Page 1

LASER TORPEDO LEVEL

MULTI-USE LASER CHALKLINE

• 77-152 •

INSTRUCTION MANUAL

MANUEL D’INSTRUCTIONS

MANUAL DE INSTRUCCIONES

LASER TORPEDO LEVEL KIT

• 77-151 •

•

• 77-190•

•

Page 2

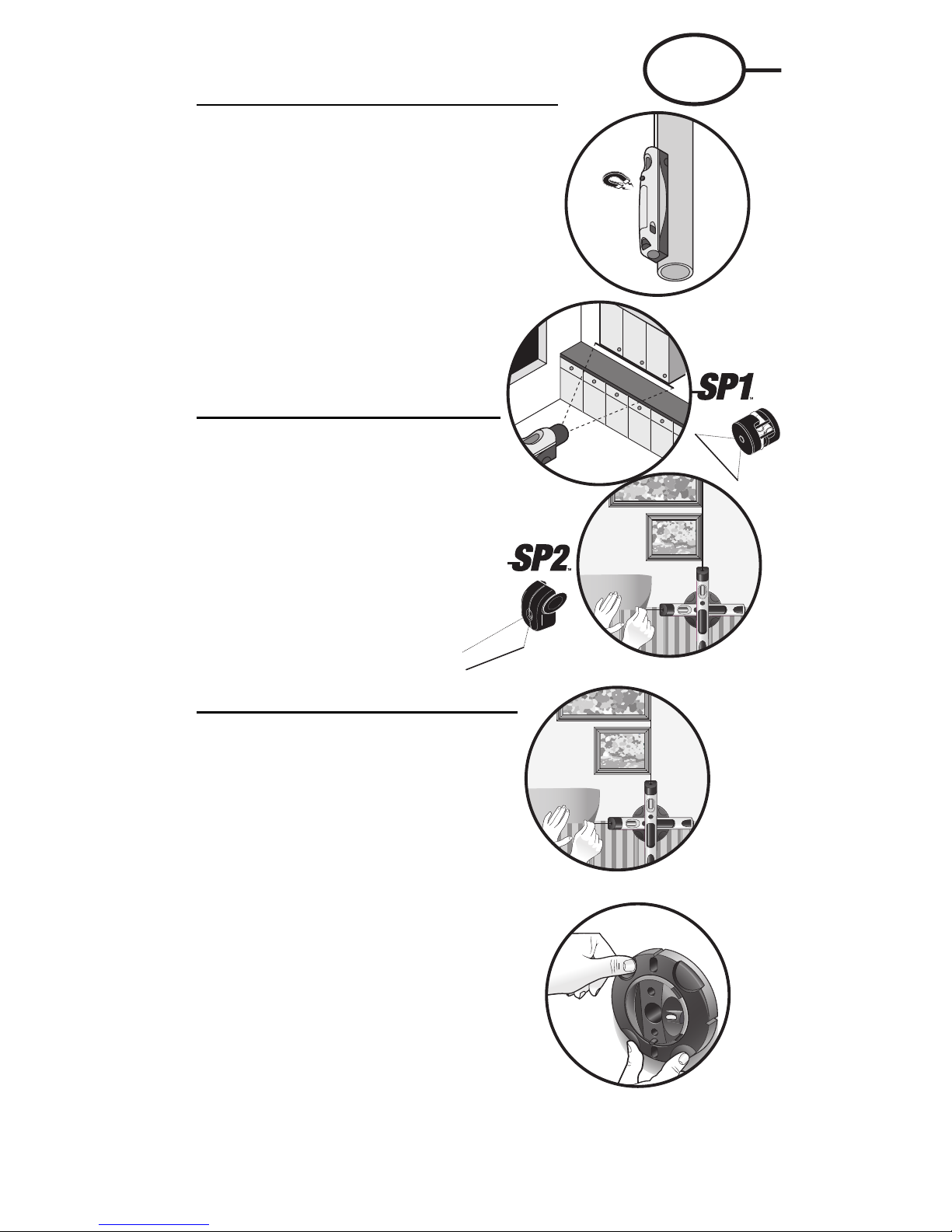

2 • SP1 and SP2

APPLICATIONS

Use as a Laser Torpedo Level:

The SP1, SP1X and SP2 Laser Level is a highly

durable, lightweight aluminum level with a red

beam laser that can be used in a variety of applications. With its level and circular plumb vials,

this state-of-the-art level projects a highly visible

red dot on almost any surface with up to

±1/4-in

@ 50-ft

(6mm accuracy at 15.3m).

