Page 1

1

Petrol snow thrower

Petrol snow thrower

SPT-182-570

SPT-270-720

SPT-302-720

GB

Original instructions

Übersetzung der Originalanleitung

Alkuperäisten ohjeiden käännös

D

FIN

Algupärase kasutusjuhendi tõlge

EE

Page 2

2

Manufactured under license by:

MATRIX GmbH • Postauer Straße 26 • D-84109 Wörth/Isar • www.matrix-direct.net

Stanley is a registered trademark of The Stanley Works or its affiliates and is used under license.

GB

Toodetud litsentsi alusel:

MATRIX GmbH·Postauer Straße·26 D-84109 Wörth/Isar·www.matrix-direct.net

Stanley® on The Stanley Worksi või selle sidusettevõtete registreeritud kaubamärk ning seda kasutatakse

litsentsi alusel.

EE

Hergestellt unter Lizenz durch:

MATRIX GmbH·Postauer Straße·26 D-84109 Wörth/Isar·www.matrix-direct.net

Stanley® ist ein eingetragenes Warenzeichen von The Stanley Works oder seinen Tochterunternehmen

und wird unter Lizenz verwendet

D

Lisenssillä valmistanut:

MATRIX GmbH·Postauer Straße·26 D-84109 Wörth/Isar·www.matrix-direct.net

Stanley® on The Stanley Works -yhtiön tai sen tytäryhtiöiden rekisteröity tavaramerkki ja sitä käytetään

lisenssillä.

FIN

Page 3

3

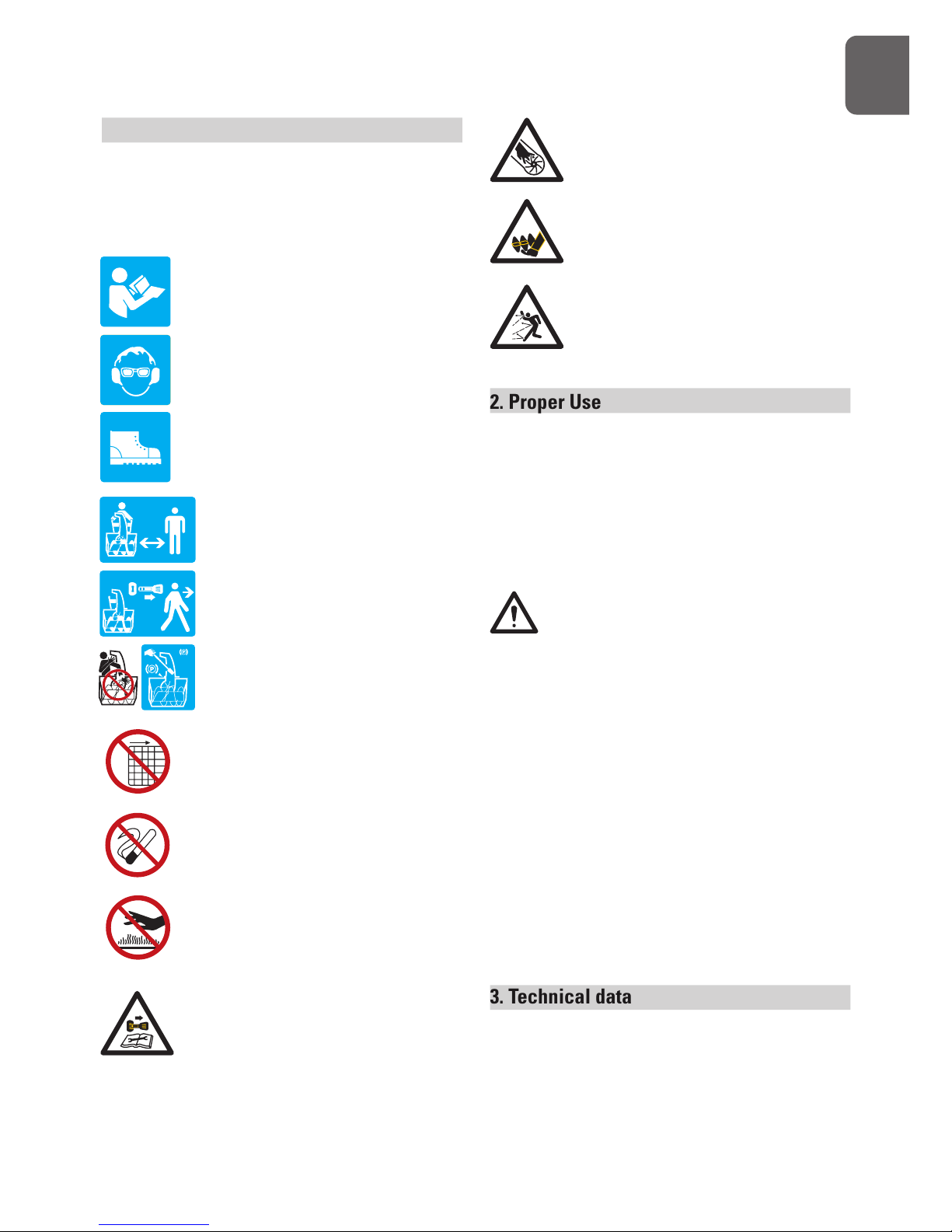

1. Notes on Safety and Warnings

The rating plate on your machine may

show symbols. These represent important

information about the product or instructions

on its use.

Read these instructions for use

carefully.

Wear eye protection.

Wear hearing protection.

Wear safety footwear.

Keep bystanders away.

Stop engine and remove ignition

key prior to leaving the operator’s

position.

Only use clean-out tool to clear

blockage. Never use your hands.

It is forbidden to remove or tamper

with the protection devices and

safety devices.

Do not smoke or have open flames.

Do not touch a hot muffler, gear

housing or cylinder.

Stop engine, remove key, read

manual before making any repairs

or adjustments.

G

B

Keep hands out of the inlet and

discharge openings while machine

is running.

Stay away from rotating augers.

Never direct discharge towards

persons or property.

2. Proper Use

Your new snow thrower will more than satisfy

your expectations. It has been manufactured

under stringent quality standards to meet

superior performance criteria. You will find it

easy and safe to operate, and with proper care, it

will give you many years of dependable service.

Carefully read through this entire operator’s

manual before using your new snow

thrower. Take special care to heed the

cautions and warnings.

Your snow thrower has many features that

will make your job faster and easier. Safety,

performance, and dependability have been

given to top priority in the development of this

machine, making it easy to maintain and operate.

The Engine manufacturer is responsible

for all engine-related issues with regards to

performance, power rating, specifications,

warranty and service. Please refer to the Engine

Manufacturer’s owner’s/operator’s manual,

packed separately with your unit, for more

information.

3. Technical data

SPT-182-570:

Engine type: OHV ,Four-stroke engine, air cooling ;

182cc

Page 4

4

Engine power: 4.0 kW

Max Power: 4,5kW, 6 HP

Starting System: 230V electric start (Optional)

Fuel Tank Capacity: 3.0L

Clearing Width 57 cm

Intake Height 53.5cm

Auger Dia. 30.0cm

Impeller Dia. 30.0cm

Speed 6F+2R

SPT-270-720 :

Engine type: OHV ,Four-stroke engine, air cooling ;

270cc

Engine power: 5,3 kW

Max Power: 6,7kW, 9 HP

Starting System: 230V electric start (Optional)

Fuel Tank Capacity: 6.0L

Clearing Width 72 cm

Intake Height 53.5 cm

Auger Dia. 30.0cm

Impeller Dia. 30.0cm

Speed 6F+2R

SPT-302-720 :

Engine type: OHV ,Four-stroke engine, air cooling ;

302cc

Engine power: 6,2 kW

Max Power: 7,5kW, 10 HP

Starting System: 230V electric start (Optional)

Fuel Tank Capacity: 4.0L

Clearing Width 72 cm

Intake Height 53.5 cm

Auger Dia. 30.0cm

Impeller Dia. 30.0cm

Speed 6F+2R

4. Notes on Safety

General Safety Rules

Understand your machine

Allow operation only by properly trained adult,

never children.

Read and understand the operator’s manual

and labels affixed to the machine. Learn its

application and limitations as well as the

specific potential hazards peculiar to it.

Be thoroughly familiar with the controls and

their proper operation. Know how to stop the

machine and disengage the controls quickly.

Make sure to read and understand all the

instructions and safety precautions as outlined

in the Engine Manufacturer’s Manual, packed

separately with your unit. Do not attempt to

operate the machine until you fully understand

how to properly operate and maintain the

Engine and how to avoid accidental injuries

and/or property damage.

Work area

Never start or run the engine inside a closed

area. The exhaust fumes are dangerous,

containing carbon monoxide, an odorless and

deadly gas. Operate this unit only in a well

ventilated outdoor area.

Never operate the machine without good

visibility or light.

Never operate the machine on a steep slope.

Personal safety

Do not operate the machine while under the

influence of drugs, alcohol, or any medication

that could affect your ability to use it properly.

Dress properly. Wear heavy long pants, boots

and gloves. Do not wear loose clothing, short

pants, and jewelry of any kind. Secure long

hair so it is above shoulder level. Keep your

hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can

be caught in moving parts.

Use safety equipment. Always wear eye

protection. Safety equipment such as a dust

mask, hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

G

B

Page 5

5

Check your machine before starting it. Keep

guards in place and in working order. Make

sure all nuts, bolts, etc. are securely tightened.

Disengage all clutches and shift into neutral

before starting the engine.

Never operate the machine when it is in need

of repair or is in poor mechanical condition.

Replace damaged, missing or failed parts

before using it. Check for fuel leaks. Keep the

machine in safe working condition.

Never tamper with safety device. Check their

proper operation regularly.

Do not use the machine if the engine’s throttle

control does not turn it on or off. Any gasoline

powered machine that can not be controlled

with the engine throttle control is dangerous

and must be replaced.

Form a habit of checking to see that keys

and adjusting wrenches are removed from

machine area before starting it. A wrench or

a key that is left attached to a rotating part of

the machine may result in personal injury.

Stay alert, watch what you are doing and use

common sense when operating the machine.

Do not overreach. Do not operate the machine

while barefoot or when wearing sandals or

similar lightweight footwear. Wear protective

footwear that will protect your feet and

improve your footing on slippery surfaces.

Keep proper footing and balance at all times.

This enables better control of the machine in

unexpected situations.

Avoid accidental starting. Be sure the engine’s

throttle control is off before transporting the

machine or performing any maintenance or

service on the unit. Transporting or performing

maintenance or service on a machine with its

throttle control on invites accidents.

Fuel safety

Fuel is highly flammable, and its vapors can

explode if ignited. Take precautions when

using to reduce the chance of serious personal

injury.

When refilling or draining the fuel tank, use

an approved fuel storage container while in

a clean, well-ventilated outdoor area. Do not

smoke, or allow sparks, open flames or other

sources of ignition near the area while adding

fuel or operating the unit. Never fill fuel tank

indoors.

Keep grounded conductive objects, such as

tools, away from exposed, live electrical parts

and connections to avoid sparking or arcing.

These events could ignite fumes or vapors.

Always stop the engine and allow it to cool

before filling the fuel tank. Never remove

the cap of the fuel tank or add fuel while the

engine is running or when the engine is hot.

Do not operate the machine with known leaks

in the fuel system.

When practical, remove the machine from the

truck or trailer and refuel it on the ground. If

this is not possible, then refuel the machine on

a trailer with a portable container, rather than

from a fuel dispenser nozzle.

Loose the fuel tank cap slowly to relieve any

pressure in the tank.

Keep the nozzle in contact with the firm of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lockopen

device.

Never over fill fuel tank. Fill tank to no more

than 12.5mm (1/2”) below the bottom of the

filler neck to provide space for expansion as

the heat of the engine and/or sun cause fuel

to expand.

G

B

Page 6

6

Replace all fuel tank and container caps

securely and wipe up spilled fuel. Never

operate the unit without the fuel cap securely

in place.

Avoid creating a source of ignition for spilled

fuel. If fuel is spilled, do not attempt to start

the engine but move the machine away

from the area of spillage and avoid creating

any source of ignition until fuel vapors have

dissipated. Serious personal injury can occur

when fuel is pilled on yourself or your clothes

which can ignite. Wash your skin and change

clothes immediately.

Store fuel in containers specifically designed

and approved for this purpose.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

Store fuel in a cool, well-ventilated area.

Safely away from sparks, open flames or other

sources of ignition.

Never store fuel or machine with fuel in the

tank inside a building where fumes may

reach a spark, open flame, or other sources

of ignition, such as a water heater, furnace,

clothes dryer and the like. Allow the engine to

cool before storing in any enclosure.

Machine use and care

Never pick up or carry a machine while the

engine is running.

Do not force the machine. Use the correct

machine for your application. The correct

machine will do the job better and safer at the

rate for which it was designed.

Do not change the engine governor settings

or over-speed the engine. The governor

controls the maximum safe operating speed

of the engine.

Do not put hands or feet near rotating parts.

Avoid contact with hot fuel, oil, exhaust fumes

and hot surfaces. Do not touch the engine or

muffler. These parts get extremely hot from

operation. They remain hot for a short time

after you turn off the unit. Allow the engine

to cool before doing maintenance or making

adjustments.

After striking a foreign object, stop the

engine, remove the wire from the spark

plug, thoroughly inspect the machine for

any damage, and repair the damage before

restarting and operating the machine.

If the machine should start to make an unusual

noise or vibration, immediately shut off the

engine, disconnect the spark plug wire, and

check for the cause. Unusual noise or vibration

is generally warning of trouble.

Use only attachments and accessories

approved by the manufacturer. Failure to do

so can result in personal injury.

Maintain the machine. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

machine’s operation. If damaged, have the

machine repaired before use. Many accidents

are caused by poorly maintained equipment.

Keep the engine and muffler free of grass,

leaves, excessive grease or carbon build up to

reduce the chance of a fire hazard.

Never douse or squirt the unit with water or

any other liquid. Keep handles dry, clean and

free from debris. Clean after each use.

Observe proper disposal laws and regulations

for gas, oil, etc. to protect the environment.

Store idle machine out of the reach of children

and do not allow persons unfamiliar with

G

B

Page 7

7

the machine or these instructions to operate

it. Machine is dangerous in the hands of

untrained users.

Service

Before cleaning, repair, inspecting, or adjusting

shut off the engine and make certain all

moving parts have stopped. Always make

sure the engine’s throttle control is in its STOP

position. Disconnect the spark plug wire, and

keep the wire away from the plug to prevent

accidental starting.

Have your machine serviced by qualified repair

personnel using only identical replacement

parts. This will ensure that the safety of the

machine maintained.

Specific Safety Rules

Do not operate without wearing adequate

winter outer garments.

Do not use the machine on a roof.

Do not run the engine indoors, except when

starting the engine and for transporting

the snow thrower in or out of the building.

Open the outside doors; exhaust fumes are

dangerous.

Always check overhead and side clearances

carefully before operation. Always be aware of

traffic when operating along streets or curbs.

Thoroughly inspect the area to be worked.

Keep the working area clean and free of toys,

doormats, newspapers, sleds, boards, wires

and other foreign objects, which could be

tripped over or thrown by the auger/impeller.

Check for weak spots on docks, ramps or

floors.

Plan your snow-throwing pattern to avoid

discharge toward people or areas where

property damage can occur.

Do not operate near drop-offs, ditches, or

embankments. Machine can suddenly turn

over if a wheel is over the edge of a cliff or

ditch, or if an edge caves in.

Keep all bystanders, children, and pets at least

23m (75 feet) away. If you are approached,

stop the unit immediately.

Use a grounded three-wire extension cord and

receptacle for all machines with electric start

engines.

Check clutch and brake operation frequently.

Adjust and service as required. All motion of

drive wheels and auger/impeller must stop

quickly when control levers are released.

Let engine and machine adjust to outdoor

temperature before starting to clear snow.

Stay alert for hidden hazards or traffic.

Do not overload machine capacity by

attempting to clear snow at too fast of a rate.

Do not throw snow any higher than necessary.

Adjust auger housing height to clear gravel

or crushed rock surfaces. Exercise extreme

caution when operating.

Exercise caution to avoid slipping or falling,

especially when operating in reverse. Never

operate machine at high transport speeds

on slippery surfaces. Always look down and

behind before and while backing.

Do not operate on steep slopes. Do not

clear snow across the face of slopes. Keep

all movement on slopes slow and gradual.

Do not make sudden changes in speed or

direction. Use a slow speed to avoid stops or

shifts on slopes. Avoid starting or stopping

on a slope. Do not park machine on a slope

unless absolutely necessary. When parking on

G

B

Page 8

8

a slope, always block the wheels.

Disengage power to the auger/impeller when

transporting or not in use.

Disengage all control levers and stop engine

before you leave the operating position

(behind the handles). Wait until the auger/

impeller comes to a complete stop before

unclogging the chute assembly, making any

adjustments, or inspections.

Hand contact with the rotating impeller inside

the discharge chute is the most common

cause of injury associated with snow throwers.

Do not unclog chute assembly while engine

is running. Shut off engine and remain behind

handles until all moving parts have stopped

before unclogging. Never put your hand in

the discharge or collector openings. Always

use the clean-out tool provided to unclog the

discharge opening.

