Page 1

SRP

COMPACTION

REVERSIBLE PLATE

SRP 2240

SRP 3860

USER MANUAL

Safety, Operation and Maintenance

© 2015 Stanley Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

74922 1/2016 Ver 2

Page 2

DECLARATION OF CONFORMITY

Weisbeck, Andy

Directive/Standards

No.

Approved body

2006/42/EG

2004/108/CE

Self

Self

Measurements:

SRP 2240 Honda

GX120 2.9 kW

SRP 3860 Honda

GX270 6.3 kW

104 dB

105 dB

105 dB*

108 dB*

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

_______________________________________________________ _______________

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

hereby declare that the equipment specified hereunder:, bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:,

déclare que l’équipement visé ci-dessous:, Por la presente declaro que el equipo se especifica a continuación:,

Dichiaro che le apparecchiature specificate di seguito:

Surname and First names/Familiennname und Vornamen/Nom et prénom/ Nombre y apellido/Cognom e e nome

Hydraulic Tools

1. Category:

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca

3. Type/Typ/Type/Tipo/Tipo: SRP 22401H, SRP 38601H

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

5. Mass/Masse/Masse/Masa/Massa 100 kg / 242 kg

Has been manufactured in conformity with, Wurde hergestellt in Übereinstimmung mit, Est fabriqué conformément

Ha sido fabricado de acuerdo con, E’ stata costruita in conformitá con

Richtlinie/Standards

Directives/Normes

Directriz/Los Normas

Direttiva/Norme

Machinery Directive

Nr

Numéro

No

n.

2006/42/EC

2006/42/CE

2000/14/EG

2000/14/EC

2000/14/CE

2005/88EG

2005/88/EC

2005/88/CE

2004/108/EG

2004/108/EC

Stanley

Compaction Reversable Plate

All

Prüfung durch

Organisme agréé

Aprobado

Collaudato

Self

Self

Self

Self

Self

Self

Self

Self

Self

Self

Messungen

Mesures

Mediciones

Misurazioni

6. Special Provisions: Harmonized standards: 7. Measurements: Measured Sound Power Level

Spezielle Bestimmungen: EN 500-1; EN500-4 Messungen Guaranteed Sound Power Level*

Dispositions particulières: Mesures Annex VIII of 2000/14/EC

Provisiones especiales: Mediciones

Disposizioni speciali: Misurazioni

8. Representative in the Union: Patrick Vervier, Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

2 ► SRP 2240 / 3860 User Manual

Done at/Ort/Fait à/Dado en/Fatto a Stanley Hydraulic Tools, Milwaukie, Oregon USA

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione Director of Product Development

Date/Datum/le/Fecha/Data 15-04-2015

Page 3

WARNING

TABLE OF CONTENTS

DECLARATION OF CONFORMITY .......................................................................................................................... 2

TABLE OF CONTENTS .............................................................................................................................................3

SAFETY SYMBOLS ..................................................................................................................................................4

FORWORD ................................................................................................................................................................ 5

SAFETY ................................................................................................................................................................6 - 7

TECHNICAL DATA ...............................................................................................................................................8 - 9

OPERATION .....................................................................................................................................................10 - 14

TRANSPORT ...................................................................................................................................................14 - 16

MAINTENANCE ...............................................................................................................................................17 - 25

TROUBLESHOOTING ............................................................................................................................................26

IMPORTANT

To ll out a Product Warranty Validation form, and for information on your warranty,

visit Stanleyhydraulics.com and select the Company tab, Warranty.

(NOTE: The warranty Validation record must be submitted to validate the warranty).

SERVICING: This manual contains safety, operation, and routine maintenance instructions. Stanley Hydraulic Tools

recommends that servicing this machine, other than routine maintenance, must be performed by an authorized and

certied dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest authorized and certied dealer, call Stanley Hydraulic Tools at the number listed on the back of this

manual and ask for a Customer Service Representative.

SRP 2240 / 3860 User Manual ◄ 3

Page 4

DANGER

WARNING

CAUTION

CAUTION

NOTICE

IMPORTANT

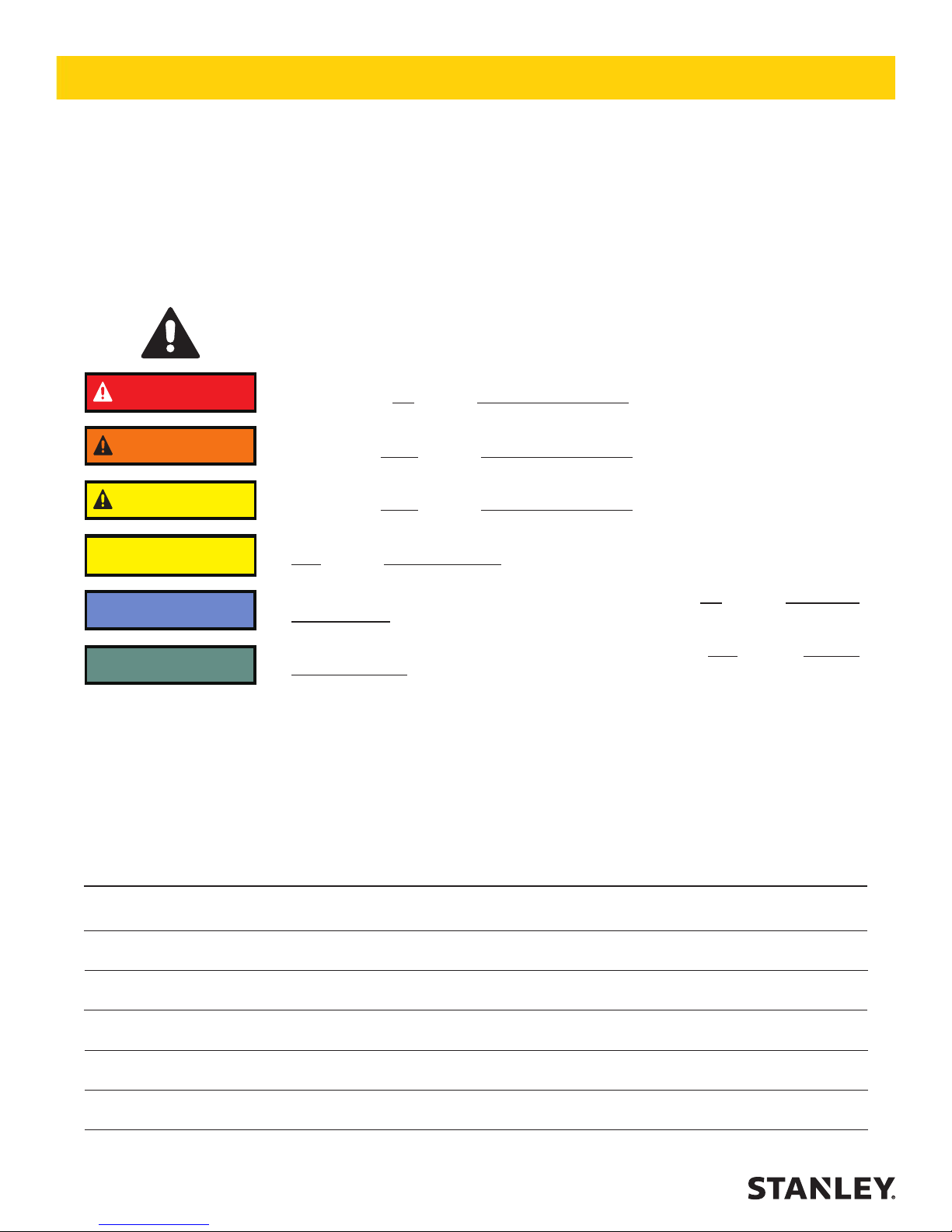

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

This safety alert and signal word indicate an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage to

the equipment.

