABLOLARININ KULLANIMI

Bir uzatma kablosu gerekli ise, bu aletin elektrik girişine

uygun, onaylı bir uzatma kablo kullanın. Minimum iletken

boyutu 1,5 mm2'dir. Bir kablo makarası kullanırken, kabloyu

daima sonuna kadar açın.

İletken boyutu (mm2)

Kablo gücü (Amper)

0,75 6

1,00 10

1,50 15

2,50 20

4,00 25

Voltaj Amper Kablo gücü (Amper)

110-127 0 - 2,0 6 6 6 6 6 10

2,1 - 3,4 6 6 6 6 15 15

3,5 - 5,0 6 6 10 15 20 20

5,1 - 7,0 10 10 15 20 20 25

7,1 - 12,0 15 15 20 25 25 -

12,1 - 20,0 20 20 25 - - -

220-240 0 - 2,0 6 6 6 6 6 6

2,1 - 3,4 6 6 6 6 6 6

3,5 - 5,0 6 6 6 6 10 15

5,1 - 7,0 10 10 10 10 15 15

7,1 - 12,0 15 15 15 15 20 20

12,1 - 20,0 20 20 20 20 25 -

İletken boyutu (mm2)

Kablo gücü (Amper)

Kablo uzunluğu (m)

7,5 15 25 30 45 60

1515

Page 16

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

ÖZELLİKLER (ŞEKİL A)

Bu alet, aşağıdaki özelliklerin bir kısmını veya tümünü

içermektedir.

1. Açma/kapama düğmesi

2. Kesintisiz çalıştırma düğmesi

3. Değişken hız kontrol düğmesi

4. Piston kilitleme kolu

5. Mil kilidi düğmesi

6. Uç girişi

7. Rotatif derinlik ayarı

8. Talaş deflektörü

9. Derinlik ayar çubuğu

10. Kesim derinliği ölçeği

11. Toz atma adaptörü

MONTAJ

UYARI! Kazara çalıştırmayı önlemek için aşağıdaki işlemleri

yapmadan önce aleti kapatın ve fişini çekin. Bunların

yapılmaması ciddi yaralanmaya yol açabilir.

Freze ucunun takılması (Şekil B)

• Talaş deflektörünü (8) çıkartın.

• Mil kilidi düğmesini (5) basılı tutun ve mil kilidi tamamen

tutunana kadar mili döndürün.

• Verilen somun anahtarını kullanarak uç girişi somunlarını

(12) gevşetin.

• Freze ucunun (13) sapını uç girişine (6) sokun. Sapın,

şekilde gösterildiği gibi uç girişinden en az 3 mm dışarı

çıktığından emin olun.

• Mil kilitleme düğmesini (5) basılı tutun ve uç girişi

somununu (12) verilen somun anahtarını kullanarak

sabitletin.

Kenar kılavuzunun takılması (Şekil C)

Kenar kesme kılavuzu, aleti bir kenara paralel olarak

ilerletmenize yardımcı olur.

• Çubukları (14), verilen iki vidayı (16) kullanarak kenar

kesme kılavuzuna (15) takın.

• Çubukları (14) gösterildiği şekilde freze tabanına sokun.

• Kenar kesme kılavuzunu istenilen mesafeye ayarlayın.

• Tespit vidalarını (17) sıkın.

Toz atma adaptörünün takılması (Şekil D)

Toz atma adaptörü alete bir elektrikli süpürge bağlamanızı

sağlar.

• Elektrikli süpürgenin hortumunu (18) adaptöre (11)

bağlayın.

Şablon siperliğinin takılması (Şekil E)

(Şablon siperliği alet ile birlikte

verilmemektedir)

• Şablon siperliğini (19) flanşla alt (iş parçası) tarafa, freze

tabanına takın.

• Alt taraftaki iki uzun vidayı (20) şablon siperliği ve

tabandaki deliklerden geçirin.

• Her bir vidanın üzerine bir somun yerleştirin ve

somunları iyice sıkın.

Mesafe parçasının takılması (Şekil F)

(Mesafe parçası alet ile birlikte

verilmemektedir)

• Mesafe parçasını (21), verilen iki vidayı kullanarak

frezenin tabanına takın.

Merkezleme piminin takılması (Şekil G)

(Merkezleme pimi alet ile birlikte

verilmemektedir)

• Merkezleme pimini (22) verilen vida (23) ile kenar

kılavuzu çubuğunun iş parçası tarafına takın ve verilen

çelik düğme (23) ile sabitleyin.

Kopya çıkarıcı ucun takılması (Şekil H)

(Kopya çıkarıcı alet ile birlikte

verilmemektedir)

• Kenar kesme kılavuzunu, Şekil C’de gösterildiği şekilde

frezeye takın.

• Çubuğu (24), verilen iki vida ve somunu kullanarak uç

siperliğinin üst tarafına takın.

• Çubuktaki dönme ataşmanını (25) kanat düğmesi (26) ile

ayarlayın.

KULLANIM

UYARI! Aletin kendi hızında çalışmasına izin verin. Aşırı

yüklenmeyin.

• Kaza ile kablonun kesilmesini önlemek için çalışırken

kabloya dikkat edin.

