Page 1

GB

D

F

I

E

PT

NL

DK

SE

FIN

NO

PL

GR

CZ

RU

HU

SK

SI

BG

RO

EE

LV

LT

Please read these instructions before operating the product

RL HW / RL HW+ / RL HGW /

RL HV / RL HVPW/RL HVPW-G

Auto-Levelling Rotary Laser Level

77-496 / 77-429 / 77-439 / 77-497 / 77-427/ 77-441

Auto-Levelling

HR

TR

Page 2

2

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

A

B

1

3

4

5

6

2

7

Page 3

3

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

RL HW

RL HW+

RL HGW

RL HV /

RL HVPW/RL HVPW-G

C

E

9

8

E

1

E

3

E

2

E

4

C

1

C

2

11

12

12

14

D

1313

10

Page 4

4

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

(+)

(-)

(+)

(-)

(+)

(-)

(+)

(-)

F

G

H

15

17

18

19

21

16

20

Page 5

5

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

J

K

23

26

24

25

27

28

29

30

31

32

22

33

34

Page 6

6

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

X1

X2

Y1

Y2

M

L

Page 7

7

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

X1

X2

Y1

D

1

D

2

D

1

D

2

D

0

20 m

20 m

20 m

20 m

2 m

N

N

1

N

2

N

3

N

4

P

D

1

P

1

P

2

1 m

2 m

1 m

D

2

D1D2D

0

P

3

A

B

A

B

Page 8

8

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Contents

• Safety

• Product Overview

• Feature Set

• Keypad, LED, and LCD

• Batteries and Power

• Set Up

• Operation

• Accuracy Check and Calibration

• Specifications

User Safety

WARNING:

• Carefully read the Safety Instructions and

Product Manual before using this product.

The person responsible for the instrument must

ensure that all users understand and adhere to

these instructions.

CAUTION:

• While the laser tool is in operation, be careful

not to expose your eyes to the emitting laser

beam . Exposure to a laser beam for an extended

time may be hazardous to your eyes.

CAUTION:

• Glasses may be supplied in some of the laser

tool kits. These are NOT certified safety glasses.

These glasses are ONLY used to enhance the

visibilty of the beam in brighter environments or

at greater distances from laser source.

Retain all sections of the manual for future reference.

WARNING:

• The following label samples are placed on

your laser tool to inform of the laser class for

your convenience and safety. Please reference

the Product Manual for the specifics on a

particular product model.

Product Overview

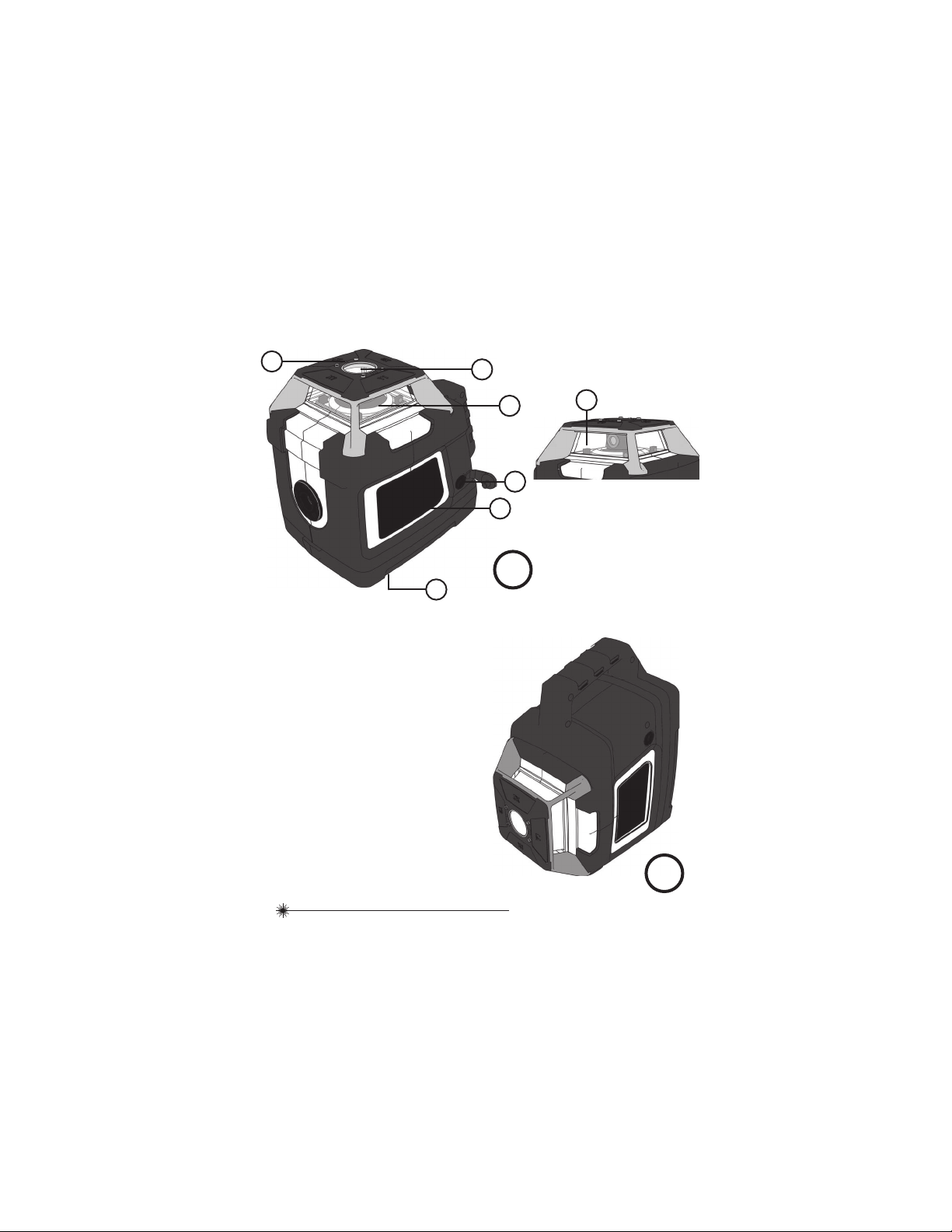

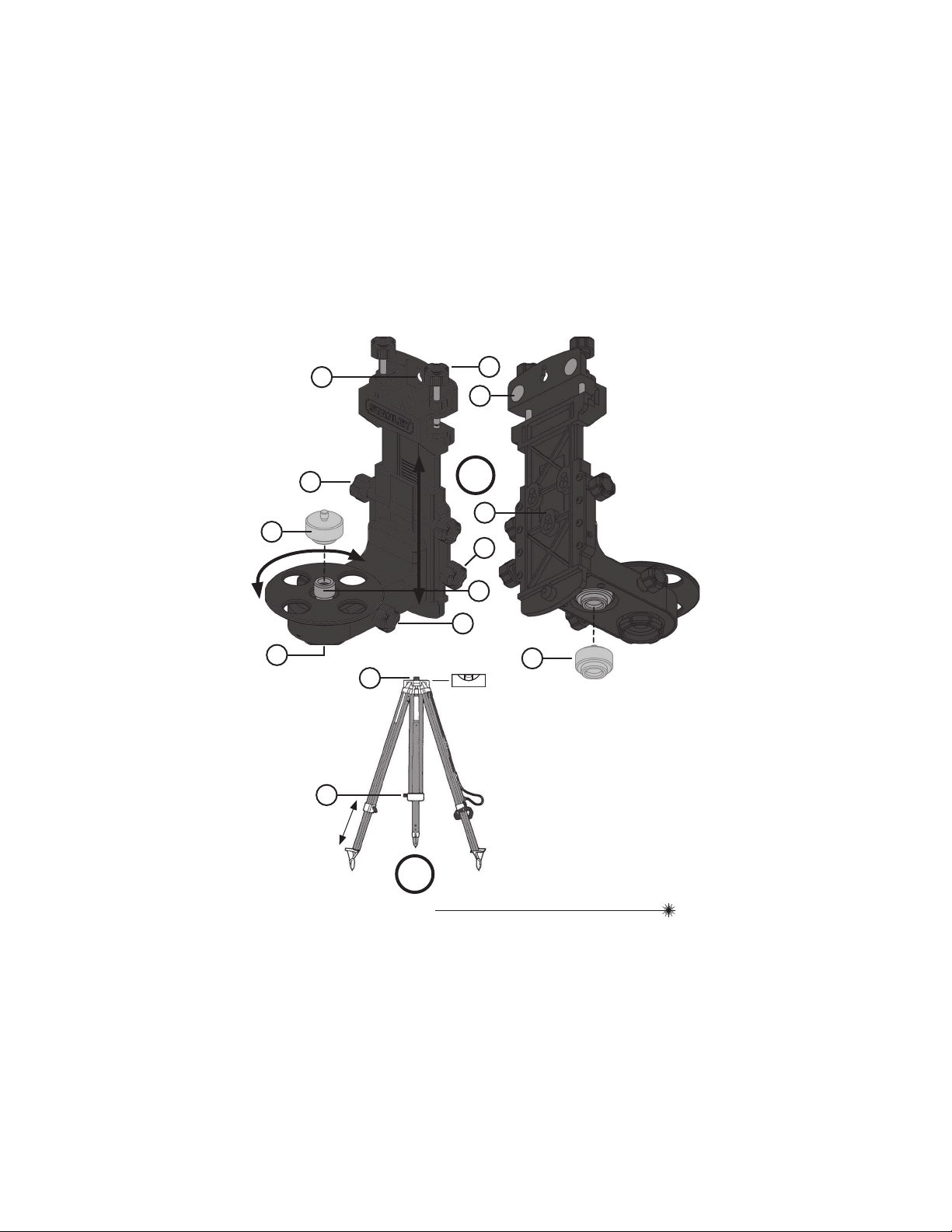

Figure A - Laser Tool in Horizontal Position

1. Alignment Sight

2. Vertical Up Beam Window (RL HV / RL HVPW)/RL

HVPW-G

3. Rotary Laser / Glass Enclosed

4. Charging / Power Adapter Plug Jack

5. Keypad (See Figure E)

6. Vertical Down Beam (RL HVPW/RL HVPW-G)

7. Infrared Sensor for Remote

(RL HW+ / RL HGW / RL HV / RL HVPW/RL HVPW-G)

Figure B - Laser Tool in Vertical Position

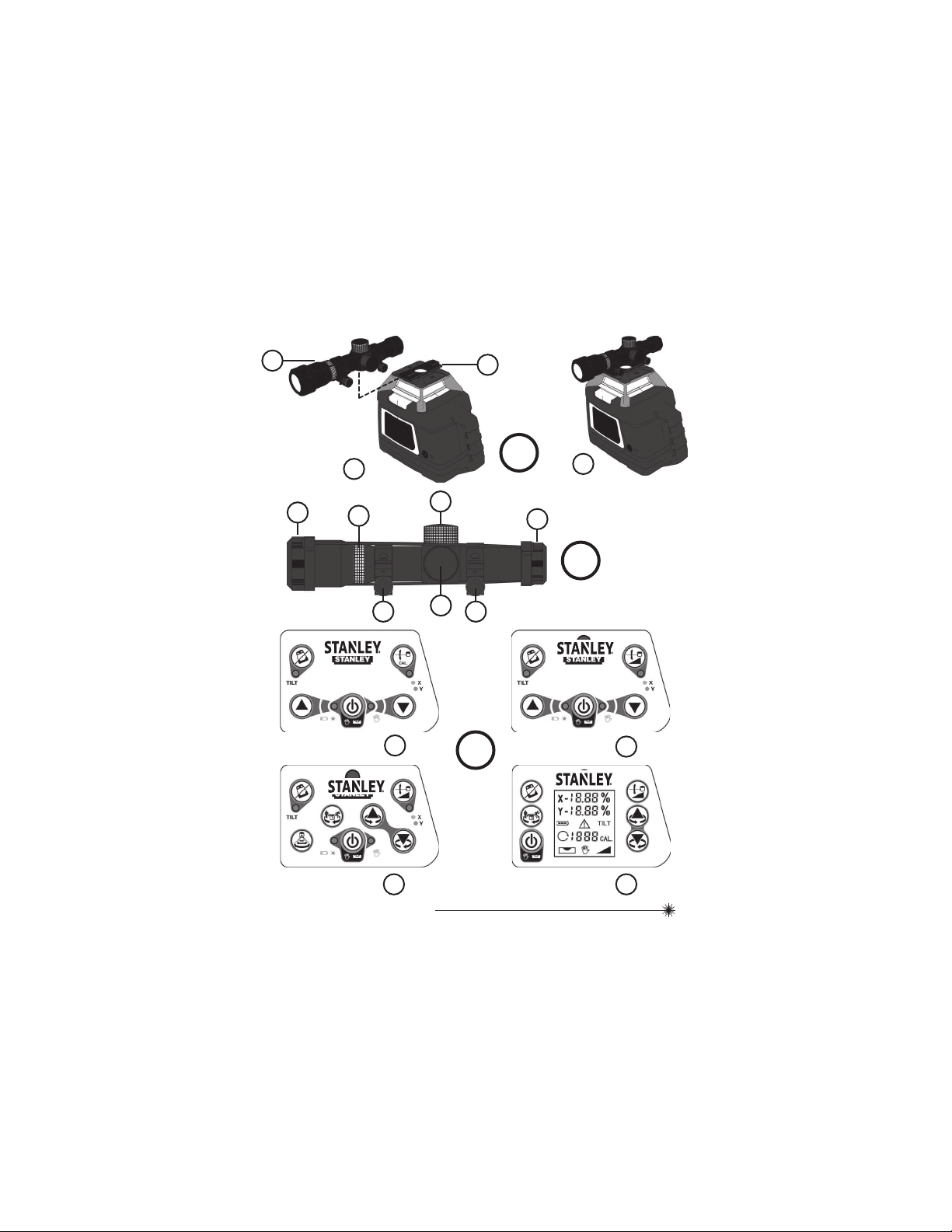

Figure C - Laser Tool with Sighting Telescope Accessory

(RL HGW)

8. Sighting Telescope

9. Sighting Telescope Mount Base

Figure D - Sighting Telescope

10. Eyepiece (Shown with Cover ON)

11. Reticle Focus

12. Windage / Elevation Adjustment Covers

(DO NOT OPEN / ADJUST)