G

B

Page 9

9

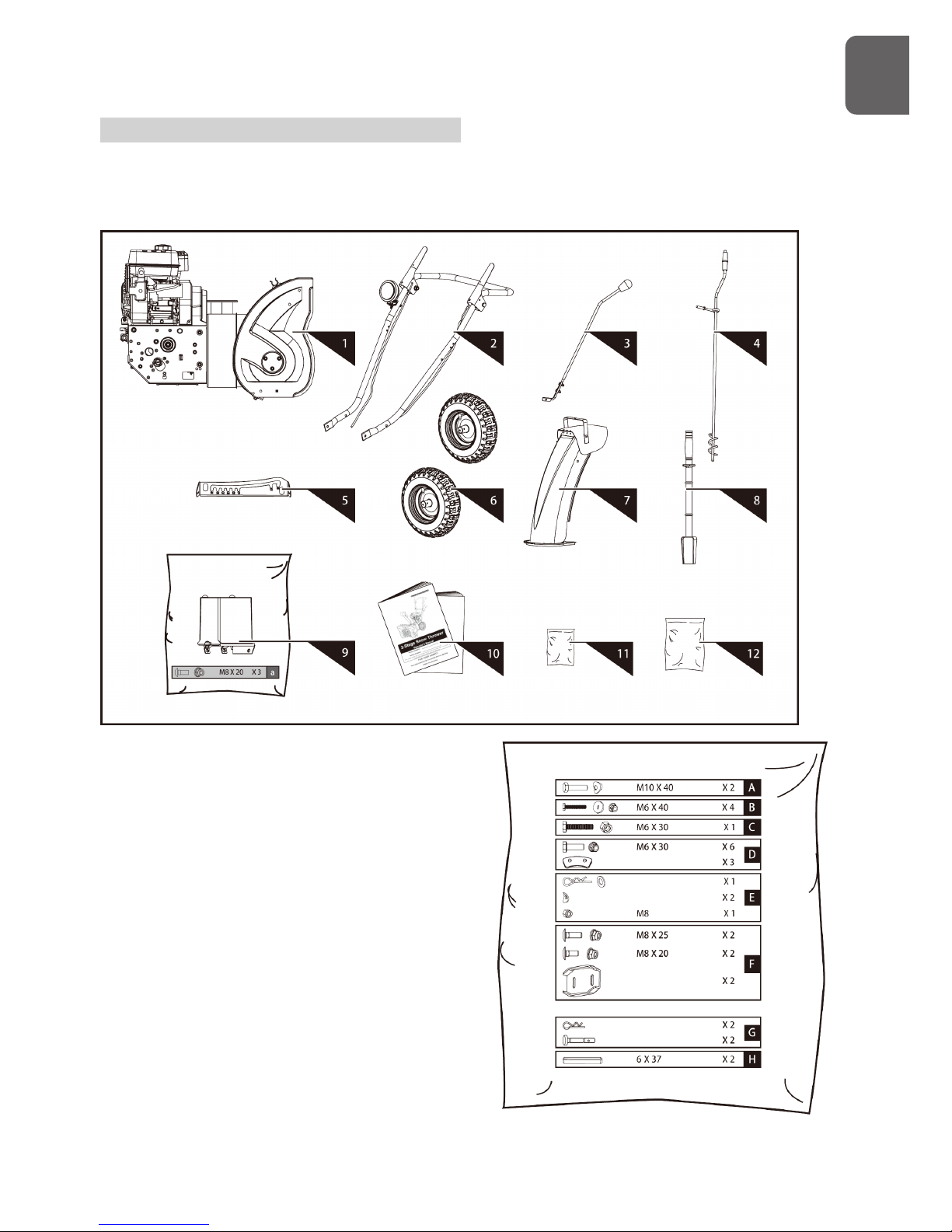

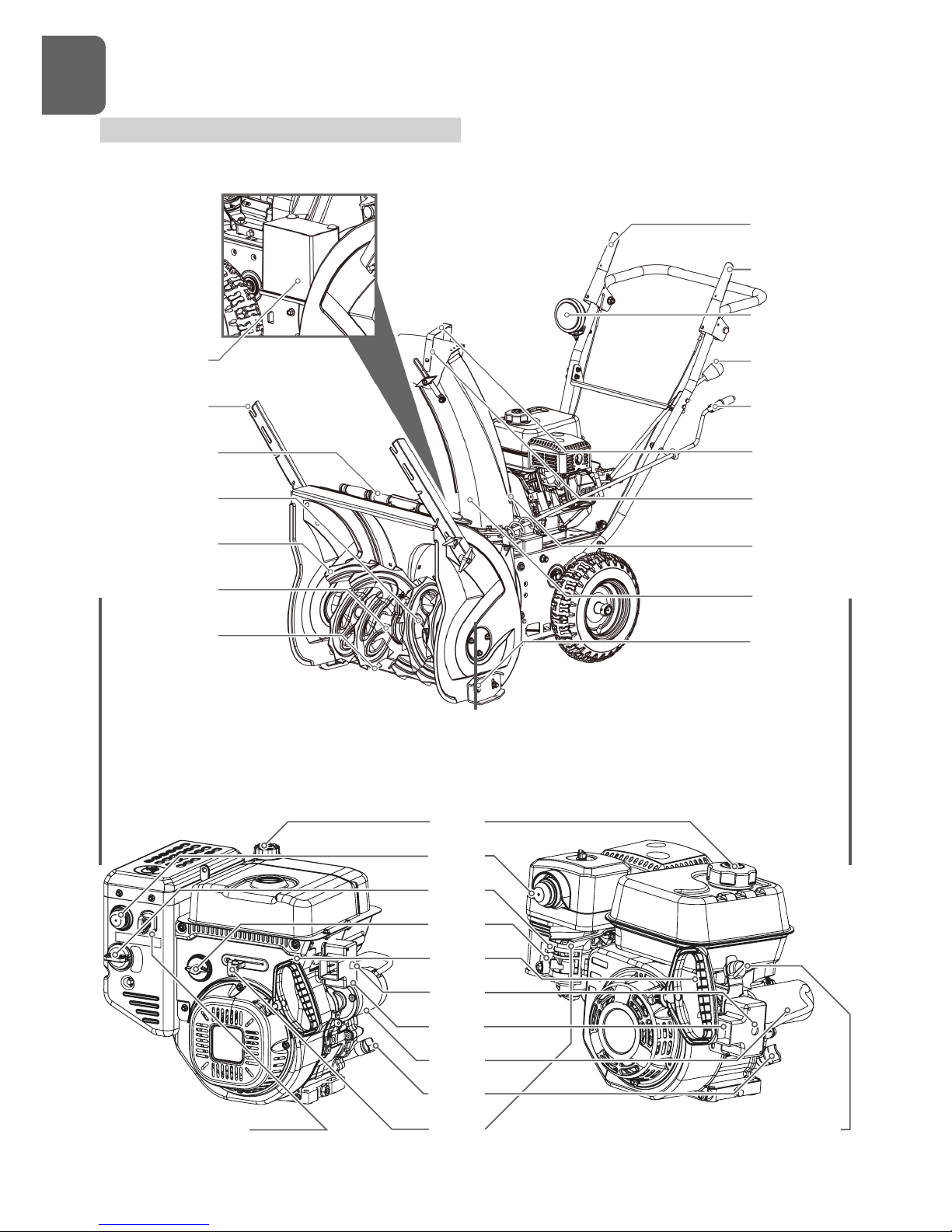

5. Overview Instrument Components

The snow thrower comes partially assembled and is shipped in carefully packed carton. After all

the parts have been removed from the carton, you should have:

Attention : All reference to the left or right side

of the snow thrower are from the

operator’s position.

1. Snow Thrower Unit

2. Handlebars

3. Shift Lever

4. Chute Crank Lever

5. Control Panel

6. Wheels (1 pair)

7. Discharge Chute

8. Chute Clean-Out Tool

9. Battery (if so equipped)

10. Operator’s Manual & Engine Manual

11. Engine Hardware Bag

12. Snow Thrower Hardware Bag, Including

G

B

Page 10

10

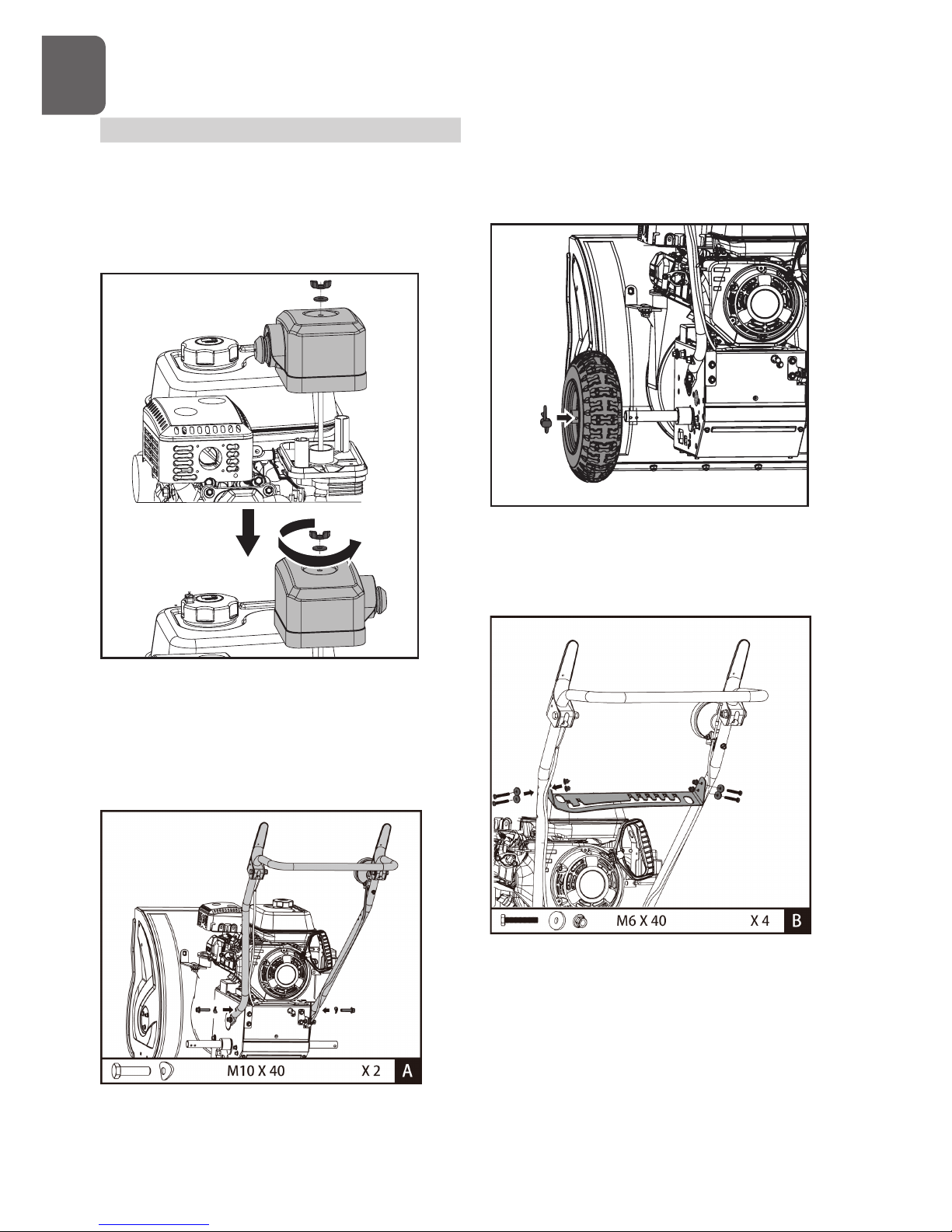

6. Assembly

Following the assembly directions below, you will

assemble the snow thrower in a few minutes

Engine

1. Remove wing nut and washer from the air

filter cover.

2. Rotate the air filter cover by 180o so that

the primer faces outside.

3. Install air filter cover and tighten wing nut.

Handlebars

1. Align the holes in the handlebars with the

side plates and secure handlebars with

the screws and the washers until they are

finger tight.

2. Remove the axle pins and slide the wheels

on the axle. Insert each axle pin through

the hole in each wheel hub and through the

hole in the axle.

3. Secure control panel to the handlebars with

screws, washers and nuts until they are

finger tight.

4. Ensure that the handles are at the same

height, and then tighten all the fasteners

securely.

G

B

Page 11

11

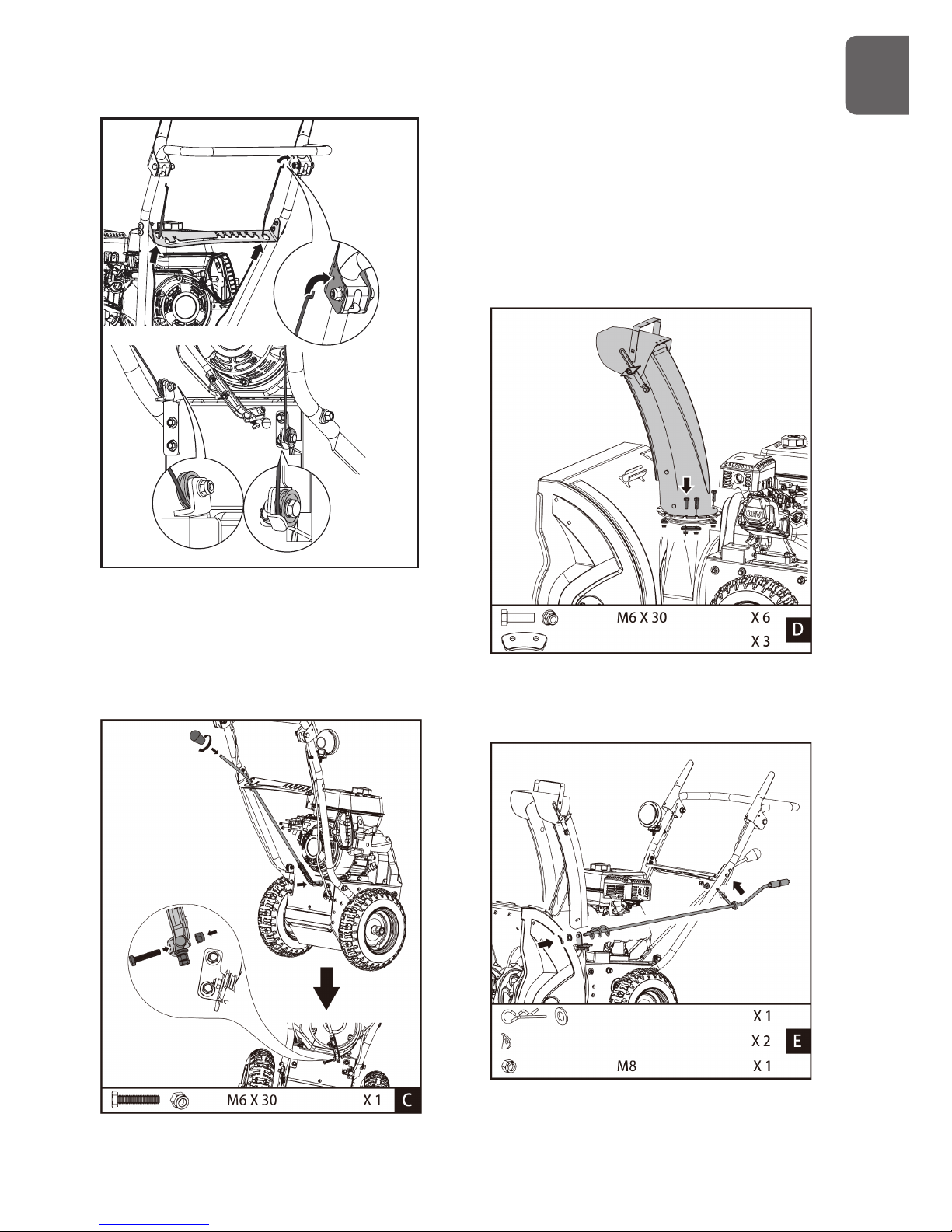

5. Slide the control cables through the holes in

the control panel. Make certain the cables are

seated properly in roller guides when hook the

cables to the clutch levers.

Speed Shift Linkage

Remove the knob to slide the shift lever

through the slot in the control panel. Secure

shift lever to the shift arm with screw and nut.

Replace the knob.

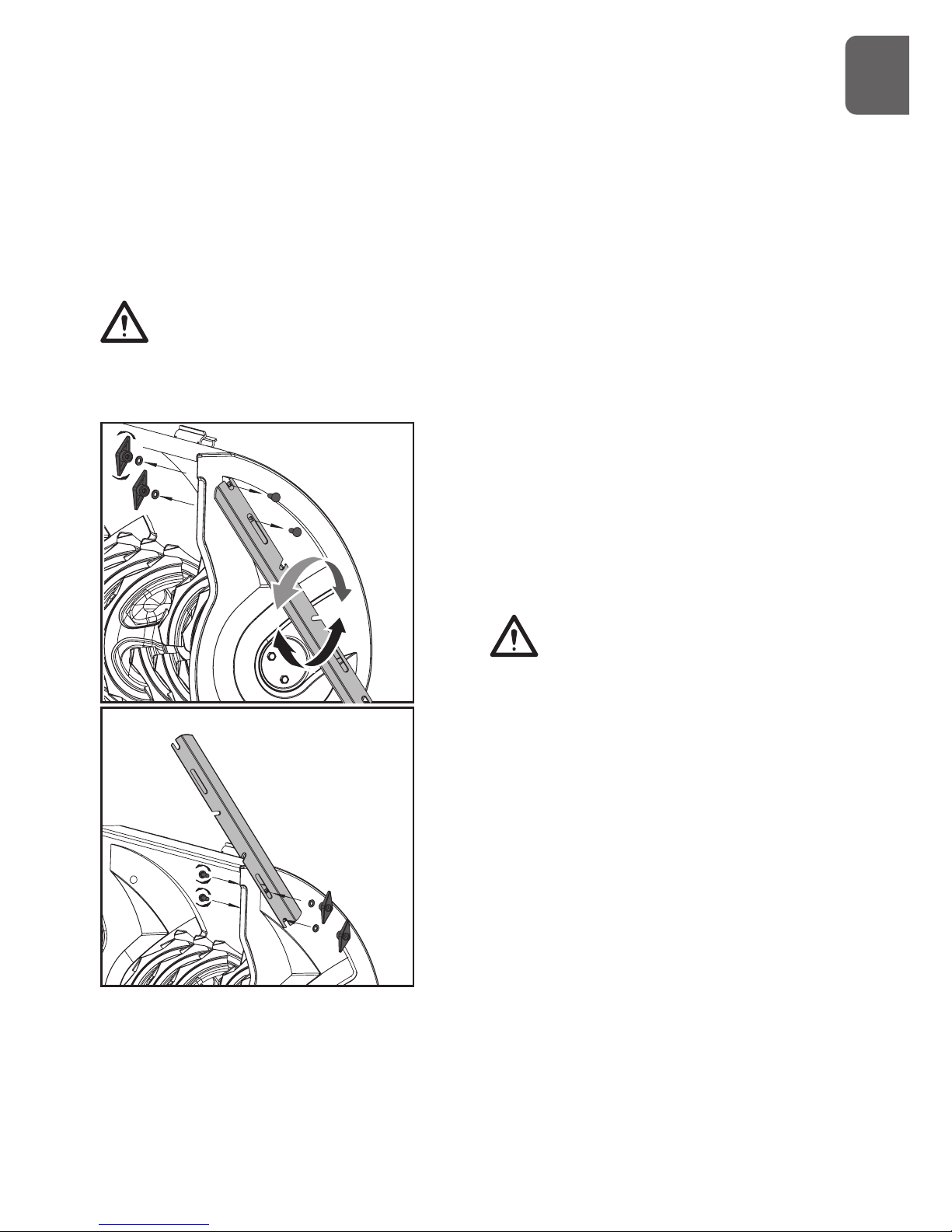

Discharge Chute

1. Grease underside of discharge chute ring (if

not already greased).