16

Page 17

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Kesim derinliğinin ayarlanması

(Şekil I, J ve K)

• Kesim derinliği, derinlik ayar çubuğu (9) ile derinlik stobu

(7) arasındaki “X” mesafesidir.

• Kesim derinliği aşağıda açıklandığı gibi iki farklı şekilde

ayarlanabilir.

Kesim derinliğinin ölçek kullanılarak

ayarlanması (Şekil J)

• Freze ucunu yukarı açıklandığı şekilde takın.

• Kilitleme vidasını (28) gevşetin.

• Piston kilitleme kolunu (4) yukarı çekin.

• Frezeyi freze ucu çalışma parçasına dokunana kadar

itin.

• Piston kilitleme kolunu (4) aşağı itin.

• İşaretçiyi (29) ölçeğin (10) üzerindeki sıfır konumuna

getirin .

• İstediğiniz kesim derinliğini başlangıç konumuna ekleyin.

• Derinlik ayar çubuğunu (9) ölçekteki hesaplanmış

konuma getirin.

• Kilitleme vidasını (28) sıkın.

• Ayarlama düğmesini (30) kullanarak ince ayar yapın.

• Piston kilitleme kolunu (4) yukarı çekin ve frezenin

başlangıç konumuna dönmesine izin verin.

• Frezeyi açtıktan sonra, aşağı itin ve istediğiniz kesimi

gerçekleştirin.

Kesim derinliğinin bir parça tahta ile

ayarlanması (Şekil K)

• Freze ucunu takın ve frezeyi yukarıda açıklandığı şekilde

aşağı itin.

• Derinlik ayar çubuğunu (9) yukarı çekin.

• İstenilen kesim derinliği kalınlığındaki bir parça tahtayı

derinlik stobu (7) ve derinlik ayar çubuğu (9) arasına

yerleştirin.

• Kilitleme vidasını (28) sıkın.

• Ayarlama düğmesini (30) kullanarak ince ayar yapın.

• Tahta parçasını kaldırın.

• Piston kilitleme kolunu (4) yukarı çekin ve frezenin

başlangıç konumuna dönmesine izin verin.

• Frezeyi açtıktan sonra, aşağı itin ve istediğiniz kesimi

gerçekleştirin.

Rotatif derinlik ayarının ayarlanması (Şekil L)

Rotatif derinlik ayarını istediğiniz ayara çevirdikten sonra,

kullanılacak derinlik ayarına ince ayar yapabilirsiniz. Farklı

kesim derinliklerine sahip birkaç kesim yapmak istiyorsanız

her bir derinlik ayarını yapın.

Hızın ayarlanması

Hız kontrol düğmesini (3) gerekli hız değerine getirin. Küçük

çaplı freze uçları için yüksek bir hız kullanın. Büyük çaplı

freze uçları için düşük bir hız kullanın.

Toz atma adaptörünün takılması (Şekil M)

Kesme kılavuzunun kullanılamadığı durumlarda, örneğin

kitaplığın raflarını desteklemek için arka panelindeki oyukları

frezelerken, aşağıdaki şekilde devam edin:

• Takoz olarak kullanmak için düzgün kenarlı bir tahta

parçası seçin.

• İş parçası üzerine bir takoz yerleştirin.

• Takozu, alete yol gösterecek doğru konuma yerleşene

kadar hareket ettirin.

• Takozu iş parçasına iyice sıkıştırın.

Şablon siperliğinin kullanılması (Şekil E)

Şablon siperliği, bir şablondan örneğin bir harf gibi kesilmiş

bir şekil hazırlamak için kullanılabilir.

• Şablonu çift taraflı bir bant veya «G» kelepçeleri ile iş

parçasının üzerine sabitleyin.

• İş parçasını şablon şeklinde kesmek için freze ucunun

şablon siperliğinin flanşının altına kadar uzanması

gerekir.

Mesafe parçasının kullanılması (Şekil F)

(Mesafe parçası alet ile birlikte

verilmemektedir)

Mesafe parçası, ahşap kesmek veya dikey olarak

katmanlara ayırmak için kullanılabilir.

Merkezleme piminin kullanılması (Şekil G)

(Merkezleme pimi alet ile birlikte

verilmemektedir)

Merkezleme pimi yuvarlak modelleri kesmek için

kullanılabilir.

• Merkezleme piminin ucu için, kesilecek dairenin

merkezinde bir delik açın.

• Frezeyi, merkezleme piminin ucu deliğe gelecek şekilde

iş parçasının üzerine yerleştirin.

• Kenar kesme kılavuzunun çubukları ile dairenin

yarıçapını ayarlayın.

• Freze artık daireyi kesmek için iş parçasının üzerinde

hareket ettirilebilir.

17

Page 18

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

Kopya çıkarıcı ucun kullanılması (Şekil H)

(Kopya çıkarıcı alet ile birlikte

verilmemektedir)

Kopya çıkarıcı uç, yamuk şekilli iş parçalarının kenarı

boyunca eşit bir kesim mesafesi sağlamaya yardımcı olur.

• Frezeyi, kopyalanacak kenardan istediğiniz bir mesafede

iş parçasının üzerine yerleştirin.

• Tekerlek, iş parçası ile temas edene kadar uç siperliğinin

çubuklarını ayarlayın.