13. Locking Screws

14. Objective (Shown with Cover ON)

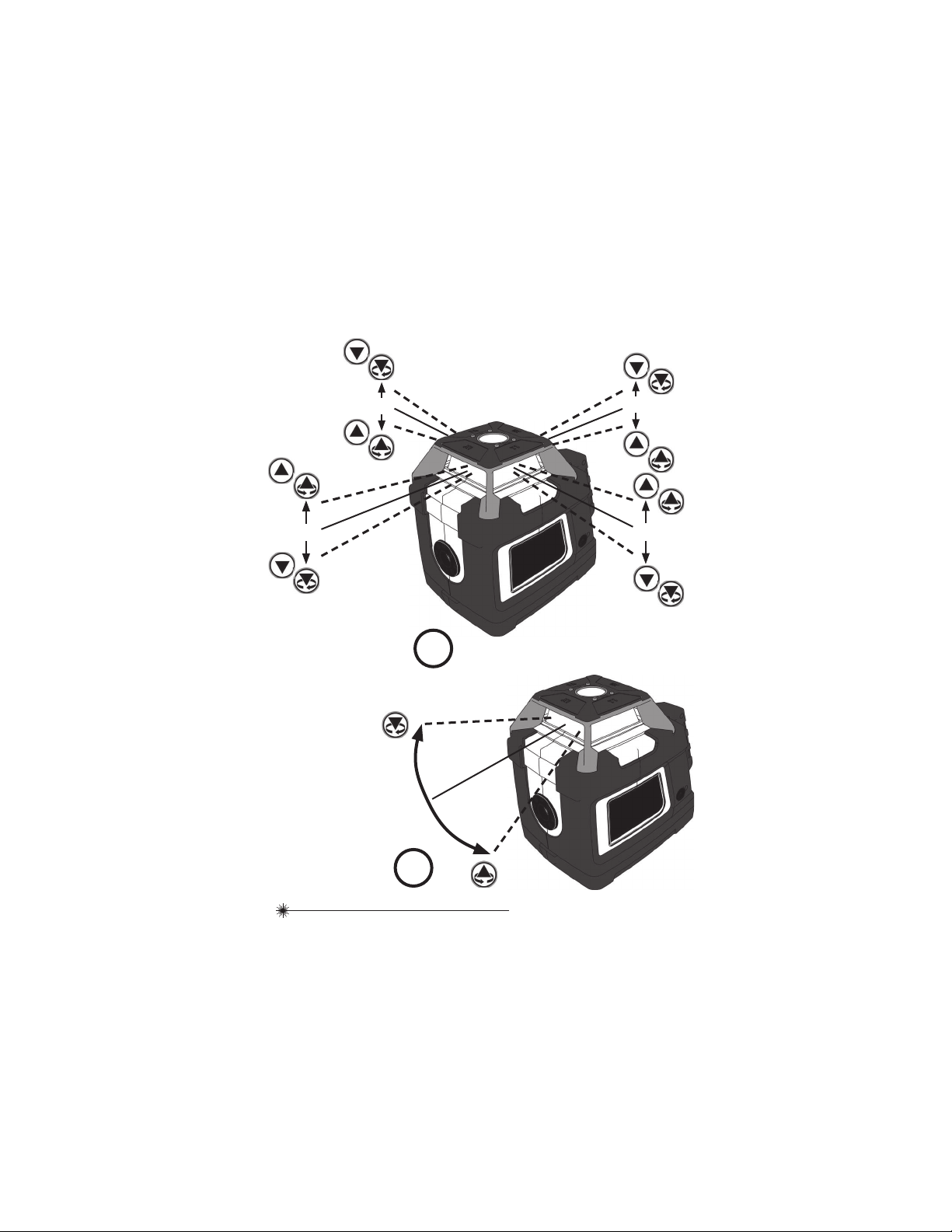

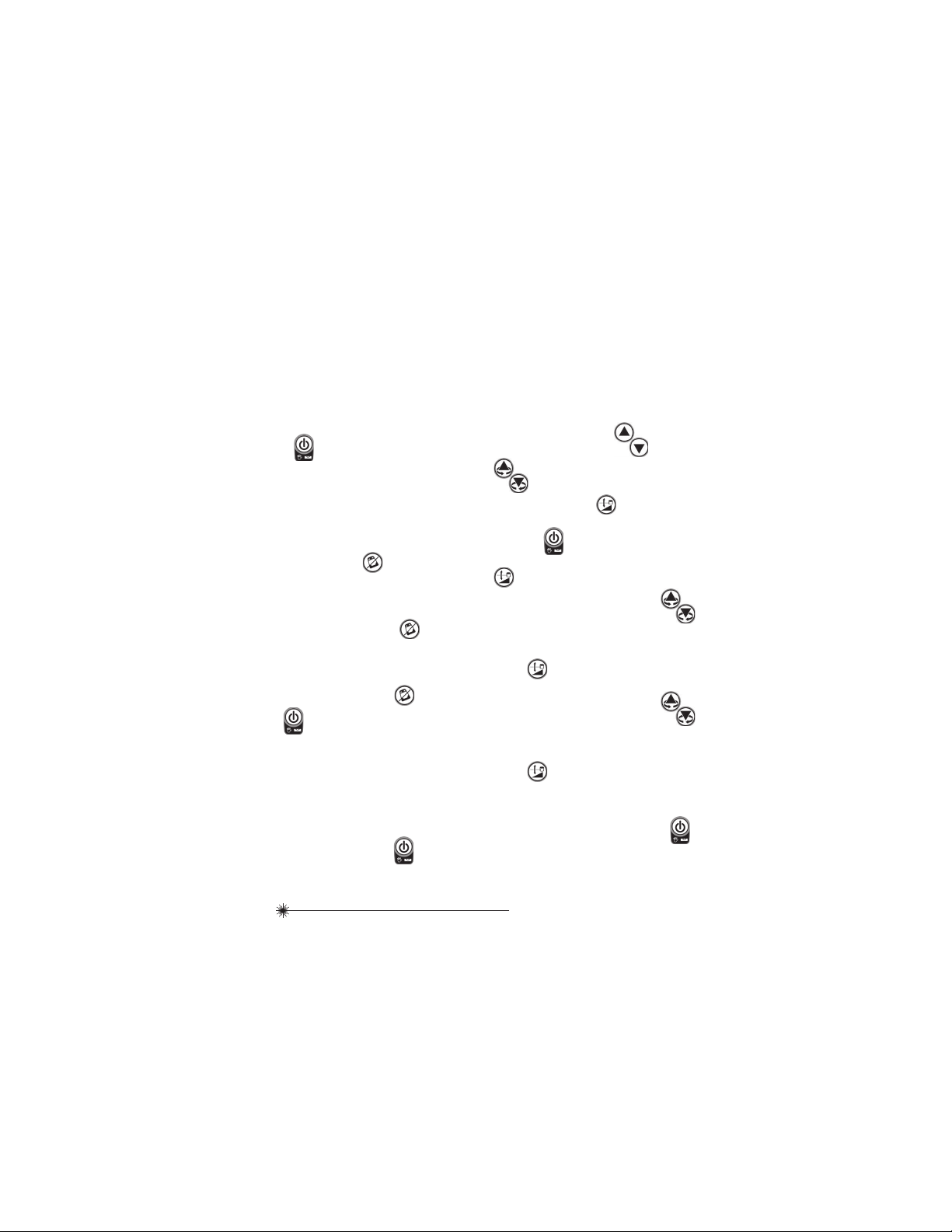

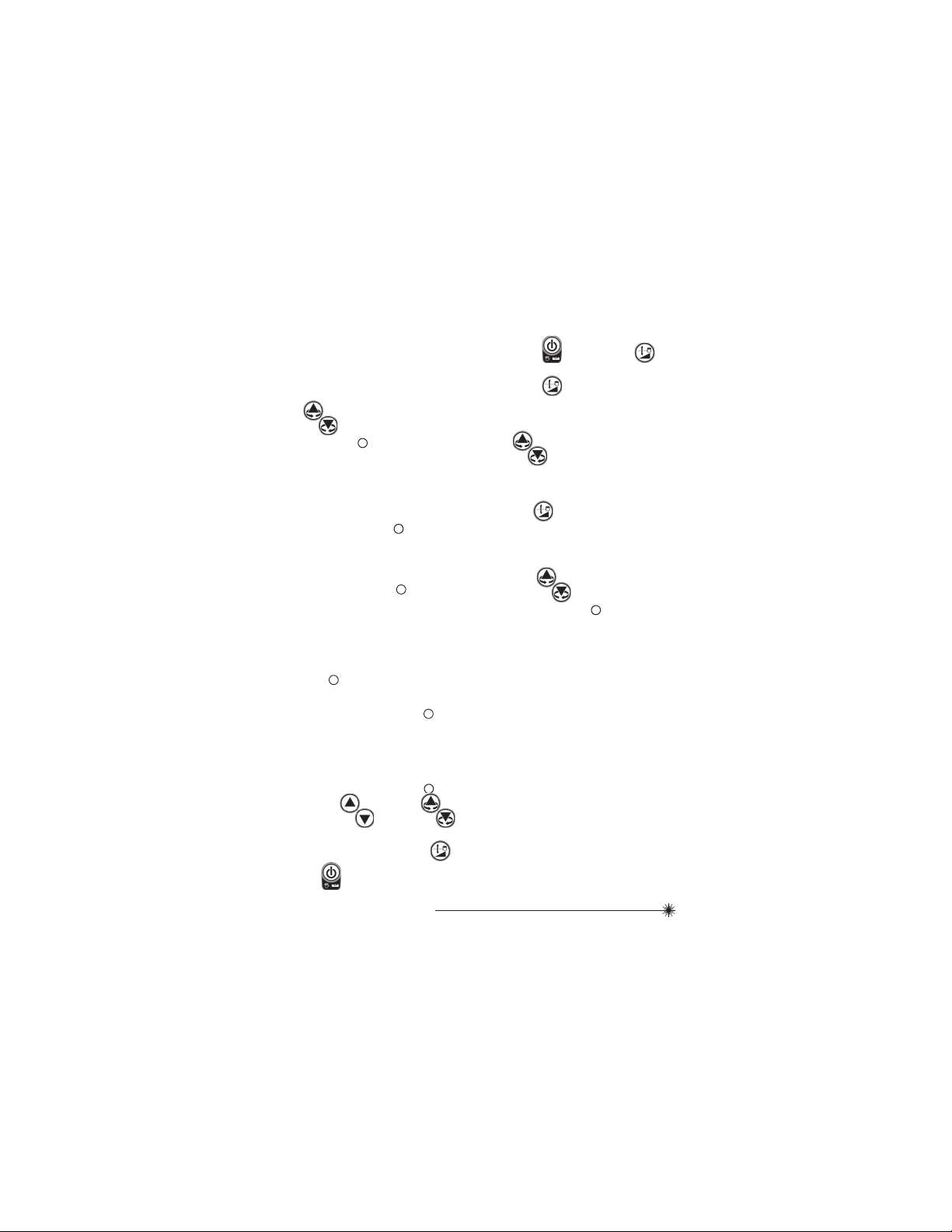

Figure E - Keypad Configurations

IEC/EN 60825-1

LAS ER R AD IA TI ON - D O NO T

STA RE I NT O TH E BE AM

CLA SS 2 L AS ER P RO DU CT

Max Out put ≤ 1 m W @ 630 - 670 nm

Page 9

9

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

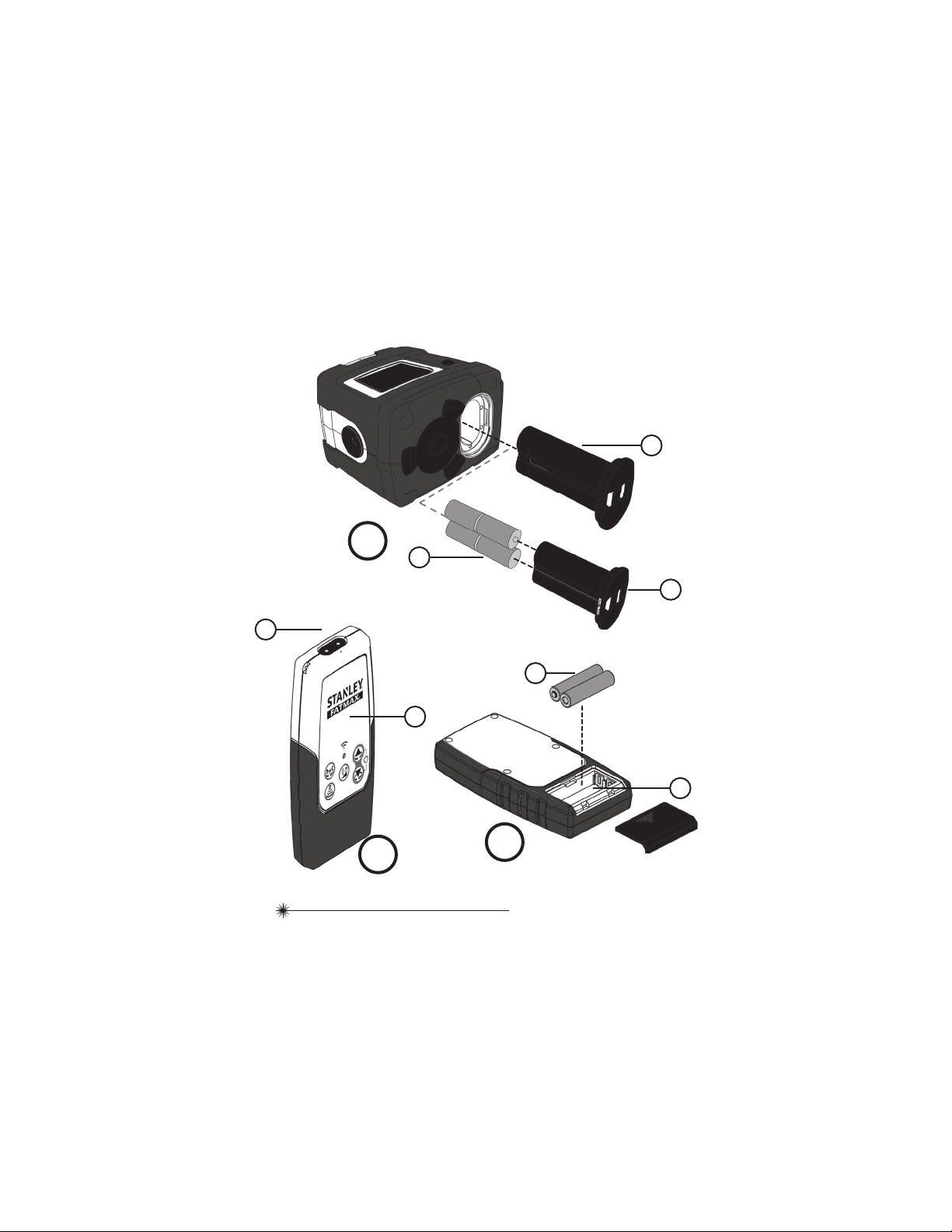

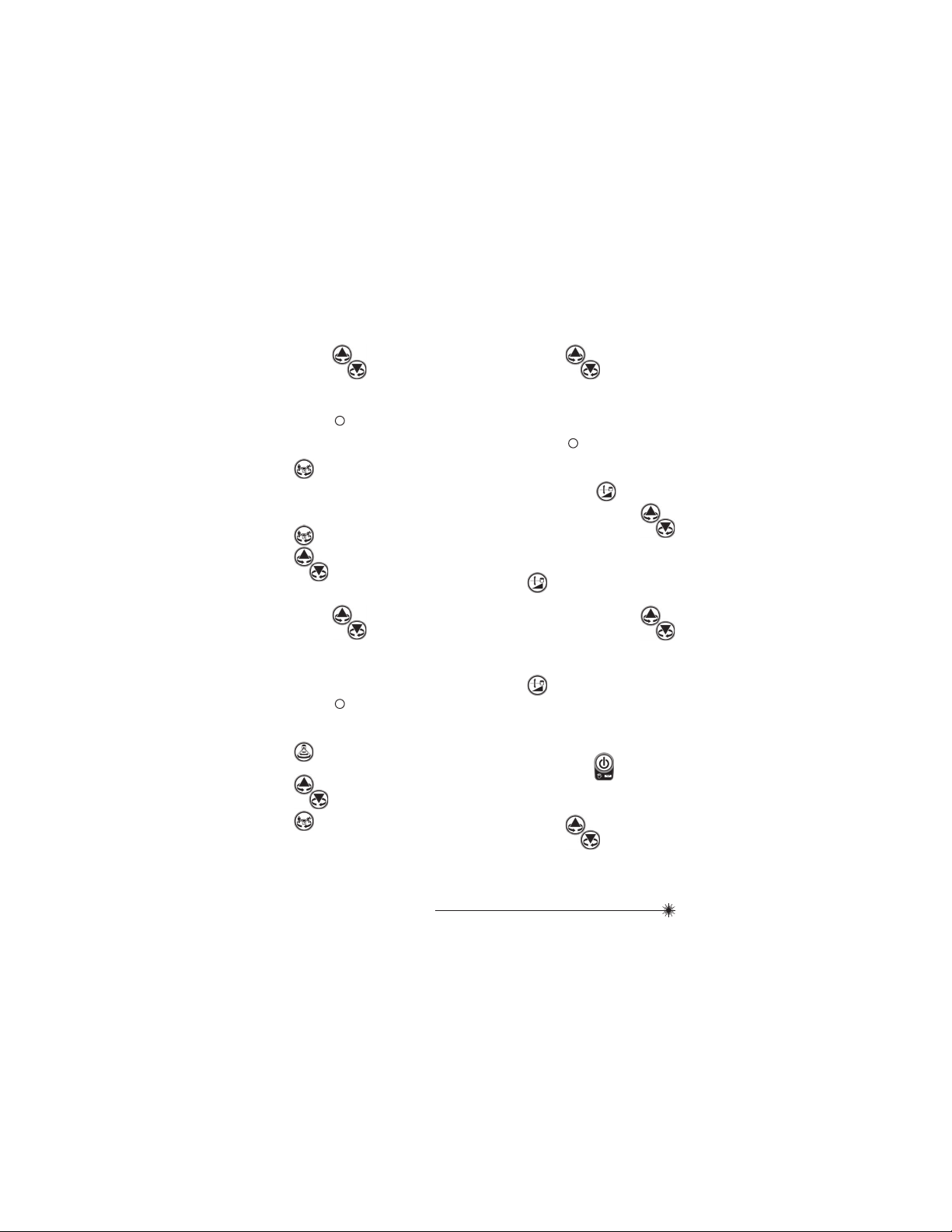

Figure F - Laser Tool Battery Location

15. Battery Pack

16. Optional Batteries - 4 x “C”

17. Battery Cartridge for use with 4 x “C” Batteries

Figure G - Remote Control

18. Infrared LED

19. Keypad

Figure H - Remote Control Battery Location

20. Batteries - 2 x “AAA”

21. Battery Compartment

Figure J - Bracket Accessory

22. Key Hole Slot for Wall Hanging

23. Ceiling Grid Clamp

24. Vertical (Up / Down) Fine Adjust Knob

25. Included 5/8 to 1/4 Adapter

26. Vertical Adjust Lock Knob

27. 5/8 Mounting Screw

28. Rotary Fine Adjust Knob

29. Tightening Knob

30. Magnetic Mount

