Page 1

Instruction Manual

QB Expert Alpha Controller

Software Version 5.2.8

English - Original Document - Revision C

© 2016 STANLEY Black and Decker, Inc. All rights reserved.

Page 2

Table of Contents

1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 What’s Included . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Controller Functions and Connections . . . . . . . . . . . . . . . 4

1.3 CE Directives (Europe) . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 Machinery Directive Compliance . . . . . . . . . . . . . . . . . . .4

1.3.2 RoHS Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.3 WEEE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4 Regulatory Notices for Radio Transmitter . . . . . . . . . . . . . . . 5

1.4.1 FCC Notice (USA) . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4.2 Canadian Compliance Notice . . . . . . . . . . . . . . . . . . . . . . .5

1.4.3 CE Notice (Europe) . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.1 Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5.2 General Power Tool Safety Warnings . . . . . . . . . . . . . . . . . . .8

1.5.3 Safety Instructions for QB Expert Alpha Controllers . . . . . . . . . . 10

1.6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6.1 Physical and Environmental Ratings . . . . . . . . . . . . . . . . . . 11

1.6.2 Electric Service Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6.3 E-Stop Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6.4 Tool Speed and Torque Scatter Versus Electric Supply . . . . . . . . . . 11

1.6.5 Tool Temperature Versus Electric Supply . . . . . . . . . . . . . . . . . . 11

1.7 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . 12

2 QPM QB Expert Alpha Controller . . . . . . . . . . . . 18

2.1 Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2 Input and Output Functions . . . . . . . . . . . . . . . . . . . 18

2.3 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Embedded PLC . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

II

QB Expert Alpha Controller

Page 3

Table of Contents

2.7 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7.1 Scroll Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7.2 Dropdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7.3 Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.4 Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.5 Character Scrollbar . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.6 Run Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.7 Fastening Cycle Log . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.7.8 Keypad Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7.9 Controller Display Icons . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.8 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.9 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3 Programming . . . . . . . . . . . . . . . . . . . . . . . 30

3.1 SETUP Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.1.1 JOBS: Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.1.2 JOBS: Manual Programming . . . . . . . . . . . . . . . . . . . . . . 37

3.1.3 COMMUNICATIONS Menu . . . . . . . . . . . . . . . . . . . . . . 52

3.1.4 OTHER Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.1.5 RESTORE FACTORY DEFAULTS Menu . . . . . . . . . . . . . . . . . . 74

3.2 SERVICE Area . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.2.1 Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.2.2 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.3 ANALYZE Area . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.3.1 TOOL Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.3.2 TRACE Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.3.3 STATS Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.3.4 LOG Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.3.5 I/O Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4 Alpha Toolbox . . . . . . . . . . . . . . . . . . . . . . . 88

4.1 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.2 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.2.1 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.2.2 Navigation Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.2.3 Import/ Export Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Instruction Manual

III

Page 4

Table of Contents

4.2.4 Manage Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.3 Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.3.1 Parameter and Data Retrieval . . . . . . . . . . . . . . . . . . . . . . 91

4.4 Trace Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4.4.1 Analyzing Traces . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.4.2 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.5 Icons and Security . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5 QPM DC Electric Tools . . . . . . . . . . . . . . . . . 104

5.1 Tool Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 104

5.1.1 Operator Protection . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1.2 Repetitive Motion . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1.3 Hearing Protection . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1.4 Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.1.5 Breathing Protection . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.1.6 Tool Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.1.7 Sockets and Adapters . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.1.8 Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.2 QPM Tool Controls and Operation . . . . . . . . . . . . . . . . . . 108

5.2.1 Start Trigger Switch . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.2.2 Tool Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.2.3 Display and Multiple Function Button . . . . . . . . . . . . . . . . . 109

5.2.4 Tool Status Lights . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.2.5 MFB Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.2.6 Worklights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.7 Program Selection . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.8 Directional Control . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.9 Tool Temperature . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2.10 Setting Torque, Angle, and Other Operating Parameter . . . . . . . . . 112

5.2.11 Assembly (Forward) Operation . . . . . . . . . . . . . . . . . . . . . 112

5.2.12 Disassembly (Reverse) Operation . . . . . . . . . . . . . . . . . 112

5.3 Special Application Tools . . . . . . . . . . . . . . . . . . . . . . .112

5.3.1 Exposed Gear Socket Tools . . . . . . . . . . . . . . . . . . . . . 112

5.3.2 Tubenut Nutrunners . . . . . . . . . . . . . . . . . . . . . . . . . 113

6 Alpha Controller Connections . . . . . . . . . . . . . . 118

IV

QB Expert Alpha Controller

Page 5

Table of Contents

6.1 Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

6.2 Tool Connector . . . . . . . . . . . . . . . . . . . . . . . . . .118

6.2.1 EA, EB and EC Tools . . . . . . . . . . . . . . . . . . . . . . . . . 118

6.2.2 E Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

6.3 USB Connector . . . . . . . . . . . . . . . . . . . . . . . . . .118

6.4 Serial Connector . . . . . . . . . . . . . . . . . . . . . . . . . .119

6.5 Alpha Toolbox Ethernet Connector . . . . . . . . . . . . . . 120

6.6 Facility/ Spindle Network Ethernet Connectors . . . . . . . . . . . 120

6.7 Ethernet/IP or Profinet Connectors . . . . . . . . . . . . . . .121

6.8 Trailing DeviceNet™ Connector . . . . . . . . . . . . . . . . . . .121

6.9 Profibus Connector . . . . . . . . . . . . . . . . . . . . . . . . . .121

6.10 Leading DeviceNet Connector . . . . . . . . . . . . . . . . . . 122

6.11 Input and Output Connector . . . . . . . . . . . . . . . . . . 122

6.12 Assignable Input and Output Functions . . . . . . . . . . . . . . .126

6.12.1 Input Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 129

6.12.2 Output Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 135

6.13 MODBUS TCP . . . . . . . . . . . . . . . . . . . . . . . . . 146

6.13.1 Example Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

7 Embedded PLC . . . . . . . . . . . . . . . . . . . . . . .152

7.1 “Rack” Layout . . . . . . . . . . . . . . . . . . . . . . . . . 152

7.1.1 Addressing Scheme . . . . . . . . . . . . . . . . . . . . . . . . . 152

7.2 Supported Instructions and File Types . . . . . . . . . . . . . . 153

7.3 PLC Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

7.3.1 Edit Page Controls . . . . . . . . . . . . . . . . . . . . . . . . . 162

7.3.2 Instruction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7.3.3 MON and MSG Instructions . . . . . . . . . . . . . . . . . . . . . 164

7.3.4 Applying a Name and Version . . . . . . . . . . . . . . . . . . . . . 164

Instruction Manual

V

Page 6

Table of Contents

7.4 Converting a RSS File . . . . . . . . . . . . . . . . . . . . . . 164

7.4.1 Invalid Characters . . . . . . . . . . . . . . . . . . . . . . . . . 166

7.4.2 Predefining String or Integer Files . . . . . . . . . . . . . . . . . 166

7.4.3 Applying a Name and Version . . . . . . . . . . . . . . . . . . . . . 166

8 Multi-Spindle . . . . . . . . . . . . . . . . . . . . . . . 170

8.1 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

8.2 Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.3 Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.3.1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

8.3.2 Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

8.4 Networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

8.5 Fastening Cycle Data . . . . . . . . . . . . . . . . . . . . . . .174

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . 178

9.1 Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . 178

9.2 Diagnostics and Troubleshooting . . . . . . . . . . . . . . . . . . 178

9.2.1 Fault Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

9.3 Message Guide . . . . . . . . . . . . . . . . . . . . . . . . . 189

9.4 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

10 Torsion Compensation . . . . . . . . . . . . . . . . .196

10.1 Torsion Factor . . . . . . . . . . . . . . . . . . . . . . . . . 196

10.2 An gle Validation . . . . . . . . . . . . . . . . . . . . . . . . . 196

VI

11 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . .200

12 Limited Warranty . . . . . . . . . . . . . . . . . . . .204

QB Expert Alpha Controller

Page 7

Table of Contents

12.1 Mechanical Products Limited Warranty . . . . . . . . . . . . . . 204

12.2 Electronic Products Limited Warranty . . . . . . . . . . . . . . 204

12.3 Software Products Limited Warranty . . . . . . . . . . . . . . 204

12.4 OEM Products Limited Warranty . . . . . . . . . . . . . . . . . . 204

12.5 General Terms . . . . . . . . . . . . . . . . . . . . . . . . . 204

12.6 Specification Changes . . . . . . . . . . . . . . . . . . . . . . 205

12.7 Warranty Claims . . . . . . . . . . . . . . . . . . . . . . . . . 205

12.8 Product Services . . . . . . . . . . . . . . . . . . . . . . . . . 205

12.9 Return Material Authorization (RMA) Procedures . . . . . . . 205

Instruction Manual

VII

Page 8

Page 9

QB Expert Alpha Controller

Introduction

1

What’s Included

Controller Functions and Connections

CE Declaration of Conformity

Regional Notices for Transmitter

Safety

Specifications

Installation Instructions

Page 10

What’s Included

1 Getting Started

This manual is intended to promote proper and safe use and give guidance to owners, employers, supervisors,

and others responsible for training and safe use by operators and maintainers. Please contact your STANLEY Sales

Engineer for further information or assistance on Stanley training or assembly tool operations.