2. Install discharge chute over opening in the

auger housing and secure with fasteners.

G

B

Page 12

12

3. Secure the upper crank lever bracket (attached

to the crank lever) to the upper left side of the

handlebar with a locknut and two curved washers.

4. Apply grease to the spiral of the crank lever.

5. Insert the spiral end of the crank lever into the

lower bracket and secure with the flat washer and

clevis pin.

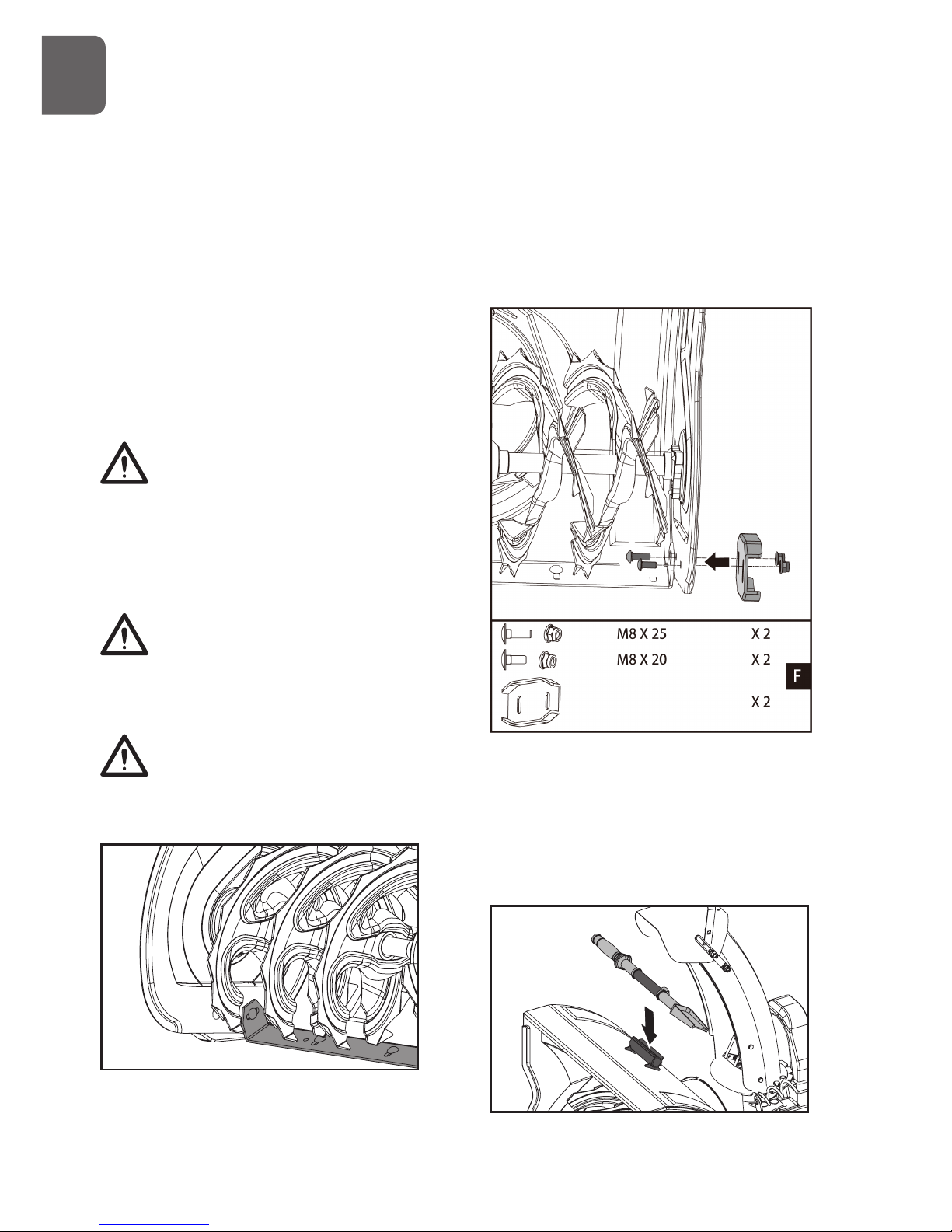

Tires

The tires are over-inflated at factory for

shipping purposes. Check the pressure in the

tires. Reduce or Increase equally in both tires

to the manufacturer’s recommended pressure.

Under any circumstance do not

exceed manufacturer’s recommended

pressure. Excessive pressure when

seating beads may cause tire/rim assembly

to burst with force sufficient to cause serious

injury. Refer to side wall of tire for recommended

pressure.

Equal tire pressure should be maintained

at all times. If the tire pressure is not

equal in both tires, the machine may not

travel in a straight path and the scraper

blade may wear unevenly.

Keep tires free of gasoline and oil,

which can harm rubber.

Skid Shoes

1. Move the machine to a level surface.

2. Support the auger blades so that they are 3mm

(1/8”) off the ground.

3. Check the scraper blade adjustment. The scraper

blade should be 3mm (1/8”) above and parallel to

a level ground. To adjust the scraper blade, loosen

the seven mounting screws (two on each side),

level the scraper blade, and tighten the mounting

screws.

4. Attach both skid shoes to the auger side plates

with the screws and nuts. Move the skid shoes

down as far as possible. Be sure both skid shoes

are adjusted evenly. Tighten securely.

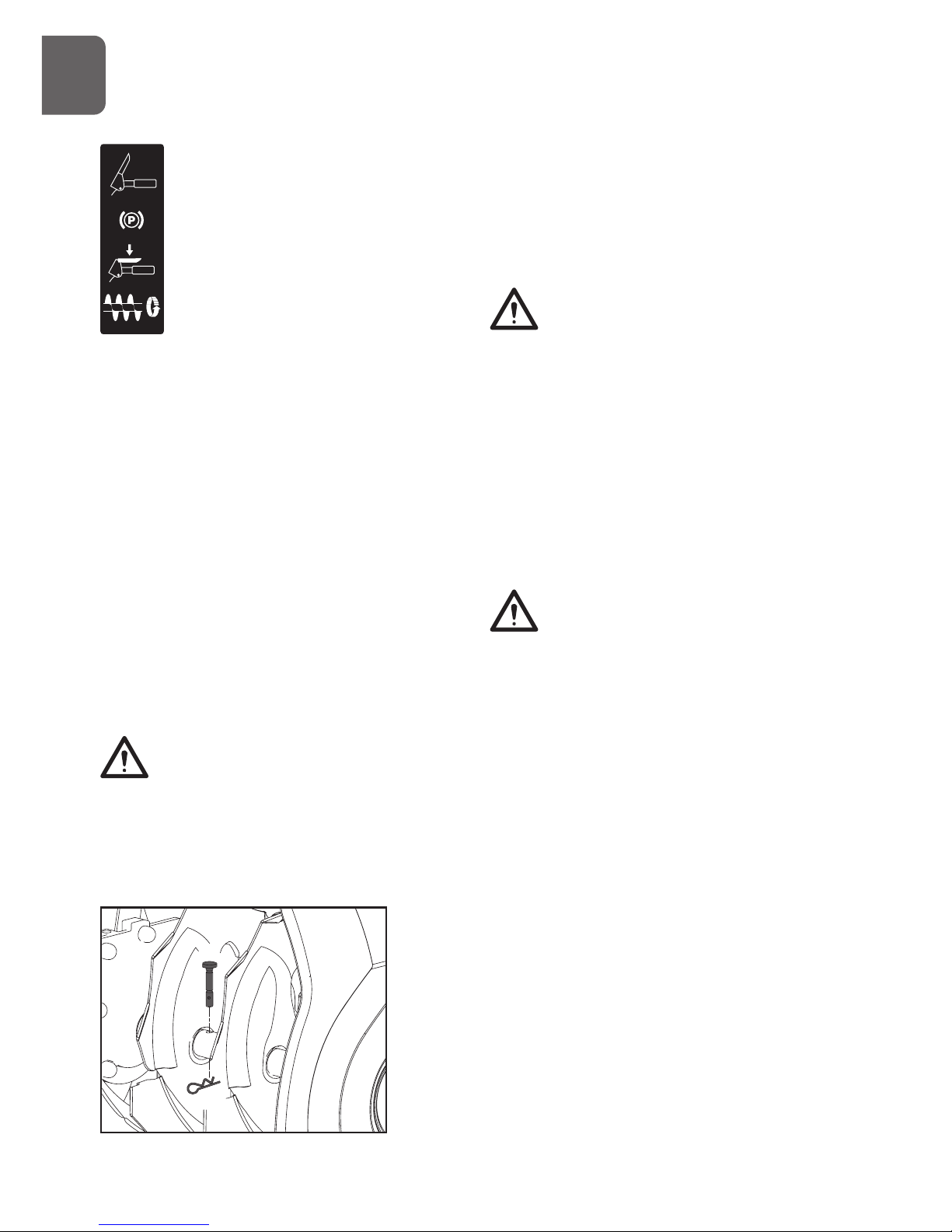

Chute Clean-Out Tool

G

B

Page 13

13

Fasten the clean-out tool to the mounting clip

on the rear of the auger housing.

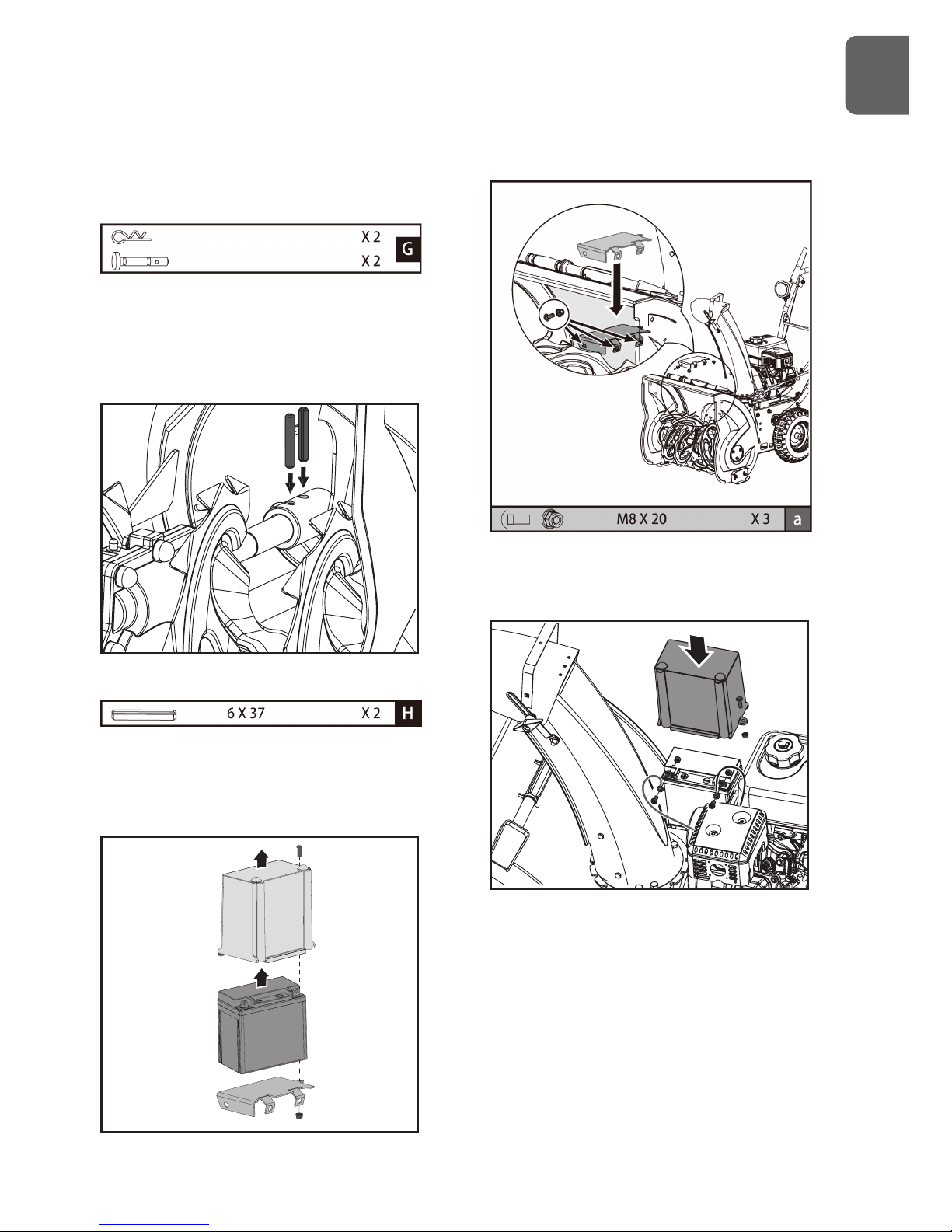

Replacement Shear Pins

A pair of replacement auger shear pins and

clevis pins are included with your snow thrower.

Store them in a safe place until needed.

Spare Roll Pins

The impeller is secured to the impeller shaft

with roll pins.

Two 6x37 roll pins for impeller are supplied

as spare in the hardware bag. Store them in a

safe place until needed.

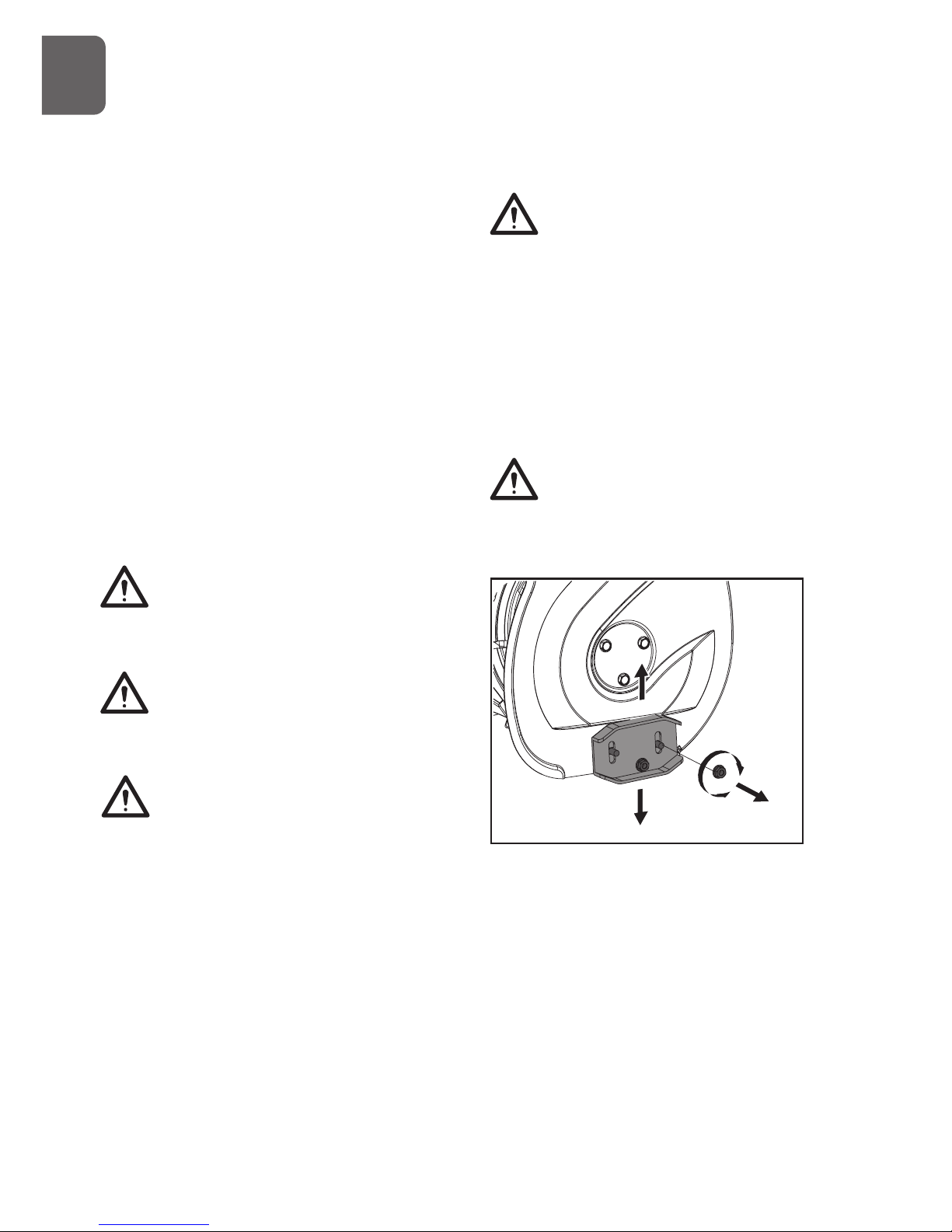

Battery (if so equipped)

1. Remove the battery cover by loosening

the screw and nut.