31. Keyhole Mount for Additional Magnet and / or Clamp

Accessories

32. Storage Location for 5/8 to 1/4 Adapter

Figure K - Tripod Mounting

33. 5/8 Center Screw

34. Leg Lock Lever

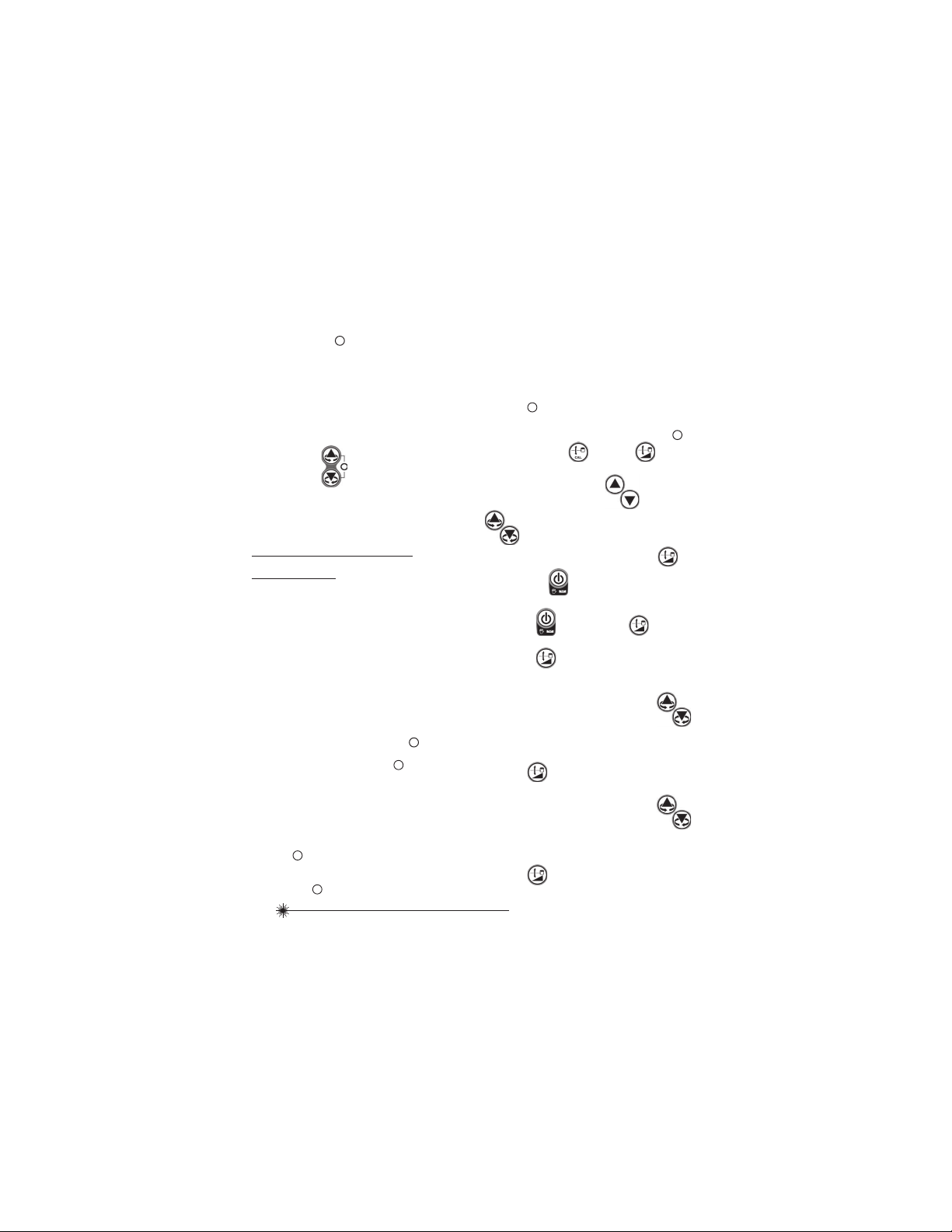

Figure L - Calibration and / or Slope Axis Direction

Figure M - Spot and / or Scan Rotation Direction

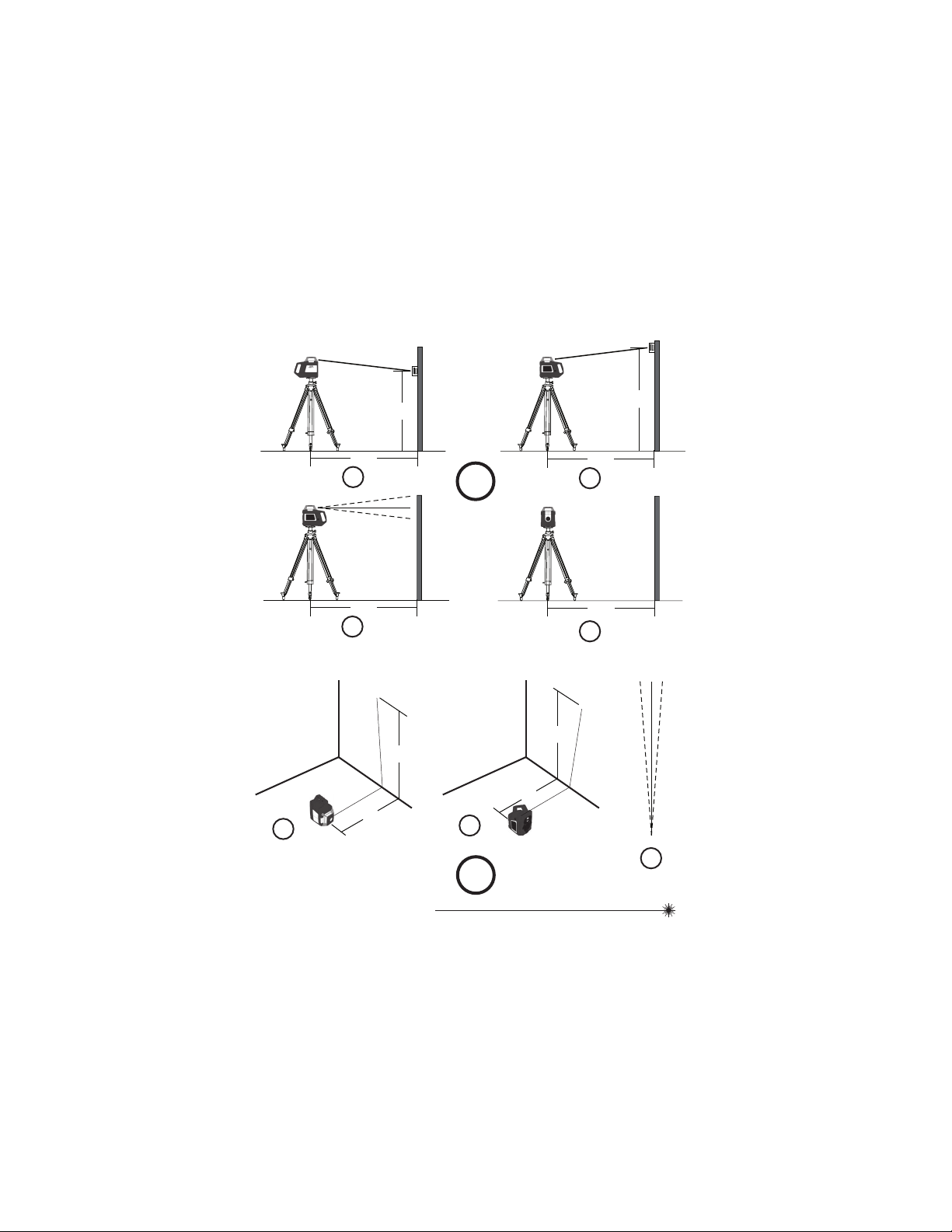

Figure N - Horizontal Check Setup

Figure P - Vertical Check Setup

RL HW RL HW+ RL HGW RL HV

RL

HVPW/-G

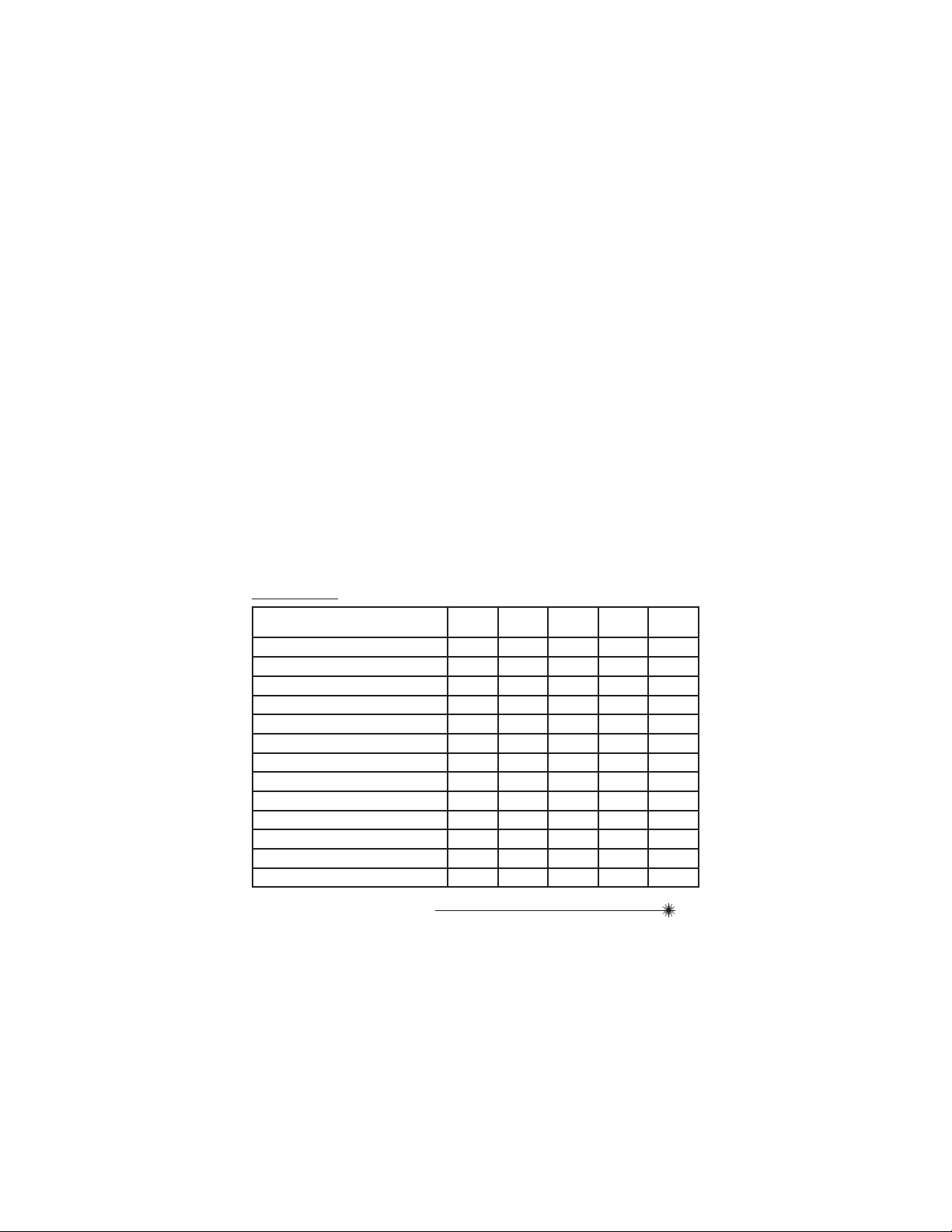

Horizontal Auto-Levelling X X X X X

Tilt Warning X X X X X

Manual Mode X X X X X

Calibration Mode X X X X X

IR sensor for remote X X X X

Vertical Auto-Levelling X X X X

Manual Slope Mode (NO Auto-Levelling) X X X X

Speed Select X X X

Spot Mode X X X

Scan Mode X X

Vertical Up Beam X X

Vertical Down Beam X

Digital Slope Mode (with Auto-Levelling) X

Feature Set

Page 10

10

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Keypad, LED, and LCD

(See figure E to reference keypad display for each

laser tool model)

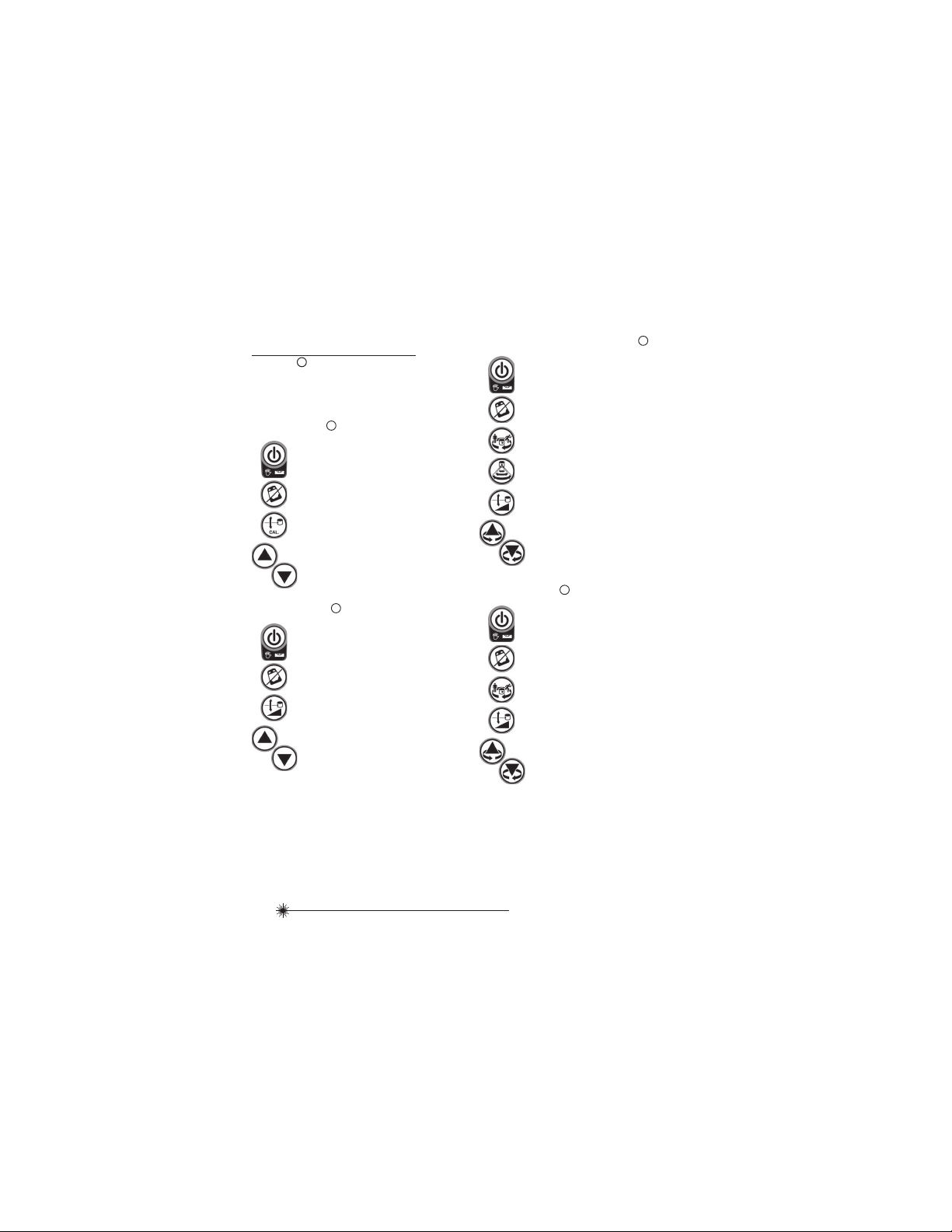

Keypads

RL HW (See Figure

E

1

)