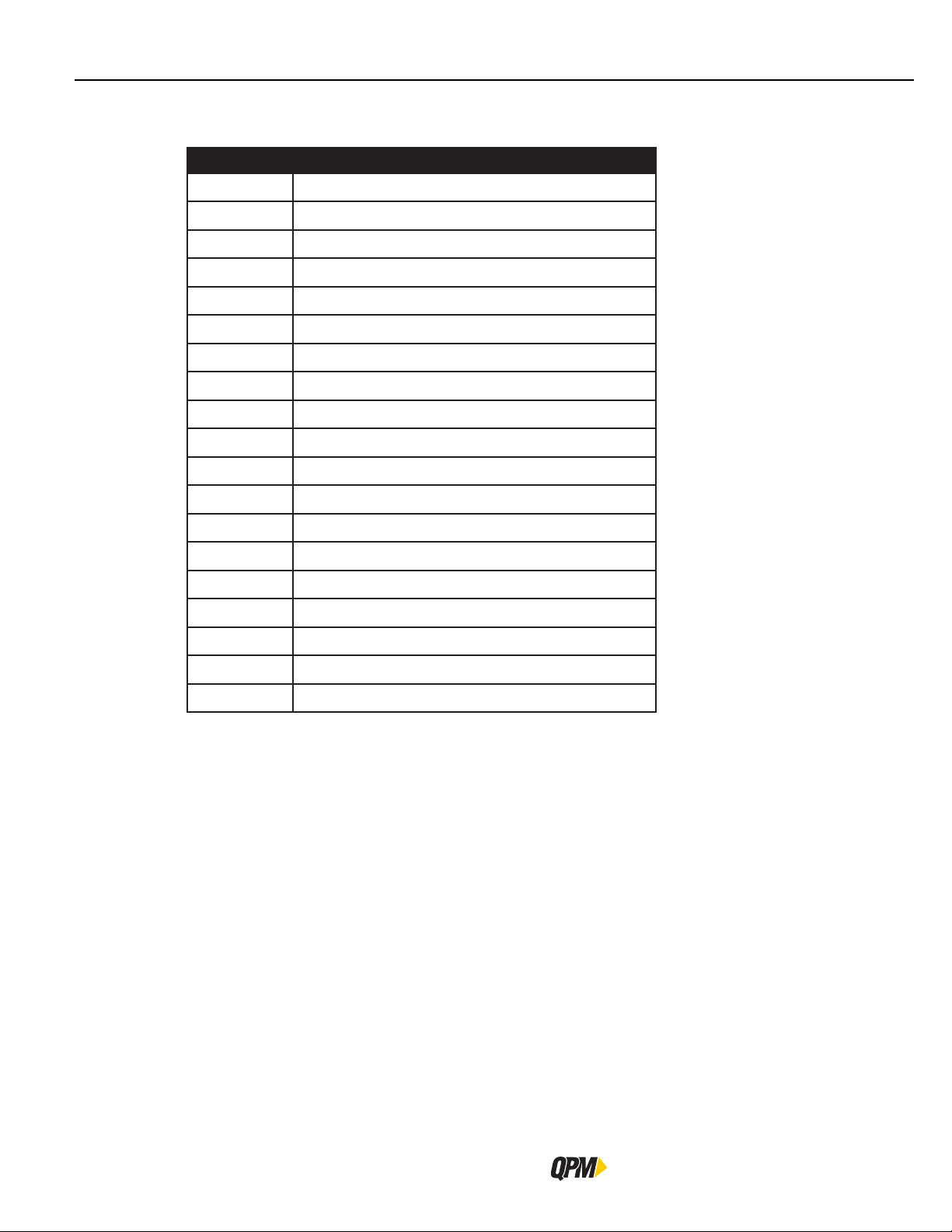

1.1 What’s Included

Included with the QB Expert Alpha controller is a power cord, plinth (for mounting), documentation (in the

envelope) and a mating connector for the I/O port. The mating connector is included so the end user may connect

wires to the controller’s I/O port to their requirements.

5

1

2

, Cleveland, OH 44143 USA

STANLEY ASSEMBLY TECHNOLOGIES

Telephone: +1 (440) 461-5500 Email: satinfo@sbdinc.com URL: http://StanleyAssembly.com

5335 Avion Park Drive

4

Item Number Description

1 QB Expert Alpha Controller

2 Plinth for mounting controller

3 Power cord

4 24 V DC I/O mating connector

3

5 Envelope with Getting Started Documentation

2

QB Expert Alpha Controller

Page 11

9

Introduction

1

4

5

2

19

3

8

11

16

POWER

TOOL

13

115/230VAC 50/60HZ

10 AMP 1/N/PE~

WARNING

!

ELECTRIC SHOCK HAZARD

To prevent injury

disconnect power cord

before removing cover

ETHERNET

I/O

AVERTISSMENT

!

RISQUE DE DECHARGE ELECTRIQUE

Pour empecher des dommages

debranches le cordon de secteur

avant d enlever la couverture

USB

SPINDLE

COM PORT

PROTECTED BY ONE OR MORE OF

THE FOLLOWING US PATENTS:

5,315,501

5,637,968

6,516,896

10

12

17

14

15

7

See Description on next page

Instruction Manual

6

FIELDBUS OPTIONS

18

3

Page 12

Controller Functions and Connections

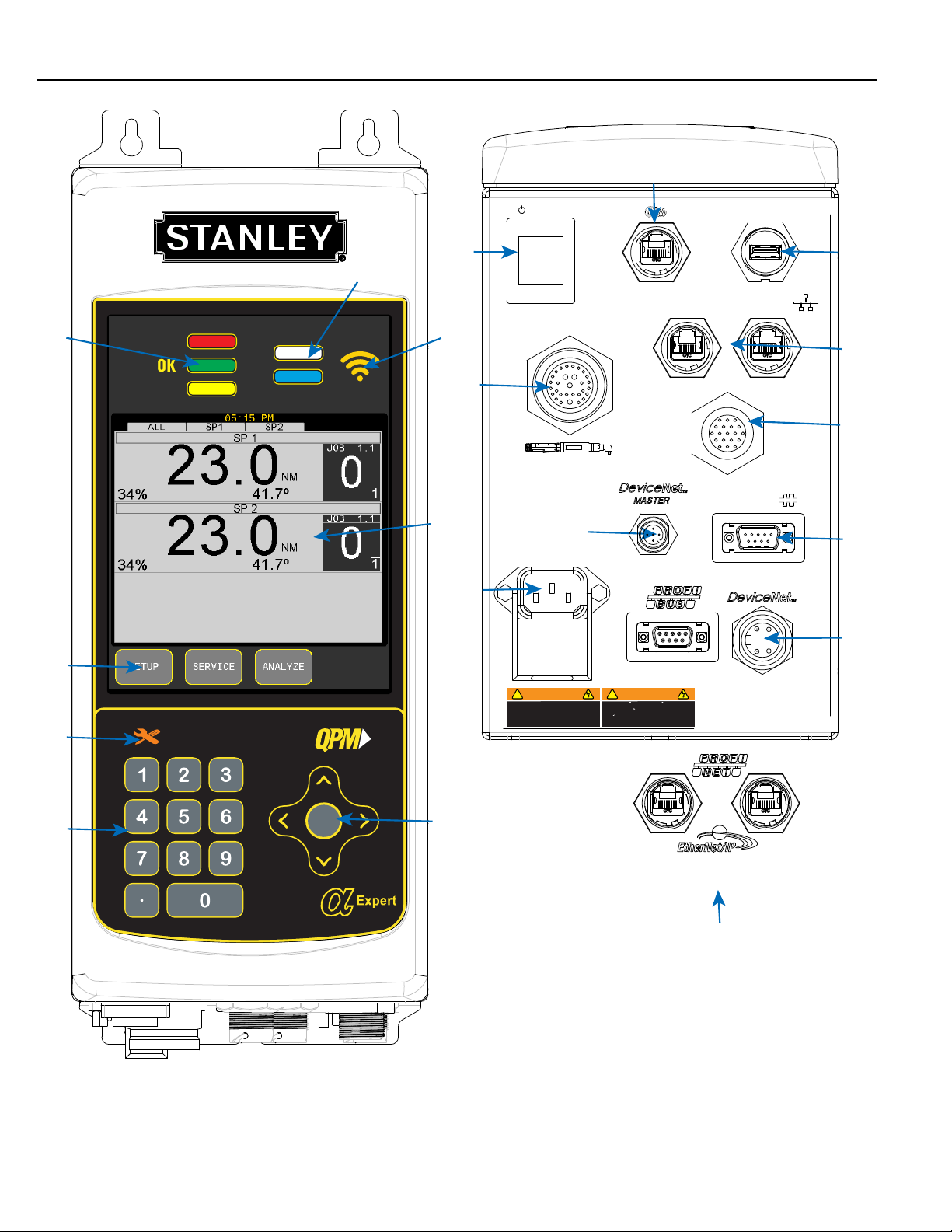

1.2 Controller Functions and Connections

This table refers to the picture on the previous page.

Item Number Functional Description

1 Red, Green, Yellow LEDs for Limits Evaluation

2 Programmable and Tool Ready LEDs

3 Display

4 Function Keys with Active Label Above

5 Maintenance Due Indicator

6 Cursor Keys with Center Button to Expand Lists

7 Numeric Keypad to Enter Numbers or Select Options

8 Power Switch

9 Alpha Toolbox Connector

10 USB Port for Data Transfer

11 Tool Connector

12 Plant/ Spindle Network Ethernet Connectors

13 Optional Master DeviceNet Connector

14 Serial Connector

15 Optional Profibus or DeviceNet Connector

16 Power Input

17 19-Pin, 24V DC Input/Output Connector

18 Optional Fieldbus Ethernet Connectors

19 Indicates WiFi Enabled (when present)

Information about these items is discussed elsewhere in this manual. Use the Table of Contents to find the page

for the item of interest. If this is an electronic document you are reading click on the item in the Table of Contents

and it will link you directly to the page. Or press CNTRL+F on the keyboard to search the document for the item

of interest.

1.3 CE Directives (Europe)

STANLEY Engineered Fastening Assembly Technologies declares that the QPM QB Expert Alpha controller

conforms to all the applicable regulations of the Machinery Directive. See the CE Declaration of Conformity that

is delivered with each QB Expert Alpha controller.

1.3.1 Machinery Directive Compliance

This product complies with the requirements of the European Machinery Directive (2006/42/EC). See the CE

Declaration of Conformity that is delivered with the product.

4

QB Expert Alpha Controller

Page 13

1.3.2 RoHS Compliance

This product and its information meets the requirements of the European Restriction of Hazardous Substances

(RoHS) Directive (2011/65/EU).

1.3.3 WEEE Compliance

This product and its information meets the requirements of the European Waste of Electrical and Electronic

Equipment (WEEE) Directive (2011/65/EU). This product is marked with a crossed trashcan, see last figure below

in section 1.5.1 Warnings and Cautions.

1.4 Regulatory Notices for Radio Transmitter

It is mandatory that national, state and local codes and standards be followed.

1.4.1 FCC Notice (USA)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• reorient or relocate the receiving antenna,

• increase the separation between the equipment and receiver,

• connect the equipment into an outlet on a circuit different from that to which the receiver is connected, or

• consult the dealer or an experienced radio/TV technician for help.

This device contains transmitter module FCC ID: TE7WR702N.

Introduction

• To satisfy FCC RF exposure requirements for mobile transmitting devices, a separation distance of 20 cm

(7.87 in) or more should be maintained between the antenna of this device and persons during operation.

To ensure compliance, operations at closer distances than this are not recommended.