Açılması ve kapatılması

Açılması

• Kesintisiz çalıştırma düğmesini (2) basılı tutarak

açma/kapama düğmesine (1) basın.

• Kesintisiz çalıştırma düğmesini bırakın.

Kapatılması

• Açma/kapama düğmesini bırakın.

UYARI! Aleti daima iki elinizle tutarak çalıştırın.

Yararlı tavsiyeler

• Dış kenarlarda çalışırken aleti saatin tersi yönde hareket

ettirin (Şekil M). İç kenarlarda çalışırken, aleti saat

yönünde hareket ettirin.

• Yumuşak ahşaplar için HSS freze uçlarını kullanın.

• Sert ahşaplar için TCT freze uçlarını kullanın.

• Aleti siperliksiz kullanabilirsiniz (Şekil O). Bu özgün ve

yaratıcı işler için kullanışlıdır. Sadece yüzeysel kesimler

yapın.

• Yaygın freze ucu tipleri için aşağıdaki tabloya bakın.

Freze uçları (ilave aksesuar) (Şekil P)

Tanım Uygulama

Düz uç (1) Oyuklar alçak kısımlar

Laminatlar veya sert ahşapları

Kesme ucu (2)

Alçaltma ucu (3)

V-oyuk açma ucu (4)

Çekirdek kalıbı ucu (5)

Girinti ucu (6)

S biçimi kalıbı çıkarma ucu (7)

Yuvarlama ucu (8) Kenarları yuvarlama

Kurtağzı ucu (9) Kurtağzı eklemeleri

Pah ucu (10) Pahlı kenarlar

kesme; şablon kullanarak doğru

profil oluşturma

Düz veya kavisli iş parçalarını

alçaltma

Oyuklar, oyma ve dekoratif

kenar kalıbı çıkarma

Oluk açma, oyma ve dekoratif

kenar kalıbı çıkarma

Dekoratif kenar kalıbı çıkarma

Dekoratif kenar kalıbı çıkarma

BAKIM

Stanley aletiniz minimum bakımla uzun bir süre çalışacak

şekilde tasarlanmıştır. Kesintisiz olarak memnuniyet verici bir

şekilde çalışması gerekli özenin gösterilmesine ve düzenli

temizliğe bağlıdır.

UYARI! Ciddi yaralanma riskini azaltmak için herhangi

bir ayar yapmadan ya da parça veya aksesuarları söküp

takmadan önce aleti kapatın ve güç kaynağından ayırın.

Aleti yeniden bağlamadan önce aletin kapalı olduğundan

emin olmak için tetik düğmesine basıp bırakın.

UYARI! Elektrikli/şarjlı alet üzerinde herhangi bir bakım

işlemi gerçekleştirmeden önce:

Yağlama

Stanley el aletleri, fabrikada uygun bir şekilde yağlanmıştır

ve çalışmaya hazırdır.

Aletler, kullanımına bağlı olarak, her sene düzenli bir şekilde

yağlanmalıdır. (Ağır hizmet tipi işlerde kullanılan ve ısıya

maruz kalan aletlere daha sık yağlama gerekebilir.) Bu

yağlama sadece Stanley servislerindeki gibi eğitimli elektrikli

el aleti tamir personeli tarafından yapılmalıdır.

Temizleme

UYARI! Aletinizdeki havalandırma deliklerini

yumuşak bir fırça veya kuru bir bezle düzenli

olarak temizleyin.

UYARI! Aletin metalik olmayan parçalarını

temizlemek için asla çözücü veya başka sert

kimyasal kullanmayın. Bu kimyasallar bu

parçalarda kullanılan malzemeleri güçsüzleştirir.

Aleti temizlemek için, sadece yumuşak sabun ve

nemli bir bez kullanın. Aletin içine sıvı kaçmasına

kesinlikle izin vermeyin; aletin herhangi bir

parçasını bir sıvı içine daldırmayın.

ÖNEMLİ! Alet EMNİYET GÜVENLİĞİ ve

GÜVENİLİRLİK için bu kılavuzda belirtilenler

dışında tamir, bakım ve ayarlamaların her zaman

orijinal yedek parça kullanılarak, yetkili servisler

tarafından yapılması gerekmektedir. Aletin içinde

bakımı kullanıcı tarafından yapılabilecek

herhangi bir parça yoktur.

İlave Aksesuarlar

UYARI! Stanley tarafından tedarik veya tavsiye

edilenlerin dışındaki aksesuarlar bu ürün

üzerinde test edilmediğinden, söz konusu

aksesuarların bu aletle birlikte kullanılması tehlikeli olabilir.

Yaralanma riskini azaltmak için bu ürünle birlikte sadece

Stanley tarafından tavsiye edilen aksesuarlar kullanılmalıdır.

18

Page 19

(Çevirisi orijinal talimatlardan yapılmıştır) TÜRKÇE

Herhangi bir elektrikli aletin performansı kullanılan

aksesuarlara bağlıdır. Stanley aksesuarları, yüksek kalite

standartlarına göre üretilmiş ve elektrikli aletinizin

performansını arttıracak şekilde tasarlanmıştır. Stanley

aksesuarlarını kullanmak, Stanley aletinizden en iyi verimi

almanızı sağlayacaktır. Stanley satış noktalarından veya

yetkili servisten temin edilebilir geniş bir aksesuar çeşidi

sunar.