Power ON / OFF Key

Tilt Warning ON / OFF Key

Calibration Mode Key

Calibration Adjust Keys

RL HW+ (See Figure

E

2

)

Power ON / OFF Key

Tilt Warning ON / OFF Key

Manual Slope Mode Key

Calibration Adjust Keys

RL HV / RL HVPW /RLHVPW-G(See Figure

E

3

)

Power ON / OFF Key

Tilt Warning ON / OFF Key

Rotation Speed Key

Scan Mode Key

Manual Slope Mode Key

Scan, Spot, Slope and Calibration Adjust

Keys

RL HGW (See Figure

E

4

)

Power ON / OFF Key

Tilt Warning ON / OFF Key

Rotation Speed Key

Auto-Levelling / Manual Slope Mode Key

Scan, Spot, Slope and Calibration Adjust

Keys

Page 11

11

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

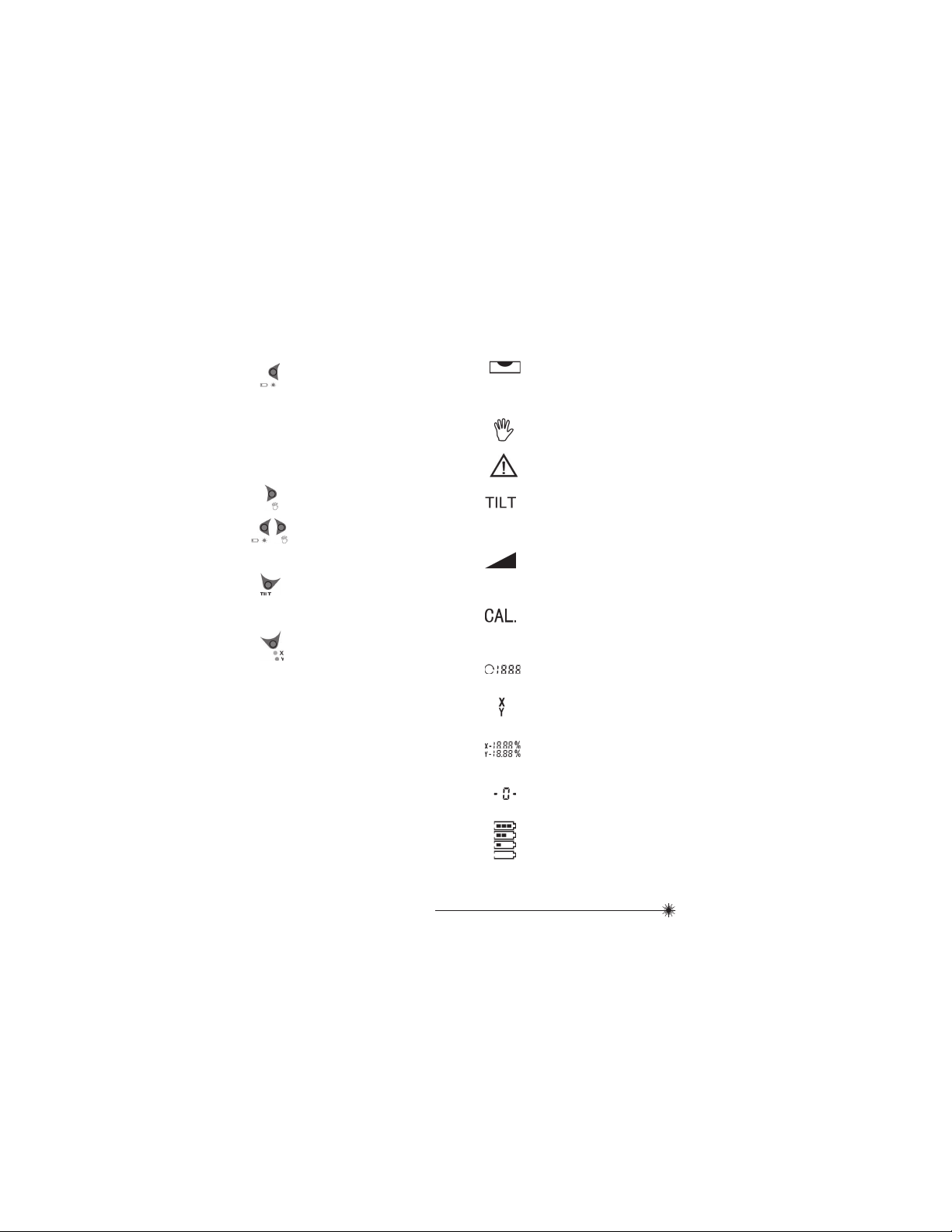

LEDs

Power LED - Blinking GREEN

• Laser Tool is Auto-Levelling

• In Calibration and / or Default Tilt Warning

Set Up

Power LED - Solid GREEN

• Auto-Levelling Complete

Power LED - Blinking RED

• Low Battery

Power LED - Solid RED

• Battery Needs Recharging

Manual LED - Blinking RED

• Manual Mode ON (Auto-Levelling OFF)

Manual LED - Blinking RED

with

Power LED - Blinking GREEN

• Out of Compensation Range

Tilt Warning LED - Solid RED

• Tilt Warning ON

Tilt Warning LED - Blinking RED

• Tilt Warning Alarm

X / Y Select LED - Solid GREEN

• X Axis Adjust Slope Mode

X / Y Select LED - Solid RED

• Y Axis Adjust Slope Mode

X / Y Select LED - Blinking GREEN

• X Axis at Maximum Allowed Slope in Slope

Mode

• X axis adjust Calibration Mode

X / Y Select LED - Blinking RED

• Y Axis at Maximum Allowed Slope in Slope

Mode

• Y axis adjust Calibration Mode

LCD Icons

Auto-Levelling Icon - Blinking

• Laser Tool is Auto-Levelling

• In Calibration and / or Default Tilt Warning

Set Up

Manual Icon - Blinking

• Manual Mode ON (Auto-Levelling OFF)

Warning Icon - Blinking

• Out of Compensation Range

• Bumped while Auto-Sloping

Tilt Icon - Solid

• Tilt Warning ON

Tilt Icon - Blinking

• Tilt Warning Alarm

Slope Icon - Solid

• Slope Mode ON

Slope Icon - Blinking

• At Maximum Allowed Slope

Calibration Icon - Solid

• Calibration Mode ON - Horizontal

Calibration Icon - Blinking

• Calibration Mode ON - Vertical

Rotation Icon with Speed Value

• Speed Setting

X / Y Icon Only - Blinking

• Adjust Shown Axis in Manual Slope and / or

Calibration Mode

X / Y Icon with Value - Value Blinking

• Adjust Shown Value in Auto-Levelling Slope

Mode

Vertical Position Icon - Solid

• Shown when Laser Tool is in Vertical Position

Battery Power - Solid

• Approximate Battery Life as Shown

Battery Power - Blinking

• Battery Needs Recharging

Page 12

12

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Batteries and Power

Battery Installation / Removal

(See figure F and G to reference battery location of

laser tool and remote control)

Laser Tool (See figure

F

)

• Press tabs to open battery compartment and slide out.

• Install / Remove batteries. Orient batteries correctly

when placing into laser tool.

• Securely close and lock battery compartment cover.

IR Remote Controller (See figure

G

)

• Open battery compartment by sliding cover off.

• Install / Remove batteries. Orient batteries correctly

when placing into laser tool.

• Securely close and lock battery compartment cover.

WARNING:

• Pay close attention to the battery holder’s (+)

and (-) markings for proper battery insertion.

Batteries must be of same type and capacity. Do

not use a combination of batteries with different

capacities remaining.

Charging Battery

• For best life, the rechargeable battery must be charged for

4 hours before first use.

• Plug charging / power adapter plug into charging jack of

laser tool

• Plug charging / power adapter into power outlet (110 V or

220 V) with appropriate plug receptacle.

• The LED on the charging / power adapter will light RED

during charge.

• Leave battery to charge for approximately 4 hours to reach

full charge.

• When battery is fully charged unplug the charging / power

adapter from laser tool and power outlet.

• The LED on the charging / power adapter will light GREEN

when charge is complete.

WARNING:

• Use charging / power adapter only with Ni-MH

battery pack supplied. Charging any other

type of battery may result in damage and/or

personal harm.

WARNING:

• The battery and charging / power adapter can be

damaged if damp. Always store and charge the

tool in a dry and covered place.

NOTE:

• For best battery life, it is recommended to charge the

battery once it has been fully discharged and avoid letting

charge for > 10 hours at a time.

Operating with Charging / Power

Adapter

• Laser tool can operate while plugged into charging / power

adapter.

• Functions and controls of laser tool are the same as when

not plugged into charging / power adapter.

Set Up

Positioning

(See Feature Set to reference which models offer AutoLevelling in the given positions)

Horizontal Position (See figure A)

• Place laser tool down on its bottom. Be sure surface is

near level. Press

to power ON.

Vertical Position (See figure B)

• Place laser tool down on its side, handle facing up. Be

sure surface is near level. Press

to power ON.

Page 13

13

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

At Angle

• Press

to power ON. Press and hold to turn

ON Manual Mode. Laser tool can now be positioned to

various angles with auto-levelling mode OFF.

NOTE:

• To change between horizontal and vertical positions the

laser tool must be powered OFF, repositioned, and then

powered ON in the new position.

Mounting on Accessories

Mounting Bracket (See figure J)

• Securely position wall bracket in a location to be

measured.

• Visually orient the bracket mounting surface so that it is

near horizontal.

• Mount the laser tool to the bracket and tighten the

tightening knob.

Tripod Mount (See figure K)

• Position a tripod in a place where it will not be easily

disturbed and near the central location of the area to

be measured.

• Extend tripod legs as required. Adjust leg positioning to

be sure tripod head is near horizontal.

• Mount the laser tool to the tripod by pushing up the 5/8

center screw and tighten.

CAUTION:

• Do not leave the laser tool unattended on an

accessory without fully tightening the center

screw. Failing to do so may lead to the laser tool

falling and sustaining possible damage.

NOTE:

• Either dome head, flat head or elevator type tripod can be

used with the laser tool.

• It is best practice to always support laser tool with

one hand when placing or removing laser tool from an

accessory.

• If positioning over a target, partially tighten the 5/8 screw

mount, align laser tool, and then fully tighten the 5/8

screw mount.

Sighting Telescope (RL HGW)

(The Alignment Sight on the top cover of the laser tool

can be used for models that do not include the Sighting

Telescope)

Mounting and Use (See figure

C

)

• Loosen both locking screws on sighting telescope. Guide

scope onto the mount base located on top of the laser

tool with the objective (smaller end) towards the target (

C

1

). Securely tighten the locking screws (

C

2

).

• Remove the lens covers from the scope and roughly aim

the laser tool / scope towards the target.

• Look through the eyepiece (larger end) and turn the

reticle focus until the reticle (cross hair) is sharp and

clearly visible.

• Look through the eyepiece to align the vertical line of the

reticle with target. Adjust the distance between the eye

and eyepiece to focus the target.

NOTE:

• Use of the alignment sight / sighting telescope is to

accurately align and square the laser tool to a target when

setting a slope for grade applications.

• The sighting telescope has been sighted-in by the

manufacturer and should not require any additional

adjustments. DO NOT attempt to adjust the windage and

elevation of the sighting telescope. Doing so may cause

inaccuracies in sighting the target and alignment of the

laser tool.

Operation

NOTE:

• See Feature Set to reference which models offer specific

functions / modes.

• See LCD / LED Descriptions for indications during

operation.

• Before operating the laser tool always be sure to check the

laser tool for accuracy.

• In Manual Mode, Auto-Levelling is OFF. The accuracy of the

beam is not guaranteed to be level.

• Laser tool will indicate when it is out of compensation

range. Reference LED / LCD Descriptions. Reposition

laser tool to be closer to level.

• When not in use, please be sure to power OFF the laser

tool.

• Because the laser tool is an instrument with high precision,

Page 14

14

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

it is preferable to use the remote whenever possible to

perform functions (when available).

• Laser tool is Auto-Levelling by default.

• Tilt Warning is ON by default when laser tool leaves the

manufacturer.

• Tilt Warning is only available in the Auto-Levelling modes.

Tilt Warning is not available while in Manual Mode.

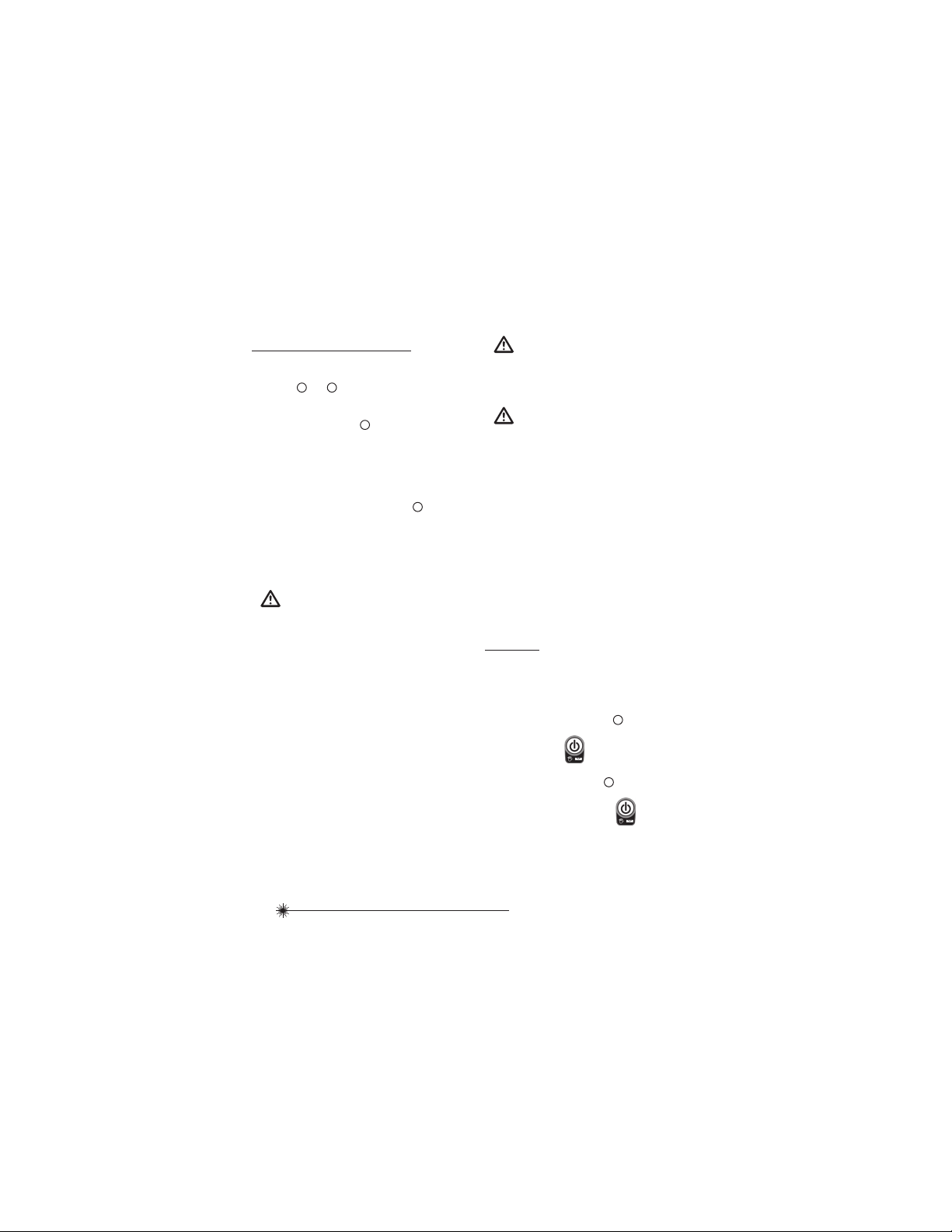

Power

• Press

to turn laser tool ON / OFF.