2. Take battery out of the tray.

3. Attach the tray to the auger housing with

screws and nuts.

4. Replace battery on the tray.

5. Connect positive (red) battery cable to

the battery terminal first, then negative

(black) battery cable. Check that all cable

connectors are tight.

6. Reinstall battery cover and tighten the

screw and nut.

G

B

Page 14

14

7. Operation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

27

18

19

20

21

22

23

24

25

26

17

28 29

G

B

Page 15

15

1. Battery

2. Drift Cutters

3. Chute Clean-Out Tool

4. Shear Pins

5. Auger

6. Auger Gearcase

7. Scraper Blade

8. Drive Clutch Lever

9. Auger Clutch Lever

10. Headlight

11. Speed Shift Lever

12. Chute Crank

13. Chute Deflector Handle

14. Chute Deflector

15. Belt Cover

16. Discharge Chute

17. Skid Shoes

18. Fuel Filler Cap

19. Primer

20. Choke

21. Fuel Shutoff Valve

22. Recoil Starter

23. Electric Start Button

24. Power Cord Plug

25. Electric Starter

26. Engine Oil Fill Cap w/ Dipstick

27. Throttle Lever

28. Safety Ignition Switch

29. ON/OFF Switch

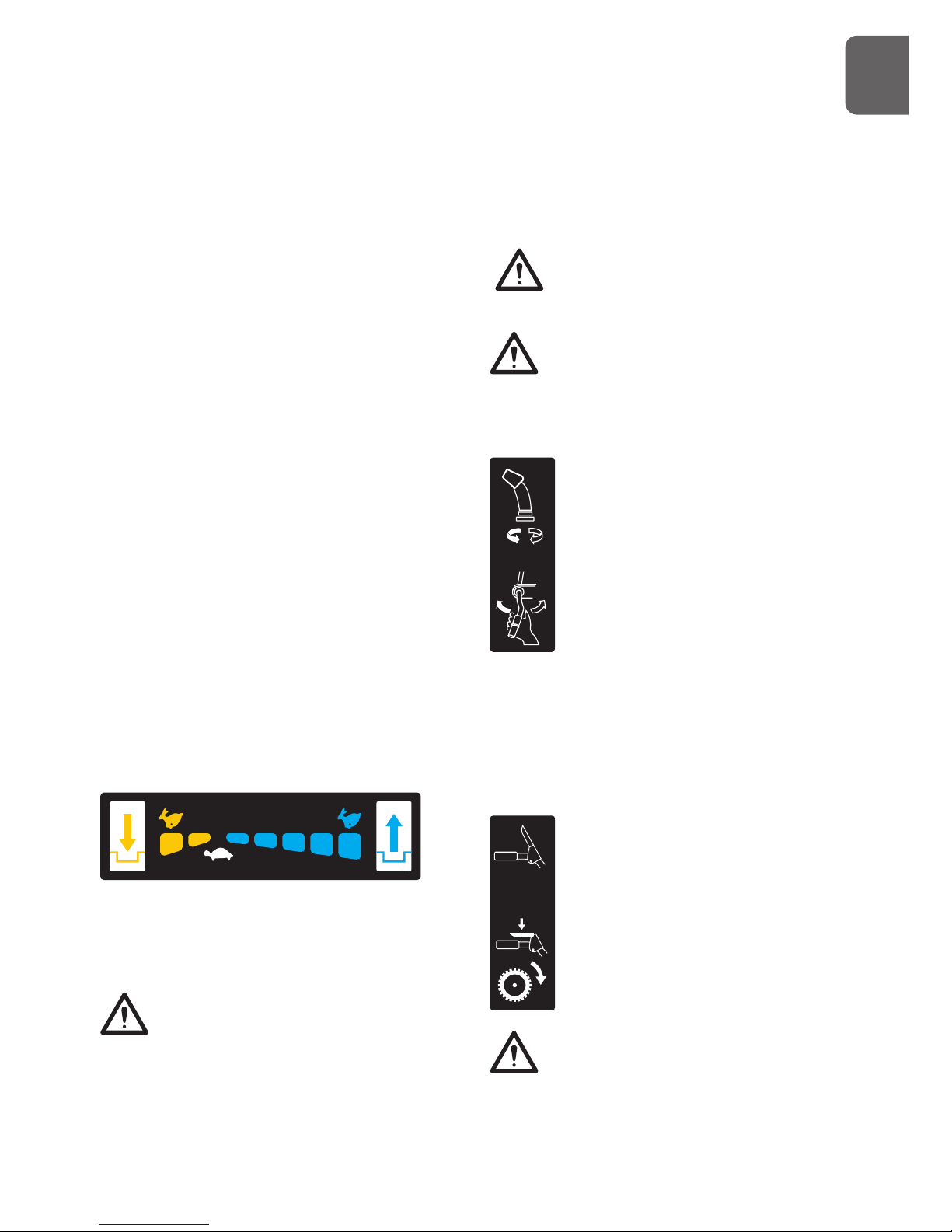

Speed Shift Lever

The speed shift lever has 8 positions: 6 forward

speeds and 2 reverse. To change speeds, move

the speed shift lever to the desired position.

The lever locks in a notch at each speed selection.

Always release the drive clutch lever

before changing speeds. Failure to

do so will result in damage to the

snow thrower.

Slower speeds are for heavier snow and faster

speeds are for light snow and transporting the

snow thrower. It is recommended that you use

a slower speed until you are familiar with the

operation of the snow thrower.

If the engine slows down under a

load or the wheels slip, shift the

machine into a lower gear.

If the front of the machine rides up,

shift the machine into a lower gear.

If the front continues to ride up, lift

up on the handles.

Discharge Chute Crank Lever

Rotate the discharge crank lever

clockwise to move the discharge

chute to the left; counterclockwise

to move the chute to the right.

Chute Deflector Handle

Move the deflector handle forward to move

the snow stream down; move it rearward to

move the snow stream up.

Drive Clutch Lever

Squeeze the clutch lever against

the handgrip to engage the wheel

drive. Release to disengage.

Always release the drive clutch lever

before changing speeds. Failure to

do so will result in damage to the

snow thrower.

G

B

Page 16

16

Auger Clutch Lever

Squeeze the clutch lever against

the handgrip to engage the auger

and start snow throwing action.

Release to disengage.

Scraper Blade & Skid Shoes

The scraper blade allows better contact with

the surface being cleared. It also prevents

damage to the housing from normal use.

The skid shoes are located on each side of

the auger housing and control the distance

between the scraper blade and the ground.

Adjust skid shoes equally to keep the scraper

blade level with the ground.

The scraper blade & skid shoes are subject

to wear and damage. Both scraper blade and

skid shoes are adjustable to compensate for

wear. They should be checked and adjusted

periodically. Replace when necessary.

Damage to auger housing will result

if scraper blade wears down too far.

Both scraper blade and skid shoes have two

wear edges. When one side wears out, they

can be rotated 180o to use the other edge.

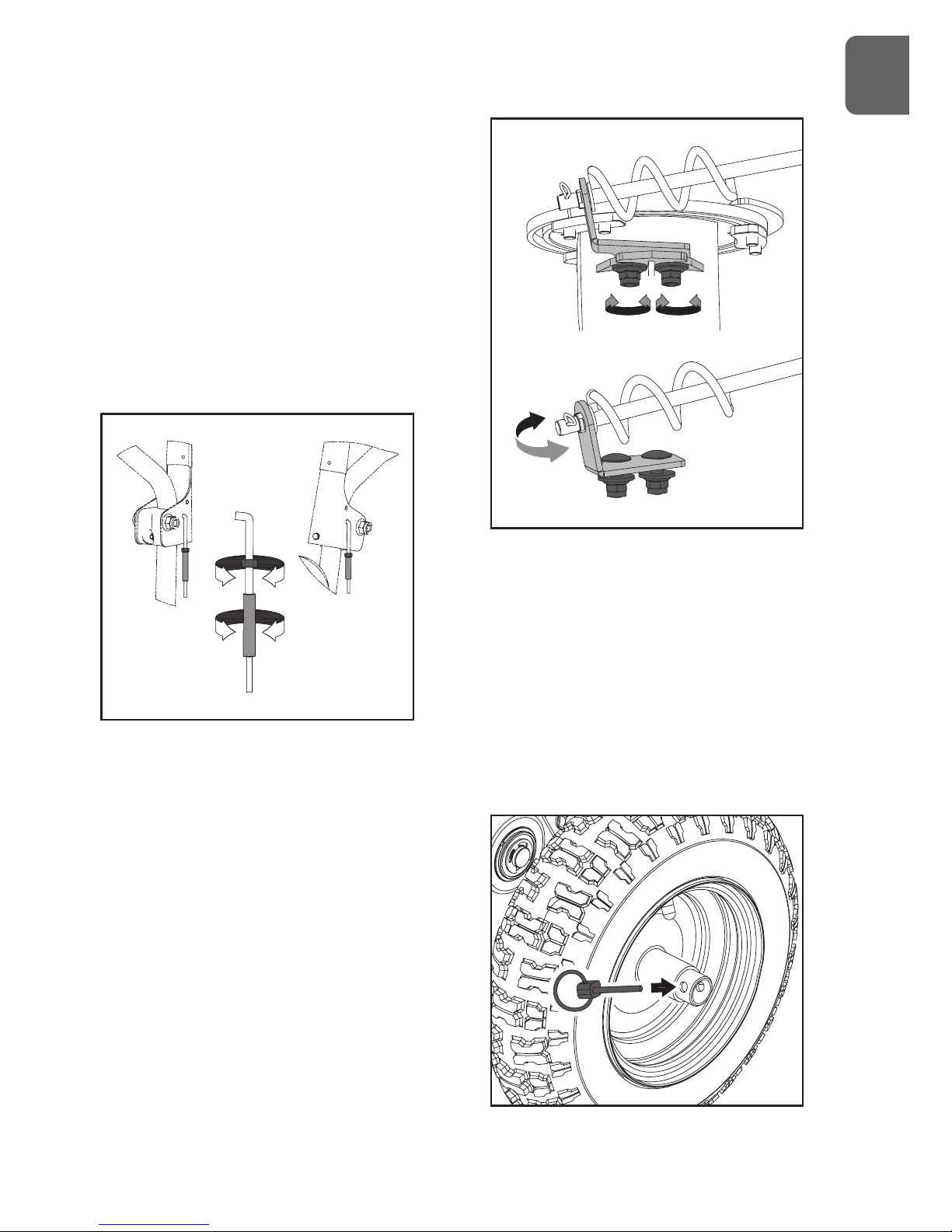

Shear Pins

The augers are secured to the auger shaft with

shear pins and clevis pins. If the auger should

strike a foreign object or ice jam, the snow

thrower is designed so that the pins may shear,

preventing damage to any other components. If

augers will not turn, check to see if the pins have

sheared. Replace the shear pins if necessary.

Do not substitute. Use only original

equipment shear pins as supplied

with your snow thrower.

Auger

When engaged, the augers rotate and draw

snow into the auger housing.

Discharge Chute

Snow drawn into the auger housing is

discharged out the discharge chute.

Chute Clean-Out Tool

Never use your hands to clear a

clogged discharge chute . Shut off

engine and remain behind handles

until all moving parts have stopped

before unclogging.

The chute clean-out tool is conveniently

fastened to the rear of the auger housing

with a mounting clip. Should snow and ice

become lodged in the discharge chute during

operation, proceed as follows to safely clean

the discharge chute and chute opening:

1. Release the auger clutch lever and shut off

the engine.

2. Remove the clean-out tool from the clip which

secures it to the rear of the auger housing.

3. Grasp the tool firmly by the handle and push and

twist the tool into the discharge chute to dislodge

the blockage.

4. Refasten the clean-out tool to the mounting

clip on the rear of the auger housing.

5. Make sure the discharge chute is pointed in a

safe direction (no vehicles, buildings, people, or

other objects are in the direction of discharge).

G

B

Page 17

17

Restart the engine. While standing in the operator’s

position (behind the snow thrower), engage the

auger control for a few seconds to clear any

remaining snow and ice from the auger housing

and the discharge chute.

Headlight (if so equipped)

The headlight provides added

safety in low-visibility conditions.

Turn the headlight switch to the

ON position to activate.

Drift Cutters (if so equipped)

Drift cutters break up snow drifts that are

taller than the auger housing and direct the

snow into the auger. Store the drift cutters on

the auger housing when not in use. Reposition

drift cutters so they face forward as shown.

Wing nuts should be fastened on the outside

of the auger housing.

Fuel Shutoff Valve

Always operate the snow thrower with the

fuel shut-off valve in the OPEN position. Close

the valve when you do not use the machine.

Throttle Lever

Move the throttle lever to the right to increase

the engine speed; move it to the left to

decrease the engine speed. Move the throttle

lever to the STOP position to stop the engine.

Choke

Engage choke by rotating lever to FULL

position whenever you are starting a cold

engine. As engine warms up, gradually rotate

the choke to the OFF position.

Do not use choke to start a warm engine.

Never use choke to stop engine.

Primer

Press the primer to pump additional fuel from

the carburetor to the cylinder for improved

cold weather starting.

Recoil Starter

The recoil starter is on the back side of the

engine. Pull the recoil starter handle to start

the engine.

Safety Ignition Switch (if so equipped)

Insert the safety ignition key for engine to

start and run. To stop the engine, remove the

key.

ON/OFF switch (if so equipped)

Used to stop the engine. Move switch to OFF

G

B

Page 18

18

position to stop engine. Place switch in ON

position for engine to start and run.

Ignition Switch (12V DC electric start)

The ignition switch is operated by a removable

key which has 3 positions of STOP, RUN and

START.

Electric Starter & Start Button (if so equipped)

The electric starter will start a properly choked

and cranked engine when the key is turned

(12V DC) or start button (120V or 230V AC) is

pushed.

To start the machine, connect the electric

starter to an electric power source with an

approved extension cord and press the start

button.

Thoroughly inspect the electrical cord

before using the machine. If the cord is

damaged, do not operate the machine.

Replace or repair the damaged cord immediately.

Connect extension cord to the electric

starter plug-in first and then to a power

outlet; disconnect the extension cord from

the power outlet first and then from the machine.

To prevent damaging the electric starter, do

not run it more than 5 continuous seconds

each time you try to start. Wait 10 seconds

between each attempt.

Adjustments

Skid Shoes

Position the skid shoes based on surface

conditions. For removal of snow in normal

conditions, such as a paved driveway or

sidewalk, place skid shoes in the higher

position to give a 3mm (1/8”) clearance

between the scraper blade and the ground.

Use a middle or lower position when the area

to be cleared is uneven, such as a gravel

driveway.

It is not recommended to operate the snow

thrower on gravel as it can easily pick up

and throw by the impeller, causing personal

injury or damage to the snow thrower and

surrounding property.

If you choose to operate the snow thrower

on a gravel surface, use extra caution and

keep the skid shoes in position for maximum

clearance between the ground and the scraper

blade.

Always adjust skid shoes after adjusting

scraper blade to prevent premature wear to

scraper blade or damage to auger housing.

To adjust the skid shoes:

1. Loosen the four hex nuts (two on each

side) and carriage bolts. Move skid shoes

to desired position.

2. Make sure the entire bottom surface of

skid shoe is against the ground to avoid

uneven wear on the skid shoes.

3. Retighten nuts and bolts securely.

Auger Clutch and Drive Clutch

When auger clutch lever or drive clutch lever

is released and in the disengaged position, the

G

B

Page 19

19

cable should have very little slack.

Auger must stop within 5 seconds when the

auger clutch lever is released. If auger clutch

does not engage or disengage properly, adjust

auger clutch before operation.

If the snow thrower’s drive is disengaging

intermittently during operation, or it drives

when you release the drive clutch lever, adjust

the drive clutch before operation.

Both auger clutch and drive clutch can be

adjusted as follows:

1. Loosen jam nut on adjustment turnbuckle.

2. Turn the adjustment turnbuckle up and down to

increase cable tension or provide more slack.

3. Retighten jam nut.

Chute Bracket

If the spiral at the bottom of the chute crank

lever is not fully engaging with the chute

assembly, the chute bracket can be adjusted.

To do so:

1. Loose the two nuts which secure the chute

bracket and reposition it slightly.