Notlar

Stanley politikası gibi, ürünlerimizi sürekli iyileştirme

amacıyla önceden haber vermeden ürün özelliklerini

değiştirme hakkını saklı tutarız. Standart ekipman ve

aksesuarlar ülkeye göre değişebilir. Ürün özellikleri ülkelere

göre farklı olabilir. Komple ürün çeşidi tüm ülkelerde geçerli

olmayabilir. Ürün çeşidi durumu hakkında lütfen en yakın

Stanley yetkili servisiyle temas kurun.

Çevrenin korunmasi

Ayrı olarak atın. Bu ürün, normal evsel atıklarla

birlikte atılmamalıdır.

STANLEY ürününüzün değiştirilmesi gerektiğini düşünmeniz

veya artık kullanılamaz durumda olması halinde onu, evsel

atıklarla birlikte atmayın. Bu ürünü, ayrı olarak toplanacak

şekilde atın.

STANLEY, hizmet ömrünün sonuna ulaşan

STANLEY ürünlerinin toplanması ve geri dönüşüme

sokulması için bir imkân sunmaktadır. Bu hizmetin

avantajlarından faydalanmak için, lütfen, ürününüzü bizim

adımıza teslim alacak herhangi bir yetkili servise iade edin.

Bu kılavuzda belirtilen listeden size en yakın STANLEY

yetkili tamir servisinin yerini öğrenebilirsiniz. Ya da, alternatif

olarak internet’ten STANLEY yetkili tamir servislerinin

listesini ve satış sonrası hizmetlerimizle ilgili tüm bilgiler ve

temas bilgilerine aşağıdaki siteden ulaşabilirsiniz.

www.2helpU.com

SERVİS BİLGİLERİ

STANLEY, kendisine ait ve yetkili servisler ile tam bir servis

ağı sunmaktadır. Tüm STANLEY Servis Merkezleri

müşterilere etkili ve güvenilir elektrikli el aleti hizmeti sunmak

için eğitimli personel ile donatılmıştır. Yetkili servis

merkezlerimiz hakkında daha fazla bilgi almak istiyorsanız

veya teknik danışmanlık, onarım ya da orijinal fabrika yedek

parçası ihtiyacınız varsa, size en yakın STANLEY satış

noktasına başvurun.

TEKNİK ÖZELLİKLERİ

EL FREZESİ SRR1200

Voltaj V 220-240

Frekans Hz 50/60

Güç W 1200

Yüksüz hızı dev/dak 8000 - 27000

Uç girişi mm 6, 6,35, 8

Kablo uzunluğu m 3

EN 60745’e göre ses basıncı düzeyi:

Ses basıncı (LpA) 91,5 dB(A), belirsizlik (K) 3 dB(A)

Akustik güç (LwA) 102,5 dB(A), belirsizlik (K) 3 dB(A)

Titreşim emisyon değeri ah:

ah = 4,0 m/s²

belirsizlik (K) = 1,5 m/s

Teknik veriler ve uygunluk beyanatı içerisinde belirtilen

titreşim emisyon değerleri EN60745 tarafından belirlenen

standart bir test yöntemine uygun olarak ölçülmektedir ve

diğer bir aletle karşılaştırma yaparken kullanılabilir. Beyan

edilen titreşim emisyon değeri aynı zamanda maruz

kalmanın önceden değerlendirilmesinde de kullanılabilir.

Uyarı: Elektrikli aletin mevcut kullanımı

sırasındaki titreşim emisyon değeri, aletin

kullanım yöntemine bağlı olarak, beyan edilen

değere göre farklılık sergileyebilir. Titreşim düzeyi belirlenen

seviyenin üzerinde artış gösterebilir.

İşyerinde düzenli olarak elektrikli alet kullanan çalışanları

korumak amacıyla 2002/44/EC tarafından getirilen elektrik

güvenliği önlemlerini belirlemek üzere titreşime maruz

kalmayı değerlendirirken, çalışma döngüsü içerisinde

örneğin aletin kapalı olduğu ve aktif durumda olmasının yanı

sıra boşta çalıştığı zamanlar gibi, bütün zaman dilimleri dahil

olmak üzere mevcut kullanım durumu ve aletin kullanım şekli

göz önünde bulundurularak değerlendirilmelidir.

2

19

Page 20

TÜRKÇE (Çevirisi orijinal talimatlardan yapılmıştır)

AT Uygunluk Beyanatı

MAKİNE DİREKTİFİ

SRR1200 El Frezesi

STANLEY, «teknik özellikleri» bölümünde açıklanan bu

ürünlerin aşağıda belirtilen yönergelere uygun olduğunu

beyan eder: 2006/42/EC, EN 60745-1:2009 + A11:2010,

EN 60745-2- 17:2010

Bu ürünler ayrıca 2014/30/EU ve 2011/65/EU Direktiflerine

de uygundur.

Daha fazla bilgi için, lütfen aşağıdaki adresten STANLEY ile

irtibata geçin veya kılavuzun arkasına bakın.

Bu belge altında imzası bulunan yetkili, teknik dosyanın

derlenmesinden sorumludur ve bu beyanı STANLEY adına

vermiştir.