1.4.2 Canadian Compliance Notice

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following

two conditions:

• This device may not cause interference, and

• This device must accept any interference, including interference that may cause undesired operation of the

device.

Cet appareil est conforme aux norms CNR exemptes de licence d’Industri Canada. Le

fonctionnement est soumis aux deux conditions suivantes:

• cet appareil ne doit pas provoquer d’interférences et

Instruction Manual

CAUTION

5

Page 14

Safety

• cet appareil doit accepter toute interérence, y compris celles susceptibles de provoquer un fonctionnement non

souhaité de l”appareil.

1.4.2.1 Industry Canada Notice (Canada)

Complies with the Canadian ICES-003 Cleass B specifications.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

This device complies with RSS 210 of Industry Canada. This device meets all the requirements of the Canadian

interference-causing equipment regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le

matériel brouilleur de Canada.

1.4.3 CE Notice (Europe)

This device has been tested and certified for use in the European Union. This product complies with the

requirements of the European Radio & Telecommunications Terminal Equipment (R&TTE) Directive (1999/5/EC).

The ‘CE’ mark has been placed on the device per the labeling requirements of the Directive.

Given that the operating frequency band is not harmonized by a few European countries, the restriction or

alert sign has been placed alongside the ‘CE’ mark as shown below. As of the date of this document, only

France has a restriction. The restriction is that, if the radio is operated outdoors in the 2450-2483.5 MHz

band, the power must be limited to 10 mW instead of 100 mW. This device is not intended for outdoor use.

1.5 Safety

1.5.1 Warnings and Cautions

The safety notices and warnings for protection against loss of life (the users or service personnel) or for the

protection against damage to property are highlighted in this document by the terms and pictograms defined

here. The terms used in this document and marked on the equipment itself have the following significance:

DANGER

WARNING

CAUTION

Indicates that death or severe personal injury will result if proper precautions are not taken.

Indicates that death or severe personal injury may result if proper precautions are not taken.

Indicates that property damage may result if proper precautions are not taken.

Indicates an electrical hazard. This icon appears as a part of a DANGER, WARNING, or CAUTION

notice.

Indicates a fire hazard. This icon appears as a part of a DANGER, WARNING, or CAUTION notice.

Indicates a general hazard. This icon appears as a part of a DANGER, WARNING, or CAUTION notice.

Indicates that eye protection should be worn. This icon appears as a part of a DANGER, WARNING, or

CAUTION notice.

6

QB Expert Alpha Controller

Page 15

Introduction

!

Read and understand all the safety recommendations and all operating instructions before operating

tools and controllers.

Indicates an item of special interest.

Indicates a pinch point hazard. This icon appears as a part of a DANGER, WARNING, or CAUTION

notice.

Indicates an open wrench pinch point hazard. This icon appears as a part of a DANGER, WARNING, or

CAUTION notice.

Indicates an environmental hazard. Do not throw equipment into the normal housekeeping refuse bin.

Instruction Manual

7

Page 16

Safety

1.5.2 General Power Tool Safety Warnings

These warnings are required by EN 60745.

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in

electric shock, fire and/ or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1. Work Area Safety

a.) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b.) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c.) Keep children and bystanders away while operating a power tool. Distractions can cause you

to lose control.

2. Electrical Safety

a.) Power tool plugs must match the outlet. Never modify the plug in any way. do not use

any adapter plugs with the earthed (grounded) power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b.) Aoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c.) Do not expose tools to rain or wet conditions. Water entering a power tool will inrease the risk

of electric shock.

d.) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e.) When operating a power tool outdoors, use an extension cord suitbable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

f.) If operating a power tool in a damp location is unavaoidable, use a residual current device

(RCD) proteted supply. Use of an RCD reduces the risk of electric shock. The term “residual

current device(RCD)” may be replaced by the term “ground fault circuit interrupter (GFCI)” or “earth

leakage circuit breaker (ELCB)”.

3. Personal Safety

a.) Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not use a power tool while you are tired or under the influence of drugs, alchohol or

medication. A moment of inattention while operating power tools may result in serious personal

injury.

b.) Use personal protective equipment. Always wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

c.) Prevent unintentional starting. Ensure the switch is in the off-position before connecting

to power source adn/ or battery pack, picking up or carrying the tool. Carrying power tools

with your finger on the switch or energising power tools that have the switch on invites accidents.

d.) Remove any adjusting key or wrench before turning the power tool on. A wrench or key left

attached to a rotating part of the power tool may result in personal injury.

WARNING

8

QB Expert Alpha Controller

Page 17

Introduction

WARNING

Continued:

e.) Do not overreach. Keep proper footing and balance at all times. This enables better control

fo the power tool in unexpected situations.

f.) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes jewellery or long hair can be caught in moving

parts.

g.) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collecton can reduce dust-related

hazards.

4. Power Too Use and Care

a.) Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

b.) Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c.) Disconnect the plug from the power source and/ or the batatery pack from the power

tool before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d.) Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e.) Maintain power tools. Chek for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained

power tools.

f.) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g.) Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

5. Service

a.) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Instruction Manual

9

Page 18

Safety

1.5.3 Safety Instructions for QB Expert Alpha Controllers

WARNING

To Avoid Injury:

• Save these instructions for future reference.

• Read and understand all the safety recommendations and all operating instructions before operating tools

and controllers. Failure to follow all instructions listed below may result in electric shock, fire and/or serious

personal injury.

• Train all operators in the safe and proper use of power tools. Operators should report any unsafe condition

to their supervisor.

• Follow all safety recommendations in the manual that apply to the controllers, tools, battery packs and

chargers being used and the nature of the work being performed.

• Verify that all warning labels illustrated in this manual are readable. Replacement labels are available at no

additional cost from STANLEY Assembly Technologies.

• Only allow suitably qualified personnel to install, program, or maintain this equipment and or system. Follow

all manufacturer installation instructions and applicable regulatory electrical codes and safety codes.

• These persons must be knowledgeable of any potential sources of danger and maintenance measures as set

out in the Installation, Operations, and Maintenance manual.

• This product must be transported, stored, and installed as intended, and maintained and operated with care

to ensure that the product functions correctly and safely.

• Persons responsible for system planning and design must be familiar with the safety concepts of automation

equipment.

• Install tools in dry, indoor, non-flammable, and non-explosive environments only–Humidity: 0 to 95% noncondensing and Temperature: 32 to 122 ºF (0 to +50 ºC).

• Do not install worn, damaged, or modified equipment that may be unsuitable for safe use.

• Controller plugs must match the outlet and must be earth grounded. Never modify a plug in any way or use

any adaptor plugs.

• Avoid body contact with electrically energized surfaces when holding a grounded tool.

• Prior to connecting a power source, always ensure the tool or controller is turned off.

• Limit controller access to trained and qualified personnel. Lock controller cabinets.

• Only use equipment and accessories specifically designed to operate with STANLEY assembly tools and use

them only in the manner for which they are intended.

• Store idle tools and accessories in a safe location accessible only by trained persons.

• Disconnect power source (battery, electricity, etc.) from tool or controller prior to making adjustments,

changing accessories, or storing.

• Prior to operation, always check and test tools and accessories for damage, misalignment, binding or any other

condition that may affect operation. Maintenance and repair should be performed by qualified personnel.

10

• Do not operate tools in or near explosive environments or in the presence of flammable liquids, gases, dust,

rain or other wet conditions.

• Keep the work area clean, well lit and uncluttered.

• Keep unauthorized personnel out of the work area.

QB Expert Alpha Controller

Page 19

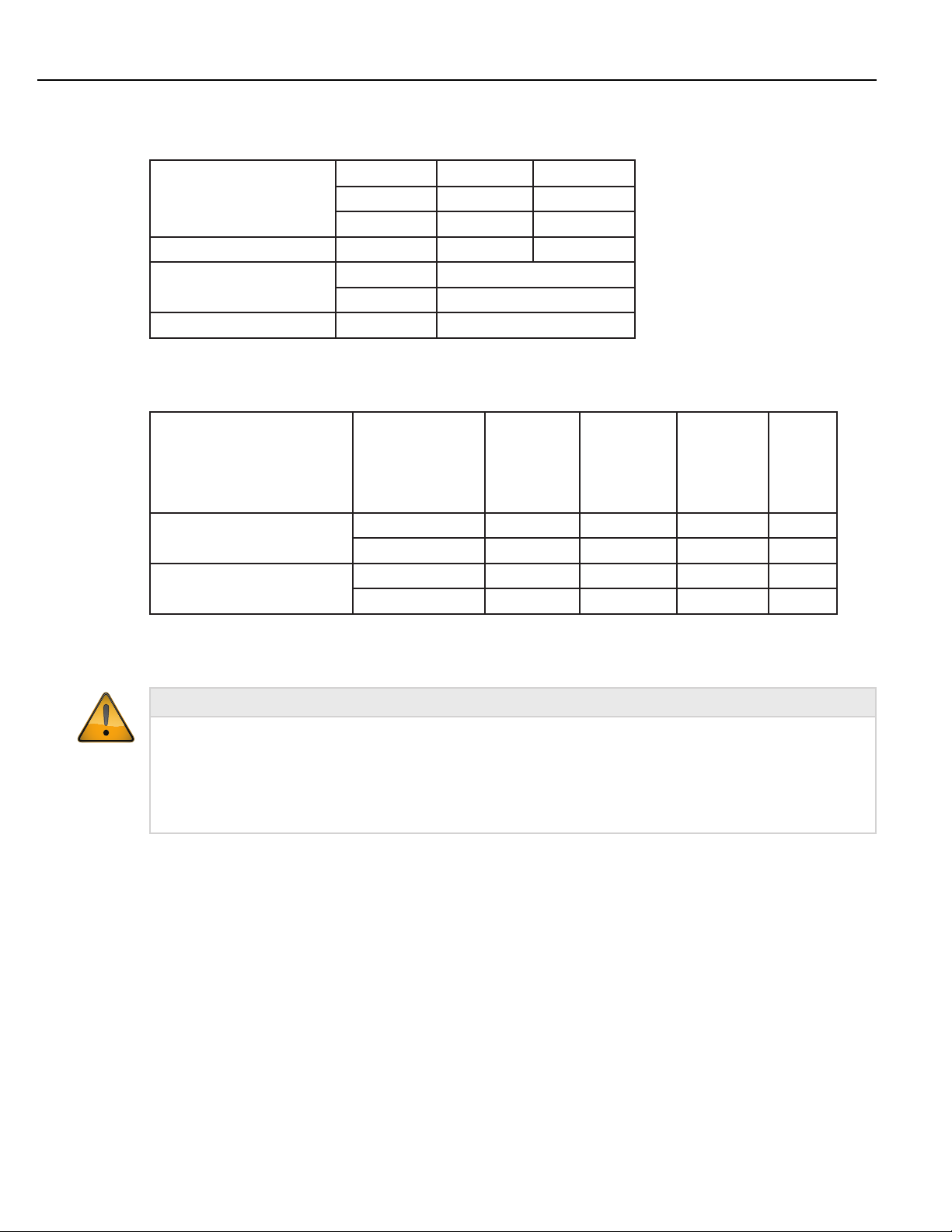

1.6 Specifications

1.6.1 Physical and Environmental Ratings

Width: 6.0 inches 152 mm

Dimensions:

Weight: 18 pounds 8.2 kgrams

Operating Conditions:

Ingress Protection Rating: IP54 NEMA 3

1.6.2 Electric Service Ratings

These are the minimum electric service ratings for the QB Expert Alpha controller and the tools it can control.