2. Retighten the nuts.

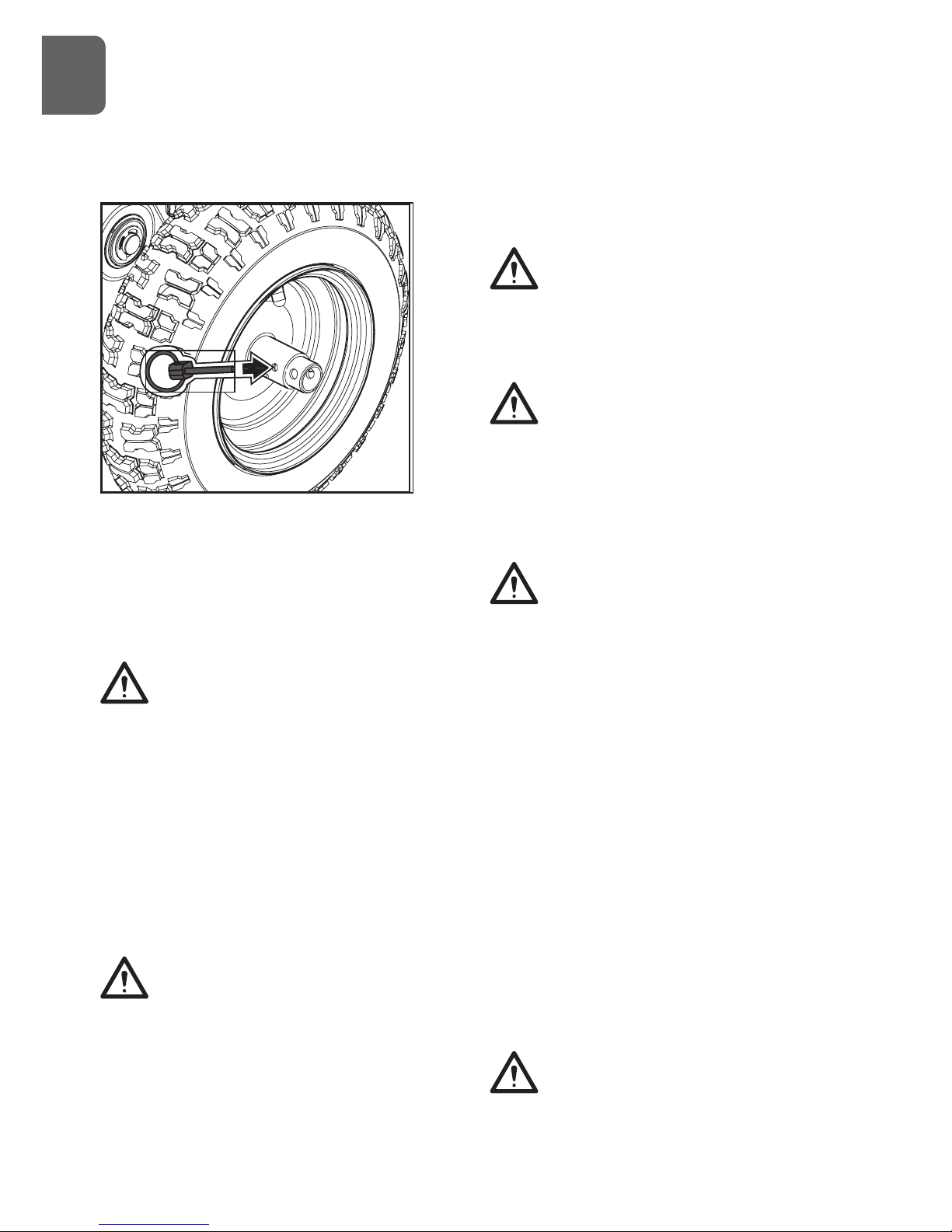

Freewheeling and Self-Propelling

To do so:

1. Loose the two nuts which secure the chute

bracket and reposition it slightly.

2. Retighten the nuts.

Freewheeling and Self-Propelling

Use the axle lock pin to lock or unlock the

right or left wheel. Lock both wheels to

increase traction; unlock one wheel to allow

for easier turning of the unit; unlock both

wheels for freewheeling.

G

B

Page 20

20

To unlock wheel, slide it inward and insert the

axle pin through the outer axle hole, but not

through the wheel hub.

To lock wheel, slide it outward and insert the

axle pin through the hole in the wheel hub and

the outer axle hole.

Starting and Stopping the Engine

Before starting the engine, check engine

oil level and ensure the engine is served as

described in the Engine Manual with the

snow blower.

Cold Start – Electric Starter (120V or 230 AC)

(if so equipped)

The engine is equipped with both A.C. electric

starter and a recoil starter. The electric starter

is equipped with a three-wire power cord and

plug and is designed to operate at the voltage

shown in the label.

Do not use the electric starter if

your household voltage different

from the one shown on the electric

starter.

1. Insert safety ignition key into ignition slot

until it clicks. Do not turn the key.

2. Be sure fuel shutoff valve is in the OPEN

position.

3. Move choke control to FULL position.

4. Push the primer 2 or 3 times. When temperature

is below -25oC (15oF), additional priming may

be needed. When temperature is above 10oC

(50oF), priming is not necessary.

Over priming may cause flooding,

preventing the engine from starting.

If you do flood the engine, wait a

few minutes before attempting to

start and do not push the primer.primer.

Some snow engine is not equipped

with primer as priming is not needed

for such engine.

5. Connect the extension cord to the engine.

6. Plug the other end of the extension cord

into a three-wire grounded receptacle.

7. Push starter button until engine starts.

To prevent damaging the electric starter, do

not run it more than 5 continuous seconds

each time you try to start. Wait 10 seconds

between each attempt.

8. When the engine starts, release the starter

button and slowly move the choke control

to the OFF position.

9. Disconnect the extension cord from the

receptacle first, then from the engine.

Cold Start – Electric Starter (12V DC) (if so

equipped)

1. Be sure fuel shutoff valve is in the OPEN

position.

2. Move choke control to FULL position.

3. Push the primer 2 or 3 times. When

temperature is below -25oC (15oF),

additional priming may be needed. When

temperature is above 10oC (50oF), priming

is not necessary.

Over priming may cause flooding,

preventing the engine from starting. If you

do flood the engine, wait a few minutes

G

B

Page 21

21

before attempting to start and do not push the

primer.

Some snow engine is not equipped

with primer as priming is not needed

for such engine.

4. Turn ignition key to the START position

until engine starts.

To prevent damaging the electric starter, do

not run it more than 5 continuous seconds

each time you try to start. Wait 10 seconds

between each attempt.

5. When the engine starts, release the ignition

key into RUN position and slowly move the

choke control to the OFF position.

Cold Start – Recoil Starter

1. Be sure fuel shutoff valve is in the OPEN

position.

2. Place ON / OFF switch in ON position.

3. Rotate choke control to FULL position.

4. Push the primer 2 or 3 times. When

temperature is below -25oC (15oF),

additional priming may be needed. When

temperature is above 10oC (50oF), priming

is not necessary.

Over priming may cause flooding,

preventing the engine from starting. If you

do flood the engine, wait a few minutes

before attempting to start and do not push the

primer.

5. Grasp recoil starter handle and pull rope out

slowly until it pulls harder. Let rope rewind slowly.

6. Pull rope with a rapid continuous full arm stroke.

Do not allow starter rope to snap back.

7. Repeat steps 5 and 6 until engine starts.

8. When the engine starts, release the recoil starter

handle and slowly move the choke control to the

OFF position.

Warm Start

Follow the steps above, keeping the choke

control in the OFF position and do not use

primer.

Allow the engine to warm up for a few

minutes, engine will not develop full power

until it has reached normal operating

temperature.

In snowy and cold conditions, some

controls and moving parts may freeze. Do

not use excessive force when trying to

operate frozen controls. If you have difficulty

operating any control or part, start the engine and

let is run for a few minutes.

Snow Throwing Tips

It is easier and more efficient to remove snow

immediately after it falls.

The best time to remove snow is the early

morning. At this time the snow is usually dry

and has not been exposed to the direct sun

and warming temperatures.

Slightly overlap each successive path to

ensure all snow will be removed.

For large areas, start in the middle and throw

snow to each side, so snow is not cleared

more than once.

For extremely heavy snow, reduce the width

of snow removal by overlapping previous path

and moving slowly.

Throw snow downwind whenever possible.

Keep engine clean and clear of snow during

use. This will help air flow and extend engine

life.

After snow-throwing is completed, let the

engine run for a few minutes to help dry

off the moisture on the engine and prevent

G

B

Page 22

22

moving parts from freezing. Engage the auger

to clear any remaining snow from inside

the housing. Rotate the discharge chute to

prevent it from freezing. Stop the engine, wait

for all moving parts to stop, and remove all

ice and snow from the snow thrower. With

the engine off, pull the recoil starter handle

several times to prevent the recoil starter from

freezing up.

8. Maintenance and Care

Engine

Refer to the Engine Operator’s Manual.

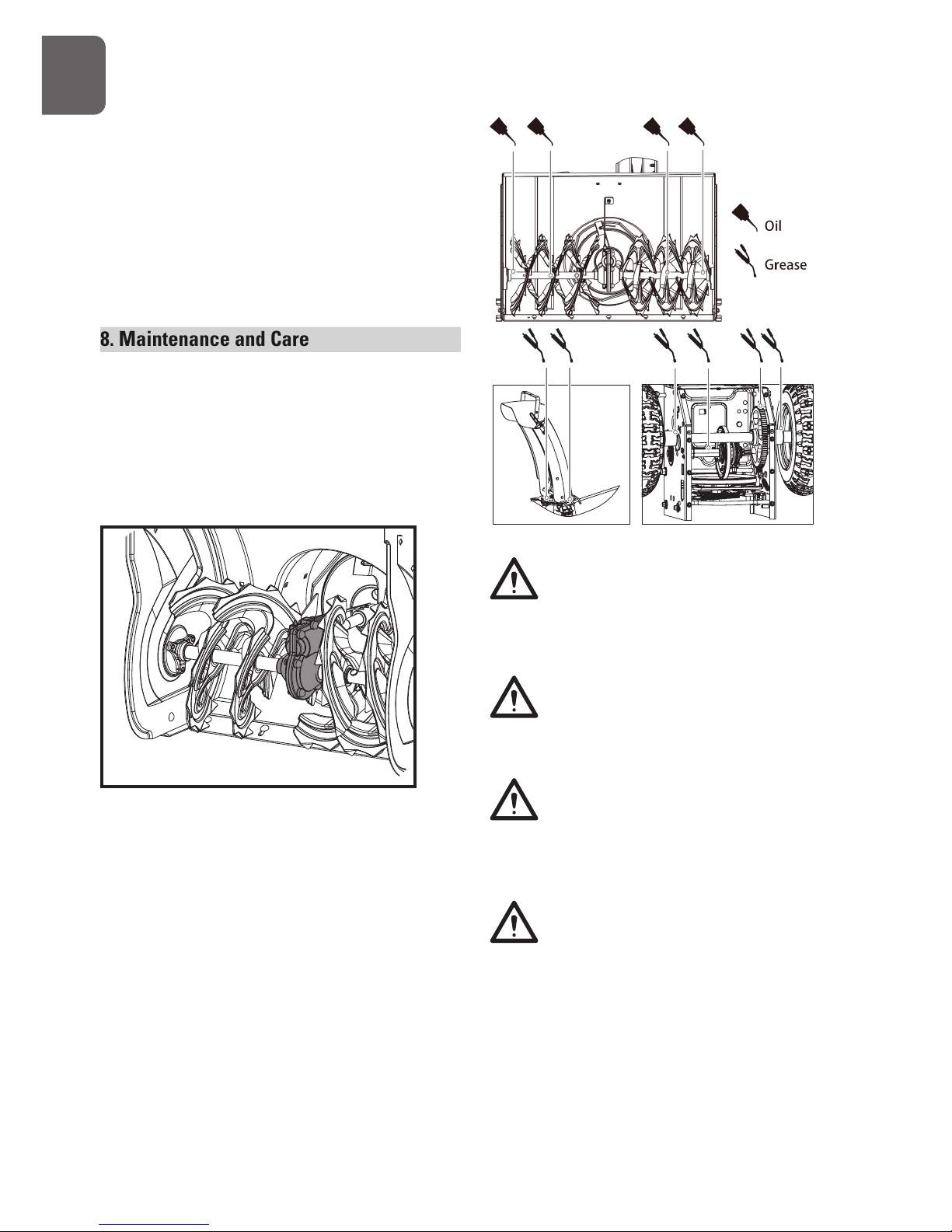

Lubrication

Auger Gearbox

The gearbox was filled with lubricant to the

proper level at the factory. Unless there is

evidence of leakage or service has been

performed on the gearbox, no additional

lubricant should be required. If lubricant is

required, use GL-5 or GL-6, SAE85-95, EP

gear oil lubricant. Do not use synthetic oil.

General Lubrication

Lightly lubricate all moving parts of the

machine at the end of the season or every 25

operating hours.

Do not allow grease or oil get on friction

disc, friction plate or belts. Do not

excessively oil the machine; extra oil may

enter the traction drive and cause the traction

drive belt to slip.

When lubricating auger shaft, remove shear

pins to apply oil inside the shaft and around

spacers and flange bearings found at either end

of the shaft.

Remove the wheels to apply grease

the wheel shaft.

Battery (if so equipped)

Battery is maintenance-free. Do not tamper

with or attempt to open battery.

Keep battery and its terminals clean.

1. Remove battery cover.

2. Detach the negative (black) battery cable from

the battery first to prevent a short circuit, then the

positive (red) battery cable.

3. Take the battery out of the tray.

G

B

Page 23

23

4. Remove corrosion from battery terminals and

cable connections with a wire brush, then wash

with weak baking soda solution.

5. Apply a thin coat of grease or petroleum jelly to

terminals and cable ends to retard corrosion.

6. Attach and tighten the positive (red) battery cab

first, then the negative (black) battery cable.

7. Place the battery on the tray and Install the

cover.

Off-Season Storage

Refer to the Engine Manual for

information on storing your engine.

At the end of the season or if the snow

thrower will not be used for 30 days longer,

follow the storage instructions below.

1. Run the engine until the fuel lines and

carburetor are empty and it stops due to

lack of fuel.

2. Remove the safety ignition key and allow

the engine to cool.

3. Lubricate the machine as instructed.

4. Clean the exterior of the engine and the

snow thrower thoroughly.

5. Touch up all rusted or chipped paint

surfaces; sand affected areas before

painting, and use a rust preventative to

prevent the metal parts from rusting.

6. Tighten all loose screws, bolts, and

locknuts. Repair or replace any damaged

parts.

7. Cover the machine and store it in a clean,

dry place out of the reach of children.

Belt Replacement

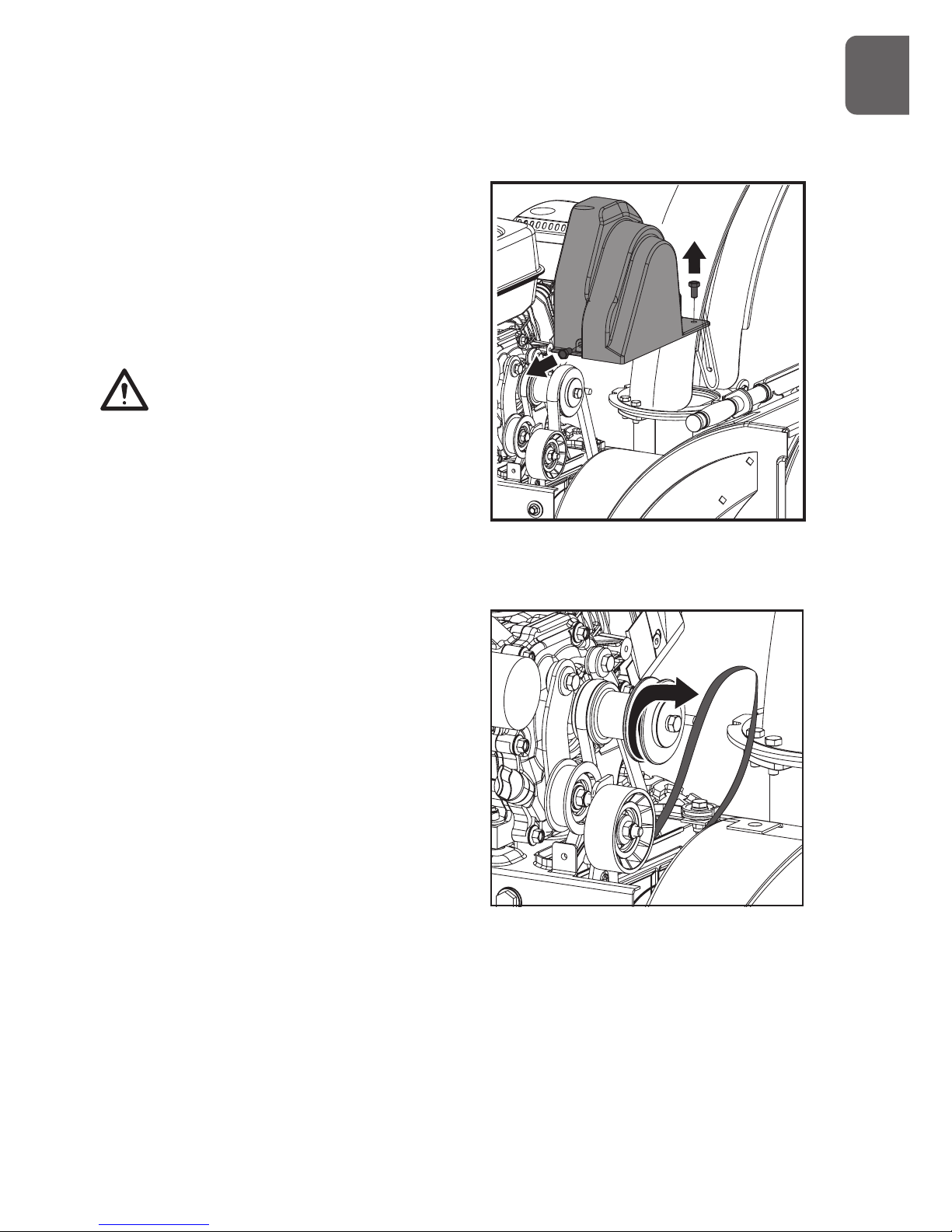

Auger Belt

If the auger belt becomes worn, oil-soaked,

or otherwise damaged, proceed as follows to

replace the belt.

1. To prevent spillage, remove all fuel from

tank by running engine until it stops.

Remove the key to avoid unintended

starting and allow unit to cool completely.

2. Remove the two screws that hold the belt

cover in place and set the cover aside.

3. Roll the auger belt(s) off the engine pulley.

4. Carefully pivot the snow thrower up and

forward so that it rests on the auger housing.

G

B

Page 24

24

5. Remove the frame cover from the underside

of the snow thrower by removing the screws

which secure the cover.