This signal word indicates a situation which, if not avoided, may result in damage

to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and maintenance personnel.

4 ► SRP 2240 / 3860 User Manual

Page 5

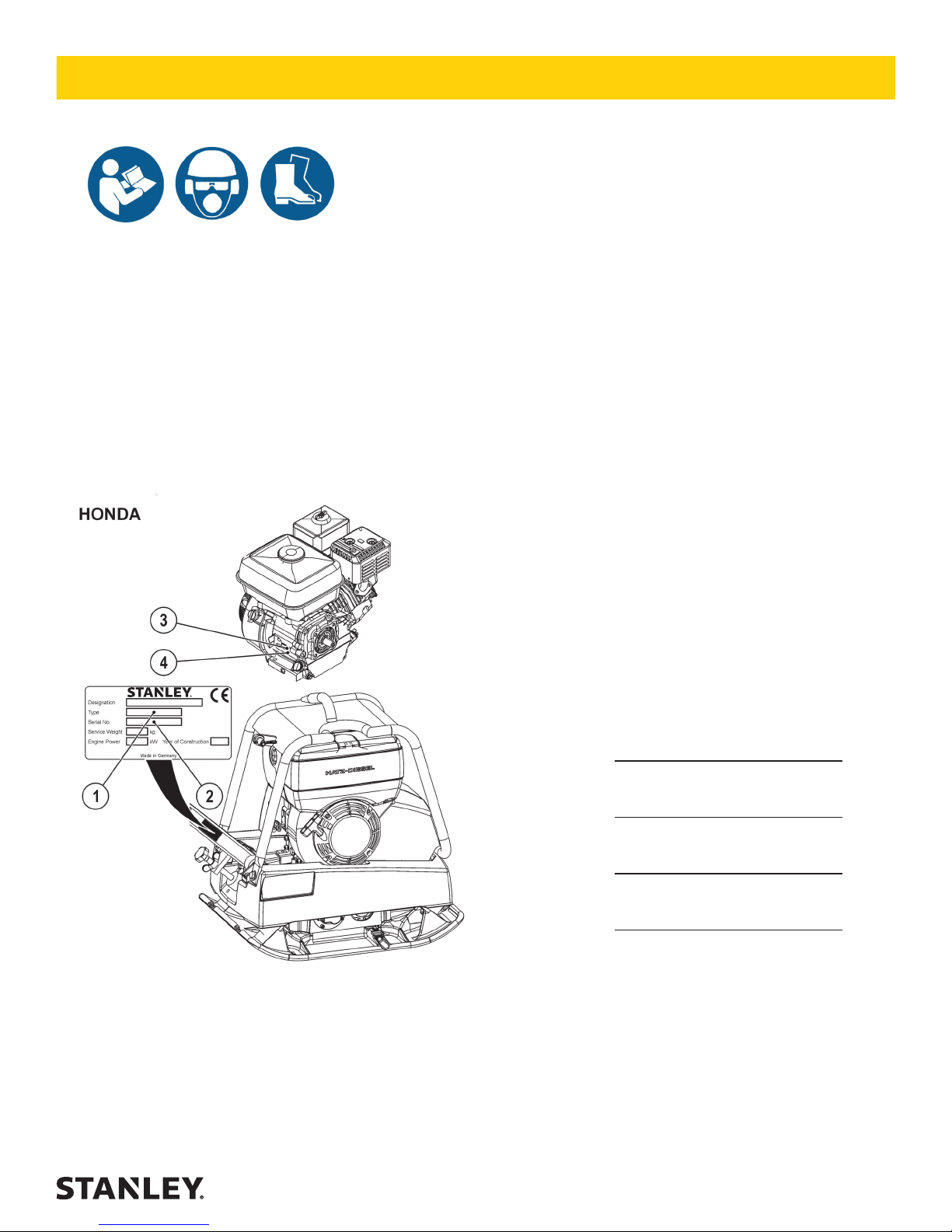

FOREWORD

These instructions include:

• Safety regulations

• Operating instructions

• Maintenance instructions

These instructions have been prepared for operation on the

construction site and for the maintenance engineer.

These instructions are intended to simplify operation of

the machine and to avoid malfunctions through improper

operation. Observing the maintenance instructions will

increase the reliability and service life of the machine when

used on the construction site and reduce repair costs and

downtimes.

Always keep these instructions at the place of use of the

machine.

Only operate the machine as instructed and follow these

instructions.

Also observe the corresponding rules and regulations valid

in your country. Always comply with the safety provisions in

your county and state.

Stanley is not liable for the function of the machine when

used in an improper manner and for other than the intended purpose.

Operating errors, improper maintenance and the use of incorrect operating materials are not covered by the warranty.

The above information does not extend the warranty and

liability conditions of business of Stanley.

We reserve us the right to make changes due to technical

development without announcement.

PLEASE ENTER (DATA ON MACHINE TYPE PLATE)

1. MACH.-TYPE:

2. MACH.-NO.:

3. ENGINE-TYPE:

4. ENGINE-NO.:

Stanley Hydraulic Tools

3810 SE Naef Rd

Milwaukie, OR 97267

Ph: 503-659-5660

Fax: 503-652-1780

www.stanleyhydraulics.com

SRP 2240 / 3860 User Manual ◄ 5

Page 6

SAFETY

This Stanley machine has been built according to the state of the

art in compliance with the pertinent rules. Nevertheless, these

machines can still constitute a hazard to persons and property if:

• not used for the intended purpose,

• not operated by suitably qualied and instructed personnel,

• modied or converted in an improper manner,

• the pertinent safety regulations are not observed

For this reason, any person entrusted with the operation, maintenance or repair of the machine is obliged to read and follow the

operating instructions and particularly to observe the safety

regulations. If necessary, it must be conrmed by the signature of

the company using the machine.