Use as Laser Chalkline:

The Laser Chalkline easily attaches to the

front of the laser level. Using the line

generator, project straight lines on any

surface. Generate level and plumb chalklines using the level and plumb vials.

Use as Laser Square –

SP2 Only (on vertical surface)

Wall, Stud & Floor Mount/90º Swivel Mount

allows 90º layout capability. Place the

mount on the surface. Press the two buttons to push the retractable pins into any

soft wood or wall-board surface. Secure

the laser level to swivel mount using the

alignment pin on the mount.

Use extra caution when handling the

mount. Retractable pins are very sharp.

Push the buttons only when you place

the mount on the surface of a soft wood

or wall-board.

The laser level can be rotated 360º (with 90º references) on the wall/stud mount.

Use level vial (1g) to mark level line. Rotate 90º

so base level vial (3a) is within line. Mark laser

chalkline. You now have a 90º square from the

level line.

To use as laser square on floor, mount laser on

wall/floor mount. Align first chalkline using

arrow marker " " on swivel base. Turn swivel

base 90º using reference mark on fixed base.

You now have 90º laser square.

EN

Page 3

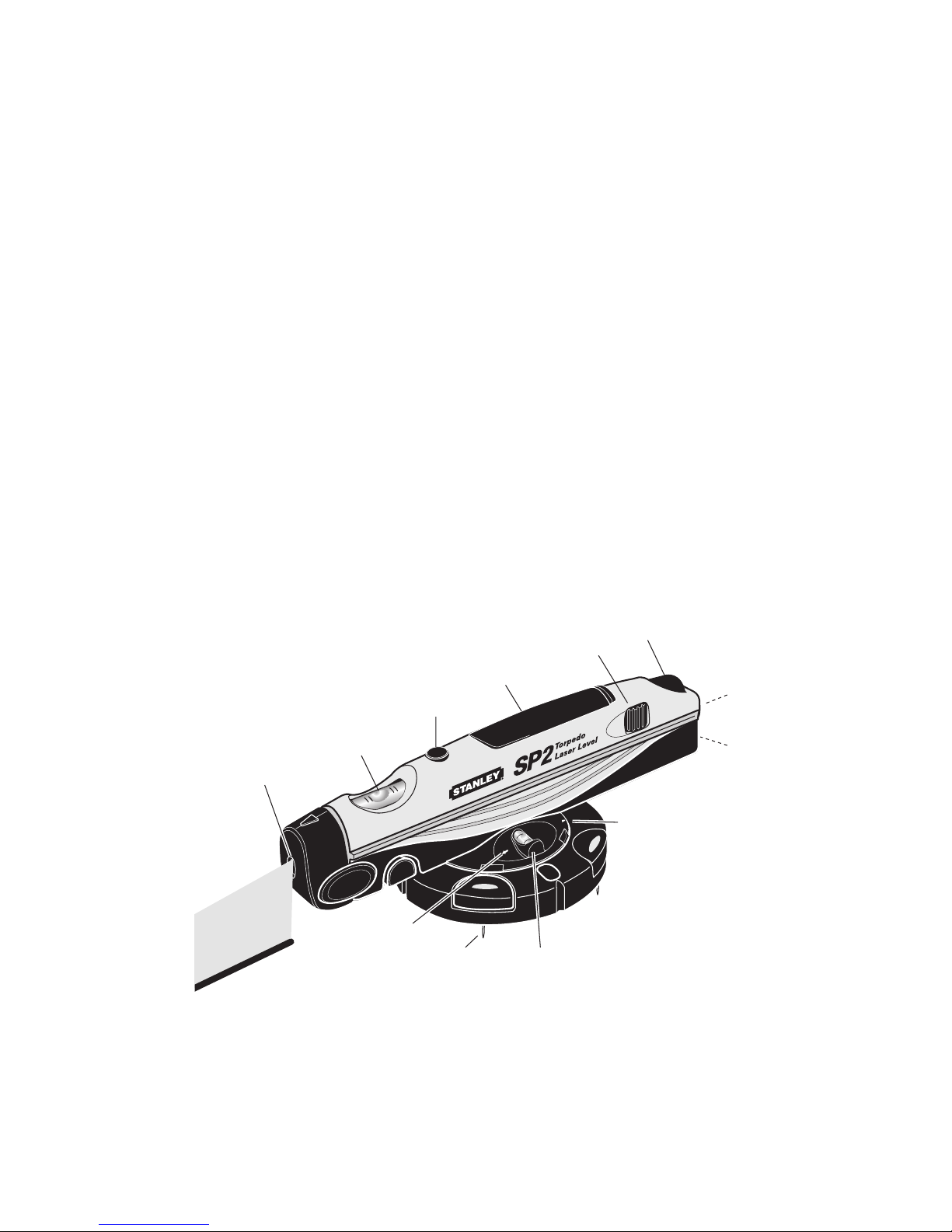

1a

1g

2a

3a

3d, 3e

1b

1c

1d

1f

1e

3b

3c

USING YOUR LASER LEVEL

The Laser Level offers a distinct advantage over regular carpenter’s levels in

its ability to project a highly visible level reference over both short and long

distances with great accuracy. The level can be placed in a central location