• When powered ON, Tilt Warning is ON by default

(default setting can be changed).

• When powered ON, Laser tool begins Auto-Levelling.

• When Auto-Levelling has completed laser will rotate at

last used RPM speed setting.

Tilt Warning (not available in Manual Mode)

• When powered ON, Tilt Warning is ON by default.

• When powered ON, press

to turn Tilt Warning

ON / OFF.

• With Tilt Warning ON, laser tool will indicate with LED

/ LCD and blinking laser beam when the laser tool has

sensed any movement.

• If an alarm has been triggered, press

to reset.

• When reset, the laser tool begins Auto-Levelling. Check

alignment with original target.

Tilt Warning Default Setting

• When powered OFF, press and hold

followed

by

.

• Release both keys.

• If Tilt LED / Icon is ON, default setting is ON. If Tilt LED /

Icon is OFF default setting is OFF.

• Laser tool begins Auto-Levelling as done when normally

powered ON.

• Repeating the steps will toggle ON / OFF the Tilt

Warning default setting.

Manual Mode

• When powered ON, press and hold

for ≥ 3

seconds to turn ON / OFF Manual Mode.

• Auto-Levelling is OFF in Manual Mode.

• Laser tool can be manually positioned at any angle.

• When Manual Mode is turned OFF, laser tool begins

Auto-Levelling as done when initially powered ON.

Calibration Mode - see Accuracy Check and

Calibration section

Manual Slope Mode

(For RL HW / RL HW+ substitute where ever

is referenced below)

• When powered ON, press

. Manual Mode turns

ON, Auto-Levelling OFF.

(For RL HGW

needs to be pressed and held for

≥ 3 seconds to enter Manual Mode prior to pressing

noted above)

• LED / LCD will indicate “X” axis adjust. Press

to adjust axis.

• LED / LCD will indicate when at maximum slope angle.

The axis will not move any further in that direction.

• Press

again to set the “X” axis and / or proceed to

the “Y” axis adjust.

• LED / LCD will indicate “Y” axis adjust. Press

to adjust axis.

• LED / LCD will indicate when at maximum slope angle.

The axis will not move any further in that direction.

• Press

again to set the “Y” axis and / or proceed to

use of laser tool in Manual Slope Mode.

• “X” and “Y” axis are now set at manually adjusted

slopes.

• To turn Manual Slope Mode OFF, press and hold

for ≥ 3 seconds.

• When Manual Mode is turned OFF, laser tool begins

Auto-Levelling as done when initially powered ON.

Page 15

15

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

NOTE:

• A single press of

will change slope by 0,01%.

• Holding the key down will move the slope axis

continuously, slowly at first, followed by a faster rate

when held for an extended time.

• Reference Figure L for resulting slope direction for

each key.

Speed

• Press

to toggle through the available speed

settings from fastest to slowest to stopped.

Spot Mode

• Press

to stopped (0 RPM) setting.

• Press

to rotate the direction of the spot.

NOTE:

• A single press of

will rotate the direction

by 0,10°.

• Holding down the key will rotate the direction

continuously, slowly at first, followed by a faster rate

when held for an extended time.

• The laser will blink 3 x prior to moving at the faster rate.

• Reference Figure

M

for resulting rotation direction

for each key.

Scan Mode

• Press

to cycle through available scan angles (15°

/ 45° / 90°).

• Press

to rotate the direction of the scan.

• Press

to turn OFF Scan Mode and return to the last

used speed setting.

NOTE:

• A single press of

will rotate the direction

by 2,0°.

• Holding down the key will rotate the direction

continuously, slowly at first, followed by a faster rate

when held for an extended time.

• The laser will blink 3 x prior to moving at the faster rate.

• Reference Figure

M

for resulting rotation direction

for each key.

Digital Slope Mode (with Auto-Levelling)

• When powered ON, press

.

• LCD will indicate “X” axis adjust. Press

to

adjust axis value.

• LCD will indicate when at maximum slope angle. The

value will not continue any further in that direction.

• Press

again to set the “X” axis and / or proceed to

the “Y” axis value adjust.

• LCD will indicate “Y” axis adjust. Press

to

adjust axis value.

• LCD will indicate when at maximum slope angle. The

value will not continue any further in that direction.

• Press

again to set the “Y” axis and / or proceed to

use of laser tool in Digital Slope Mode.

• Laser tool begins Auto-Levelling as done when initially

powered ON and then the “X” and “Y” axis will slope to

the set values.

• To turn Digital Slope Mode OFF, the laser tool power

needs to be cycled. Press

2x to power OFF and

back ON.

NOTE:

• A single press of

will change the value by

0,01%.

• Holding the key down will move the value continuously,

slowly at first, followed by a faster rate when held for

an extended time.

Page 16

16

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

• There is no need to adjust calibration if the distance

between reference point “D

1

” and “D2” is < 2,0 mm.

• If the distance measured is ≥ 2,0 mm then a calibration

adjustment is necessary.

• Perform the same steps for the “Y” axis as was done

for the “X” axis. Replace “X1” and “X2” with Y1” and

“Y2” (

N

4

).

Horizontal Calibration (See Figure

N

)

(For RL HW substitute

where ever is

referenced below)

(For RL HW / RL HW+ substitute where ever

is referenced below)

• With laser tool powered OFF, press and hold

followed by

.

• Release

and continue to hold for ≥ 3

seconds.

• Release

.

• The LED/LCD will indicate laser tool is in Calibration

mode.

• If necessary, adjust the “X” axis by pressing

until the laser beam is aligned with “D0”. “D0” is the

halfway point between “D

1

” and “D2” during “X” axis

check.

• Press

again to set the “X” axis and / or proceed to

the “Y” axis adjust.

• If necessary, adjust the “Y” axis by pressing

until the laser beam is aligned with “D0”. “D0” is the

halfway point between “D

1

” and “D2” during “Y” axis

check.

• Press

again to set the “X” axis and / or proceed to

• Reference Figure L for resulting slope direction for

each key.

Remote Control

• The same functions / modes for each specific laser tool

are accessible through use with the keys available on

the remote.

• The laser tool can be powered OFF with the remote by

pressing both

at the same time. The laser tool

can only be powered ON with the power key on the

laser tool.

Accuracy Check and

Calibration

NOTE:

• See Feature Set to reference which models offer specific

functions.

• The laser tools are sealed and calibrated at the factory to

the accuracies specified.

• It is recommended to perform a calibration check prior to

its first use and then periodically during future use.

• Be sure to allow the laser tool adequate time to Auto-Level

(< 60 seconds) prior to a calibration check.

• The laser tool should be checked regularly to ensure its

accuracies, especially for precise layouts.

Horizontal Check (See Figure

N

)

• Set the laser tool on a tripod 20 m away from a wall

with the ”X1” side facing the wall (

N

1

).

• Power ON the laser tool and allow the laser tool to

Auto-Level and be sure laser is rotating.

• Go to the wall and mark a reference point “D

1

” where

the laser line is on the wall. If available, using a

detector may help in locating the beam more easily.

• Loosen the laser tool from the tripod and rotate the

laser tool 180° so that the “X2” side is now facing the

wall (

N

2

).

• Go back to the wall and measure the distance between

the first reference point “D

1

” and the second reference

point “D

2

” (

N

3

).

Page 17

17

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

exit Calibration Mode.

• Axis settings are now saved, Calibration Mode is OFF,

and laser tool begins Auto-Levelling as done when

initially powered ON.

NOTE:

• A press of

will slope the axis by 3,5 arc

seconds. Reference Figure

L

for resulting slope direction

for each key.

• If the laser tool can still not be calibrated after

following the Calibration procedure, please send

the laser tool into an Authorized Service Center for

repair.

Vertical Check (See Figure

P

)

(Only necessary on models with Vertical Auto-Levelling)

• Set the laser tool on a stable surface in its vertical

position 1 m away from a wall that extends ≥ 2 m high

with the ”Y1” side facing that wall (

P

1

).

• Power ON the laser tool and allow the laser tool to

Auto-Level and be sure laser is rotating.

• Mark reference points “A” (where laser line is on

floor 1 m away from wall), “B “ (where laser beam

is at corner), and “D1” (where laser beam is 2 m

up the wall).

• Rotate the laser tool 180° so that the “Y2” side is now

facing the wall (

P

2

).

• Align the laser beam with reference points “A” and “B”

and then go back to the wall and measure the distance

between the reference point “D

1

” and “D2” (

P

3

).

• There is no need to adjust calibration if the distance

between reference point “D

1

” and “D2” is < 1,0 mm.

• If the distance measured is ≥ 1,0 mm then a calibration

adjustment is necessary.

Vertical Calibration (See Figure

P

)

(For RL HW+ substitute

where ever is

referenced below)

• With laser tool powered OFF, press and hold

followed by

.

• Release and continue to hold for ≥ 3

seconds.

• Release

.

• The LED/LCD will indicate laser tool is in Calibration

mode.

• If necessary, adjust the vertical “X” axis by pressing

until the laser beam is aligned with “D0”.

“D

0

” is the halfway point between “D

1

” and “D2”

during vertical axis check.

• .

• Press

to set the vertical “X” axis.

• Axis setting is now saved, Calibration Mode is OFF,

and laser tool begins Auto-Levelling as done when

initially powered ON.

NOTE:

• A press of

will slope the axis by 3,5 arc

seconds. Reference Figure L for resulting slope direction

for each key.

• If the laser tool can still not be calibrated after

following the Calibration procedure, please send

the laser tool into an Authorized Service Center for

repair.

Page 18

18

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Specifications

Laser Tool

RL HWRL

HW+

RL HGW RL HV

RL

HVPW

RL HVPW-G

Horizontal Rotary

Accuracy:

±1.5 mm/30 m (±10”)

Vertical Rotary Accuracy: ±3 mm/30 m (±20”)

Vertical Up Beam

Accuracy:

±3 mm/30 m (±20”)

Vertical Down Beam

Accuracy:

±9 mm/30 m (±60”)

Slope Accuracy: +/-15mm/30m (+/-100”)

Compensation Range: ≥ 5°±1° (dual axis)

Slope Range: ±10% (dual axis)

Minimum Increment: 0,01%

Scan Range: 10°/45°/90° ±20%

Working Range Diameter

with Detector:

≤ 600 m

Leveling Time ≤ 20 seconds

Rotation Speed: 600 rpm ±10%

1000/600/300/150/0

rpm ±10%

600/300/150/0 rpm ±10%

Laser Class: Class 2 (IEC/EN 60825-1)

Class 3R (IEC/

EN60825-1)

Laser Wavelength: 635 nm 515-540nm

Operating Time: ≥ 20 hours (Ni-MH) ≥ 12 hours(Ni-MH)

Recharge Time: ≤ 4 hours

Power Source: NI-MH Battery Pack

IP Rating: IP66

Operating Temperature

Range:

-10° C ~ +50° C

Storage Temperature

Range:

-25° C ~ +70° C

Page 19

19

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Remote Controller

Infrared

40 m

2 x AAA Batteries (Alkaline)

Type:

Indoor Operating Range:

Power Source:

Sighting Telescope

2,5 x

5° 36’

8 mm

32 mm

≤ 8°

85 mm

Magnification:

Field of View:

Visual Diameter:

Objective Diameter:

Resolving Power:

Eye Relief:

Notes

Page 20

20

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

WARNUNG:

• Die folgenden Beispiele für Etiketten sind

auf Ihrem Lasergerät angebracht, um Sie zu

Ihrer Annehmlichkeit und Sicherheit über die

Laserklasse zu informieren. Bitte wenden Sie

sich an das Produkthandbuch bezüglich

der technischen Daten eines speziellen

Produktmodells.

IEC/EN 60825-1

LASERSTRAHLUNG - NICHT IN DEN

STRAHL BETRACHTEN

LASERPRODUKT DER KLASSE 2

Maximale Leistung ≤ 1 mW @ 630 - 670 nm

Inhaltsverzeichnis

• Sicherheit

• Produktüberblick

• Funktionsumfang

• Tastatur, LED-Anzeige und LCD

• Batterien und Stromversorgung

• Konfiguration

• Bedienung

• Genauigkeitsprüfung und Kalibrierung

• Technische Daten

Produktüberblick

Abbildung A - Lasergerät in horizontaler Position

1. Ausrichtung Sichtweite

2. Fenster für vertikalen Aufwärtsstrahl (RL HV / RL

HVPW/ RL HVPW -G)

3. Rotationslaser / Glasgehäuse

4. Aufladung / Stromadapterstecker

5. Tastatur (Siehe Abbildung

E

)

6. Vertikaler Abwärtsstrahl (RL HVPW / RL HVPW -G)

Abbildung B - Lasergerät in vertikaler Position

Abbildung C - Lasergerät mit Zielfernrohr (RL HGW)

7. Infrarotsensor für Fernbedienung

8. Zielfernrohr

9. Zielfernrohr Aufsatzteil

Abbildung D - Zielfernrohr

10. Sucher (Dargestellt mit aufgesetzter Abdeckung)

11. Fadenkreuz

12. Abdeckungen für Seiten- / Höhenanpassung

(NICHT ÖFFNEN / MODIFIZIEREN)

13. Verschlussschrauben

14. Objektiv (Dargestellt mit aufgesetzter Abdeckung)

Abbildung E - Konfigurationen des Tastenfelds

Abbildung F - Batteriefach im Lasergerät

15. Batteriesatz

16. Geeignete Batterien - 4 x “C”

17. Batteriefach zur Verwendung mit 4 x "C"-Batterien

Benutzersicherheit

WARNUNG:

• Lesen Sie vor Verwendung des Produkts

aufmerksam die Sicherheitsanweisungen und

das Produkthandbuch. Die für das Instrument

verantwortliche Person muss gewährleisten,

dass sämtliche Benutzer die darin enthaltenen

Anweisungen verstehen und befolgen.

ACHTUNG:

• Während das Lasergerät in Betrieb ist, seien

Sie vorsichtig, dass Ihre Augen nicht dem

austretenden Laserstrahl ausgesetzt werden

(rote Lichtquelle). Wenn Ihre Augen dem

Laserstrahl für längere Zeit ausgesetzt sind, kann

das für Ihre Augen gefährlich sein.