Furthermore, the following must be made known and observed:

• pertinent regulations for the prevention of accidents,

• generally recognized safety rules,

• country-specic regulations

Normal use

The machine is suitable for all compaction jobs in civil works and

road construction. All ground materials such as sand, gravel,

sludge, crushed stone, asphalt and composite sett paving can be

compacted.

Improper use

The machine can constitute hazards if not used by instructed

personnell or for other than the intended purpose.

Weighing down and riding on the machine is forbidden.

The machine must not be used on slopes with a gradient of more

than 25° (Honda 20°).

Do not use the machine on hard concrete, set asphaltic surfaces,

highly frozen or unstable surfaces.

Who is allowed to operate the machine?

Only suitable qualied, instructed and authorised persons over 18

years of age may operate the machine.

In variance from this, minors can be employed, as long as it is

necessary to their training objective and their protection is assured

by a supervisor.

Persons under the inuence of alcohol, medication or drugs must

not operate, maintain or repair the machine.

Maintenance and repairs, in particular of hydraulic systems and

electronic components require special knowledge and must be

carried out only by skilled persons (mechanics specialising in

construction and agricultural machinery).

Conversions and modications to the machine

Unauthorized modications and conversion of the machine are not

permitted for safety reasons.

Spare parts and special equipment not delivered by us are also

not approved by us. The installation and/or the use of such parts

can also have a detrimental effect on the operating safety.

The manufacturer disclaims all liability for any damage resulting

from the use of non-original parts or special equipment.

Safety information contained in the operating and maintenance

instructions

The following terms and symbols are used in this operating

manual that draw attention to important information:

Refers to special information and/or orders and

prohibitions directed towards preventing damage

Attention

Refers to orders and prohibitions designed to

prevent injury or extensive damage.

Danger

Refers to special information on how to use the machine

most efciently.

Important

Transporting the machine

Only load and transport the machine as specied in the operating

instructions.

Only use suitable means of transport and hoisting with sufcient

loading capacity!

Attach suitable slinging means to the points of attachment

provided.

Secure the machine to prevent it from tilting or slipping.

It is highly dangerous to walk or stand under suspended loads.

Secure the machine on transport vehicles to prevent it from

rolling, slipping and tilting.

Starting the machine

Prior to starting

Familiarise yourself with the operating and control elements and

the mode of operation of the machine and the working environment. This includes, e.g. obstacles in the working area, loading

capacity of the ground and the necessary safety provisions.

Use personal protective equipment (safety footwear, hearing

protectors, etc.).

Check to ensure that all safety devices are rmly in place.

Do not start the machine if instruments or control devices are

faulty.

Starting

For machines with hand start, only use the safety cranks tested by

the manufacturer, and precisely follow the operating instructions

of the motor manufacturer.

To crank-start diesel motors; Important is the correct position to

the motor and the correct hand position on the crank.

The hand crank must be turned with maximum force until the motor starts, otherwise the crank can rebound.

Precisely follow the starting and stopping procedures specied in

the operating instructions and observe indicator lights.

Only start and operate machines with an electrical starter from the

instrument panel.

Starting and operation of the machine in potentially explosives

atmospheres is forbidden!

Starting with battery junction cables

Connect «positive» to «positive» and «negative» to «negative»

(earthing lead). Always connect the earthing lead last and discon-

nect rst! Incorrect connection will cause serious damage to the

electrical system.

Starting in enclosed spaces, tunnels, mines or deep ditches

Engine exhaust gas are highly dangerous!

For this reason, when operating the machine in enclosed spaces,

tunnels, mines or deep ditches, it is important to ensure that there

is sufcient air to breath (see UVV «Construction work», BGV

C22, paragraphs 40 and 41).

6 ► SRP 2240 / 3860 User Manual

Page 7

SAFETY

Machine control

Operating devices which adjust themselves automatically when

released in normal use, must not be locked.

Check protective devices and brakes for proper functioning prior

to operation.

When reversing, particularly on the edges and banks of ditches,

as well as in front of obstacles, the machine operator cannot fall

or be crushed.

Always keep a safe distance away from the edges and banks

of ditches and refrain from any actions which could cause the

machine to topple over!

Always control the machine, so that hand injuries through hard

objects are avoided!

Always ascend slopes carefully in a direct path.

Reverse up steep slopes to prevent the machine from toppling

over on to the machine operator.

If faults on the safety devices or other faults detrimental to the

safe operation of the machine are noticed, operation of the machine must be stopped immediately and the faults remedied.

When undertaking compaction work in the vicinity of buildings or

above pipelines and similar, check the effect of the vibrations on

the buildings and pipes and stop compaction work if necessary.

Parking the machine

Park the machine on a rm and level surface.

Shutdown the drive and secure it to prevent accidental movement and unauthorized use. If available, close the fuel valve. Do

not place or store equipment with integrated moving gear on the

chassis. The moving device is intended only for transportation

purposes.

Filling Fuel

Only ll fuel by switched-off motor. No open re, do not smoke.

Do not spill any fuel, collect discharging fuel in a suitable

container, prevent fuel from seeping into the soil.

Ensure that the ller cap is tight.

Leaky fuel tanks constitute an explosion hazard and must therefore be replaced immediately.

Maintenance and repairs

Observe the maintenance, inspection and adjustments and intervals specied in the operating instructions, as well as the information for part replacement.

Maintenance work must be undertaken only by qualied and

authorised persons.

Maintenance and repairs only by switched-off drive.

Only carry out maintenance and repairs when the machine is

parked on a rm and even surface and is secured to prevent it

from rolling.

When changing larger assemblies and individual components,

only use suitable and perfectly functioning hoisting and lifting

gears with suitable loading capacity. Attach and secure parts on

hoisting carefully!

Spare parts must comply with the technical requirements of the

manufacturer. Therefore only use original spare parts.

Hydraulic lines must previously be rendered pressureless, before

working on them. Hydraulic oil discharging under pressure can

cause serious injuries.

Work on hydraulic devices must be undertaken only by persons

with a special knowledge of hydraulics and the necessary

experience!

Do not adjust pressure relief valves.

Drain hydraulic oil at operating temperature—caution risk of

scalding!

Collect discharging hydraulic oil and dispose of the same in an

environmentally-friendly manner.

Do not start the motor when hydraulic oil has been drained off.

After completing all work (by pressureless system), inspect all

connections and bolted connections for leaks.

Inspect all hoses and bolted connections for leaks at regular

intervals and externally visible damage! Rectify any damage

immediately.

Replace externally damaged hydraulic hose lines at regular

intervals (depending on time used), even when no safety-relevant

faults are visible.

Before working on the electrical system of the machine,

disconnect the battery and insulate by covering or remove.

Inspect the electrical equipment of the machine at regular intervals. Faults such as loose connections, worn or scorched cables

must be immediately eliminated.

During transport, secure the battery to prevent it from tilting, shortcircuit, slipping and damage.

Dispose of used batteries in a proper manner. Do not place any

tools on the battery.