to transfer a level reference point anywhere you need it, useful when

installing wainscoting, tile, or cabinets, or leveling posts.

With its on-board circular bubble vial, the level can also be used in a vertical

position to plumb studs or transfer points from floor to ceiling.

To reference the bottom of the level, locate the center of the laser dot and

subtract 1-ft (25mm).

For best results position the tool to project the line from left to right or top to

bottom. The use of the unit from right to left and/or bottom to top will not

guarantee the same level of precision or accuracy.

MAINTENANCE

Designed to be weather resistant and construction-site tough; but as with

any precision instrument, care should be taken to avoid damage.

• Dry unit immediately if wet.

• The precision vials are protected; however, avoid hard contact with the

vials.

• Clean the front lens with a lint-free cloth or swab using a premium glass

cleaner solution.

• Clean the outside of the level with a damp cloth and dry with a soft lintfree cloth.

SP1 and SP2 • 3

1. Laser Level– SP1, SP1X & SP2

1a. Power switch

1b. Battery cartridge

1c. Trivet height adjustment knob

1d. Trivet activator button

1e. Trivet retractor button

1f. Circular plumb vial

1g. Primary level vial

1h. Magnetic base

1i. Leveling feet (trivet)

2. Laser Chalkline

2a. Special lens for laser chalkline–SP2

The Beam Bender on the SP1 deflects a

beam to 90º from horizontal in any direction.

3. Wall/floor & stud mount– SP2

3a. Level vial (base)