Height: 16.0 inches 406 mm

Depth: 10.4 inches 264 mm

Temperature: 32 to 122 ºF (0 to +50 ºC)

Humidity: 0 to 95 % non-condensing

Introduction

Tool Model: E02-E23

EA23

EB02−EB22

EC02−EC22

100 − 126.5V AC 15 A 15 A 20 A * 30 A *

Current for Supply Voltage:

200 − 253V AC 10 A 10 A 10 A 10 A

Standby 0.2 A 0.2 A 0.2 A 0.2 A

Power Consumption:

Continuous 0.3 kVA 0.7 kVA 1.0kVA 2.2 kVA

* 200−240V AC highly recommended

1.6.3 E-Stop Precaution

WARNING

INTEGRATED E-STOP CIRCUIT NOT PRESENT

To Avoid Injury:

• When a QB Expert Alpha controller connects to a tool where a fault can result in personal injury or substantial

damage to property, an E-stop circuit is required. An E-stop circuit must be created in the external electrical

service supply line.

1.6.4 Tool Speed and Torque Scatter Versus Electric Supply

The minimum electric supply voltage required to attain catalog speeds is 104V AC or 208V AC depending which

supply voltage system is used. Supply voltages above these minimums should have NO effect on reducing speed.

Supply voltages BELOW these minimums will reduce maximum free speed proportionally; actual speed should be

the LOWER of the speed command or the maximum attainable speed. Slow Seek and downshift speeds should

not be affected unless they are set close to maximum attainable speed. Similarly torque scatter should NOT be

affected by reduced supply voltages.

E33-E34

EA33−EA34

EB33-EB34

EC33-EC34

E44-E45

EB44-EB45

EC44

E55

EB55

1.6.5 Tool Temperature Versus Electric Supply

Supply voltages that remain within recommended limits during the fastening cycle will provide shortest cycle

times and lowest tool temperatures. Tool temperatures on applications with moderate to high prevailing torque

levels and/or low (i.e. soft) torque rates stand the most chance of being negatively impacted by low or “sagging”

Instruction Manual

11

Page 20

Installation Instructions

supply voltages. Voltage “sag” is a reduction in voltage which occurs when high current draw causes a voltage

drop in the supply wiring which reduces voltage at the power plug and consequently reduces maximum attainable

tool speed under load. Fuses and breakers are also more likely to blow or trip under these conditions. To minimize

these effects, always connect the system to electric service that meets the recommended supply service ratings.

1.7 Installation Instructions

ELECTRICAL HAZARD

To Avoid Injury:

• This product should be located away from heat sources such as radiators or other devices that produce heat.

• This product should not be subjected to vibration or shock or in close contact with water or other liquids.

• To minimize electrical interference, place the module as far away from possible sources of electrical noise,

such as arc welding equipment.

• Install tools and controllers in dry, indoor, non-flammable, and non-explosive environments only.

• Do not use this product near water, for example near a washbowl, wet basement, or the like.

• Avoid body contact with electrically energized surfaces when holding a grounded tool.

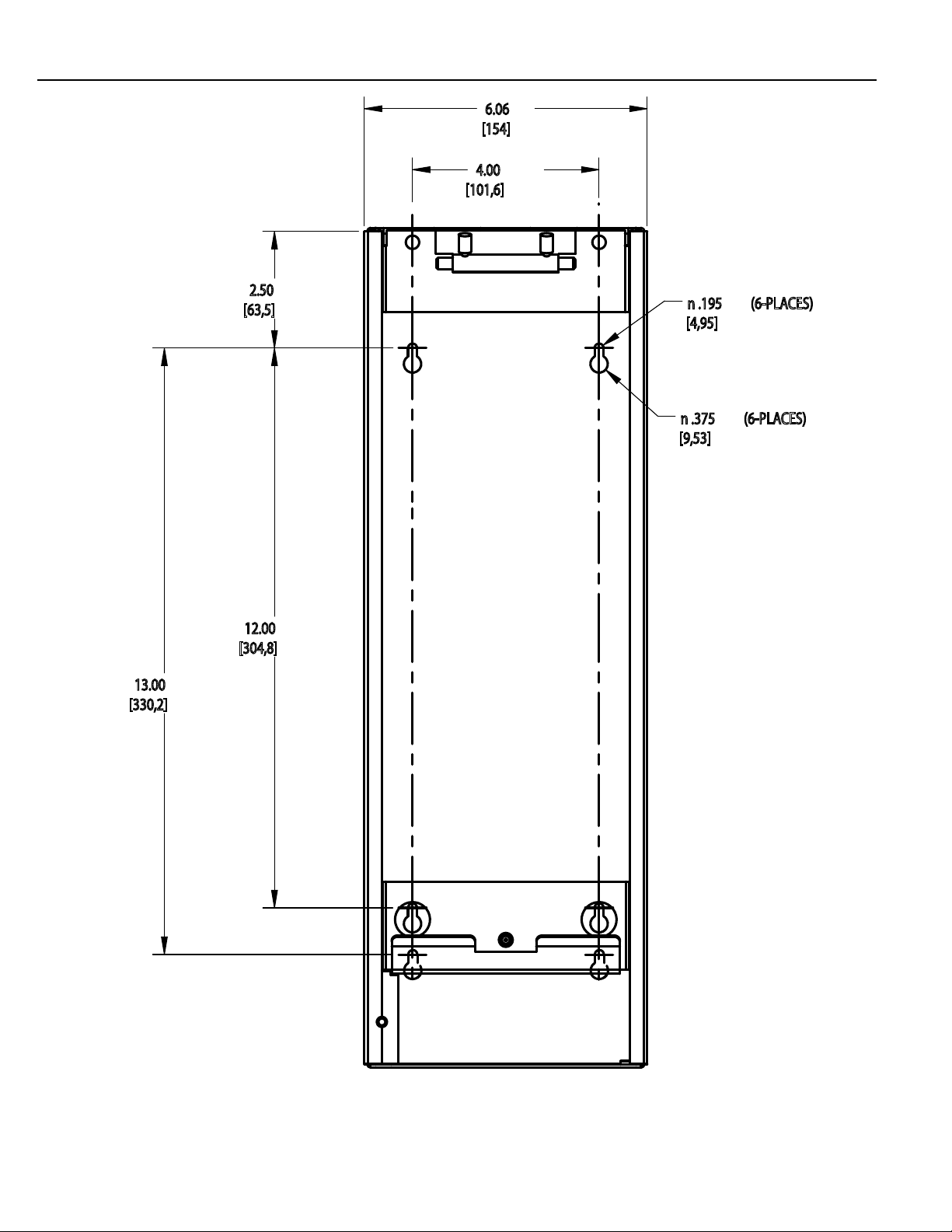

Please refer to the picutres of a plinth and mounting of the QB Expert Alpha controller on the next two pages.

Plinths connect to each other with four 10-32 machine screws through openings on the top and right side to

threaded openings on the bottom and left side. When mounting plinths are placed next to each other, the centerto-center distance between the mounting holes in different plinths is 2” (50.8 mm). When mounting plinths are

place one above another, the center-to-center distance between the mounting holes in different plinths is 6”

(152.4 mm).

Install the QB Expert Alpha Controller either directly to the wall or to a plinth (part number 21E204300).

Fasteners through four mounting holes secure plinths to a wall or other surface. Plinths can be connected using

10-32 threaded holes on the bottom and left side and through holes on the top and right side.