Handling acid-batteries

Transport lled batteries upright to prevent acid spillage.

Keep away from sparks, open re and other sources of ignition.

Avoid contact of acid with skin and clothing. In case of contact,

wash off acid immediately with clear water and go to medical

institution.

Properly ret and inspect all protective devices after maintenance

and repairs.

Testing

Road rollers, trench rollers and vibrating plates must be tested for

safety by an expert depending on the particular application and

operating conditions as required, however at least once a year.

Disposal of the machine after nish of its service life

At disposal of the machine after nish of its service life, the owner

is obliged to comply with national regulations and laws on wastes

and protection of environment. Therefore we recommend in

such cases to contact the following:

• professional specialized companies engaged in such activities

and having the relevant certicate

• the manufacturers or contracting service organizations authorized by him.

The manufacturer is not responsible for damages to health of

owners neither for damages to the environment in events of failing

to comply with above mentioned hygienic and ecological

principles.

SRP 2240 / 3860 User Manual ◄ 7

Page 8

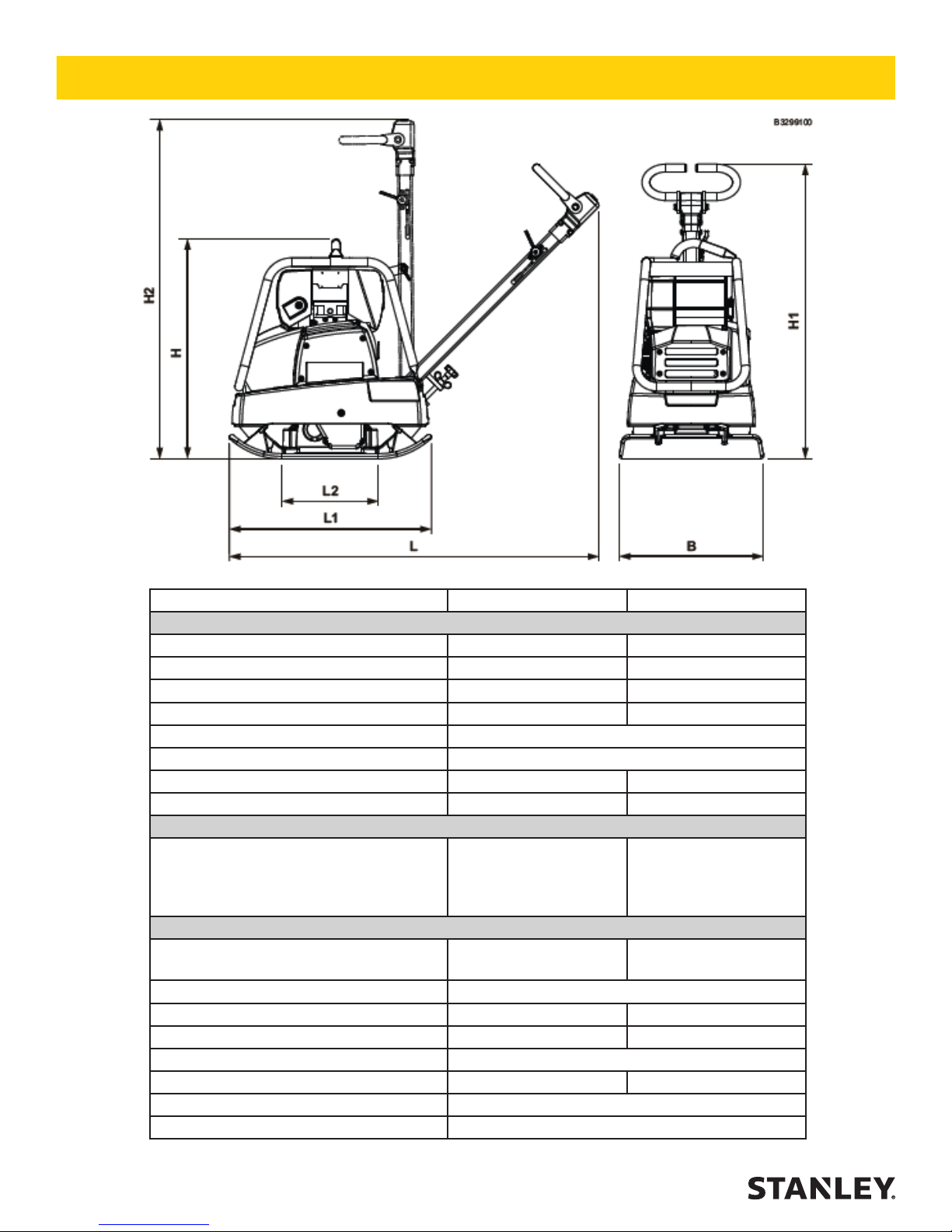

TECHNICAL DATA

SRP 2240 (HONDA) SRP 3860 (HONDA)

1. DIMENSIONS

LENGTH L 1140 MM / 44.8 IN 1365 MM / 53.7 IN

LENGTH L1 600 MM / 23.6 IN 860 MM / 33.8 IN

LENGTH L2 254 MM / 10.0 IN 410 MM / 16.1 IN

HEIGHT H 610 MM / 24.0 IN 750 MM / 29.5 IN

HEIGHT H1 1000 MM / 39.3 IN

HEIGHT H2 1180 MM / 46.4 IN

WORKING WIDTH B1 400 MM / 15.7 IN 450 MM / 17.7 IN

WORKING WIDTH B2 ---- 600 MM / 23.6 IN

2 WEIGHTS

BASIC UNIT B1

BASIC UNIT B2

TRANSPORTATION KIT

ELECTRICAL STARTER

3. DRIVE

MOTOR-TYPE

TYPE OF CONSTRUCTION 1-CYL-4-STROKE GASOLINE

POWER 2.9 KW (4.0 HP) 6,3 KW (8,6 HP)