3b. Vertical mount retractable pins

3c. 90º reference mark

3d. Alignment arrow

3e. Base reference marks

Page 4

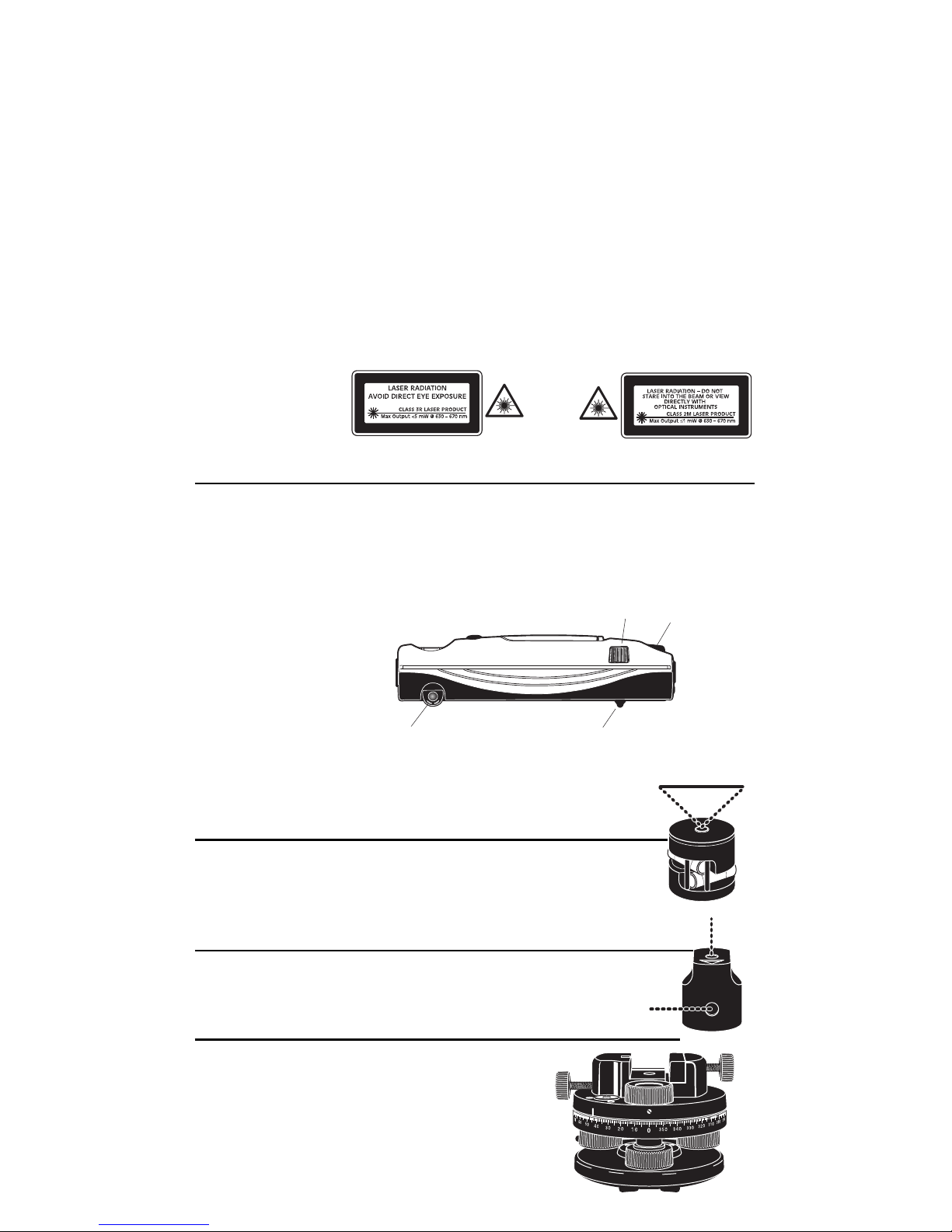

CALIBRATION

Factory set and sealed for life.

SPECIFICATIONS

Level Beam Accuracy: ±1/4-in @ 50-ft (6.3mm at 16.5m) in dot mode

Line Accuracy: ±3/8-in @ 30-ft (±9.5mm at 10m)

Working Range: Up to 50-ft (15m) indoors depending on lighting conditions

Vial Sensitivity: Level, ±20 minutes; plumb, ±30 minutes

Power: Three “AA” batteries provide 100 hours of intermittent use

Laser Diode: Class 2M/3R (>1mW), 635nm to 670nm. This product complies

with 21 CFR 1040.10 and 1040.11

Specifications subject to change without notice.

How to use the “built-in” leveling feature

Place unit on any flat, firm surface and switch on the laser. Swing out (1)

leveling feet

and push the (2) trivet activator button.

Use (3) trivet height adjustment knob to center the bubble. The laser

beam is now projecting a visible reference to the center of the laser’s aperture.

ACCESSORIES

LBS Beam Spreader– Included with SP1, SP1X

Creates a laser “chalk line” to level or plumb frames, tiles,

shelves, etc. 35 minute vial accuracy. The above items magnetically attach to the metal “donut” on the front of the level.

LBL Beam Splitter– Included with SP1X

Two beams create a 90° reference. Use to align and square corners or tiles, plumb studs, and more.

TM1 Rotary Adapter

Allows 360° rotation of level with or without tripod.

Use to transfer elevations, grade, more.

4 • SP1 and SP2

1

3

2

4

Page 5

Mini Laser Tripod– Included with SP1X

Tilts in two directions allowing the laser to set at any angle.

WARRANTY

90 day Warranty

This SP1, SP1X, SP2 is warranted to the original purchaser to be free from

defects in workmanship and material. Stanley Works will repair or replace

any defective part which may malfunction under normal and proper use

within a period of ninety (90) days from the date of purchase without charge

of parts and labor, once delivered and shipped prepaid to CST/berger, division of Stanley Works, together with proof of date and place of purchase.