R.Laverick

Mühendislik Bölümü Müdürü

STANLEY , Europe, Egide Walschaertsstraat14-18,

2800 Mechelen, Belçika

01.2017

İki yıl garanti

Sahip olduğunuz STANLEY ürünü satın alma tarihinden

itibaren 24 ay içinde hatalı malzeme veya işçilik nedeniyle

bozulursa, STANLEY aşağıdaki şartlara uyulması koşuluyla

ücretsiz olarak tüm kusurlu parçaların yenilenmesini veya

-kendi inisiyatifine bağlı olarak- satın alınan ürünün

değiştirilmesini garanti eder:

• Ürün, hatalı kullanılmamış kullanım kılavuzuna uygun

kullanılmıştır.

• Ürün yıpranmamış, hırpalanmamış ve aşınmamıştır;

• Yetkili olmayan kişilerce tamire çalışılmamıştır.

• Satın alma belgesi (fatura) ibraz edilmiştir;

• STANLEY ürünü, tüm orijinal parçaları ile birlikte iade

edilmiştir;

• Ürün kiralama amacıyla kullanılmamıştır.

Garanti talebinde bulunmak için, lütfen satıcıyla irtibata geçin

veya STANLEY katalogunda belirtilen size en yakın

STANLEY yetkili satıcı adresini kontrol edin veya ürünün

kılavuzunda belirtilen adresteki yerel STANLEY yetkili tamir

servisi ile temas kurun. İnternet’ten STANLEY yetkili tamir

servislerinin listesine ve satış sonrası hizmetlerimizle ilgili

tüm bilgilerine aşağıdaki siteden ulaşabilirsiniz:

www.2helpU.com

Sanayi ve Ticaret Bakanlığı tebliğince kullanım ömrü 7 yıldır.

Türkiye Distribütörü

STANLEY BLACK&DECKER TURKEY ALET URETIM SAN.

TIC. LTD.STI.

Kozyatağı Mh Değirmen Sk. Nida Kule

No:18 Kat:6 34742 Kadıköy İstanbul

Tel : (0216) 665 29 00

Faks : (0216) 665 29 01

E-posta: info-tr@sbdinc.com

14

20

Page 21

(Перевод с оригинала инструкции) РУССКИЙ

Назначение

Ваш фрезер Stanley SRR1200 предназначен для

фрезерования древесины и изделий из дерева. Данный

инструмент предназначен для профессионального

использования.

ИНСТРУКЦИИ ПО ТЕХНИКЕ

БЕЗОПАСНОСТИ

Общие правила безопасности при работе с

электроинструментами

ВНИМАНИЕ! Внимательно прочтите все

инструкции по безопасности и

руководство по эксплуатации.

Несоблюдение всех перечисленных ниже правил

безопасности и инструкций может привести к

поражению электрическим током, возникновению

пожара и/или получению тяжёлой травмы.

Сохраните все инструкции по безопасности и

руководство по эксплуатации для их дальнейшего

использования. Термин «Электроинструмент» во всех

привёденных ниже указаниях относится к Вашему

сетевому (с кабелем) или аккумуляторному

(беспроводному) электроинструменту.

1. Безопасность рабочего места

а. Содержите рабочее место в чистоте и хорошо

освещенным. Беспорядок на рабочем месте или

отсутствие освещения рабочего места может

привести к аварии.

b. Не работайте с электроинструментом в месте

хранения взрывоопасных материалов,

например, в присутствии огнеопасных

жидкостей, газов или пыли. Электрические

инструменты создают искры, которые могут

воспламенить пыль или пары.

с. Дети и посторонние лица должны находиться как

можно дальше во время работы с

электроинструментом. Вы можете отвлечься и

потерять контроль.

2. Электробезопасность

а. Вилка электроинструмента должна

соответствовать розетке. Никогда не

модифицируйте вилку каким-либо образом. Не

используйте никакие вилки-переходники с

заземленными (замкнутыми на землю)

электроинструментами. Вилки и розетки, которые

не подвергались никаким изменениям снижают риск

поражения электрическим током.

b. Избегайте контакта тела с заземленными

поверхностями, такими как трубы, радиаторы,

плиты и холодильники. Существует повышенный

риск поражения электрическим током, если ваше

тело заземлено.

с. Избегайте любого воздействия дождя или влаги

на электроинструменты. Вода, попавшая в

электроинструмент, увеличивает риск поражения

электрическим током.

d. Аккуратно обращайтесь со шнуром питания.

Никогда не используйте шнур питания для

переноски, перемещения или извлечения вилки

из розетки. Держите шнур вдали от источников

тепла, масла, острых краев или движущихся частей.

Поврежденные или запутанные шнуры увеличивают

риск поражения электрическим током.

е. При работе с электроинструментом на улице,

используйте удлинитель, подходящий для

наружного использования. Использование кабеля,

пригодного для использования на открытом воздухе,

снижает риск поражения электрическим током.

f. При необходимости работы с

электроинструментом во влажной среде,

используйте устройство защитного отключения

(УЗО). Использование УЗО снижает риск поражения

электрическим током. ПРИМЕЧАНИЕ: Термин

«устройство защитного отключения (УЗО)» может

быть заменён на «аварийный прерыватель

заземления» или «автоматический выключатель тока

утечки».