BY SPEED 3600 1/MIN 3100 1/MIN

COOLING SYSTEM AIR

FUEL CONSUMPTION 0.9 L/H 2,1 L/H

MAX. SLOPING POSITION 20°

MAX. GRADE ABILITY 35 %

100 KG / 220.4 LB

----

+ 8 KG

----

HONDA

GX 120

242 KG / 533.5 LB

257 KG / 566.5 LB

----

----

HONDA

GX 270

8 ► SRP 2240 / 3860 User Manual

Page 9

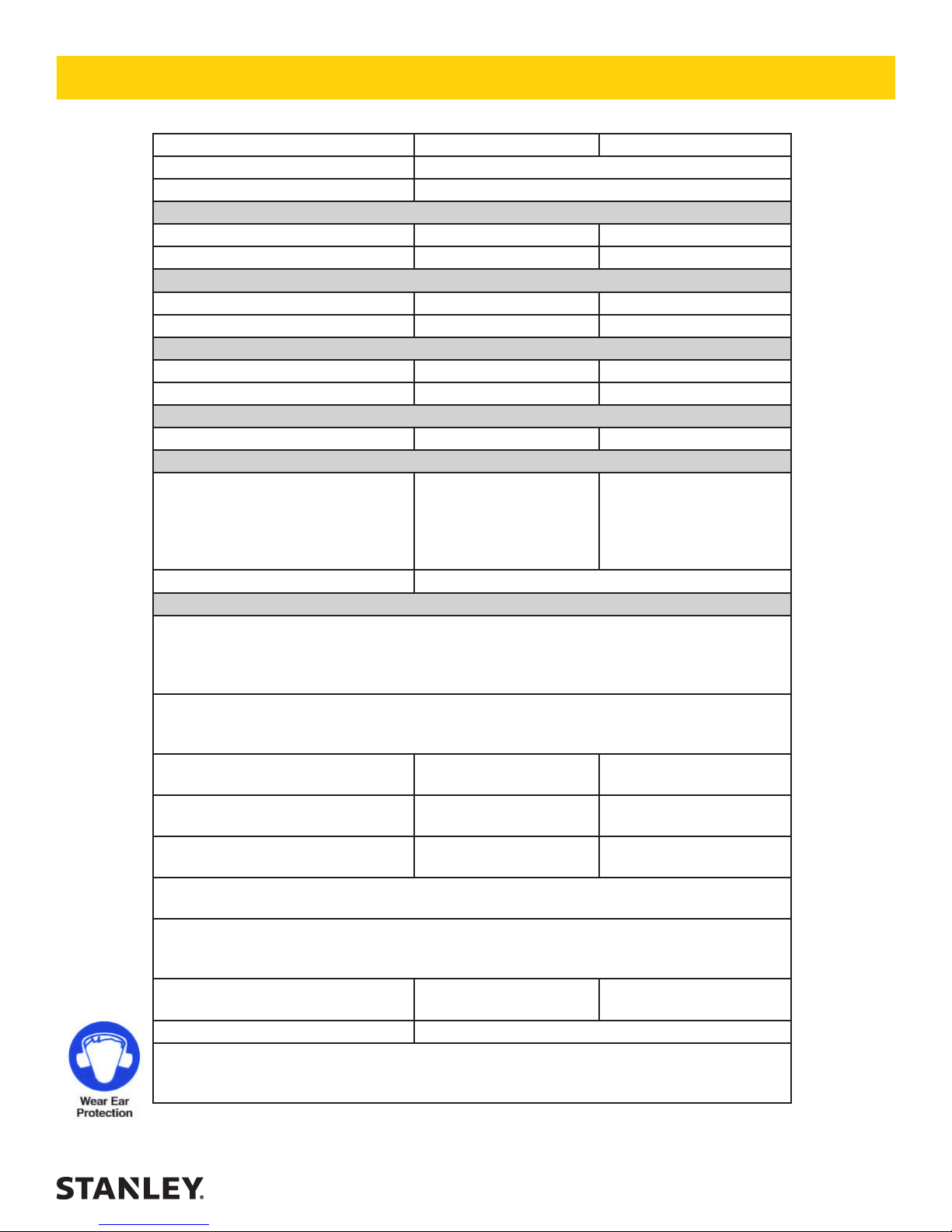

TECHNICAL DATA

SRP 2240 SRP 3860

DRIVE VIA CENTRIFUGAL CLUTCH AND V-BELT

SHIFT (FORWARD / REVERSE) HYDRAULIC

4. SPEED

BASIC UNIT B1 0-25 M/MIN 0-26 M/MIN

BASIC UNIT B2 ---- 0-26 M/MIN

5. VIBRATION

CENTRIFUGAL FORCE 22 KN 38 KN

VIBRATION FREQUENCY 98 HZ 65 HZ

6. MAXIMUM PERFORMANCE

BASIC UNIT B1 600 m²/h 700 m²/h

BASIC UNIT B2 936 m²/h

7. FILLING QUANTITIES

2.5 l 6.0 l

8. OPTIONAL EQUIPMENT

VULKOLLAN MAT 16 IN.

VULKOLLAN MAT 24 IN.

P/N-75185

---

---

P/N-75264

TRANSPORTATION WHEELS

O = Option / S = Serial / — = Not available

9. NOISE AND VIBRATION DATA

THE FOLLOWING NOISE AND VIBRATION DATA ACCORDING TO EC MACHINERY DIRECTIVE

IN THE VERSION (2006/42/EC), WAS DETERMINED, TAKING INTO ACCOUNT THE FOLLOWING

STANDARDS AND DIRECTIVES. IN OPERATIONAL USE, VALUES CAN DEVIATE DEPENDING ON

THE PREVAILING CONDITIONS.

9.1 NOISE DATA

THE NOISE DATA SPECIFIED IN APPENDIX 1, SUB-CLAUSE 1.7.4.U OF THE EC MACHINERY

DIRECTIVE IS FOR:

SOUND PRESSURE LEVEL AT THE

OPERATOR PLACE LPA

MEASURED SOUND POWER LEVEL

LWA,M

GUARANTED SOUND POWER LEVEL

LWA,G

THE NOISE VALUES WERE DETERMINED, TAKING INTO ACCOUNT THE FOLLOWING DIRECTIVES AND STANDARDS: DIRECTIVE 2000/14/EC / EN ISO 3744 / EN 500-4

9.2 VIBRATION DATA

HAND/ARM VIBRATION VALUES ACCORDING TO APPENDIX 1, SUB-CLAUSE 3.6.3.1 OF THE EC

MACHINERY DIRECTIVE:

TOTAL VIBRATION VALUE OF THE

ACCELERATION AHV

UNCERTAINTY K 0.5 m/s²

THE ACCELERATION VALUE WAS DETERMINED, TAKING INTO ACCOUNT THE FOLLOWING

DIRECTIVES AND STANDARDS: EN 500-4 / DIN EN ISO 5349

P/N-75885

97.3 dB 103.7 dB

104 dB 105 dB

105 dB 108 dB

4.3 m/s² 2.0 m/s²

---

1) AS THE PERMISSIBLE RATING SOUND LEVEL OF 85 DB (A) CAN BE EXCEEDED BY THIS MACHINE, OPERATORS

MUST WEAR HEARING PROTECTORS.

SRP 2240 / 3860 User Manual ◄ 9

Page 10

OPERATION

Description

The SRP 2240/3860 is a reversible vibrating plate operating on the basis of the twin-shaft vibration system principle. The engine drives the exciter on the baseplate via

a centrifugal clutch and a V-belt. The exciter produces the

vibration required for compaction as a result of the built-in

imbalance.

The machine is guided at the tow-bar grip. It is operated

with the operating controls on the tow-bar.

The SRP 2240/3860 is suitable for all compaction work in

the elds of civil engineering and road construction. It can

be used to compact all ground materials such as sand,

gravel, slag, crushed stone, asphalt and composite sett

paving.