CST/berger

division of Stanley Works

255 W. Fleming Street

Watseka, IL 60970

ph: (815) 435-859

This warranty is not subject to misuse, abuse, assignment or transfer. The

exclusive remedy under any and all warrants and guarantees, expressed or

implied, is limited to repair and/or replacement as provided herein, and

Stanley shall not be liable for damages from loss or delay of equipment uses,

consequential or incidental damage.

SP1 and SP2 • 5

1. 1/4x20 thread adapts to 5/8x11

2. Platform swivels in both

directions to allow laser line

positioning at any angle

3. Positioning Knobs

4. Folding tripod legs with non-skid

rubber feet

5. 5/8x11 thread mounts to surveying

tripod

1

5

2

4

3

Page 6

APPLICATIONS

Utilisation comme niveau laser :

Le niveaux laser SP1, SP1X et SP2 sont des niveaux en aluminium, robustes et légers, qui projettent un point laser rouge haute visibilité

et peuvent être utilisés pour de nombreuses applications. Ils sont équipés de

niveau tubulaire et sphérique, respectivement pour le plan horizontal et le

plan vertical ; leur précision est de 6 mm à 15 m.

Utilisation comme ligne laser :

Lorsque la tête magnétique est fixée sur la partie avant des niveaux, on produit une ligne laser qui peut être projetée sur toute surface. Grâce aux

niveaux tubulaire et sphérique, on peut tracer une ligne horizontale et une

ligne verticale en aplomb.

Utilisation comme équerre sur une surface verticale (uniquement SP2) :

La base tournante, qui peut être fixée sur une paroi ou posée à même le sol,

permet de tracer des angles à 90°. Posez la base sur la surface et appuyez

sur les deux boutons latéraux de manière à ce que les deux pointes en

dessous fixent la base en question. Montez le niveau sur la base : grâce aux

points de référence à angle droit, présents sur le bord de la base, vous pouvez tracer des lignes ou des points à l’équerre.

Le niveau laser peut tourner sur 360° (avec repères tous les 90°) sur la base

tournante.

Équerrage sur paroi

Utilisez le niveau tubulaire (1 g) comme référence pour tracer une ligne

laser. Tournez la base de manière à ce que le niveau (3a) soit aligné avec la

ligne que vous venez de tracer. Tracez de nouveau la ligne laser. Les deux

lignes sont à l’équerre entre elles.

Équerrage sur le sol.

Alignez avant tout la ligne laser, à l’aide du signe en forme de flèche se trouvant sur la base, avec l’un des repères latéraux. Tracez la ligne laser.

Tournez la base de 90° et tracez la nouvelle ligne laser.

Maniez la base très attentivement. Les deux pointes escamotables sont très

pointues. Appuyez sur les boutons latéraux après avoir posé la base sur une

surface.

UTILISATION DU NIVEAU LASER

Comparé à un niveau traditionnel à bulle, le niveau laser offre l’avantage de

projeter un point ou une ligne laser très visible à courte ou à moyenne distance avec une grande précision. Le niveau laser peut être positionné centralement de manière à projeter le rayon laser dans une direction

quelconque. Il est particulièrement utile pour le montage de plinthes, sols,

armoires ou cloisons.

Grâce à la bulle sphérique, le niveau peut être utilisé en position verticale

pour mettre d’aplomb des montants ou transférer des points du sol au

plafond.

Souvenez-vous que le centre du point laser est situé 25 mm plus haut que la

base du niveau.

6 • SP1 and SP2

F

Page 7

Pour obtenir de meilleurs résultats, il est conseillé de projeter la ligne de

gauche à droite, ou le point du haut vers le bas. L’utilisation de la ligne de

droite à gauche – ou du point du bas vers le haut – ne garantit pas la même

précision.

ENTRETIEN

Bien que résistant aux conditions atmosphériques défavorables et à l’emploi

sur le chantier, ce niveau laser doit être utilisé et manié avec attention.

• essuyez-le immédiatement s’il a été mouillé,

• évitez tout choc violent sur les bulles,

• nettoyez la lentille frontale avec un tampon d’ouate et du liquide pour

lentilles,

• nettoyez le niveau avec un chiffon humide et essuyez-le avec un tampon d’ouate.

CALIBRAGE

Effectué en usine et garanti à vie.