3. Личная безопасность

a. Будьте внимательны, смотрите, что вы делаете,

используйте здравый смысл при работе с

электроинструментом. Не используйте

электроинструмент, если вы устали или находитесь

под влиянием наркотиков, алкоголя или лекарств.

Малейшая неосторожность при работе с

электроинструментом может привести к серьезным

травмам.

b. Используйте средства индивидуальной защиты.

Всегда надевайте защитные очки. Другое

защитное оборудование, включая респиратор,

ботинки на нескользящей подошве, защитный

шлем или средства защиты органов слуха,

используемые в надлежащих условиях, уменьшат

риск получения травмы.

с. Для предотвращения случайного запуска,

убедитесь, что переключатель находится в

выключенном положении перед подключением к

источнику питания и/или аккумуляторной

батарее, поднятия или переноски инструмента. Не

переносите электроинструмент с пальцем на

выключателе и не включайте питание на инструмент

с включенным выключателем, что может привести к

несчастному случаю.

1521

Page 22

РУССКИЙ (Перевод с оригинала инструкции)

d. Перед включением электроинструмента

снимайте регулировочный или гаечный ключ.

Гаечный или регулировочный ключ, оставленный на

вращающейся части электроинструмента, может

привести к травме.

е. Не тянитесь. Сохраняйте правильную стойку и

баланс все время. Это позволяет лучше

контролировать инструмент в неожиданных

ситуациях.

f. Одевайтесь правильно. Не надевайте свободную

одежду или украшения. Держите волосы, одежду

и перчатки вдали от движущихся частей.

Свободная одежда, украшения или длинные

волосы могут попасть в движущиеся части.

g. Если имеются устройства для подключения

пылесборника или вытяжки, убедитесь в том,

что они подсоединены и используются

правильно. Использование пылесборника снижает

вероятность возникновения рисков, связанных с

пылью.

4. Использование и уход за электроинструментом

a. Не перегружайте электроинструмент.

Используйте подходящий электрический

инструмент для соответствующего применения.

Правильно подобранный электроинструмент

позволит выполнить работу лучше и безопаснее при

скорости, для которой он был разработан.

b. Не используйте электроинструмент, если

переключатель не может его включить и

выключить. Любой электроинструмент, который

нельзя контролировать с помощью переключателя,

опасен и должен быть отремонтирован.

c. Отключите кабель питания от источника питания

и/или аккумуляторный блок от электрического

инструмента перед выполнением любых

регулировок, замены принадлежностей или при

хранении электроинструмента. Такие

профилактические меры безопасности уменьшают

риск непреднамеренного запуска электрического

инструмента.

d. Храните неиспользуемые электроинструменты в

недоступном для детей месте и не позволяйте

лицам, не знакомым с электроинструментом или

данными инструкциями, работать с

электроинструментом. Электроинструменты опасны

в руках неопытных пользователей.

е. Поддержание электроинструмента. Проверяйте

разрегулированность или cоединение

подвижных частей, поломки частей и любые

другие условия, которые могут повлиять на

работу электроинструмента. При наличии

повреждения, отремонтируйте

электроинструмент перед использованием.

Многие несчастные случаи являются следствием

плохого ухода за электроинструментом.

f. Держите режущий инструмент острым и чистым.

Хорошо ухоженный режущий инструмент с острыми

режущими кромками легче контролировать.

g. Используйте электроинструмент,

принадлежности, насадки и т.д. в соответствии с

этими инструкциями, принимая во внимание

рабочие условия и характер выполняемой

работы Использование электроинструмента иным

способом может привести к опасным ситуациям.

5. Обслуживание

а. Обеспечьте, чтобы обслуживание и ремонт

вашего электроинструмента проводился в

авторизованном сервисном центре по ремонту с

использованием только оригинальных запасных

частей. Это станет гарантией безопасности

электроинструмента.

ДОПОЛНИТЕЛЬНЫЕ ПРАВИЛА

БЕЗОПАСНОСТИ ПРИ РАБОТЕ

ФРЕЗЕРАМИ

• Держите электроинструмент за изолированные

поверхности, поскольку фреза может задеть

собственный кабель. Разрезание находящегося

под напряжением провода делает не покрытые

изоляцией металлические части электроинструмента

«живыми», что создает опасность поражения

электрическим током.

• Используйте струбцины или другие

приспособления для фиксации обрабатываемой

детали, устанавливая их только на неподвижной

поверхности. Если держать обрабатываемую

деталь руками или с упором в собственное тело, то

можно потерять контроль над инструментом или

обрабатываемой деталью.

• Диаметр хвостовика используемой фрезы должен

соответствовать размерам цангового патрона Вашего

фрезера.

• Используйте только фрезы, пригодные для скорости

вращения без нагрузки данного фрезера.

22

Page 23

(Перевод с оригинала инструкции) РУССКИЙ

• Ни в коем случае не используйте фрезы диаметром

больше максимального диаметра, указанного в

разделе «Технические характеристики».

• Не используйте фрезер в перевернутом положении.

• Не пытайтесь использовать Ваш фрезер в

стационарном режиме.

• Соблюдайте особую осторожность при

фрезеровании ДСП или поверхностей, покрытых

красками на свинцовой основе.