ACHTUNG:

• In einigen Ausrüstungssets der Laser sind

Schutzbrillen beigefügt. Diese sind NICHT

als Sicherheitsbrillen zertifziert. Diese Brillen

werden NUR verwendet, um die Sicht auf

den Strahl in helleren Umgebungen oder bei

größeren Entfernungen zur Laserquelle zu

verbessern.

Bewahren Sie alle Abschnitte des Handbuchs auf, um in

Zukunft darauf jederzeit Zugriff zu haben.

D

Page 21

21

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Abbildung G - Fernbedienung

18. Infrarot-LED

19. Tastenfeld

Abbildung H - Batteriefach der Fernbedienung

20. Batterien - 2 x "AAA"

21. Batteriefach

Abbildung J - Zubehörhalterung

22. Schlüssellochschlitz für Wandaufhängung

23. Deckengitterklammer

24. Knauf zur (Aufwärts- / Abwärts-) vertikalen Feinjustierung

25. Einschließlich 5/8- bis 1/4-Adapter

26. Knauf zur vertikalen Einstellsperre

27. 5/8-Aufsatzschraube

28. Knauf zur Feinjustierung der Rotation

29. Knauf zum Festziehen

30. Magnethalterung

31. Schlüssellochaufsatz für zusätzliches Magnet- und / oder

Klammerzubehör

32. Aufbewahrungsort des 5/8- bis 1/4-Adapters.

Abbildung K - Stativaufsatz

33. Zentrale 5/8-Schraube

34. Beinverriegelungshebel

Abbildung L - Kalibrierung und / oder Neigungsachsen-

ausrichtung

Abbildung M - Punkt- und / oder Abtastrotationsaus-

richtung

Abbildung N - Horizontale Prüfungskonfiguration

Abbildung P - Vertikale Prüfungskonfiguration

RL HW RL HW+ RL HGW RL HV

RL

HVPW/-G

Horizontale automatische Nivellierung X X X X X

Verkippungswarnung X X X X X

Manueller Modus X X X X X

Kalibrierungsmodus X X X X X

IR-Sensor für Fernbedienung X X X X

Vertikale automatische Nivellierung X X X X

Manueller Neigungsmodus (OHNE automatische

Nivellierung)

X X X X

Auswahl Geschwindigkeit X X X

Punktmodus X X X

Abtastmodus X X

Vertikaler Aufwärtsstrahl X X

Vertikaler Abwärtsstrahl X

Digitaler Neigungsmodus (mit automatischer

Nivellierung)

X

Funktionsumfang

Page 22

22

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Tastatur, LED-Anzeige und

LCD

(Siehe Abbildung E bezüglich der Nutzung der

Tastaturanzeige für jedes Laser-Modell)

Tastenfelder

(RL HW+

E

2

)

Ein-/Ausschalttaste

Neigungswarnungstaste EIN / AUS

Taste manueller Neigungsmodus

Tasten zur Neigungs- und Kalibrierungsanpassung

(RL HGW

E

4

)

Ein-/Ausschalttaste

Neigungswarnungstaste EIN / AUS

Taste Rotationsgeschwindigkeit

Taste zur automatischen Nivellierung /

manueller Neigungsmodus

Tasten zur Punkt-, Neigungs- und

Kalibrierungsanpassung

(RL HV / RL HVPW / RL HVPW -G

E

3

)

Ein-/Ausschalttaste

Neigungswarnungstaste EIN / AUS

Taste Rotationsgeschwindigkeit

Abtastmodustaste

Taste manueller Neigungsmodus

Tasten zur Abtastungs-, Punkt-, Neigungs- und Kalibrierungsanpassung

(RL HW

E

1

)

Ein-/Ausschalttaste

Neigungswarnungstaste EIN / AUS

Kalibrierungsmodustaste

Kalibrierungsanpassungstaste

Page 23

23

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

LEDs

Power LED - Blinkt GRÜN

• Der Laser nivelliert sich automatisch

• Bei der Kalibrierung und / oder der Einrichtung der Standardneigungswarnung

Power LED - Leuchtet GRÜN

• Automatische Nivellierung abgeschlossen

Power LED - Blinkt ROT

• Batterie fast leer

Power LED - Leuchtet ROT

• Die Batterien müssen neu aufgeladen

werden

Manuell-LED - Blinkt ROT

• Manueller Modus EIN (Automatische

Nivellierung AUS)

Manuell-LED - Blinkt ROT

mit

Power LED - Blinkt GRÜN

• Außerhalb des Ausgleichsbereichs

Neigungswarnungs-LED - Leuchtet ROT

• Neigungswarnung EIN

Neigungswarnungs-LED - Blinkt ROT

• Neigungswarnungsalarm

X / Y-Auswahl-LED - Leuchtet GRÜN

• X-Achsenanpassung Neigungsmodus

X / Y-Auswahl-LED - Leuchtet ROT

• Y-Achsenanpassung Neigungsmodus

X / Y-Auswahl-LED - Blinkt GRÜN

• X-Achse bei maximal zulässiger Neigung im

Neigungsmodus

• X-Achsenanpassung Kalibrierungsmodus

X / Y-Auswahl-LED - Blinkt ROT

• Y-Achse bei maximal zulässiger Neigung im

Neigungsmodus

• Y-Achsenanpassung Kalibrierungsmodus

LCD-Symbole

Symbol automatische Nivellierung - Blinkt

• Der Laser nivelliert sich automatisch

• Bei der Kalibrierung und / oder der Einrichtung der Standardneigungswarnung

Symbol manuell - Blinkt

• Manueller Modus EIN (Automatische

Nivellierung AUS)

Symbol Warnung - Blinkt

• Außerhalb des Ausgleichsbereichs

• Zusammenstoß während der automatischen

Neigungseinstellung

Symbol Verkippung - Leuchtet

• Neigungswarnung EIN

Symbol Verkippung - Blinkt

• Neigungswarnungsalarm

Symbol Neigung - Leuchtet

• Neigungsmodus EIN

Symbol Neigung - Blinkt

• Bei maximal zulässiger Neigung

Symbol Kalibrierung - Leuchtet

• Kalibrierungsmodus EIN - Horizontal

Symbol Kalibrierung - Blinkt

• Kalibrierungsmodus EIN - Vertikal

Symbol Rotation mit Geschwindigkeitsangabe

• Geschwindigkeitseinstellung

Nur X / Y Symbol - Blinkt

• Anpassung angezeigte Achse in manueller

Neigung und / oder Kalibrierungsmodus

X / Y Symbol mit Angabe - Angabe blinkt

• Anpassung des angzeigten Werts im Neigungsmodus mit automatischer Nivellierung

Batterieleistung - Leuchtet

• Ungefähre Batterielebensdauer wie

angezeigt

Batterieleistung - Blinkt

• Die Batterien müssen neu aufgeladen

werden

Symbol Vertikale Position - Leuchtet

• Wird angezeigt, wenn das Lasergerät sich in

vertikaler Position befindet

Page 24

24

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Batterien und

Stromversorgung

Einlegen / Entfernen der Batterien

(Siehe Abbildung F und G zum Zugriff auf die

Batterien des Lasergeräts und Fernsteuerung)

• Drücken Sie auf den Verschluss, um das Batteriefach zu

öffnen und diese zu entnehmen.

• Batterien einlegen / entfernen. Batterien beim Einlegen

in das Lasergerät ordnungsgemäß ausrichten.

• Batteriefachabdeckung sicher schließen und verriegeln.

Lasergerät (Siehe Abbildung

F

)

IR-Fernbedienung (Siehe Abbildung

G

)

• Öffnen Sie das Batteriefach, indem Sie die Abdeckung

wegschieben.

• Batterien einlegen / entfernen. Batterien beim Einlegen

in das Lasergerät ordnungsgemäß ausrichten.

• Batteriefachabdeckung sicher schließen und verriegeln.

WARNUNG:

• Achten Sie besonders auf die Markierungen

(+) und (-) der Batterien, so dass diese richtig

eingelegt sind. Die Batterien müssen vom

gleichen Typ sein und die gleiche Spannung

aufweisen. Verwenden Sie keine kombinierten

Batterien mit unterschiedlichen Restladungen.

Batterien aufladen

• Für die größtmögliche Lebensdauer müssen die

wiederaufladbaren Batterien vor dem ersten Gebrauch für 4

Stunden aufgeladen werden.

• Stecken Sie das Ladegerät / den Adapter in die Buchse

des Lasergeräts.

• Verbinden Sie das Ladegerät / den Adapter mit einem

Stromanschluss (110 V oder 220 V) mit einer passenden

Steckdose.

• Die LED auf dem Ladegerät / dem Adapter leuchtet ROT

während des Ladevorgangs.

• Lassen Sie die Batterie für ungefähr 4 Stunden aufladen,

um eine volle Aufladung zu erreichen.

• Sobald die Batterien voll aufgeladen sind, trennen Sie

das Ladegerät / den Adapter vom Lasergerät und von der

Steckdose.

• Die LED auf dem Ladegerät / dem Adapter leuchtet GRÜN,

wenn die Aufladung abgeschlossen ist.

WARNUNG:

• Verwenden Sie das Ladegerät / den Adapter

nur zusammen mit dem mitgelieferten Satz NiMH-Batterien. Beim Laden von Batterien eines

anderen Typs kann dies zu Schäden und/oder

Verletzungen führen.

WARNUNG:

• Die Batterien und das Ladegerät / der Adapter

können Schaden nehmen, wenn Sie Dampf

ausgesetzt werden. Lagern und laden Sie das

Gerät stets an einem trockenen und geschützten

Ort.

HINWEIS:

• Für die größtmögliche Lebensdauer der Batterien wird

empfohlen, die Batterien zu laden, sobald sie vollständig

entladen sind und sie nicht länger als > 10 Stunden

aufzuladen.

Betrieb mit dem Ladegerät /

Stromadapter

• Das Lasergerät kann betrieben werden, während es an das

Ladegerät / den Stromadapter angeschlossen ist.

• Funktionen und die Steuerung des Lasergeräts sind

dieselben, wie wenn es nicht am Ladegerät / am

Stromadapter angeschlossen ist.

Konfiguration

Positionierung

(Siehe Funktionsumfang der einzelnen Modelle

und welche automatische Nivellierung sie in den

vorgegebenen Positionen bieten)

Horizontale Position (Siehe Abbildung

A

)

• Stellen Sie das Lasergerät auf seine Unterseite. Stellen

Sie sicher, dass der Laser auf "Nah" eingestellt ist.

Drücken Sie

um das Gerät EIN zu schalten.

Page 25

25

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Vertikale Position (Siehe Abbildung B)

• Stellen Sie das Lasergerät auf seine Seite, mit dem

Griff nach oben. Stellen Sie sicher, dass der Laser auf

"Nah" eingestellt ist. Drücken Sie

um das Gerät

EIN zu schalten.

Angewinkelt

• Drücken Sie

um das Gerät EIN zu schalten.

Drücken Sie und halten Sie

gedrückt, um den

manuellen Modus EIN zu schalten. Das Lasergerät kann

nun in verschiedenen Winkeln positioniert werden,

wobei der automatische Nivellierungsmodus AUS

geschaltet ist.

HINWEIS:

• Um zwischen horizontalen und vertikalen Positionen zu

wechseln, muss das Lasergerät AUS geschaltet, neu

positioniert und dann in der neuen Position wieder EIN

geschaltet werden.

Aufsetzen auf das Zubehör

Montagebügel (Siehe Abbildung J)

• Positionieren Sie die Wandhalterung sicher an einem

Ort, der ausgemessen werden soll.

• Orientieren Sie die Aufsatzfläche der Halterung nach

Augenmaß so, dass sie nahezu horizontal ausgerichtet

ist.

• Setzen Sie das Lasergerät auf die Halterung und ziehen

Sie den Befestigungsknauf fest.

Stativaufsatz (Siehe Abbildung

K

)

• Positionieren Sie ein Stativ an einem Ort, an dem

keine Störungen vorhanden sind und in der Nähe des

Zentrums des Bereichs, der vermessen werden soll.

• Ziehen Sie die Beine des Stativs aus wie erforderlich.

Passen Sie die Position der Beine so an, um

sicherzustellen, dass der Stativkopf nahezu horizontal

ausgerichtet ist.

• Setzen Sie das Lasergerät auf das Stativ, indem Sie

es auf die zentrale 5/8-Schraube aufsetzen und sie

festziehen.

ACHTUNG:

• Lassen Sie das Lasergerät nicht unbeaufsichtigt

auf einem Zubehör, ohne dass die zentrale

Schraube fest angezogen ist. Das kann dazu

führen, dass das Lasergerät herunterfällt und

möglicherweise langfristige Schäden auftreten.

HINWEIS:

• Mit dem Lasergerät können entweder Stative mit

Kugelkopf, Flachkopf oder Kurbelstative benutzt werden.

• Optimal ist es, das Lasergerät immer mit einer Hand zu

halten, wenn das Lasergerät auf ein Zubehör aufgesetzt

oder davon entfernt wird.

• Wenn Sie das Lasergerät auf ein Ziel ausrichten, ziehen

Sie die 5/8-Schraube des Aufsatzes nur teilweise fest,

richten Sie das Lasergerät aus und ziehen Sie dann erst die

5/8-Schraube vollständig fest.

Zielfernrohr (RL HGW)

(Die Zielausrichtung auf dem oberen Gehäuse des

Lasergeräts kann bei Modellen verwendet werden, die

über kein Zielfernrohr verfügen)

Aufsatz und Verwendung (Siehe Abbildung

C

)

• Lösen Sie beide Verschlussschrauben des Zielfernrohrs.

Schieben Sie das Fernrohr auf die Basis des Aufsatzes

auf dem Lasergerät mit dem Objektiv (schmaleres

Ende) auf das Ziel gerichtet (

C

1

). Ziehen Sie die

Verschlussschrauben wieder fest (

C

2

).

• Entfernen Sie die Objektivabdeckungen vom Fernrohr

und richten Sie das Lasergerät / Fernrohr grob auf das

Ziel aus.

• Blicken Sie durch den Sucher (dickeres Ende) und drehen

Sie die Scharfeinstellung bis das Ziel (Fadenkreuz)

scharf und deutlich sichtbar ist.

• Sehen Sie durch den Sucher zur Ausrichtung der

vertikalen Linie des Fadenkreuzes auf das Ziel.

Stellen Sie den Abstand zwischen dem Auge und der

Sucherlinse ein, um das Ziel zu fokussieren.

HINWEIS:

• Verwendung des Zielfernrohrs / Sucherteleskops ist zur

genauen Ausrichtung und Anwinkelung des Lasergeräts

auf das Ziel, wenn eine Neigung für den Einsatz bei Gefälle

eingestellt wird.

Page 26

26

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Bedienung

HINWEIS:

• Siehe Funktionsumfang der Modelle und welche spezifischen

Funktionen / Modi sie bieten.

• Siehe LCD / LED Beschreibungen der Anzeigen während

des Betriebs.

• Vor Inbetriebnahme des Lasergeräts stellen Sie stets sicher,

das Lasergerät auf Genauigkeit zu überprüfen.

• Im manuellen Modus ist die automatische Nivellierung AUS.

Es ist nicht garantiert, dass der Strahl genau eben ist.

• Das Lasergerät zeigt an, wenn er sich außerhalb

des Toleranzbereichs befindet. Referenz LED / LCD

Beschreibungen. Richten Sie das Lasergerät neu aus, damit

es möglichst eben ist.

• Stellen Sie sicher, dass das Lasergerät AUS geschaltet ist,

wenn es nicht benutzt wird.

• Weil das Lasergerät ein Instrument mit hoher Präzision ist,

ist es vorzuziehen, die Fernbedienung einzusetzen, wann

immer dies zur Ausführung der Funktionen möglich ist (sofern

vorhanden).

• Das Lasergerät nivelliert sich automatisch.

• Neigungswarnung ist standardmäßig EIN geschaltet, wenn

das Lasergerät das Werk verlässt.