SP1 and SP2 • 7

1a

1g

2a

3a

3d, 3e

1b

1c

1d

1f

1e

3b

3c

1. Niveaux laser SP1, SP1X et SP2

1 a. marche

1 b. logement des piles

1 c. vis de réglage vertical

1 d. bouton d’activation du réglage vertical

1 e. bouton de désactivation du réglage

vertical

1 f. bulle circulaire

1 g. bulle tubulaire principale

1 h. base magnétique

1 i. pieds de mise à niveau

2. Ligne laser

2 a. SP2: tête magnétique générant une ligne

laser.

SP1: tête magnétique générant un point à l’équerre, orientable dans toutes les directions

3. Base de fixation SP2

3 a. bulle tubulaire

3 b. pointes escamotables pour fixation verticale

3 c. repère à 90°

3 d. flèche d’alignement

3 e. signes de référence de la base

Page 8

CARACTERISTIQUES TECHNIQUES

Précision du rayon laser:

6,3 mm à 16,5 m (point laser)

Précision de la ligne laser:

± 9,5 mm à 10 m

Portée: 15 m (à l’intérieur)

Sensibilité des bulles niveau tubulaire : ±20’ – niveau circulaire : ±30’

Alimentation: 3 piles alcalines type « AA » – 100 heures d’autonomie

Diode laser: Classe 2M/3R (> 1mW), 635-670 nm. Ce produit est conforme aux

normes 21 CFR 1040.10 et 1040.11

Les caractéristiques techniques peuvent être modifiées sans préavis

Utilisation du réglage vertical

Appuyez le niveau sur une surface plane et stable. Allumez le laser. Tournez

les pieds (1) vers le bas et activez le réglage vertical en appuyant sur le bouton (2).

Utilisez la vis de réglage vertical (3) pour centrer le niveau tubulaire. Le

rayon laser est parfaitement horizontal et peut être utilisé comme point de

référence.

ACCESSOIRES

Tête magnétique LBS (SP1, SP1X)

Elle crée une ligne laser pour mettre de niveau ou d’aplomb des

étagères, des sols, etc. Elle est équipée de deux niveaux tubulaires de référence (précision : 35’) pour le plan horizontal et

pour le plan vertical. Elle est aimantée pour se fixer sur la partie avant

du niveau.

Tête magnétique LBL (SP1X

Elle projette deux rayons à l’équerre entre eux. Idéale pour

aligner et équerrer en même temps.

Base de mise à niveau TM1

Elle permet de fixer le niveau sur un trépied muni

d’un filetage standard 5/8” x 11. Tournant sur 360°,

elle est munie de vis de mise à niveau et de bulle

circulaire de référence.

8 • SP1 and SP2

1

3

2

4

Page 9

Mini-Trépied – Compris avec le SP1X

Filets pour socle de 15,87 mm (5/8 po) X 11 (trépied de relèvement)

Filets pour socle de 6,35 mm (1/4 po)

X 20 (trépied d’appareil photo)

1. Le filetage de 6,35 mm (1/4

po) x 20 s’adapte à celui de

15,87 mm (5/8 po) x 11.

2. La plate-forme pivote des

deux côtés pour permettre le

positionnement de la ligne

laser à tout angle.

3. Boutons de positionnement

4. Pattes de trépied pliantes avec

patins de caoutchouc antidérapants

5. Le filetage de 15,87 mm (5/8 po) x 11 se

monte sur le trépied de relèvement.

GARANTIE

Le fabricant accorde une garantie de 3 mois sur ces appareils contre tout

défaut de matière ou de fabrication à condition toutefois que l’appareil ait

été utilisé correctement. Les piles et le boîtier des piles sont toujours exclus

de la garantie. La garantie commence à dater de l’achat (date figurant sur la

facture ou sur le ticket de caisse).

Pour l’assistance après-vente, s’adresser au revendeur le plus proche ou

directement au service après-vente du fabricant en votre país. Dans un cas

comme dans l’autre, si l’appareil doit être expédié, les frais de transport sont

pris en charge par le client.

Toute tentative de réparation de l’appareil de la part d’un service non agréé

annule la validité de la garantie.

L’appareil doit être accompagné du coupon de garantie annexé à la

présence notice, dûment rempli, de la facture d’achat et des indications du

défaut constaté.

En cas de recours à la garantie, la période de garantie ne s’étend ni pour

l’appareil ni pour les pièces remplacées.