Take great care on downslopes. The machine

Danger

could slip down due to loose material or if the

surface is slippery.

Do not use the machine on hard concrete, set

asphaltic surfaces, highly frozen or unstable

surfaces.

2

Operating control at the tow-bar

1 Control lever

The control lever serves for adjustment of the unbalances

in the exciter and in turn for coninuous regulation.

I Forward

0 Point compacting

II Reverse

The control lever remains automatically in position only

when set to the maximum forward travel setting (a). In any

other position, the control lever moves in the direction of

maximum forward travel when released.

If the control lever is operated too quickly several times, the

shift lever will block in reverse travel. In this case:

• Release lever in forward travel position up to maximum

forward travel position

• Blocking is cleared within a few seconds and perfect

shifting is possible.

1 Engine

2 Central point suspension

3 Tow-bar

4 Operating control/tow-bar

5 Base plate with exciter

6 Transport truck (Special equipment)

10 ► SRP 2240 / 3860 User Manual

The control lever can be operated only with the engine

running. The lever blocks if operated when the machine is

stationary. Blocking is immediately cleared when the engine

is restarted.

2 Engine speed control lever

STOP Engine stop (SRP 3860 only)

MIN Idle (detent position)

MAX Full load.

The motor speed can be adjusted steplessly with the control lever. At minimum motor speed (min), the drive to the

exciter is disconnected at the centrifugal clutch and the motor idles. The centrifugal clutch engages when the control

lever is moved approximately ¼ of its adjustment travel.

Page 11

OPERATION

Before Operation

Use personal protective equipment (in particular

Danger

• Stand the machine on an even surface.

• Check

- the Engine oil level

- the hydraulic oil level

- the fuel supply

- that screw connections are secure

- condition and function of hydraulic hose lines

- the condition of the Engine and the machine.

• Top-off any missing lubrication in accordance with the

lubrication table.

hearing protectors and safety shoes). Risk of loss

of hearing!

Observe the safety conditions.

Observe the operation and maintenance

instructions.

Read the Engine operating instructions. Observe

the Importants on safety, operation and maintenance contained in them.

Adjusting / Locking the tow-bar

Adjusting the tow-bar

By turning adjustment-screw (2), the tow-bar (1) can be set

to any positions so as to obtain the best working height on

the tow-bar grip.

Locking the tow-bar

In case of loading and transport the tow-bar (1) has to be

locked in an upright position by turning up the locking bolt

(3).

SRP 2240 / 3860 User Manual ◄ 11

Page 12

OPERATION

Engine Operation - Honda

Starting the engine

• Move the fuel valve lever (2) to the «ON» position.

• Turn the engine switch (4) to the «ON» position.

• Move the choke lever (3) to the «CLOSE» position.

• Set the engine speed lever (1) to MIN.

If the motor doesn't start, set the throttle lever

Important

12 ► SRP 2240 / 3860 User Manual

about 1/3 of the way to «MAX».

• Pull the starter grip (5) lightly until you feel resistance,

then pull briskly in the direction of the arrow as shown

above.

• Return the starter grip gently.

Do not allow the starter grip (5) to snap back

Important

against the engine. Return it gently to prevent

damage to the starter.

Page 13

OPERATION

Warm up Instructions

• Set the engine speed lever (1) to idle (MIN).

• Allow the engine to run for 1-2 minutes in order to

warm up.

Stopping the engine

To stop the engine in an emergency, simply

Important

• Set the engine speed lever (1) to the «MIN» position.

turn the engine switch to the «OFF» position.

• If the choke lever (3) has been moved to the «CLOSED»

position to start the engine, gradually move it to the

«OPEN» position as the engine warms up.

• Turn the engine switch (4) to the «OFF» position.

• Turn the fuel valve lever (2) to the «OFF» position.

SRP 2240 / 3860 User Manual ◄ 13

Page 14

OPERATION / TRANSPORT

Operation

• Set the engine speed lever (2) to full load (MAX).

Operate the machine only at full throttle and turn

the machine in the idle position. Otherwise could

Attention

cause clutch damage or slipping of centrifugal

clutch.

Loading and Transportation

Only use sufciently strong and secure loading

Danger

ramps when loading.

Check the contact points (frame, lifting rings)

before use for damage and wear. Immediately replace damaged parts.

Secure the machine against rolling or slipping off

and against tipping over.

Ensure that no persons will be endangered.

When loading, lashing down and lifting the

machine always use the provided lifting points.

Persons are in danger, if they :

• go near swinging loads or

• stand under swinging loads

Lock the tow-bar to loading and transport.

• The proper position for the operator is behind the machine.

• Control and steer the machine using the tow bar grip (1).

• Set the travel direction and speed with the travel lever (2).

For compaction of paving stones, it is recom-

Important

mended to use Vulkollan plates and protective brackets (special accessories) to prevent

damages to the compaction material and to the

machine.

14 ► SRP 2240 / 3860 User Manual

After loading the machine should be lashed in place.

Use the centre-of-gravity suspension point (2) in order to lift

the machine.

Page 15

TRANSPORT

Transportation Trolley

During longer work breaks, e.g. at the end of the

work day, do not place the machine on the trans-

Danger

The transport trolley can be used for problem-free transport

of the machine.

port trolley so that the stability of the machine is

not compromised.

Take care when riding over uneven or sloping

oors. The machine can slip or tip over.

• Position the towing bar (1) vertically.

• Position the towing bar (1) horizontally and lock in

position (4).

• Remove the undercarriage (2) from the mounting bracket

(3) and place it on the oor.

• With the towing bar locked in position tip the machine on

to the front edge, the undercarriage will swing under the

board.

Be careful when raising and lowering the machine.

Danger

Do not place your feet under the raised base plate.

Danger of foot injuries!

SRP 2240 / 3860 User Manual ◄ 15

Page 16

TRANSPORT

• Using the towing bar, tilt the machine backwards until the

machine is horizontally seated on the undercarriage. The

device is ready to be moved.

• After transport hook the undercarriage back into position

by proceeding in reverse order.

1)Special equipment

16 ► SRP 2240 / 3860 User Manual

Page 17

MAINTENANCE

General Information

Maintenance:

increased service life

increased function

reduced downtimes

increased reliability

reduced repair costs

– Observe the safety regulations!

– Maintenance work should only be carried out when

the engine is shut off.

– The engine and machine should be cleaned thorougly

before carrying out maintenance work.

– Park the machine on a at surface and secure it against

rolling away and slipping.

– Ensure that operating materials and replaced parts are

disposed of safely and in an environmentally-friendly

way.