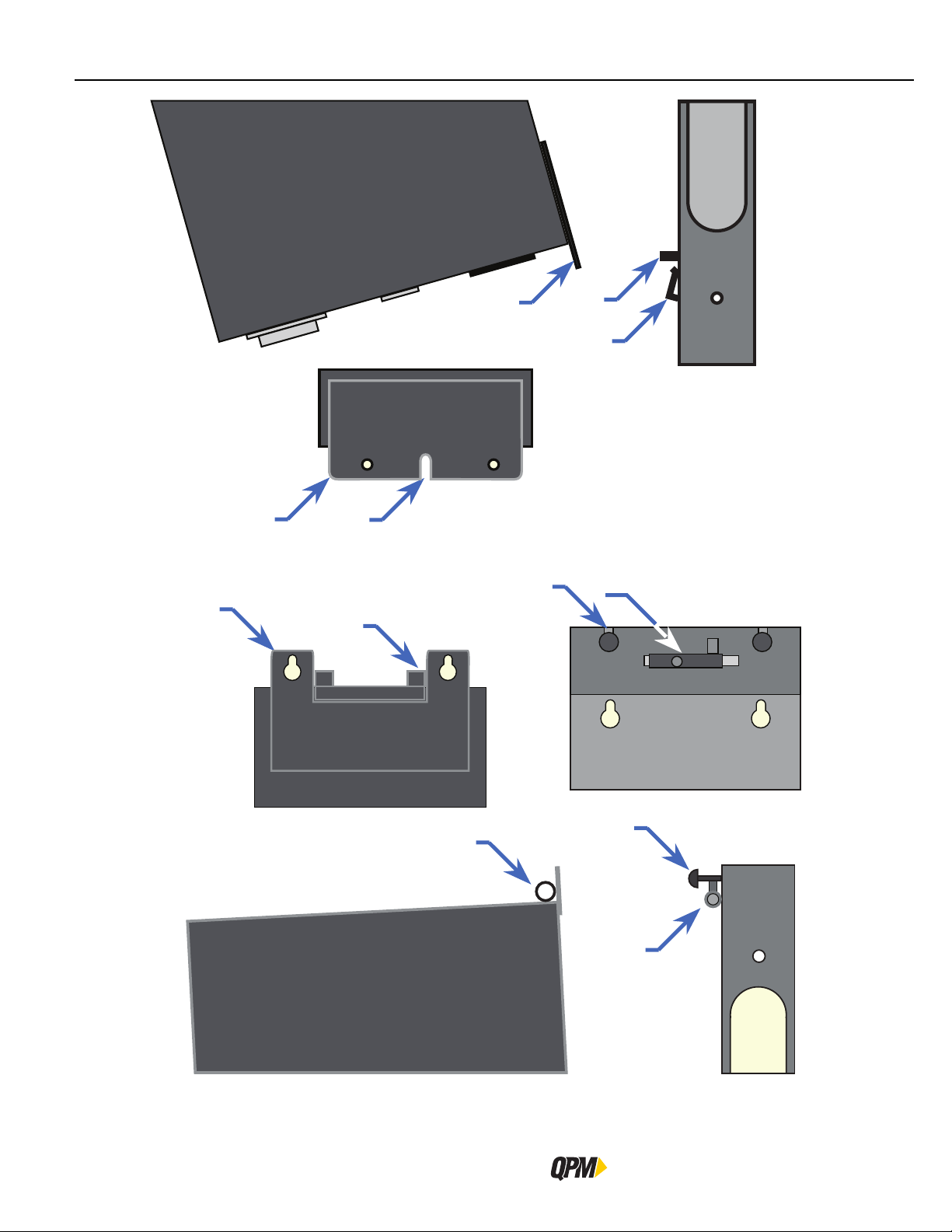

Make sure the bolts of the barrel-latches [5] on the plinth are retracted. Place the lower flange of the QB Expert

Alpha controller [1] into the lip [2] on the plinth.

Align the slot [3] in the flange with the lower mounting-pin [4] on the plinth while placing. Rotate the top of the

controller back towards the plinth.

Place the openings on the upper flange of the controller [6] over the upper mounting pins [7] on the plinth.

Release the bolts on the barrel-latches [5] making sure the bolts enter the two barrels [8] on the controller.

Connect the QB Expert Alpha Controller to a power source.

Connect one end of the tool cable to the tool and the other end to the QB Expert Alpha controller and press the

power switch on the controller.

The controller displays a language list at the first boot up. Press the up/down arrows to select a language, then

press either NEXT from the interactive menu button or use the Toggle button to save the selection.

The controller next prompts for regional settings like Time Zone, Time and Date. Follow the prompts until the run

screen appears indicating the controller is ready for programming and operation.

WARNING

12

QB Expert Alpha Controller

Page 21

6.06

18.00

[457,2]

[154]

4.00

[101,6]

Introduction

13.00

[330,2]

2.50

[63,5]

12.00

[304,8]

n .195 (6-PLACES)

[4,95]

n .375 (6-PLACES)

[9,53]

Instruction Manual

Plinth 21E204300

13

Page 22

6

1

8

3

1

7

4

2

5

14

8

7

5

Mounting QB Alpha Expert Controller onto Plinth

QB Expert Alpha Controller

Page 23

Introduction

Instruction Manual

15

Page 24

Page 25

QB Expert Alpha Controller

Controller Operation

2

Data Storage

Input and Output Functions

Spoftware

Embedded PLC

Networking

Navigation

Display

Faults

Messages

Page 26

Data Storage

2 QPM QB Expert Alpha Controller

The QB Expert Alpha controller is a modular, high-end, full-featured controller for QPM DC servo power tools with

torque transducers. It will control any QPM E, EA, EB or EC series servo motor-powered tool. It utilizes closed

loop control of torque, speed and angle so that it can perform various routines for the tool to secure each fastener

with the highest quality results. The high precision torque and angle sensors in the tool provide feedback to the

QB Expert Alpha controller’s digital control circuit. This circuit compares the feedback values to the programmed

values and adjusts the tool’s power and speed values to maintain the programmed speed on the output of the

tool until the fastener has achieved the programmed target torque and/or angle value. Once the programmed

value is sensed the control circuit turns off the tool leaving the fastener with the desired amount of preload or

clamping force.

The QB Expert Alpha controller is certified to IP54 level to withstand the dust, dirt and liquids found in industrial

facilities. Installing into other panels is not necessary.

QB Expert Alpha controllers have an IEEE 802.11b/g/n radio so that the QPM Cordless line of tools may be added

to it as well. Software version 5.2.5 is the first software version to support the QPM cordless tools.

The QB Expert Alpha controller is designed to be a lead controller in a multiple tool system. Multiple systems of

up to 24 spindles can be configured and managed by the QB Expert Alpha controller. Trailing controllers used in

multiple spindle systems can be QB Advanced Alpha or QB Node Alpha or the new QPM Cordless tools.

The QB Expert Alpha controller can be used as a standalone system as it runs its own tool.

2.1 Data Storage

Data associated with 30,000 fastening cycle results and 10,000 traces is stored in the QB Expert Alpha controller.

This data is retrieved with a USB memory stick or Alpha Toolbox. SPC analysis is performed by the QB Expert

Alpha controller on the stored data.

2.2 Input and Output Functions

Bolt Count or Error Proofing functions are an integral part of the QB Expert Alpha controller’s functions. Its eight

inputs and eight outputs on the 24V DC I/O connector support these functions to provide expert plant integration

to external devices such as a PLC.

The inputs and outputs are assignable, and configurable.

The QB Expert Alpha controller supports other bus types such as ModbusTCP, which is standard, plus optional

Ethernet/IP, Profibus, ProfiNet and DeviceNet. DeviceNet can be ordered as either a scanner or device.

2.3 Software

Any computer with a modern web browser connected wirelessly or with an Ethernet cable on the Ethernet

network port, or the ATB port, is used to view the QB Expert Alpha controller’s web-based application called

Alpha Toolbox. Software is not loaded onto a computer to access the data or configure the controller. Alpha

Toolbox updates come with the controller updates.

2.4 Embedded PLC

The QB Expert Alpha controller comes with a software PLC that emulates many commands and features of the

Allen Bradley SLC-500 series controller. Anyone with logic writing skills and the Alpha Toolbox PLC Editor can

program a logic file to add more versatility to the already abundant features of the QB Expert Alpha controller.

2.5 Networking

Ethernet and the Internet Protocol using Transport Control Protocol are a powerful and robust means of moving

data from one computer to another. Many end users rely on it to collect information from plant floor equipment.

The QB Expert Alpha controllers support the XML (2.0, 2.1), PFCS, NPL, TOOLSNET, OPEN and FORD protocols.

18

QB Expert Alpha Controller

Page 27

For those that haven’t switched to this more robust means of collecting data, the QB Expert Alpha controller

supports the PFCS, OPEN and Toyota PI protocols over a serial connection.

2.6 Navigation

The QB Expert Alpha controller’s four navigation and input areas facilitate menu navigation, selection and data

input:

– Interactive Menu buttons

– Arrows and Toggle button

– Keypad

– Touch screen

5

1

6

4

Controller Operation

Labels for the four interactive menu buttons [1] change with menu selection.

If the label is blank, the button has no function for the current screen.

The up/down arrows [2] navigate menu and character selections; the left/

right arrows enable backspace and space, as well as navigate between tabs.

The Toggle button [3] switches between modes and selects/accepts choices

(synonymous with OK interactive menu button).

The numeric keypad [4] facilitates data input and menu selection (where

applicable) and Job/Task selection when enabled.

The five LEDs [5] specify status of the fastening cycle for spindle 1:

– Red indicates high torque/angle;

– Green indicates an OK fastening cycle;

– Yellow indicates low torque/angle;

– White is programmed by the embedded PLC, and

3

2

– Blue indicates when the tool is enabled to run.

The Orange Wrench icon [6] indicates preventive maintenance is due on the

tool of spindle 1.

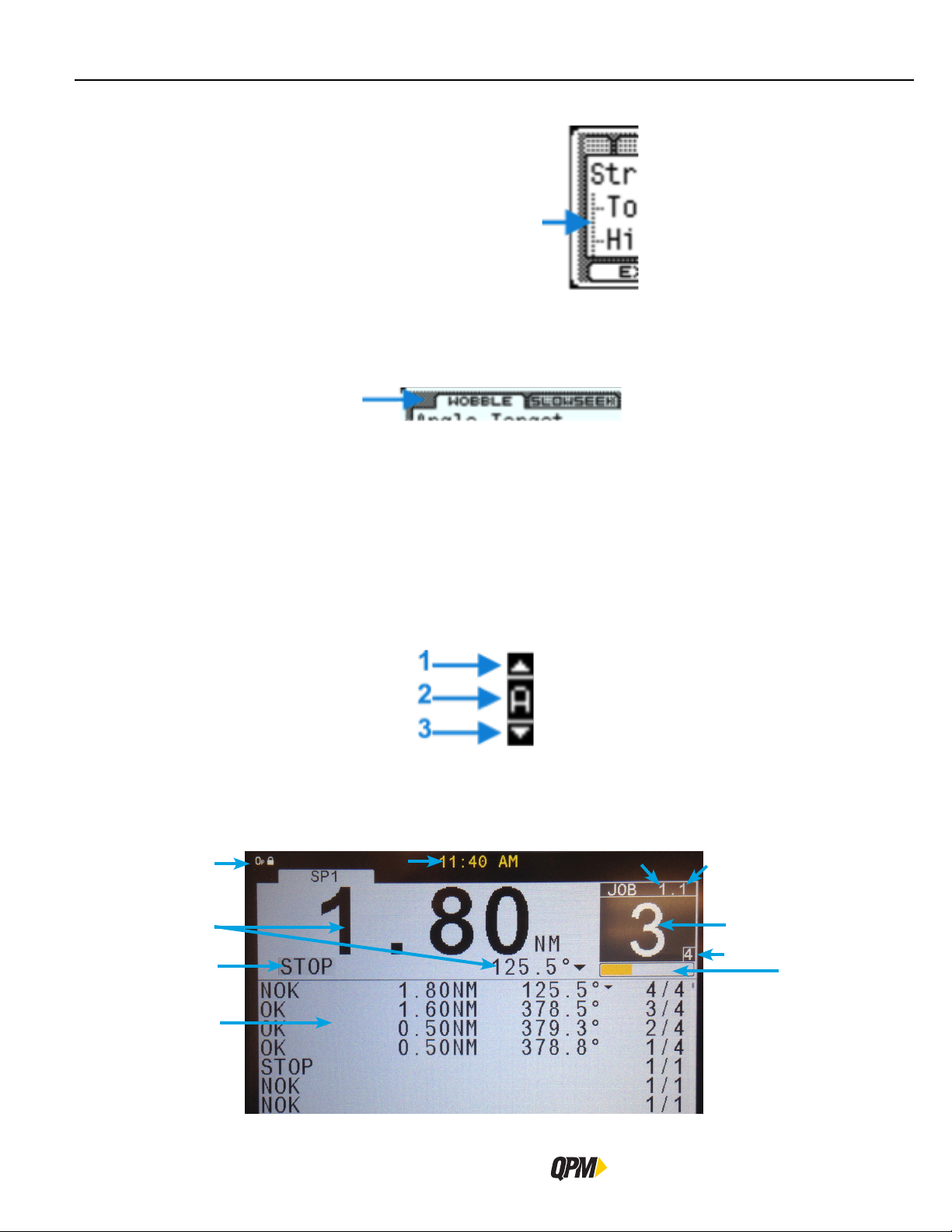

2.7 Display

2.7.1 Scroll Bar

A scroll bar appears on the right of the screen when more items are available than the display allows to view at

one time. The black scroll bar indicates which list items are currently displayed. No scroll bar means all items are

currently displayed.