Les pièces remplacées deviennent la propriété du fabricant.

IMPORTANT!

L’utilisateur est responsable de la bonne utilisation et de l’entretien de cet

appareil. Il s’engage également à contrôler le travail au fur et à mesure que

celui-ci avance et par conséquent le calibrage de l’appareil. Le calibrage et

l’entretien ne sont pas couverts par la garantie.

La sté Stanley Works se réserve d’apporter les modifications techniques

jugées utiles sans obligation de préavis.

SP1 and SP2 • 9

1

5

2

4

3

Page 10

APLICACIONES

Uso como nivel láser:

Los niveles láser SP1, SP1X y SP2 son niveles de aluminio

sólidos y livianos que proyectan un punto láser rojo de alta visibilidad y

pueden utilizarse para muchas aplicaciones. Están provistos de nivel tubular

para la superficie horizontal y nivel esférico para la superficie vertical.

Precisión: 6 mm a 15 m.

Uso como línea láser:

Fijando la cabeza magnética en la parte delantera de los niveles, se genera

una línea láser que puede proyectarse hacia cualquier superficie. Gracias al

nivel tubular y al nivel esférico, es posible trazar una línea horizontal y una

línea vertical plomada.

Uso como escuadra en una superficie vertical (sólo SP2):

La base giratoria, que puede fijarse en una pared o apoyarse sobre el piso,

permite trazar ángulos de 90°. Apoyar la base sobre la superficie y pulsar los

dos botones laterales, de modo que las dos puntas puestas debajo fijen la

base misma. Montar el nivel en la base; utilizando los puntos de referencia

de ángulo recto presentes en el borde de la base misma, podrán trazarse

líneas o puntos de escuadra.

El nivel láser puede girarse 360° (con referencias cada 90°) en la base

giratoria.

Escuadra de pared

Utilizar el nivel tubular (1 g) como referencia para trazar una línea láser.

Girar la base, de modo que el nivel (3a) se alinee con la línea trazada

anteriormente. Trazar de nuevo la línea láser. Las dos líneas láser están

escuadradas entre sí.

Escuadra de piso

Primero alinear la línea láser, utilizando la “flecha” representada en la base

por una de las referencias laterales. Trazar la línea láser. Girar la base 90° y

marcar la nueva línea láser.

Manejar la base con mucho cuidado. Las dos puntas retráctiles son muy

puntiagudas. Pulsar los botones laterales sólo tras haber apoyado la base

sobre una superficie.

USO DEL NIVEL LÁSER

El nivel láser, respecto a un nivel de burbuja tradicional, ofrece la ventaja de

proyectar con gran precisión un punto o una línea láser muy visible, tanto a

corta distancia como a mediana distancia. El nivel láser puede colocarse en

un punto central, de manera de proyectar el rayo láser hacia cualquier

dirección. Resulta particularmente útil durante el montaje de rodapiés,

pavimentos, armarios o paneles.

Gracias a la burbuja esférica, es posible utilizar el nivel en posición vertical

para plomar montantes o transferir puntos del piso al techo; hay que

considerar que el centro del punto láser se encuentra 25 mm sobre la base

del nivel.

Para obtener mayores resultados, proyectar la línea de izquierda a derecha

o el punto de arriba hacia abajo. El uso de la línea de derecha a izquierda o

del punto de abajo hacia arriba, no garantiza la misma precisión.

MANTENIMIENTO

10 • SP1 and SP2

E

Page 11

Si bien el nivel láser resiste a condiciones atmosféricas desfavorables y al

uso en la obra, debe utilizarse y manejarse con mucha atención.

• Secarlo inmediatamente, si se ha mojado

• Evitar golpes violentos en las burbujas

• Limpiar la lente delantera con un poco de algodón y líquido para lentes

• Limpiar el nivel con un paño húmedo y secarlo con algodón.

CALIBRACIÓN

Realizada en fábrica y garantizada de por vida.

ESPECIFICACIONES TÉCNICAS

Precisión del rayo láser:

6,3 mm a 16,5 m (punto láser)

Precisión de la línea láser:

± 9,5 mm a 10 m

Alcance: 15 m (en interiores)

Sensibilidad de las burbujas: nivel tubular: ±20’ – nivel circular: ±30’

Alimentación: 3 pilas alcalinas tipo “AA” – 100 horas de autonomía

Diodo láser: Clase 2M/3R (> 1mW), 635-670 nm. Este producto cumple con

las normas 21 CFR 1040.10 y 1040.11

Especificaciones sujetas a cambio sin obligación de previo aviso.