Maintenance Schedule

MaintenanceWorks

Clean machine

Check engine oil level 1)

Change engine oil 1)

Check the water trap 1)

Clean engine oil lter 1)

Clean fuel lter 1)

Change fuel lter 1)

Check air lter 1)

Change air lter element 1)

Check valve clearance 1)

Exciter: Check oil level

Exciter: Change oil ²)

Check rubber buffers

Check hydraulic oil level

Change hydraulic oil

Check the hydraulic hose lines ²)

Check V-belt

Check screwed connections for

tightness

1

)See engine operating manual

2

)or annually

3

)for the rst time

Intervals

Daily 20 h 50 h 100 h 200 h 250 h 400 h

•

•

3

•

) •

•

3

•

)

•

3

•

) •

3

•

) •

– Before commencing work on any electrical equipment,

disconnect the battery and cover it with insulating materials.

– Do not exchange «PLUS» and «MINUS» poles on the

battery.

– It is essential that short-circuits be prevented in cables

carrying current.

– Before welding work on the machine disconnect all battery connections and cables.

– Burn-out lightbulbs in indicator lamps should be

replaced immediately.

– When cleaning the machine with a high-pressure water

jet, do not spray the electrical components directly.

– After cleaning the components, blow-dry them with compressed air in order to prevent surface corrosion.

If

Necessary

•

•

•

•

3

•

) •

•

•

•

SRP 2240 / 3860 User Manual ◄ 17

Page 18

Lubrication Schedule

MAINTENANCE

Lubricating point Quantity

1. Engine

SRP 2240 0.6 l

SRP 3860 1.1 l

2. Exciter

SRP 2240 0.5 l

SRP 3860 1.0 l

2. Hydraulic

SRP 2240 0.17 l

SRP 3860 0.65 l

Changing intervals

[operating hours]

First time after 20 h;

then every 100 h

First time after 100 h

the every 500 h or

annually

Not Necessary

Lubricant

Engine oil

API SG-CE

SAE 10W40

Engine oil

API SG-CE

SAE 10W40

Hydro-Oil

HVLP 46

Alternative Lubrication Schedule

18 ► SRP 2240 / 3860 User Manual

Page 19

MAINTENANCE

Maintenance Work (Honda)

Only the maintenance work which has to be performed

daily is included in the Operating Manual. Please refer

to the engine Operating Manual and to the maintenance

instructions and intervals listed therein.

Filling-up with fuel

Only add fuel when engine is off and has

cooled down.

Danger

No open ame. Do not smoke.

Do not ll-up in closed rooms. Do not inhale

petrol fumes.

Collect spilt fuel in a suitable container and

prevent spillage entering the soil.

SRP

SRP

Checking the engine oil level

Immediately replace damaged seals.

Collect old oil and dispose of it in an environment friendly manner.

Environment

Do not permit oil to run onto the oor into

the drains.

– Stand the machine horizontally.

– Stop the engine.

– Stop the engine.

– Clean around the fuel ller socket.

– Open the fuel ller socket and visually check the fuel

level. Rell the tank if the fuel level is low.

Never use stale or contaminated gasoline or an

Important

oil/gasoline mixture. Avoid getting dirt or water

in the fuel tank.

– Add fuel to the bottom of the maximum fuel level limit of

the fuel tank. Do not overll. Use unleaded automotive

gasoline only.

– Wipe up spilled fuel before starting the engine.

– Close the tank tightly.

– Remove the oil ller cap/dipstick (1) and wipe it clean.

– Insert the oil ller cap/dipstick (1) into the oil ller neck as

shown, but do not screw it in, then remove it to check the

oil level.

– If the oil level is near or below the lower limitmark on the

dip- stick, ll with the recommended oil to the upper limit

mark (bottom edge of the oil ll hole). Do not overll.

– Reinstall the oil ller cap/dipstick (1).

SRP 2240 / 3860 User Manual ◄ 19

Page 20

MAINTENANCE

Clean the air lter

Change the lter element:

Attention

– if the lter element is damaged

– if moist or oily deposits are present

– if engine performance reduces

– minimum once a year

Never operate the engine without air lter. Do

not allow dust to enter into carburator.

– Paper air lter element:

- Blow compressed air [not exceeding 207 kPa (2.1 kgf/

cm,30 psi)] through the lter element (4) from the inside.

– Foam air lter element (5):

- Clean in warm soapy water, rinse, and allow to dry thor-

oughly. Or clean in non-ammable solvent and allow to

dry.

- Dip the lter element (5) in clean engine oil, then

squeeze out all excess oil. The engine will smoke when

started if too much oil is left in the foam.

– Wipe dirt from the inside of the air cleaner case and

cover using a moist rag. Be careful to prevent dirt from

entering the air duct that leads to the carburetor.

– Place the foam air lter element (5) over the paper ele

ment (4).

– Reinstall the assembled air lter. Be sure the gasket is in

place beneath the air lter.

– Tighten the air lter wing nut securely.

– Install the air cleaner cover (2), and tighten the wing nut

securely.

– Remove the wing nut (1) from the air cleaner cover (2),

and remove the cover.

– Remove the wing nut from the air lter (3), and remove

the lter.

– Remove the foamlter (5) from the paper lter (4).

– Inspect both air lter elements, and replace them if they

are damaged. Clean the air lter elements if they are to

be reused:

Never use petrol or cleaning solutions with a

low ash point for cleaning the lter element!

Danger

Do not smoke in the working area; avoid

open re and sparks – re and explosion

hazard!

Risk of eye injuries! – Wear safety goggles.

20 ► SRP 2240 / 3860 User Manual

Page 21

MAINTENANCE

Maintenance work - Machine

Cleaning

Clean the machine thoroughly daily.

For cleaning, do not use any ammable or

Attention

aggressive materials.

When cleaning the machine with a pressure

washer, do not spray the electrical components

directly.

When cleaning the machine with a pressure

washer, do not hold it directly over the air lter.

Tightening Torque

Torque Information

• Clean the machine on a daily basis.

• After cleaning all cables, hoses and connections check

the unit for leakage on hoses or at connections. Check for

chang points and other damage.

Do not use your hand to check hoses for leaks as this

could cause pressurized oil injection into body.

• Detected faults are to be eliminated immediately.

Strength grades for screws with untreated, unlubricated

surfaces.

The values show 90% use of the yield strength; at a friction

coef- cient of µtot = 0.14.

Tightening torque is controlled with torque wrenches.

The values given do not apply when MoS2 lubrication is

used.

Replace all self-locking nuts after each

Important

disassembly.

SRP 2240 / 3860 User Manual ◄ 21

Page 22

MAINTENANCE

Screw Connections

With vibrating devices, it is important to check intermittently

the screw connections for tightness. Pay attention to the

tightening torque.

Checking the rubber buffers

Check the rubber buffers (1) for tears and outbreaks, as

well as for secure t. If they are damaged, replace them

immediately.

22 ► SRP 2240 / 3860 User Manual

Page 23

MAINTENANCE

V-Belt: Tension / Condition - SRP 2240 V-Belt: Tension / Condition - SRP 3860

• Remove V-belt guard.