To navigate between menu items, use the up/down arrows or, if available, use the keypad to identify the

corresponding menu item number.

2.7.2 Dropdown

A dropdown arrow appears to the right of menu items with multiple choices. To view choices, highlight the menu

item using the up/down arrows then use the Toggle button to expand the dropdown. Use up/down arrows to

scroll and the toggle or interactive menu button to select/accept.

Instruction Manual

19

Page 28

Display

2.7.3 Menu Tree

A menu tree appears beside related menu items.

2.7.4 Tabs

Tabs appear at the top when multiple menu selections exist. To navigate between tabs, use the left/right arrows.

The active tab is white; inactive tabs are grey.

2.7.5 Character Scrollbar

This scrollbar enables adding: a-z, A-Z, 0-9, space, _, -, &, *, $, #, @, !, and a period (language and/or field

determines character availability). The up arrow [1] and down arrow [3] direct scrolling with the active character

[2] displayed between. Use the QB Expert Alpha controller’s up/down arrows to scroll through character choices.

The left arrow backspaces. The right arrow moves one position to the right to input the next character. Push

Toggle button or OK interactive menu button to accept entry.

The following screens contain the character scrollbar option: ALL, Job (Name), Task (Name) Step (Name), System

(Name General), System (Users), WIFI (SSID, Password).

2.7.6 Run Display

The Run screen displays normal operating information one spindle at a time. To display a different spindle on a

multiple spindle unit press the right or left arrow key to switch to the next spindle tab.

1

2

8

9

20

10

6

7

4

3

11

QB Expert Alpha Controller

Page 29

Controller Operation

Icons identify events [1], see list below. Displays last torque and angle readings with units, when a tool is connected

[2]. Up/down arrows next to the torque or angle value indicate the last fastening cycle NOK status whether it

exceeded (up) or did not achieve (down) torque or angle limits.

Identifies the active Job [6] and active Task [7]. Identifies Target batch count [3] and Accumulated bolt count [4]

for the active Job. The side scroll bar indicates events are available in the Event Log. Press the down arrow to

view the events. The number of fastening cycle attempts indicator is below the bolt count box. The run screen

displays unless other programming functions [5] are in use. A Shutoff code is also displayed when applicable [8].

The display also has the current time [10] for the specified region and fastening cycle history in the Fastening cycle

Log [9].

This [11] portion of the screen changes to an orange bar with white background when either Limit Rejects or Job

Timer parameters are used. The orange bar increments in one division of the width equal to the Reject Count value

each time a NOK cycle occurs. This bar also acts as a progress bar for the Job Timer to indicate the progress of

the timer.

The time display [10] will change in the following manner:

When a Part ID is received the time will change to the Part ID for 5 seconds and then return to the clock.

If the Job or Task has been selected the Job Name:Task Name appear on the screen until the batch count (Job) has

been completed and then returns to the clock.

The display background color turns red in the event of a fault; see section “2.8 Faults” on page 25.

The run display changes to indicate the step in which the tool stopped (providing it did not stop during the audit

step).

The Fastening Cycle Log [9] lists the fastening cycles that have occurred in the QB Expert Alpha controller. While

viewing the Run Display press the down arrow to access the Fastening Cycle Log.

Use the up/down arrow keys to scroll through the data listed chronologically (newest at the top, oldest at the

bottom). Each line identifies a fastening cycle. The first column indicates the fastening cycle status or shutoff

code. The second column indicates the achieved torque during the fastening cycle. The third column indicates the

achieved angle during the fastening cycle. The fourth column indicates the working bolt count.

2.7.7 Fastening Cycle Log

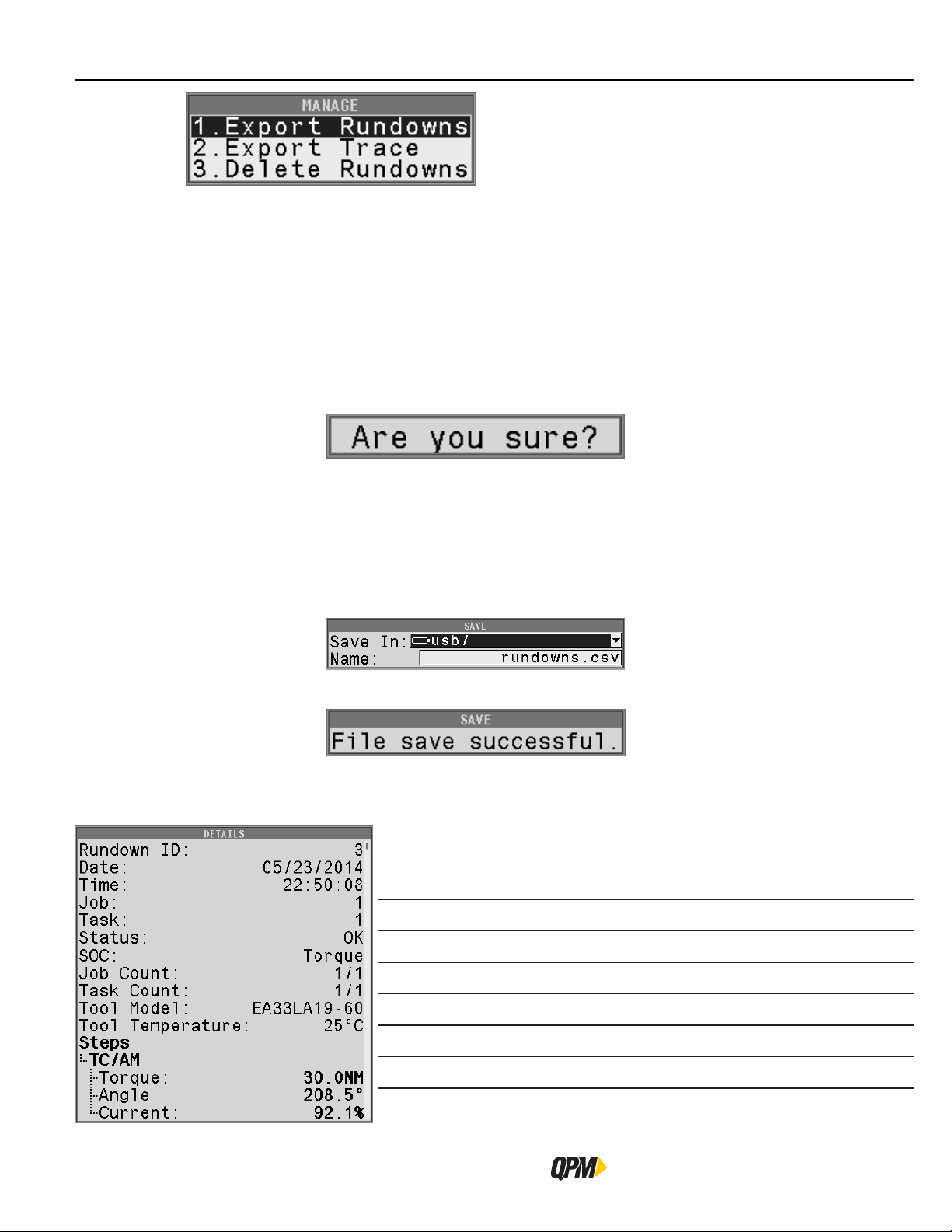

Press the interactive MANAGE button after selecting a data line to display the MANAGE dialog box.

Instruction Manual

5

21

Page 30

Display

Use the up/down arrow keys and the interactive OK button, or the Toggle button, or the number keys, to select

the action required.

Export Rundowns will transfer all fastening cycle data to the USB memory stick after choosing a file name.

Export Trace will transfer fastening cycle trace data to the USB memory stick after choosing a file name. Choose

between the selected trace, the number of traces in the population size or all traces to be exported. When

exporting the SELECTED trace it exports as a comma seperated value file. If POPULATION or ALL are selected the

appropriate number of traces are placed into a zip file before exporting. If selecting All, be aware it will take a

significant amount of time before all traces are put into the zip file and exported.

Delete Rundowns will delete all fastening cycle and trace data from the QB Alpha Expert controller. This action

cannot be undone.

Press the interactive YES button to delete the data. Press the interactive NO button to cancel the delete action.

Use the following sequence to save a Rundown or Trace file.

Insert a USB memory stick into the USB port on the bottom of the QB Expert Alpha controller. Use the down

arrow to select the Name field. Use the Toggle button to enter edit mode. Use the left arrow to delete the name.

Use the up/down arrows or the numeric keypad to write a new file name if required. Press the interactive OK

button or the Toggle button to accept the file name.

Press again to save the file to the USB memory stick.

Press the interactive EXIT button to return to the Run screen.

2.7.7.1 Fastening Cycle Details

Not all items are shown

Press the interactive DETAILS button or the Toggle button after selecting a data line

to display the details.

Details about the event and when it occurred are listed.

Rundown ID: The sequential number of the fastening cycle data

Date: The date the fastening cycle was ran.

Time: The time the fastening cycle completed.

Job: The active Job number in which the fastening cycle ran.

Task: The active Task number in which the fastening cycle ran.

Status: The overal status of the fastening cycle.

22

QB Expert Alpha Controller

Page 31

Controller Operation

SOC: Shutoff Code, see section “2.7.7.2 Shutoff Codes” on page 23

Job Count: The active fastener number for the Job.

Task Count: The active fastener number for the Task.