• Надевайте респиратор, специально разработанный

для защиты от пыли и паров, выделяемых красками

на свинцовой основе, и следите, чтобы лица,

находящиеся в рабочей зоне, также были

обеспечены средствами индивидуальной защиты.

• Не позволяйте детям или беременным женщинам

находиться в рабочей зоне.

• Не принимайте пищу, не пейте и не курите в рабочей

зоне.

• Удаляйте частицы пыли и прочие отходы

безопасным для окружающей среды способом.

• Всегда надевайте респиратор.

• Использование инструмента детьми и неопытными

лицами допускается только под контролем

ответственного за их безопасность лица. Не

позволяйте детям играть с инструментом.

ЛИЧНАЯ БЕЗОПАСНОСТЬ

• Не допускайте детей или беременных женщин в

рабочую зону, где выполняется шлифование

окрашенных поверхностей до тех пор, пока рабочая

зона не будет полностью очищена.

• Все люди, входящие в рабочую зону, должны

надевать пылезащитные маски или респираторы.

Фильтр следует заменять ежедневно или по мере

его загрязнения.

Примечание: Следует использовать только те

пылезащитные маски, которые предназначены для

работы с пылью и парами красок, содержащих

свинец. Обычные маски для лакокрасочных работ

не обеспечивают достаточной защиты. Купите в

строительном магазине респиратор, утверждённого

Национальным институтом США по охране труда и

промышленной гигиене (NIOSH) типа.

МАРКИРОВКА ИНСТРУМЕНТА

На приборе имеются следующие знаки по коду даты:

ВНИМАНИЕ! Полное ознакомление с

руководством по эксплуатации перед

использованием инструмента снизит риск

получения травмы.

Используйте средства защиты органов слуха.

Надевайте защитные очки или маску.

V Вольт

A Ампер n

Hz Герц

W Ватт

min минут

Переменный

ток

Место положения кода даты (Рис. А)

Код даты, который также включает в себя год

изготовления, отштампован на поверхности корпуса

инструмента.

Пример:

2016 XX JN

Год изготовления

Постоянный ток

Скорость без нагрузки

0

Конструкция Класса II

Клемма заземления

Символ опасности

Кол-во оборотов или

/min.

шагов в минуту

КОМПЛЕКТ ПОСТАВКИ

В упаковку входят:

1 Фрезер

3 Цанговых патрона: 6 мм, 6,35 мм и 8 мм

1 Направляющая для кромки

2 Стержня направляющей для кромки

1 Переходник для подключения устройства

пылеудаления

1 Ключ

6 Фрез (дополнительные принадлежности; могут

отсутствовать в комплекте поставки)

1 Руководство по эксплуатации

23

Page 24

РУССКИЙ (Перевод с оригинала инструкции)

• Проверьте инструмент, детали и дополнительные

приспособления на наличие повреждений, которые

могли произойти во время транспортировки.

• Перед началом работы необходимо внимательно

прочитать настоящее руководство и принять к

сведению содержащуюся в нем информацию.

ЭЛЕКТРОБЕЗОПАСНОСТЬ

Данный инструмент защищён двойной

изоляцией, что исключает потребность в

заземляющем проводе. Всегда проверяйте,

соответствует ли напряжение, указанное на

табличке с техническими параметрами,

напряжению электросети.

ВНИМАНИЕ! Во избежание повреждений или

получения травмы, замена повреждённого

кабеля питания должна производиться только

на заводе-изготовителе, в авторизованном

сервисном центре Stanley или

квалифицированным персоналом. При

замене кабеля питания квалифицированным

лицом, но не имеющим авторизацию Stanley,

гарантия на продукт будет недействительной.

ИСПОЛЬЗОВАНИЕ УДЛИНИТЕЛЬНОГО

КАБЕЛЯ

При необходимости использования удлинительного

кабеля, используйте только утверждённые кабели

промышленного изготовления, рассчитанные на

мощность не меньшую, чем потребляемая мощность

данного инструмента. Минимальный размер проводника

должен составлять 1,5 мм². При использовании

кабельного барабана, всегда полностью разматывайте

кабель.

Поперечное сечение

проводника (мм2)

Номинал кабеля (Ампер)

0,75 6

1,00 10

1,50 15

2,50 20

4,00 25

Поперечное сечение

проводника (мм2)

Номинал кабеля (Ампер)

Длина кабеля (м)

7,5 15 25 30 45 60

Напряжение

110-127 0 - 2,0 6 6 6 6 6 10

220-240 0 - 2,0 6 6 6 6 6 6

Ампер Номинал кабеля (Ампер)

2,1 - 3,4 6 6 6 6 15 15

3,5 - 5,0 6 6 10 15 20 20

5,1 - 7,0 10 10 15 20 20 25

7,1 - 12,0 15 15 20 25 25 -

12,1 - 20,0 20 20 25 - - -

2,1 - 3,4 6 6 6 6 6 6

3,5 - 5,0 6 6 6 6 10 15

5,1 - 7,0 10 10 10 10 15 15

7,1 - 12,0 15 15 15 15 20 20

12,1 - 20,0 20 20 20 20 25 -

ОПИСАНИЕ (Рис. А)

Данный инструмент может содержать все или некоторые

из перечисленных ниже составных частей:

1. Пусковой выключатель

2. Кнопка защиты от непреднамеренного пуска

3. Поворотный переключатель скорости вращения

электродвигателя

4. Рычаг стопора

5. Кнопка блокировки шпинделя

6. Цанговый патрон

7. Револьверный ограничитель глубины фрезерования

8. Щиток для отвода опилок

9. Шток ограничителя глубины

10. Шкала глубины фрезерования

11. Переходник для подключения устройства

пылеудаления

СБОРКА

ВНИМАНИЕ! Чтобы избежать случайного включения,

перед проведением нижеследующих действий

выключите инструмент и отсоедините его от источника

питания. Несоблюдение этого требования может

привести к получению тяжёлой травмы.