• Neigungswarnung ist nur verfügbar in den automatischen

Nivellierungsmodi. Neigungswarnung ist nicht verfügbar im

manuellen Modus.

Einschalten

• Drücken Sie

um das Lasergerät EIN / AUS zu

schalten.

• Wenn es EIN geschaltet ist, ist die Neigungswarnung

standardmäßig EIN (Standard kann verändert werden).

• Wenn es EIN geschaltet ist, beginnt das Lasergerät mit der

automatischen Nivellierung.

• Sobald die automatische Nivellierung abgeschlossen

ist, rotiert der Laser mit der zuletzt verwendeten RPMGeschwindigkeitseinstellung.

Neigungswarnung (nicht verfügbar im manuellen Modus)

• Wenn EIN geschaltet, ist die Neigungswarnung standardmäßig EIN geschaltet.

• Das Zielfernrohr wurde vom Hersteller voreingestellt und

sollte keine zusätzlichen Anpassungen erfordern. Versuchen

Sie NICHT, die Seiten- und Höhenausrichtung des

Zielfernrohrs anzupassen. Das kann zu Ungenauigkeiten bei

der Sicht auf das Ziel und der Ausrichtung des Lasergeräts

führen.

• Wenn EIN geschaltet, drücken Sie um die Neigungswarnung EIN / AUS zu schalten.

• Mit der Neigungswarnung EIN, zeigt das Lasergerät mit LED

/ LCD und blinkendem Laserstrahl, wenn das Lasergerät

irgendeine Bewegung entdeckt hat.

• Wenn ein Alarm ausgelöst wurde, drücken Sie

um

ihn zurückzusetzen.

• Wenn der Alarm zurückgesetzt wurde, beginnt das

Lasergerät mit der automatischen Nivellierung. Prüfen Sie

die Ausrichtung auf das ursprüngliche Ziel.

Neigungswarnung Standardeinstellung

• Wenn sie AUS geschaltet ist, drücken Sie

und halten

Sie sie gedrückt, gefolgt von

.

• Lassen Sie beide Tasten los.

• Wenn Verkippungs-LED / Symbol EIN ist, ist die Standardeinstellung EIN. Wenn Verkippungs-LED / Symbol AUS ist,

ist die Standardeinstellung AUS.

• Das Lasergerät beginnt mit der automatischen Nivellierung,

wie es normalerweise geschieht, wenn das Gerät

eingeschaltet wird.

• Die Schritte zu wiederholen schaltet um zwischen EIN /

AUS der Standardeinstellung der Neigungswarnung.

Manueller Modus

• Wenn EIN geschaltet, drücken Sie

und halten Sie sie

gedrückt für ≥ 3 Sekunden, um den manuellen Modus EIN

/ AUS zu schalten.

• Im manuellen Modus ist die automatische Nivellierung

AUS.

• Das Lasergerät kann manuell in jedem Winkel positioniert

werden.

• Wenn der manuelle Modus AUS geschaltet ist, beginnt

das Lasergerät mit der automatischen Nivellierung, wie es

geschieht, wenn das Gerät erstmals EIN geschaltet wird.

Kalibrierungsmodus - siehe Genauigkeitsprüfungs- und

Kalibrierungs-Abschnitt

Manueller Neigungsmodus

Page 27

27

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

(Für RL HW / RL HW+ Ersatz wo immer

unten darauf Bezug genommen wird)

• Wenn EIN geschaltet, drücken Sie

. Manueller

Modus EIN geschaltet, automatische Nivellierung AUS.

(Für RL HGW muss

gedrückt werden und für

≥ 3 Sekunden gedrückt gehalten werden, um in den

manuellen Modus zu gehen, bevor Sie

drücken,

wie oben beschrieben)

• LED / LCD zeigt Anpassung der “X”-Achse. Drücken Sie

zur Anpassung der Achse.

• LED / LCD zeigt an, wenn der maximale Neigungswinkel

erreicht ist. Die Achse wird sich in dieser Richtung nicht

weiter bewegen.

• Drücken Sie noch einmal

um die “X”-Achse zu setzen

und / oder mit der Anpassung der “Y”-Achse fortzufahren.

• LED / LCD zeigt Anpassung der “Y”-Achse. Drücken Sie

zur Anpassung der Achse.

• LED / LCD zeigt an, wenn der maximale Neigungswinkel

erreicht ist. Die Achse wird sich in dieser Richtung nicht

weiter bewegen.

• Drücken Sie noch einmal

um die “Y”-Achse zu

setzen und / oder das Lasergerät weiterhin im manuellen

Neigungswinkel zu verwenden.

• "X"- und "Y"-Achse sind nun auf die manuell ausgerichteten

Neigungen eingestellt.

• Um den manuellen Neigungsmodus AUS zu schalten, drük-

ken Sie

und halten Sie sie für ≥ 3 Sekunden gedrückt.

• Wenn der manuelle Modus AUS geschaltet ist, beginnt

das Lasergerät mit der automatischen Nivellierung, wie es

geschieht, wenn das Gerät erstmals EIN geschaltet wird.

HINWEIS:

• Einmaliges Drücken auf ändert die Neigung

um 0,01%.

• Halten Sie die Taste gedrückt, um die Neigungsachse ununterbrochen zu bewegen, zuerst langsam, dann schneller,

wenn sie für längere Zeit gehalten wird.

• Referenzabbildung

L

mit der resultierenden Neigungs-

richtung für jede Taste.

Geschwindigkeit

• Drücken Sie

um zwischen den verfügbaren Geschwindigkeitseinstellungen von sehr schnell, bis sehr langsam, bis

angehalten, umzuschalten.

Punktmodus

• Drücken Sie

zur Einstellung angehalten (0 RPM).

• Drücken Sie

um die Richtung des Punkts zu

drehen.

HINWEIS:

• Einmaliges Drücken auf

dreht die Richtung

um 0,10°.

• Halten Sie die Taste gedrückt, um die Richtung ununterbrochen zu drehen, zuerst langsam, dann schneller, wenn sie

für längere Zeit gehalten wird.

• Der Laser blinkt 3 x bevor er sich schneller bewegt.

• Referenzabbildung

M

mit der resultierenden Drehrich-

tung für jede Taste.

Abtastmodus

• Drücken Sie um die verfügbaren Abtastwinkel

durchzuschalten (15° / 45° / 90°).

• Drücken Sie

um die Richtung Abtastung zu

drehen.

• Drücken Sie

um den Abtastmodus AUS zu schalten

und zur letzten verwendeten Geschwindigkeitseinstellung

zurückzukehren.

Page 28

28

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

HINWEIS:

• Einmaliges Drücken auf

dreht die Richtung

um 2,0°.

• Halten Sie die Taste gedrückt, um die Richtung ununterbrochen zu drehen, zuerst langsam, dann schneller, wenn sie

für längere Zeit gehalten wird.

• Der Laser blinkt 3 x bevor er sich schneller bewegt.

• Referenzabbildung

M

mit der resultierenden Drehrich-

tung für jede Taste.

• Digitaler Neigungsmodus (mit automatischer

Nivellierung)

• Wenn EIN geschaltet, drücken Sie

.

• LCD zeigt Anpassung der “X”-Achse. Drücken Sie

zur Anpassung des Achsenwerts.

• LCD zeigt an, wenn der maximale Neigungswinkel erreicht

ist. Der Wert wird sich in dieser Richtung nicht weiter

bewegen.

• Drücken Sie noch einmal

um die “X”-Achse zu

setzen und / oder mit der Anpassung des “Y”-Achsenwerts

fortzufahren.

• LCD zeigt Anpassung der “Y”-Achse. Drücken Sie

zur Anpassung des Achsenwerts.

• LCD zeigt an, wenn der maximale Neigungswinkel erreicht

ist. Der Wert wird sich in dieser Richtung nicht weiter

bewegen.

• Drücken Sie noch einmal

um die “Y”-Achse zu

setzen und / oder das Lasergerät weiterhin im digitalen

Neigungsmodus zu verwenden.

• Das Lasergerät beginnt mit der automatischen Nivellierung

wie es geschieht, wenn es erstmals EIN geschaltet wird

und dann neigt sich die "X"- und die "Y"-Achse auf die

eingestellten Werte.

• Um den digitalen Neigungsmodus AUS zu schalten, muss

das Lasergerät einmal AUS und wieder EIN geschaltet

werden. Drücken Sie

2x um AUS und wieder EIN

zu schalten.

HINWEIS:

• Einmaliges Drücken auf

ändert den Wert um

0,01%.

• Halten Sie die Taste gedrückt, um den Wert ununterbrochen

zu bewegen, zuerst langsam, dann schneller, wenn sie für

längere Zeit gehalten wird.

• Referenzabbildung

L

mit der resultierenden Neigungs-

richtung für jede Taste.

Fernbedienung

• Auf die gleichen Funktionen / Modi für jedes spezifische

Lasergerät kann durch die Verwendung der auf der Fernbedienung verfügbaren Tasten zugegriffen werden.

• Das Lasergerät kann mit der Fernbedienung EIN geschaltet

werden, wenn beide

zur gleichen Zeit gedrückt

werden. Das Lasergerät kann nur EIN geschaltet werden

mit der Einschalttaste auf dem Lasergerät.

Genauigkeitsprüfung und

Kalibrierung

HINWEIS:

• Siehe Funktionsumfang der Modelle und welche

spezifischen Funktionen sie bieten.

• Die Lasergeräte werden im Werk versiegelt und kalibriert

gemäß den angegebenen Genauigkeiten.

• Es wird empfohlen, vor der ersten Nutzung eine

Kalibrierungsprüfung durchzuführen und dann regelmäßig

während der weiteren Nutzung.

• Stellen Sie sicher, dass Sie dem Lasergerät angemessene

Zeit geben für die automatische Nivellierung (> 60

Sekunden) vor der Kalibrierung.

• Das Lasergerät sollte regelmäßig überprüft werden, um

seine Genauigkeiten, insbesondere für präzise Einsätze,

sicherzustellen.

Horizontale Prüfung (Siehe Abbildung )

• Setzen Sie das Lasergerät auf ein Stativ 20 m entfernt

von einer Wand, wobei die ”X1”-Seite zur Wand hin

weist (

N

1

).

Page 29

29

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

• Schalten Sie den Laser EIN, lassen Sie den Laser die

automatische Nivellierung durchführen und stellen Sie

sicher, dass sich der Laser dreht.

• Gehen Sie zur Wand und markieren Sie einen

Referenzpunkt “D

1

” wo sich die Laserlinie auf der

Wand befindet. Wenn verfügbar, verwenden Sie einen

Detektor, der Ihnen dabei helfen kann, den Strahl

leichter zu lokalisieren.

• Lösen Sie den Laser vom Stativ und drehen Sie den

Laser um 180°, so dass die "X2"-Seite nun zur Wand

gerichtet ist (

N

2

).

• Gehen Sie zurück zur Wand und messen Sie den

Abstand zwischen dem ersten Referenzpunkt “D

1

” und

dem zweiten Referenzpunkt “D

2

” (

N

3

).

• Es ist nicht notwendig, die Kalibrierung anzupassen,

wenn der Abstand zwischen dem ersten Referenzpunkt

“D

1

” und “D2” weniger als < 2,0 mm beträgt.

• Wenn der gemessene Abstand mehr als ≥ 2,0 mm

beträgt, ist eine Anpassung der Kalibrierung erforderlich.

• Führen Sie die gleichen Schritte für die “Y”-Achse durch,

wie sie für die “X”-Achse durchgeführt wurden. Ersetzen

Sie “X1” und “X2” mit Y1” und “Y2” (

N

4

).

Horizontale Kalibrierung (Siehe

Abbildung N)

(Für RL HW Ersatz

wo immer unten darauf

Bezug genommen wird)

(Für RL HW / RL HW+ Ersatz

wo immer

unten darauf Bezug genommen wird)

• Wenn das Lasergerät AUS geschaltet ist, drücken Sie

und halten Sie sie gedrückt, gefolgt von .

• Lassen Sie die Taste

los und halten Sie

gedrückt für ≥ 3 Sekunden.

• Loslassen

.

• Die LED/LCD zeigt an, dass das Lasergerät sich im

Kalibrierungsmodus befindet.

• Wenn notwendig, passen Sie die “X”-Achse an, indem

Sie

drücken, bis der Laserstrahl auf “D0”

ausgerichtet ist. “D

0

” liegt auf halber Strecke zwischen

“D

1

” und “D2” während der Prüfung der “X”-Achse.

• Drücken Sie noch einmal

um die “X”-Achse zu

setzen und / oder mit der Anpassung der “Y”-Achse

fortzufahren.

• Wenn notwendig, passen Sie die “Y”-Achse an, indem

Sie

drücken, bis der Laserstrahl auf “D0”

ausgerichtet ist. “D0” liegt auf halber Strecke zwischen

“D

1

” und “D2” während der Prüfung der “Y”-Achse.

• Drücken Sie noch einmal

um die “X”-Achse zu

setzen und / oder mit dem Verlassen des Kalibrierungsmodus fortzufahren.

• Die Achseneinstellungen sind nun gespeichert, der

Kalibrierungsmodus ist AUS, und das Lasergerät beginnt

mit der automatischen Nivellierung, wie es geschieht,

wenn es erstmals EIN geschaltet wird.

HINWEIS:

• Einmaliges Drücken auf

wird die Achse um 3,5

Bogensekunden neigen. Referenzabbildung

L

mit der

resultierenden Neigungsrichtung für jede Taste.

• Wenn der Laser nach Ablauf der Kalibrierungsprozedur noch immer nicht kalibriert werden kann,

schicken Sie das Lasergerät bitte zur Reparatur an

ein autorisiertes Service Center.

Vertikale Prüfung (Siehe Abbildung

P

)

(Nur notwendig bei Modellen mit vertikaler automatischer Nivellierung)

• Stellen Sie das Lasergerät auf eine stabile Oberfläche in

seiner vertikalen Position 1 m entfernt von einer Wand,

die höher ist als ≥ 2 m, wobei die ”Y1”-Seite gegen die

Wand gerichtet istl (

P

1

).

• Schalten Sie den Laser EIN, lassen Sie den Laser die

automatische Nivellierung durchführen und stellen Sie

sicher, dass sich der Laser dreht.

Page 30

30

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

• Markieren Sie Referenzpunkte “A” (wo sich die

Laserlinie 1 m entfernt von der Wand befindet), “B

“ (wo sich der Laserstrahl in einer Ecke befindet),

und “D

1

” (wo sich der Laserstrahl 2 m in Höhe der

Wand befindet).

• Drehen Sie das Lasergerät um 180° so dass die “Y2”Seite zur Wand zeigt (

P

2

).

• Richten Sie den Laserstrahl auf die Referenzpunkte

“A” und “B” aus, gehen Sie dann zurück zur Wand und

messen den Abstand zwischen den Referenzpunkten

“D

1

” und “D2” (

P

3

).

• Es ist nicht notwendig, die Kalibrierung anzupassen,

wenn der Abstand zwischen dem ersten Referenzpunkt

“D

1

” und “D2” weniger als < 1,0 mm beträgt.

• Wenn der gemessen Abstand mehr als ≥ 1,0 mm

beträgt, ist eine Anpassung der Kalibrierung erforderlich.

Vertikale Kalibrierung (Siehe Abbildung

P

)

(Für RL HW+ Ersatz

wo immer unten

darauf Bezug genommen wird)

• Wenn das Lasergerät AUS geschaltet ist, drücken Sie

und halten Sie sie gedrückt, gefolgt von .

• Lassen Sie die Taste los und halten Sie sie

gedrückt

für ≥ 3 Sekunden.

• Loslassen

.

• Die LED/LCD zeigt an, dass das Lasergerät sich im

Kalibrierungsmodus befindet.

• Wenn notwendig, passen Sie die vertikale “X”-Achse

an, indem Sie drücken, bis der Laserstrahl auf “D0”

ausgerichtet ist. “D0” liegt auf halber Strecke zwischen

“D

1

” und “D2” während der Prüfung der vertikalen

Achse.