6. Remove the belt(s) from around the auger

pulley, and slip the belt(s) between the

support bracket and the auger pulley.

7. Replace the auger belt(s) by following

instructions in reverse order.

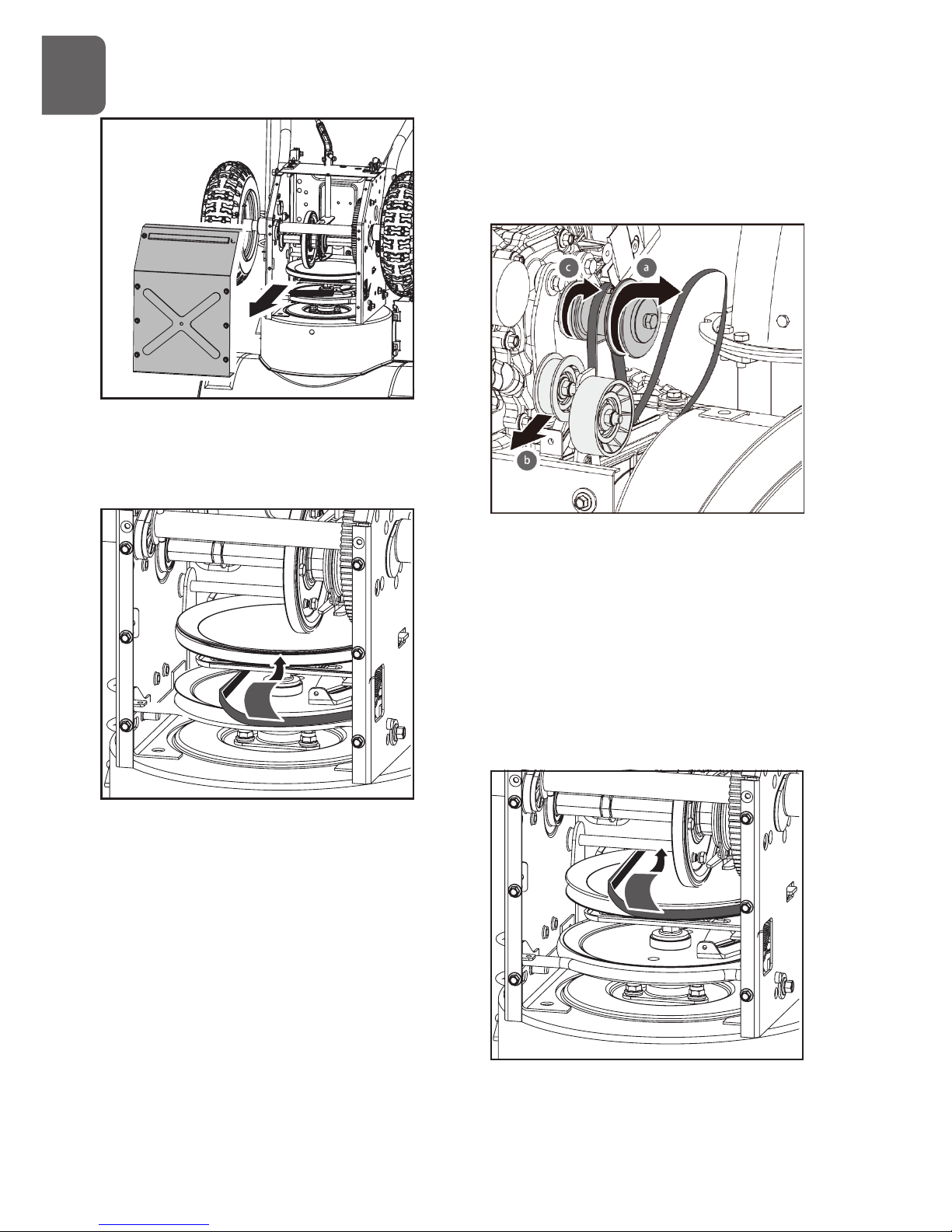

Drive Belt

If the drive belt becomes worn, oil-soaked, or

otherwise damaged, proceed as follows to

replace the belt.

1. To prevent spillage, remove all fuel from

tank by running engine until it stops.

Remove the key to avoid unintended

starting and allow unit to cool completely.

2. Remove the two screws that hold the belt

cover in place and set the cover aside.

3. Remove the belt as follows.

a. Roll the auger belt off the engine pulley.

b. Pivot the idler pulley toward the right

to relieve tension.

c. Lift the drive belt off engine pulley.

4. Carefully pivot the snow thrower up and

forward so that it rests on the auger housing.

5. Remove the frame cover from the underside

of the snow thrower by removing the screws

which secure the cover.

G

B

Page 25

25

8. Place belt(s) onto engine sheave(s).

9. Reinstall the chute crank lever.

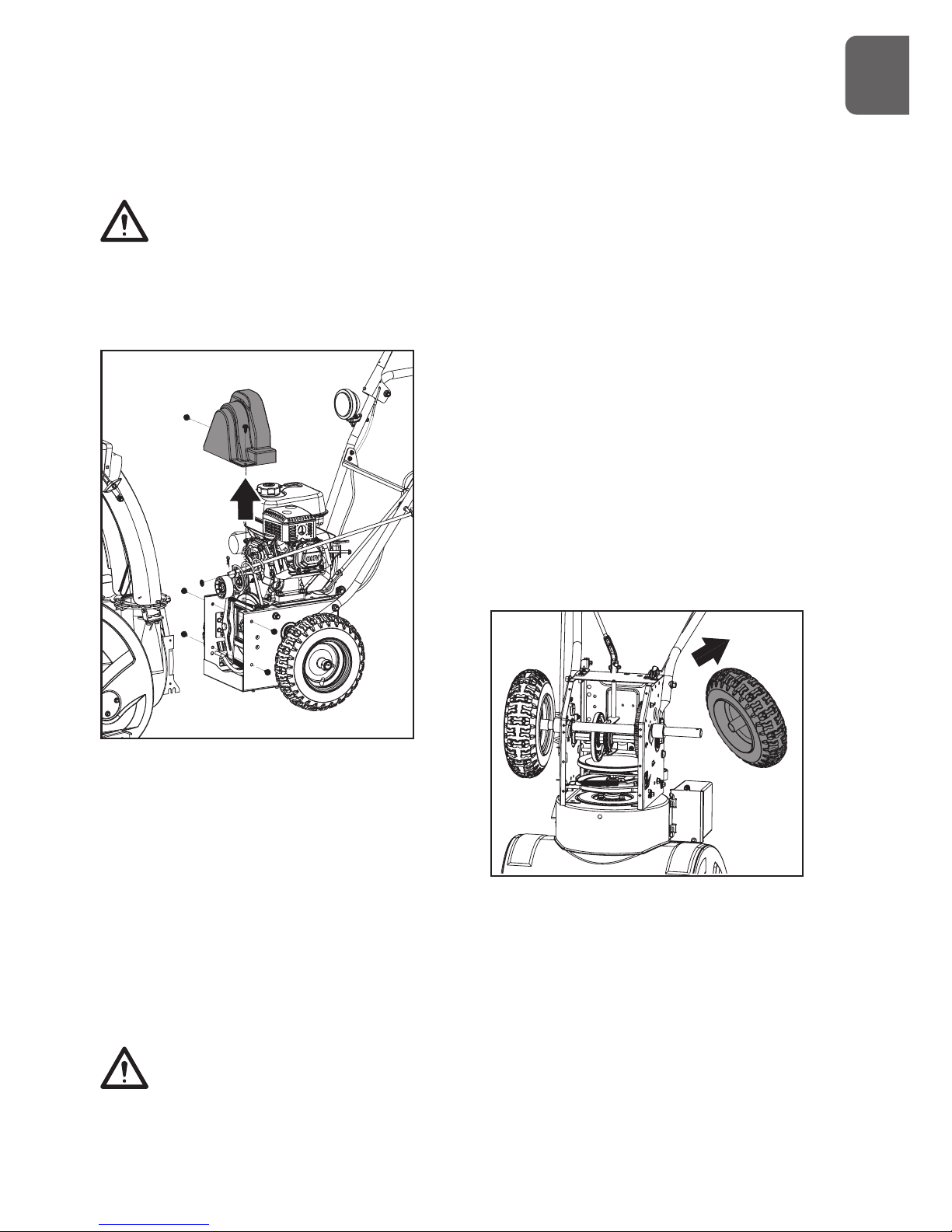

Friction Wheel Replacement

If the snow thrower fails to drive with the drive

clutch engaged, and performing the clutch

control cable adjustment fails to correct the

problem, the friction wheel may need to be

replaced.

1. To prevent spillage, remove all fuel from

tank by running engine until it stops.

Remove the key to avoid unintended

starting and allow unit to cool completely.

2. Carefully pivot the snow thrower up and

forward so that it rests on the auger housing.

3. Remove the frame cover(s) from the

underside of the snow thrower by

removing the screws which secure the

cover(s).

4. Remove the right-hand wheel by removing

the axle lock pin.

6. Slip the drive belt off the pulley and between

friction wheel and friction wheel disc.

7. Remove and replace belt in the reverse order.

Holding down the drive clutch lever

will ease reinstallation of the belt.

If an assistant is available, you can also

separate the auger housing from the frame

assembly to replace belts.

1. Shut off engine, remove key, disconnect spark

plug wire and allow unit to cool completely.

2. Remove belt cover.

3. Remove the clevis pin and washer from the chute

crank lever to remove it from the lower branket.

4. Remove bottom cover to avoid bending it

when tipping unit apart.

5. Remove the screws securing auger housing to

the frame (two on each side).

Tip auger housing and frame apart.

6. Replace auger belt or drive belt.

7. Tip auger housing and frame back together

and secure with screws.

Holding down the auger clutch lever

will ease reconnection of the auger

housing and frame.

G

B

Page 26

26

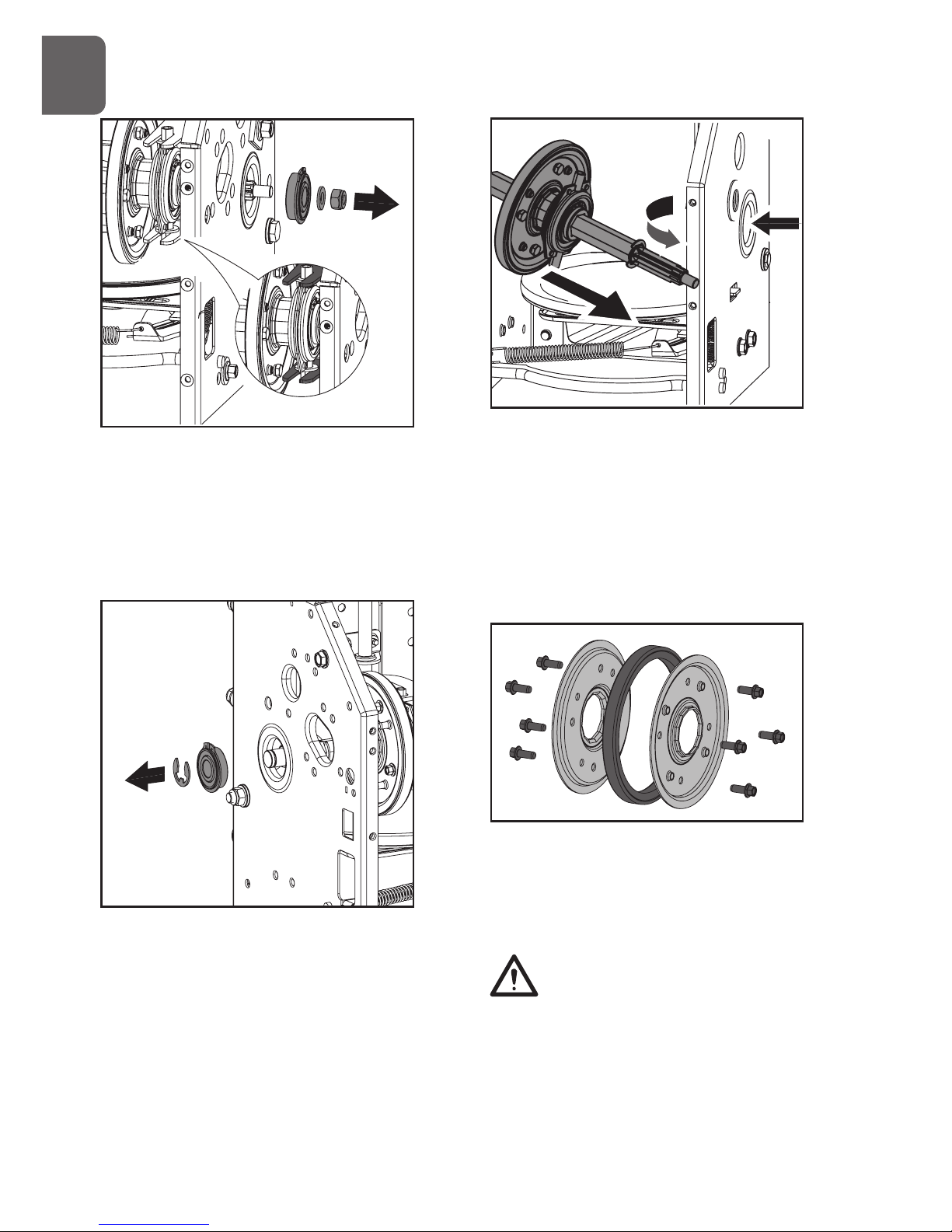

5. Carefully remove the hex nut which

secures the hex shaft to the snow thrower

frame and lightly tap the shaft’s end to

dislodge the ball bearing from the right

side of the frame. Be careful not to damage

the threads on the shaft.

6. Remove the other bearing from the left side

of the frame by removing the snap ring.

7. Carefully position the hex shaft downward

and to the left before carefully sliding the

friction wheel assembly off the shaft.

8. Follow the previous steps in reverse order

to reassemble.

If you only want to replace the rubber ring,

proceed as follows:

1. Remove the eight screws which secure the

friction wheel’s side plates together.

2. Remove the rubber ring from between the plates.

3. Reassemble the side plates with a new rubber

ring.

When reassembling the friction wheel

assembly, make sure that rubber ring is

centered and seated properly between the

side plates. Tighten each screw only one rotation

before turning the wheel clockwise and

proceeding with the next screw on the other side

of the wheel. Repeat this process several times to

G

B

Page 27

27

Secure unit chassis to transport vehicle. Never

secure from rods or linkages that could be

damaged.

10. ENVIRONMENTAL

Recycle unwanted materials instead

of disposing of them as waste. All

tools, hoses and packaging should

be resorted, taken to the local

recycling center and disposed off in

an environment-friendly safe way.

ensure the plates are secured with equal force

between 90N.m(6 ft-lbs) and 130N.m(9 ft-lbs).

4. Slide the friction wheel assembly back

onto the hex shaft. Make sure the shift

lever pin is in place in the bearing housing.

Follow the steps above in reverse order to

reassemble components.

Charging Battery (if so equipped

Follow the instructions below to charge

battery:

1. Remove battery cover.

2. Disconnect negative (black) battery cable

first, then positive (red) battery cable.

3. Take battery out of the tray and place it on

bench or other well-ventilated place.

4. Connect positive (+) lead of charger to

positive (+) terminal, and negative (-) lead

to negative (-) terminal.

5. Charge the battery at two and a half amps

for ten hours.

6. Reinstall battery into unit.

9 . Transport

To travel from one work area to another:

1. Set throttle to slow or part-throttle position.

2. On wheeled model, press down on handle bars

enough to raise front of unit slightly off surface; on

tracked model, move the track lock lever into the

transport position.

3. Engage drive clutch without engaging auger

clutch.

Always shut off engine, remove key, and

close fuel shut-off valve when transporting

unit on a truck or trailer. Do not transport

machine while engine is running.

Use extra care when loading or unloading unit

onto trailer or truck.