SP1 and SP2 • 11

1a

1g

2a

3a

3d, 3e

1b

1c

1d

1f

1e

3b

3c

1. Nivel láser SP1 y SP2

1 a. encendido

1 b. alojamiento pilas

1 c. tornillo de ajuste vertical

1 d. botón de activación del ajuste vertical

1 e. botón de desactivación del ajuste vertical

1 f. burbuja circular

1 g. burbuja tubular principal

1 h. base magnética

1 i. patas de nivelación

2. Línea láser

2 a. SP2: cabeza magnética que genera una línea

láser.

SP1: cabeza magnética que genera un punto

de escuadra, orientable hacia cualquier dirección

3. Base de fijación SP2

3 a. burbuja tubular

3 b. puntas retráctiles para la fijación en vertical

3 c. referencia 90°

3 d. flecha de alineación

3 e. marcas de referencia de la base

Page 12

Cómo usar el ajuste vertical

Apoyar el nivel sobre una superficie llana y estable. Encender el láser. Girar

hacia abajo las patas (1) y activar el ajuste vertical, pulsando el botón (2).

Utilizar el tornillo de ajuste vertical (3) para centrar el nivel tubular. El rayo

láser es perfectamente horizontal y puede utilizarse como punto de referencia.

ACCESORIOS OPCIONALES

Cabeza magnética LBS (SP1, SP1X)

Crea una línea láser para nivelar o plomar estanterías, pavim

entos etc. Está provista de dos niveles tubulares de referencia

(precisión 35’), uno para la superficie horizontal y el otro para la

superficie vertical. Se fija magnéticamente a la parte delantera

del nivel.

Cabeza magnética LBL (SP1X)

Proyecta dos rayos de escuadra entre sí. Ideal para alinear y

escuadrar al mismo tiempo.

Base de nivelación TM1

Permite fijar el nivel sobre un trípode con rosca

estándar 5/8” x 11. Gira a 360° y está provista de

tornillos de nivelación y burbuja circular

de referencia.

12 • SP1 and SP2

1

3

2

4

Page 13

Mini-Tripode– Incluido con el SP1X

Se inclina en dos direcciones permitiendo

que el rayo láser sea ajustado a cualquier

ánguloRosca base de 5/8” x 11 (trípode de

topografía)

Rosca base de 1/4” x 20 (trípode de cámara)

1. Rosca de 1/4” x 20 se adapta a 5/8” x 11

2. La plataforma gira en ambas direcciones para permitir la ubicación de la

línea láser en cualquier ángulo

3. Perillas de ubicación

4. Patas de trípode plegables con patas de caucho antiresbalantes

5. Las roscas de 5/8” x 11 montan en un trípode de topografía

GARANTÍA

El productor garantiza el SP1 / SP2 contra deficiencias en materiales o mano

de obra durante los 90 días posteriores a la fecha de compra.

Los productos defectuosos serán reparados o reemplazados, a elección de

Stanley Works, tras ser recibidos, a porte pagado, junto con su prueba de

compra en Stanley Works.

Esta garantía no cubre deficiencias causadas por daños accidentales, desgaste por el uso o usos diferentes de los indicados por el fabricante o

reparaciones o alteraciones de estos productos no autorizadas por Stanley

Works.

Cualquier reparación o reemplazo durante la vigencia de esta Garantía no

afecta a su fecha de vencimiento.

Dentro de lo autorizado por la legislación vigente, Stanley Works no se

obliga por esta Garantía a compensar pérdidas como resultado de deficiencias en el producto.

Para informaciones sobre la garantía, pongase en contacto con CST/berger,

una división de STANLEY WORKS, al número (815) 432-5237, o por e-mail a

sales@cstsurvey.com.

SP1 and SP2 • 13

1

5

2

Page 14

©2004 THE STANLEY WORKS:

Stanley Tools Product Group,

480 Myrtle Street, New Britain, CT 06053 U.S.A.

Tel 1-800-262-2161 Fax 860-643-3756

www.stanleyworks.com

Z94-77151N (0405)

Loading...

Loading...