• .

• Drücken Sie

zum Setzen der vertikalen “X”-

Achse.

• Die Achseneinstellungen sind nun gespeichert, der

Kalibrierungsmodus ist AUS, und das Lasergerät

beginnt mit der automatischen Nivellierung, wie es

geschieht, wenn es erstmals EIN geschaltet wird.

HINWEIS:

• Einmaliges Drücken auf

wird die Achse um 3,5

Bogensekunden neigen. Referenzabbildung

L

mit der

resultierenden Neigungsrichtung für jede Taste.

• Wenn der Laser nach Ablauf der Kalibrierungsprozedur noch immer nicht kalibriert werden kann,

schicken Sie das Lasergerät bitte zur Reparatur an

ein autorisiertes Service Center.

Technische Daten

Fernbedienung

Infrarot

40 m

2 x AAA Batterien (Alkali)

Typ:

Reichweite in Gebäuden:

Stromversorgung:

Zielfernrohr

2,5 x

5° 36’

8 mm

32 mm

≤ 8°

85 mm

Vergrößerung:

Sichtfeld:

Sichtdurchmesser:

Objektivdurchmesser:

Auflösungsvermögen:

Augenabstand:

Page 31

31

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Technische Daten

Lasergerät

RL HW

RL

HW+

RL HGW RL HV

RL

HVPW

RL HVPW-G

Horizontale

Rotationsgenauigkeit:

±1.5 mm/30 m (±10”)

Vertikale

Rotationsgenauigkeit:

±3 mm/30 m (±20”)

Vertikale

Aufwärtsstrahlgenauigkeit:

±3 mm/30 m (±20”)

Vertikale

Abwärtsstrahlgenauigkeit:

±9 mm/30 m (±60”)

Neigungsgenauigkeit: +/-15mm/30m (+/-100”)

Kompensierungsbereich: ≥ 5°±1° (Doppelachse)

Neigungsbereich: ±10% (Doppelachse)

Mindestschrittweite: 0,01%

Abtastbereich: 10°/45°/90° ±20%

Arbeitsbereichsdurchmesser

mit Detektor:

≤ 600 m

Nivellierungszeit ≤ 20 Sekunden

Rotationsgeschwindigkeit:

600 U/Min

±10%

1000/600/300/150/0 U/

Min ±10%

600/300/150/0 U/Min ±10%

Laserklasse: Klasse 2 (IEC/EN60825-1)

Klasse 3R (IEC/

EN60825-1)

Laserwellenlänge: 635 nm 515-540nm

Betriebsdauer: ≥ 20 Stunden (Ni-MH)

≥ 20 Stunden

(Ni-MH)

Wiederaufladezeit: ≤ 4 Stunden

Stromversorgung: NI-MH-Batteriesatz

IP-Klasse: IP66

Betriebstemperaturbereich: -10° C ~ +50° C

Lagertemperaturbereich: -25° C ~ +70° C

Page 32

32

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

AVERTISSEMENT:

• Les étiquettes suivantes sont collées sur votre

outil laser afin de vous indiquer la classe du

laser pour votre confort et votre sécurité.

Veuillez vous référer au manuel d'utilisation

pour connaître les spécificités d'un modèle en

particulier.

IEC/EN 60825-1

RAYON NE MEN TS LAS ER - NE PAS

FIXE R L E FAIS CE AU DES YE UX

PROD UIT L ASE R D E

CLA SSE 2

Puissance de sortie maximale ≤1mW @ 630 - 670nm

Table des matières

• Sécurité

• Aperçu du produit Fonctionnalités

• Clavier, diodes et écran LCD

• Piles et alimentation

• Configuration

• Fonctionnement

• Vérification de la précision et calibrage

• Spécifications techniques

Aperçu du produit

Figure A - Outil laser en position horizontale

1. Repère d'alignement

2. Fenêtre pour laser à faisceau vertical ascendant(RL HV /

RL HVPW /RL HVPW-G)

3. Laser rotatif / Tête en verre

4. Prise jack pour adaptateur d'alimentation / de

rechargement

5. Clavier(Voir figure E)

6. Faisceau laser vertical descendant (RL HVPW /RL

HVPW-G)

Figure B - Outil laser en position verticale

Figure C - Outil laser avec télescope(RL HGW)

7. Télescope

8. Base de fixation du télescope

Figure D - Télescope

9. Oculaire de visée (présenté avec cache)

10. Molette de mise au point du réticule

11. Couvercles de réglage des fonctions anti-vibrations /

élévation

(NE PAS OUVRIR / RÉGLER)

12. Vis de fixation

13. Objectif (présenté avec cache)

Figure E - Configurations du clavier

14. Capteur infrarouge pour télécommande

Figure F - Emplacement des piles de l'outil laser

15. Bloc-piles

Sécurité de l'utilisateur

AVERTISSEMENT:

• Lisez attentivement les consignes de sécurité

et le manuel d'utilisationavant d'utiliser ce

produit. La personne responsable de l'instrument

doit s'assurer que tous les utilisateurs

comprennent ces instructions et y adhèrent.

MISE EN GARDE:

• Lors de l'utilisation de l'outil laser, veillez à

ne pas exposer vos yeux au faisceau laser.

L'exposition prolongée des yeux au faisceau

laser peut être dangereuse.

MISE EN GARDE:

• Tous les kits d'outils laser ne comprennent

pas de lunettes. Ces lunettes ne sont PAS

des lunettes de protection certifiées. Elles

sont UNIQUEMENT destinées à améliorer la

visibilité du faisceau dans des environnements

très lumineux ou à de grandes distances de la

source du laser.

Conservez l'ensemble des sections de ce manuel pour une

consultation ultérieure.

F

Page 33

33

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

16. Piles (non fournies) - 4 x «C»

Cartouche à piles pour utilisation avec des piles 4 x «C»

Figure G - Télécommande

17. Diode infrarouge

18. Clavier

Figure H - Emplacement des piles de la télécommande

19. Piles - 2 x «AAA»

20. Compartiment à piles

Figure J - Support de fixation

21. Encoche en trou de serrure pour fixation

22. Vis de fixation pour grille de plafond

23. Molette de réglage (Haut / Bas)

24. Adaptateur 5/8 à 1/4 intégré

25. Molette de réglage vertical

26. Vis de fixation 5/8

27. Molette de réglage rotative

28. Molette de serrage

29. Fixation à aimant

30. Encoche en trou de serrure pour aimant supplémentaire

et / ou vis de fixation

31. Compartiment de stockage pour adaptateur 5/8 à 1/4

Figure K - Trépied

32. Vis centrale 5/8

33. Levier de verrouillage du pied

Figure L - Calibrage et / ou sens de l'axe de la pente

Figure M - Repère et /ou sens de rotation du balayage

Figure N - Définition de la vérification horizontale

Figure P - Définition de la vérification verticale

RL HW RL HW+ RL HGW RL HV

RL

HVPW/-G

Mise à niveau horizontale automatique X X X X X

Avertisseur d'inclinaison X X X X X

Mode Manuel X X X X X

Mode Calibrage X X X X X

Capteur infrarouge pour télécommande X X X X

Mise à niveau verticale automatique X X X X

Mode Pente manuel (PAS de mise à niveau

automatique)

X X X X

Sélection de la vitesse X X X

Mode Repère X X X

Mode Balayage X X

Faisceau vertical ascendant X X

Faisceau vertical descendant X

Mode Pente numérique(avec mise à niveau

automatique)

X

Fonctionnalités

Page 34

34

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Clavier, diodes et écran LCD

(Voir figure pour de plus amples informations sur l'affichage du clavier pour chaque modèle d'outil laser)

Claviers

(RL HW+ )

Bouton de mise SOUS / HORS TENSION

Bouton MARCHE / ARRÊT de l'avertisseur

d'inclinaison

Touche Mode Pente manuel

Touches de réglage de la pente et du

calibrage

(RL HGW )

Bouton de mise SOUS / HORS TENSION

Bouton MARCHE / ARRÊT de l'avertisseur

d'inclinaison

Touche Vitesse de rotation

Touche Mode Mise à niveau automatique /

Mode Pente manuel

Touches de réglage du repère, de la

pente et du calibrage

(RL HV / RL HVPW /RL HVPW-G )

Bouton de mise SOUS / HORS TENSION

Bouton MARCHE / ARRÊT de l'avertisseur

d'inclinaison

Touche Vitesse de rotation

Touche Mode BALAYAGE

Touche Mode Pente manuel

Touches de réglage du balayage, du

repère, de la pente et du calibrage

(RL HW )

Bouton de mise SOUS / HORS TENSION

Bouton MARCHE / ARRÊT de l'avertisseur

d'inclinaison

Touche Mode Calibrage

Touches de réglage du calibrage

Page 35

35

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Diodes

Témoin lumineux d'alimentation - VERT clignotant

• L'outil laser est équipé d'une fonction de mise à

niveau automatique

• En cours de calibrage et / ou de configuration par

défaut de l'avertisseur d'inclinaison

Témoin lumineux d'alimentation - VERT fixe

• Mise à niveau automatique terminée

Témoin lumineux d'alimentation - ROUGE clignotant

• Piles faibles

Témoin lumineux d'alimentation - ROUGE fixe

• Les piles nécessitent un rechargement

Témoin lumineux du mode manuel - ROUGE

clignotant

• Mode manuel ACTIVÉ (Mise à niveau

automatique DESACTIVÉE)

Témoin lumineux du mode manuel - ROUGE

clignotant

avec

Témoin lumineux d'alimentation - VERT

clignotant

• Plage de compensation dépassée

Témoin lumineux d'avertisseur d'inclinaison

- ROUGE fixe

• Avertisseur d'inclinaison ACTIVÉ

Témoin lumineux d'avertisseur d'inclinaison

- ROUGE clignotant

• Alarme signalant une inclinaison

Témoin lumineux Sélection X / Y - VERT fixe

• Mode Pente - réglage de l'axe des X

(abscisses)

Témoin lumineux Sélection X / Y - ROUGE fixe

• Mode Pente - réglage de l'axe des Y

(ordonnées)

Témoin lumineux Sélection X / Y - VERT

clignotant

• Axe des X réglé au maximum de pente

autorisé en mode Pente

• Mode Calibrage - réglage de l'axe des X

(abscisses)

Témoin lumineux Sélection X / Y - ROUGE

clignotant

• Axe des Y réglé au maximum de pente

autorisé en mode Pente

• Mode Calibrage - réglage de l'axe des Y

(ordonnées)

Icônes de l'écran LCD

Icône Mise à niveau automatique - Clignotante

• L'outil laser est équipé d'une fonction de

mise à niveau automatique

• En cours de calibrage et / ou de configuration par défaut de l'avertisseur d'inclinaison

Icône Mode manuel - clignotante

• Mode manuel ACTIVÉ (Mise à niveau

automatique DÉSACTIVÉE)

Icône Avertissement - clignotante

• Plage de compensation dépassée

• Secousse lors du réglage automatique de

la pente

Icône Inclinaison - fixe

• Avertisseur d'inclinaison ACTIVÉ

Icône Inclinaison - clignotante

• Alarme signalant une inclinaison

Icône Pente - fixe

• Mode Pente ACTIVÉ

Icône Pente - clignotante

• Outil réglé sur la pente maximum autorisée

Icône Calibrage - fixe

• Mode Calibrage ACTIVÉ - Horizontal

Icône Calibrage - clignotante

• Mode Calibrage ACTIVÉ - Vertical

Icône Rotation avec valeur de vitesse

• Paramétrage de la vitesse

Icône X / Y seule - clignotante

• Réglage de l'axe affiché en mode Pente

manuel et / ou en mode Calibrage

Icône X / Y avec valeur- Valeur clignotante

• Réglage de la valeur affichée en mode Pente

avec mise à niveau automatique

Niveau des piles - Fixe

• Durée de vie approximative des piles telle

qu'affichée

Niveau des piles - clignotant

• Les piles nécessitent un rechargement

Icône Position verticale - fixe

• S'affiche lorsque l'outil laser est en position

verticale

Page 36

36

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Piles et alimentation

Installation / Retrait des piles

(Voir figures F et G pour connaître l'emplacement des

piles de l'outil laser et de la télécommande)

• Appuyez sur les languettes pour ouvrir le compartiment

à piles et le faire coulisser.

• Installez/Retirez les piles. Orientez correctement les

piles lors de leur insertion dans l'outil laser.

• Fermez et verrouillez le couvercle du compartiment

à piles.

Outil laser(Voir figure F )

Télécommande infrarouge(Voir figure G)

• Ouvrez le compartiment à piles en faisant coulisser le

couvercle.

• Installez/Retirez les piles. Orientez correctement les

piles lors de leur insertion dans l'outil laser.

• Fermez et verrouillez le couvercle du compartiment

à piles.

AVERTISSEMENT:

• Pour une bonne insertion des piles, prêtez

attention aux symboles (+) et (-) figurant dans le

compartiment à piles. Les piles doivent être du

même type et de la même puissance. N'utilisez

pas de piles de puissances différentes.

Rechargement des piles

• Pour optimiser la durée de vie des piles rechargeables, ces

dernières doivent être rechargées pendant 4heures avant

leur première utilisation.

• Branchez la prise du chargeur / de l'alimentation dans la

prise jack de l'outil laser

• Branchez la prise de l'adaptateur d'alimentation / de

rechargement dans une prise électrique adaptée (110V

ou 220V)

• La diode de l'adaptateur d'alimentation / de rechargement

restera ROUGE pendant toute la durée de chargement.

• Laissez les piles en charge pendant environ 4heures pour

un rechargement total.

• Une fois les piles entièrement rechargées, débranchez

l'adaptateur d'alimentation / de rechargement de l'outil

laser et de la prise électrique.

• La diode de l'adaptateur d'alimentation / de rechargement

deviendra VERTE lorsque le rechargement sera terminé.

AVERTISSEMENT:

• Utilisez l'adaptateur d'alimentation / de

rechargement uniquement avec le bloc-piles

Ni-MH fourni. Le chargement de tout autre type

de piles peut endommager le produit et / ou

provoquer des dommages corporels.

ATTENTION:

• Les piles et l'adaptateur d'alimentation / de

rechargement peuvent être endommagés en

cas de contact avec de l'eau. Entreposez et

rechargez toujours l'outil dans un endroit sec

et couvert.

REMARQUE:

• Pour optimiser la durée de vie des piles, il est

recommandé de ne recharger ces dernières qu'une fois

celles-ci entièrement déchargées ainsi que d'éviter de les

laisser en charge pendant plus de 10heures.

Utilisation de l'outil laser

lorsqu'il est connecté à

l'adaptateur d'alimentation / de

rechargement

• L'outil laser peut être utilisé lorsqu'il est connecté à

l'adaptateur d'alimentation / de rechargement.

• Les fonctions et commandes de l'outil laser sont les

mêmes que lorsque ce dernier n'est pas connecté à

l'adaptateur d'alimentation / de rechargement.

Page 37

37

77-496 / 77-429 / 77-439 / 77-497 / 77-427 / 77-441

Configuration

Positionnement

(Consultez la section Fonctionnalités pour connaître les

modèles permettant une mise à niveau automatique dans

les positions suivantes)

Position horizontale (Voir figure A)

• Posez l'outil laser sur sa partie inférieure. Assurez-vous

que la surface du sol est à niveau (ou presque). Appuyez

sur le bouton

pour mettre l'outil SOUS TENSION.

Position verticale (Voir figure B)

• Posez l'outil laser sur sa face latérale, poignée vers le

haut. Assurez-vous que la surface du sol est à niveau (ou

presque). Appuyez sur le bouton

pour mettre l'outil

SOUS TENSION.

Position avec un angle

• Appuyez sur le bouton

pour mettre l'outil SOUS

TENSION.. Appuyez sur la touche

et maintenez

cette dernière enfoncée pour activer le mode manuel.