G

B

Page 28

28

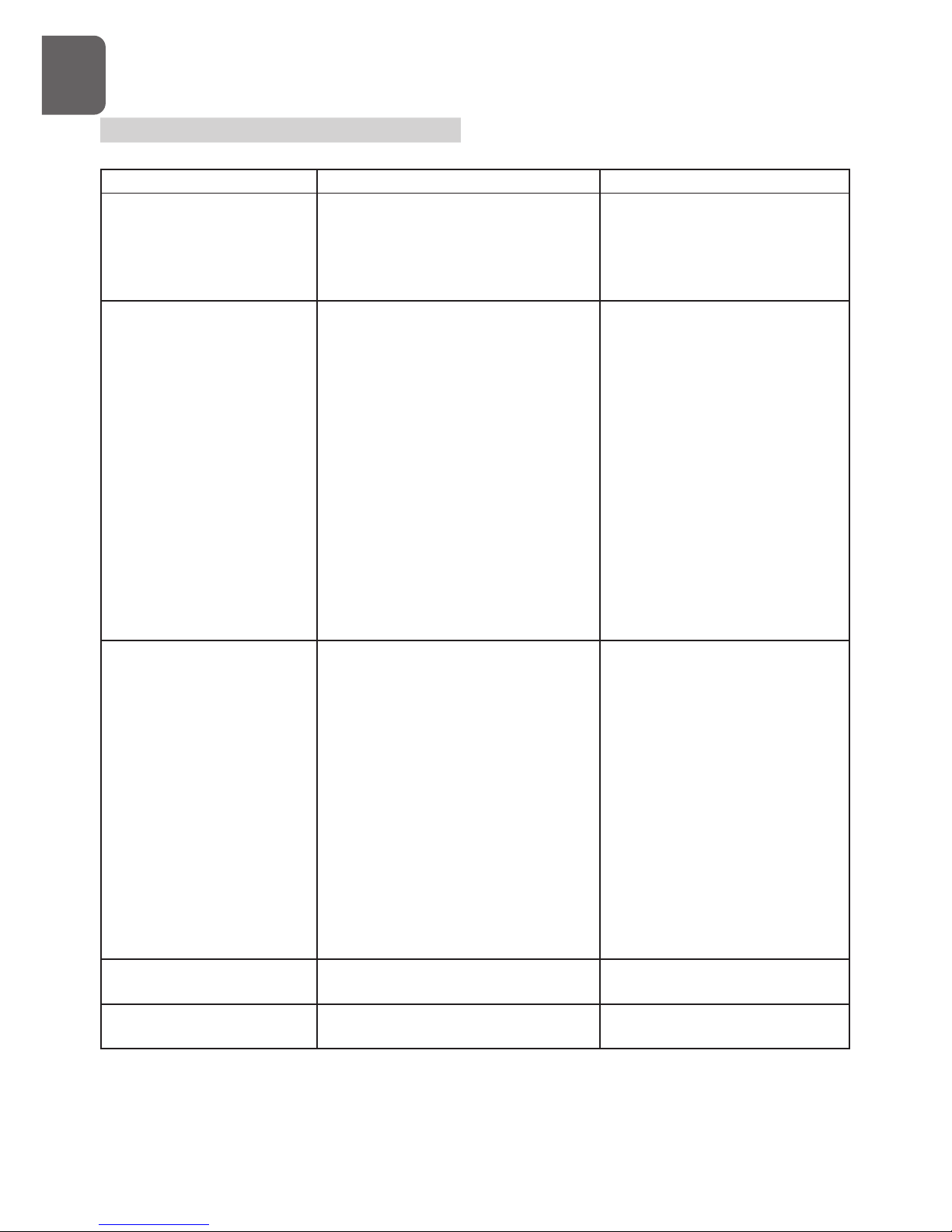

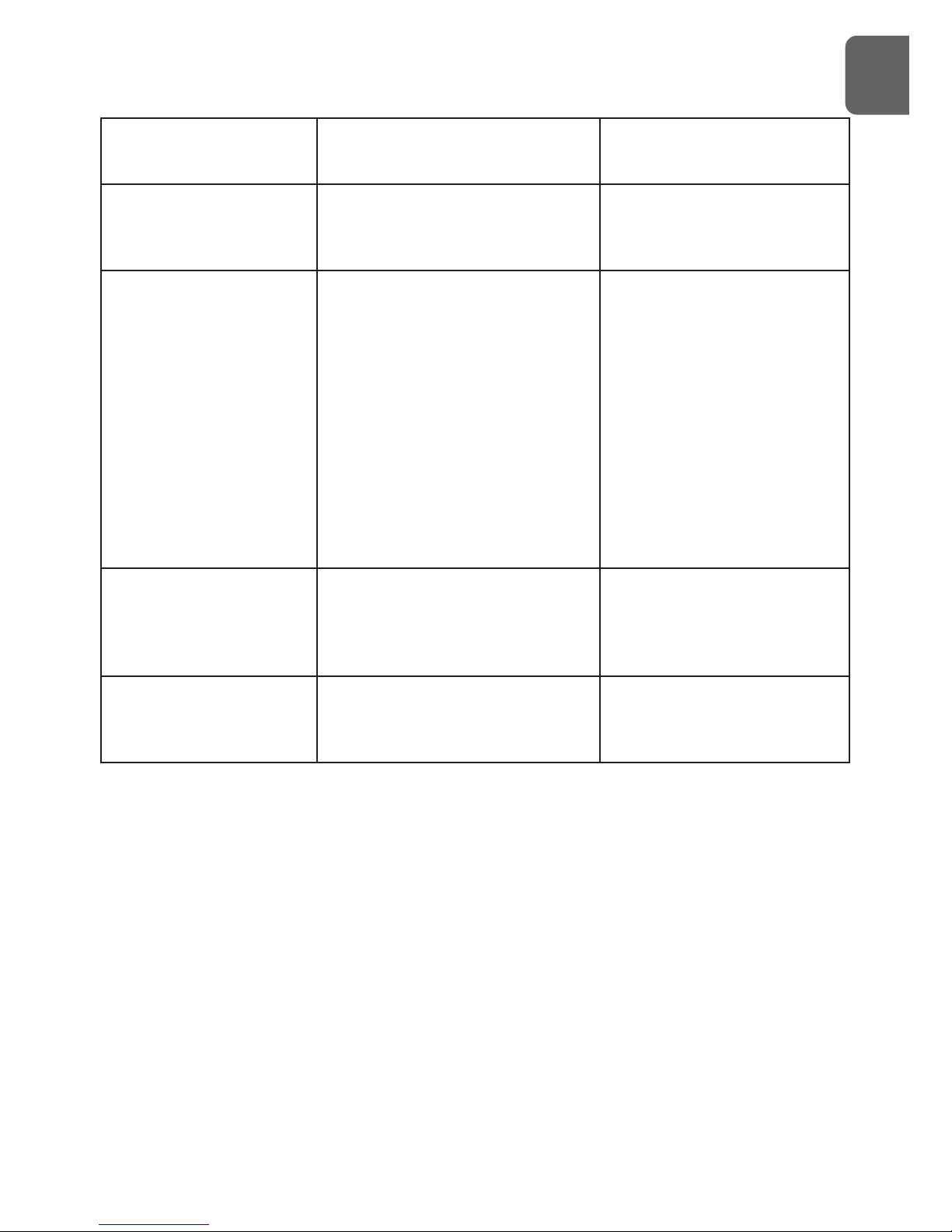

11. TROUBLE SHOOTING

Problem Cause Remedy

Electric starter does

not turn(on models so

equipped)

1. Extension cord not connected.

2. The extension cord is worn,

corroded, or damaged.

3.The power outlet is not energized.

1. Connect the extension cord to

the outlet and/or the machine.

2.Replace the extension cord.

3. Have a qualified electrician

energize the outlet.

Engine fails to start 1. Choke not in CHOKE position.

2.Engine not primed.

3.Engine is flooded.

4.Fuel shut-off valve closed.

5. Throttle in STOP position or ON/

OFF switch is OFF.

6. Spark plug wire loose or

disconnected.

7.Fuel tank empty or stale fuel.

8.Faulty spark plug.

9.Safety ignition key is not inserted.

10. The engine oil level in the engine

crankcase is too low or too high

1. Move choke to CHOKE position.

2. Prime engine as instructed in

this manual.

3. Wait a few minutes before

restarting, do not prime.

4.Open fuel shut-off valve.

5. Move throttle to FAST position

or ON/OFF switch to ON Position.

6. Connect or tighten spark plug

wire.

7. Fill tank with clean, fresh

gasoline.

8. Clean, adjust gap, or replace.

9. Insert safety ignition key.

10. Add or drain oil to adjust the oil

level in the engine crankcase.

Engine idles or runs

roughly

1. Engine running on CHOKE.

2. Fuel tank is nearly empty or stale

fuel.

3.Contaminated fuel supply.

4.Carburetor out of adjustment.

5.Engine over-governed.

6. The fuel shutoff valve is not

completely open or blockage in

fuel line.

7.Spark plug wire loose.

8.Faulty spark plug.

9. The engine oil level in the engine

crankcase is too low or too high.

1. Move choke lever to RUN

position.

2. Fill tank with clean, fresh

gasoline.

3. Replace with clean fuel.

4 . Contact a qualified repair

personnel.

5. Contact a qualified repair

personnel.

6. Open the fuel shutoff valve or

clean fuel line.

7. Tighten spark plug wire.

8. Clean, adjust gap, or replace.

9. Add or drain oil to adjust the oil

level in the engine crankcase.

The engine overheats Carburetor not adjusted properly. Contact a qualified repair

personnel.

Excessive vibration Loose parts or damaged parts. Tighten all fasteners or replace

damaged parts.

G

B

Page 29

29

Loss of power 1. Spark plug wire loose.

2. Gas gap vent hole plugged.

3. Dirty or clogged muffler.

1. Tighten spark plug wire.

2. Clean or replace fuel cap.

3. Clean or replace muffler.

Loss of traction drive 1. Drive control cable not adjusted

properly.

2. Drive belt loose or damaged.

3. Friction wheel worn.

1. Adjust drive control cable.

2. Replace drive belt.

3. Replace friction wheel.

Loss of snow discharge or

slowing of snow discharge

1. Discharge chute clogged.

2. Augers or impeller jammed.

3. Auger control cable not adjusted

properly.

4. Auger belt loose or damaged.

5.Shear pin(s) sheared.

6. Throttle not in FAST position

when throwing snow.

7. Moving too fast to clear the snow.

8. Throwing too much snow.

9. Trying to remove extremely heavy

or wet snow.

10. Auger is frozen in place.

1. Unclog discharge chute.

2. Remove debris or foreign object

from augers or impeller.

3. Adjust auger control cable.

4. Replace auger belt.

5. Replace with new shear pin(s).

6. Move throttle to FAST position.

7. Shift into a lower gear.

8. Reduce speed and width of

swath.

9. Do not overload with extremely

heavy or wet snow.

10. Move unit to a warm place to

thaw.

Discharge chute either

does not lock into place or

does not move

1. The discharge chute control not

adjusted properly.

2. Chute assembly incorrectly

1. Adjust the discharge chute

control.

2. Disassemble chute control and

reassemble as instructed in this

manual.

Machine does not properly

clear the snow of the surface

1. The skid shoes and/or scraper

blade not adjusted properly.

2. The pressure in the tires not equal.

1. Adjust the skid shoes and/or the

scraper blade.

2. Check and adjust the pressure

in one or both tires.

G

B

Page 30

30

1. SÜMBOLID

Seadme andmesildil võidakse kasutada sümboleid.

Need näitavad olulist infot toote või selle

kasutamise kohta.

Need juhised tuleb tähelepanelikult läbi

lugeda.

Kanda tuleb kaitseprille.

Kasutada kuulmekaitsevahendeid.

Jalga tuleb panna kaitsejalatsid.

Läheduses ei tohi viibida kõrvalisi

isikuid.

Kasutaja peab enne seadme juurest

lahkumist seiskama mootori ja

eemaldama süütevõtme.

Ummistuse kõrvaldamiseks tuleb

alati kasutada puhastustööriista.

Seda ei tohi kunagi teha käega.

Keelatud on eemaldada kaitse- ja

ohutusseadiseid või muuta nende

konstruktsiooni.

Seadme lähedal ei tohi suitsetada ega

kasutada lahtist tuld.

Kuuma summutit, reduktori korpust või

silindrit ei tohi puudutada.

Enne seadme remontimist või

reguleerimist tuleb alati seisata mootor

ja eemaldada süütevõti. Vt juhendit.

E

E

Seadme töötamise ajal tuleb jälgida, et

kätt ei panda sissevõtu- ja väljutuskoha

juurde.

Hoida pöörlevast tigumehhanismist

eemale.

Lund ei tohi kunagi väljutada inimeste

või asjade suunas.

2. SISSEJUHATUS

See lumepuhur ületab kõik teie ootused. Selle

seadme tootmisel on parimate tööomaduste

tagamiseks järgitud rangeid kvaliteedistandardeid.

Seda on lihtne ja ohutu kasutada ning õige

hooldamise korral töötab see veel palju aastaid.

Enne lumepuhuri kasutuselevõtmist tuleb

kogu kasutusjuhend tähelepanelikult läbi

lugeda. Eriti tuleb tähelepanu pöörata

ettevaatusmeetmetele ja hoiatustele.

Lumepuhuril on palju omadusi, mis teevad selle

kasutamise kiiremaks ja kergemaks. Selle seadme

väljatöötamisel seati eesmärgiks ohutus, jõudlus ja

töökindlus, nii et hooldamine ja kasutamine on

lihtne.

Mootori tootja vastutab kõige eest, mis on seotud

mootoriga: jõudlus, nimivõimsus, tehnilised

andmed, garantii ja hooldus. Lisateave on esitatud

mootori tootja koostatud kasutusjuhendis, mis on

eraldi pakendis seadmega kaasas.

3. Tehnilised andmed

SPT-182-570:

Mootori tüüp: OHV, neljataktiline mootor,

õhkjahutuse; 182 cc

Mootori võimsus: 4,0 kW

Maksimaalne võimsus: 4,5kW, 6 HP

Käivitussüsteem: 230V elektri start (valikuline)

Page 31

31

Kütusepaagi maht: 3.0L

Puhastuslaius 57 cm

Sissevõtu kõrgus 53,5 cm

Teo läbimõõt 30,0 cm

Rootori läbimõõt 30,0 cm

Käik 6 edasi + 2 tagasi

SPT-270-720:

Mootori tüüp: OHV, neljataktiline mootor,

õhkjahutuse; 182 cc

Mootori võimsus: 5,3 kW

Maksimaalne võimsus: 6,7kW, 9 HP

Käivitussüsteem: 230V elektri start (valikuline)

Kütusepaagi maht: 6.0L

Puhastuslaius 72 cm

Sissevõtu kõrgus 53,5 cm

Teo läbimõõt 30,0 cm

Rootori läbimõõt 30,0 cm

Käik 6 edasi + 2 tagasi

SPT-302-720:

Mootori tüüp: OHV, neljataktiline mootor,

õhkjahutuse; 302cc

Mootori võimsus: 6,2 kW

Maksimaalne võimsus: 7,5kW, 10 HP

Käivitussüsteem: 230V elektri start (valikuline)

Kütusepaagi maht: 4.0L

Puhastuslaius 72 cm

Sissevõtu kõrgus 53,5 cm

Teo läbimõõt 30,0 cm

Rootori läbimõõt 30,0 cm

Käik 6 edasi + 2 tagasi

4. OHUTUS

Üldised ohutusnõuded

Seadme tundmaõppimine

Seadmega on lubatud töötada ainult täiskasvanutel,

kes seda tunnevad. Kunagi ei tohi seda seadet

kasutada lapsed.

Kasutusjuhend ja seadmel paiknevad sildid tuleb

läbi lugeda, nii et neist on aru saadud. Tundma

tuleb õppida nii seadme kasutamist ja piiranguid

kui ka võimalikke ohte.

Põhjalikult tuleb tutvuda juhtseadiste ja nende õige

kasutamisega. Õppida selgeks, kuidas saab

seadme peatada ja juhtseadised kiiresti vabastada.

Seadme komplekti kuuluvast mootori tootja

kasutusjuhendist tuleb kindlasti läbi lugeda kõik

juhiseid ja ohutusnõuded. Seadet ei tohi kasutama

hakata enne, kui olete täielikult aru saanud sellest,

kuidas mootor õigesti tööle rakendada ja kuidas

seda hooldada. Samuti tuleb teada, kuidas vältida

kehavigastusi ja/ või varalist kahju.

Tööpiirkond

Mootorit ei tohi kunagi käivitada ega lasta sellel

töötada kinnises ruumis. Heitgaas on ohtlik,

sisaldades vingugaasi, mis on lõhnatu ja eluohtlikult

mürgine gaas. Seda seadet tohib kasutada ainult

hea õhuvahetusega välistingimustes.

Seadmega ei tohi kunagi töötada halva nähtavuse

korral või pimedas.

Seadet ei tohi kunagi kasutada järsul kallakul.

Kasutaja ohutus

Seadmega ei tohi töötada narkootiliste ainete,

alkoholi

või mistahes ravimi mõju all olles, mis võib

mõjutada kasutaja võimet seadet õigesti kasutada.

Kanda tuleb asjakohast riietust. Kasutada tuleb

tugevaid pikki pükse, saapaid ja kindaid. Rõivad ei

tohi olla liiga avarad, kanda ei tohi lühikesi pükse

ega mingeid ehteid. Pikad juuksed tuleb kinni

panna, et need oleksid õlgadest kõrgemal. Hoida

juuksed, rõivad ja kindad liikuvatest osadest eemal.

Liiga avarad rõivad, ehted ja pikad juuksed võivad

takerduda seadme liikuvate osade vahele.

Kasutada tuleb kaitsevarustust. Töötades

tuleb alati kanda kaitseprille. Asjakohane

kaitsevarustus (nt tolmurespiraator, kaitsekiiver

või kuulmekaitsevahendid) aitab vähendada

tervisekahjustuste ohtu.

E

E

Page 32

32

Enne töölerakendamist tuleb seade üle kontrollida.

Kaitsekatted peavad olema oma kohale paigaldatud

ja töökorras. Kontrollida, et kõik mutrid, poldid jms

on tugevalt kinni. Enne mootori käivitamist tuleb

vabastada kõik sidurid ja seada käiguvahetushoob

neutraalasendisse.

Seadet ei tohi kunagi kasutada, kui see vajab

remonti või on tehniliselt halvas seisukorras.

Kahjustunud, puuduvad või rikkis osad tuleb enne

seadme kasutamist uutega asendada. Kontrollida,

et ei esine kütuseleket. Jälgida, et seade on alati

töökorras ja ohutu.

Kunagi ei tohi omavoliliselt muuta ohutusseadiseid.

Regulaarselt tuleb kontrollida, et need

funktsioneerivad õigesti.

Seadet ei tohi kasutada, kui mootori seguklapi

hoova abil ei saa seda sisse ja välja lülitada.

Bensiinimootoriga seade on alati ohtlik, kui seda

ei saa seguklapi hoova abil lülitada. Sel juhul tuleb

seguklapi hoob enne seadme kasutamist välja

vahetada.

Harjumuseks peab saama, et enne

käivitamist kontrollitakse, kas mutrivõtmed

ja reguleerimistööriistad on seadme juurest

eemaldatud. Seadme pöörleva osa külge jäetud

tööriist või mutrivõti võib põhjustada kehavigastuse.

Seadmega töötades tuleb olla tähelepanelik, jälgida

oma tegevust ja kasutada tervet mõistust.

Liiga palju ei tohi ette kummarduda. Seadmega ei

tohi töötada paljajalu ega kandes sandaale vms

kergeid jalatseid. Kanda tuleb turvajalatseid, mis

kaitsevad jalgu ja pakuvad libedatel pindadel

kindlamat jalgealust. Alati tuleb seista kindlal

pinnal ja töötada stabiilses asendis. See võimaldab

seadet ootamatus olukorras paremini kontrollida.