• Check V-belt for tension and condition.

• Tension if necessary:

SRP

• Unscrew the nuts (1) of the rubber stops on the outside.

• Push the upper tray (2) upwards on both sides.

It is important to ensure that the frame is also

actually pushed on the rubber stop contact

Important

surfaces and not just the rubber elements are

stretched and then spring back again. If necessary apply light blows with a hammer to knock

the rubber stops downwards.

• Remove V-belt guard.

• Check V-belt for tension and condition.

• Tension if necessary:

SRP 3860

• Loosen set screws (1), do not unscrew.

• Insert auxiliary tools (ø 6 mm) into bores (2) and (3).

• Tension vee-belt by turning clutch halves (2) and (3) in

opposite directions

• Tension clutch halves (2) and (3). X= 10 mm.

• Crank the drive manually and re-check tension and

correct if necessary.

• Replace V-belt guard.

• Both buffers should be equally pre-tensioned.

• Tighten nuts (1).

• Crank the drive manually and re-check tension and

correct if necessary.

• Replace V-belt guard.

Do not start the engine without V-belt

Danger

guard. Danger of injuries.

• Check the tension of the V-belt after 25 op. hrs. again.

Adjust the tension if necessary.

Do not start the engine without V-belt

guard. Danger of injuries.

Danger

• Check the tension of the V-belt after 25 op. hrs. again.

Adjust the tension if necessary.

SRP 2240 / 3860 User Manual ◄ 23

Page 24

MAINTENANCE

Exciter: Oil Level / Oil Change

Check / change exciter oil when its warm.

SRP 3860: The venting screw (3) must always

Important

rst be unscrewed when checking the oil level

or changing the oil.

• Unscrew venting screw (3), oil lling plug/dipstick (1) and

oil drain plug (2).

• Drain-off old oil.

• Fill-in new oil through the oil ll hole (1). See lubrication

plan for quantity and quality.

When the dipstick is screwed in, the optimal

oil level is between the «MIN» and «MAX»

Attention

markings.

• Replace oil lling plug/dipstick (1) and venting screw (3).

• Unscrew oil lling plug/dipstick (1), check the oil level

again and top up with oil if necessary.

Care is to be taken with the draining of

Danger

hot oil: Danger of scalding!

Collect oil which has run out or over-

owed and dispose it in an environment

Environment

friendly manner.

• Screw-in oil drain screw (2).

24 ► SRP 2240 / 3860 User Manual

Page 25

MAINTENANCE

Filling and Bleeding the Circuit Hydraulic Hose Lines

SRP

SRP 3860

• Release locking screw (1).

• Set throttle lever (2) to «V».

• Pour in hydraulic uid while continually changing the

throttle lever position. To ensure correct bleeding, at

times place the shaft vertically.

• Stop lling when

- a distinct «clicking»-noise is heard in the exciter

while shifting the lever

- you will no longer feel a cushion of air when

moving the throttle lever.

1 Serial No.

2 Manufacturer/Month and year of manufacture

3 Max. operating pressure

The function of hydraulic hose lines must be tested at

regular intervals (minimum once a year) by an expert (with

a knowledge of hydraulics).

Hose lines must immediately be replaced in the following

instances:

• Damage to the outer layer to the inner lining (abrasion

marks, cracks, cuts, etc.).

• Brittleness of the outer layer (cracking of hose covering).

• Unnatural deformations of the hose line. This applies to

both a pressureless and pressurised condition (e.g. layer

separation, blister formation, crushed areas, kinks).

• Leaks.

• Damage or deformation of hose ttings (impaired sealing

function).

• Hose slips out of the tting.

• Corrosion of tting (degrading of function and strength).

• Improper installation.

• Use beyond the expiry date of max. 6 years.

When lling, the circuit path is shortened.

Important

• To check oil level, start engine and bring up to operating

speed.

• Move throttle lever several times backwards and for

wards between «V» and «R».

• The correct oil level should be somewhere in the area

shown (See Illus.); at this point the throttle lever must be

in the «V» position.

• If the level is too low, top up with hydraulic uid; if too

high, drain off excess uid.

• With the machine running and the throttle lever in the

«V» position, close locking screw (1).

SRP 2240 / 3860 User Manual ◄ 25

Page 26

TROUBLESHOOTING

General Information

• Observe the safety information

• Only qualied and authorised persons may carry out

repair work (mechanics specialising in construction and

agricultural machinery).

• In case of faults, the operating and maintenance instruc tions must be referred to for correct operation and main tenance.

Fault Table

Possible cause Remedy Remarks

Engine does not start

Speed control lever in «STOP»-position

No fuel

– Tank run dry

– Fuel lter blocked

– Fuel valve «OFF»

– Defective feed pump

Oil pressure lost

Compression too low

Set lever to «START»-position

Add fuel

Renew fuel lter

Move lever to «ON» position

Function must be checked

Check engine oil level

Contact a Stanley-service center

• If the cause of the fault cannot be located or remedied, an

authorised Stanley Service Center should be contacted.

• Always rst check the most likely causes (fuses,

LEDs, etc.).

HONDA

Engine switch «OFF»

Choke «OPEN»

Spark plug faulty, fouled or improperly

gapped

Spark plug wet with fuel (ooded engine)

Turn engine switch to «ON» position

Move lever to «CLOSE» position

Gap or replace spark plug

Dry and reinstall spark plug

Engine stops by itself during regular operation

Fuel supply is interrupted

– Tank run dry

– Fuel lter blocked

– Defective feed pump

Oil pressure lost

Mechanical defects

Add fuel

Renew fuel lter

Function must be checked

Check engine oil level

Contact a Stanley-service center

Reduced engine performance

Fuel supply is obstructed

– Tank run dry

– Fuel lter blocked

– Tank venting is inadequate

– Leaks at pipes unions

Air cleaner blocked

Incorrect valve clearance

Too much oil in engine

Too much oil in exciter

Default in hydraulic system

Add fuel

Renew fuel lter

Ensure that tank is adequately vented

Check threaded pipe unions

Remove dirt from air cleaner

Adjust valve clearance

Correct the engine oil level

Check exciter oil level

Contact a Stanley-service center

Engine runs, machine does not move forward

Insufcient V-belt tension

V-belt broken

Centrifugal clutch lining worn

Too much oil in exciter

Default in hydraulic system

Retention V-belt

Replace V-belt

Replace linings and springs

Check exciter oil level

Contact a Stanley-service center

HONDA

HONDA (Unless the engine is warm)

HONDA

HONDA (Start engine with throttle

lever in «MAX» position)

26 ► SRP 2240 / 3860 User Manual

Page 27

NOTES

SFP 2240 / 3860 User Manual ◄ 27

Page 28

Stanley Hydraulic Tools

3810 SE Naef Road

Milwaukie, Oregon 97267-5698 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyhydraulics.com

Loading...

Loading...