Tool Model: The model number of the tool used during this fastening cycle.

Tool Serial: The serial number of the tool used during this fastening cycle.

Tool

Temperature:

Part ID: The value in the Part ID buffer when the fastening cycle ran.

Steps: List the steps used during the fastening cycle. The Audit step

TC/AM The Strategy or Smart Step used in the current step.

Torque: The Torque value achieved in the current step.

Angle The Angle value achieved in the current step.

Current The Current value achieved in the current step.

Rate The Rate value achieved in the current step (if enabled)

Deviation The Rate Deviation achieved in the current step (if enabled)

Use the up/down arrows to scroll through the Details.

Press the interactive BACK button to return to the Fastening Cycle Log.

2.7.7.2 Shutoff Codes

Shutoff Codes on the display indicate why a fastening cycle terminates prior to completion.

Shutoff Code Description

The temperature of the tool at shutoff.

values are in Bold.

TIME Fastening cycle time exceeds programmed Cycle Abort time value.

STOP Spindle stopped by either the operator or other device.

>115% Spindle stopped due to torque achieving greater than 115% torque limit for the tool.

FAULT The tool shutoff due to a Fault. See section “2.8 Faults” on page 25.

STALL Spindle stopped due to a stall.

SYNC Spindle failed fastening cycle due to a synchronization error.

T1≠T2 Primary and secondary redundant transducer values are outside comparative limits.

A1≠A 2 Primary and secondary redundant angle values are outside comparative limits.

TD Spindle stopped due to torque dropping below Torque Drop Threshold

YIELD Spindle stopped due to bailout on detecting yield during an Angle Control strategy.

[T] A torque/angle window violation for the Torque Monitoring portion of the fastening cycle.

RATE

I Current has exceeded the High Current Limit or not achieved the Low Current Limit.

Instruction Manual

Torque Rate has exceeded the High Limit or not achieved the Low Limit during a Rate

Monitoring portion of the fastening cycle.

23

Page 32

Display

2.7.7.3 Fastening Cycle Trace

Press the interactive TRACE button after scrolling through the log and highlighting a particular line. A Torque vs.

Time trace screen is drawn for the highlighted line.

Press the third interactive menu button to change the trace axes.

Use the up/down arrow keys and the interactive OK button or the Toggle button, or the number keys, to select

the type required.

1. Torque – Torque vs. time

2. Angle – Angle vs. time

3. Torque/Angle – Torque vs. Angle

4. Speed – Tool Speed vs. time.

Press the interactive BACK or EXIT buttons to leave the trace screen.

2.7.8 Keypad Mode

When Keypad Mode is set to Job or Task Select (see “3.1.4.1 General Tab” on page 60) at the run screen press

the Toggle button or a number on the keypad. A Job/Task window opens. Use the numbers on the keypad to

type in a Job/Task to be selected to run. Use the toggle or interactive OK button to accept and switch controller

operation to the selected Job/Task number.

When the Keypad Mode is set to PART ID (see “3.1.4.1 General Tab” on page 60) at the run screen press the

Toggle button or a number on the keypad. A PART ID window opens. Use the up/down arrows to write a character,

then the right arrow to move to the next character value to use as the PART ID. The numeric keypad may also be

used to write numbers as PART ID. Press the OK interactive menu button to save it. The limit is 32 characters.

2.7.9 Controller Display Icons

The QB Expert Alpha Controller has Icons in the upper left corner of the screen to indicate the following:

Icon Status Description

24

Locked A password is required to make edits.

Unlocked Edits are possible, automatically re-locks in time.

Busy/working Wait for icon to clear before continuing.

QB Expert Alpha Controller

Page 33

Controller Operation

Icon Status Description

Fault; system not operable Check the run screen for Fault message.

2.8 Faults

Remote User

Audi Command Port Connected

Audi Results Port Connected

PFCS Solicited Port Connected

PFCS Un-Solicited Port Connected

OPEN Connected The controller is connected to an OPEN protocol server.

Toolsnet Connected The controller is connected to a Toolsnet protocol server.

ToytotaPI Connected The controller is connected to a ToyotaPI protocol server.

The display background color in normal operation is white. In the event of a fault, the spindle display and the time

display backgrounds turn red and the fault description appears on screen. The background color reverts to original

only when the fault is cleared.

A user is editing the parameters in the controller

remotely, i.e. through Alpha Toolbox.

The controller is connected to an AUDI XML protocol

server on the Command port.

The controller is connected to an AUDI XML protocol

server on the Results port.

The controller is connected to a PFCS protocol server on

the Solicited port.

The controller is connected to a PFCS protocol server on

the Un-Solicited port.

Here is a list of the Faults in the QB Expert Alpha controller:

Total Current – the controller software limits the current applied to any tool

Overcurrent Fault!

GFI Fault!

Logic Voltage Fault!

Position Feedback Fault!

Transducer Span Fault!

Transducer Zero Fault!

based on what the tool can handle. This fault is asserted if the total current

applied is greater than allowed.

The Ground Fault Interrupter has exceeded its current trip point. A current

detector monitors the current through the three phases of the motor and asserts

this fault when the total current applied to the tool does not equal the total

current returned from the tool. All phases are turned off immediately to protect

the controller from shorts at the tool end.

The controller monitors the +5VDC, -5VDC and +12VDC of its onboard Power

Supply. This fault is asserted when those voltages fall outside of nominal range.

The controller is constantly monitoring the resolver zero and span points and

asserts this fault if they go outside specification.

This fault is asserted when the transducer zero point has shifted far enough to

prevent a full scale reading from the transducer.

This fault is asserted when the transducer zero point has shifted far enough to

prevent drift compensation at the zero point.

Instruction Manual

25

Page 34

Messages

Temperature Fault!

This fault is asserted when the tool temperature detector has reached the

temperature limit set by the Temperature Limit parameter. It resets after detected

temperature has dropped by 5°C.

Unrecognized Tool!

Tool Communications! The controller is not communicating to a tool.

Transducer Current Fault!

Unsupported Tool!

Servo Connection Fault!

Spindle Communications The lead controller loses communications with a trailing spindle controller.

2.9 Messages

Messages appear on the screen when certain non-critical conditions exist. They may appear on any screen at any

time.

Communication Fault

Count Fault

The controller is communicating to the tool but does not recognize the model

number written in the tool memory board.

Transducer current has fallen outside nominal values. For EA, EB and EC series

tools that is 4.16 mA +/- 75% (1 to 7mA).

The wrong tool type has been connected to the controller. The Alpha controller

cannot run the tool that is connected.

The CPU has lost communication to the DSP on the Logic board. This may

happen on a reboot after and upgrade as the CPU resets before the DSP.

Used for Toyota PI protocol only. Controller has lost communications to the PI

box.

Used for Toyota PI protocol only. Controller and PI box have a bolt count

mismatch.

Program Fault

Tool Update Failed Controller failed to update the tool configuration.

PLC Message A user defined message controlled by the internal PLC.

Invalid PLC File Appears when an invalid PLC file is imported into the controller.

Identifying Spindle

Used for Toyota PI protocol only. More Fastening cycles were performed than the

PI box expected.

Appears when the Expert is identifying a trailing spindle when the trailing

spindle connects or when the interactive IDENTIFY button is pressed.

26

QB Expert Alpha Controller

Page 35

Tool Disabled

Controller Operation

Along with the onscreen indication, the blue light on the controller and tool MFP

extinguishes and the STOPPED output asserts.

Tool Disabled Explanations:

Undefined Task – The selected Task is not programmed to run an audit step;

select another Task or program currently selected Task.

Invalid Job/Task – Appears when a Job or Task number less than one or greater

than 255 is selected.

Network Protocol – The plant control system issued a Stop via a network

protocol. Wait for the protocol to remove the Stop command.

Error Proofing – Error Proofing is turned on and either a Batch count has been

met, or the Job has not been reset. Reset with a Job Reset input.

Stop Issued – An Input is disabling the tool; remove the Stop input. May also be

caused by Job/ Task Verify inputs not matching selected Job/ Task.

System Initializing – The controller is booting up, please wait.

Cycle Lock-out – The Cycle Lockout timer is active, wait for it to reset.

Reject Count Exceeded – Indicates the Reject Count has been exceeded.

Internal PLC – The internal PLC is commanding the tool to STOP.

Not Armed – There are two things that can cause this event:

1. Tubenuts – By default tubenut tools require arming by tapping the MFB

before the trigger is pressed to run the tool.

2. Reset Reject – The fastening cycle is NOK and the MFB mode is set to Reset

Reject preventing the tool from running until the MFB is pressed to reset the

NOK.

Instruction Manual

27

Page 36

Page 37

QB Expert Alpha Controller

Programming

3

SETUP Area

SERVICE Area

ANALYZE Area

Page 38

SETUP Area

3 Programming

EXCESSIVE TORQUE CONDITION

To Avoid Injury:

• Only trained and qualified personnel should program controllers.

• Never set control limits above the maximum rating of the tool.

• Setting control limits above the maximum rating of the tool can cause high reaction torque.

• Always test for proper tool operation after programming the controller.

The controller uses three main menus to display information and enable programming:

– SETUP menu

– SERVICE menu

– ANALYZE menu

Fields with bold font are editable. Fields with gray font are not editable.

WARNING

To begin programming a tool strategy, press the SETUP interactive menu button.

1. Jobs – use to perform tool strategy programming such as torque and speed parameters.

2. Communications – use to program Ethernet, serial port, fieldbus and network protocol options.

3. Other – use to set parameters for all other features, including system level, users, passwords, I/O and tool

functions.

4. Restore Factory Defaults – use to backup/restore/delete programming and return controller to factory defaults.

To access, press the corresponding menu number on the keypad, or use the up/down arrow keys to highlight then

press the Toggle button.

3.1 SETUP Area

This area changes the settings of the Job,s Tasks, Steps, tool strategies, error-proofing, and bolt counting. Users

must have SETUP or ADMINISTRATOR access level to modify values in this area.

3.1.1 JOBS: Wizard

Jobs controls tool operation for tightening a fastener: one to ninety-nine Tasks and one to twelve Steps. Most

controllers operate with a single Job and Task with one or two Steps. Users must have ADMINISTRATOR or SETUP

access in order to modify Job settings. This includes Wizard, Manage and Step parameters.

The Wizard automatically appears after selecting Jobs if a tool is attached and when a Job or Task is added. The

Wizard sets up a Job or Task for simple or complex fastening cycles using the optional strategy controls called

Smart Steps.