24

Page 25

(Перевод с оригинала инструкции) РУССКИЙ

Установка фрезы (Рис. В)

• Снимите с инструмента щиток для отвода опилок (8).

• Удерживая нажатой кнопку блокировки шпинделя

(5), поворачивайте шпиндель до его ощутимой

фиксации.

• Ослабьте гайку цангового патрона (12) входящим в

комплект поставки гаечным ключом.

• Вставьте хвостовик фрезы (13) в цанговый патрон

(6). Убедитесь, что хвостовик выступает из цангового

патрона минимум на 3 мм, как показано на рисунке.

• Удерживая нажатой кнопку блокировки шпинделя

(5), затяните гайку (12) цангового патрона входящим

в комплект поставки гаечным ключом.

Установка направляющей для кромки

(Рис. C)

Направляющая для кромки позволяет вести фрезер

параллельно кромке заготовки.

• Вставьте стержни (14) в направляющую (15),

используя 2 винта (16), входящие в комплект

поставки.

• Вставьте стержни (14) в основание фрезера, как

показано на рисунке.

• Установите направляющую на необходимом

расстоянии.

• Затяните установочные винты (17).

Установка переходника для подключения

устройства пылеудаления (Рис. D)

• Переходник позволяет подключить к фрезеру

пылесос.

• Подключите шланг пылесоса (18) к переходнику (11).

Установка направляющей для шаблона

(Рис. Е)

(Направляющая для шаблона не входит в

комплект поставки)

• Установите направляющую для шаблона (19) на

основание фрезера, чтобы втулка была направлена

в сторону обрабатываемой заготовки.

• Вставьте оба длинных крепёжных винта (20) с

нижней стороны направляющей в отверстия в

основании.

• На каждый винт наверните гайку и надежно

затяните.

Установка подкладки (Рис. F)

(Подкладки не входит в комплект

поставки инструмента)

Установите подкладку (21) под основание фрезера с

помощью входящих в комплект поставки винтов.

Установка центрирующего штифта (Рис. G)

(Центрирующий штифт не входит в

комплект поставки инструмента)

• Установите центрирующий штифт (22) на стержни

направляющей со стороны заготовки и затяните его

при помощи входящей в комплект поставки стальной

рукоятки (23).

Установка роликового копира (Рис. Н)

(Роликовый копир не входит в комплект

поставки инструмента)

• Установите направляющую на фрезер, как показано

на Рисунке С.

• Установите кронштейн (24) на верхней стороне

направляющей, используя оба входящих в комплект

поставки винта с гайками.

• Закрепите роликовую насадку (25) на кронштейне

барашковым винтом (26).

ЭКСПЛУАТАЦИЯ

ВНИМАНИЕ! Не форсируйте рабочий процесс.

Избегайте перегрузки инструмента.

• Следите за положением кабеля, чтобы случайно его

не разрезать.

Установка глубины фрезерования

(Рис. I, J и K)

• Глубина фрезерования равна зазору «X» между

штоком ограничителя глубины (9) и винтовым упором

(7) ограничителя глубины фрезерования.

• Глубину фрезерования можно установить двумя

различными способами, описанными ниже.

Настройка глубины фрезерования с

помощью шкалы (Рис. J)

• Установите фрезу, как было описано выше.

• Ослабьте установочный винт (28).

• Переведите рычаг стопора (4) в верхнее положение.

• Направляйте фрезер вниз до момента, пока фреза

не войдет в контакт с обрабатываемой заготовкой.

25

Page 26

РУССКИЙ (Перевод с оригинала инструкции)

• Переведите рычаг стопора (4) в нижнее положение.

• Двигая указатель (29), установите его на ноль по

шкале (10).

• Приплюсуйте величину необходимой глубины

фрезерования к начальной позиции.

• Передвиньте шток ограничителя глубины (9) по

шкале на расчетную позицию.

• Затяните установочный винт (28).

• Произведите точное регулирование регулировочной

рукояткой (30).

• Переведите рычаг стопора (4) в верхнее положение

и верните фрезер в исходное положение.

• После включения фрезера, направьте его вниз, и

фрезеруйте в соответствии с установленными Вами

параметрами.

Регулирование глубины фрезерования с

помощью деревянного бруска (Рис. K)

• Установите фрезу и направьте её вниз, как описано

выше.

• Поднимите шток ограничителя глубины (9) вверх.

• Между винтовым упором (7) ограничителя глубины

фрезерования и штоком (9) установите деревянный

брусок, толщина которого равна необходимой

глубине фрезерования.

• Затяните установочный винт (28).

• Произведите точное регулирование регулировочной

рукояткой (30).