Vältida tuleb tahtmatut käivitumist. Enne seadme

transportimist, reguleerimist või hooldustööde

tegemist tuleb alati üle kontrollida, et seguklapi

hoob on väljalülitatud asendis. See, kui seguklapi

hoob on transportimise, reguleerimise või

hooldustööde ajal sisselülitatud asendis, võib

põhjustada õnnetusjuhtumi.

Kütuse ohutu käitlemine

Kütus on väga tuleohtlik ja selle aur võib süttimisel

plahvatada. Raskete kehavigastuste

ohu vähendamiseks tuleb rakendada

ettevaatusmeetmeid.

Kütusepaaki on lubatud täita või tühjendada ainult

välistingimustes, puhtas ja hea õhuvahetusega

kohas, kasutades nõuetekohast kütusekanistrit.

Selle koha lähedal, kus kütust lisatakse või

seadet kasutatakse, ei tohi suitsetada ega

tekitada sädemeid, kasutada lahtist tuld või muid

süütamisohtlikke asju.

Kunagi ei tohi kütust lisada sisetingimustes.

Sädemete või elektrikaare vältimiseks tuleb

maandatud pingealtid esemed (näiteks tööriistad)

hoida eemal pingestatud elektriahelatest ja

ühendustest, mis on katmata. Muidu tekib heitgaasi

või bensiiniauru süttimise oht.

Enne kütusepaagi täitmist tuleb mootor alati seisata

ja lasta sellel jahtuda. Siis, kui mootor töötab või on

töötamisest veel soe, ei tohi eemaldada ütusepaagi

korki ega lisada paaki kütust. Seadet ei tohi

kasutada, kui kütusesüsteemis on leke.

Kui see on võimalik, tuleb seade kütuse lisamiseks

veokilt või haagiselt maapinnale tõsta. Kui see ei

ole võimalik, tuleb haagisel olevasse seadmesse

kütust lisada teisaldatavast kanistrist, mitte tankuri

püstolist.

Kütusepaagi kork tuleb lahti keerata aeglaselt, et

kütusepaak jõuaks rõhu alt vabaneda.

Tankuri püstolit tuleb kuni täitmise lõpetamiseni

hoida pidevalt kokkupuutes kütusepaagi või kanistri

ava servaga. Kasutada ei ole lubatud fikseeritava

avamisseadisega püstolit.

Kunagi ei tohi kütusepaaki panna liiga täis. Paaki ei

tohi lisada rohkem kütust kui kuni 12,5 mm (1/2“)

E

E

Page 33

33

allpool täiteava, et jätta ruumi kütuse paisumiseks

mootori ja/või päikese soojuse mõjul.

Seejärel tuleb kütusepaagi ja kanistri kork taas

kindlalt kinni keerata ning pühkida mahaloksunud

kütus ära. Seadet ei tohi kasutada, kui kütusepaagi

kork ei ole kindlalt kinni.

Vältida tuleb süütamisohtlike asjade sattumist mahaloksunud kütuse lähedale. Kui kütust on maha

loksunud, siis ei tohi mootorit käivitada, vaid seade

tuleb kütuseloigust eemale viia ja vältida igasugust

süttimisohtu, kuni kütuseaur on hajunud. Nahale või

riietele loksunud kütus võib süttida ja põhjustada

raskeid kehavigastusi. Nahk tuleb kohe puhtaks

pesta ja riided vahetada.

Kütust tuleb hoida spetsiaalsetes kanistrites, mis

on selleks otstarbeks lubatud.

Kanistreid ei tohi kunagi täita sõiduki sees ega

veoki või haagise plastkattega kastis. Kanistrid

tuleb enne täitmist alati paigutada sõidukist eemal

maapinnale.

Kütust tuleb hoida jahedas, hea õhuvahetusega

kohas, ohutult eemal sädemetest, lahtisest tulest

või muudest süütamisohtlikest asjadest.

Kütust või seadet, mille paagis on kütust, ei tohi

kunagi hoida hoones, kus kütuseaur võib kokku

puutuda sädemete, lahtise tule või süütamisohtlike

asjadega (boiler, küttekolle, pesukuivati jms). Enne

seadme hoiulepanekut kinnisesse ruumi tuleb

mootoril alati lasta jahtuda.

Seadme kasutamine ja hooldamine

Seadet ei tohi kunagi üles tõsta ega kanda, kui

selle mootor töötab.

Seadet ei tohi üle koormata. Kasutada tuleb

konkreetseks tööks sobivat seadet. Seade töötab

kõige paremini ja ohutumalt, kui seda kasutatakse

ettenähtud koormusel.

Mootori pöörlemissageduse regulaatori seadistust

ei tohi muuta, samuti ei tohi mootorit käitada liiga

suurel kiirusel. Mootori pöörlemissageduse

regulaator tagab mootori maksimaalse ohutu

töökiiruse.

Käsi ja jalgu ei tohi panna seadme pöörlevate

osade lähedale.

Vältida tuleb kokkupuutumist kuuma kütuse, õli,

heitgaasi ja kuumade pindadega. Mootorit ja

summutit ei tohi puudutada. Need osad lähevad

töötamise ajal väga kuumaks ja on mõnda aega

kuumad ka pärast seadme väljalülitamist. Enne

hooldustööde tegemist või reguleerimist tuleb

mootoril lasta jahtuda.

Kui põrgatakse millegi vastu, siis tuleb mootor

seisata, võtta juhe süüteküünla küljest lahti ja

kontrollida põhjalikult üle, et seade ei ole saanud

kahjustada. Enne taaskäivitamist ja tööleasumist

tuleb kahjustused ära parandada.

Kui seade hakkab tegema ebaharilikku müra

või vibreerima, tuleb mootor kohe välja lülitada,

ühendada süüteküünla juhe lahti ja selgitada välja

müra või vibratsiooni põhjus. Ebatavaline müra või

vibratsioon annab tavaliselt märku rikkest.

Kasutada võib ainult neid lisaseadiseid ja tarvikuid,

mida tootja on lubanud. Selle nõude eiramine võib

põhjustada kehavigastusi.

Seade tuleb hoida töökorras. Kontrollida, et liikuvad

osad on õiges asendis ja saavad vabalt liikuda.

Samuti tuleb kontrollida, et osad ei ole purunenud,

ning jälgida kõike muud, mis võib mõjutada seadme

tööd. Seadet võib kasutada alles siis, kui

kahjustused on parandatud. Paljud õnnetused

juhtuvad halvasti hooldatud seadme tõttu.

Mootor ja summuti tuleb tuleohu vähendamiseks

hoida puhas rohust, lehtedest, liigsest määrdest ja

tahmast.

Seadme peale ei tohi kunagi pritsida ega valada

vett ega muud vedelikku. Käepidemed tuleb hoida

kuivad, puhtad ja prahist vabad. Pärast iga

kasutuskorda tuleb seade puhastada.

E

E

Page 34

34

Keskkonna kaitsmiseks tuleb jälgida bensiini, õli

jms jäätmekäitluse kohta kehtivaid õigusnorme.

Kui seadet ei kasutata, tuleb seda hoida sellises

kohas, kus lapsed seda kätte ei saa. Seadet ei tohi

lubada kasutada isikutel, kes seda ei tunne ega ole

tutvunud selle kasutusjuhendiga. Väljaõppeta

kasutaja käes on seade ohtlik.

Hooldus

Enne seadme puhastamist, remontimist,

ülevaatamist või reguleerimist tuleb mootor välja

lülitada ja kontrollida, et kõik liikuvad osad on

seiskunud. Alati tuleb üle kontrollida, et mootori

seguklapi hoob on asendis STOP. Ühendada

süüteküünla juhe lahti ning hoida juhe juhusliku

käivitumise vältimiseks süüteküünlast eemal.

Seadet võib lasta hooldada ainult asjakohase

kvalifikatsiooniga tehnikul, kes kasutab identseid

varuosi. Nii on seadme ohutus tagatud.

Seadmekohased ohutusnõuded

Seadmega ei tohi töötada isik, kes ei kanna

sobivaid talverõivaid.

Seadet ei ole lubatud kasutada katusel.

Mootoril ei tohi lasta töötada siseruumis, välja

arvatud mootori käivitamise ajal ja lumepuhurit

hoonesse või välja teisaldades. Sel juhul tuleb

avada välisuksed, sest heitgaas on ohtlik.

Enne seadme kasutamist tuleb alati tähelepanelikult

kontrollida, et üleval ja külgedel jääb piisavalt vaba

ruumi. Tänavatel või teepeenardel töötades tuleb

alati jälgida liiklust.

Tööpiirkond tuleb põhjalikult üle vaadata.

Tööpiirkond tuleb hoida puhas, seal ei tohi olla

mänguasju, uksematte, ajalehti, kelke, lumelaudu,

juhtmeid ega mingeid muid esemeid, millele

lumepuhur võib otsa sõita või mille võib teo/

rootoriga eemale paisata. Kontrollida tuleb nõrku

kohti sildadel, kaldteedel ja põrandatel.

Lumekoristuse marsruut tuleb plaanida nii, et

välditakse lume heitmist inimeste poole või

kohtadesse, kus võib tekkida varakahju.

Töötada ei tohi järsakute, kraavide või

kaldapealsete läheduses. Kui ratas liigub üle

järsaku või kraavi serva või serv variseb, võib

seade ootamatult ümber minna.

Kõik kõrvalised isikud, lapsed ja loomad tuleb hoida

vähemalt 23 m kaugusel. Kui keegi läheneb, tuleb

seade kohe seisata.

Elektrilise käivitiga mootori korral tuleb alati

kasutada kolmesoonelist maandatud pikendusjuhet

ja pistikupesa.

Regulaarselt tuleb kontrollida, et sidur ja pidur on

töökorras. Vajaduse korral tuleb neid reguleerida ja

hooldada. Veorataste ja teo/rootori liikumine peab

kiiresti lõppema, kui juhthoovad vabastatakse.

Enne lumekoristuse alustamist tuleb mootoril ja

seadmel lasta kohanduda välistemperatuuriga.

Tähelepanelik tuleb olla varjatud ohtude ja liikluse

suhtes.

Seadet ei tohi üle koormata, koristades lund liiga

suurel kiirusel.

Lund ei tohi heita kõrgemale, kui on vajalik.

Kruusa- või killustikupinna puhastamiseks tuleb teo

korpus seada kõrgemale ja seadmega töötades olla

väga ettevaatlik.

Töötades tuleb olla ettevaatlik, et vältida libisemist

ja kukkumist, eriti tagasikäigu korral. Libeda pinna

korral ei tohi seadmega kunagi liikuda liiga suurel

kiirusel. Enne tagurdamist ja tagurdamise ajal tuleb

vaadata alla ja tahapoole.

Järsul kallakul ei tohi seda seadet kasutada. Lund

ei tohi koristada kallakuga risti. Mistahes liikumine

peab kallakutel olema aeglane ja sujuv. Seadme

kiirust ja suunda ei tohi järsult muuta. Kasutada

tuleb aeglast käiku, et vältida kallakul peatumist ja

E

E

Page 35

35

käiguvahetust.

Mootori käivitamist ja seiskamist tuleb kallakul

vältida.

Ilma hädavajaduseta ei tohi seadet kallakul parkida.

Kallakul parkimiseks tuleb rattad alati tõkestada.

Kui seadet ei kasutata või seda teisaldatakse, tuleb

vabastada teo/rootori jõuülekanne.

Enne seadme juhthoobade juurest lahkumist tuleb

kõik juhthoovad vabastada ja seisata mootor. Enne

ummistuste kõrvaldamist rennisüsteemist,

reguleerimist või kontrollimist tuleb alati oodata,

kuni tigu/ rootor on täielikult seiskunud.

Lumepuhuri korral on kõige levinum vigastus, mis

saadakse, puudutades käega väljutusrennis

pöörlevat rootorit. Väljutusrennisüsteemi ei tohi

puhastada sel ajal, kui mootor töötab. Ummistuse

kõrvaldamiseks tuleb kõigepealt lülitada mootor

välja ja seejärel oodata käepidemete taga, kuni

liikuvad osad on seiskunud.

Kunagi ei tohi kätt panna väljutusavasse või koguri

avasse. Väljutusava ummistuse kõrvaldamiseks

tuleb alati kasutada puhastustööriista.

E

E

Page 36

36

5. TARNEKOMPLEKT

Lumepuhur tarnitakse osaliselt kokkupanduna ja korralikult pappkasti pakituna. Pärast kõigi osade kastist

väljavõtmist tuleb kontrollida, et kõik allnimetatud osad on olemas.

Tähelepanu: Kõik viited lumepuhuri vasakule või

paremale küljele on tehtud kasutaja kohalt

vaadates.

1. Lumepuhur

2. Suunamiskäepidemed

3. Käiguvahetushoob

4. Renni tõstehoob

5. Juhtpaneel

6. Rattad (1 paar)

7. Väljutusrenn

8. Väljutusrenni puhastustööriist

9. Aku (kui kuulub komplekti)

10. Seadme kasutusjuhend ja mootori

kasutusjuhend

11. Mootori tarvikute kott

12. Lumepuhuri tarvikute kott, mis sisaldab järgmist:

E

E

Page 37

37

6. KOKKUPANEK

Kui järgitakse alljärgnevaid juhiseid, võtab

lumepuhuri kokkupanek vaid mõne minuti.

Mootor

1. Õhufiltri kattelt tuleb eemaldada tiibmutter ja

seib.

2. Keerata õhufiltri katet 180o võrra, nii et

eeltäitenupp jääb väljapoole.

3. Paigaldada õhufiltri kate ja keerata tiibmutter

kinni.

Suunamiskäepidemed

1. Suunamiskäepidemete ja küljeplaatide avad

tuleb kohakuti seada ning keerata käepidemed

poltide ja seibidega käe jõul kinni.

2. Eemaldada telje tihvt ja lükata ratas telje otsa.

Panna telje iga tihvt läbi rattarummus oleva ava

ja läbi teljes oleva ava.

3. Kinnitada juhtpaneel suunamiskäepidemete

külge, keerates poldid, seibid ja mutrid käe jõul

kinni.

4. Kontrollida, et käepidemed on ühel kõrgusel, ja

seejärel keerata kõik kinnitusdetailid tugevasti

kinni.

E

E

Page 38

38

5. Panna juhttrossid läbi juhtpaneeli avade. Trosside

ühendamisel sidurihoobadega tuleb kontrollida,

et trossid paiknevad juhtrullikutel õigesti.

Käiguvahetushoovastik

Käiguvahetushoova lükkamiseks läbi juhtpaneeli

pilu tuleb eemaldada nupp. Käiguvahetushoob

tuleb käiguvarda külge kinnitada poltide, seibide ja

mutritega. Panna nupp tagasi.

Väljutusrenn

1. Määrida väljutusrenni võru alumine pool (kui

see ei ole juba määritud).

2. Väljutusrenn tuleb paigaldada teo korpuses oleva

ava kohale ja kinnitada kinnitusdetailidega.

E

E

Page 39

39

3. Tõstehoova ülemine tugi (kinnitatud tõstehoova

külge) tuleb lukustusmutri ja kahe lainelise seibiga

kinnitada üleval suunamiskäepideme vasaku

poole külge.

4. Määrida tõstehoova spiraal.

5. Tõstehoova spiraali ots tuleb panna alumise toe

sisse ning kinnitada lameseibi ja splindi abil.

Rehvid

Transportimiseks on rehvides suurem rõhk.

Rehvirõhku tuleb kontrollida ja mõlemas rattas

võrdselt vajadust mööda alandada või tõsta.

Mingil juhul ei tohi ületada tootja soovitatud

rõhku. Liigne rõhk võib põhjustada rehvi/

velje koostu lõhkemise jõuga, mis võib

tekitada raskeid vigastusi. Kontrollida rehvi

külgseinalt, et rõhk on soovitatud piirides.

Rehvide rõhk peab alati olema võrdne.

Kui mõlema ratta rehvirõhk ei ole sama,

siis ei pruugi seade liikuda sirgjooneliselt

ja kaabitera võib kuluda ebaühtlaselt.

Vältida tuleb bensiini või õli sattumist

rehvidele, sest need võivad kummit

kahjustada.

Juhttallad

1. Seade tuleb paigutada ühetasasele pinnale.

2. Teo terad tuleb toestada, et need jääksid

maapinnast 3 mm (1/8“) kõrgusele.

3. Kontrollida tuleb kaabitera seadistust. Kaabitera

peab paiknema maapinnast 3 mm (1/8“) kõrgusel

ja olema sellega paralleelne. Kaabitera

reguleerimiseks tuleb lahti keerata 7 kinnituskruvi

(kaks igal küljel), seada kaabitera horisontaalseks

ja seejärel keerata kinnituskruvid taas kinni.

4. Mõlemad juhttallad tuleb poltide ja mutritega

kinnitada teo küljeplaatide külge. Liigutada

juhttallad nii alla, kui on võimalik. Kontrollida, et

mõlemad juhttallad on seatud ühekaugele. Keerata

tugevasti kinni.

Väljutusrenni puhastustööriist

E

E

Page 40

40

Puhastustööriist tuleb kinnitada teokorpuse

tagaküljel oleva kinnitusklambri külge.

Varu-lõiketihvtid

Üks varupaar teo tihvte ja lõiketihvte on

lumepuhuriga kaasas. Need tuleb edaspidiseks

kindlas kohas alles hoida.

Varutihvtid

Rootor on võlli külge kinnitatud tihvtidega.

Kaks 6x37 mm tihvti on tarvikute kotis rootori jaoks

varuosana olemas. Need tuleb edaspidiseks

kindlas kohas alles hoida.

Aku (kui kuulub komplekti)