30

QB Expert Alpha Controller

Page 39

If no tool is attached or if at least one Job exists, the Job tab appears allowing for expert user programming.

3.1.1.1 Wizard Screens

The Wizard presents programming parameters and gives a list of strategy controls (Smart Steps). The first 2

Wizard screens define the Audit step of the Task. The Smart Steps are helper steps inserted either before or after

the Audit step. Smart Steps cannot be audit steps. Only STRATEGY steps can be audit steps. A Task must have

at least one STRATEGY (non-Smart step) step. When complete the Wizard will have created the Job, Task and

appropriate steps based on programming input.

Programming

Strategy

Batch Count

Instruction Manual

Identifies the values used for controlling the tool during the a step. Choose the strategy

required for the Audit step of the Job and Task being programmed. See section “3.1.2.4

Step Button” on page 43 for an explanation of the strategies.

• TORQUE - Torque Control/ Angle Monitor (TC/AM)

• ANGLE - Angle Control/ Torque Monitor (AC/TM)

• TORQUE & ANGLE - Torque Control/ Angle Control (TC/AC)

The number of fasteners required to be secured in a Task. Typically used with an error

proofing scheme and remote input and output device. Acceptable values are between 1

and 99. The default value is 1.

31

Page 40

SETUP Area

Tool operating units: = 1 FT LB = 1 NM

• NM, Newton Meters

• FT LB, Foot Pounds

• IN LB, Inch Pounds

Units

Thread Direction

To modify a parameter, select the parameter using the up/down arrow keys then press the Toggle button. Enter

the appropriate value then press the TOGGLE button. After all parameters/ selections/options are finished, press

the NEXT interactive menu button to advance through the Wizard. Repeat for subsequent windows. Press the

PREV interactive menu button to move back to previously programmed screens within the Wizard. Press the

CANCEL interactive menu button at any time to stop Wizard operation.

• IN OZ, Inch Ounces

• KG M, Kilogram Meters

• KG CM, Kilogram Centimeters

• N CM, Newton Centimeters

• N DM, Newton Decimeters

Use CW (clockwise) for tightening right hand fasteners. Use CCW (counter-clockwise) for

tightening left hand fasteners.

1.355818 1

1 0.7375621

12 8.850745

192 141.6119

0.1382552 0.1019716

13.82552 10.19716

135.5818 100

13.55818 10

TC/AM Selected

High Torque

Low Torque

Speed

The maximum allowed torque during this step. The Wizard uses the rated torque for the

connected tool.

The minimum allowed torque during this step. The Wizard uses zero as the low torque

limit of the strategy.

The speed of the tool’s output in Revolutions Per Minute (RPM). The Wizard uses the

maximum speed of the connected tool.

AC/TM Selected

Snug Torque The point in this step when the controller begins to monitor the tool’s output angle.

High Angle

The maximum allowed angle in degrees during this step. The Wizard chooses the

maximum value as default.

32

QB Expert Alpha Controller

Page 41

Programming

Low Angle

The minimum allowed angle during this step. The Wizard chooses the value of zero

degrees as default.

AC/TC Selected

See parameter definitions from the other selected strategies.

The Audit step is now defined. The Wizard uses the median value, between the High and Low parameters, as the

Target. It also calculates and programs other parameters automatically, including: Snug Torque, Threshold Torque,

Statistical Torque and High Angle Bailout. Change these values after saving Wizard programming if desired.

Next, select the controls (Smart Steps) specific to your application.

Multiple step strategies are ways of using more than one step to meet the requirements of a difficult joint. The

following features are available through multiple strategies programmed via the Wizard.

Use the Toggle button to select or deselect the controls specific to your application. Press the NEXT interactive

menu button to view the option screens for each specific control chosen. The Wizard makes assumptions,

calculates and presents specific values. Modify these values if necessary.

Instruction Manual

Not Selected

Selected

33

Page 42

SETUP Area

Creates a Smart Step with an Angle Control/Torque Monitoring strategy that rotates the

fastener in the opposite direction as the Audit step is programmed. The fastener threads

align with the locking device threads before standard forward rotation and high speed

are applied (prevents cross-threads). If selected, this is the first step in the tool strategy.

Options include:

Wobble

Slow Seek

Angle Target

Speed

Max Torque

Creates a Smart Step with an Angle Control/Torque Monitoring strategy that rotates the

fastener in the same direction as the Audit step is programmed. The flats of the socket

align with the flats on the fastener before standard forward rotation and high speed are

applied. Using Slow Seek as a first step also allows for cross-thread and re-hit detection. If

selected, this is the first step AFTER Wobble. Options include:

Angle Target

Speed

Max Torque

The number of degrees of rotation the socket turns during this step.

The Wizard uses 360˚ by default.

The speed of the tool’s output in Revolutions Per Minute (RPM). The

Wizard uses 60 RPM as default.

The maximum allowed torque during this step. A low value is

calculated by the Wizard to detect cross-threads and double hits (Rehits).

The number of degrees of rotation the socket turns during this step.

The Wizard uses 180˚ by default.

The speed of the tool’s output in Revolutions Per Minute (RPM). The

Wizard uses 60 RPM as default.

The maximum allowed torque during this step. A low value is

calculated by the Wizard to detect cross-threads and double hits

(Re-hits).

34

Self Tap

In some fastening situations, the initial fastening cycle torque is as high as or higher than

the target torque specification limit for the joint. In other cases, such as thread rolling

or forming, overcoming friction in getting the fastener started causes the high initial

torque. In order to compensate for this high initial torque, the Self Tap control allows the

controller to drive the tool for a specified amount of angle at the start of a fastening cycle.

Creates a Smart Step with an Angle Control/Torque Monitoring strategy in the same

direction as the Audit step is programmed. If selected, this is the first step AFTER Slow

Seek. Options include: Snug Torque, Angle Target, Speed, Max Torque.

Snug Torque

Angle Target

Speed

Max Torque

The point in this step when the controller begins to monitor the tool’s

output angle.

The number of degrees of rotation the socket turns during this step.

The Wizard uses 800˚ by default.

The speed of the tool’s output in Revolutions Per Minute (RPM). The

Wizard uses the rated speed of the tool in RPM as default.

The maximum allowed torque during this step. The Wizard uses the

tool’s rated torque to prevent any interference.

QB Expert Alpha Controller

Page 43

Programming

Creates two Smart Steps before the Audit step. The first step is a Torque Control/Angle

Monitoring strategy that rotates the fastener in the same direction as the Audit step is

programmed. This runs a fastener down to an initial torque level. The second is a Back off

strategy which partially removes the fastener.

The purpose of this procedure is to polish the threads and reduce friction variation during

the Audit step. This ensures more consistent results. If selected, this is the first step AFTER

Self Tap and Pre-Torque. Options include:

Condition

Fastener

Pre-Torque

Down Target

Torque

Delay Time

Max Time

Angle Target

The pre-torque runs the fastener to a preliminary torque level and suspends the fastening

cycle for a period of time. After a time delay, the Audit step begins. Creates a Smart Step

with a Torque Control/Angle Monitoring strategy in the same direction as the Audit step is

programmed. If selected, this is the first step AFTER Self Tap. Options include:

Torque Target

Delay Between

Steps

The Target Torque for this step prior to the Back off.

The time delay before the controller starts the next sequential step.

Triggered when the tool meets the Down Torque Target and entered in

seconds. The Wizard uses 0.05 seconds by default.

The maximum time permissible to have the tool energized during this

step. Entered in seconds.

The target angle for the Back off step. The Wizard uses 360˚ by

default.

The Target Torque for this step. The Wizard uses the Audit step’s

Low Torque value by default.

The time period to suspend the tool strategy before continuing

entered in seconds. The Wizard uses 0.05 seconds as default.

Instruction Manual

35

Page 44

SETUP Area

AC TC

TC AM

Torque Recovery

Creates a Torque Control/ Angle Monitor Strategy step AFTER the Audit step and will make

the Torque Recovery step the Audit step. The torque parameters of the Torque Recovery

step are the same as the Audit step. Sets Merge Torque to Yes. Sets Accumulate Angle to

Yes. Sets Torque Display to Final for both steps.

This is the value for the Delay Between Steps of the Audit step prior

Relaxation Time

Speed

Rotation

Threshold

to running the Torque Recovery step. The Wizard uses 0.05 seconds

as default.

The Speed of the tool’s output in Revolutions Per Minute (RPM)

during the Torque Recovery step. The Wizard uses 10 RPM as

default.

If the achieved angle in the Torque Recovery step exceeds the

Rotation Threshold the torque and angle values displayed and saved

are the final torque and final angle of the Torque Recovery step.

If the achieved angle in the Torque Recovery step does not exceed

the Rotation Threshold in the Torque Recovery step, the torque and

angle values displayed and saved are the final torque and final angle

of the Audit step.

The Wizard uses 0 degrees as default.

Backout

Fastener

Fastener Release

Accommodates assembly procedures requiring partial removal of the fastener before

additional components can be added to the joint. Creates a Back off strategy Smart Step

after the Audit step. The tool stops after achieving either the angle or torque target. If

selected, this is the first step AFTER the Audit step. Options include:

Angle Target

Torque Target

Speed

In some fastening situations sockets become stuck on the fasteners. This step reverses

the tool and releases the socket without loosening the fastener. Creates an Angle Control

or Torque Control (AC/TC) strategy Smart Step that rotates the fastener in the opposite

direction of the Audit step. Options include:

Angle Target

Speed

The number of degrees of rotation the socket turns during this step.

The Wizard uses 1800˚ by default.

The Target Torque for this step. The Wizard uses the tool’s rated

torque as default.

The speed of the tool’s output in Revolutions Per Minute (RPM). The

Wizard uses the rated speed of the tool in RPM as default.

The number of degrees of rotation the socket turns during this step.

The Wizard uses 50˚ by default.

The speed of the tool’s output in Revolutions Per Minute (RPM). The

Wizard uses the rated speed of the tool in RPM as default.

36

Max Torque

Press the FINISH interactive menu button to close the Wizard.

The maximum allowed torque during this step. The Wizard uses

50% of the rated torque of the tool by default.

QB Expert Alpha Controller

Page 45

The Job tab screen appears. This allows manual editing of parameters prior to saving Wizard programming. To

save, press the EXIT interactive menu button.

Press the YES interactive menu button to save changes. This saves the parameters and opens the Run screen.

3.1.2 JOBS: Manual Programming

Jobs, Tasks and Steps are required to setup a tool strategy. Inputs and Triggers are used to select specific Jobs or